Integrated dynamic vehicle performance test platform and integrated dynamic vehicle performance test method

A technology of comprehensive testing and dynamic performance, applied in the field of vehicle testing, which can solve the problems of long time consumption, single testing items, and undetectable functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

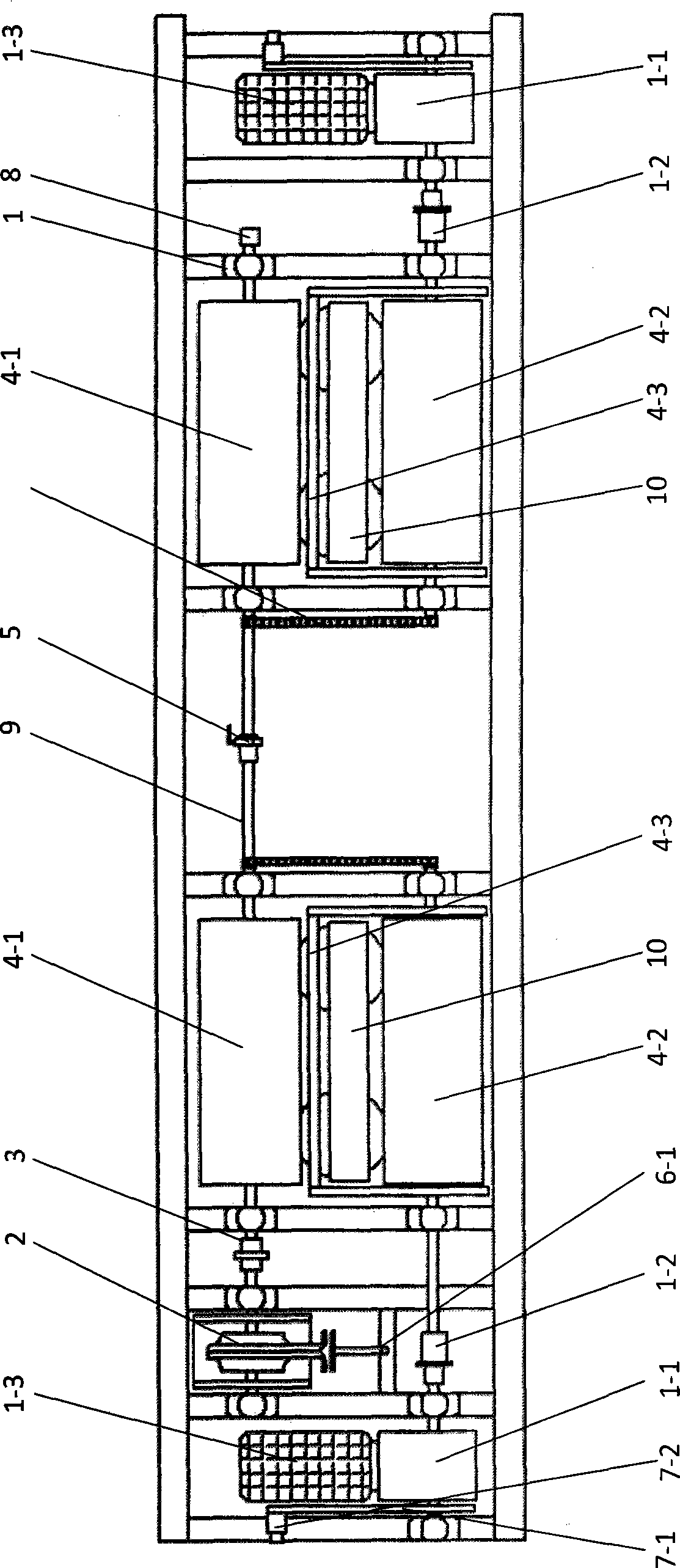

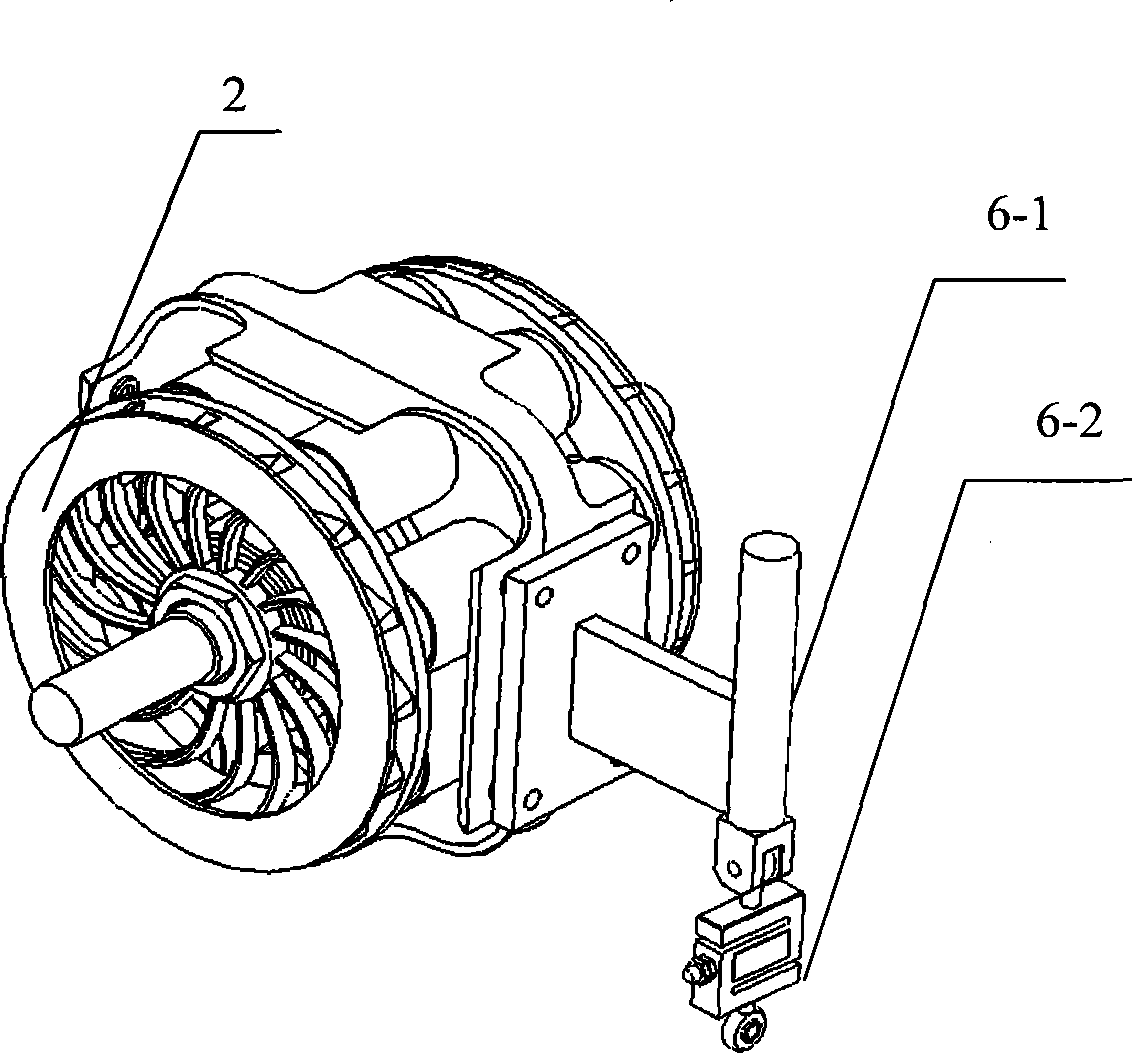

[0040] Embodiment 1: see attached figure 1 , a vehicle dynamic performance comprehensive test bench, it includes: a frame 1, a brake drive device, an air-cooled eddy current dynamometer 2, a coupling 3, a roller set, a clutch A5, a driving force test device 6, a system Dynamic testing device 7, speed sensor 8, synchronizing device 9 and lifting device 10;

[0041] The brake drive device has the same two groups, which are respectively installed on the left and right sides of the frame 1, and each includes: a motor 1-3, a torque box 1-3 for decelerating and increasing the output of the motor 1-3 1 and the clutch B1-2 connecting the torque box 1-1 and the roller group; wherein, the housing of the torque box 1-1 is connected to the frame 1 through a bearing, and can be rotated around its output shaft relative to The frame 1 swings;

[0042] The roller group has the same two groups, each including: a front roller 4-1, a rear roller 4-2 and a third roller 4-3; the outer surface of...

Embodiment 2

[0048] Embodiment 2, according to the vehicle dynamic performance comprehensive test platform described in Embodiment 1, wherein the speed sensor 8 adopts a photoelectric encoder.

Embodiment 3

[0049] Embodiment 3, a kind of vehicle dynamic performance comprehensive test method, it is based on a kind of vehicle dynamic performance comprehensive test platform as described in embodiment 1 or 2, and comprises the steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com