Ultralow-temperature rolling bearing service life test device

A life test device, a technology of rolling bearings, applied in the direction of mechanical bearing testing, etc., can solve problems such as the inability to detect the friction loss of the test bearing and the inability to completely simulate the bearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

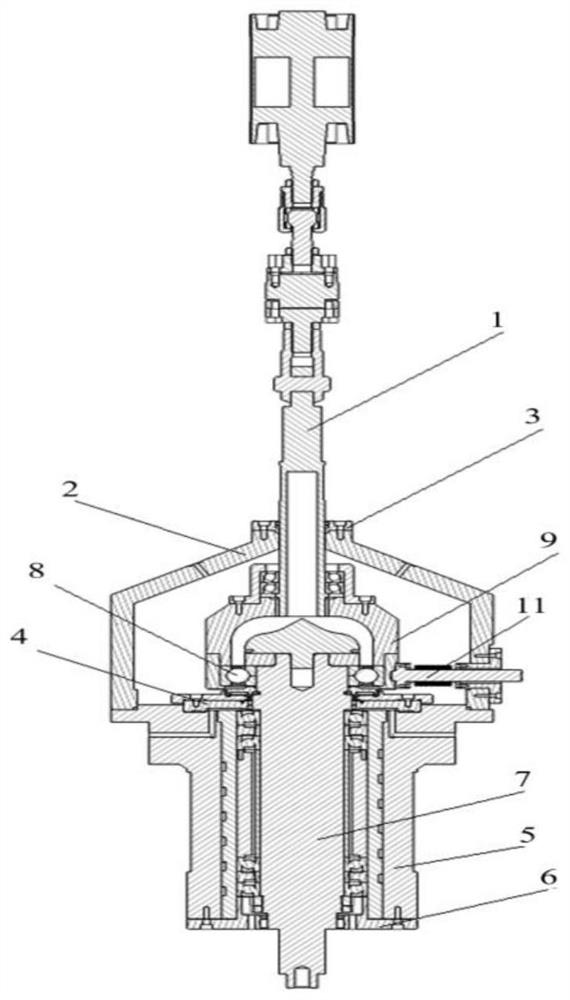

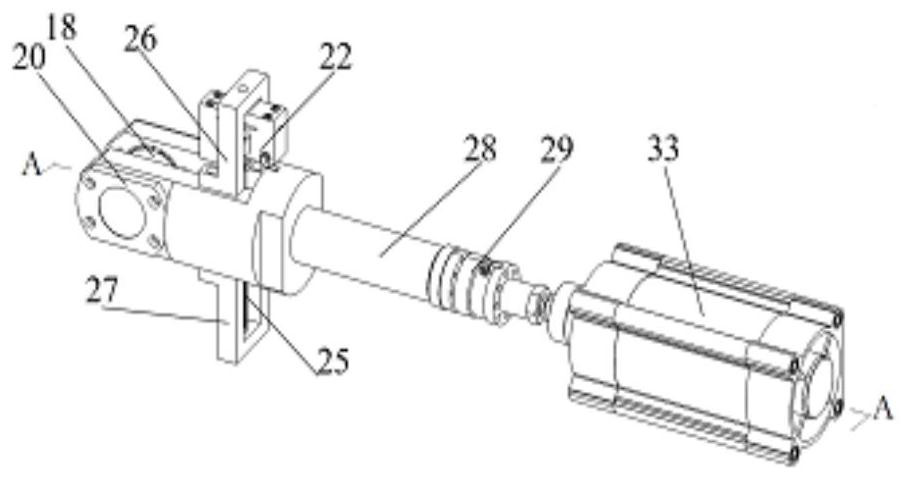

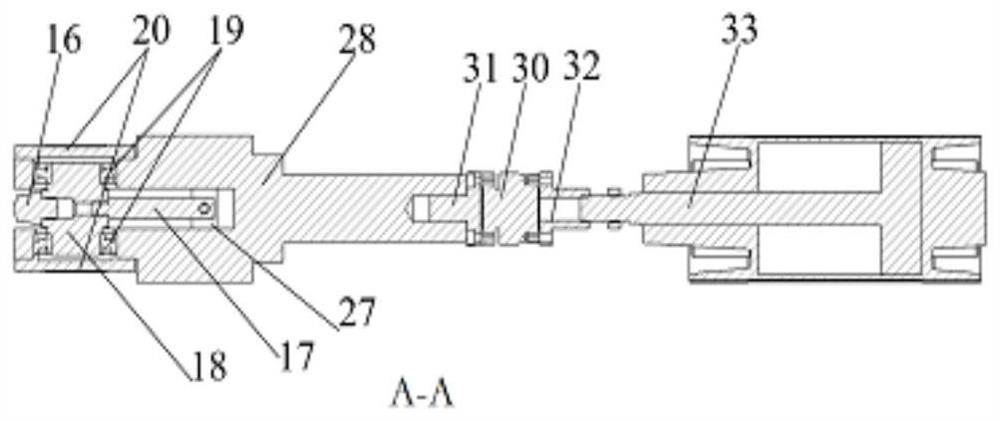

[0051] An improved ultra-low temperature rolling bearing life test device includes a test section, an axial loading mechanism 1, a radial loading mechanism, a driving motor and a monitoring system. Among them, the test section, the axial loading mechanism 1, the drive motor and the detection system are all existing technologies; on the basis of the existing technology, a radial loading mechanism is added and key components are improved to realize the radial loading mechanism. Use effectively.

[0052] The test section includes a test cavity and a test shaft system. The test chamber consists of two parts, the low temperature chamber is located at the upper end of the oil-air lubrication chamber; there is a combined sealing structure 4 between the low-temperature chamber and the oil-air lubrication chamber. The low temperature cavity is a cavity surrounded by the low temperature cavity shell 2, the combined sealing structure 4 and the low temperature cavity sealing end cover 3;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com