Patents

Literature

31results about How to "Meet performance testing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

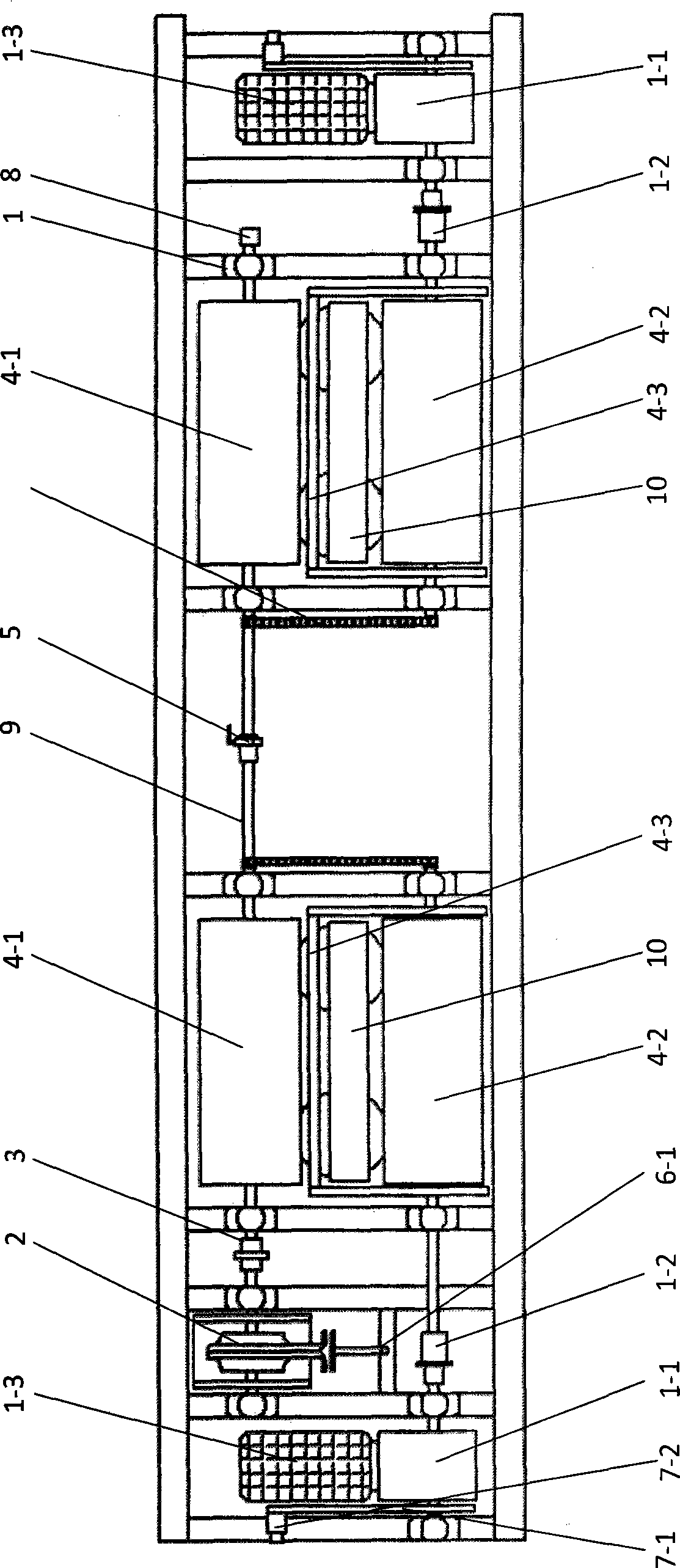

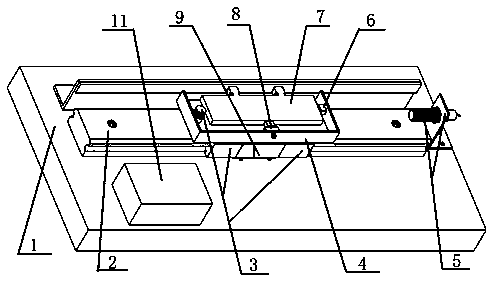

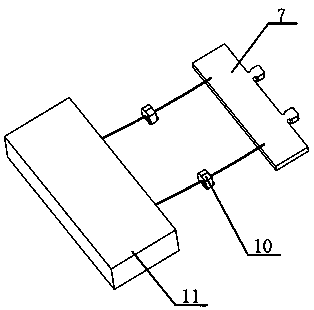

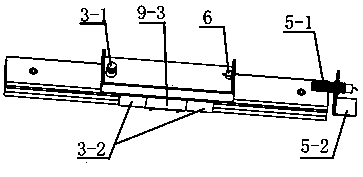

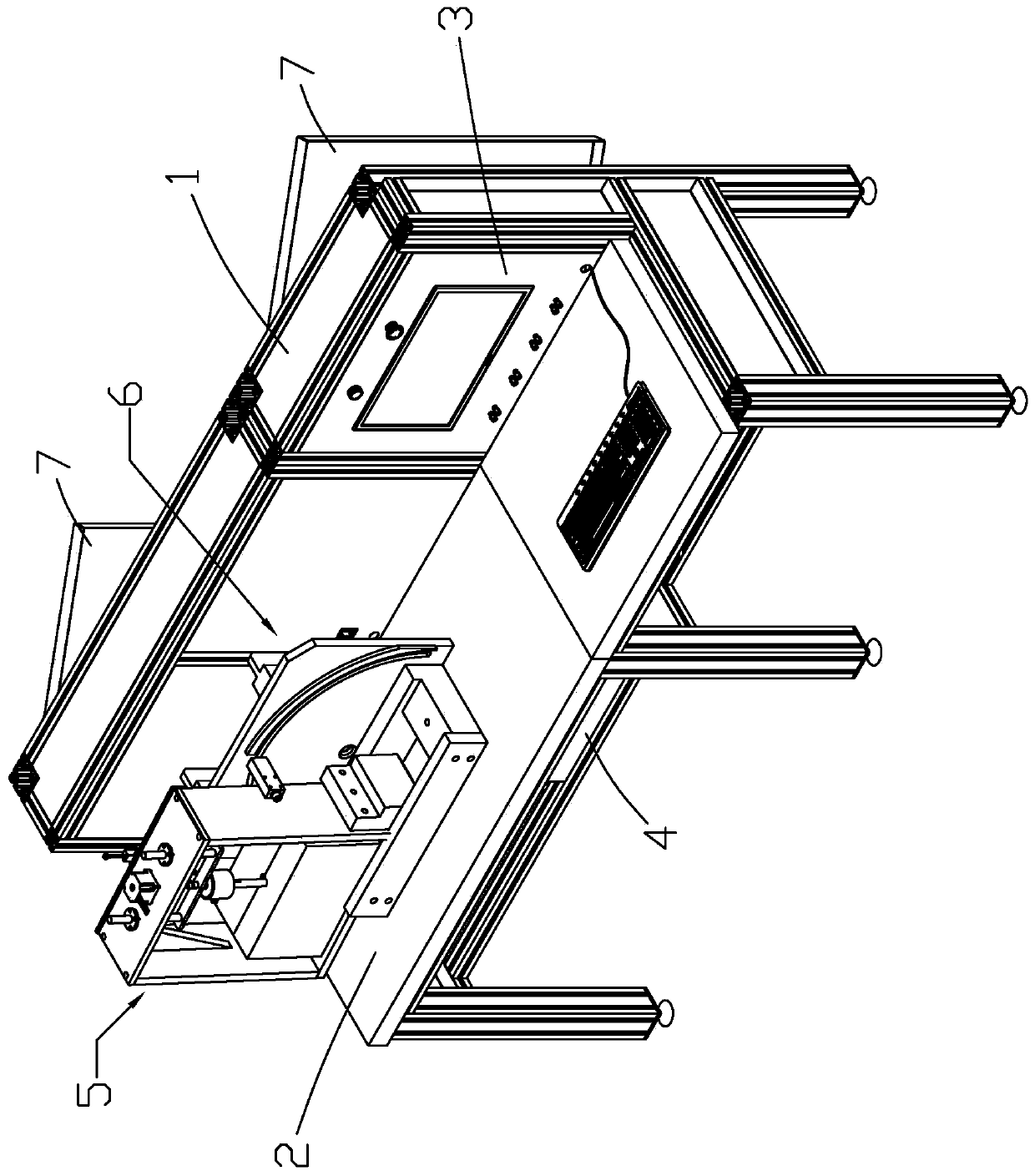

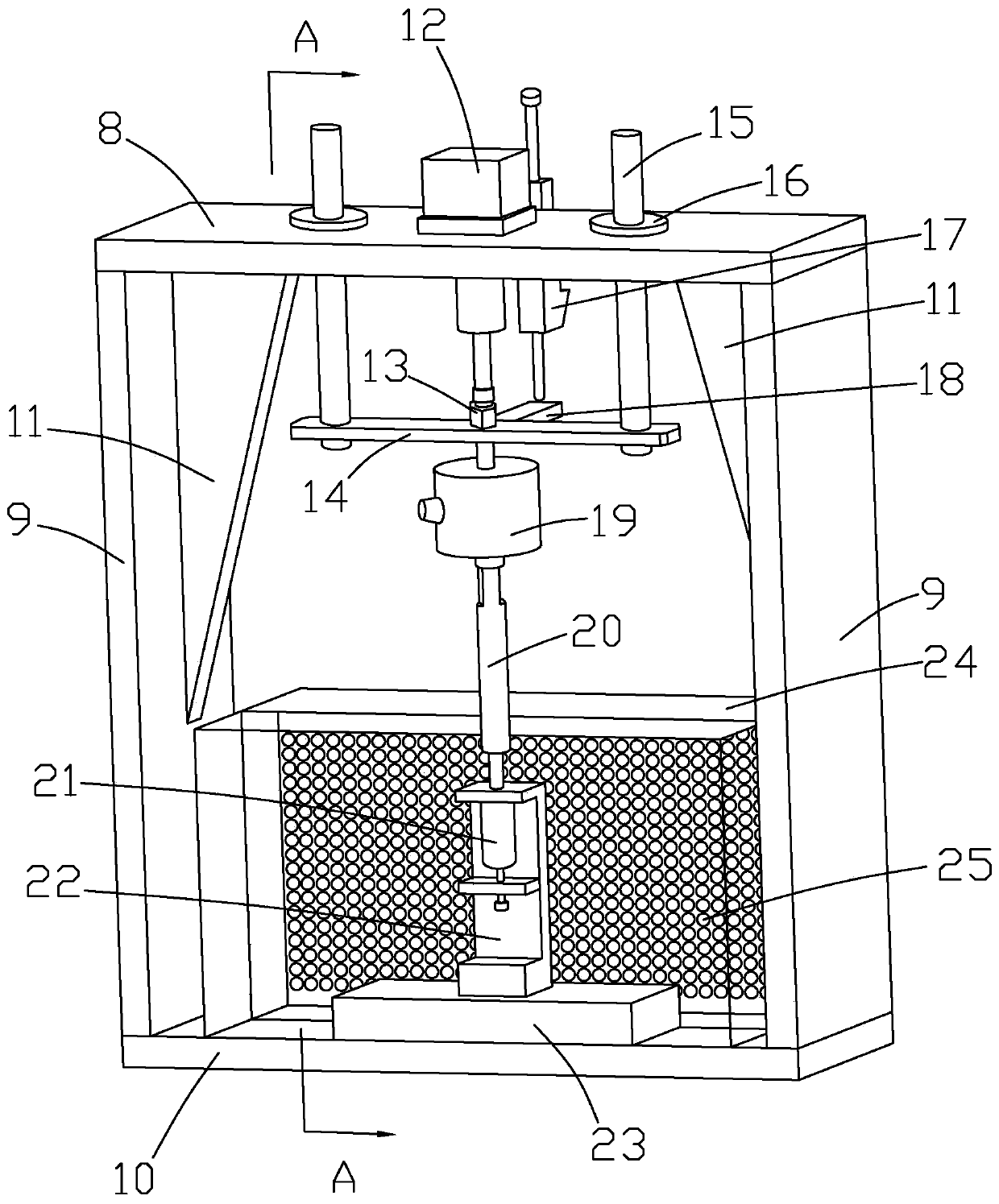

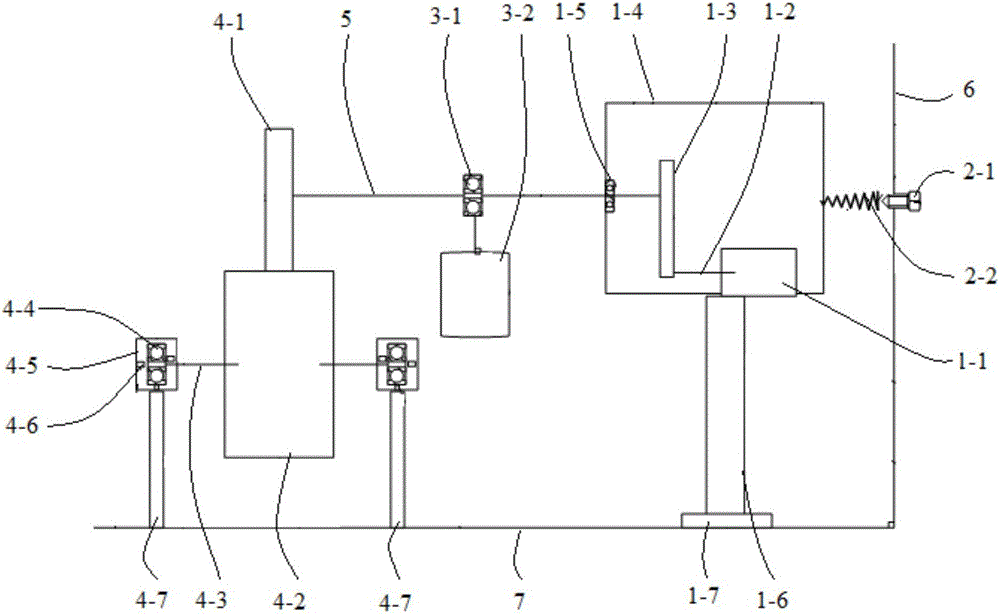

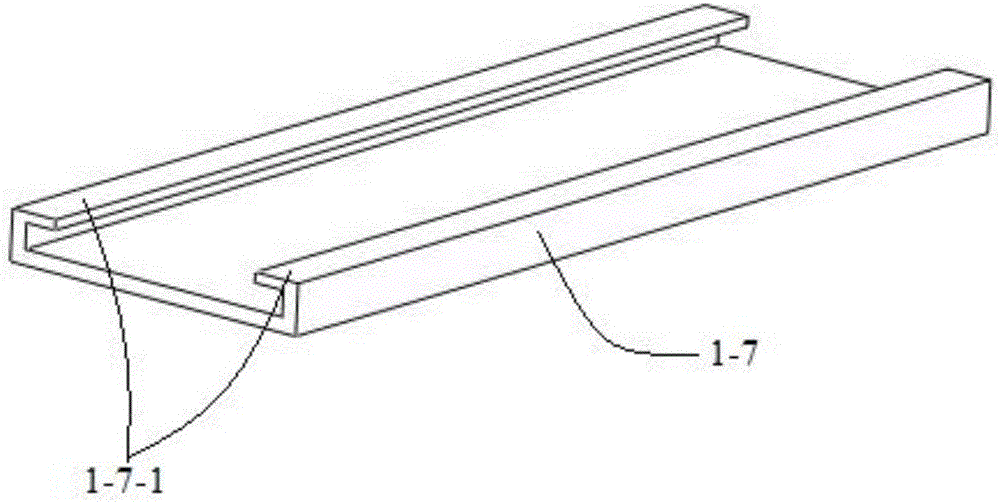

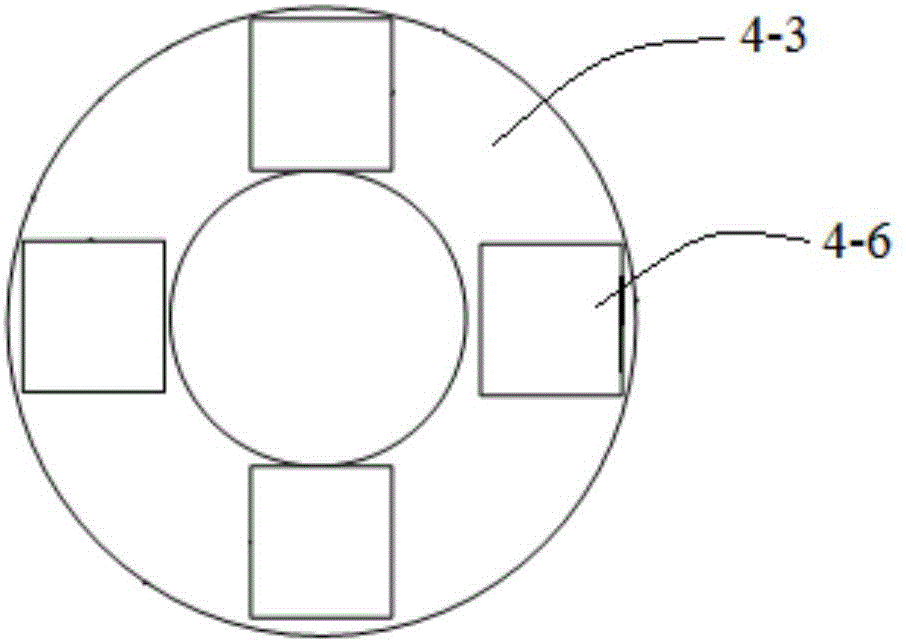

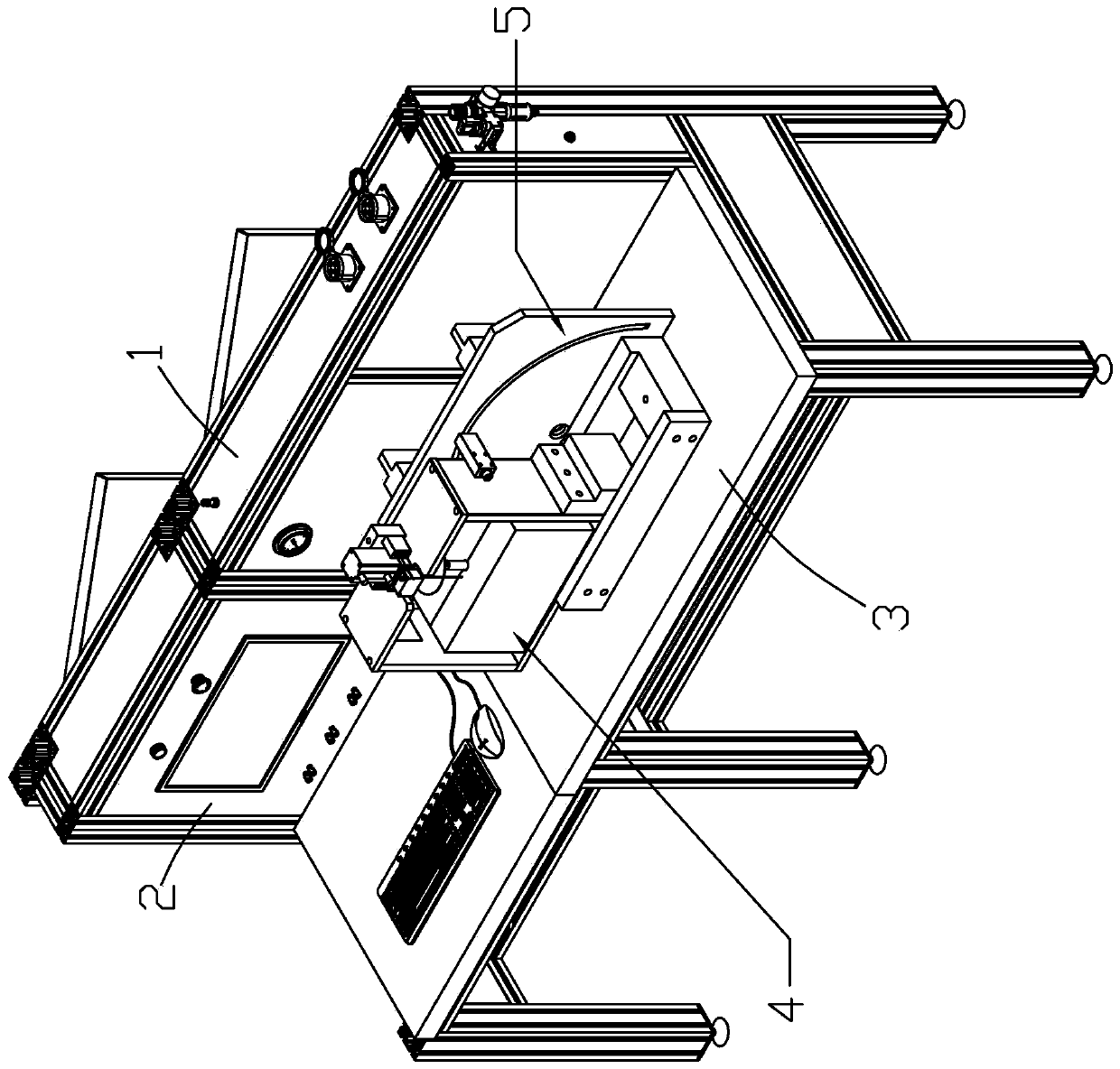

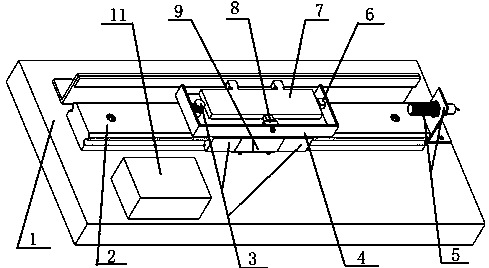

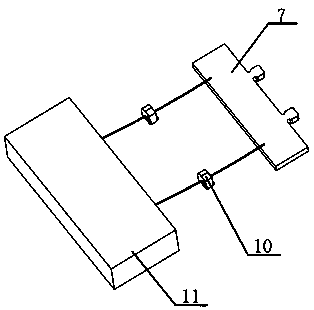

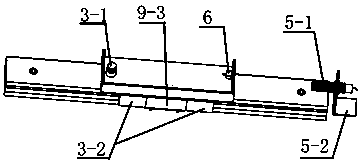

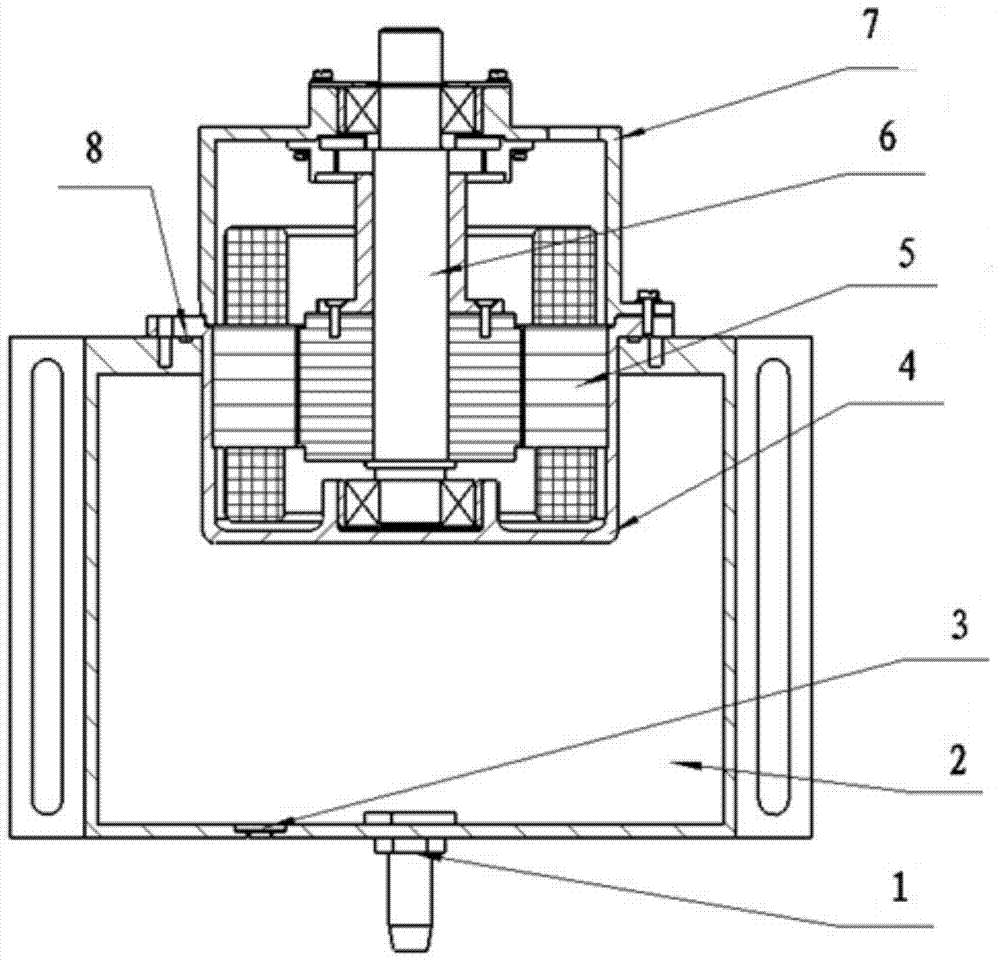

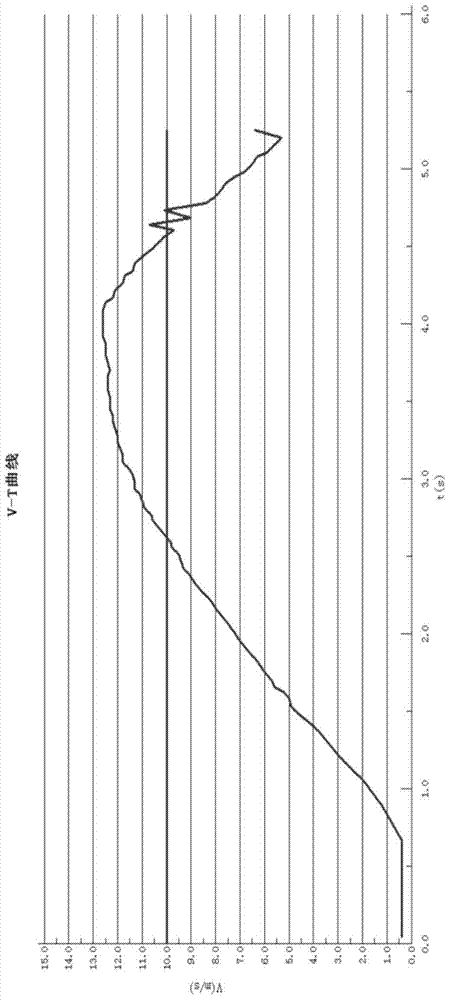

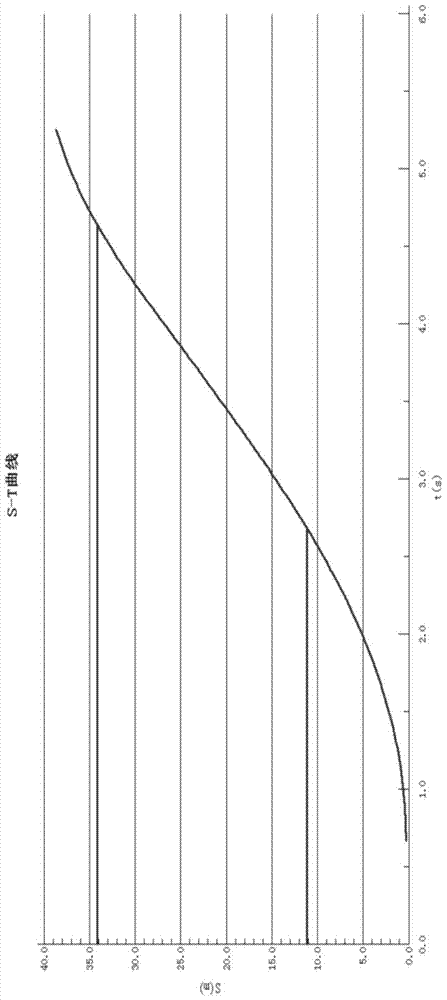

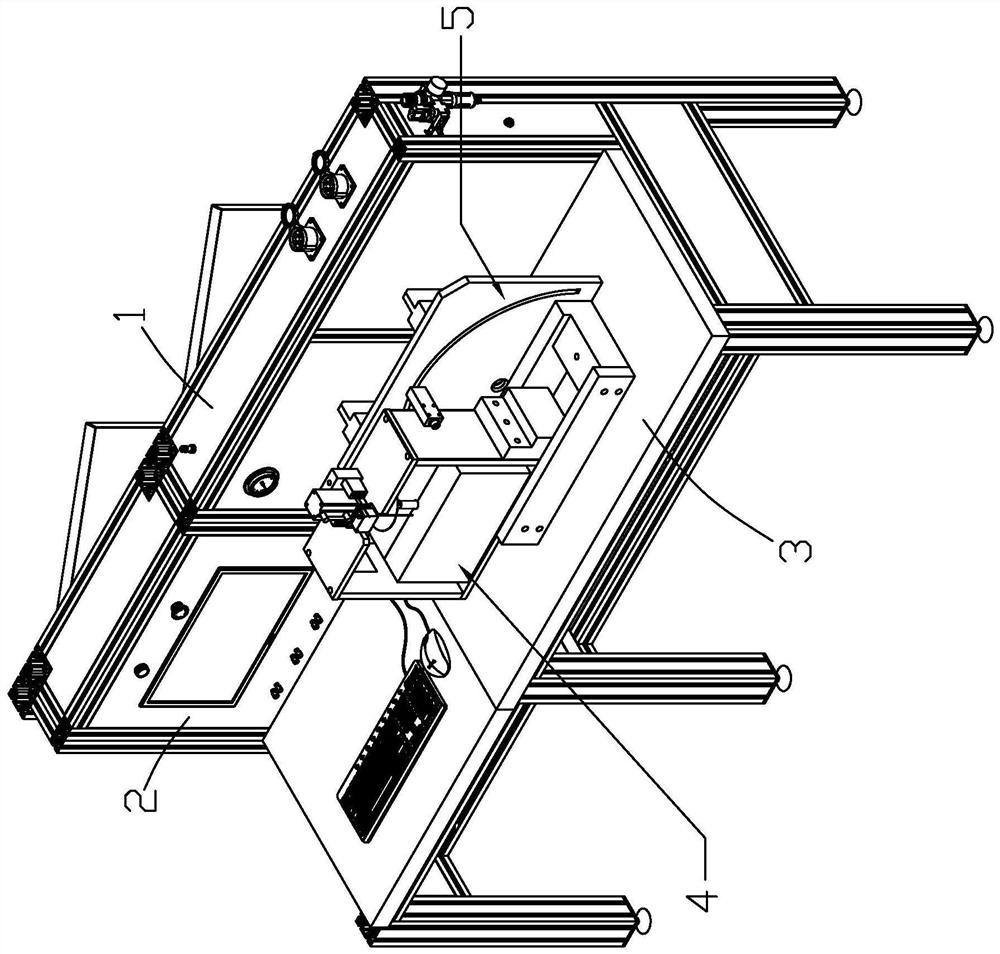

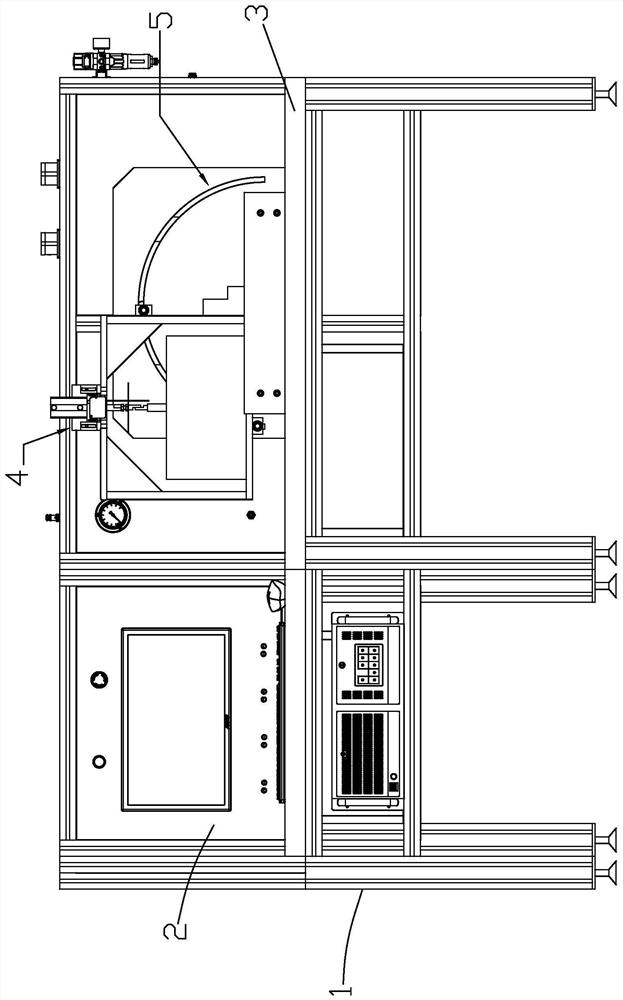

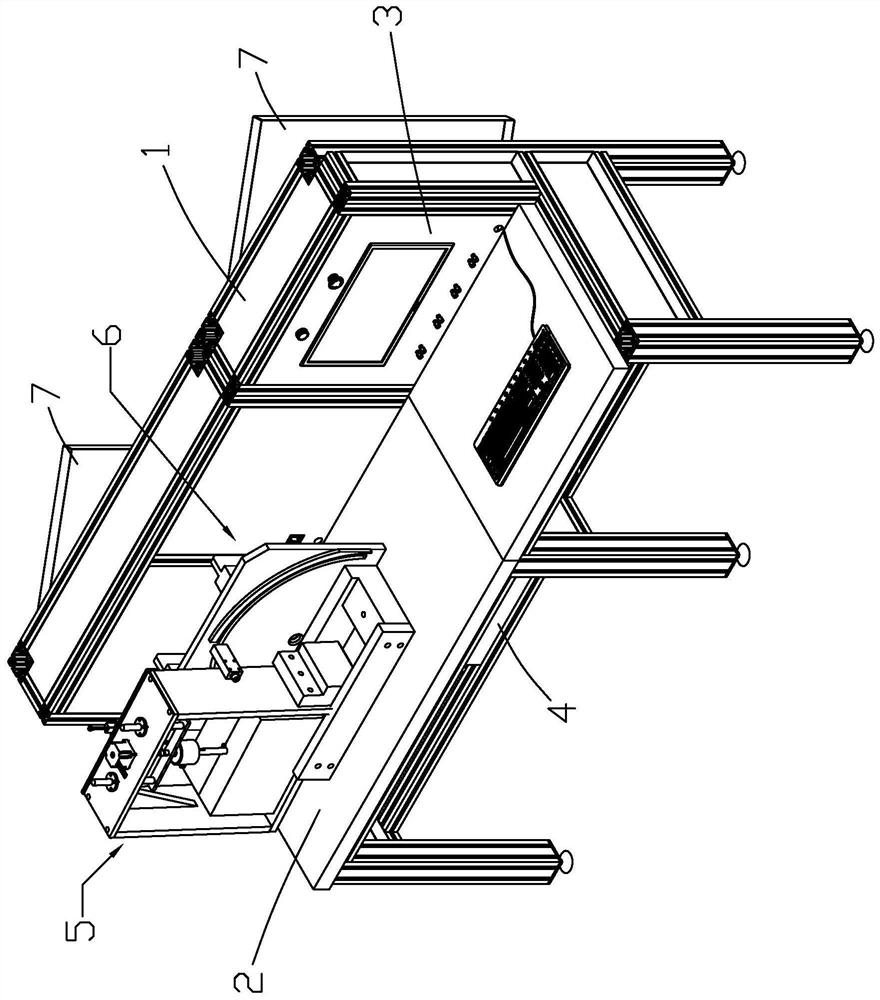

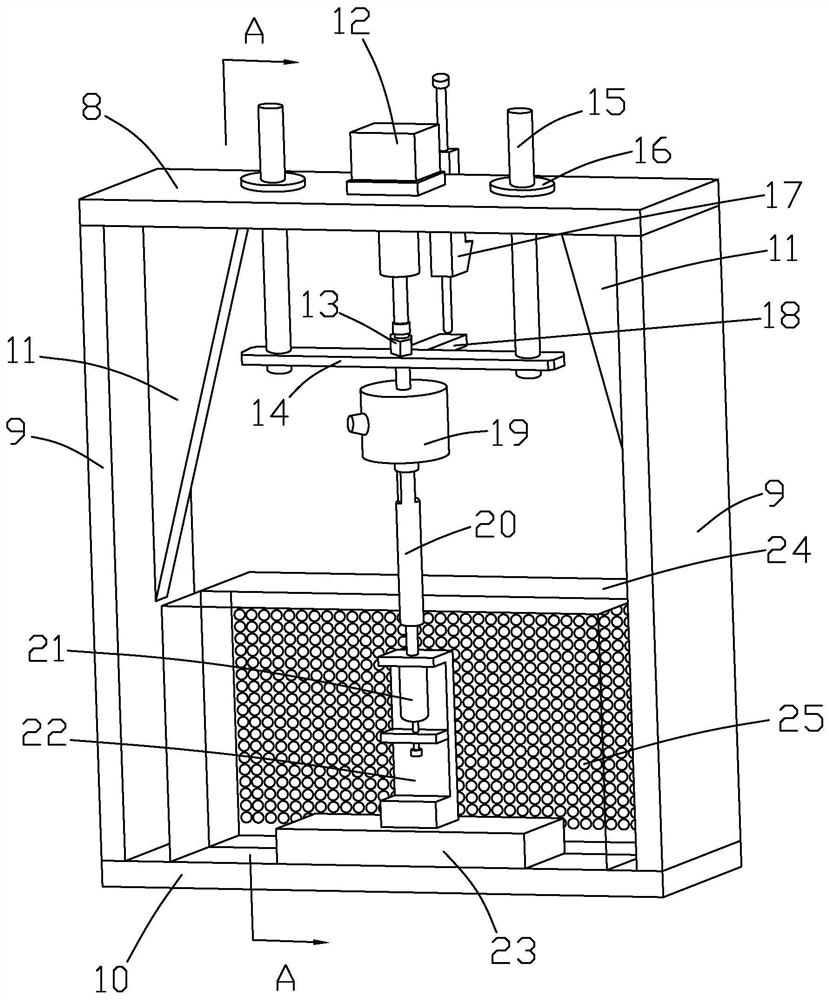

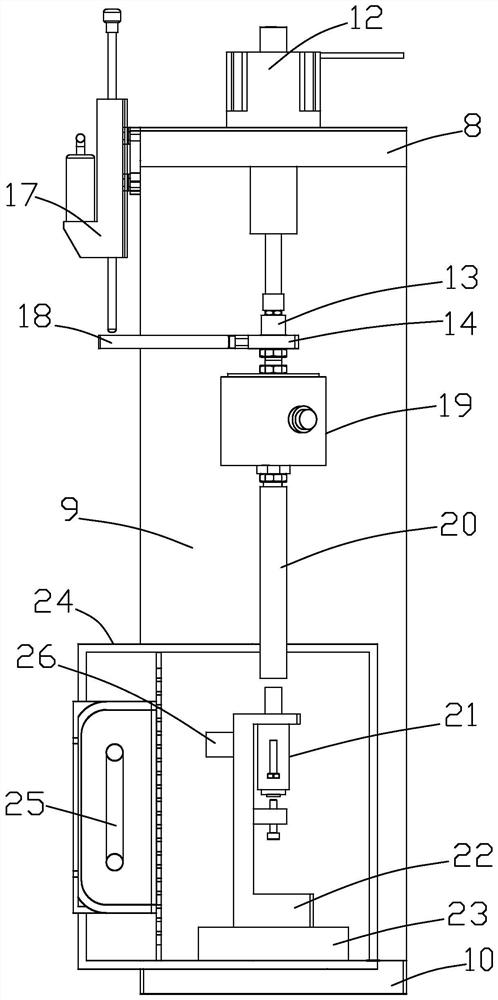

Integrated dynamic vehicle performance test platform and integrated dynamic vehicle performance test method

InactiveCN103175692AMeet performance testing requirementsImprove carrying capacityVehicle testingWork measurementCombined testVehicle detection

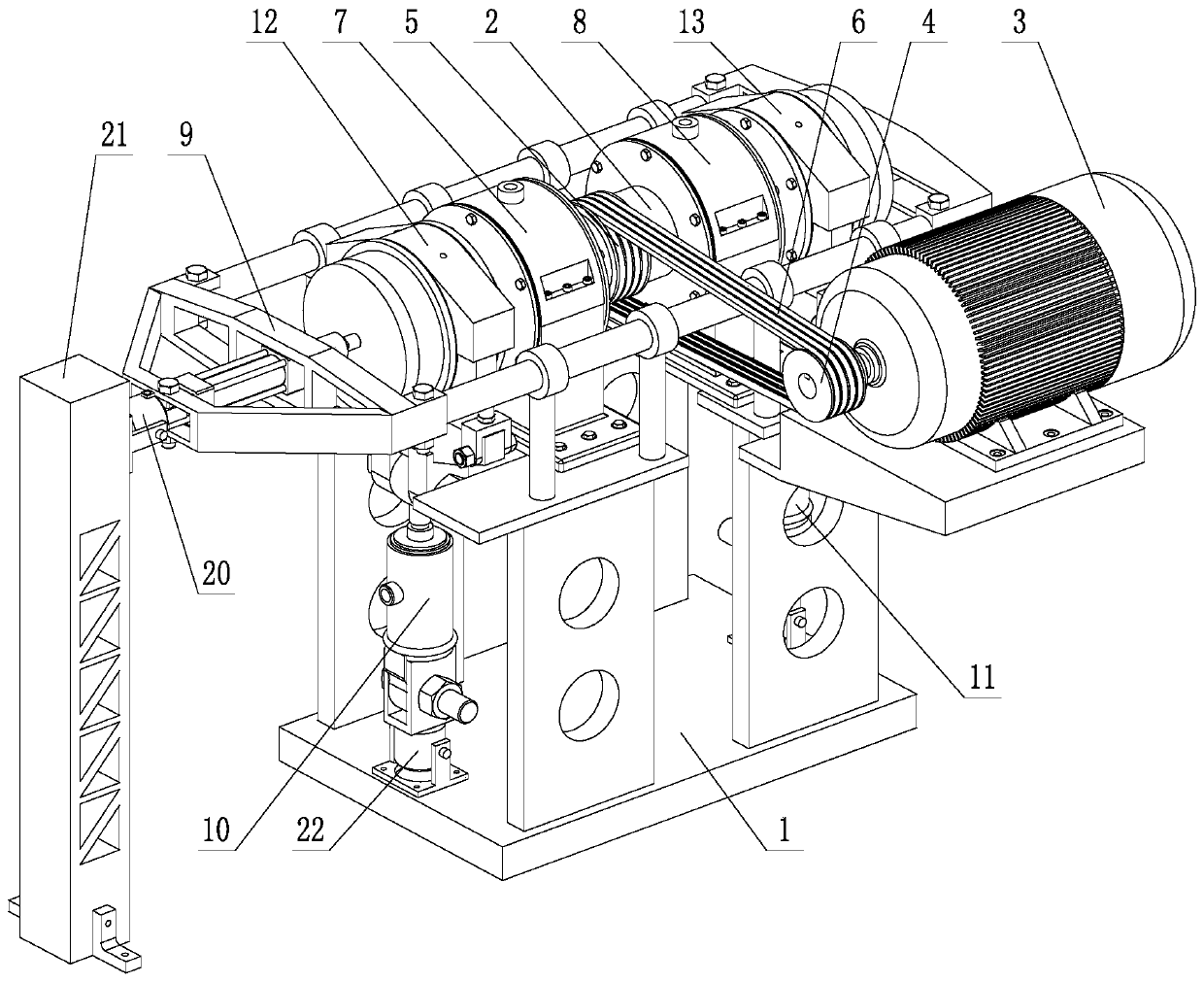

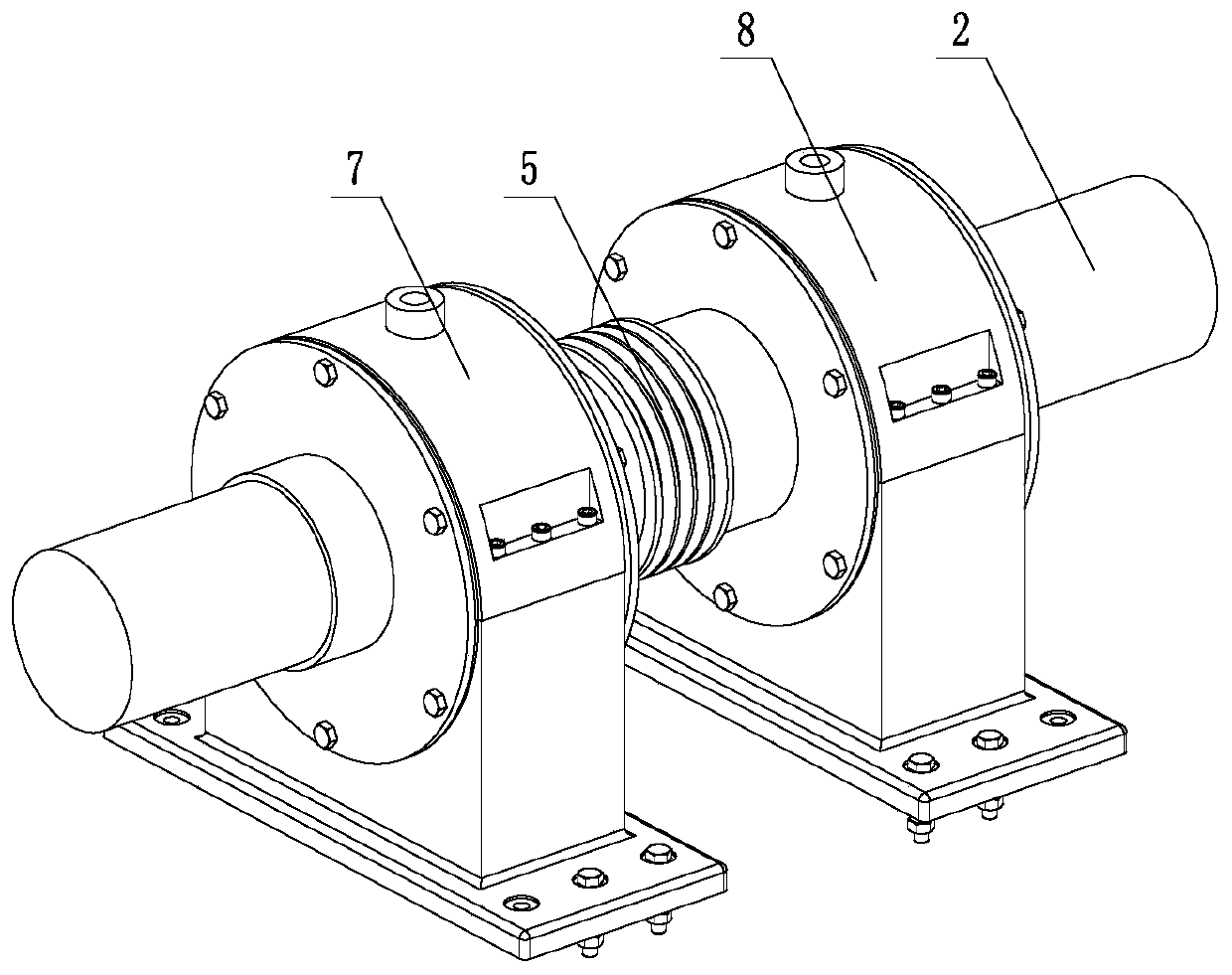

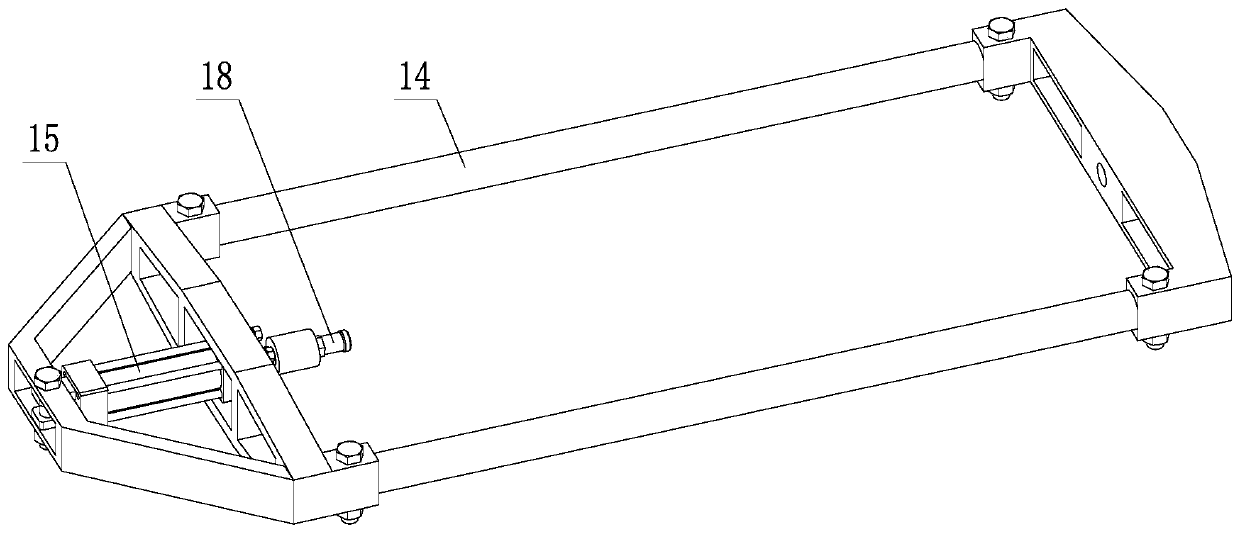

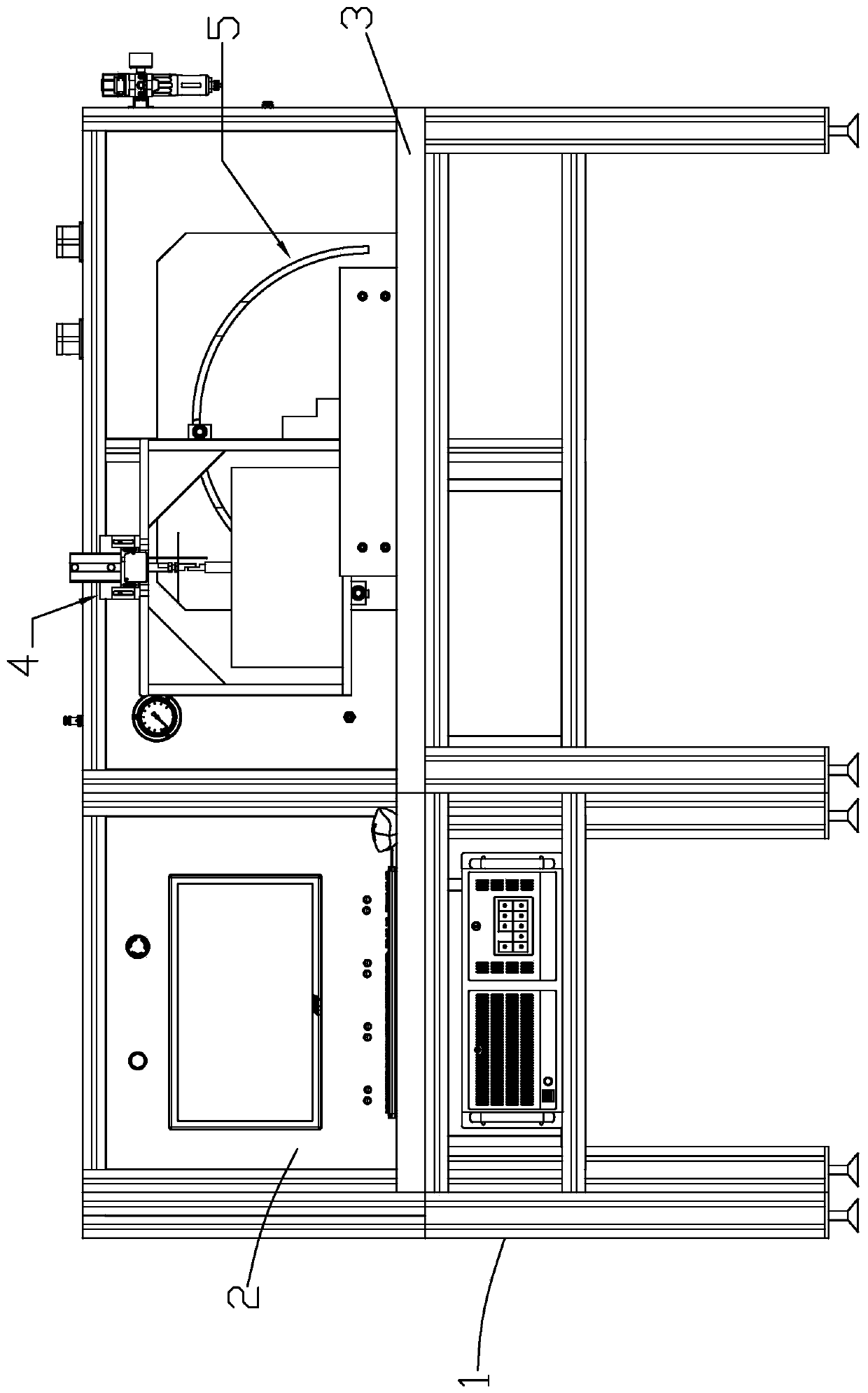

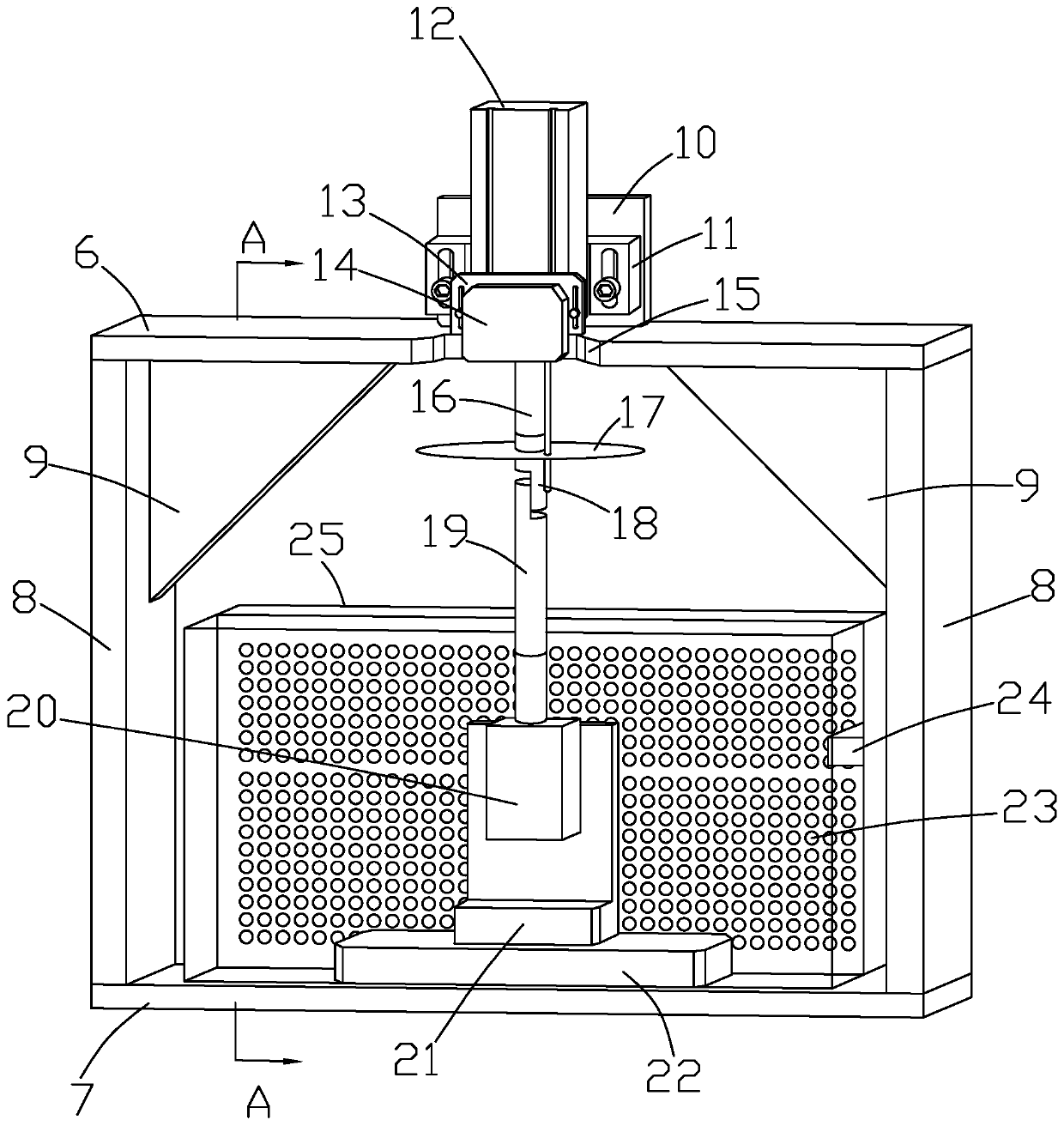

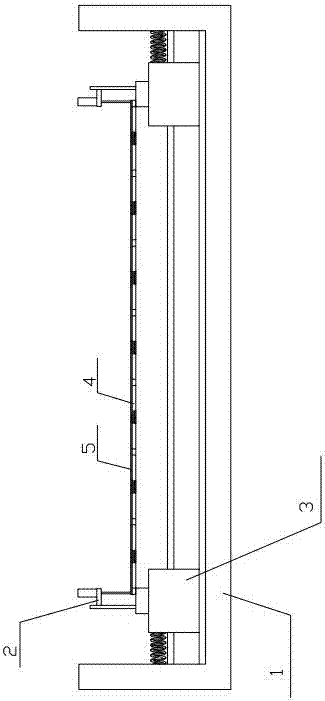

The invention belongs to the technical field of vehicle detection and particularly relates to an integrated dynamic vehicle performance test platform and an integrated dynamic vehicle performance test method. According to the technical scheme, the integrated dynamic vehicle performance test platform comprises a framework (1), a brake driving device, an air cooling eddy current power measurer (2), a coupler (3), a drum group, a clutch A (5), a driving force test device, a brake force test device, a speed sensor (8), a synchronizing device (9) and a lifting device (10). The integrated dynamic vehicle performance test method includes steps of A, shaft weight detection, B, speed detection, C, brake performance detection, and D, rim output power detection. By adopting modularized design concept, the integrated dynamic vehicle performance test platform can be combined according to requirements of test vehicles, and detection requirements of special multi-axle all-wheel drive heavy vehicles are met.

Owner:中国人民解放军第二炮兵装备研究院第三研究所

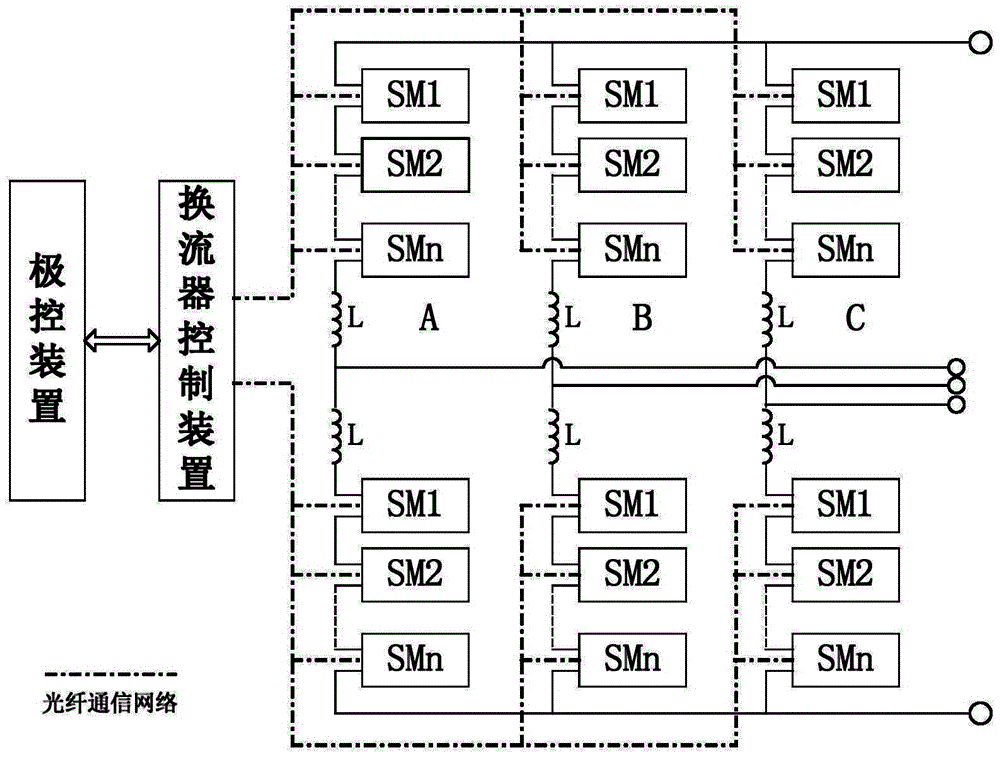

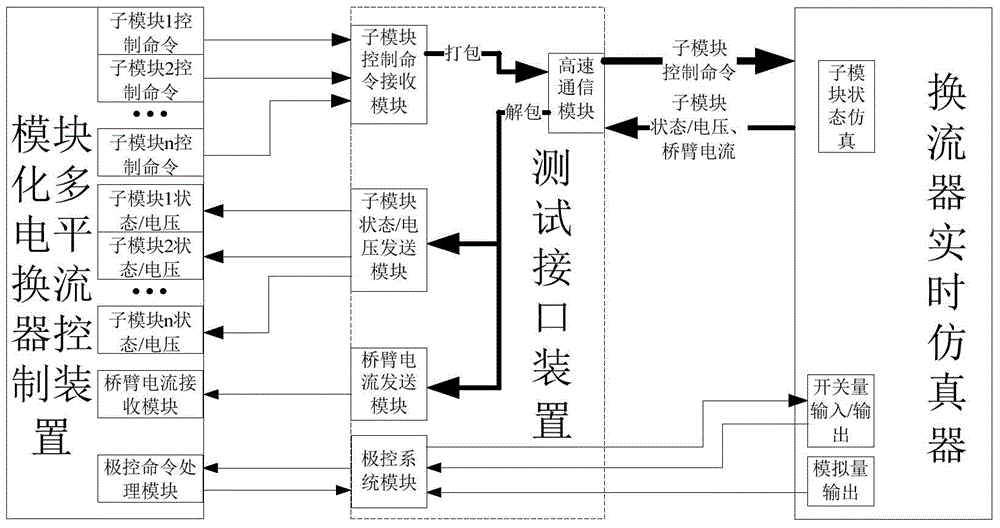

Closed-loop test system and method of modular multilevel converter control apparatus

InactiveCN105005292AMeet performance testing requirementsElectric testing/monitoringFiberControl system

The invention discloses a closed-loop test system and method of a modular multilevel converter control apparatus. The system comprises the modular multilevel converter control apparatus, a converter real-time simulator and a test interface apparatus. The test interface apparatus is composed of a submodule control command receiving module, a submodule state / voltage sending module, a leg current sending module, a polar control system module and a high-speed communication module. The modular multilevel converter control apparatus is connected with the test interface apparatus through fibers, and the test interface apparatus is connected with the converter real-time simulator through fibers and cables to form the closed-loop test system. The test system is simple and easy to use and can conveniently carry out performance testing on the modular multilevel converter control apparatus.

Owner:NR ELECTRIC CO LTD +1

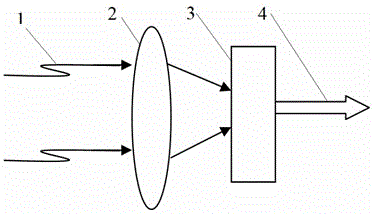

Testing evaluation device for pyroelectric non-refrigeration infrared focal plane detector

InactiveCN105092054AMeet the requirements that require modulationMeet performance testing requirementsPyrometry using electric radation detectorsElectricityPyroelectric detectors

The invention provides a testing evaluation device for a pyroelectric non-refrigeration infrared focal plane detector. The device comprises a light source black body, an adaptive board, a data collection card, a data processing module, a computer system module, and other computer general modules. A block body radiation modulation device is disposed between the light source black body and a non-refrigeration infrared focal plane detector, and is electrically connected with a synchronizing device. The synchronizing device is connected with a data collection pre-triggering device, and the data collection pre-triggering device is electrically connected with the data collection card through an amplification signal outputted by the non-refrigeration infrared focal plane detector. The device achieves the modulation of infrared radiation, meets the requirements of performance test of a pyroelectric detector, solves a problem that the testing and evaluation of the pyroelectric non-refrigeration infrared focal plane detector cannot be carried out in the prior art, enables the scale production of the pyroelectric non-refrigeration infrared focal plane detector to be possible, and reduces the testing cost.

Owner:KUNMING INST OF PHYSICS

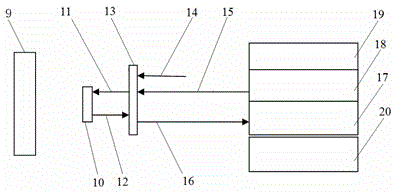

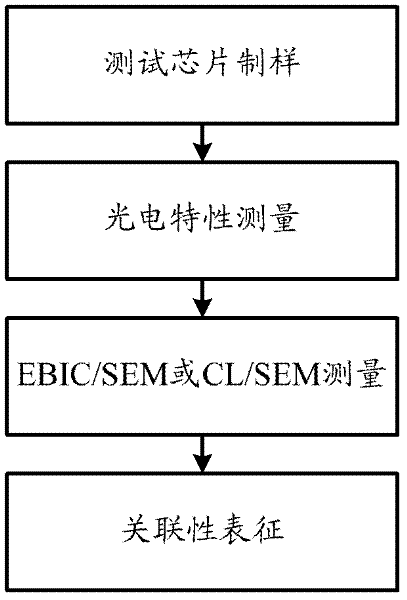

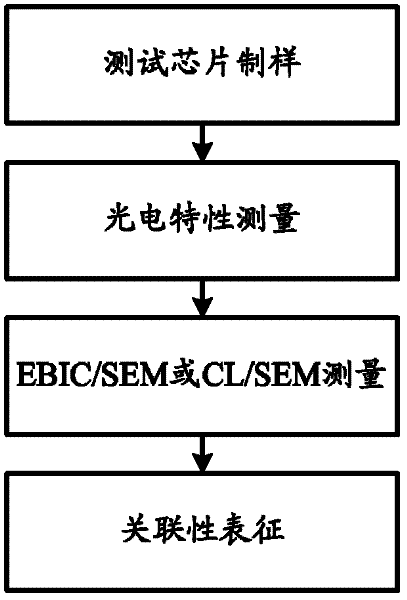

Systematic characterization method for relation between defects of photovoltaic detection materials and performance of devices

InactiveCN102645443AEasy to manufactureMeet performance testing requirementsMaterial analysis by measuring secondary emissionTest sampleStatistical analysis

The invention relates to a systematic characterization method for the relation between the defects of photovoltaic detection materials and the performance of devices, which includes the following steps: according to the variety and characteristics of a photovoltaic detection material, a test chip is designed and packaged to form a test sample; the photoelectric characteristics of the test sample are measured and characterized; on the same test sample, an electron beam-induced current / scanning electron microscope or cathodoluminescence / scanning electron microscope combination-combined method is used for carrying out the measurement, characterization and statistical analysis of performance-related defects; and according to the directly related test characterization result obtained in the previous step, systematic characterization is carried out on the relation between the defects of the material and the performance of the device. The systematic characterization method can prevent the problems of uncertainty and randomness existing in the relation between the performance of the device made from the material and the measured defects of the material.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

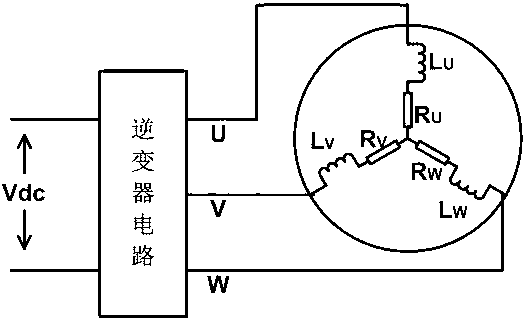

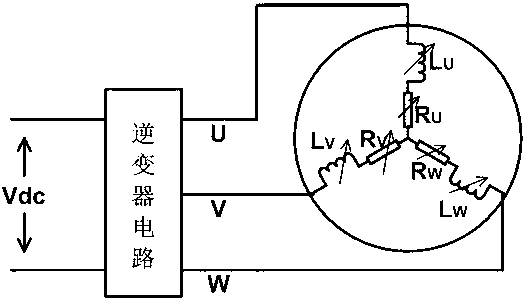

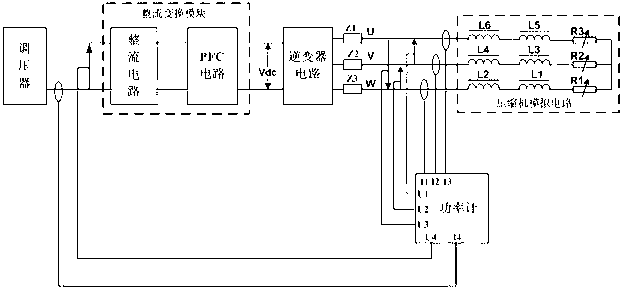

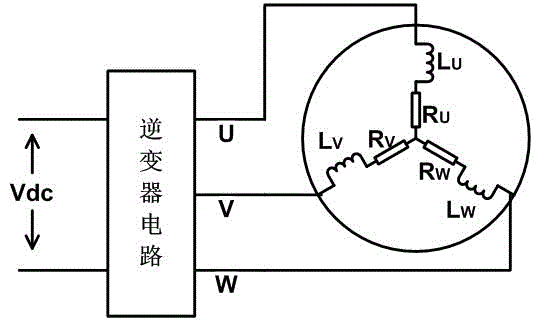

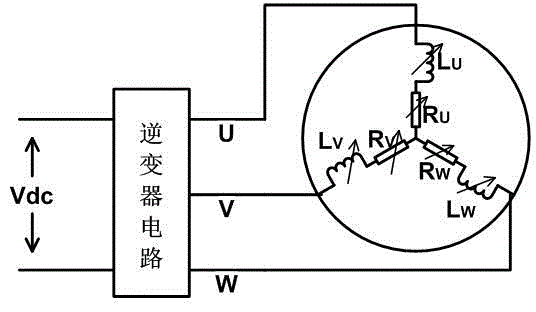

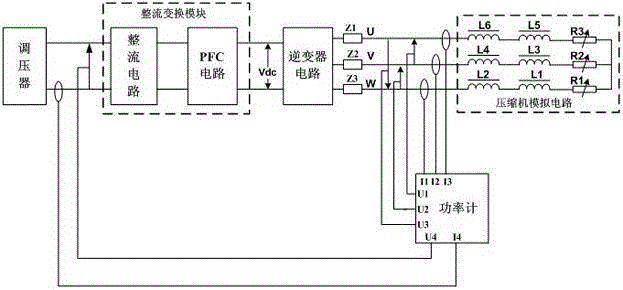

Performance testing method and testing device of inverter circuit

ActiveCN102998568AMeet performance testing requirementsControl up to boundary conditionsElectrical testingElectrical resistance and conductancePower inverter

The invention discloses a performance testing method and a testing device of an inverter circuit. Inductors and resistors are used to simulate a three-phase winding of a compressor, and a set of compressor analog circuits is designed; the compressor analog circuits are used as loads of the inverter circuit and connected to an alternating current output side of the inverter circuit; parameter values of the inductors and the resistors in the compressor analog circuits are changed to obtain different loads; and relevant parameters of the inverter circuit under different loads are detected to finish the performance testing of the inverter circuit. According to characteristics of an air condition compressor, the set of compressor analog circuits is designed to replace an actual compressor, used as the loads of the inverter circuit and applied to the performance testing process of the inverter circuit so that troubles that the compressor is required to be installed and replaced according to traditional test methods are solved, different loads can be conveniently obtained by changing parameters of devices in the compressor analog circuits, and performance testing requirements of the inverter circuit under different loads can be met.

Owner:青岛海信网络能源股份有限公司

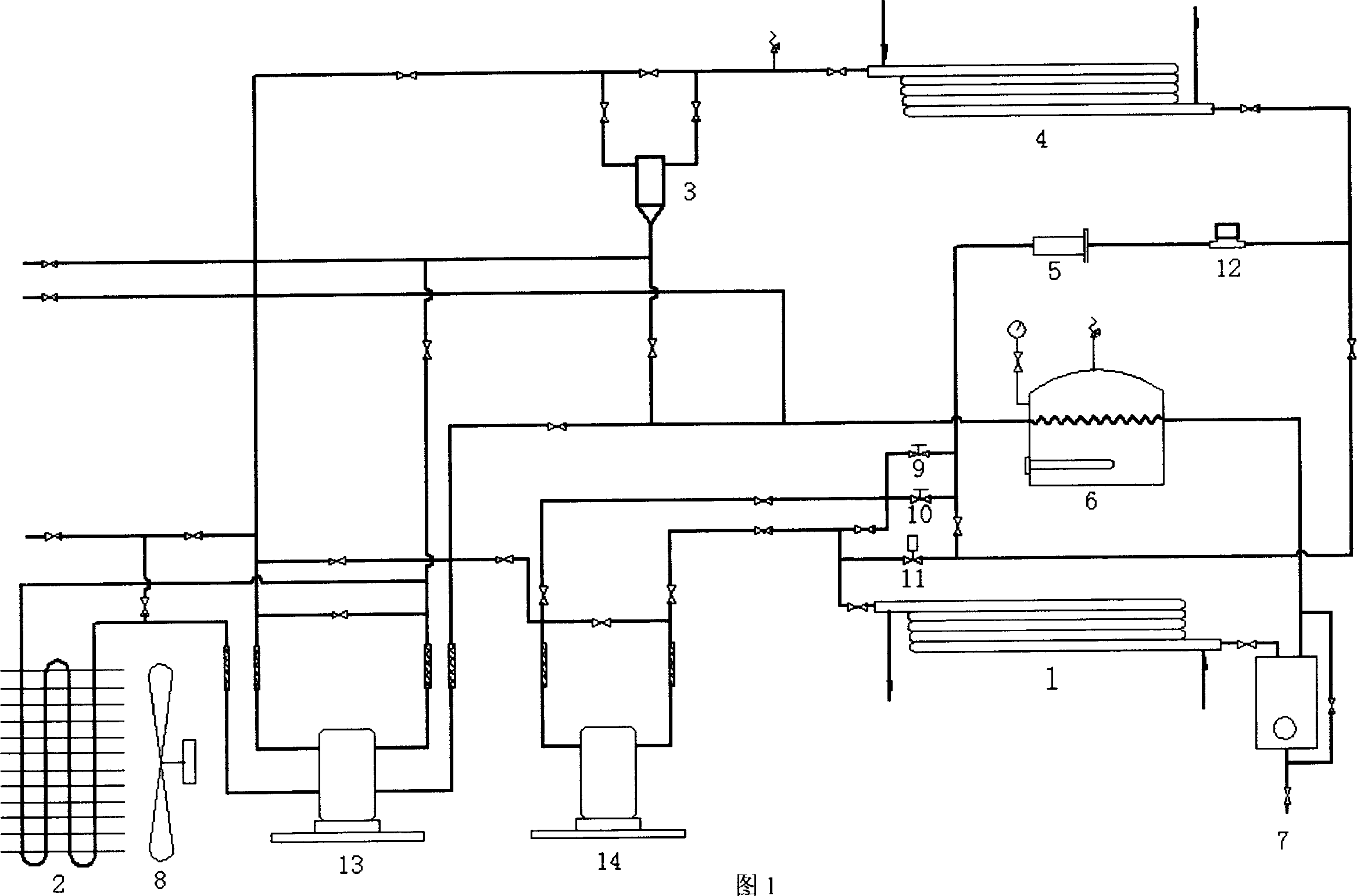

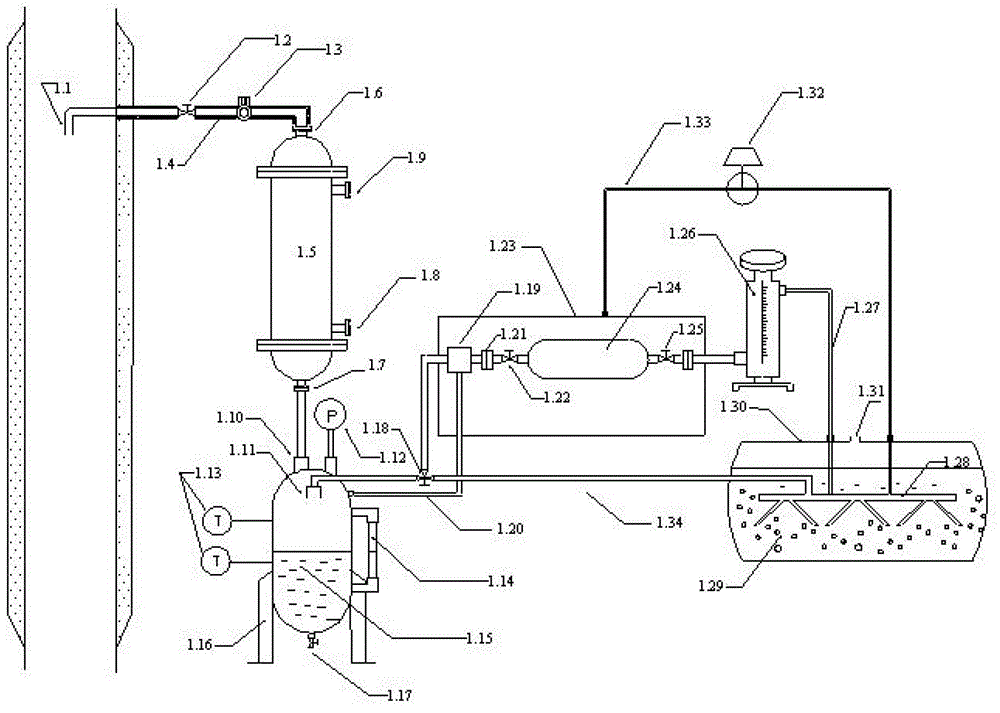

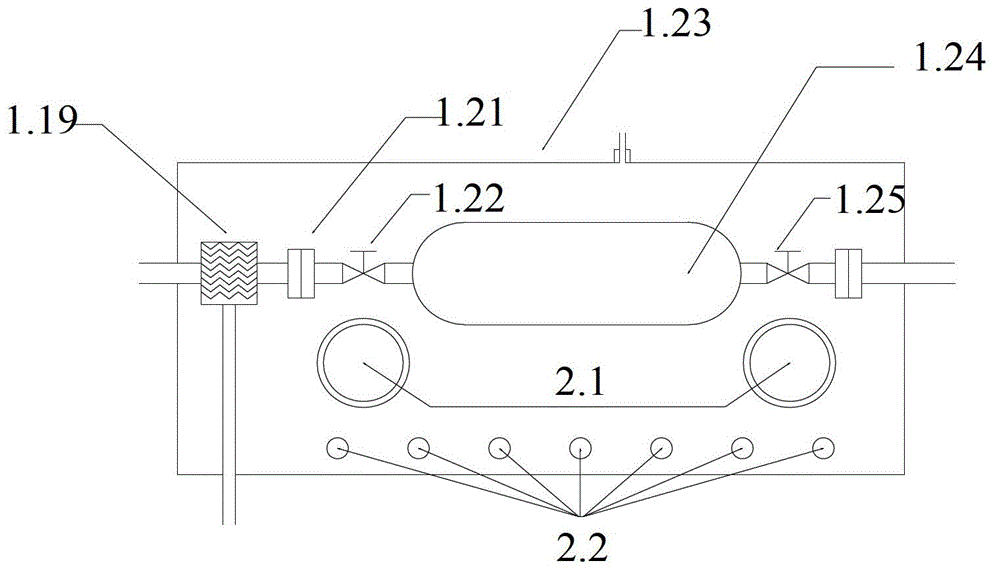

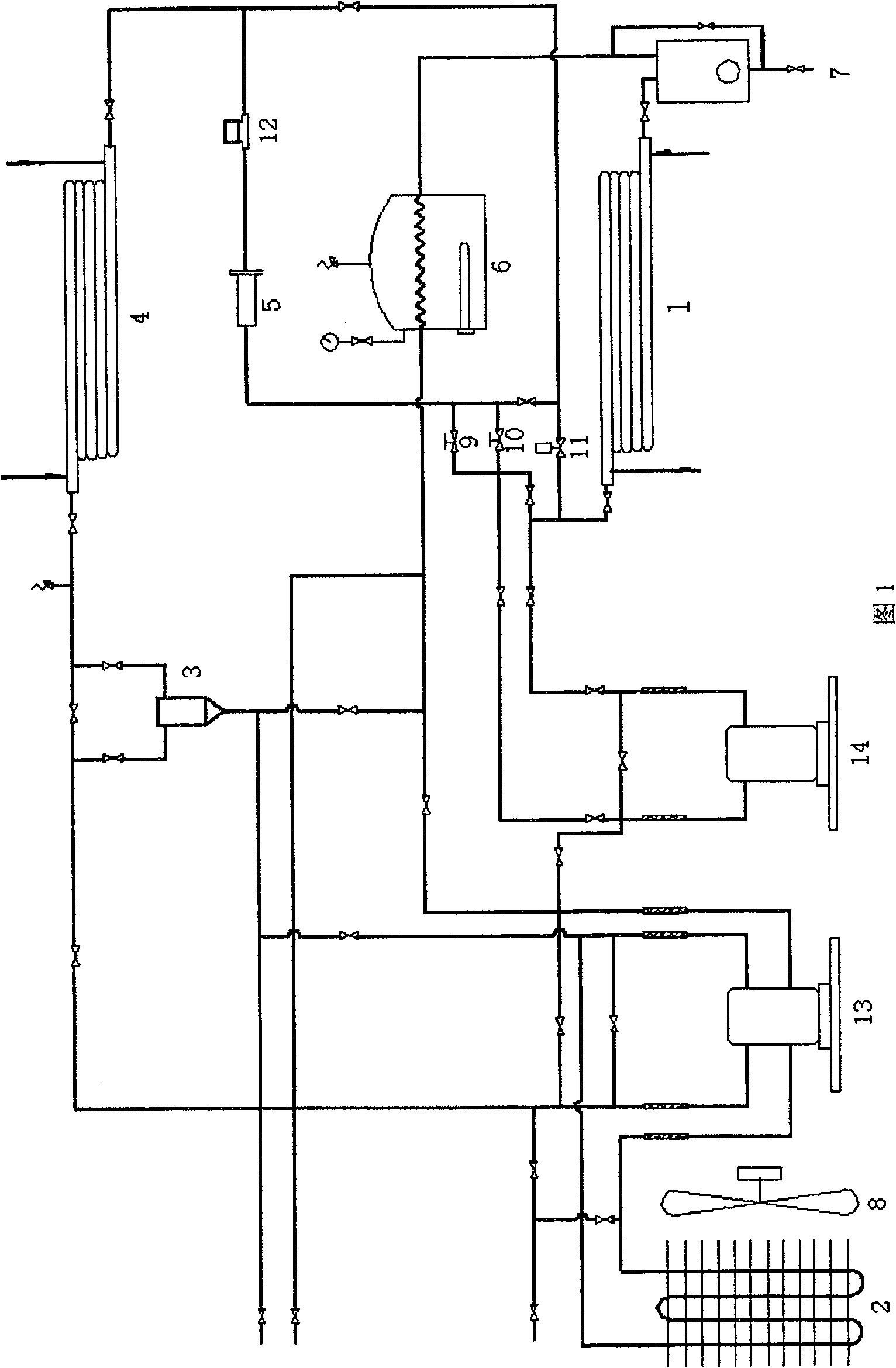

CO2 compressor-expander performance testing system

InactiveCN1844883AMeet performance testing requirementsSimple structureStructural/machines measurementElectricityVapor–liquid separator

The invention discloses a test system for testing the property of carbon dioxide compressor-expander, belonging to the refrigerating technique. Wherein, the outlet of evaporator is connected to the inlet of gas-liquid separator; the outer part of cooling fan is fixed on the front surface of middle cooler; the middle cooler and oil separator are connected to the tested compressor; the inlet of gas cooler is connected to the outlet of coolant of oil separator; the outlet of gas cooler is connected to the inlet of quality flow meter and the inlet of electric expand valve; the outlet of quality flow meter is connected to the inlet of expand valve; the outlet of expand valve is connected to the inlet of tested expander; the outlet of evaporator is connected to the inlet of gas-liquid separator; the outlet of gas-liquid separator is connected to the inlet of electric heater; the outlet of electric heater is connected to the first-stage gas inlet of tested compressor. The invention has simple structure, lower cost, and flexible operation, which can be used to test the property of full-closed carbon dioxide compressor-expander.

Owner:SHANGHAI JIAO TONG UNIV

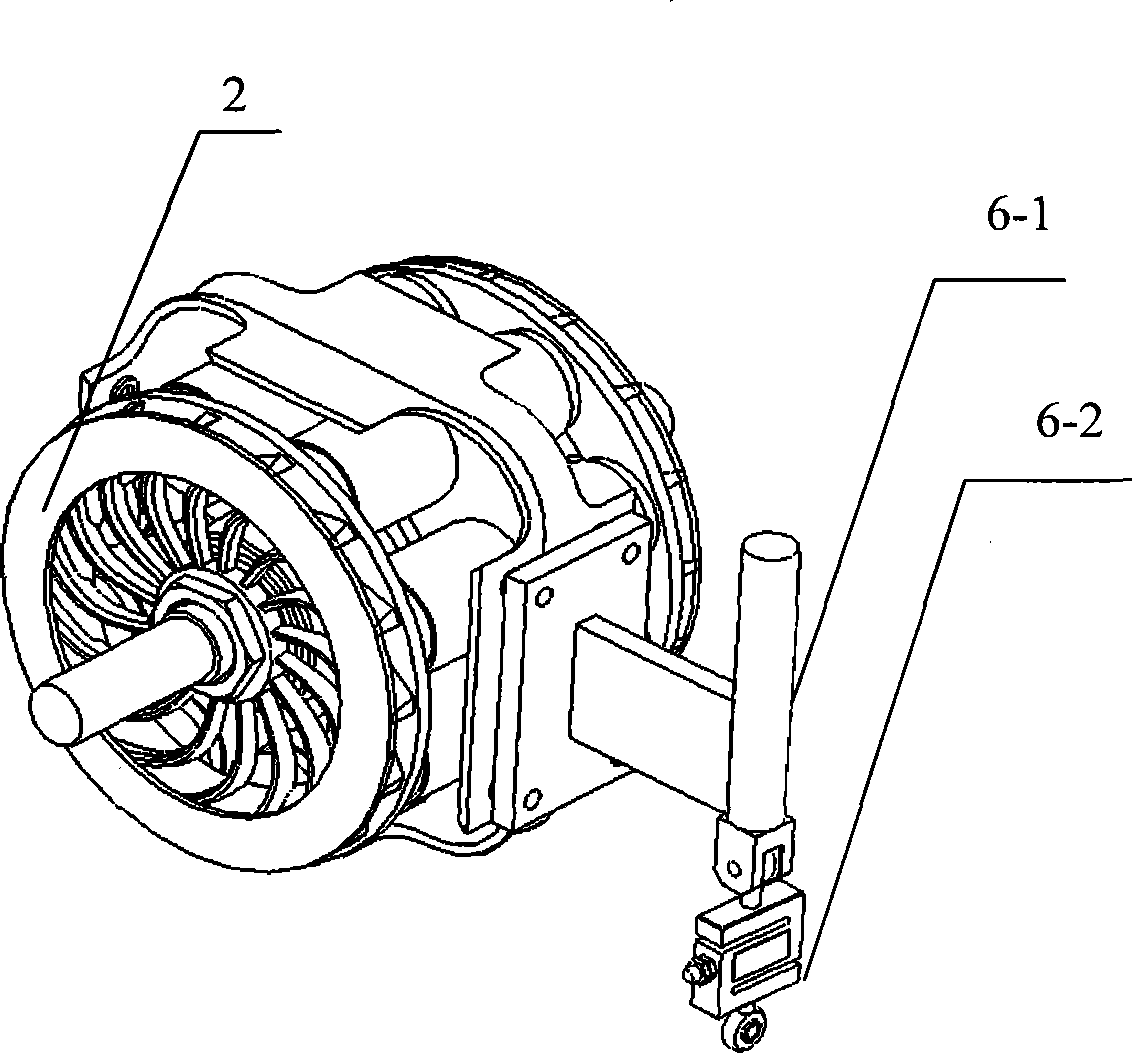

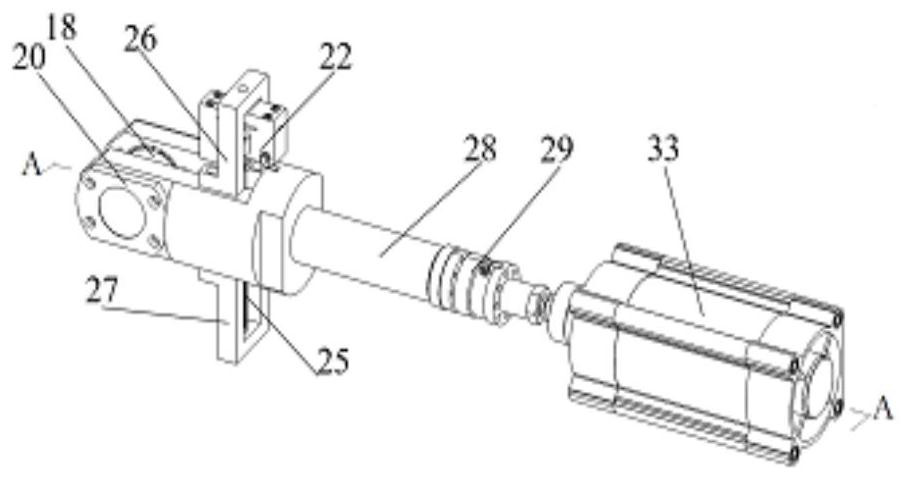

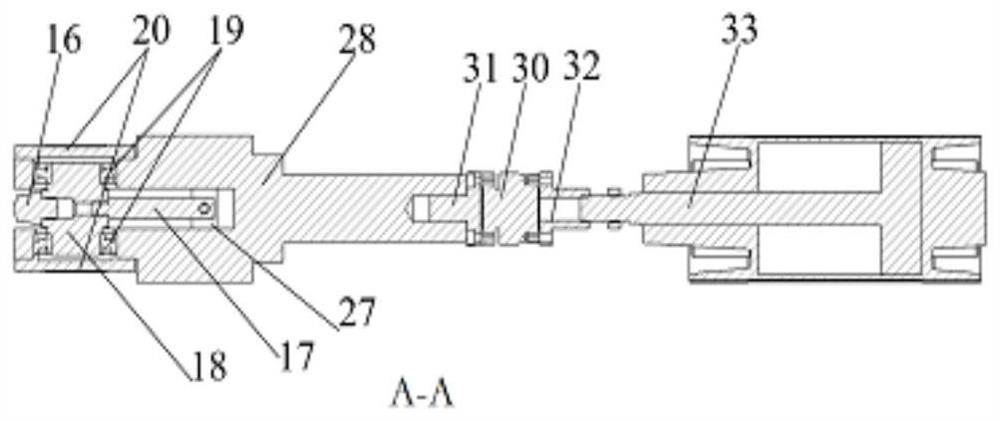

Linear small and special motor performance automatic testing system

ActiveCN109031123ARealize simulationMeet performance testing requirementsDynamo-electric machine testingElectric machineEngineering

The invention discloses a linear small and special motor performance automatic testing system. The system aims at solving the problem that the current linear small and special motor performance testing system is single in measurement parameter, low in integration, and capable of importing error by own. Resistive load and inertia load commonly form a load loading device to simulate various potentially faced working conditions of the to-be-tested motor. By adopting the testing system disclosed by the invention, the preload, the operation load parameter, the output thrust, the operation displacement speed acceleration, the motor input voltage, the input current, the input-output power of the motor, the efficiency and the life of the to-be-tested motor under various working conditions can be directly or indirectly acquired.

Owner:JIANGSU UNIV

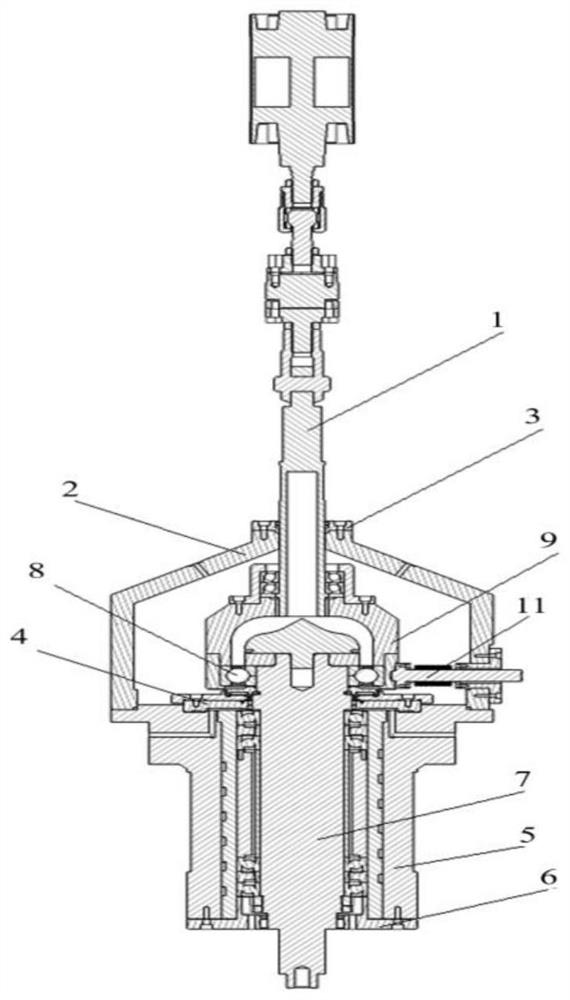

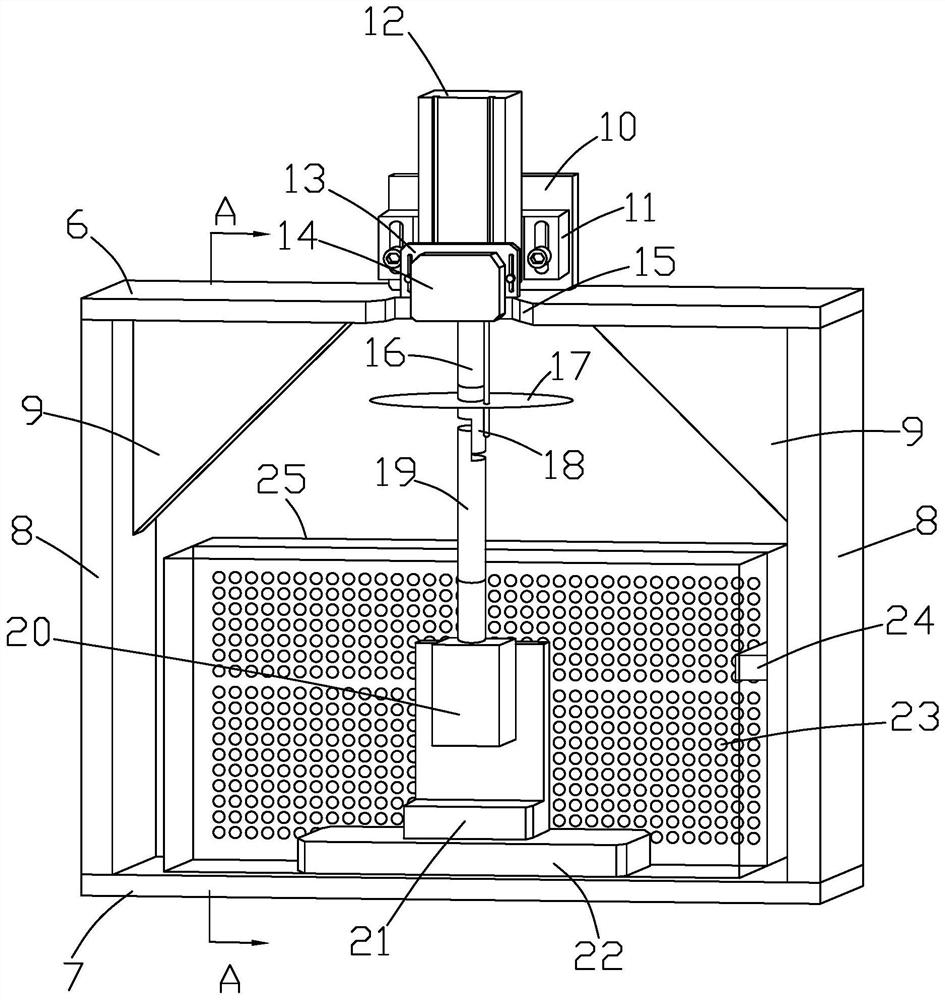

High speed train bearing performance testing device

InactiveCN110017990AMeet performance testing requirementsImprove reliabilityMachine bearings testingHydraulic cylinderEngineering

The invention discloses a high speed train bearing performance testing device. The high speed train bearing performance testing device includes a base frame, main shafts, main shaft supporting bearingseats, an axial loading assembly and a radial loading assembly; the main shafts are arranged at the top of the base frame through the two main shaft supporting bearing seats and is driven by a belt of a motor; to-be-tested high speed train bearings placed in bearing boxes are correspondingly mounted on the main shafts of the outer sides of the two bearing seats; the axial loading assembly is usedfor applying axial loads on the to-be-tested high speed train bearings, the radial loading assembly is used for applying axial loads on the to-be-tested high speed train bearings; the axial loading assembly includes an axial loading frame and axial loading hydraulic cylinders, the axial loading hydraulic cylinders are connected between the bearing boxes and the axial loading frame correspondingly, and pressure sensors are correspondingly mounted between the axial loading hydraulic cylinders and the bearing boxes; the radial loading assembly includes radial loading hydraulic cylinders and force transmission frames, piston rods of the radial loading hydraulic cylinders are connected with the bearing boxes through the force transmission frames, and pull-press sensors are mounted on the forcetransmission frames; and vibration generators are correspondingly mounted at the bottom ends of the axial loading hydraulic cylinders and the bottom ends of the radial loading hydraulic cylinders.

Owner:NORTHEASTERN UNIV LIAONING

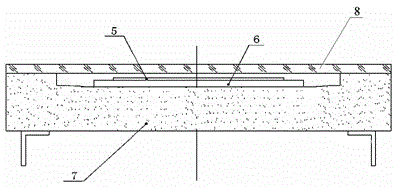

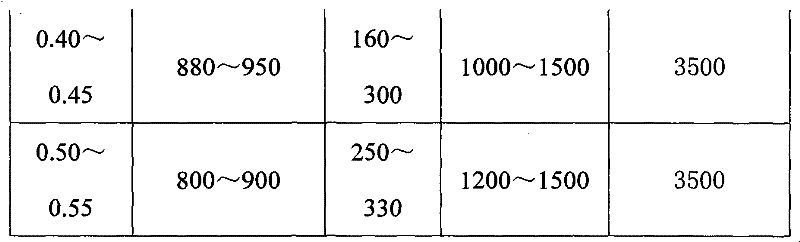

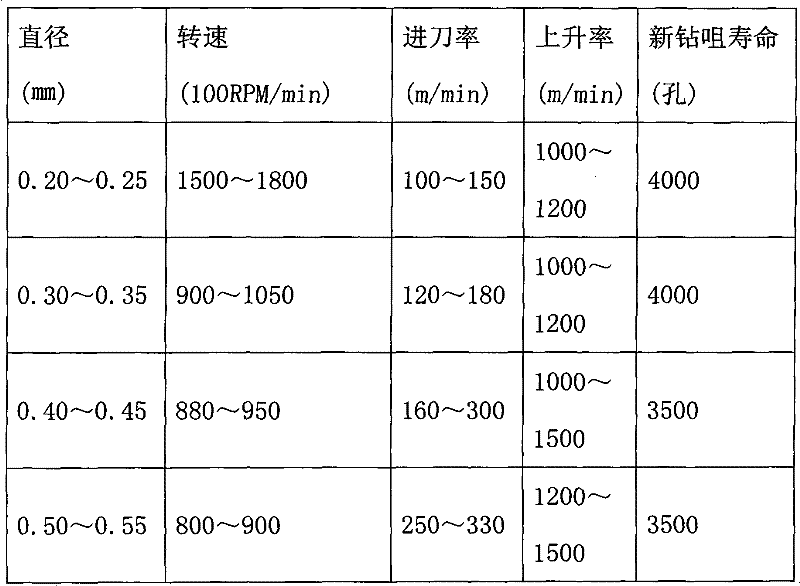

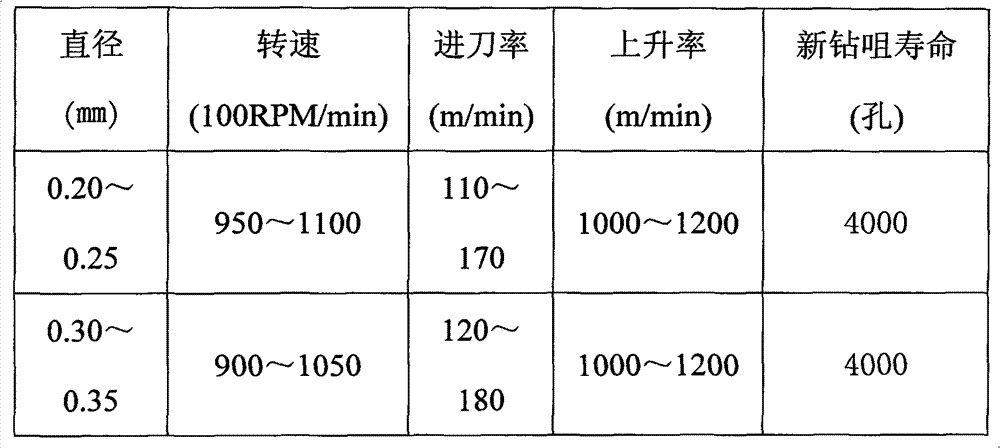

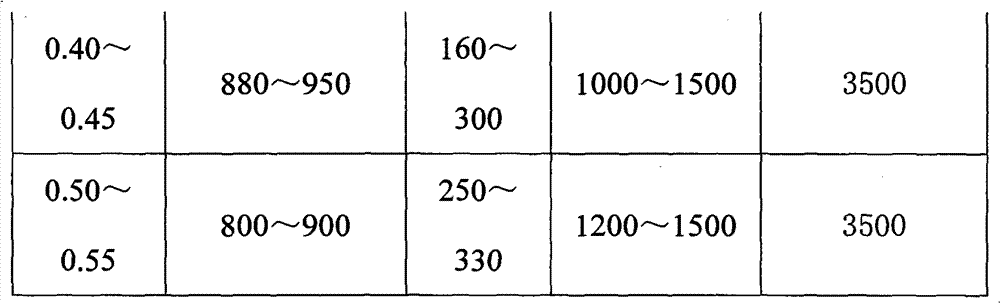

Drilling process of induction magnetic ring plate

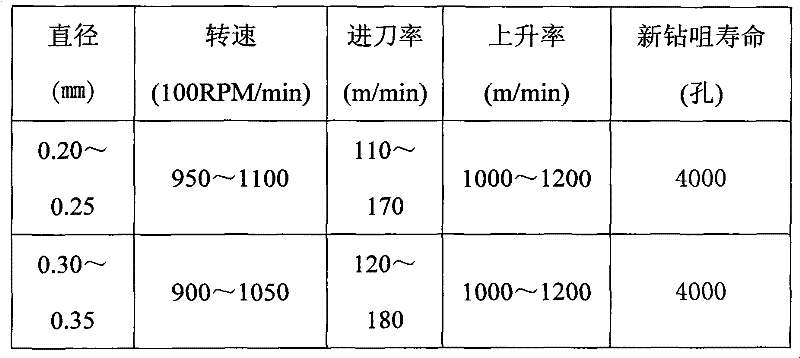

InactiveCN102300411AEasy to cut offEasy chip removalPrinted circuit manufactureFiberContinuous design

The invention discloses a drilling manufacturing process of an induction magnet ring plate. A continuous drilling method is adopted in a common multi-layer plate hole drilling manufacturing process applied to a computer and network equipment at present; the electric property of a product is affected by hole roughness; the continuous drilling generates larger impact force on a hole wall; wire drawing is easy to generate; and the drill bit heat can not be effectively released. In the drilling manufacturing process provided by the invention, hole location, hole number, hole diameter, hole shape,inter-line spacing and layout design can be finished by utilizing line plate auxiliary software genesis; the drilling manufacturing process comprises location hole drilling, laminating, primary hole drilling, secondary hole drilling, hole blowing and checking; continuous-hole drilling is changed into separated-hole drilling; two same cutters are utilized for production; the inter-hole spacing is maintained at 0.75mm; the drilling rotation speed mainly targets the continuous design parameter which is more than or equal to 0.25mm; the rotation speed is high and the cutting rate is low; and wiredrawing cannot be generated easily in the production process, thus overcoming hole roughness and wick effect caused by hole burning and fiber break in drilling process since the inter-line spacing issmall; and all performance test requirements can be met.

Owner:SHENZHEN TONGXIN CIRCUIT ELECTRONICS

Multifunctional static electromagnet test device

ActiveCN110501660AImprove stabilityImprove reliabilityMagnetic property measurementsMagnetic measurement environmental aspectsMeasurement deviceEngineering

The invention discloses a multifunctional static electromagnet test device, which comprises a frame body. A desktop and a control console are arranged on the frame body. The test device also comprisesa static performance test mechanism and an angle adjustment device. The static performance test mechanism comprises an electromagnet test frame, a linear guide device, a displacement test device, a force measurement device and a temperature control device. The linear guide device is connected to the electromagnet test frame; the force measurement device is connected under the linear guide device;the inner bottom of the electromagnet test frame is provided with an electromagnet fixing device and the temperature control device; and the bottom of the electromagnet test frame is connected to thedesktop through the angle adjustment device. The test device can complete multi-item test through one clamping, greatly shortens the time required for clamping and improves test efficiency, can alsocomplete test of different types of electromagnets, can meet performance test requirements of electromagnets under different clamping angles, integrates the temperature control device and can completeperformance test under different ambient temperatures.

Owner:ZHEJIANG UNIV

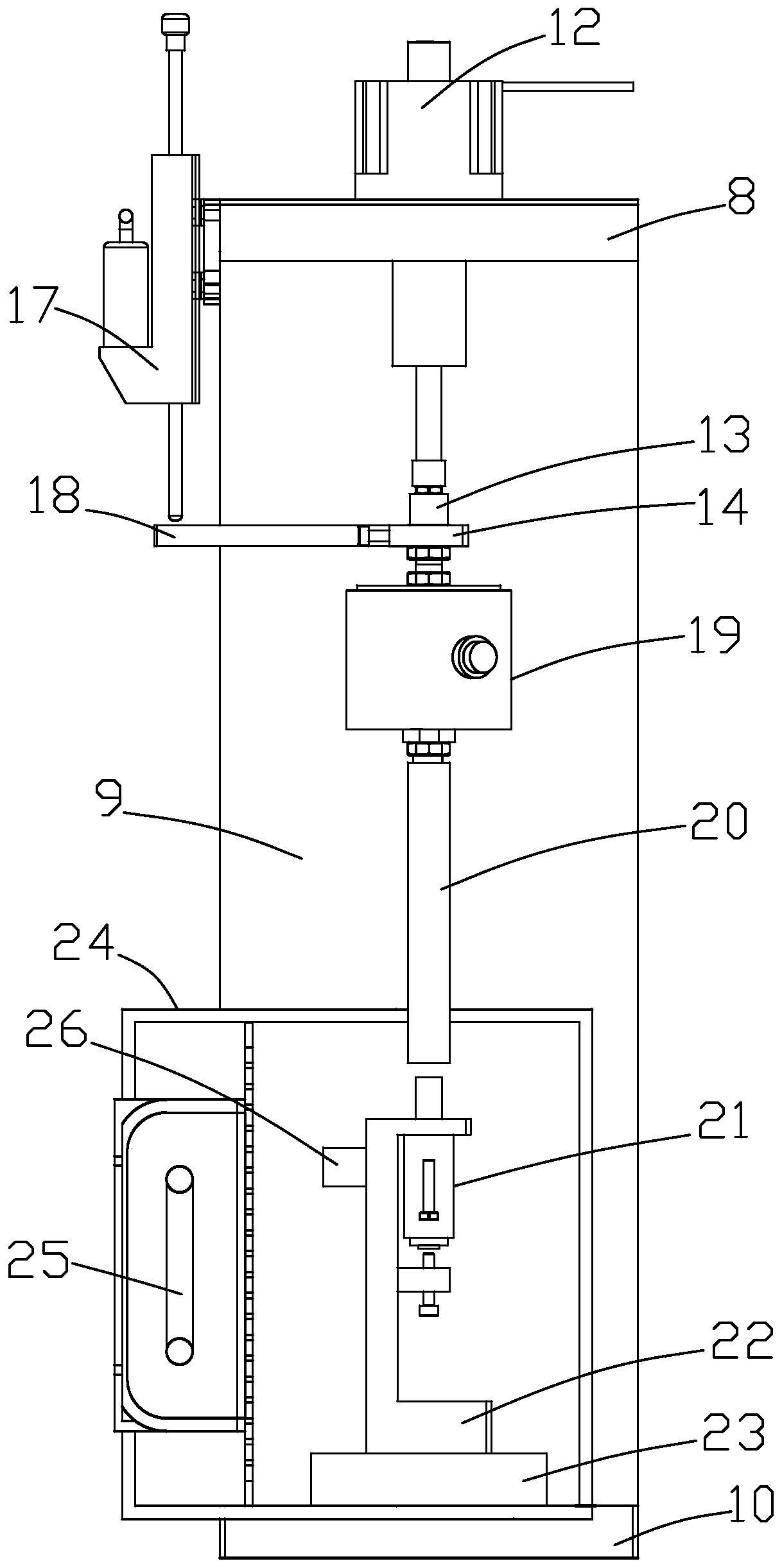

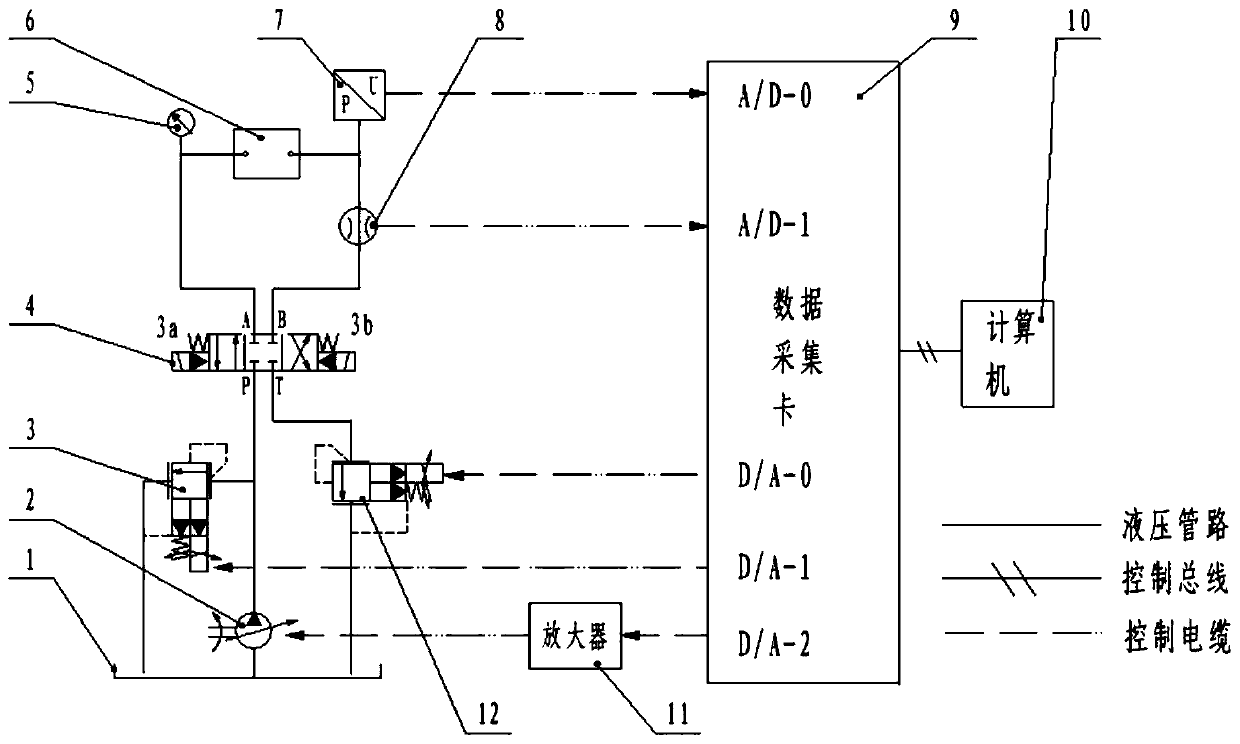

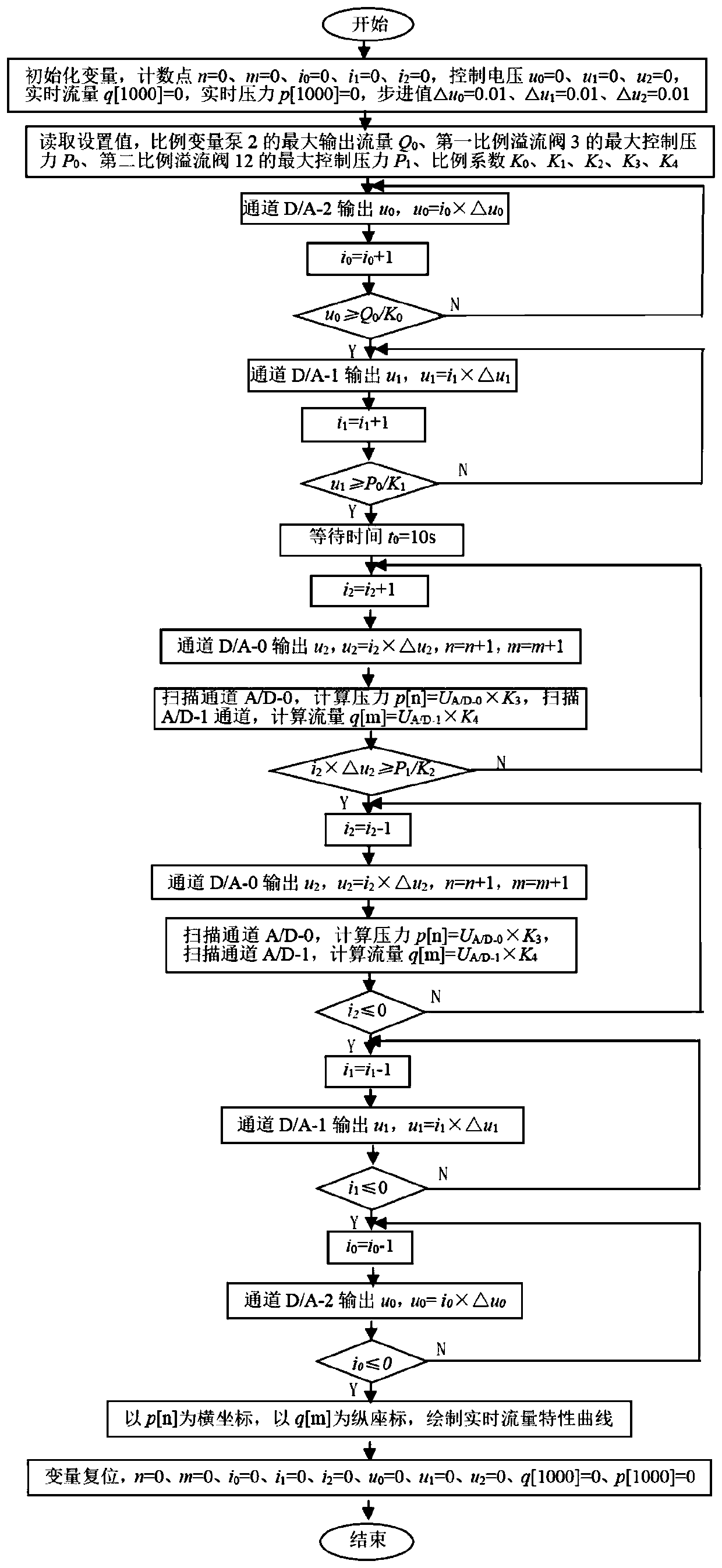

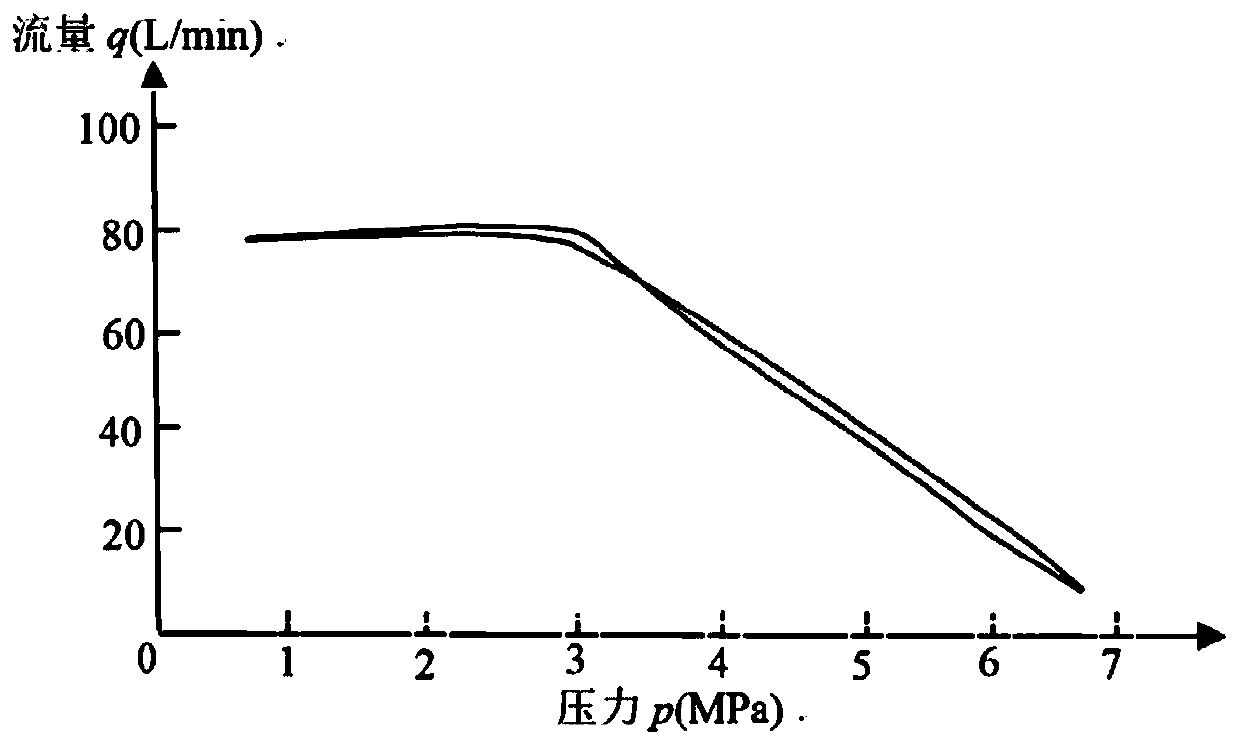

Speed limiting valve real-time flow characteristic testing device and testing method thereof

InactiveCN109869375ASimple side view systemMeet performance testing requirementsFluid-pressure actuator testingServomotor componentsData acquisitionEngineering

The invention relates to a speed limiting valve real-time flow characteristic testing device and a testing method thereof. According to the technical scheme, an oil pressing hole of a proportional variable pump (2) is communicated with an oil inlet of a first proportional overflow valve (3) and a P port of an electro-hydraulic reversing valve (4); an A port of the electro-hydraulic reversing valve(4) is communicated with an inlet of a flowmeter (8) through a tested speed limiting valve (6); a B port of the electro-hydraulic reversing valve (4) is communicated with an outlet of the flowmeter (8); a T port of the electro-hydraulic reversing valve (4) is communicated with an inlet of a second proportional overflow valve (12); a pressure sensor (7), the flowmeter (8), the first proportional overflow valve (3), the second proportional overflow valve (12) and an amplifier (11) are connected with an input / output channel corresponding to a data acquisition card (9); a signal input end of theproportional variable pump (2) is connected with an output channel of the amplifier (11); and the data acquisition card (9) and an auxiliary test software are installed in a computer (10). The speed limiting valve real-time flow characteristic testing device has the advantages of simple system, high testing precision, convenience in installation and high automation degree.

Owner:WUHAN UNIV OF SCI & TECH

Test apparatus used for measuring interaction force between tyre and pavement

ActiveCN106596142AChange the lateral reaction forceExtend your lifeMeasurement of force componentsVehicle tyre testingActive forceRoad surface

The invention discloses a test apparatus used for measuring an interaction force between a tyre and a pavement. The apparatus comprises a power unit, a side force regulation and control unit, a vertical force regulation and control unit, a tyre test unit, a first shaft and a side wall. The side wall is arranged vertically to a horizontal plane. The power unit and the tyre test unit are connected through a tyre shaft. The vertical force regulation and control unit is installed on a first shaft. One end of the side force regulation and control unit is installed on the power unit. The other end of the side force regulation and control unit is installed on the side wall. In the invention, a tangential reaction force, a lateral reaction force and a vertical reaction force between the tyre and the ground are simultaneously measured and great convenience is provided for an aspect of tyre performance research. The structure is greatly simplified and great convenience is provided for an aspect of measuring mutual active forces between different series of tyres and the ground.

Owner:CHANGAN UNIV

Multi-function dynamic electromagnet test device

ActiveCN110501661AFunction as a rotating supportSmooth rotationMagnetic property measurementsMagnetic measurement environmental aspectsTemperature controlTest efficiency

The invention discloses a multi-function dynamic electromagnet test device, which comprises a support frame. A desktop and a control console are arranged on the support frame. The test device also comprises a dynamic test mechanism and an angle adjustment device. The dynamic test mechanism comprises an electromagnet test frame, a cylinder adjustment device, a laser displacement test device, an electromagnet fixing device and temperature control device. The cylinder adjustment device is connected to the electromagnet test frame. The laser displacement test device is connected to the cylinder adjustment device. The electromagnet fixing device and temperature control device are connected to the inner bottom portion of the electromagnet test frame. The bottom portion of the electromagnet testframe is connected to the tabletop through the angle adjustment device. The device can complete multi-item test in one clamping, greatly shortens the time required for clamping and improves test efficiency, can complete test of different types of electromagnets, such as push-type, pull-type and push-pull type electromagnets, can complete dynamic performance test of the electromagnets and can output a real-time change curve of displacement over time.

Owner:ZHEJIANG UNIV

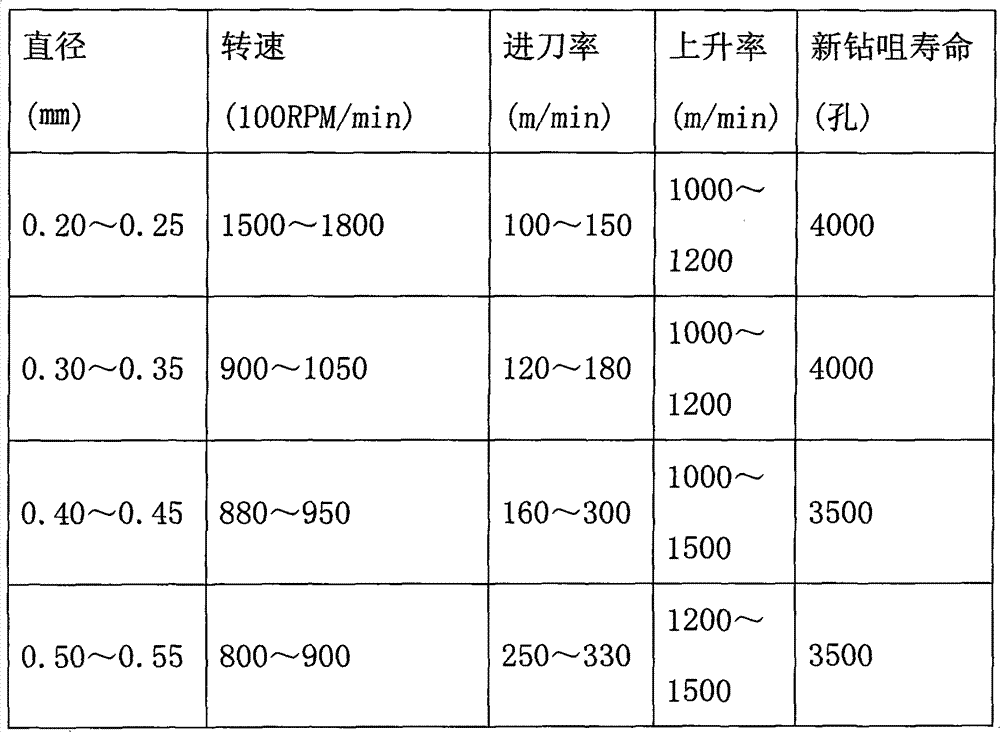

Spring test apparatus

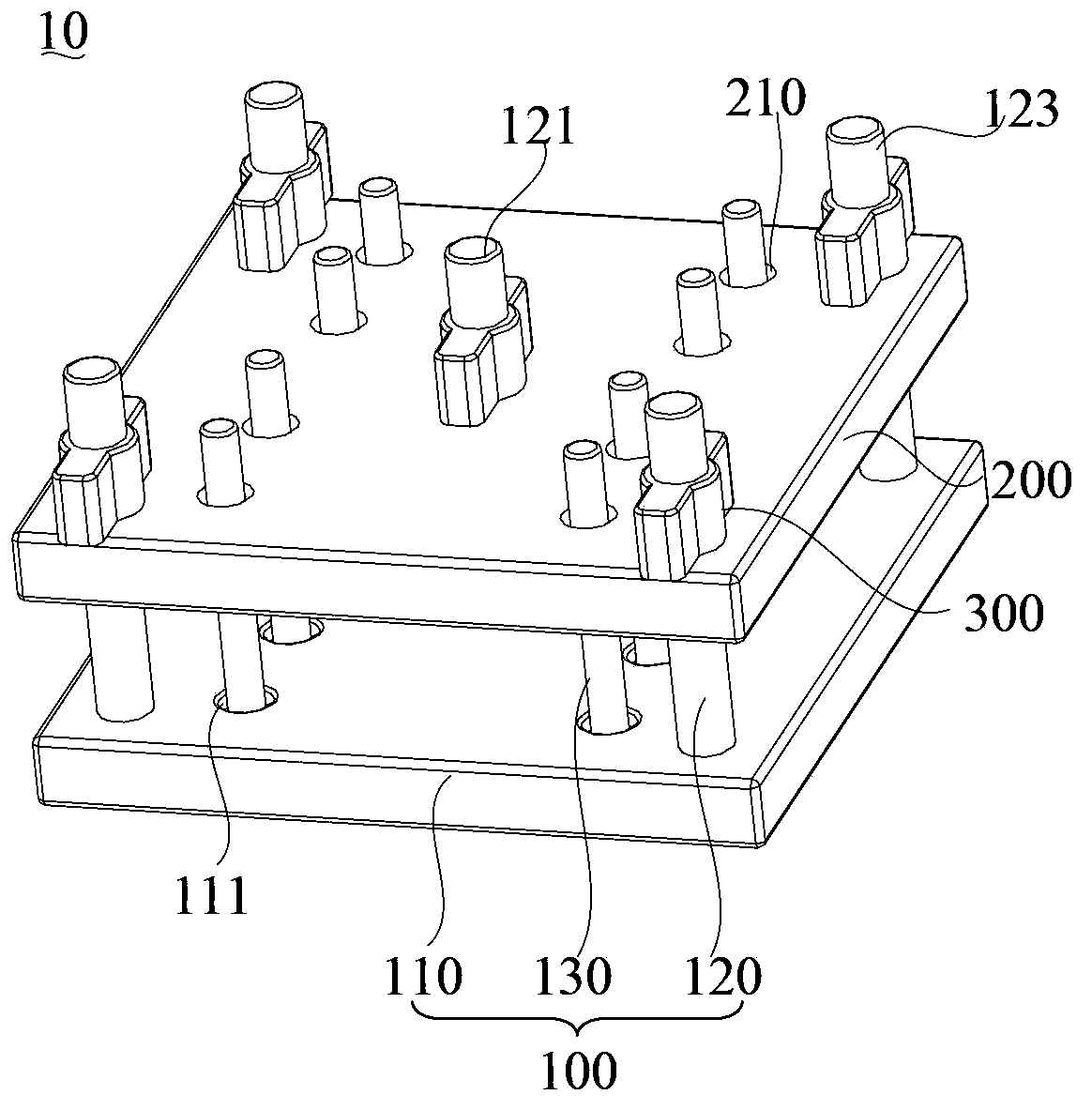

ActiveCN103837407AImprove efficiencyAvoid deformationMaterial strength using tensile/compressive forcesFastenerEngineering

A spring test apparatus comprises a pedestal, a fixed cover and fasteners. The pedestal comprises: a pedestal body provided with first spacing grooves; a plurality of fixed columns arranged on the pedestal body at intervals; and a plurality of spring positioning columns arranged in the first spacing grooves and fixedly connected with the bottoms of the first spacing grooves, wherein springs sheath the spring positioning columns respectively, one ends of the springs are accommodated in the first spacing grooves respectively, and the spring positioning columns are arranged between two fixed columns. The fixed cover is arranged over the pedestal, the free ends of the fixed columns and the spring positioning columns traverse through the fixed cover. The fasteners are fixedly connected with the free ends of the fixed columns, abut against the side surface of the fixed cover far from the pedestal body, and space the fixed cover. The spring positioning columns can prevent the transverse deformation of the springs. The first spacing grooves can space the springs to prevent the shift of the springs in an extrusion process. The spring test apparatus can guarantee the uniform elastic deformation of the springs.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

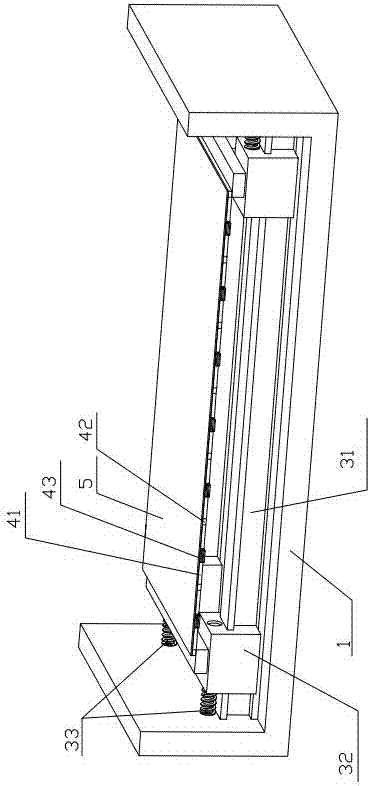

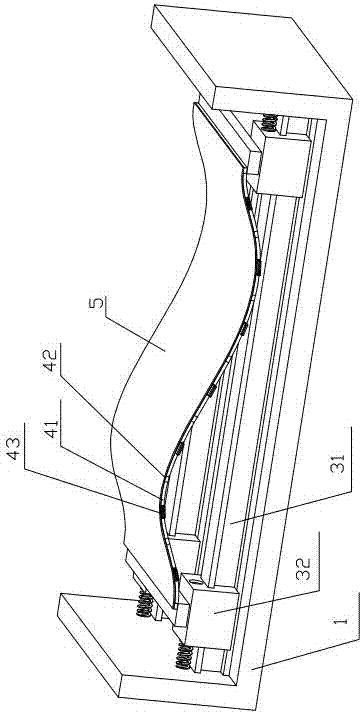

Device and method for controlling shape change of flexible electronic device

ActiveCN107978539AImprove production and processing technologyPrecise control of deformationSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingShape changeEngineering

The invention provides a device and method for controlling the shape change of a flexible electronic device and aims to solve the problem that the shape change of an existing flexible electronic device cannot be controlled precisely. The device comprises a support and a controller and is characterized in that a slide mechanism and a plurality of first shape change components are arranged on the support, the first shape change components are parallelly arranged, each first shape change component is connected with the controller and provided with a second shape change component fitting a to-be-detected flexible electronic device, and each second shape change component is fixed on the slide mechanism through a clamp component and has a first position during mounting and a second position driven by the corresponding first shape change component below the second shape change component to have shape change. The method includes: using the controller to perform shape change control on shape change parts on different first shape change components so as to precisely control the shape change of the flexible electronic device. The device is small in applied voltage, safe and reliable in action, long in service life and the like.

Owner:JIAXING UNIV

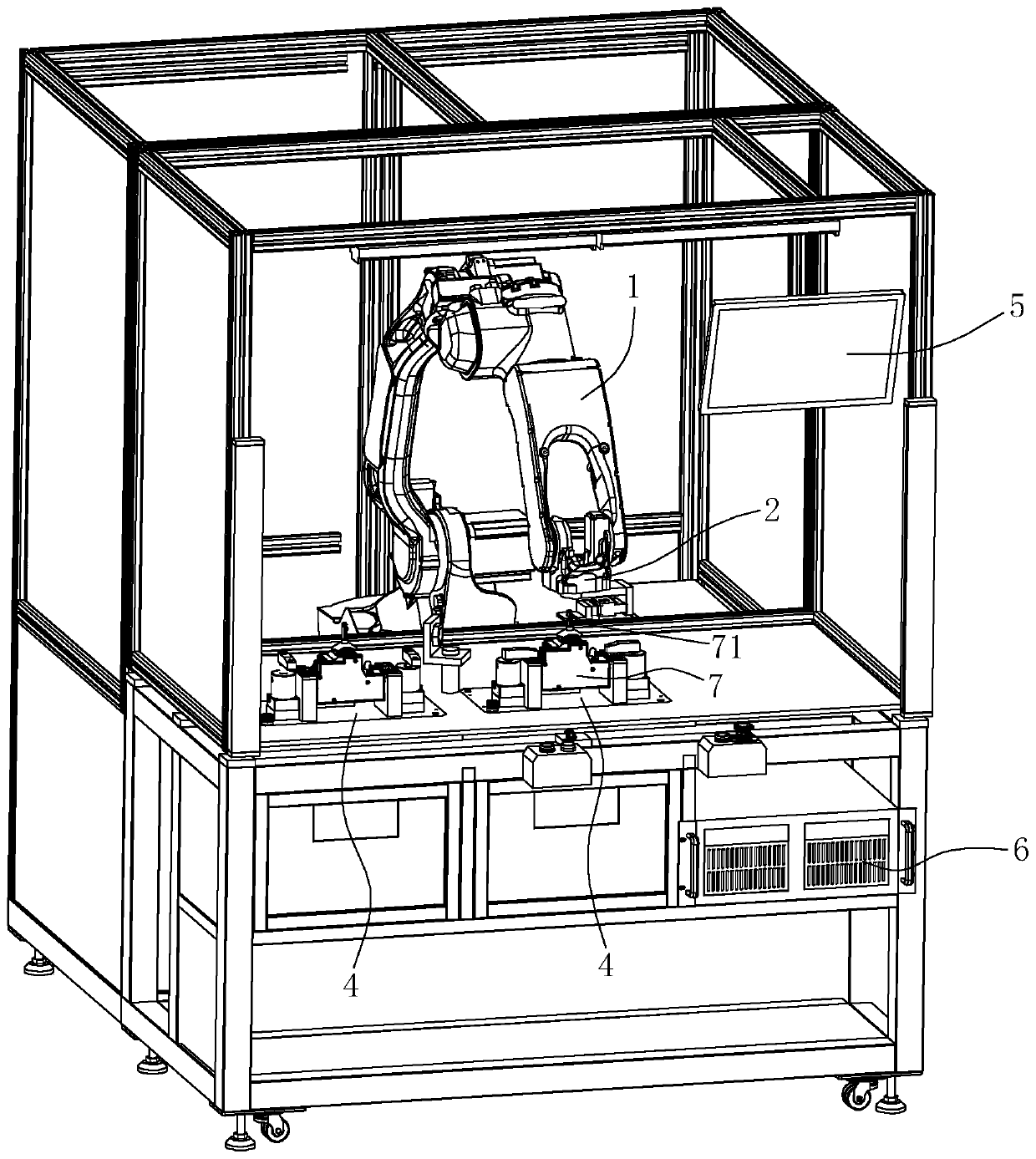

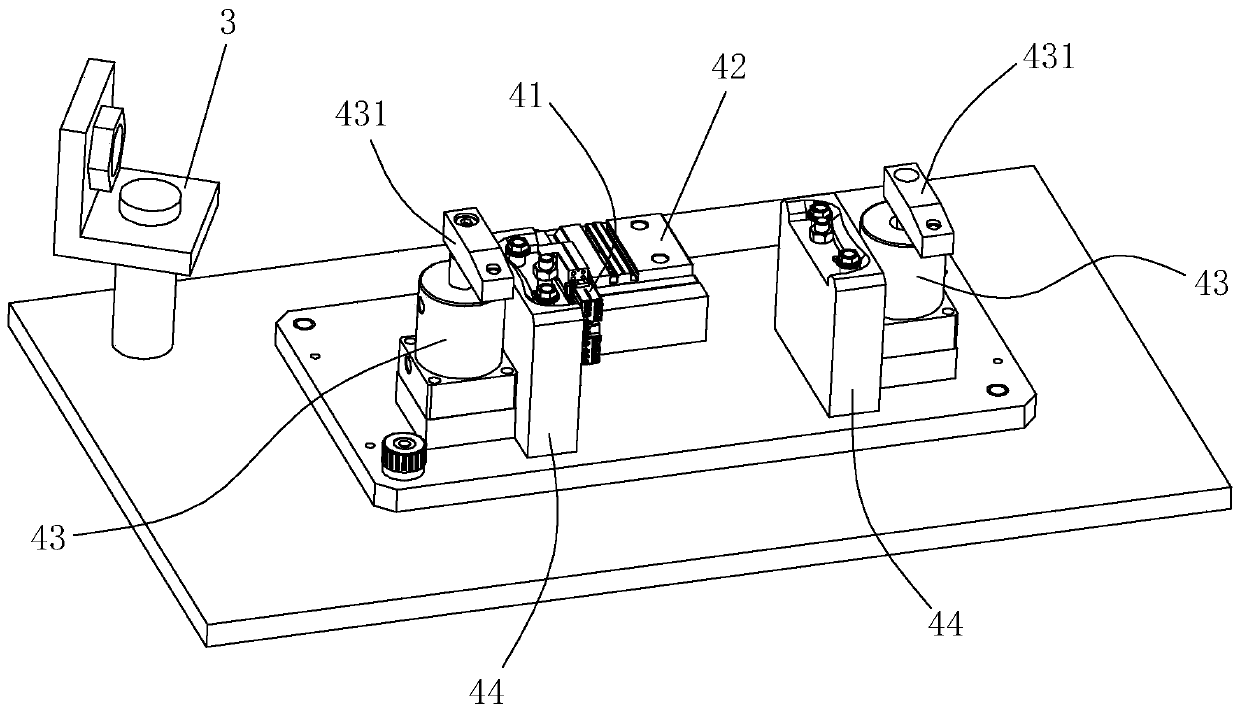

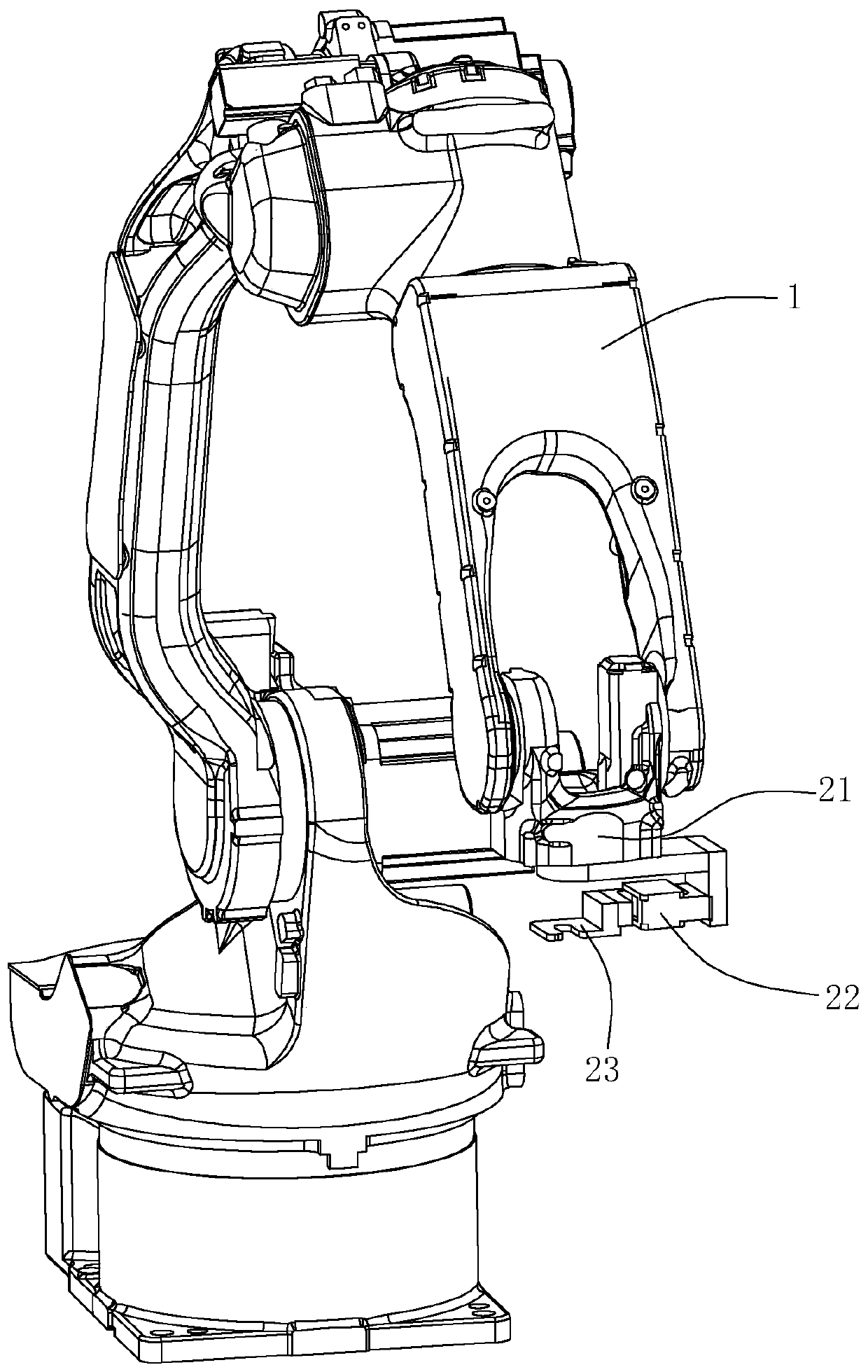

Fully-automatic gear performance detecting system and method for automobile component line-controlled gear shifter

ActiveCN109870301ARealize fully automatic detectionQuality assuranceMachine gearing/transmission testingProduction lineDisplay device

The invention discloses a fully-automatic gear performance detecting system and method for an automobile component line-controlled gear shifter. The system comprises a test bench, a detecting component, and a manipulator, a position sensor, a fixed fixture component, a display and a controller that are mounted on the test bench, wherein the detecting component is mounted on the manipulator, the detecting component comprises a force detector, an angle detector and a clamping fixture, the manipulator clamps the clamping fixture, the force detector and the angle detector are both arranged on theclamping fixture, the clamping fixture is used to clamp a shift level of the line-controlled gear shifter, and the controller is respectively connected to the manipulator, the force detector, the angle detector, the position sensor, the fixed fixture component and the display. The system can realize the fully-automatic gear self-learning and performance detection of the line-controlled gear shifter, improves the automation degree of a production line, reduces the production cost, and ensures the quality of the line-controlled gear shifter. The invention discloses a detection method thereof atthe same time.

Owner:GAC COMPONENT CO LTD

An automatic performance test system for linear micro-special motors

ActiveCN109031123BMeet performance testing requirementsVarious types of loadDynamo-electric machine testingElectric machineControl engineering

The invention discloses a linear small and special motor performance automatic testing system. The system aims at solving the problem that the current linear small and special motor performance testing system is single in measurement parameter, low in integration, and capable of importing error by own. Resistive load and inertia load commonly form a load loading device to simulate various potentially faced working conditions of the to-be-tested motor. By adopting the testing system disclosed by the invention, the preload, the operation load parameter, the output thrust, the operation displacement speed acceleration, the motor input voltage, the input current, the input-output power of the motor, the efficiency and the life of the to-be-tested motor under various working conditions can be directly or indirectly acquired.

Owner:JIANGSU UNIV

A test method for liquid-cooled motor

ActiveCN104407296BEasy to disassembleNot easy to damageDynamo-electric machine testingElectric machineShort terms

The present invention designs a test method for liquid-cooled motors, which is used for rapid test detection of liquid-cooled motors designed for mechatronics, and adopts a simple external cooling method to replace the complex cooling structure and liquid-cooled circulation system of the original liquid-cooled motors, reducing the number of motors. The risk of damage caused by disassembly and assembly can meet the short-term high-power cooling requirements of the motor.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

Ultralow-temperature rolling bearing service life test device

PendingCN114235402AMeet performance testing requirementsGuarantee authenticityMachine bearings testingCompliant mechanismFriction torque

The invention discloses an ultralow-temperature rolling bearing service life testing device. A radial loading mechanism and a friction torque measuring assembly are additionally arranged on the ultralow-temperature rolling bearing service life testing device. In order to ensure that the radial loading mechanism is not influenced by an ultralow-temperature environment, the outer surface of the circumference of the radial loading mechanism is wrapped with a flexible corrugated pipe, and the radial loading mechanism is effectively isolated from the ultralow-temperature environment; meanwhile, in order to ensure that the friction torque measuring assembly is not influenced by an ultralow-temperature environment, the friction torque measuring assembly is arranged on a transmission path of a radial airborne mechanism and is measured through a torque balance method, and in order to ensure the authenticity and credibility of the friction torque, the loading mechanism and the friction torque measuring assembly adopt flexible mechanisms. The friction torque is arranged in the transmission path of the radial loading mechanism, so that the friction torque of the test bearing under different loads and rotating speeds can be measured, the same mechanism is used for measuring the friction torque and applying the radial load, the structure is simplified, and the space is saved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

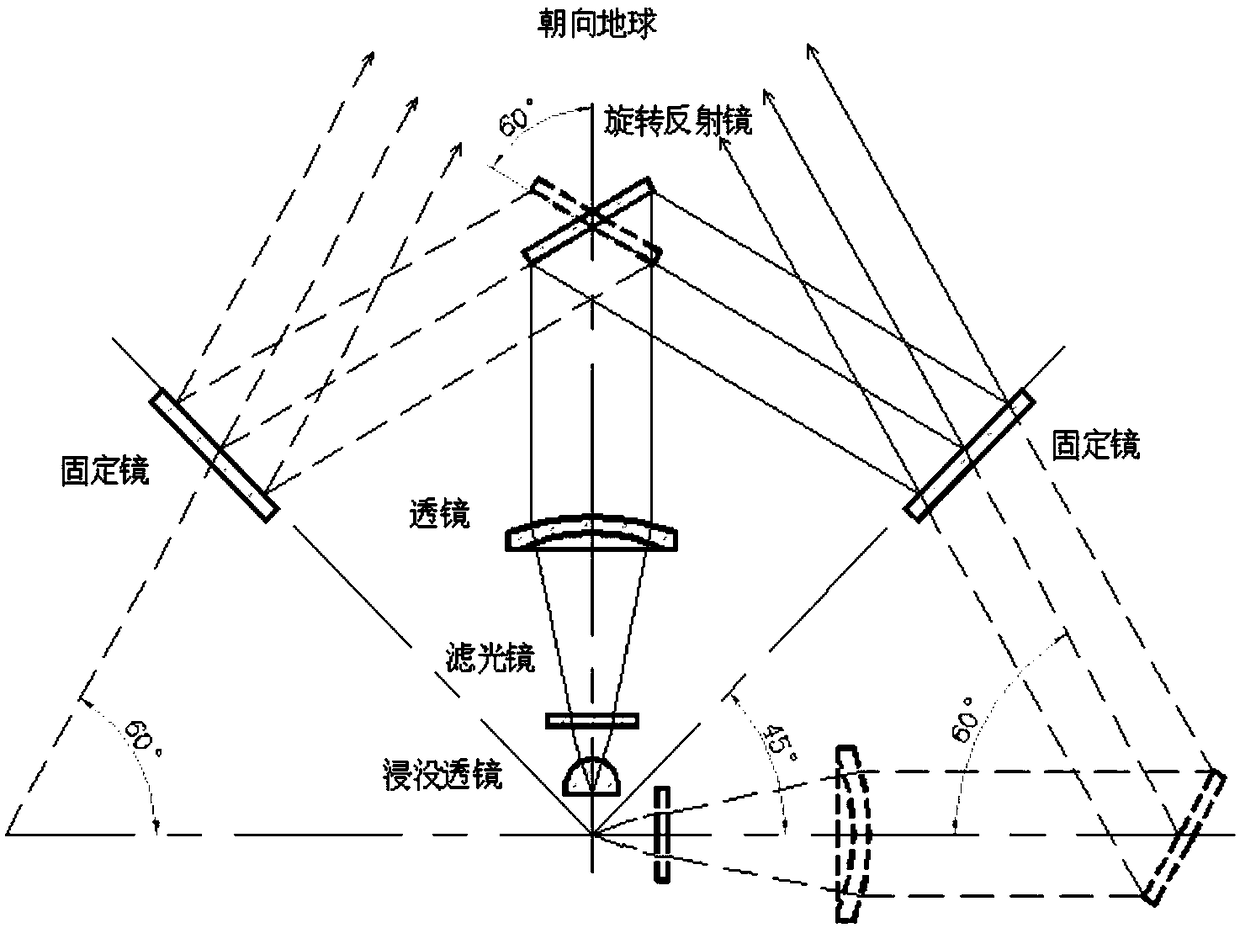

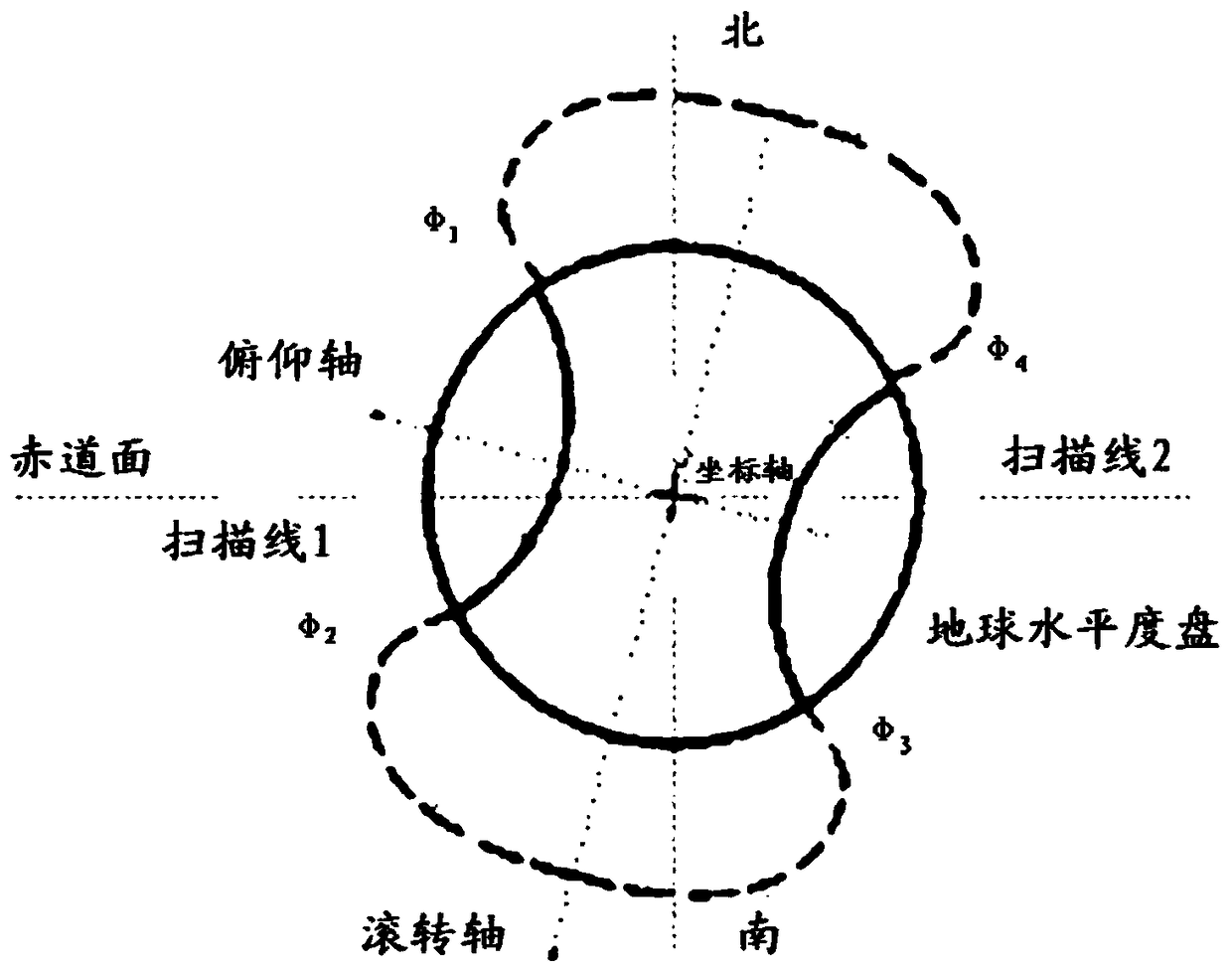

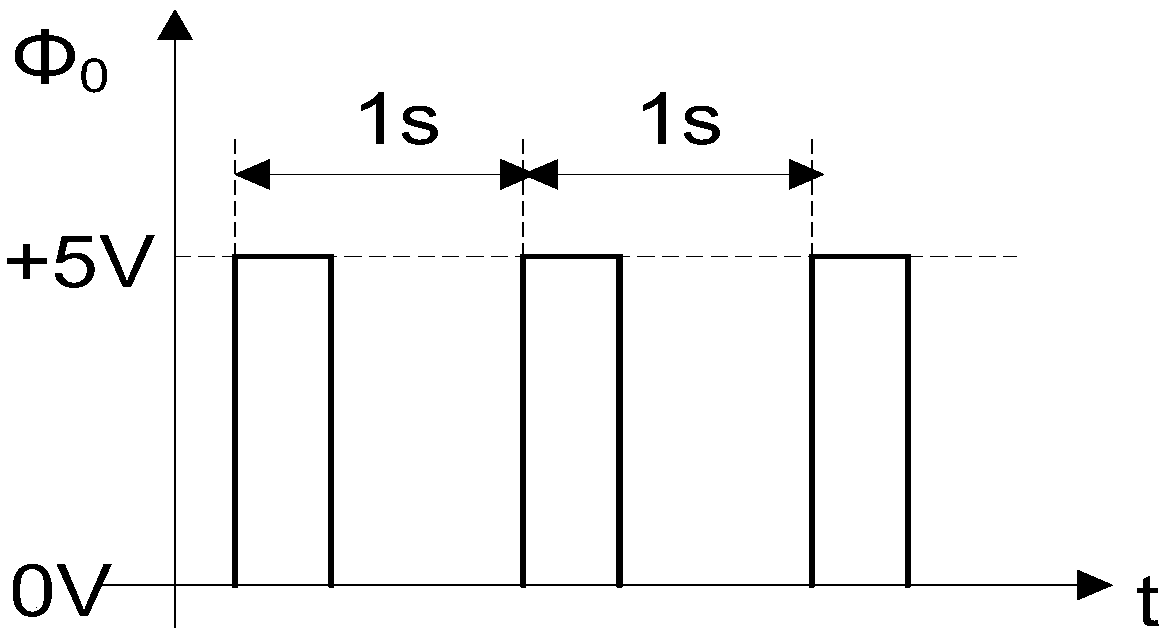

A test method and test system based on earth signal simulation

ActiveCN106404003BEasy to testSimple test operationMeasurement devicesEngineeringComputational physics

The invention relates to a test method and a test system based on earth signal analog. A kinematic calculation controller calculates a cross angle calculated value of an infrared earth sensor according to the current satellite attitude and outputs a time value corresponding to the cross angle calculated value; a simple earth signal device receives the time value output by the kinematic calculation controller and reference pulse and a counting frequency signal which are extracted from the infrared earth sensor to generate an earth analog signal; the infrared earth sensor receives the earth analog signal, performs earth signal detection and reads and outputs cross angle information; an external computer receives the cross angle information output by the infrared earth sensor to perform attitude calculation and acquires an attitude measured value of the infrared earth sensor. Product tests are performed in an electric signal generation analog manner, and high efficiency and accuracy of tests on the double-cone scanning type infrared earth sensor product are guaranteed.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

Performance testing method and testing device of inverter circuit

ActiveCN102998568BMeet performance testing requirementsControl up to boundary conditionsElectrical testingElectrical resistance and conductancePower inverter

The invention discloses a performance testing method and a testing device of an inverter circuit. Inductors and resistors are used to simulate a three-phase winding of a compressor, and a set of compressor analog circuits is designed; the compressor analog circuits are used as loads of the inverter circuit and connected to an alternating current output side of the inverter circuit; parameter values of the inductors and the resistors in the compressor analog circuits are changed to obtain different loads; and relevant parameters of the inverter circuit under different loads are detected to finish the performance testing of the inverter circuit. According to characteristics of an air condition compressor, the set of compressor analog circuits is designed to replace an actual compressor, used as the loads of the inverter circuit and applied to the performance testing process of the inverter circuit so that troubles that the compressor is required to be installed and replaced according to traditional test methods are solved, different loads can be conveniently obtained by changing parameters of devices in the compressor analog circuits, and performance testing requirements of the inverter circuit under different loads can be met.

Owner:青岛海信网络能源股份有限公司

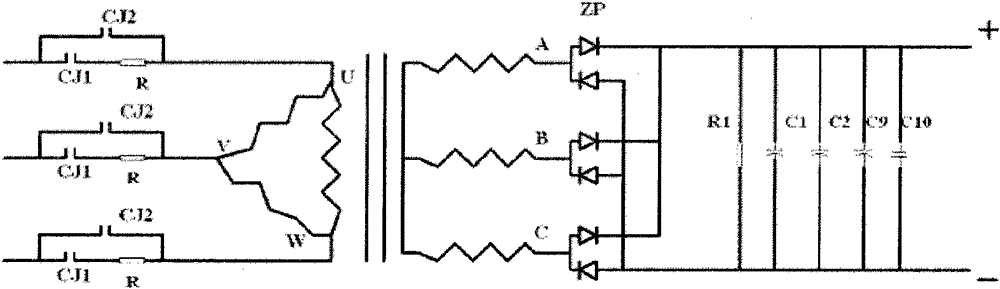

Auxiliary power supply circuit structure for high-voltage high-power motor performance test

InactiveCN104993723AMeet performance testing requirementsSimple structureAc-dc conversionTransformerThree-phase

The invention relates to an auxiliary power supply circuit structure for a high-voltage high-power motor performance test. The auxiliary power supply circuit structure comprises a three-phase isolation insulating transformer. The three-phase isolation insulating transformer has a primary winding and a secondary winding, wherein the primary winding is connected with an external three-phase power supply output end. The circuit structure also comprises a rectifier circuit, wherein the rectifier circuit is connected between the secondary winding and a DC voltage output end of circuit structure, and the DC voltage output end is connected with a voltage input end of an external motor to be tested. According to the auxiliary power supply structure of the high-voltage high-power motor performance test, which adopts the structure, 150VDC voltage can be output by the DC voltage output end of the secondary winding side when the primary winding is connected with an external three-phase power supply 500V / 400A, so that 340A load can operate normally so as to satisfy the requirement for the high-voltage high-power motor performance test; and the auxiliary power supply structure has the advantages of simple structure, low cost and wide application range.

Owner:南京星霸科技有限公司

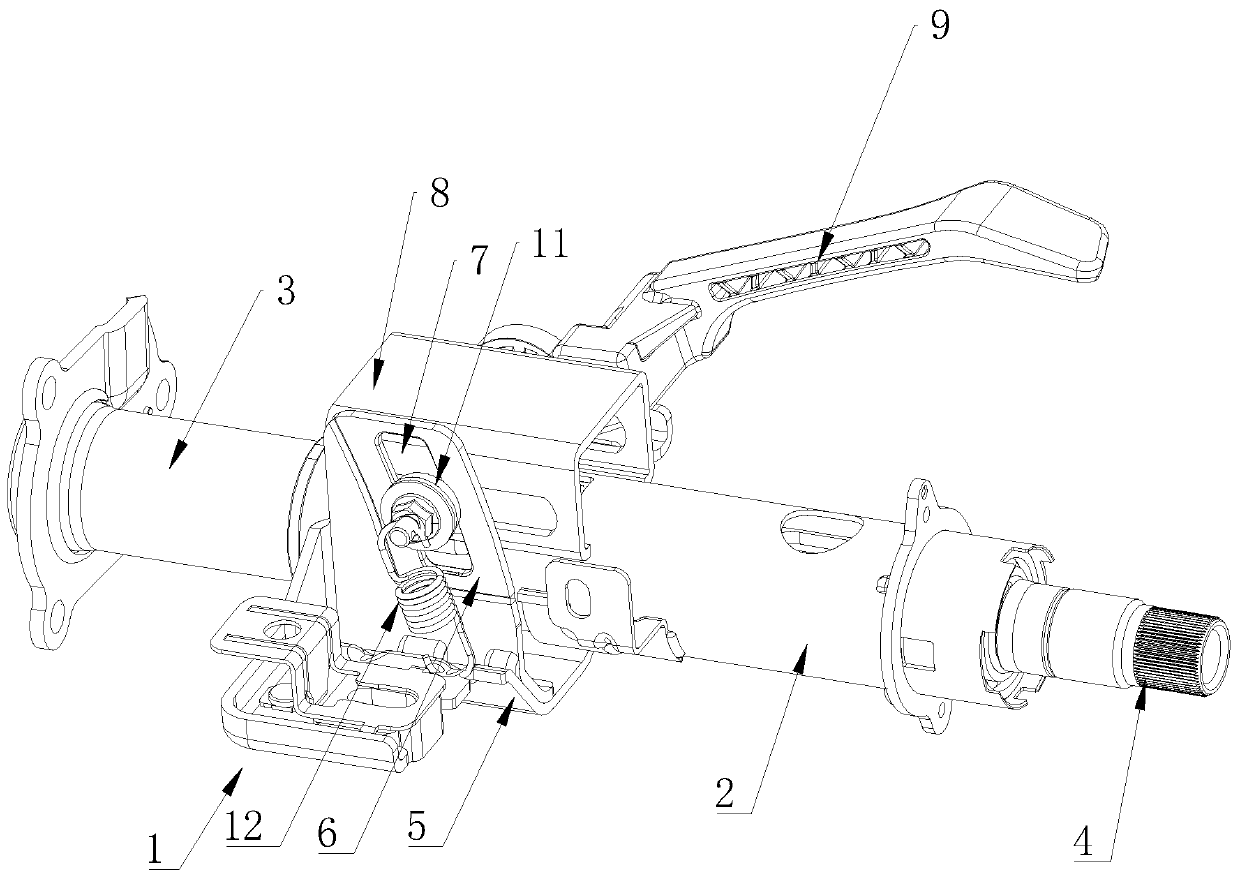

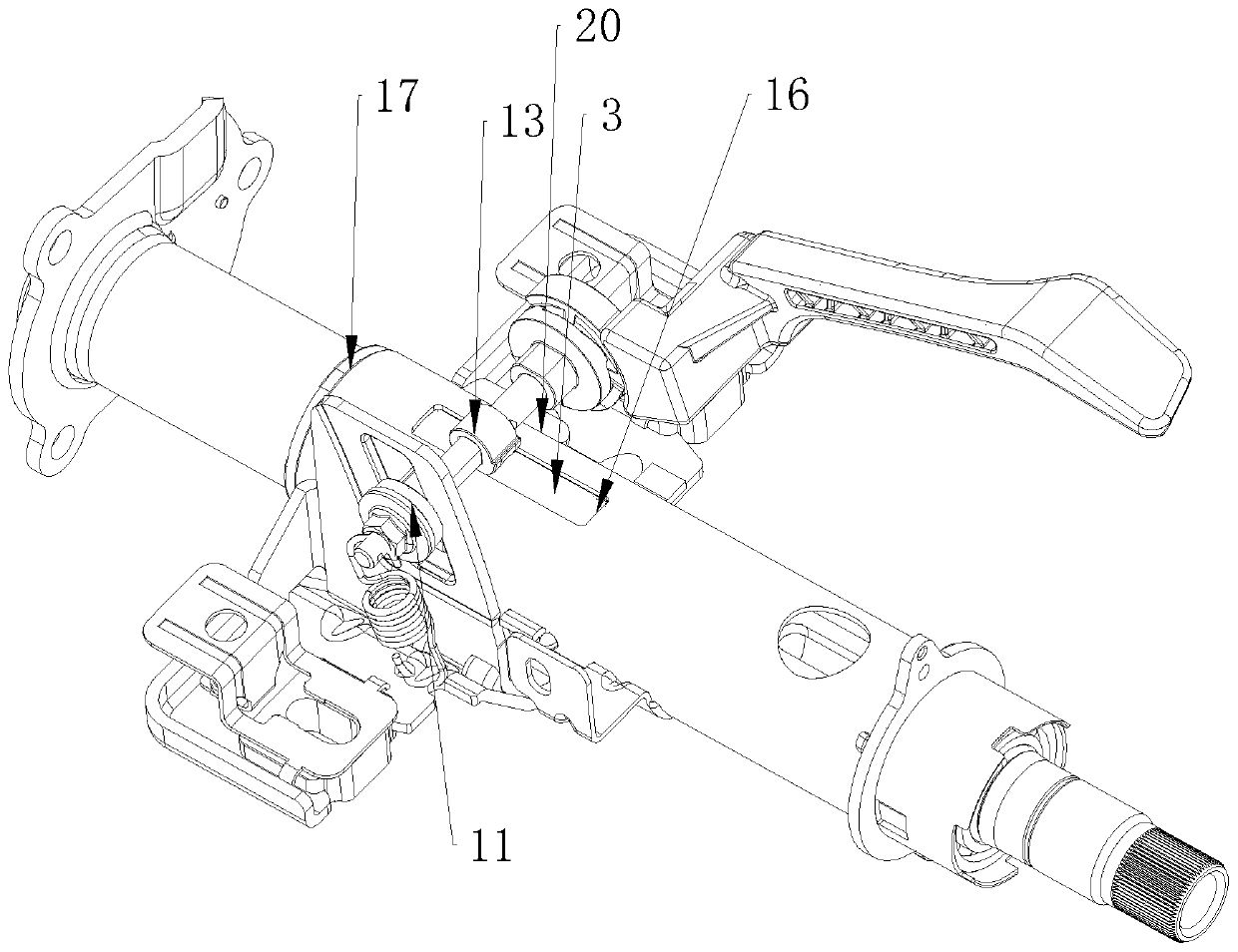

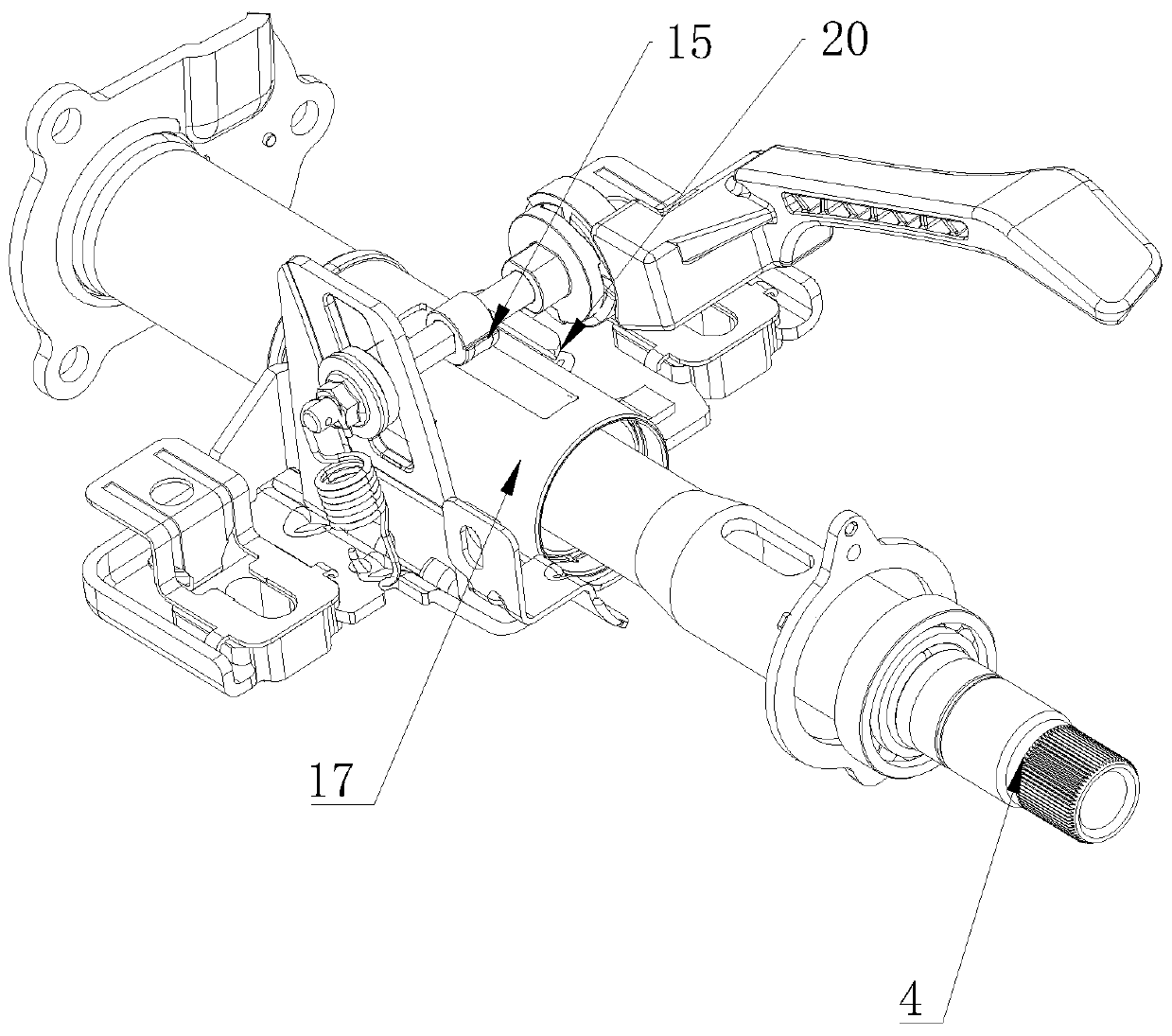

Four-way adjustment steering column assembly

The invention discloses a four-way adjustment steering column assembly. The technical scheme of the invention is that the four-way adjustment steering column assembly comprises a support, an upper tubular column, a lower tubular column and the steering shafts arranged in the upper tubular column and the lower tubular column. The upper tubular column and the lower tubular column are both made of iron, the support comprises a supporting base, and a limiting plate is arranged on the supporting seat; an adjusting hole is formed on the limiting plate, the limiting plate is connected with the supporting sleeves arranged at the two sides of the outer wall of the upper pipe column, and the adjusting handles are arranged at the sides, opposite to the limiting plate, of the supporting sleeves. The adjusting handles are connected with the adjusting shafts inserted into the supporting sleeves and the limiting plates, the adjusting bolts abutting against the limiting plate are arranged at the tailends of the adjusting shafts, and the springs are arranged between the adjusting shafts and the supporting base. A pressing block is arranged on each adjusting shaft, an annular part and a protrudingpart with the diameter larger than that of the annular part are arranged on the outer wall of the pressing block, and the pressing block penetrates through a through hole to directly abut against theouter wall of the lower tubular column. According to the scheme provided by the invention, the cost is low, and the sliding force can be adjusted on the basis of not influencing the handle force.

Owner:지엠프리시젼인더스트리오토모티브콤포넨츠(쑤저우)캄퍼니리미티드

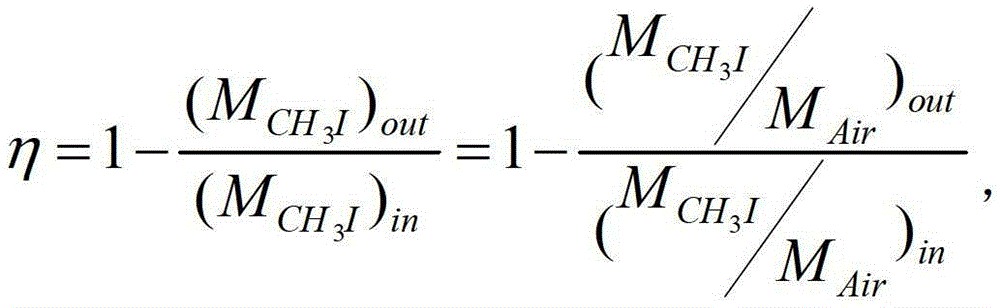

Methyl iodide gas sampling system applicable to high pressure steam pipeline environment

ActiveCN103197341BMeet performance testing requirementsWithdrawing sample devicesRadiation measurementProcess engineeringProduct gas

Owner:HARBIN ENG UNIV

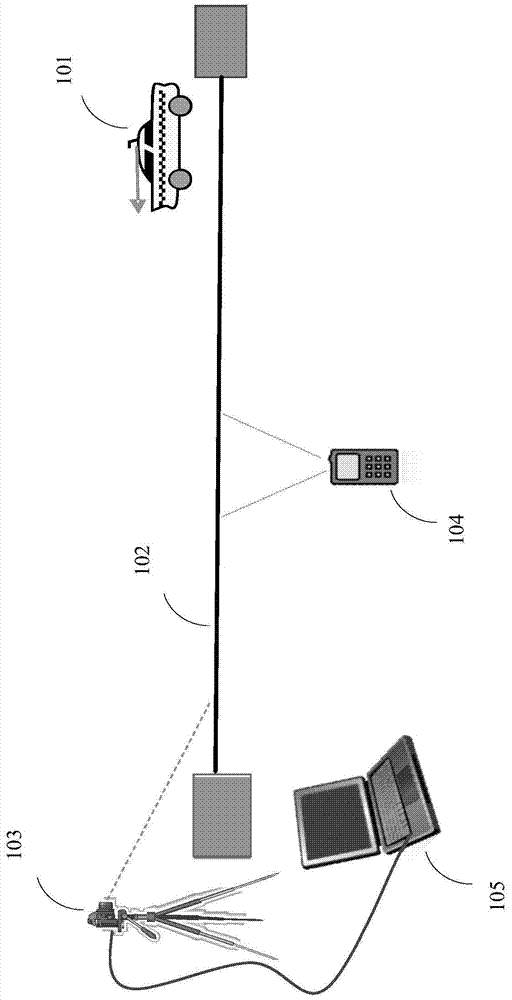

rfid mobile test system

ActiveCN104281861BMeet performance testing requirementsMeet test measurement accuracy requirementsCo-operative working arrangementsSensing record carriersMobile vehicleRadar

Owner:CHINA ELECTRONICS STANDARDIZATION INST +1

Drilling manufacturing process of induction magnet ring plate

InactiveCN102300411BEasy to cut offEasy chip removalPrinted circuit manufactureFiberContinuous design

The invention discloses a drilling manufacturing process of an induction magnet ring plate. A continuous drilling method is adopted in a common multi-layer plate hole drilling manufacturing process applied to a computer and network equipment at present; the electric property of a product is affected by hole roughness; the continuous drilling generates larger impact force on a hole wall; wire drawing is easy to generate; and the drill bit heat can not be effectively released. In the drilling manufacturing process provided by the invention, hole location, hole number, hole diameter, hole shape,inter-line spacing and layout design can be finished by utilizing line plate auxiliary software genesis; the drilling manufacturing process comprises location hole drilling, laminating, primary hole drilling, secondary hole drilling, hole blowing and checking; continuous-hole drilling is changed into separated-hole drilling; two same cutters are utilized for production; the inter-hole spacing is maintained at 0.75mm; the drilling rotation speed mainly targets the continuous design parameter which is more than or equal to 0.25mm; the rotation speed is high and the cutting rate is low; and wiredrawing cannot be generated easily in the production process, thus overcoming hole roughness and wick effect caused by hole burning and fiber break in drilling process since the inter-line spacing issmall; and all performance test requirements can be met.

Owner:SHENZHEN TONGXIN CIRCUIT ELECTRONICS

Spring test device

ActiveCN103837407BAvoid deformationUniform elastic deformationMaterial strength using tensile/compressive forcesEngineeringSpring Test

A spring testing device includes a base, a fixed cover and a fastener. The base includes a base body provided with a first limiting groove; and a plurality of fixing columns arranged at intervals on the base body. A plurality of spring positioning columns arranged in the first limiting groove and fixedly connected with the bottom of the first limiting groove, the spring is sleeved on the spring positioning column, one end of the spring is accommodated in the first limiting groove, and the spring The positioning column is arranged between the two fixing columns. The fixed cover is arranged on the base, and the free ends of the fixed post and the spring positioning post pass through the fixed cover. The fastener is fixedly connected to the free end of the fixing post, and the fastener abuts against the side of the fixed cover away from the base body, and the fastener limits the fixed cover. The spring positioning post can prevent the spring from being deformed laterally. The first limiting groove can limit the spring to prevent the spring from being displaced during extrusion. Therefore, the above-mentioned spring testing device can ensure uniform elastic deformation of the spring.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

CO2 compressor-expander performance testing system

InactiveCN100529719CMeet performance testing requirementsSimple structureStructural/machines measurementElectricityVapor–liquid separator

The invention discloses a test system for testing the property of carbon dioxide compressor-expander, belonging to the refrigerating technique. Wherein, the outlet of evaporator is connected to the inlet of gas-liquid separator; the outer part of cooling fan is fixed on the front surface of middle cooler; the middle cooler and oil separator are connected to the tested compressor; the inlet of gas cooler is connected to the outlet of coolant of oil separator; the outlet of gas cooler is connected to the inlet of quality flow meter and the inlet of electric expand valve; the outlet of quality flow meter is connected to the inlet of expand valve; the outlet of expand valve is connected to the inlet of tested expander; the outlet of evaporator is connected to the inlet of gas-liquid separator; the outlet of gas-liquid separator is connected to the inlet of electric heater; the outlet of electric heater is connected to the first-stage gas inlet of tested compressor. The invention has simple structure, lower cost, and flexible operation, which can be used to test the property of full-closed carbon dioxide compressor-expander.

Owner:SHANGHAI JIAOTONG UNIV

A multifunctional dynamic electromagnet testing device

ActiveCN110501661BShorten the timeImprove test efficiencyMagnetic property measurementsMagnetic measurement environmental aspectsTemperature controlTest efficiency

The invention discloses a multifunctional dynamic electromagnet testing device, which includes a support frame, a desktop and a console are arranged on the support frame, a dynamic testing mechanism and an angle adjustment device, and the dynamic testing mechanism includes an electromagnet testing frame and a cylinder adjusting device , laser displacement testing device, electromagnet fixing device and temperature control device, the cylinder adjustment device is connected to the electromagnet test frame, the laser displacement testing device is connected to the cylinder adjustment device, the electromagnet fixing device and the temperature control device are connected to the electromagnet test The inner bottom of the frame, the bottom of the electromagnet test frame is connected to the desktop through an angle adjustment device. The invention can complete multi-item tests with one clamping, greatly shorten the time required for clamping, improve test efficiency, and can complete different types of electromagnet tests, such as push-type, pull-type, and push-pull type electromagnets, and can complete electromagnet testing. Dynamic performance test can output the real-time change curve of displacement with time.

Owner:ZHEJIANG UNIV

A multifunctional static electromagnet testing device

ActiveCN110501660BMeet performance testing requirementsShorten the timeMagnetic property measurementsMagnetic measurement environmental aspectsTemperature controlTest efficiency

The invention discloses a multifunctional static electromagnet testing device, which comprises a frame body, on which a desktop and a console are arranged, and also includes a static performance testing mechanism and an angle adjustment device. The static performance testing mechanism includes an electromagnet testing frame, a linear Guide device, displacement test device, force measuring device and temperature control device, the linear guide device is connected to the electromagnet test frame, the force measuring device is connected under the linear guide device, and the inner bottom of the electromagnet test frame is equipped with an electromagnet fixing device And the temperature control device, the bottom of the electromagnet test frame is connected to the desktop through the angle adjustment device. The present invention can not only complete multi-item tests with one clamping, greatly shorten the time required for clamping, improve test efficiency, but also complete different types of electromagnet tests, and can meet the performance test requirements of electromagnets under different clamping angles. The integrated temperature control device can complete performance tests under different ambient temperatures.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com