Fully-automatic gear performance detecting system and method for automobile component line-controlled gear shifter

A technology for auto parts and shift-by-wire, which is applied in the field of automatic gear performance detection systems, can solve the problems of inability to stably maintain product test conditions, large differences in operator methods, and high labor intensity, and achieves a reduction in labor. The effect of labor intensity, reducing production cost, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

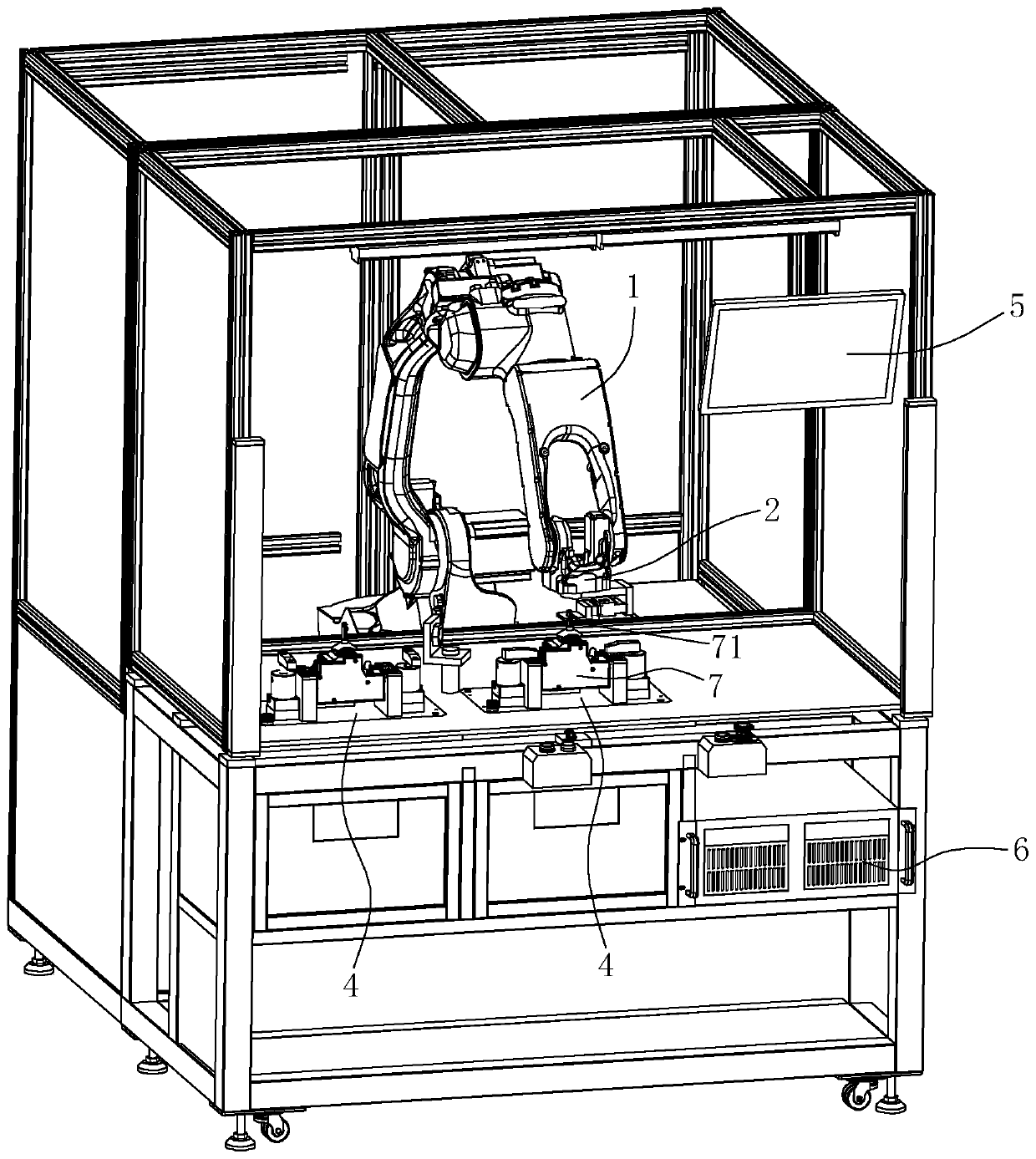

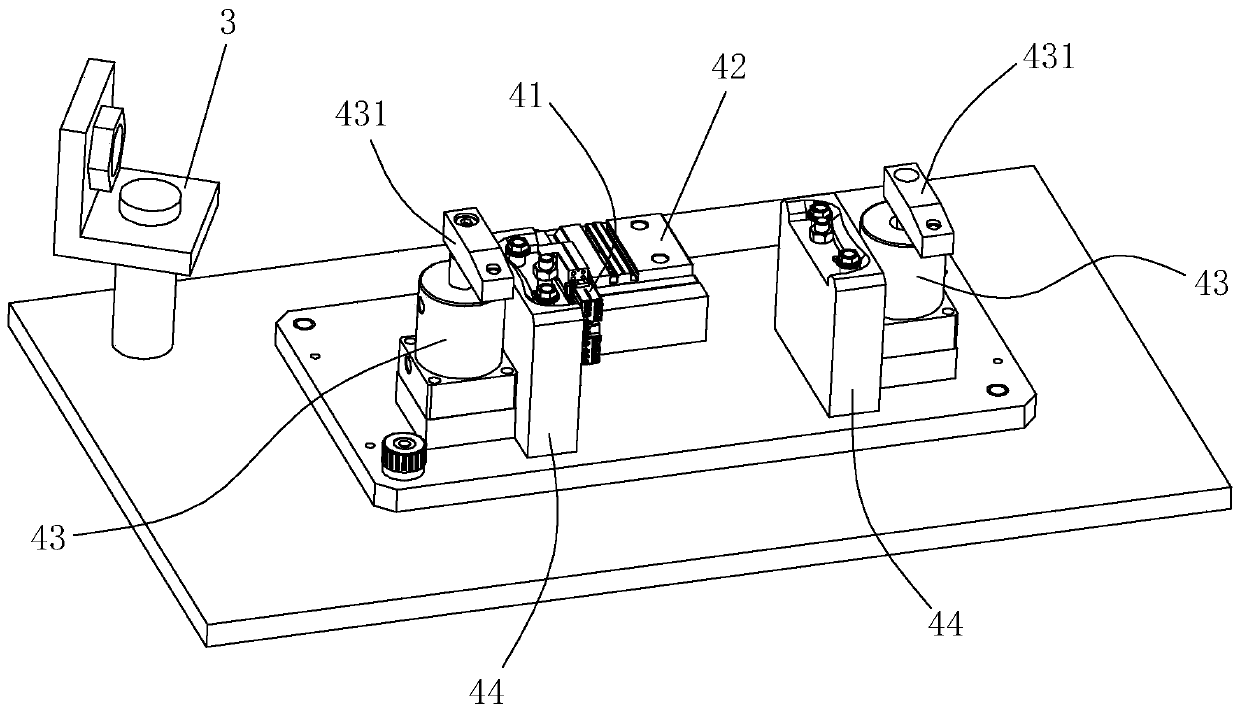

[0035] Such as Figure 1 to Figure 4 The automatic gear performance detection system for the shift-by-wire shifter of the auto parts shown includes a test bench, a detection component 2, a manipulator 1 installed on the test bench, a position sensor 3, a fixed tooling component 4, a display 5 and a control 6, the detection component 2 is installed on the manipulator 1, and the detection component 2 is controlled by the manipulator 1, and the fixed tooling component 4 is used to install and position the wire-controlled shifter 7 of the auto parts to be detected, and control the wire-controlled shifter 7. The conduction or disconnection of electricity.

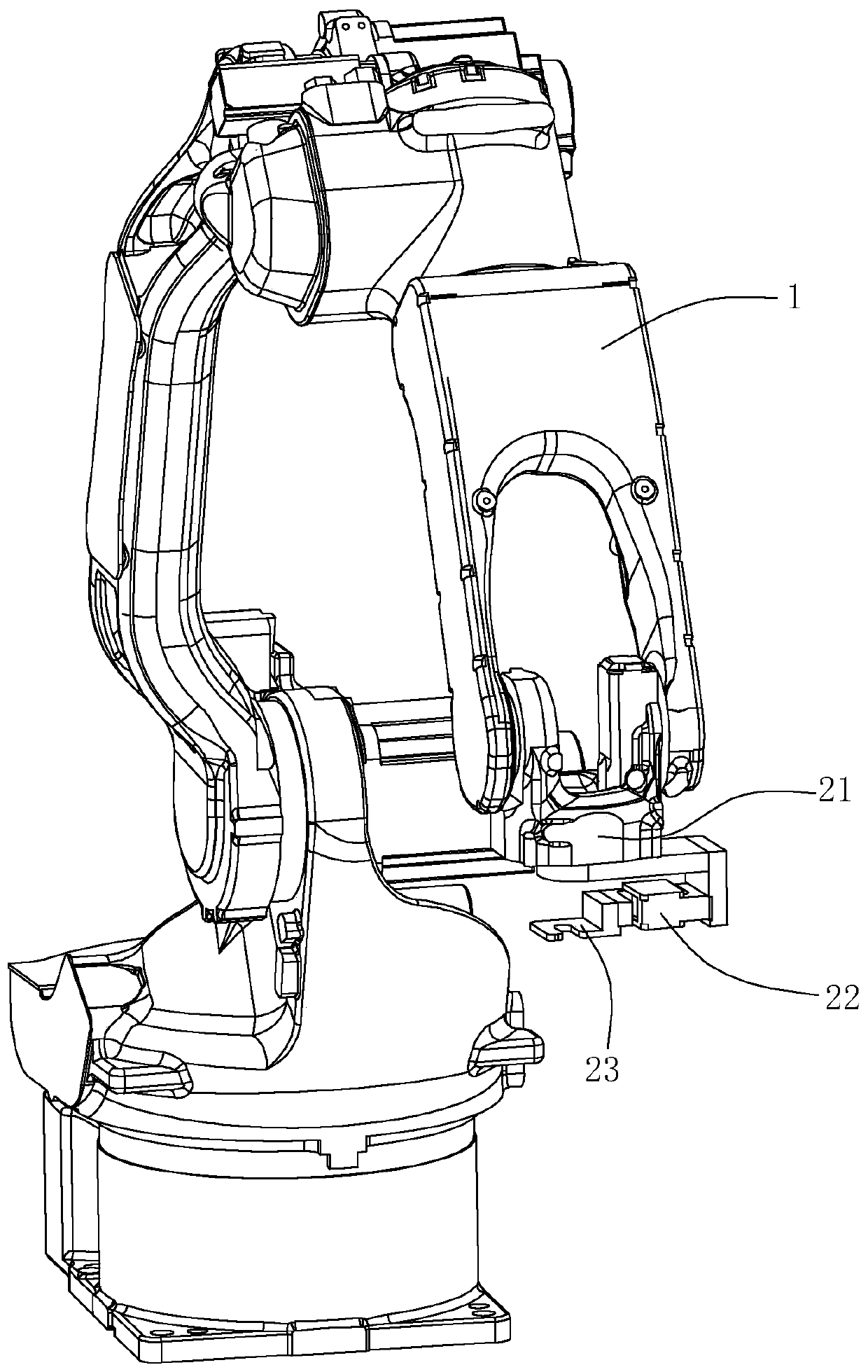

[0036] The detection component 2 includes a force detector 21, an angle detector 22 and a clamping tooling 23. The manipulator 1 clamps the clamping tooling 23, and the force detector 21 and the angle detector 22 are all installed on the clamping tooling 23, and the clamping tooling 23 For blocking the shift lever 71 of the wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com