Patents

Literature

77results about How to "Hinders provision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

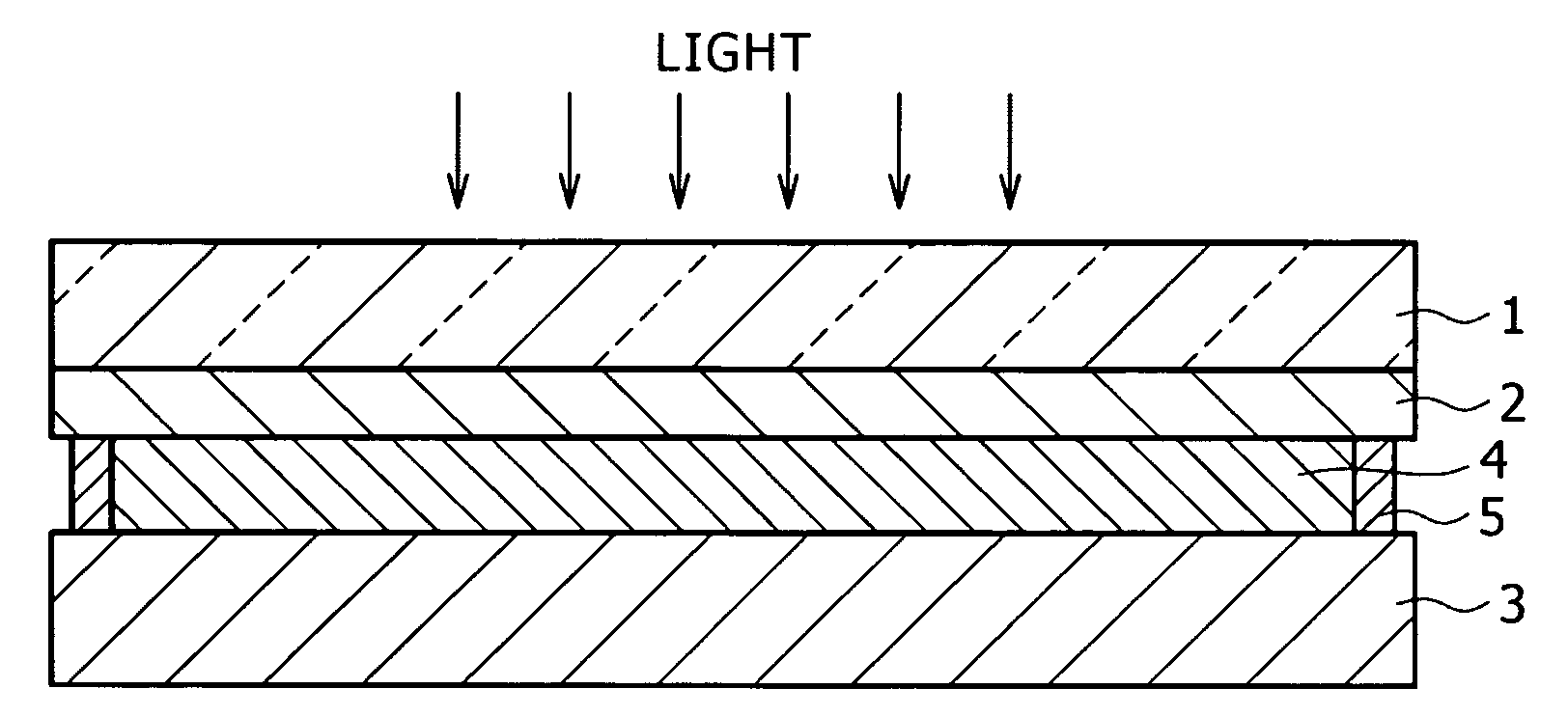

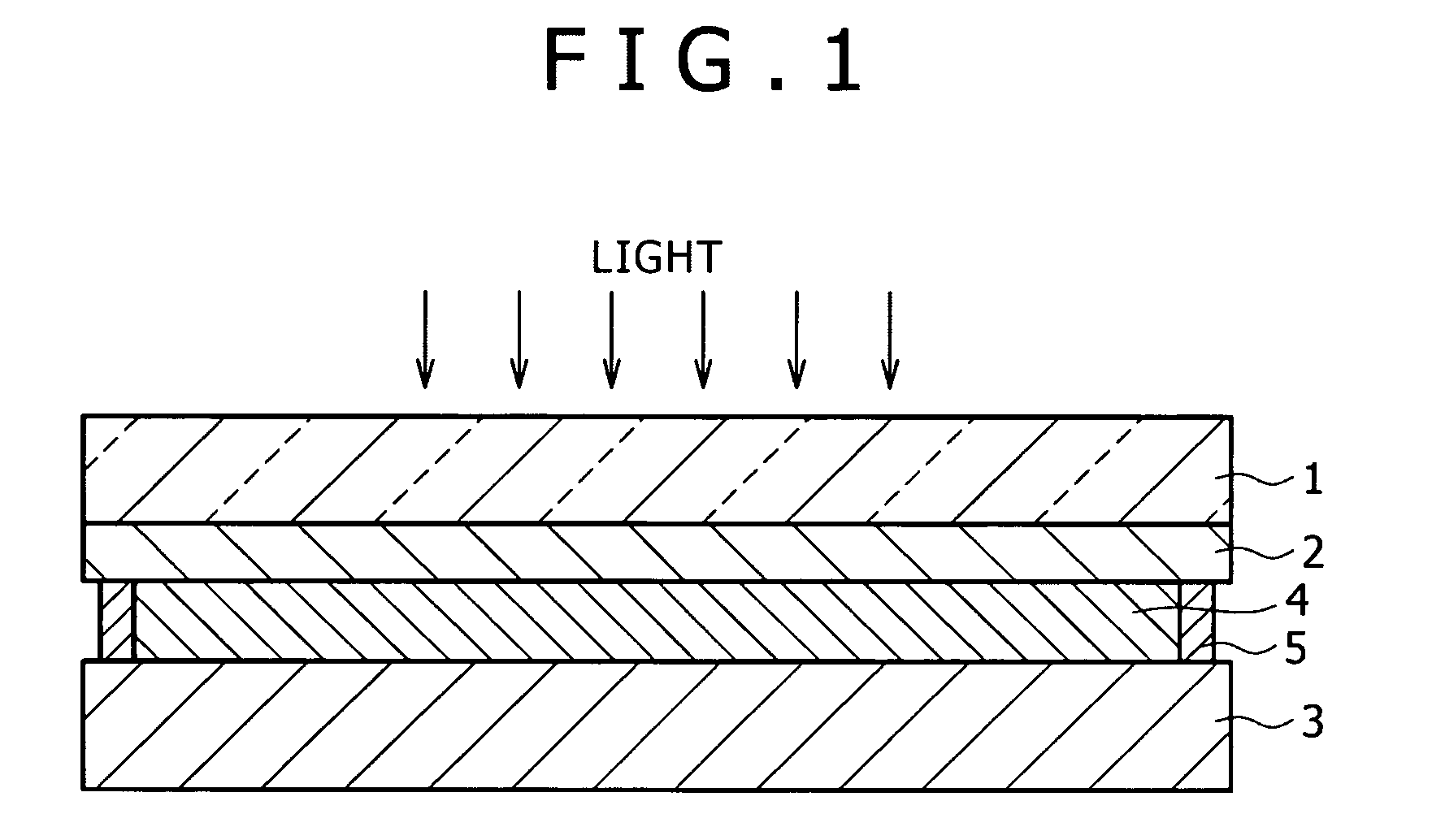

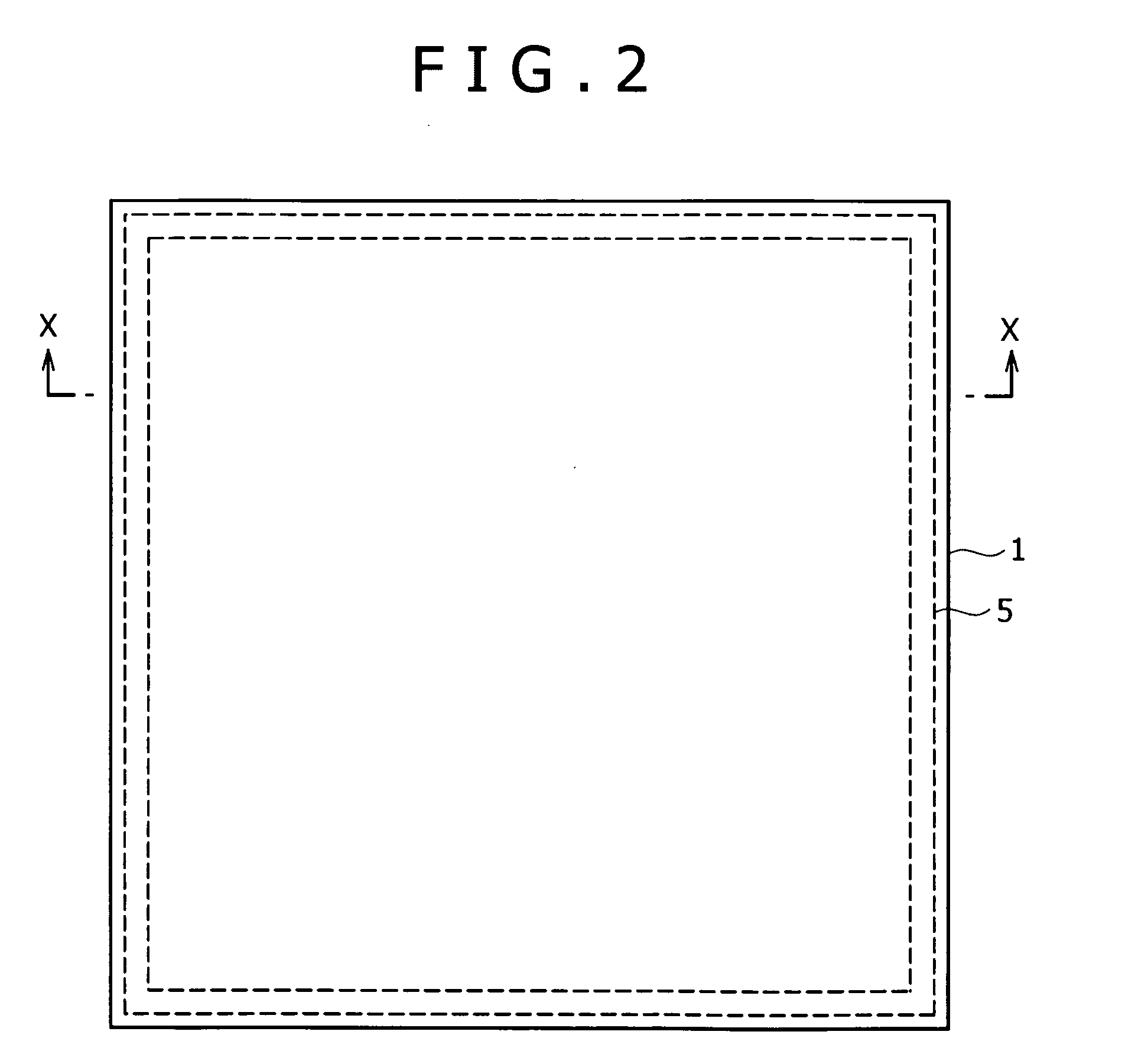

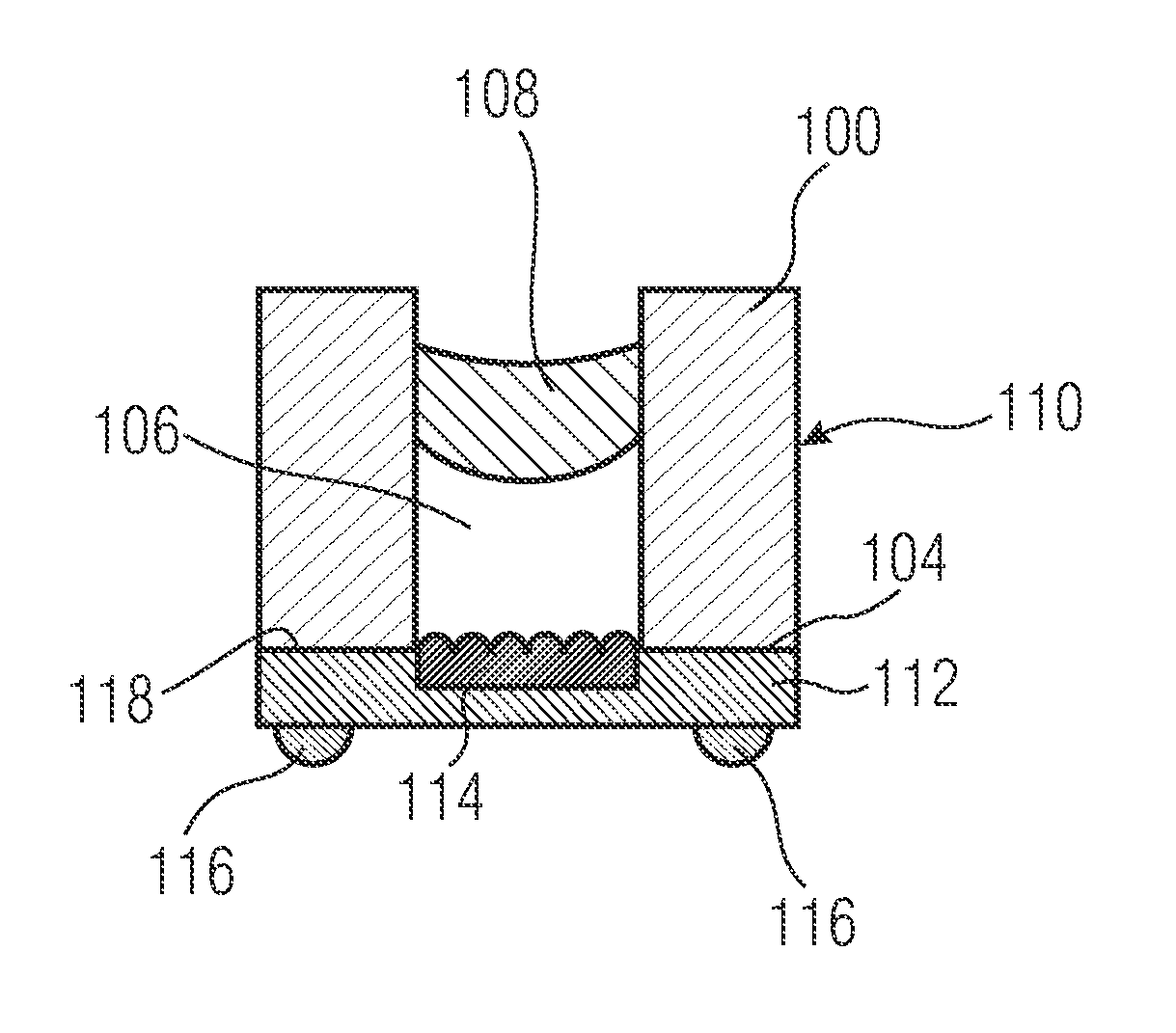

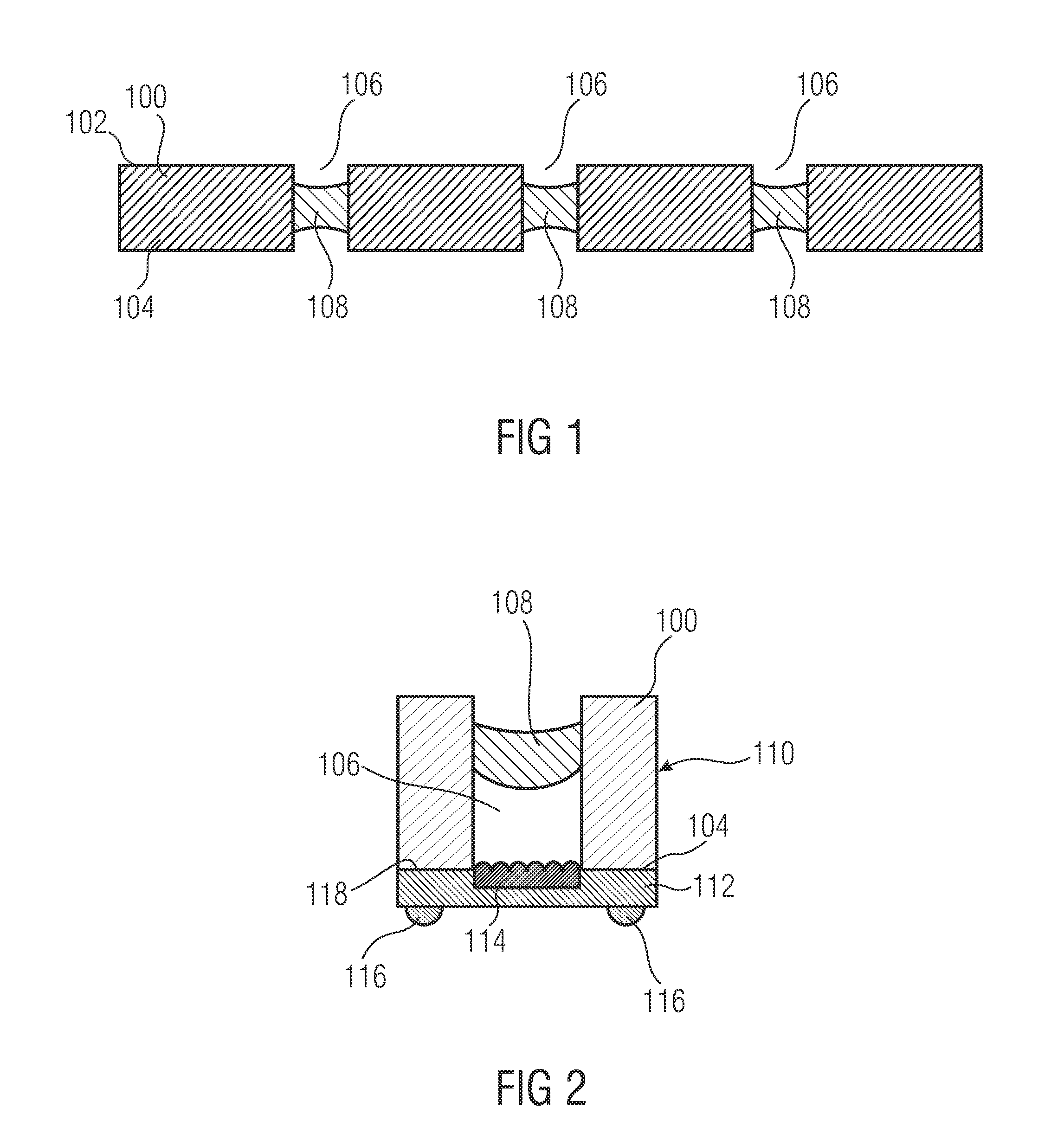

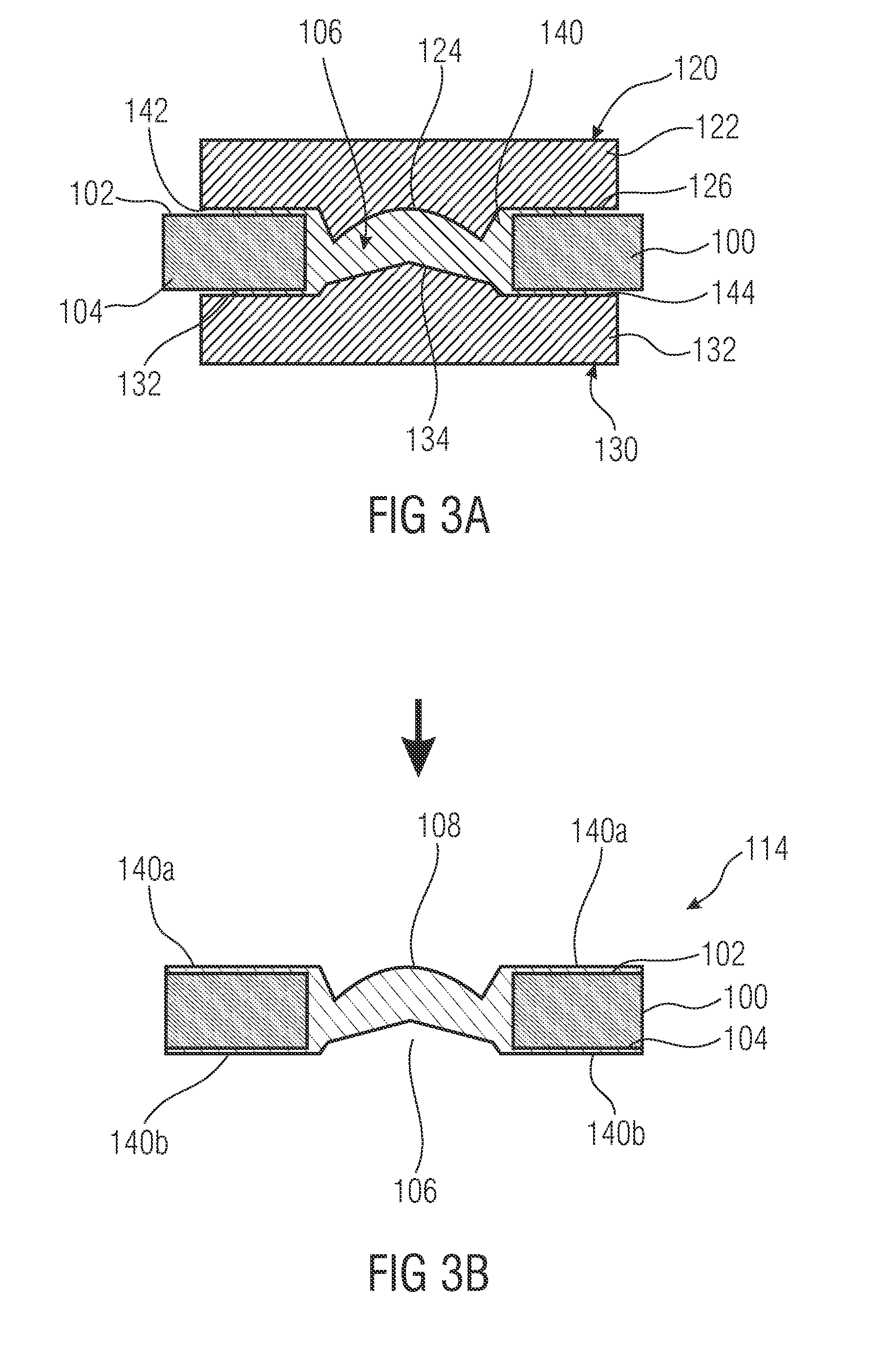

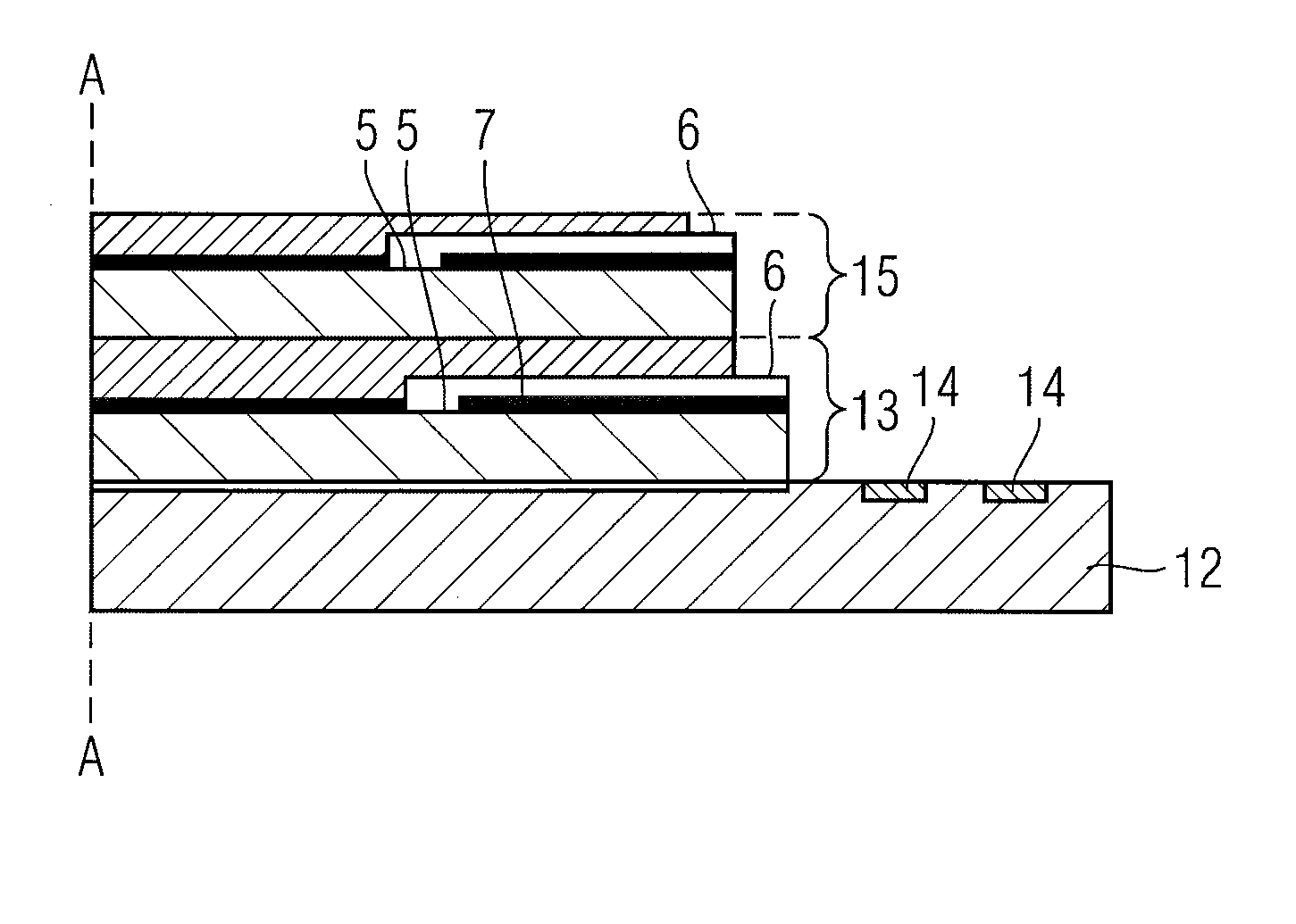

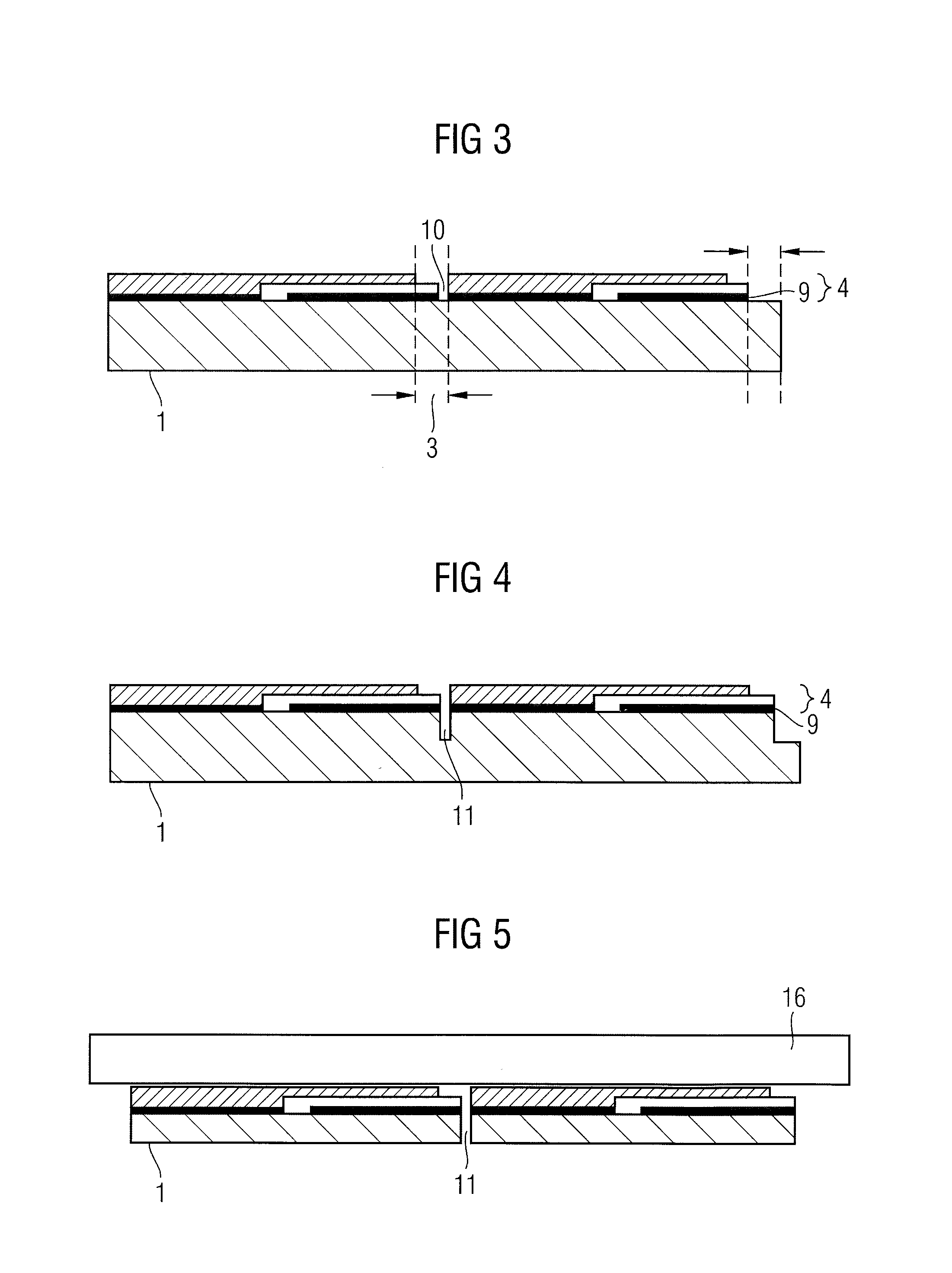

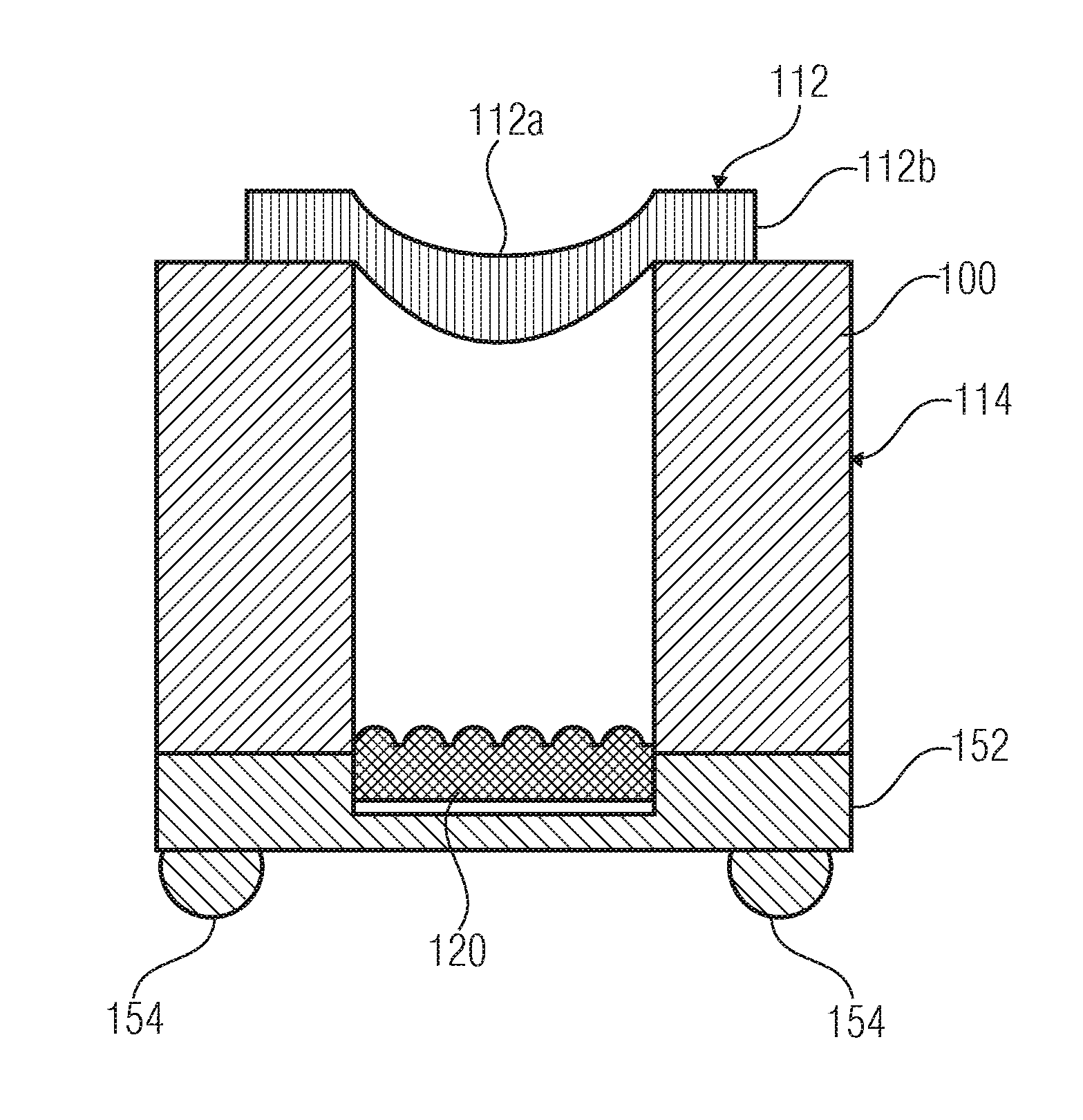

Dye-sensitized photoelectric conversion device and method of manufacturing the same

InactiveUS20100101648A1Reduced durabilityReduced strengthElectrolytic capacitorsFinal product manufactureAtmospheric airPhotoelectric conversion

A method of manufacturing a dye-sensitized photoelectric conversion device is provided by which a dye-sensitized photoelectric conversion device being excellent in strength and durability and free of any projection, as a result of the absence of need for an end seal, can be fabricated through simple manufacturing steps. In manufacturing a dye-sensitized photoelectric conversion device which has an electrolyte between a dye-sensitized semiconductor layer and a counter electrode and which also has a first armor member provided on the outside of the dye-sensitized semiconductor layer and a second armor member provided on the outside of the counter electrode, a sealing material and the electrolyte are formed at predetermined locations of one or both of the first armor member and the second armor member, thereafter the first armor member and the second armor member, with the sealing material and the electrolyte sandwiched therebetween, are adhered to each other with the sealing material under a gas pressure of not higher than the atmospheric air pressure and not lower than the vapor pressure of the electrolyte.

Owner:SONY CORP

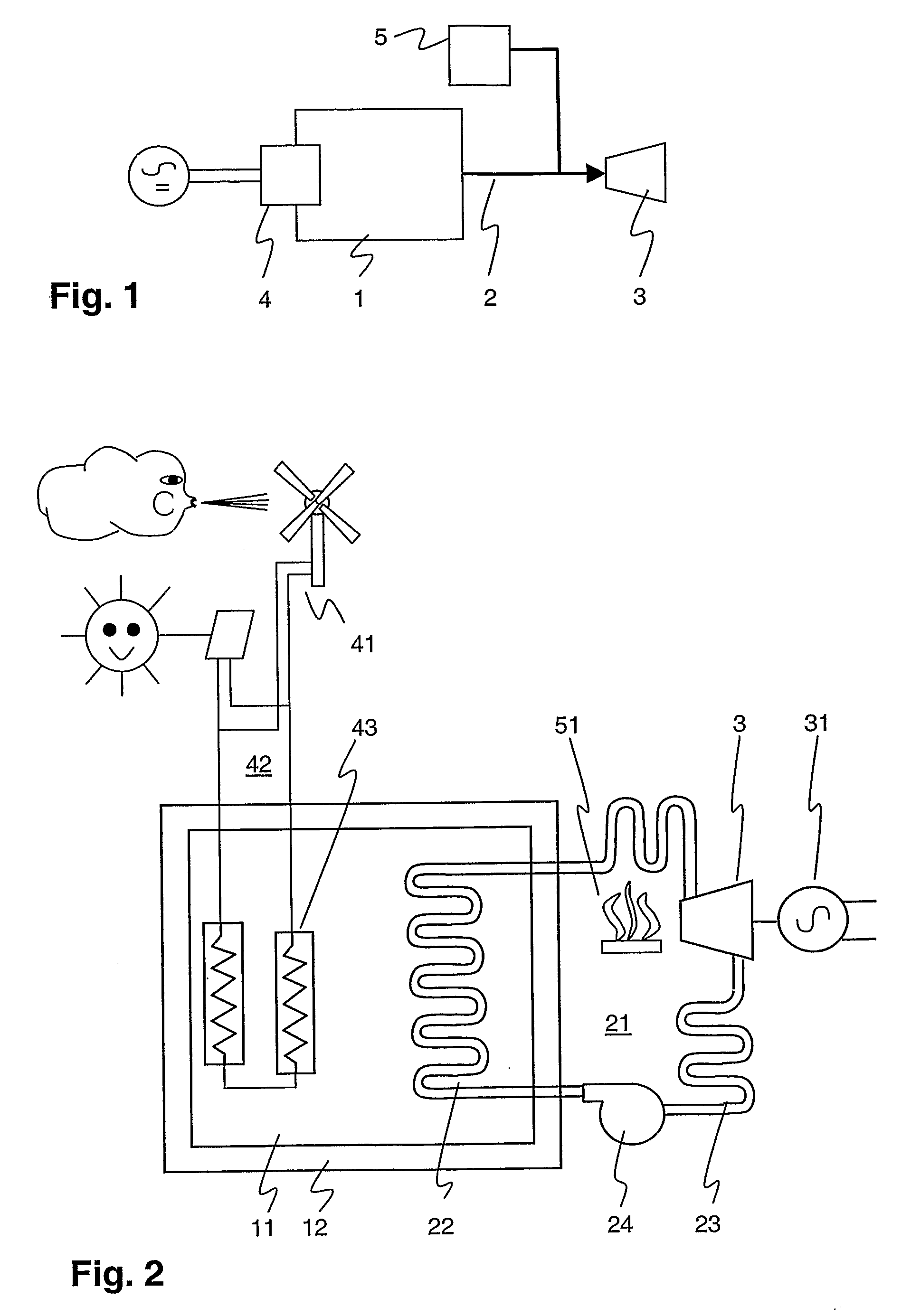

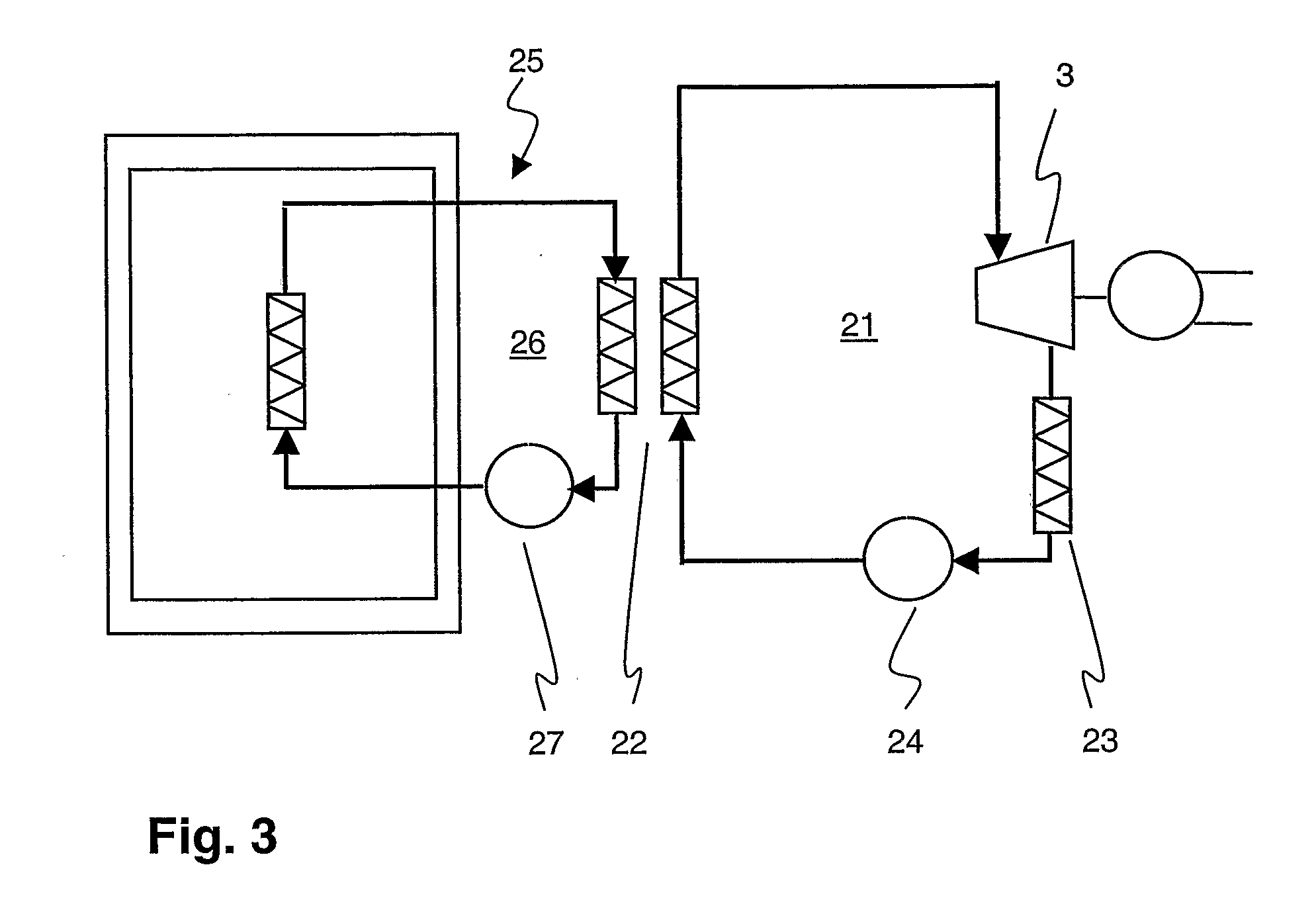

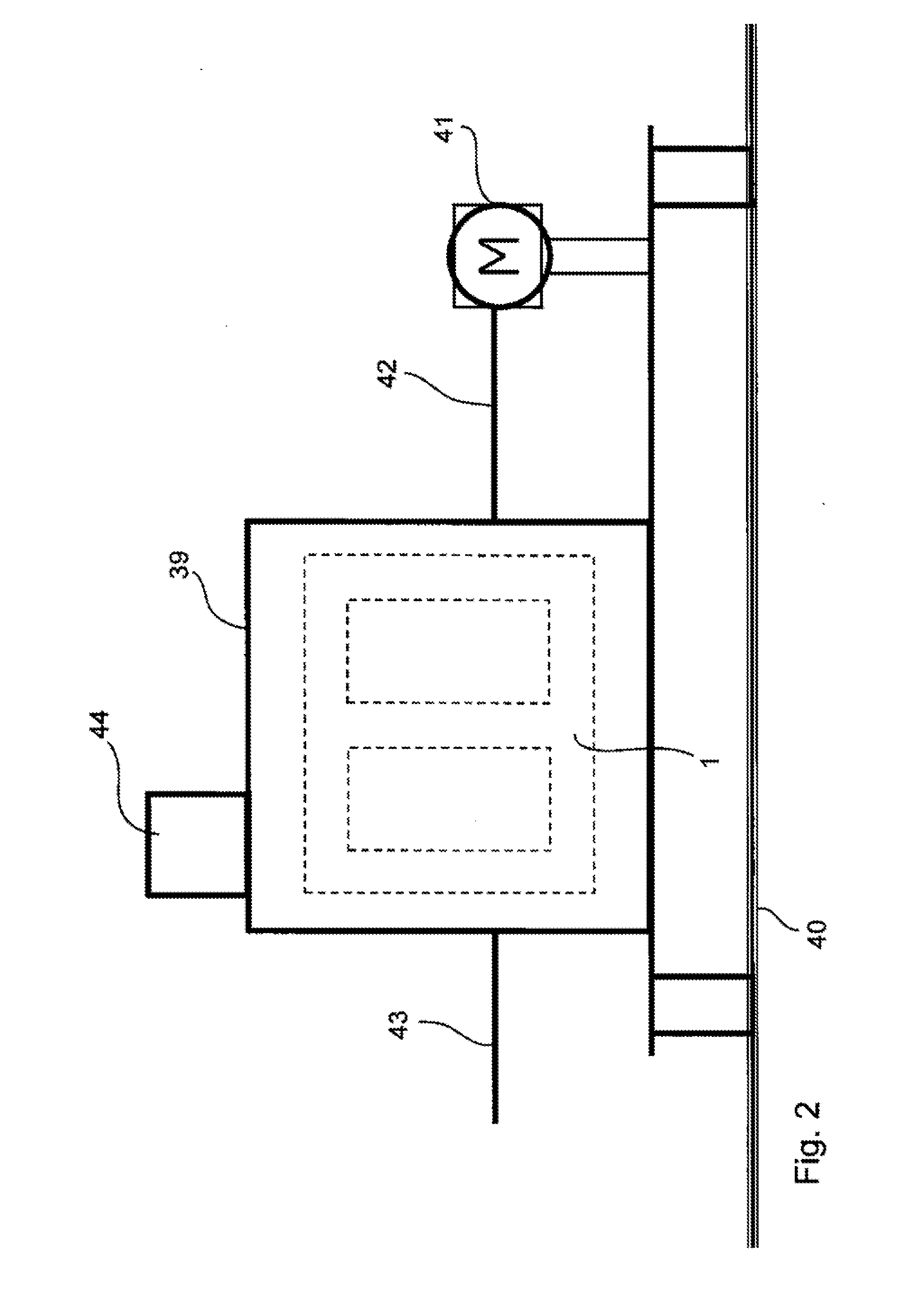

Storing Thermal Energy and Generating Electricity

InactiveUS20080022683A1Avoid componentsAvoid doublingAuxillary drivesHeat storage plantsComing outThermal energy

Because the efficiency of the thermal energy storage technology is inherently restricted, its beneficial use is limited to very particular economic boundary conditions, i.e. a large difference between the value of electricity going into the unit and the value of electricity coming out of the unit. With the reduction in wind power equipment prices and the cost of fossil fuels and / or their combustion products this is occasionally the case for wind power. Wind is a free fuel and the value of wind power when there is too little load demand is essentially zero, and the value of wind power when there is demand is considerable indeed. Under these circumstances, a combination of electrothermal energy storage and combustion of (fossil) fuels as an auxiliary heat source provides for a cost efficient system for storing energy and an economical way of generating electricity.

Owner:ABB RES LTD

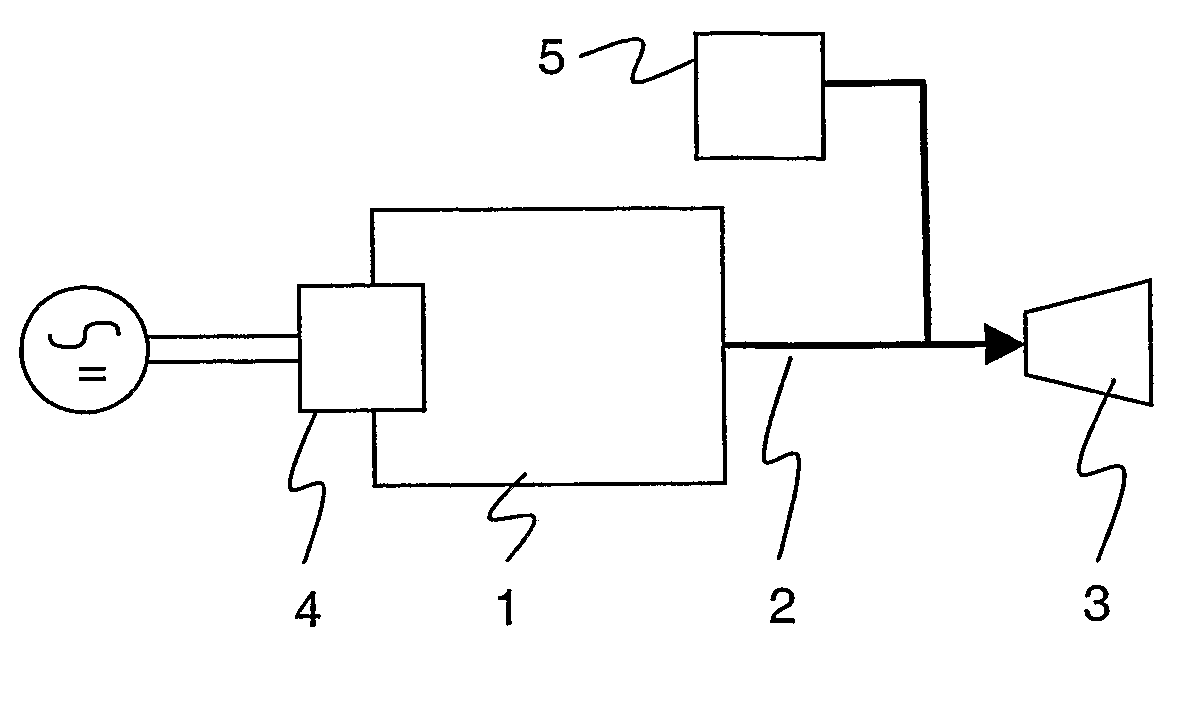

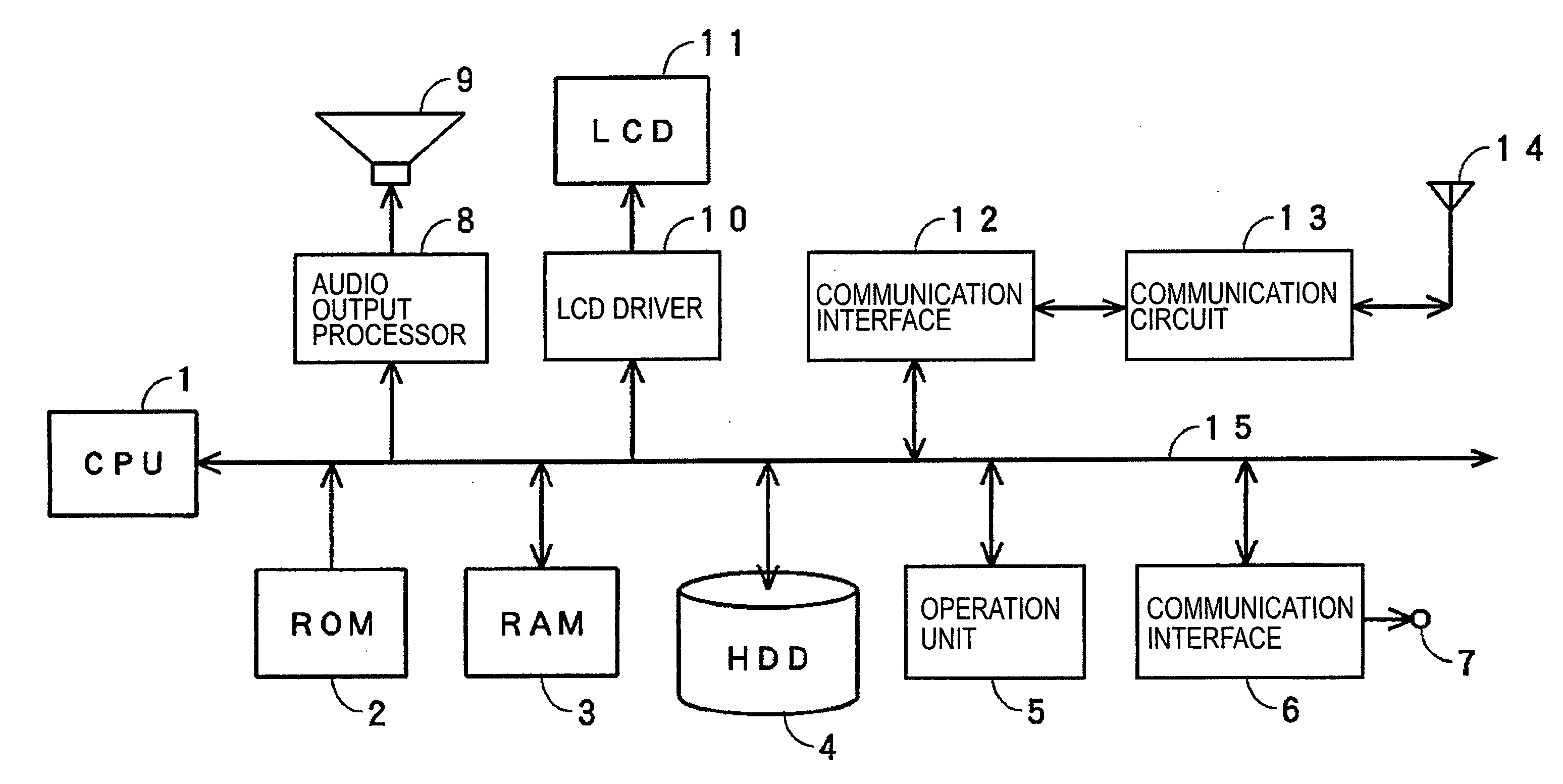

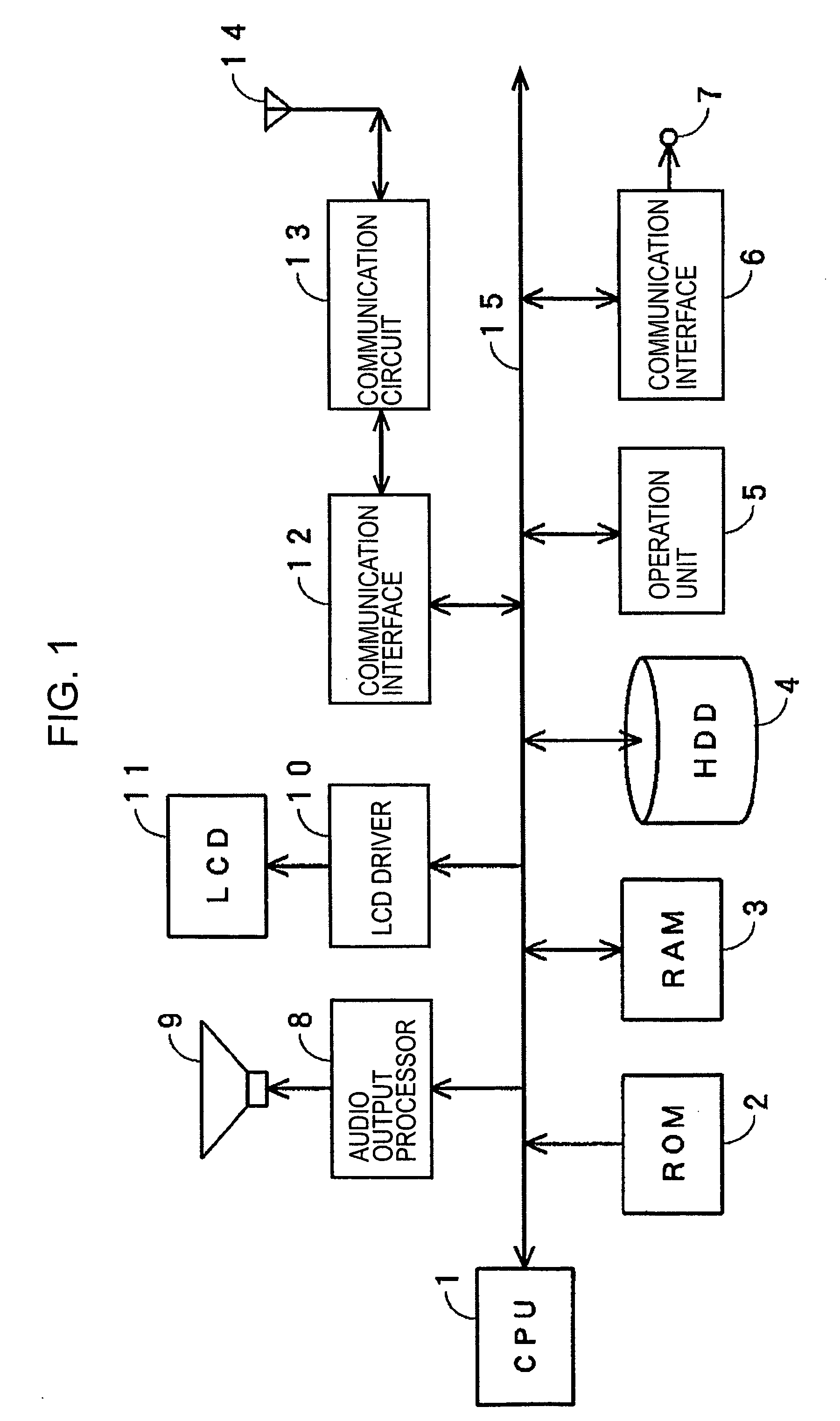

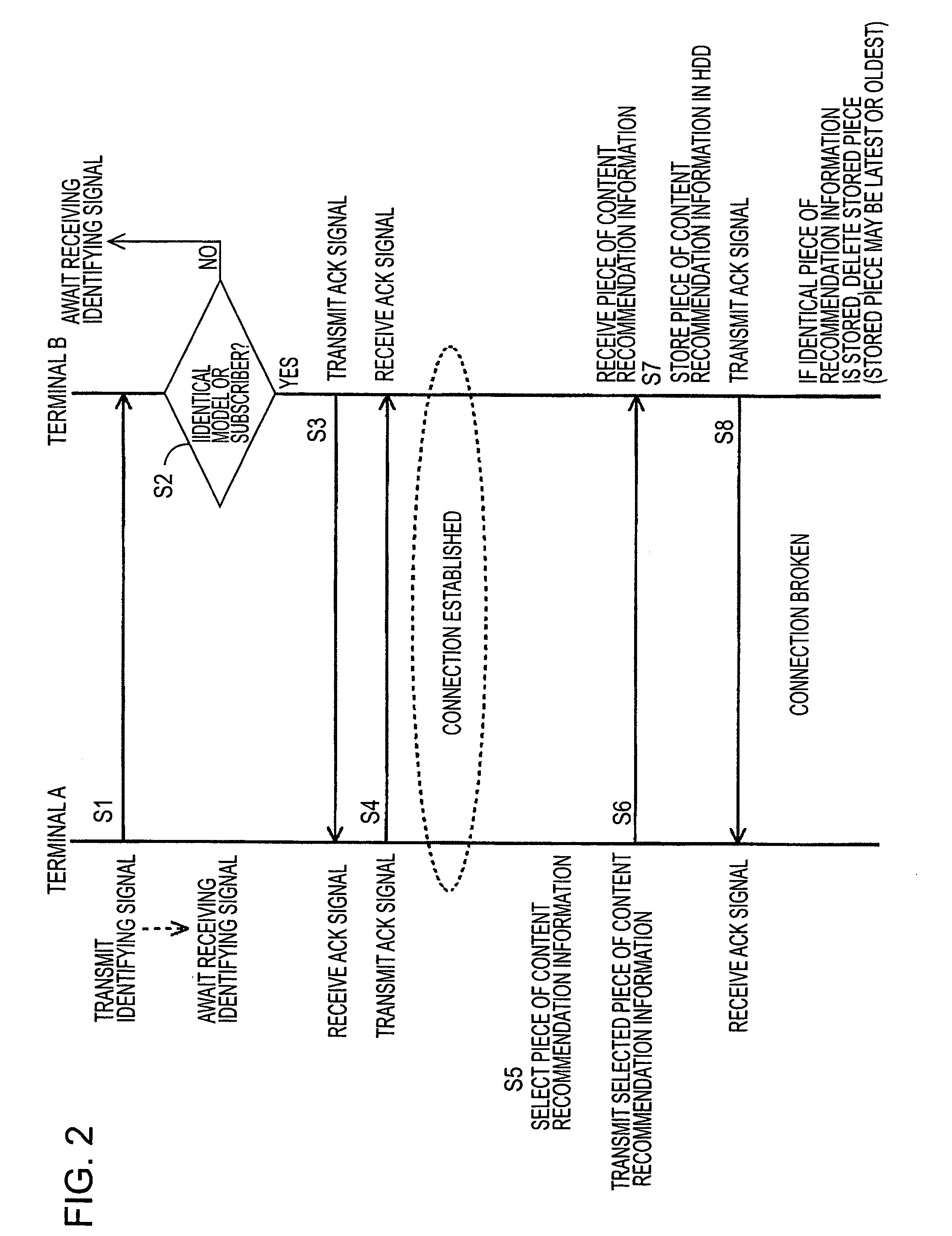

Content recommendation system and method, and communication terminal device

ActiveUS20060250994A1Provide accuratelyHinders provisionMultiplex system selection arrangementsSpecial service provision for substationTerminal equipmentLibrary science

A content recommendation system includes first and second communication devices which are connected to each other and in which content recommendation information is transmitted and received between both devices. The first communication device includes a storage section for storing pieces of content recommendation information to be transmitted, a selecting section for selecting a piece of content recommendation information to be transmitted from the storage section, and a transmitting section for transmitting the selected piece of content recommendation information. The second communication device includes a receiving section for receiving the piece of content recommendation information transmitted from the first communication device, and a storage section for storing the received piece of content recommendation information.

Owner:SONY CORP

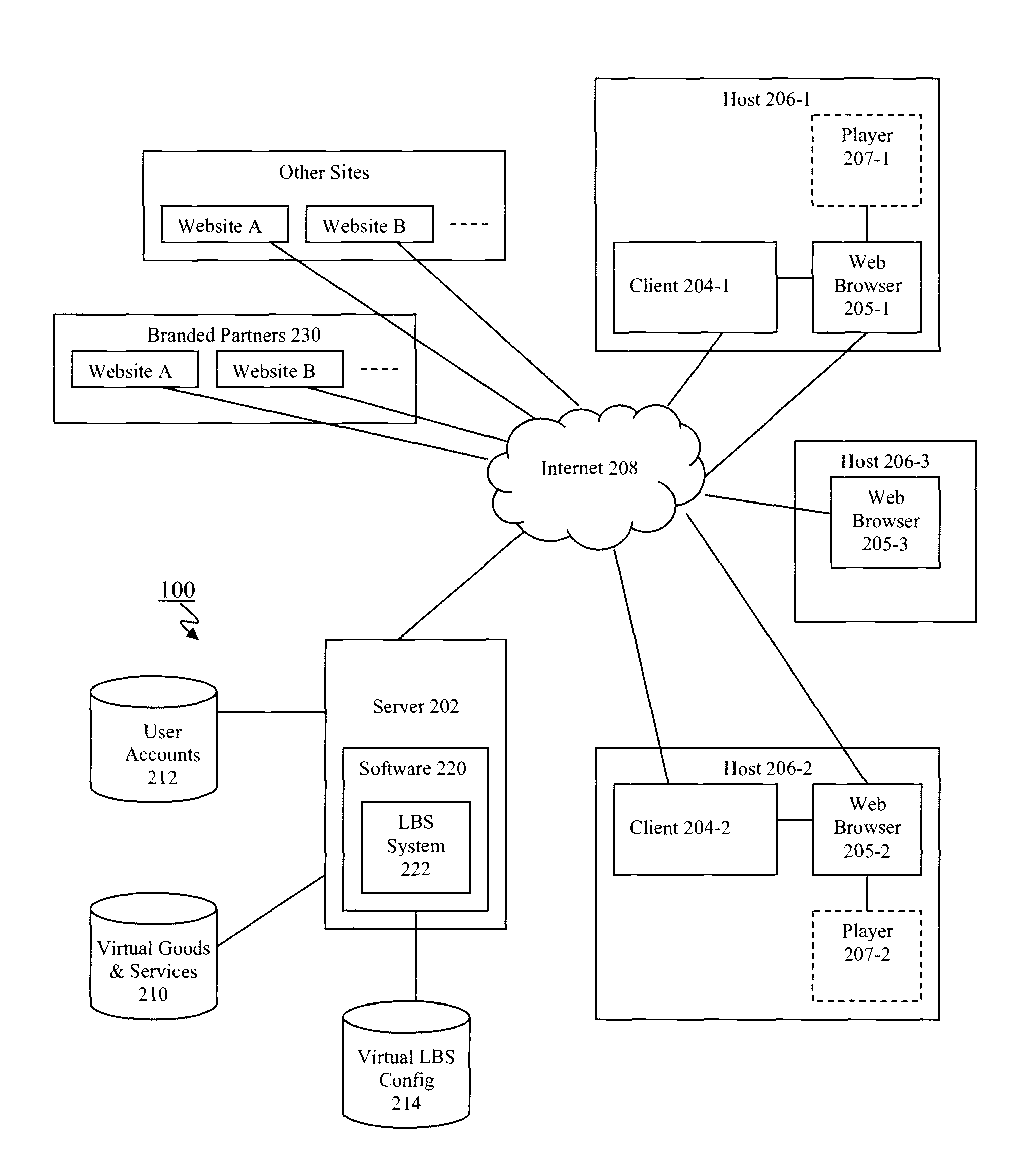

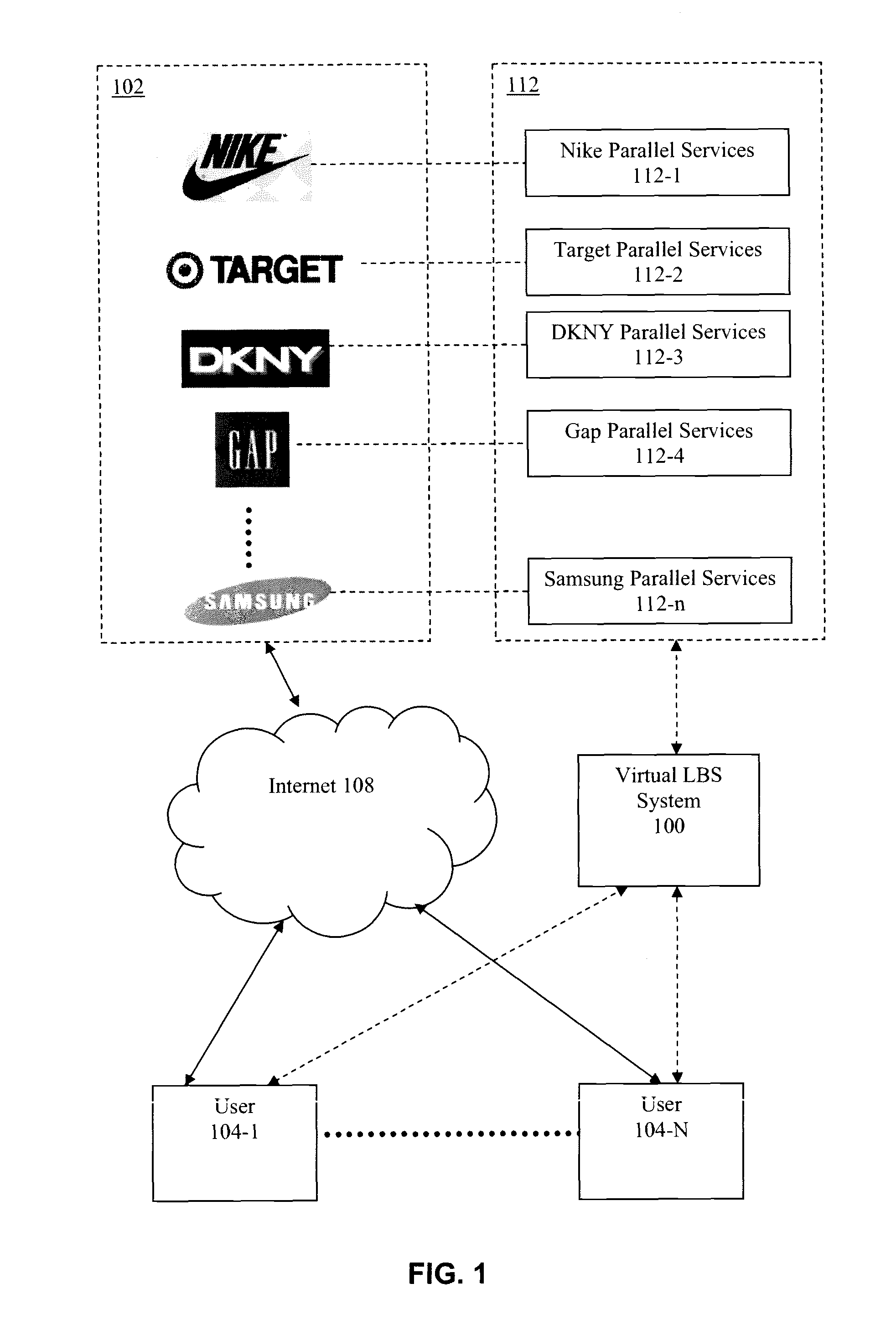

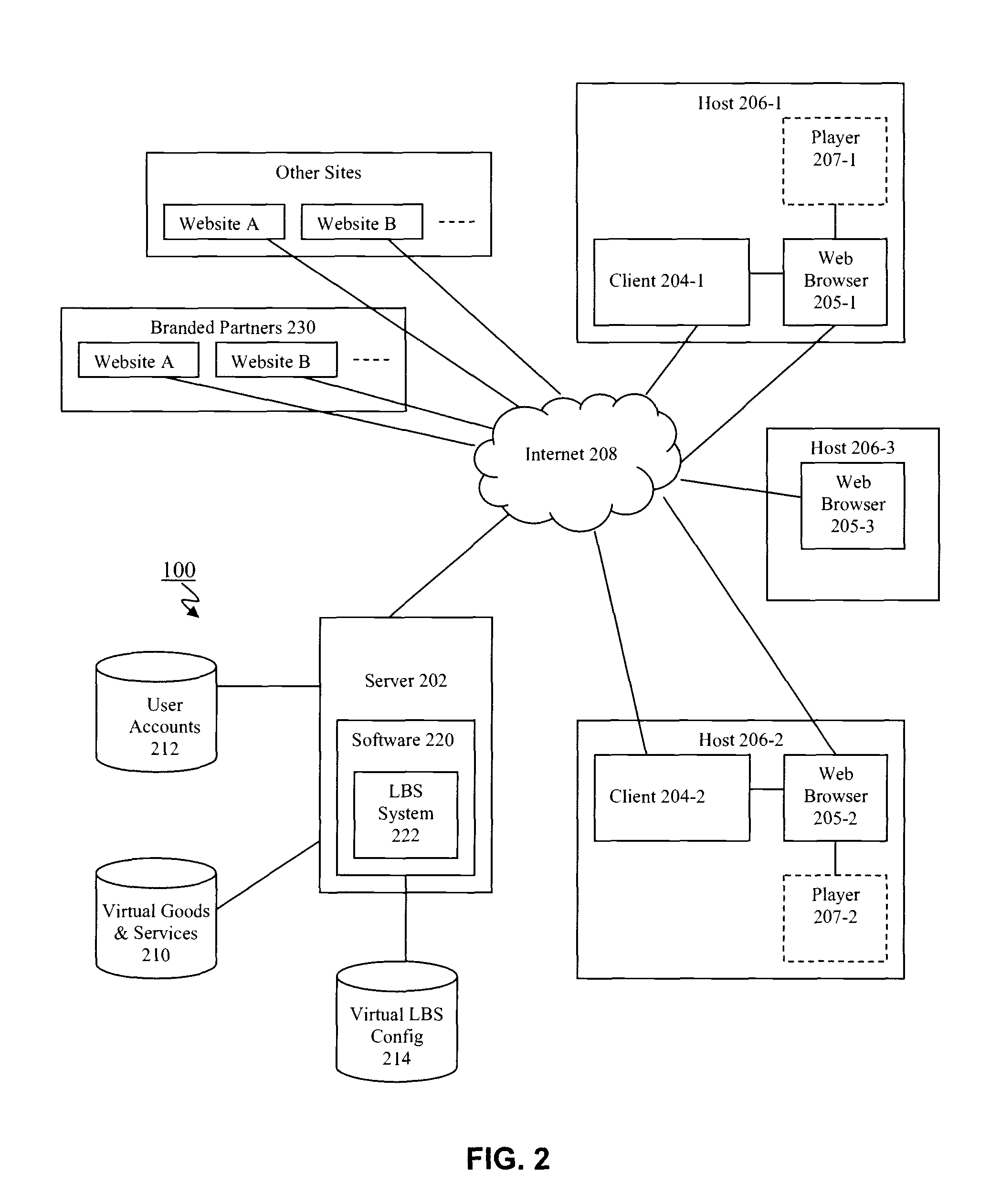

Method and apparatus for virtual location-based services

InactiveUS8190733B1Hinders provisionArtificial lifeMultiple digital computer combinationsVirtual positionLocation-based service

The present invention relates generally to the field of computer and network software, and more particularly it relates to a method and apparatus for providing virtual goods and / or on-line services based on a user's virtual location while surfing the web. According to certain aspects, the invention allows interactive objects, virtual goods and on-line services to be automatically provided to users when they visit predetermined partner sites or perform some predetermined on-line activity. According to other aspects, the invention automatically provides parallel destinations for predetermined partner sites that only users of the system can visit, and where such users can receive virtual goods and on-line services, among other content.

Owner:LAVAMIND

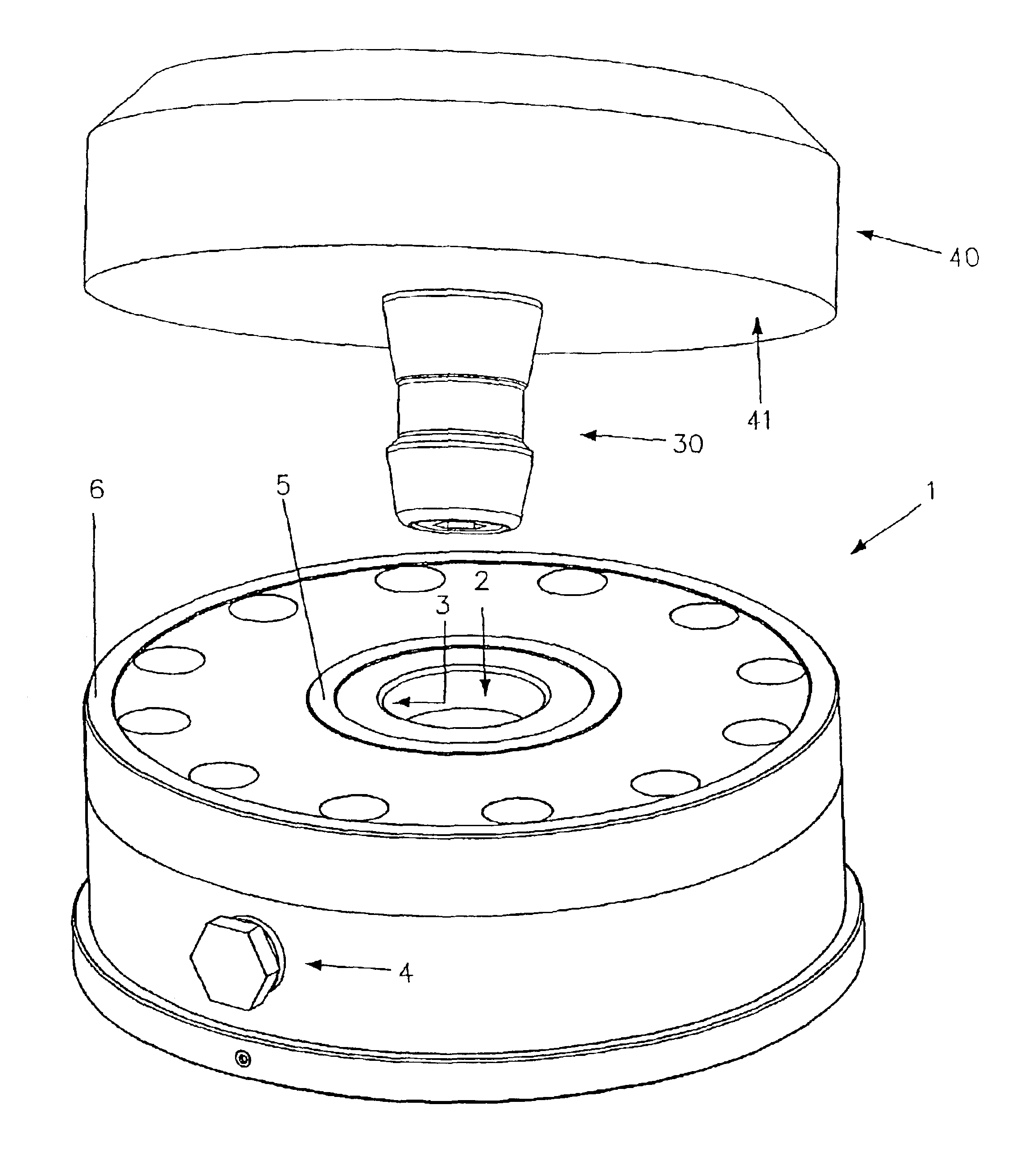

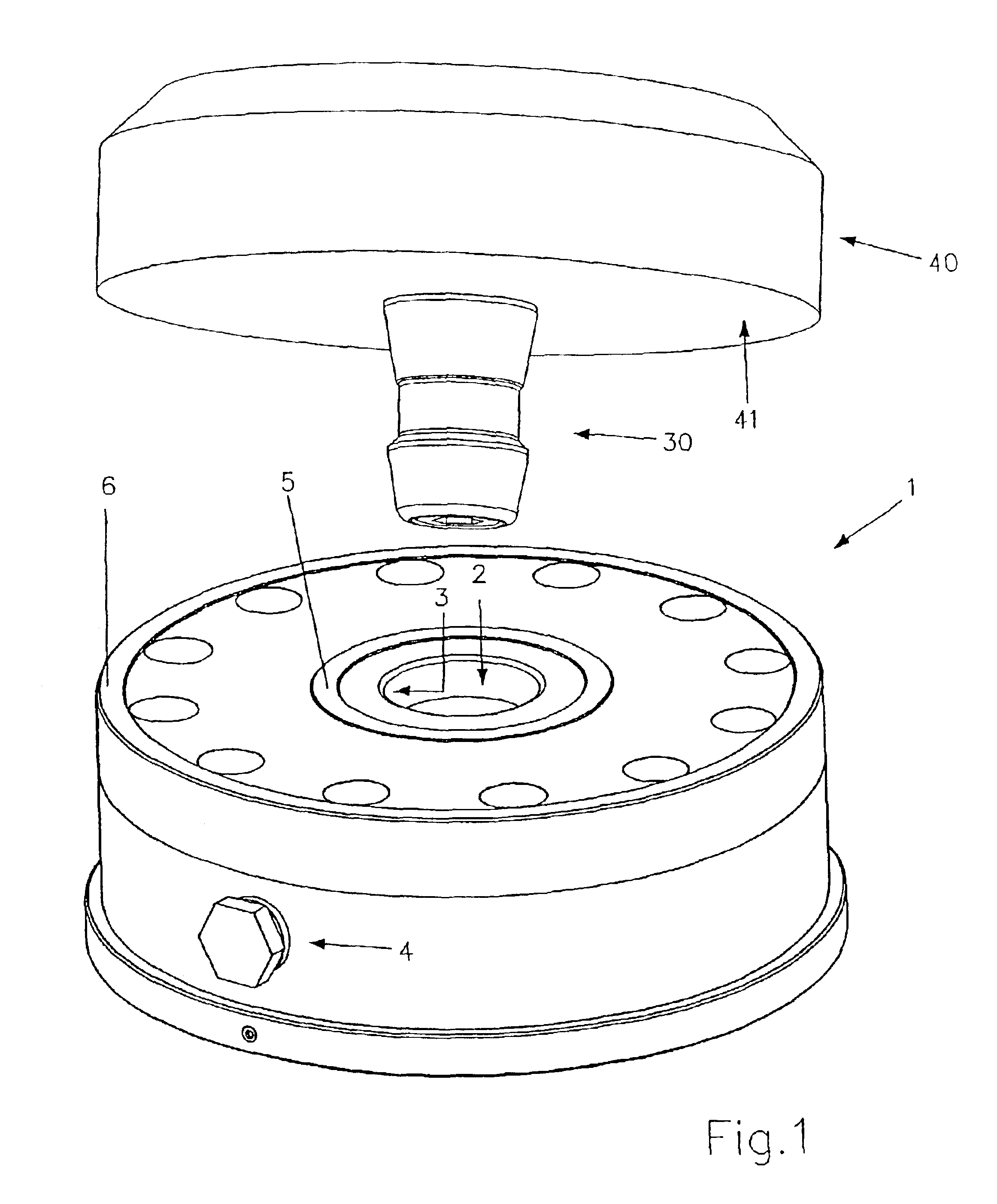

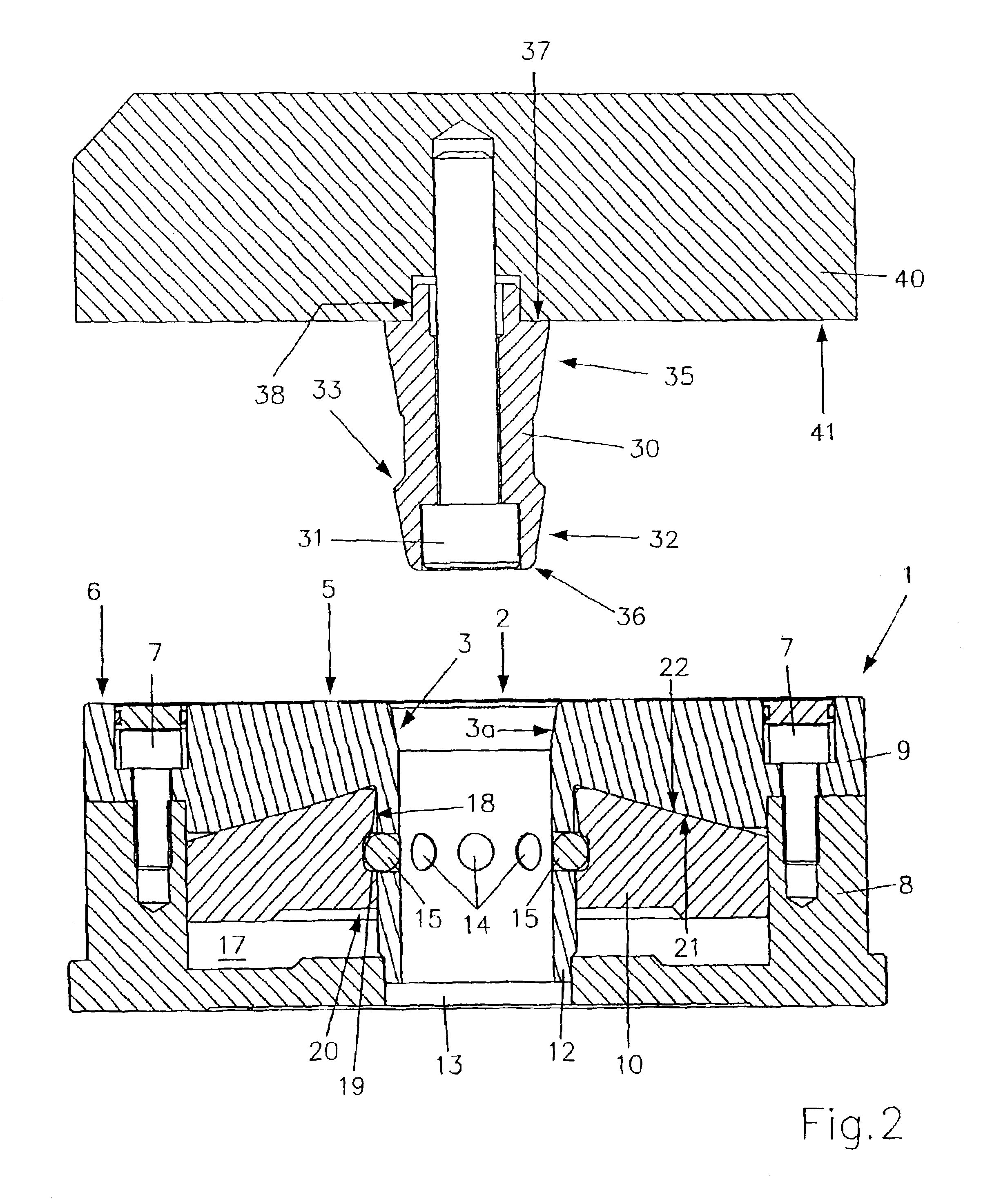

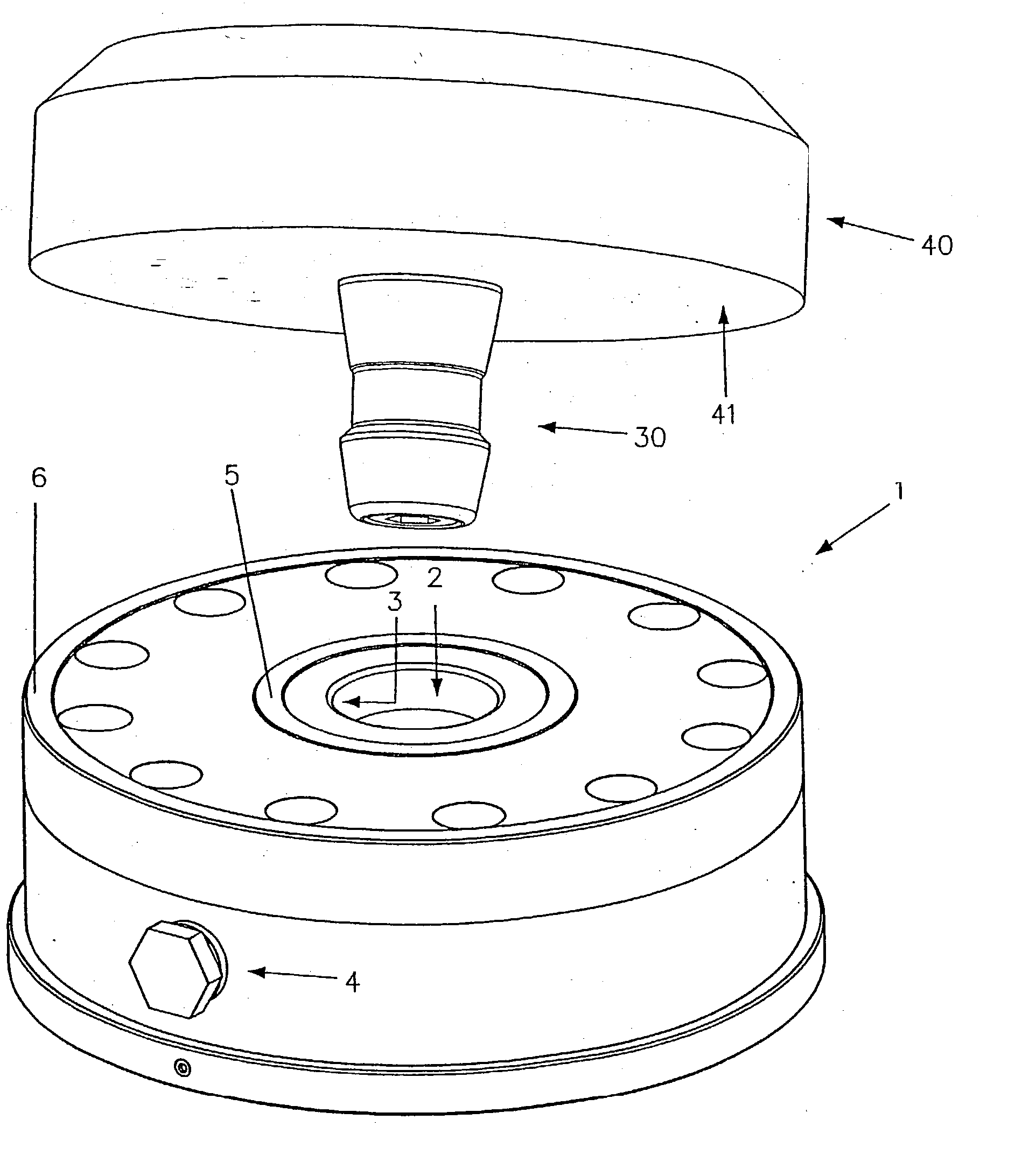

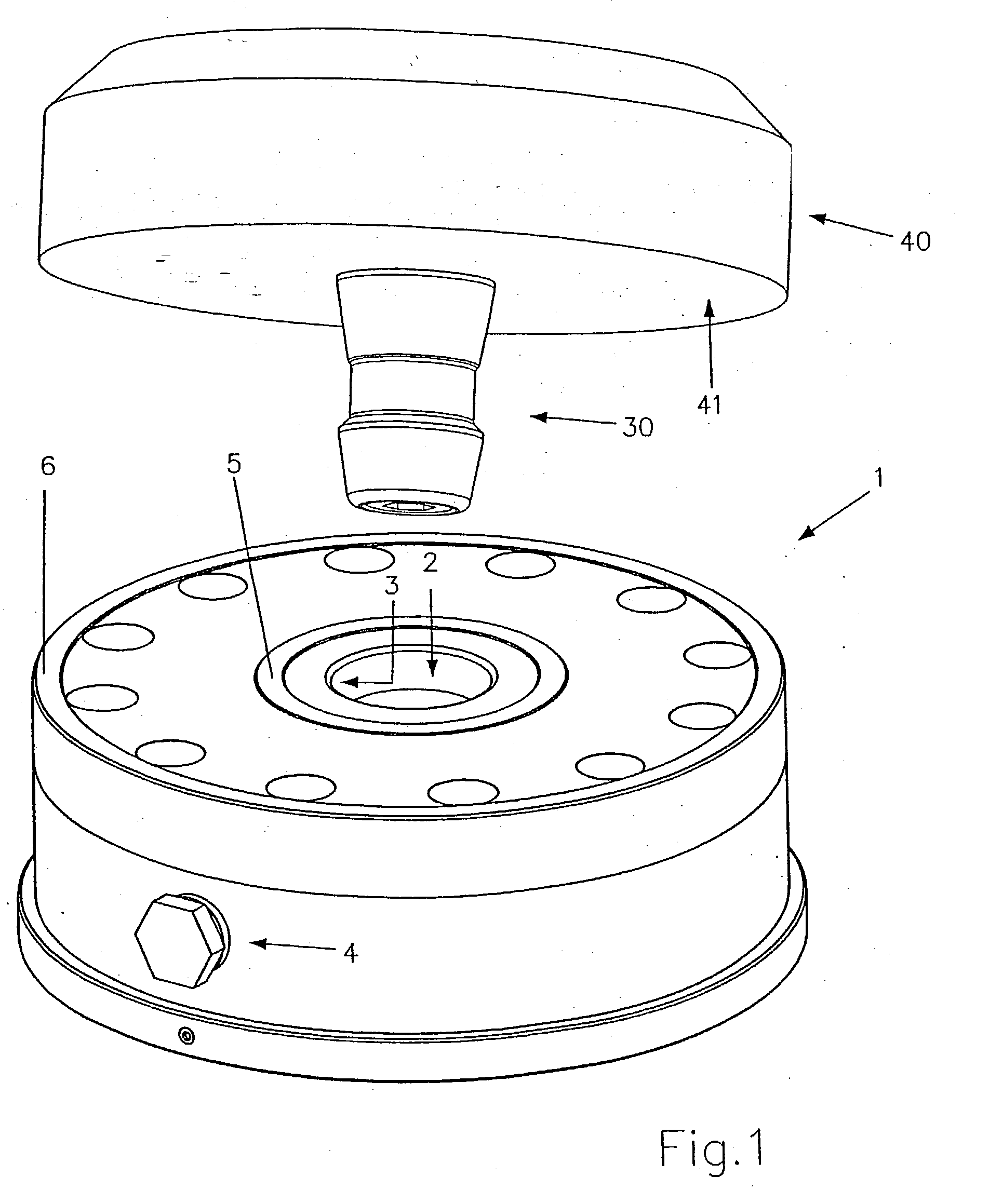

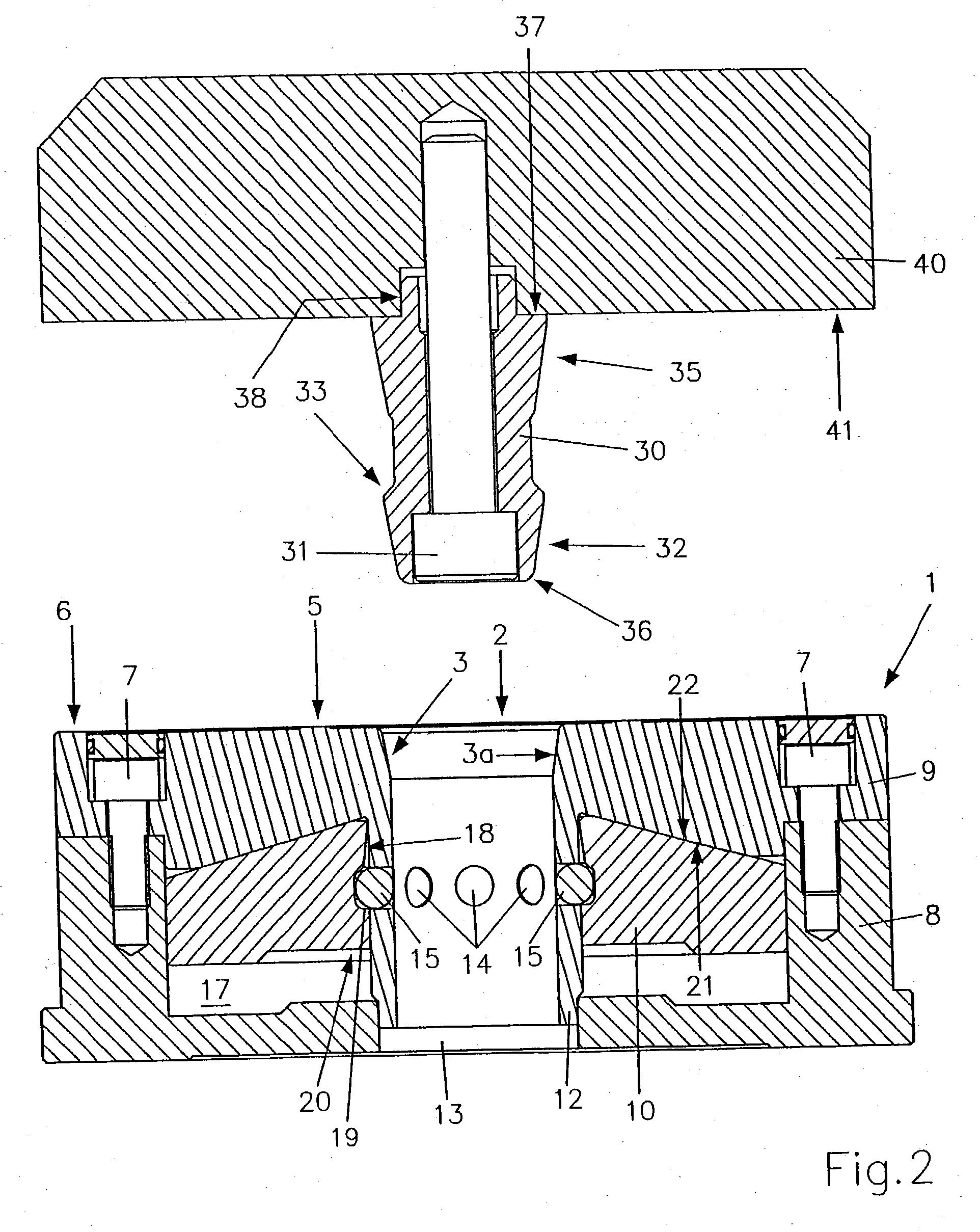

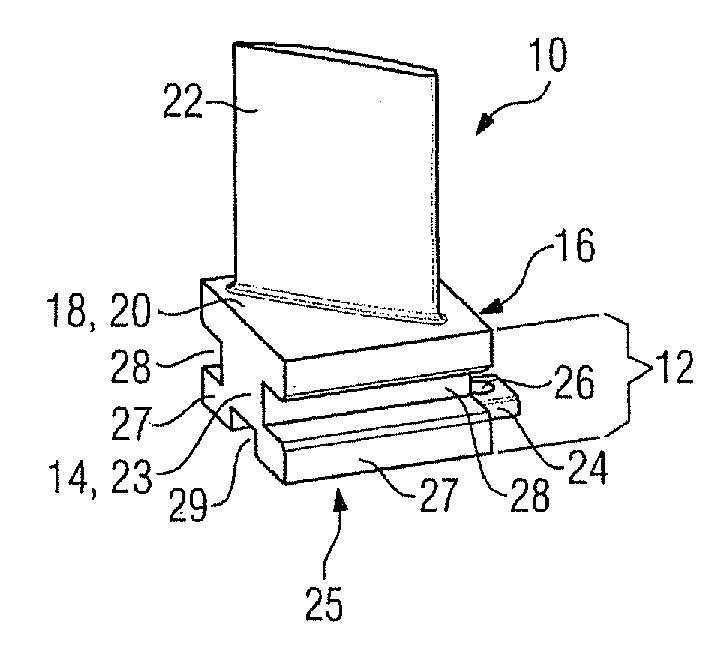

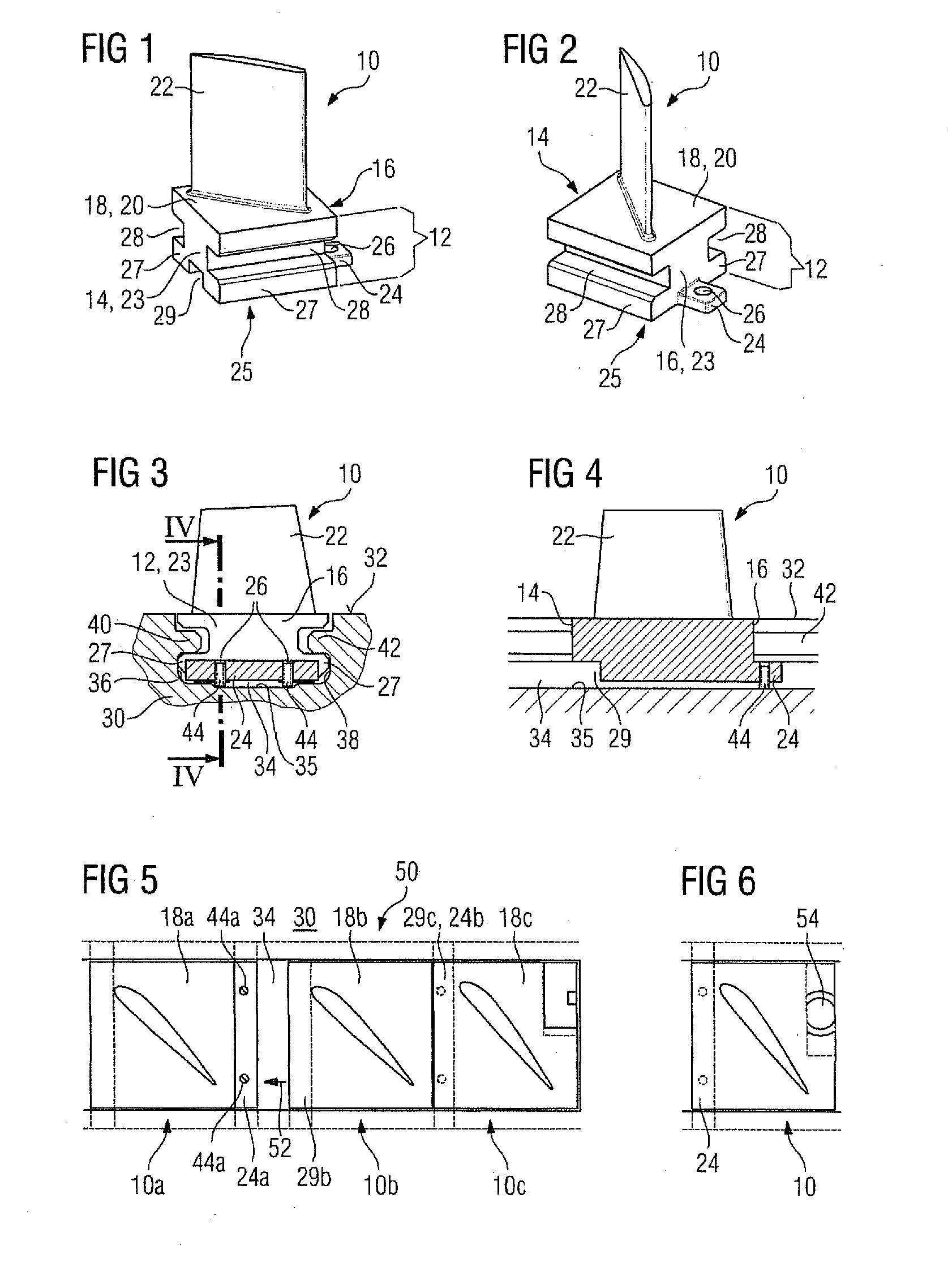

Clamping apparatus with a clamping chuck and a work piece carrier releasably connectable thereto

Owner:EROWA

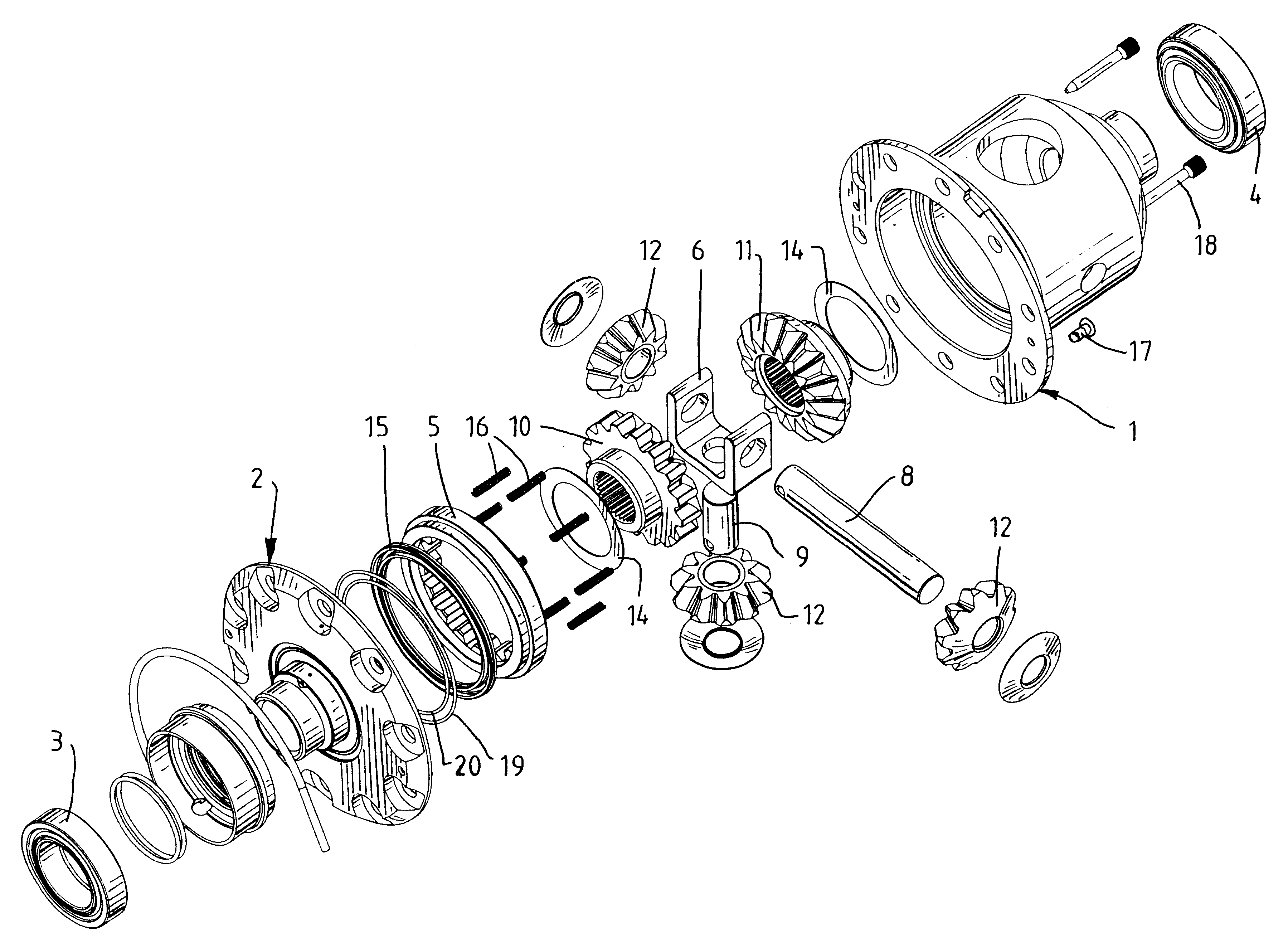

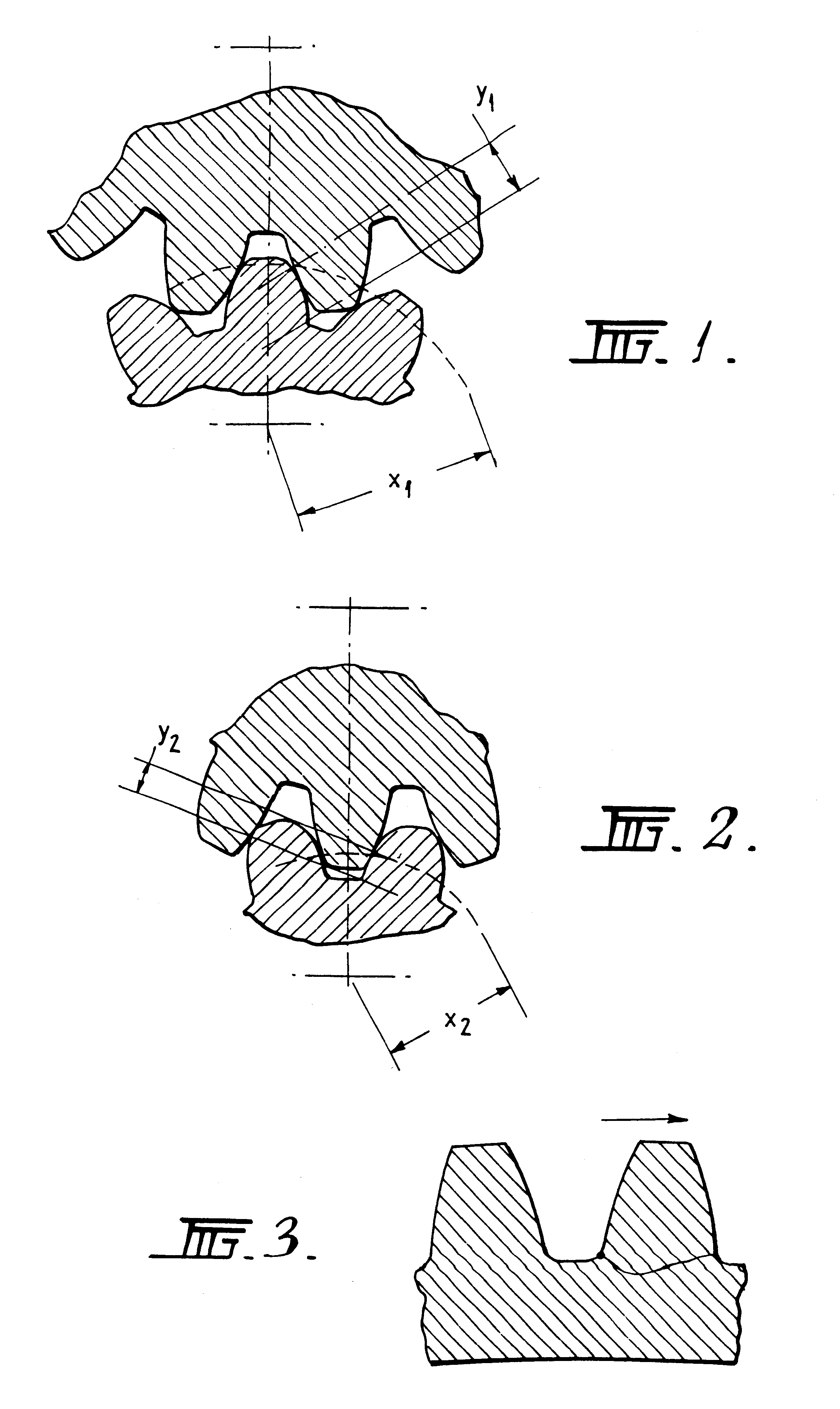

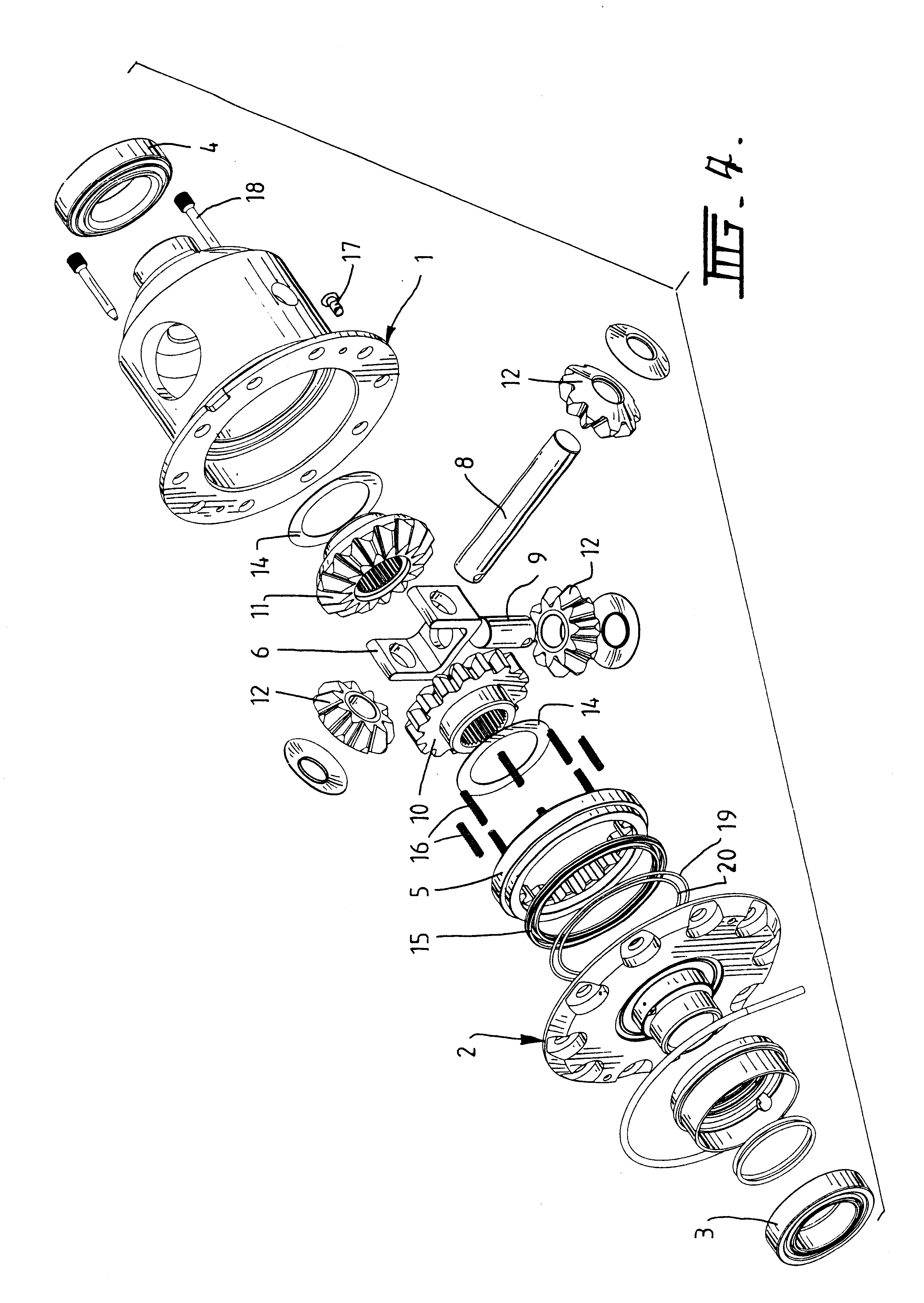

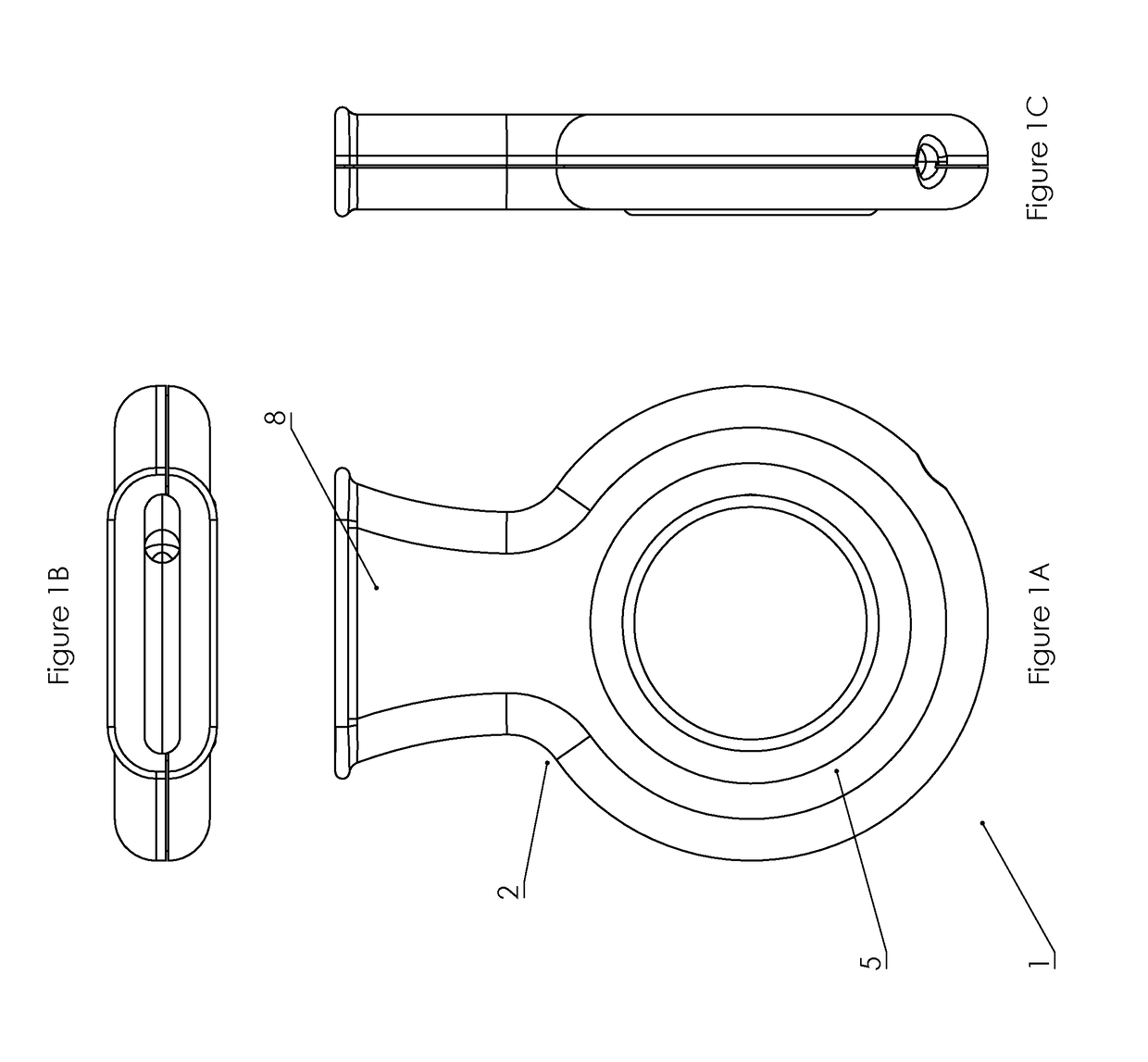

Locking differential with improved tooth meshing configuration

InactiveUS6394927B1Reduce the possibilityOptimizationTransmission elementsDifferential gearingsGear wheelEngineering

A locking differential including a differential carrier or housing 1 closed by a flange cap 2 engaging locking gear 2A, the housing 1 and flange cap 2 supporting side gears 10 and 11 which mesh with pinion gears 12 supported by cross shafts 8 and 9, the cross shafts engaging mounting holes in the housing 1, each pinion gear having an even number of teeth, and each side gear having a number of teeth which is a multiple of two where two pinions are at 180° to each other, three where three pinion gears are at 120° to each other, four where three or four pinion gears are at 90° to each other, or five where five pinions are at 72° to each other, the locking means further including a clutch gear 5 which slidably engages the locking gear 2A and the teeth on side gear 10 in the locked position, the cross shafts 8 and 9 being in a fixed relationship to the locking gear 2A.

Owner:ARB CORP LTD

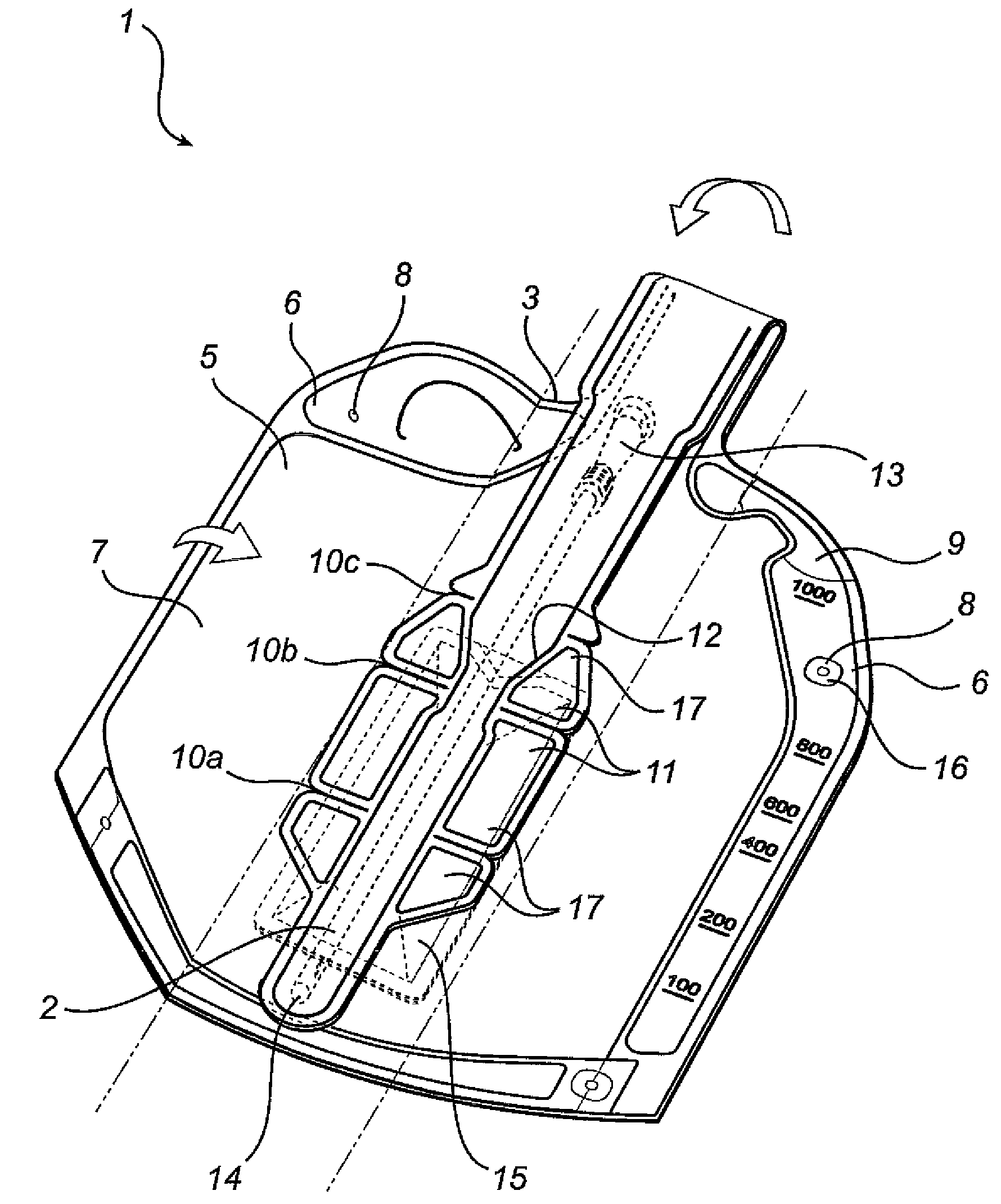

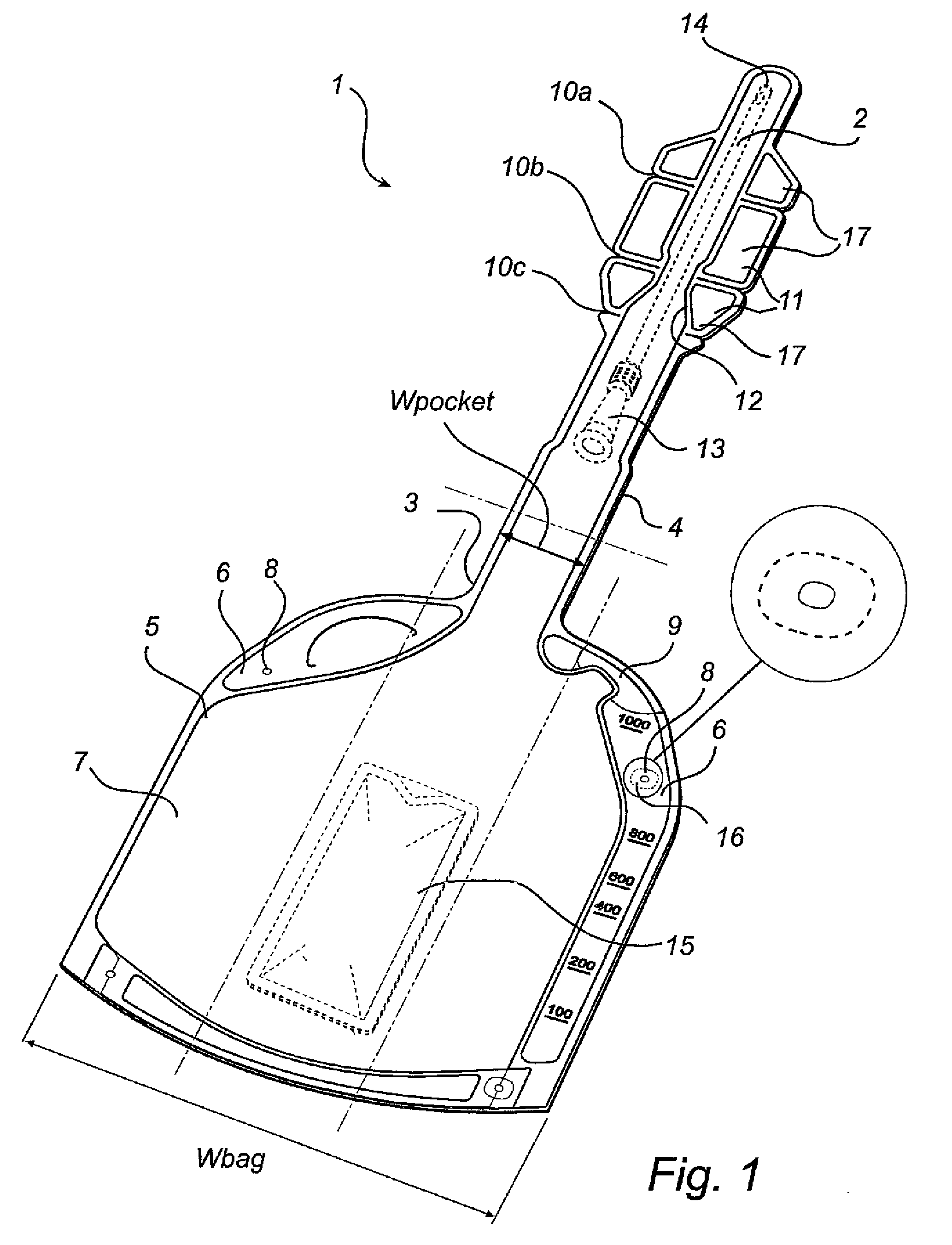

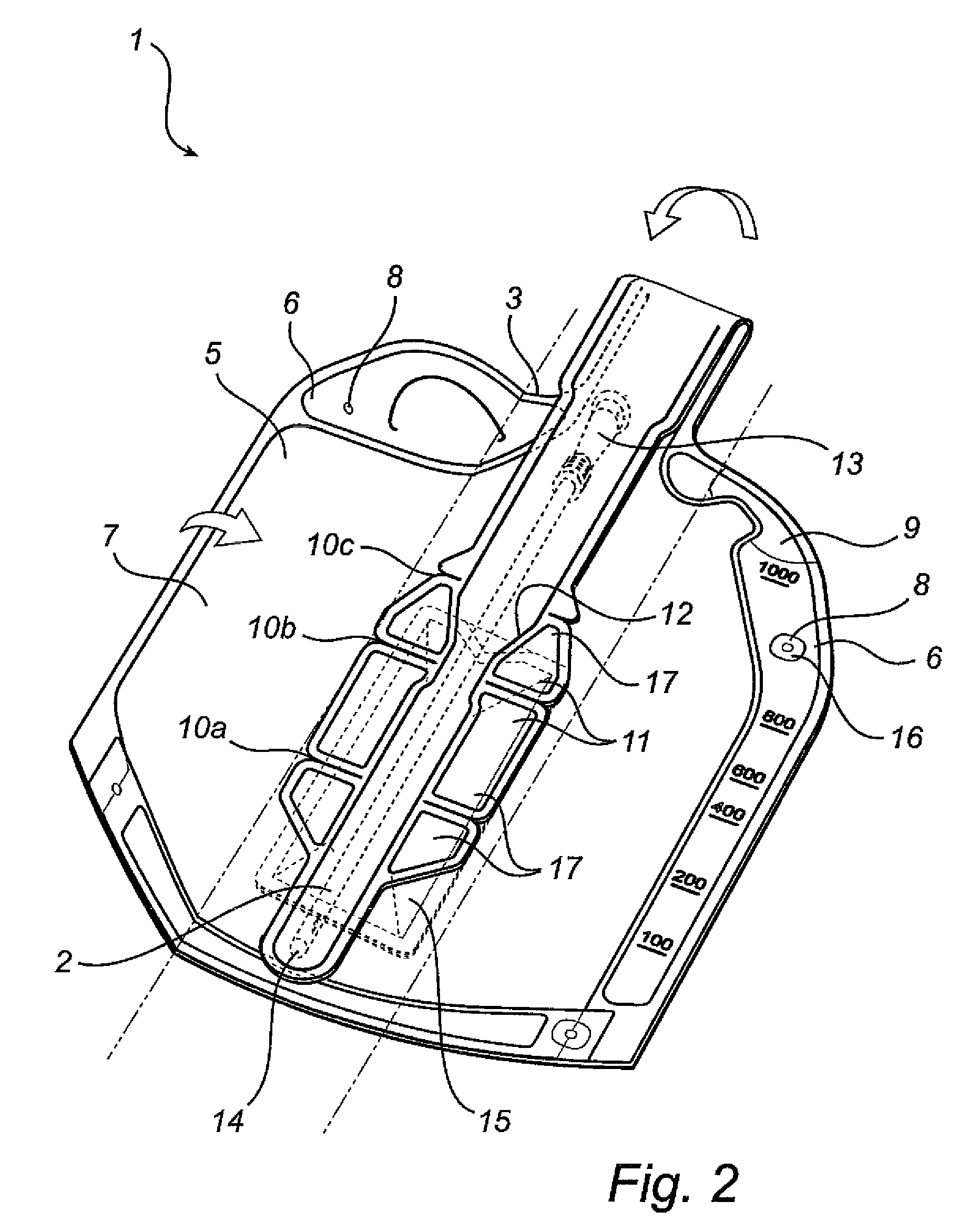

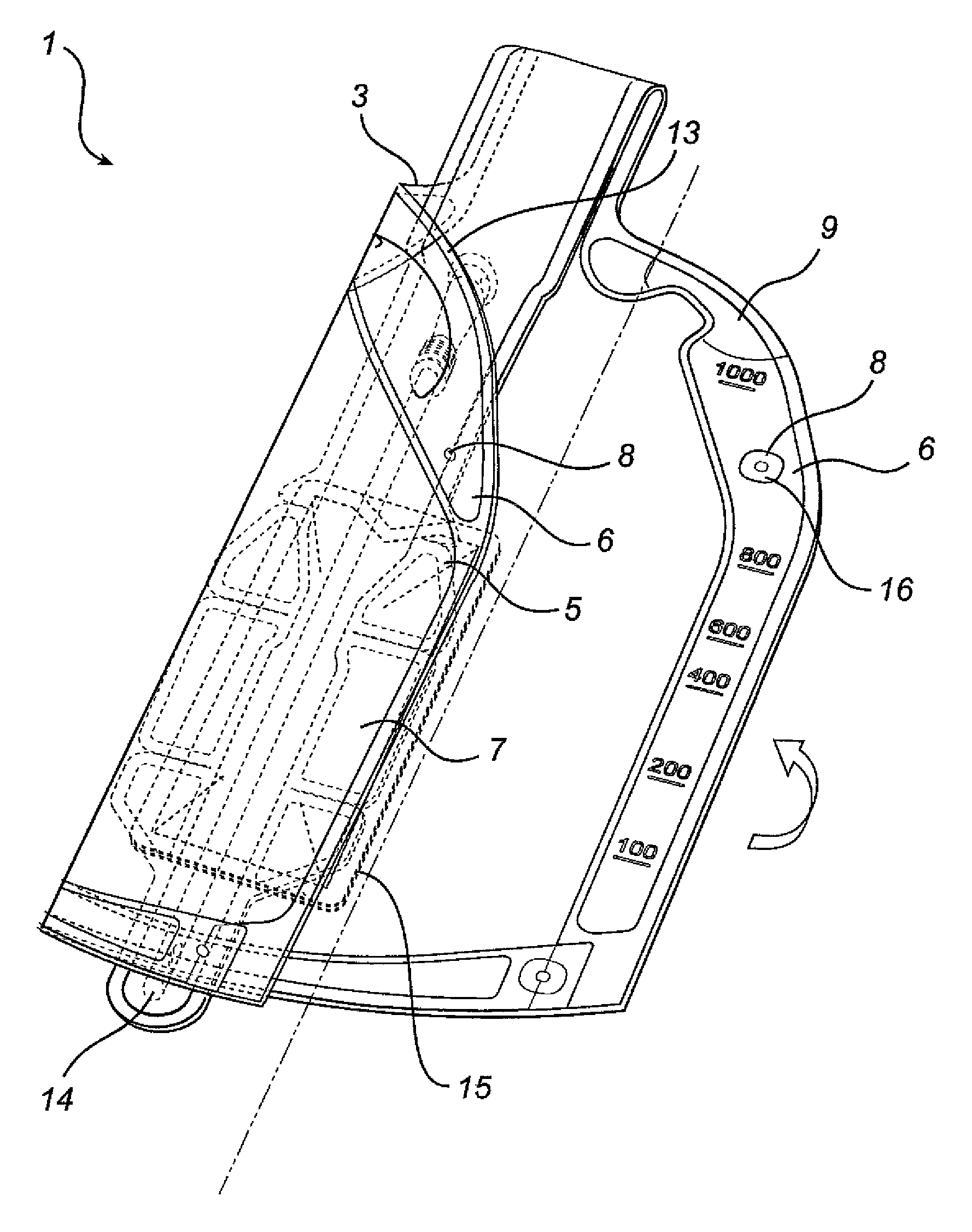

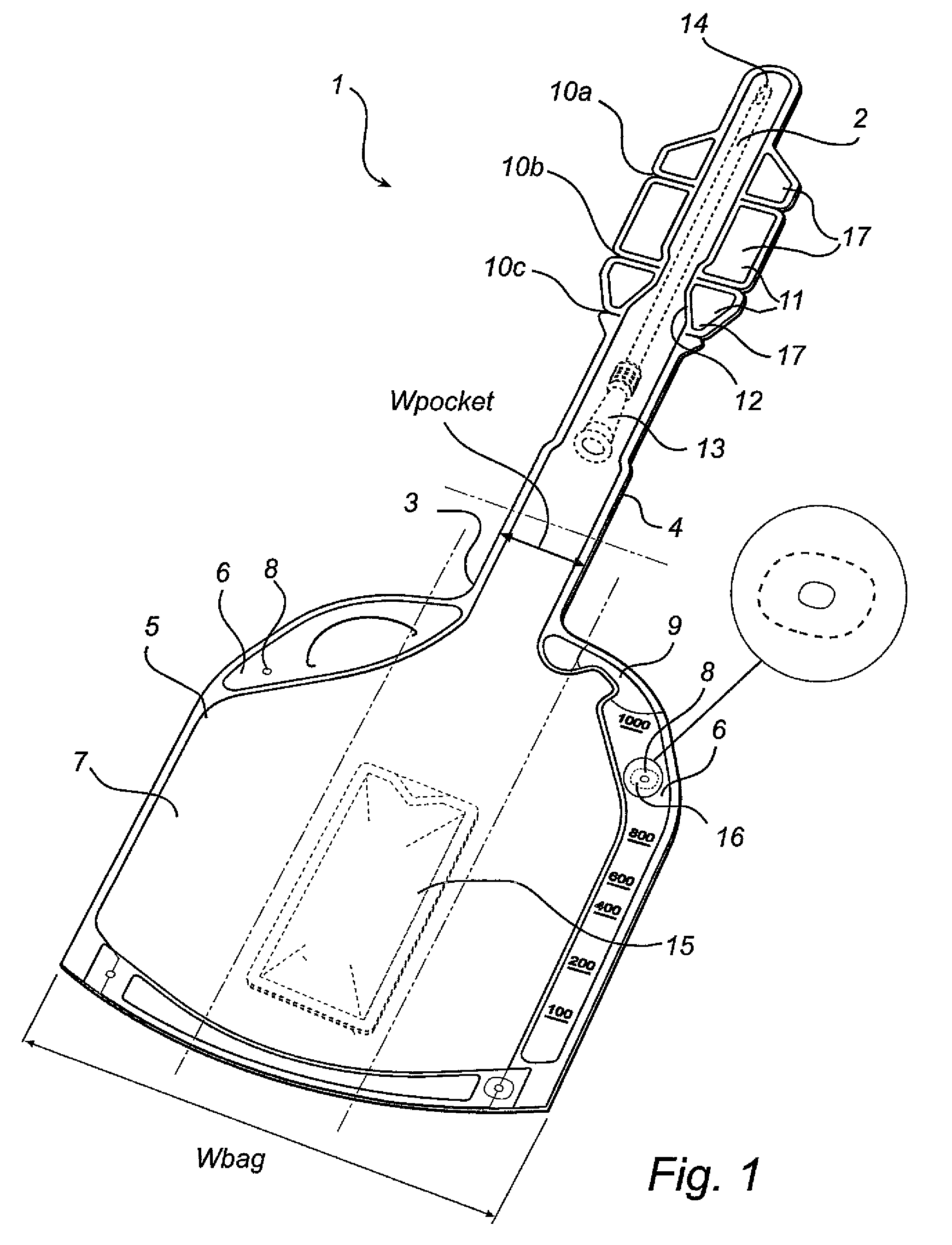

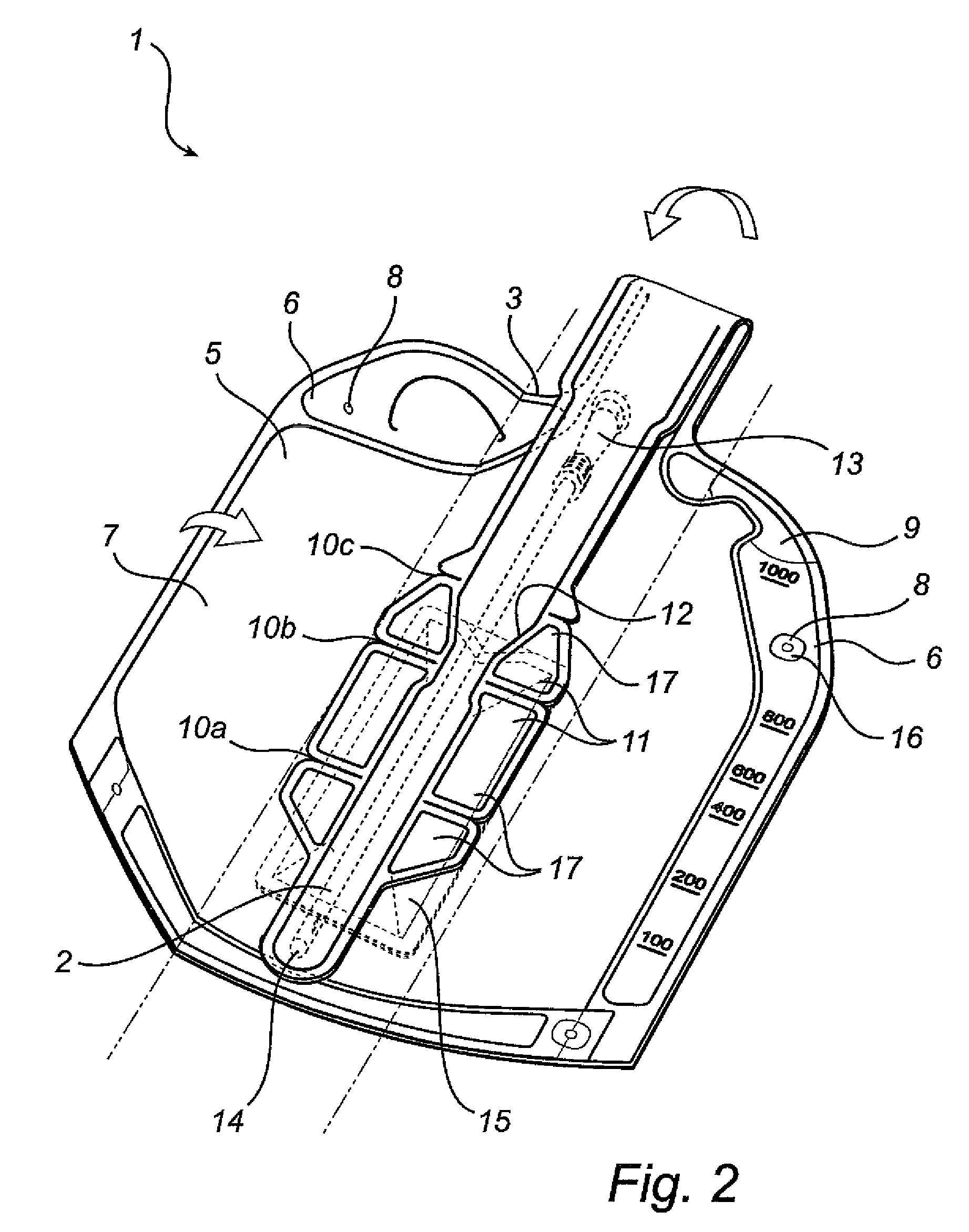

Catheter assembly with a folded urine collection bag

ActiveUS20090163884A1Maximum hold capacityEasy to storeWound drainsWrapper folding/bending apparatusUrologyUrine collection

There is disclosed a catheter assembly comprising a catheter and a receptacle. The receptacle has an elongate pocket, for accommodating at least an insertable end of said catheter, a urine collection bag, having a width extension wider than a greatest width of said elongate pocket, and at least two tab areas on at least one tab are arranged at the periphery of the urine collection bag on opposite sides of said bag. Further, in a storage state, said elongate pocket is folded over said urine collection bag, and lateral parts of said urine collection bag extending outside said elongate pocket are folded towards each other over said elongate pocket, said lateral parts being dimensioned to overlap each other in the folded disposition, and wherein said tab areas are arranged on said lateral parts and are attached to each other, in at least one point of attachment, to releasably maintain said catheter assembly in a folded disposition during storage.

Owner:ASTRA TECH SE

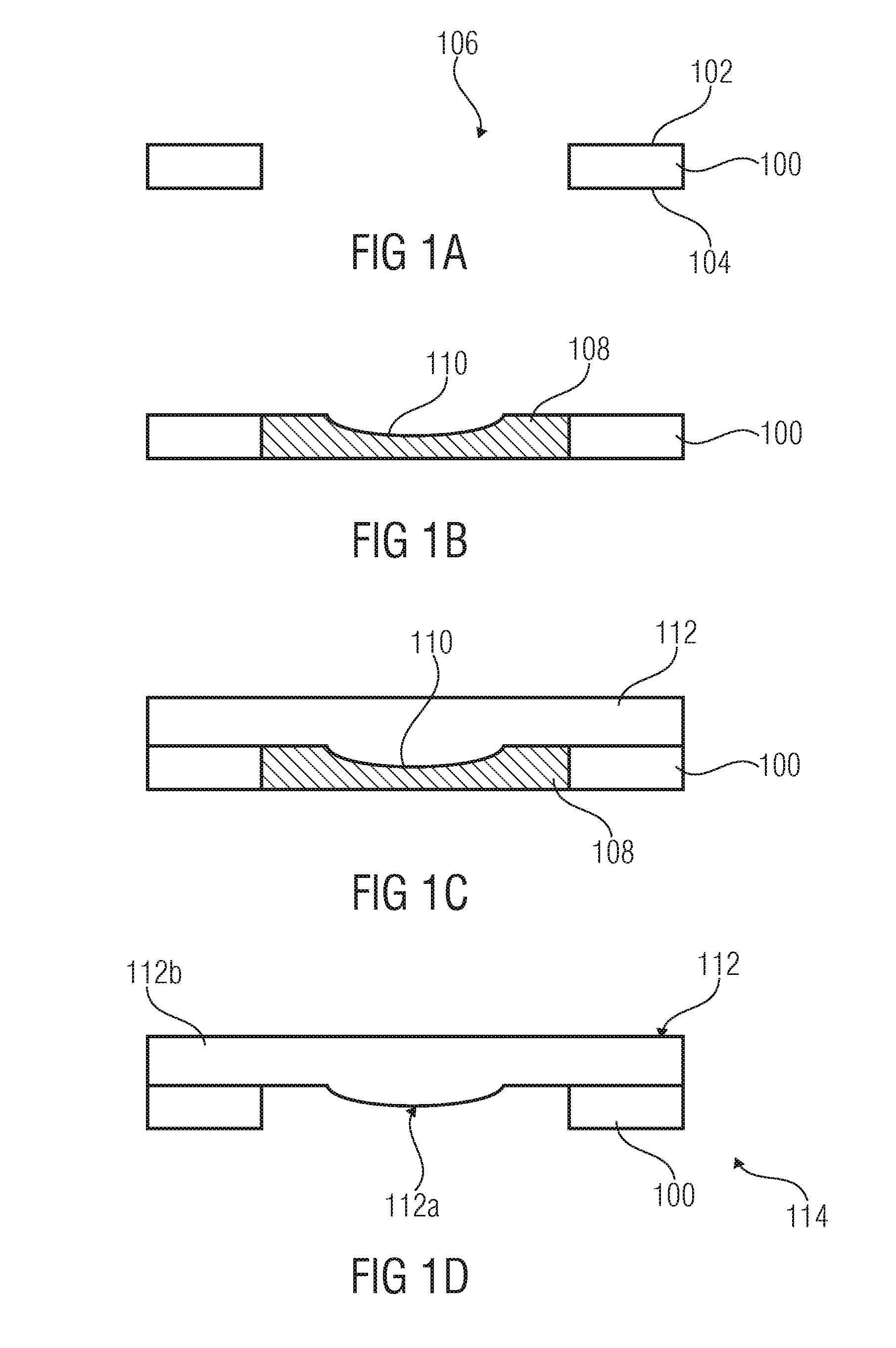

Lens and method for manufacturing same

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

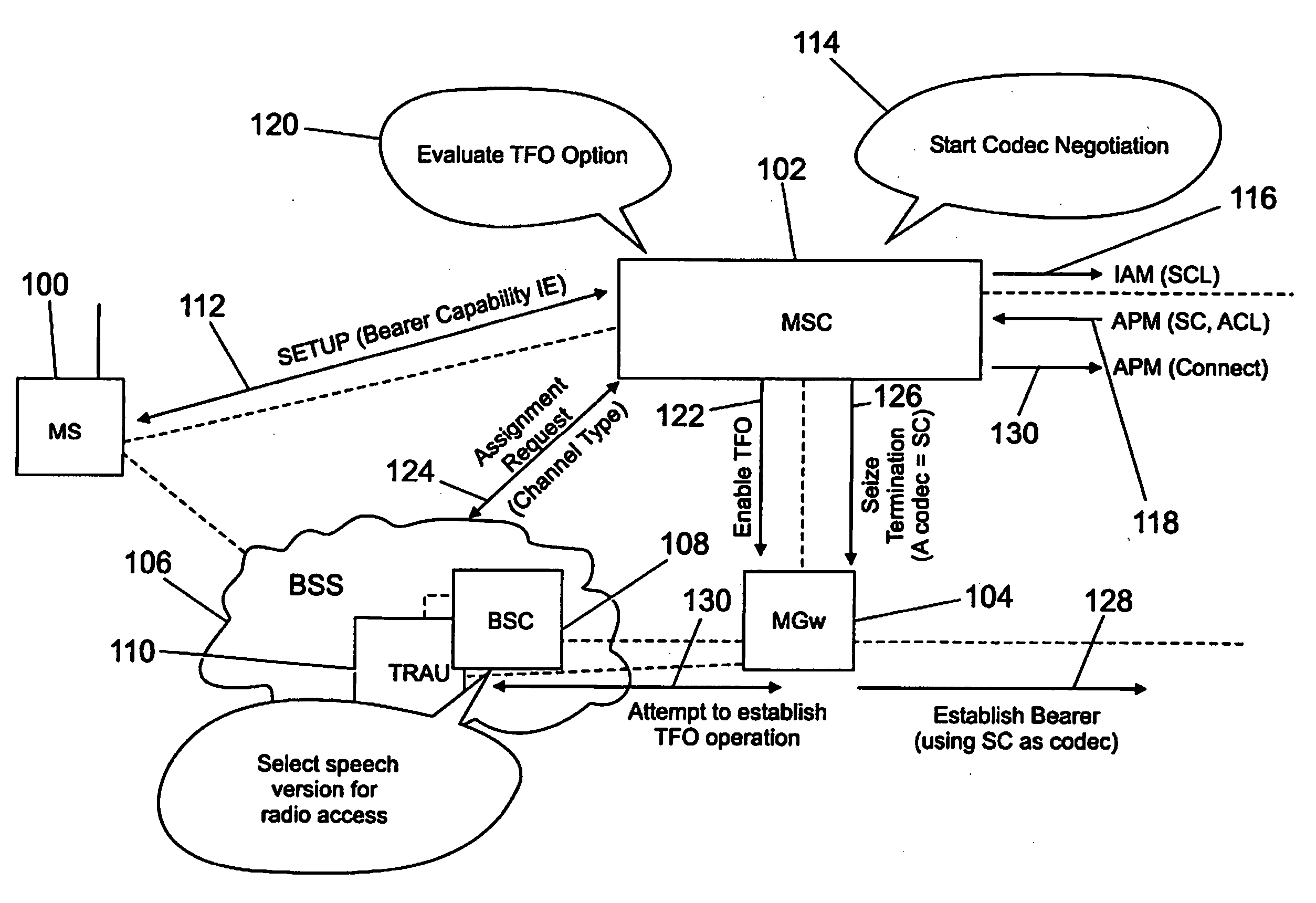

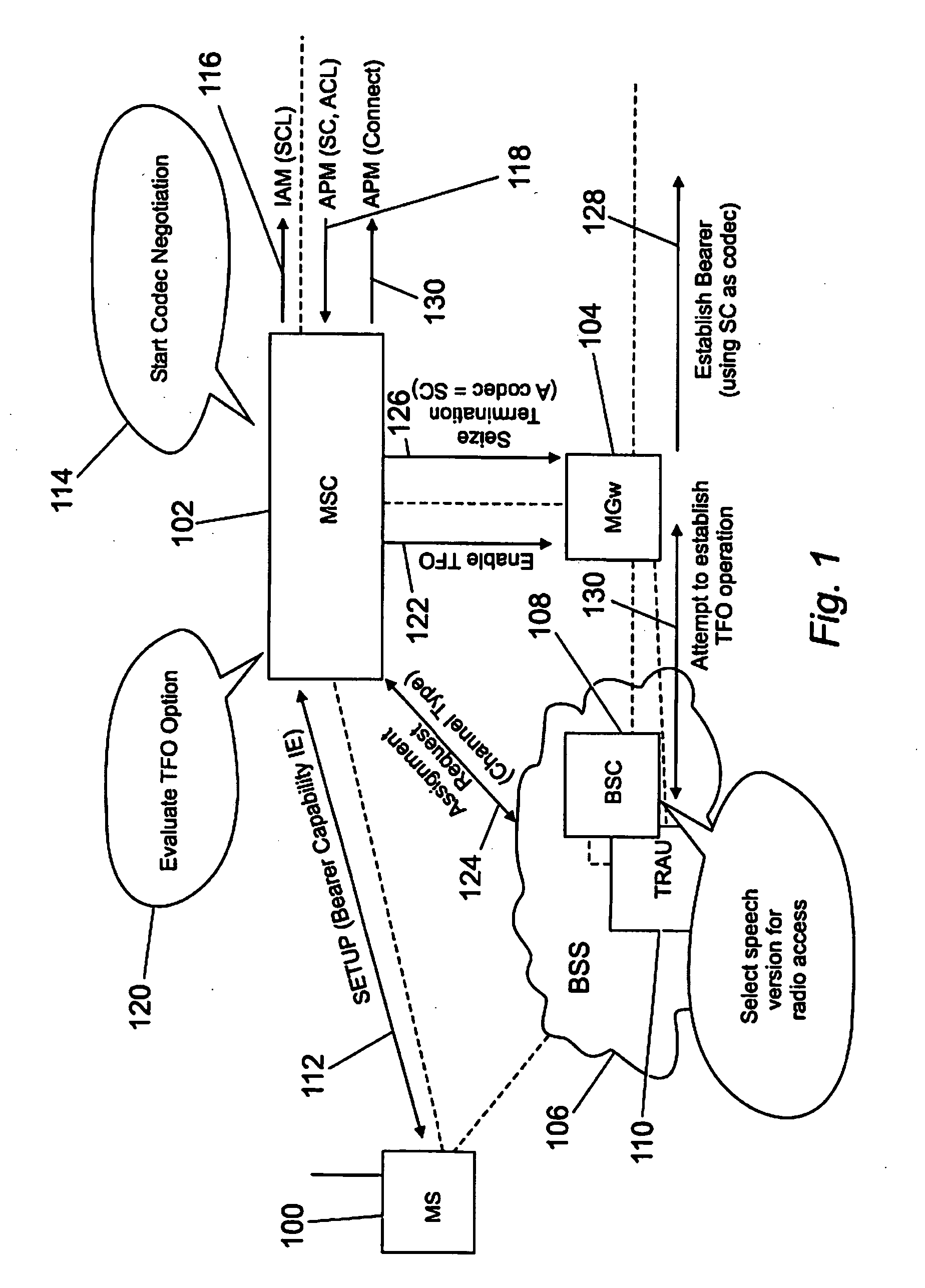

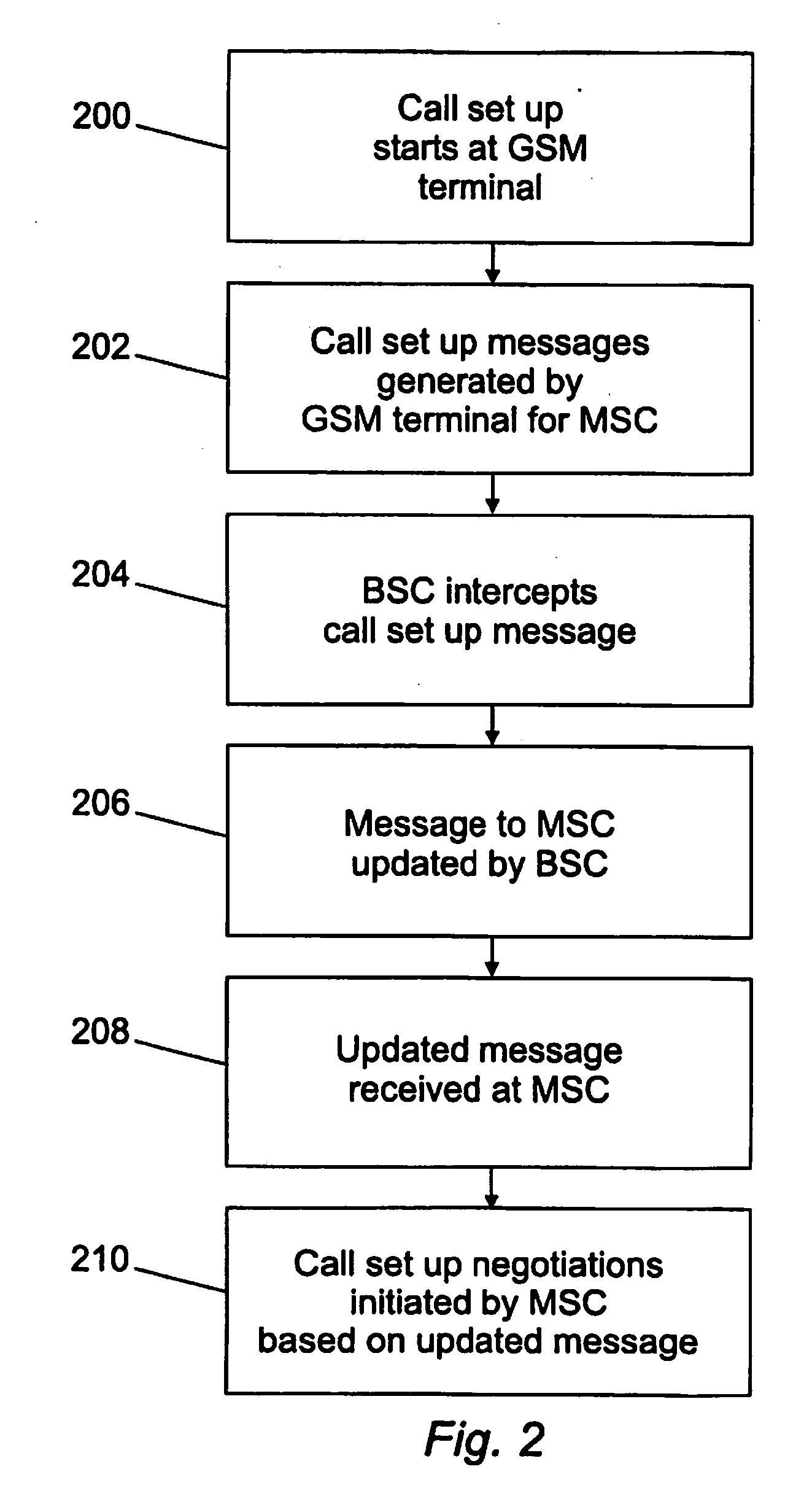

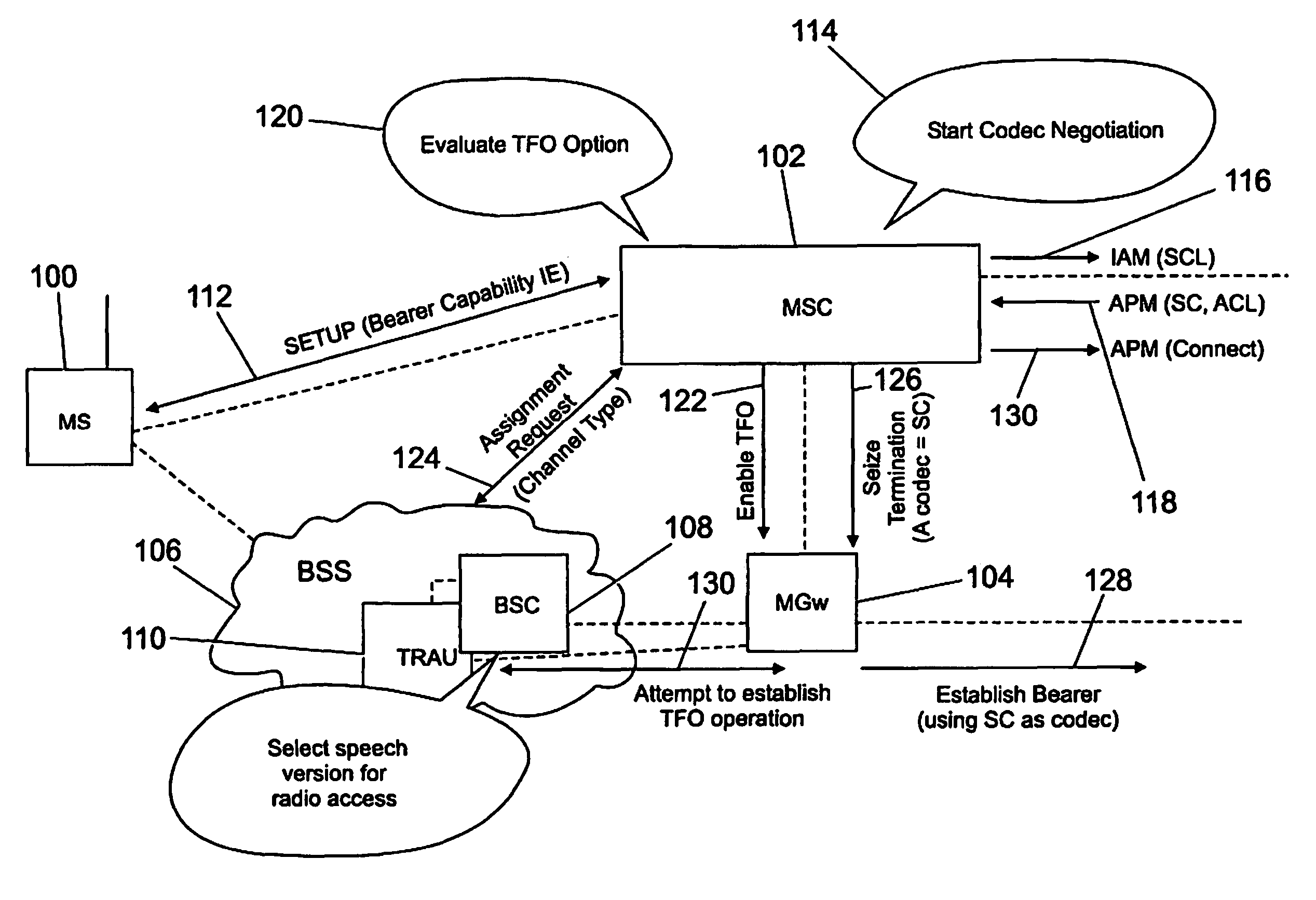

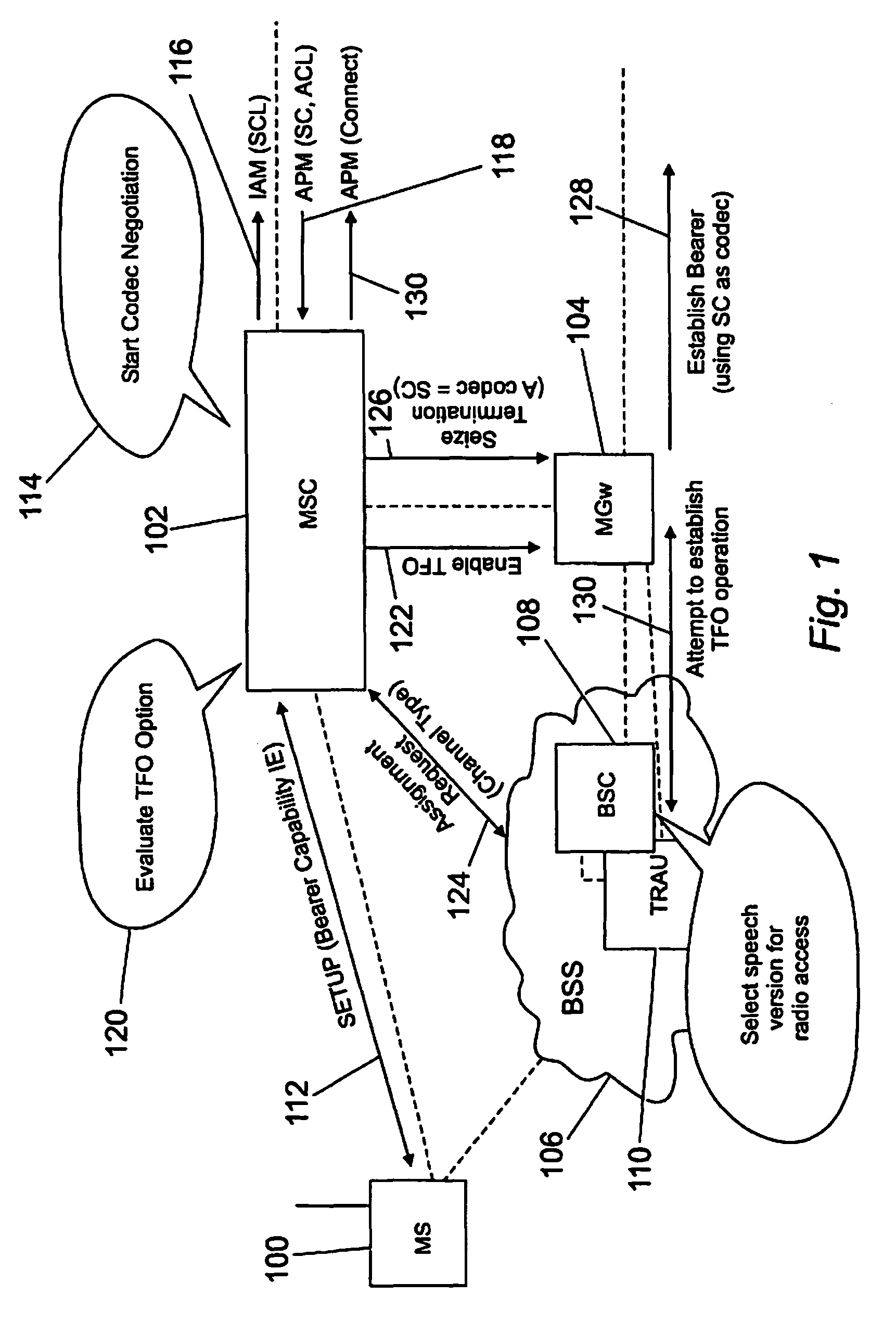

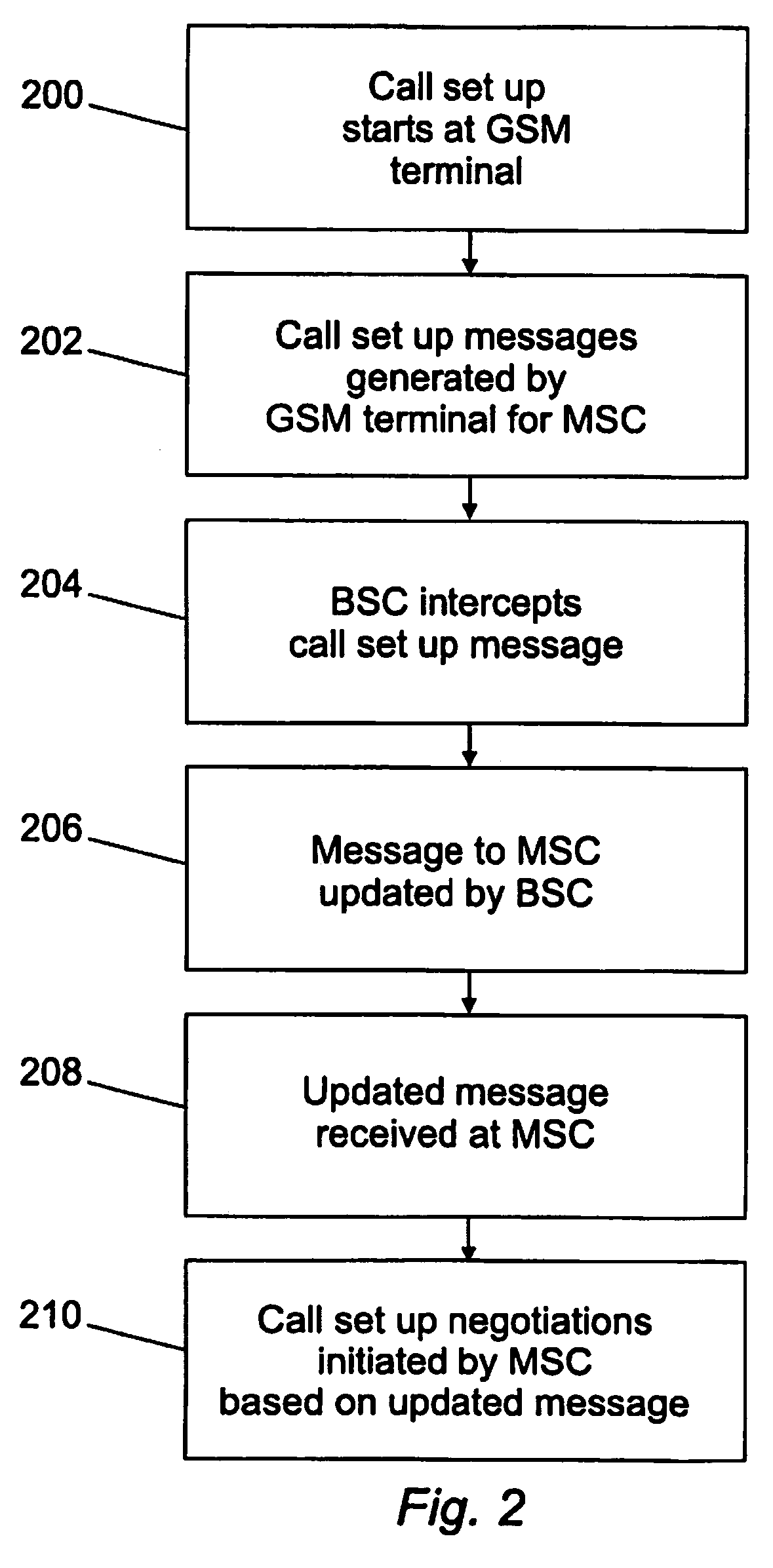

Method for codec negotiation and selection

ActiveUS20090047936A1Improve coordinationEasy to operateNetwork traffic/resource managementSpecial service for subscribersCall setup

A method of modifying a call setup message for a call from a first terminal to a second terminal, the call setup message being sent from the first terminal to a network node via an intermediate node which handles at least some signaling or traffic associated with the call, wherein the network node is responsible for negotiating call setup requirements for the call to the second terminal, the method comprising the steps of: intercepting the call setup message at the intermediate node; identifying one or more preferences or capabilities associated with the intermediate node which may impact the way in which the intermediate node can handle signaling or traffic associated with the call; modifying the call setup message based on information relating to said preferences or capabilities; and sending the modified call setup message to the network node, in order that the node can effect said negotiations based on the modified message.

Owner:TELEFON AB LM ERICSSON (PUBL)

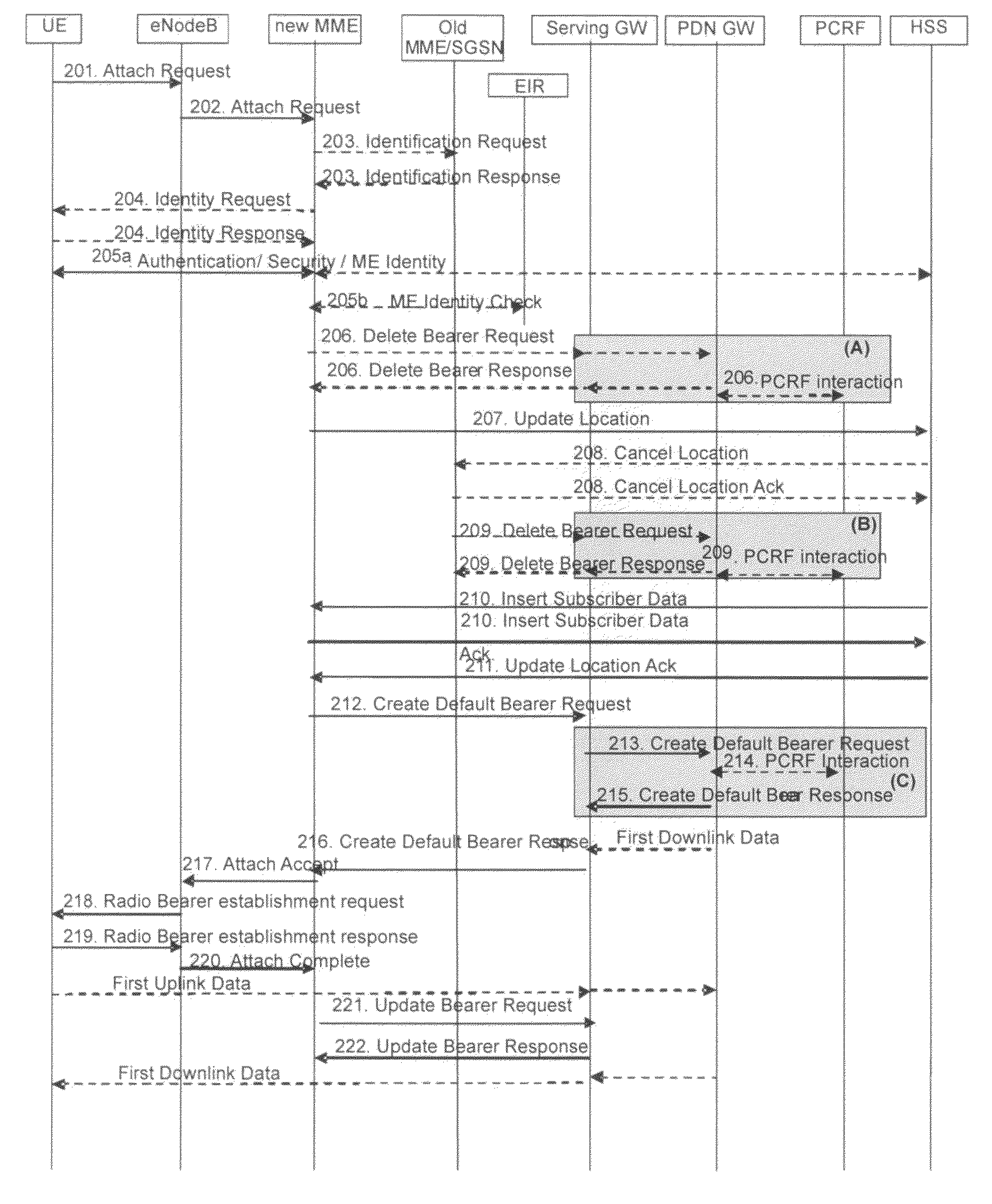

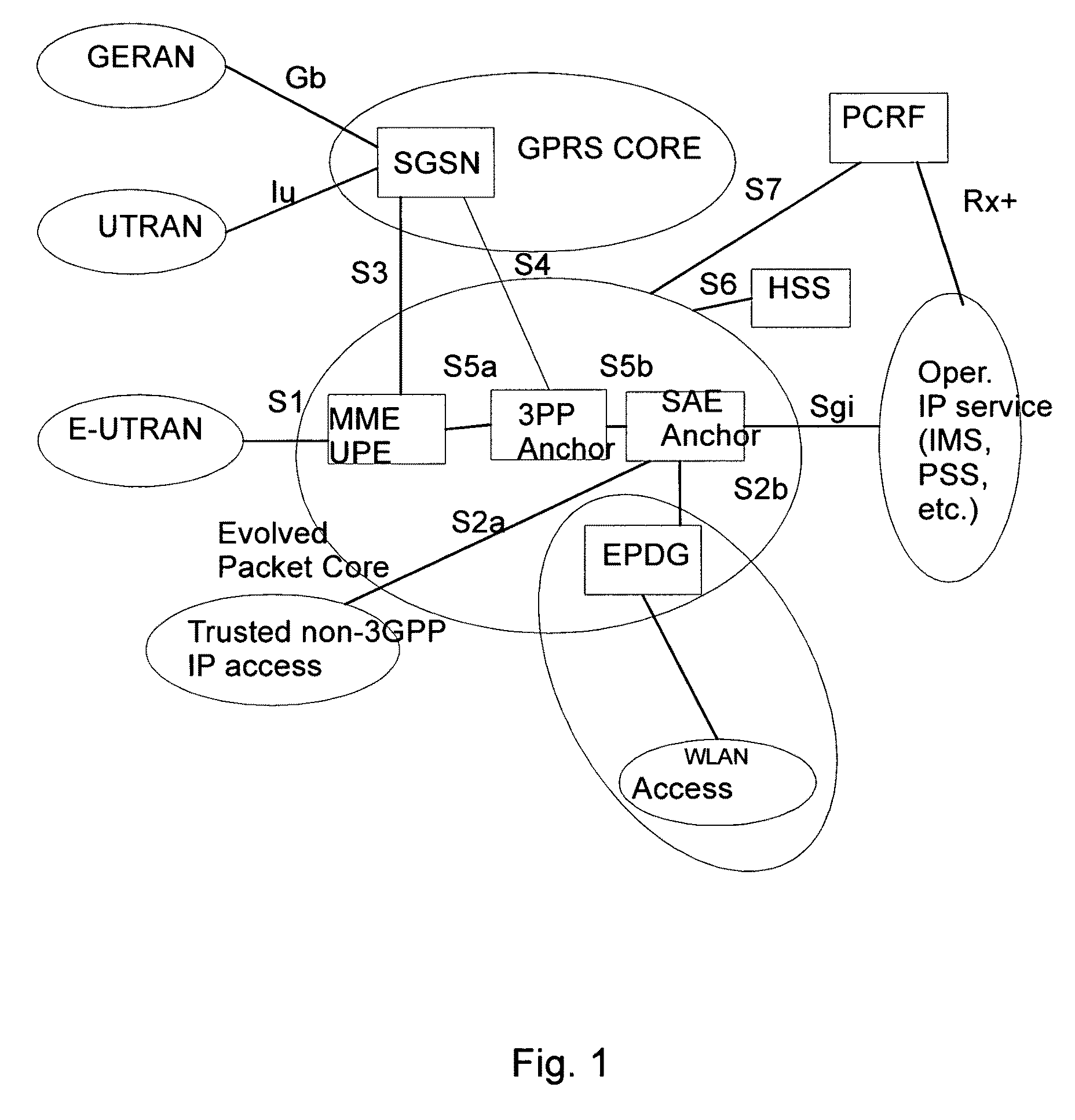

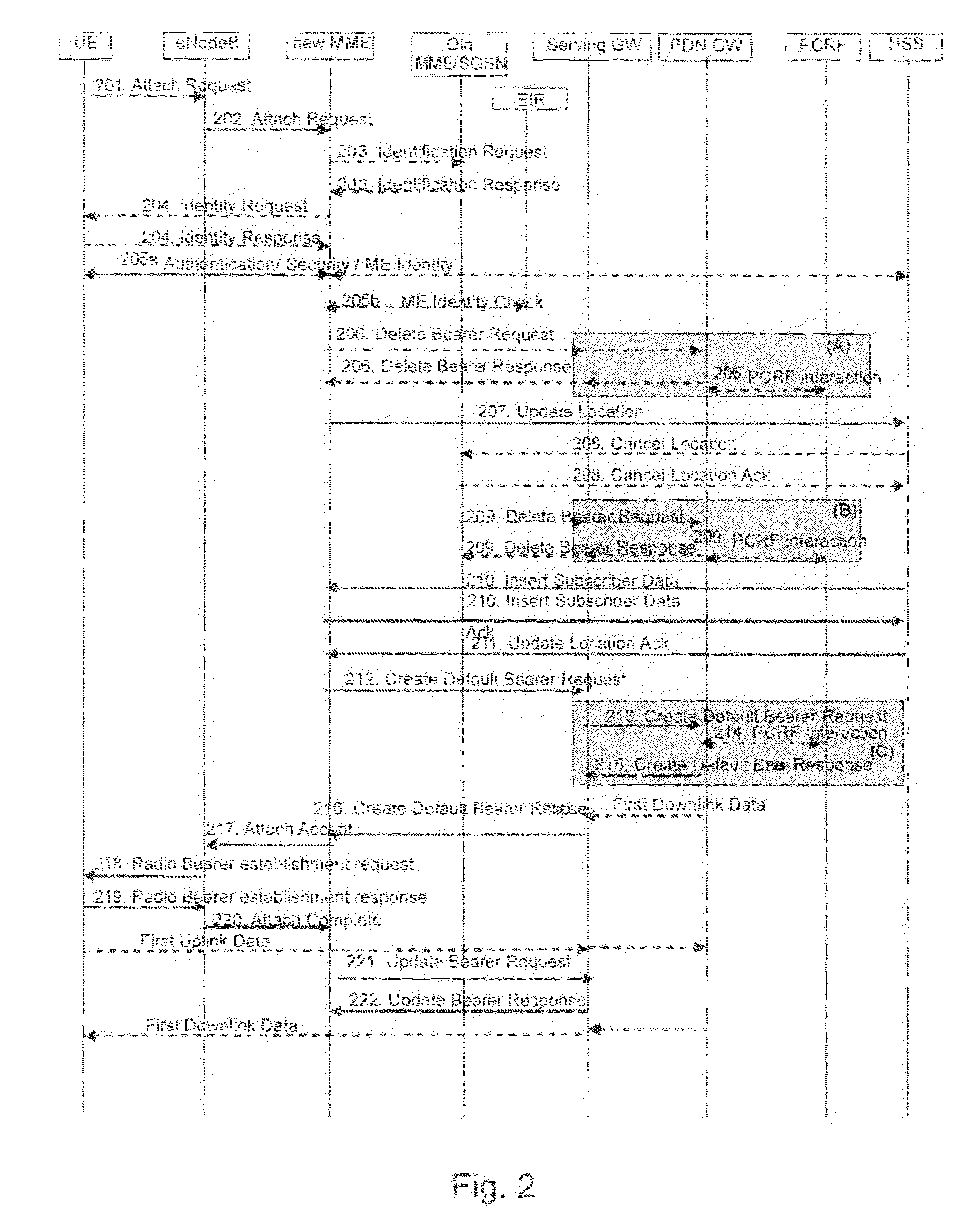

Transition between IP protocol versions

A method comprising: receiving, in a network element of a packet data core network, a network resource request from a user equipment, said request including indication on the user equipment's Internet Protocol (IP) version capability; creating, in said network element, a set of parameters for guiding the user equipment in IP address allocation at least in one packet data network, said set of parameters including at least a recommended version of IP address type to be used; and signalling said set of parameters to the user equipment as a response to the network resource request.

Owner:NOKIA TECHNOLOGLES OY

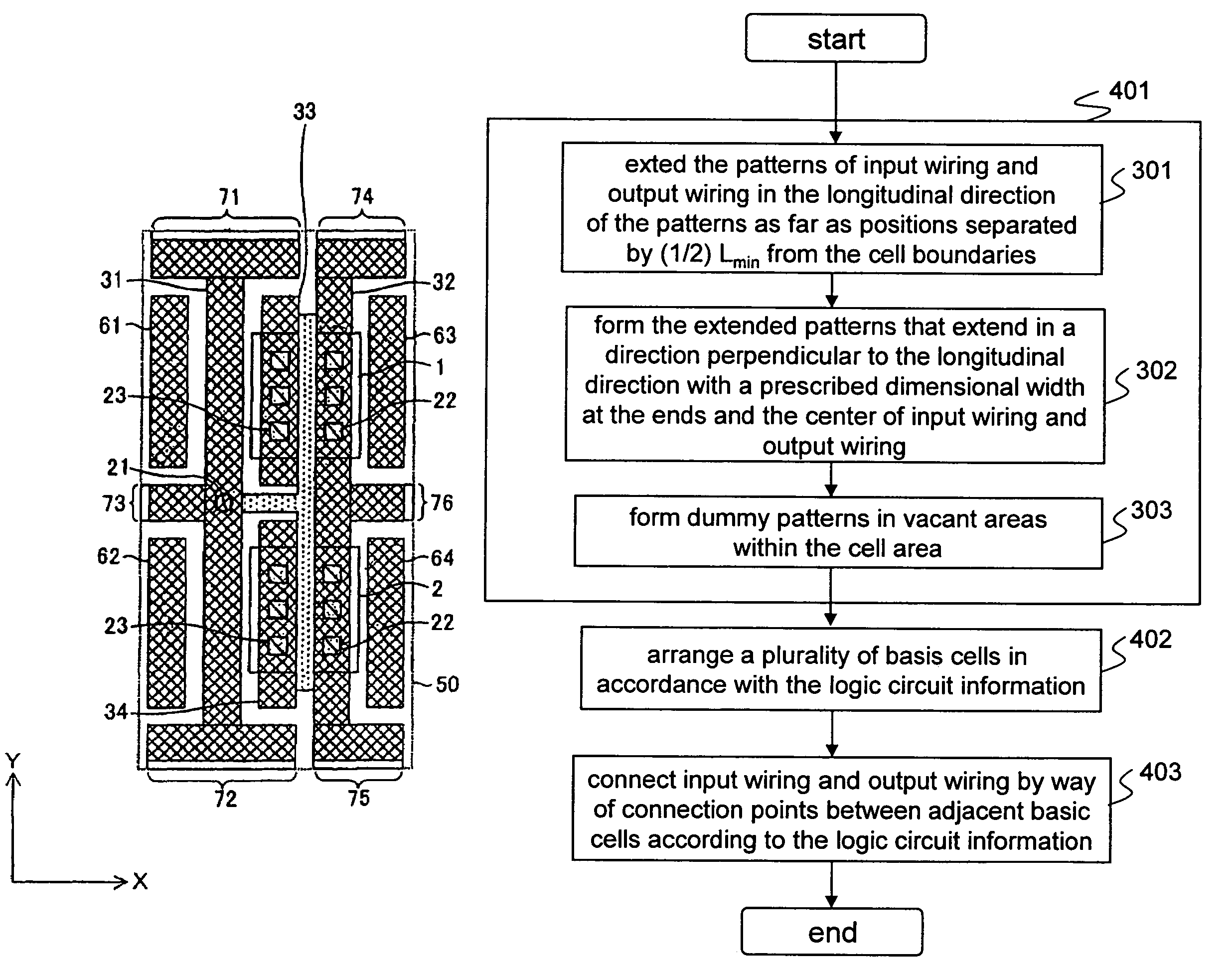

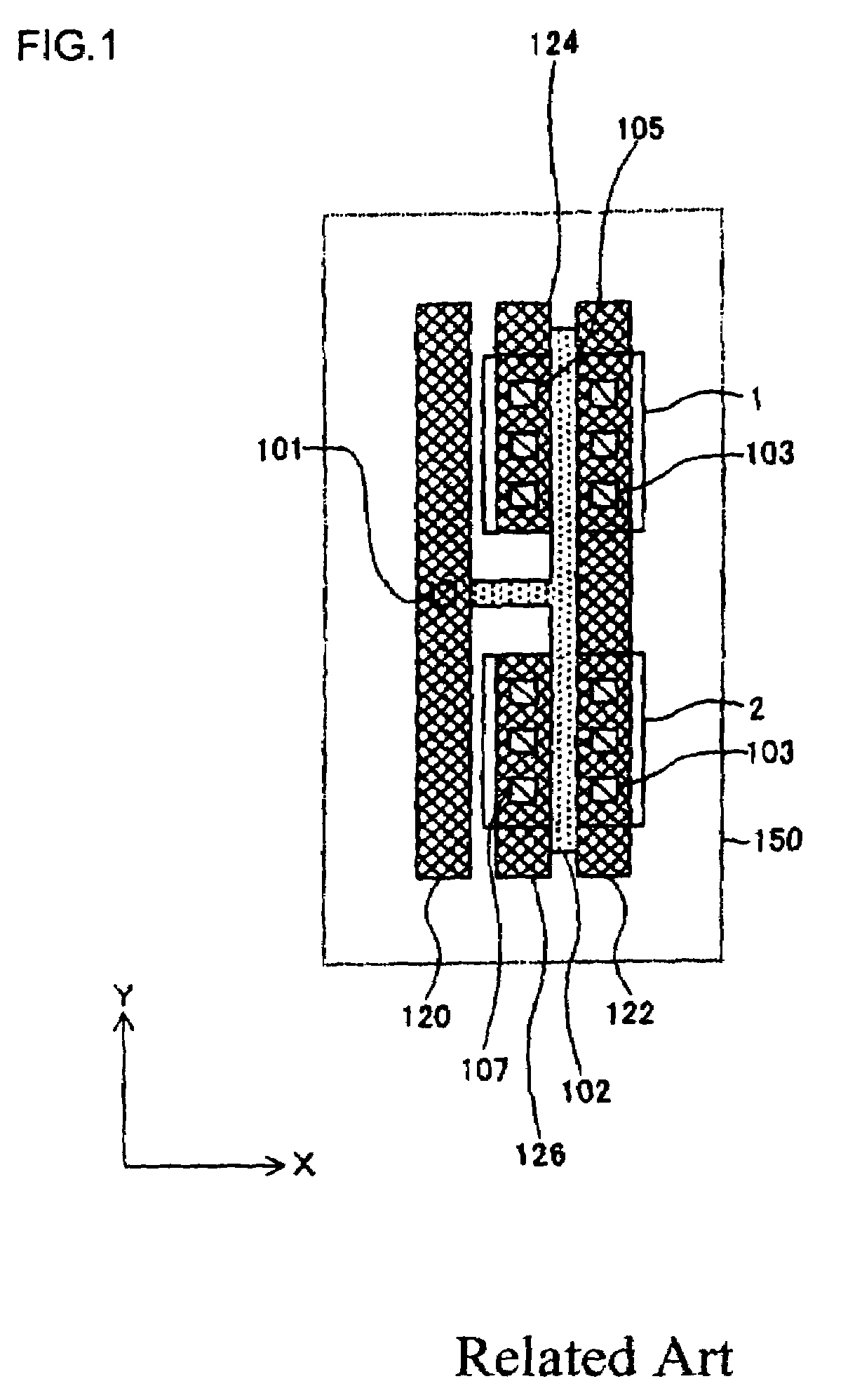

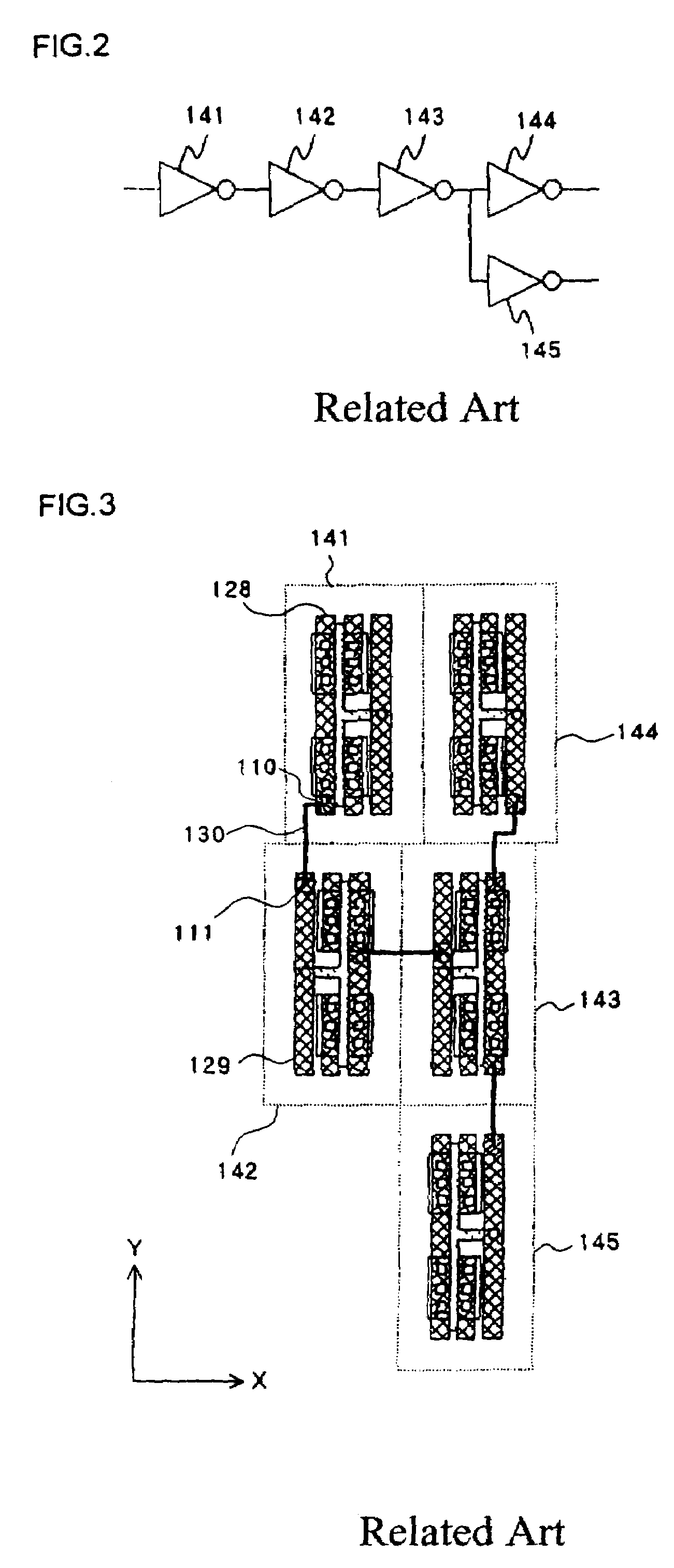

Basic cell design method for reducing the resistance of connection wiring between logic gates

ActiveUS7647574B2Reduce resistanceIncrease freedomCAD circuit designSpecial data processing applicationsElectrical resistance and conductanceElectrical battery

The basic cell design method of the present invention is a method for carrying out: extended pattern formation for extending the patterns of input wiring and output wiring in the longitudinal direction, forming first extended patterns that extend with a prescribed dimensional width in a direction perpendicular to the longitudinal direction at the ends of the extended patterns, and forming second extended patterns that extend with the prescribed dimensional width from the input wiring and the output wiring at the center of the cell in the longitudinal direction; and dummy pattern formation for subsequently arranging dummy patterns in vacant areas within the cell.

Owner:MICRON TECH INC

Catheter assembly with a folded urine collection bag

There is disclosed a catheter assembly comprising a catheter and a receptacle. The receptacle has an elongate pocket, for accommodating at least an insertable end of said catheter, a urine collection bag, having a width extension wider than a greatest width of said elongate pocket, and at least two tab areas on at least one tab are arranged at the periphery of the urine collection bag on opposite sides of said bag. Further, in a storage state, said elongate pocket is folded over said urine collection bag, and lateral parts of said urine collection bag extending outside said elongate pocket are folded towards each other over said elongate pocket, said lateral parts being dimensioned to overlap each other in the folded disposition, and wherein said tab areas are arranged on said lateral parts and are attached to each other, in at least one point of attachment, to releasably maintain said catheter assembly in a folded disposition during storage.

Owner:ASTRA TECH SE

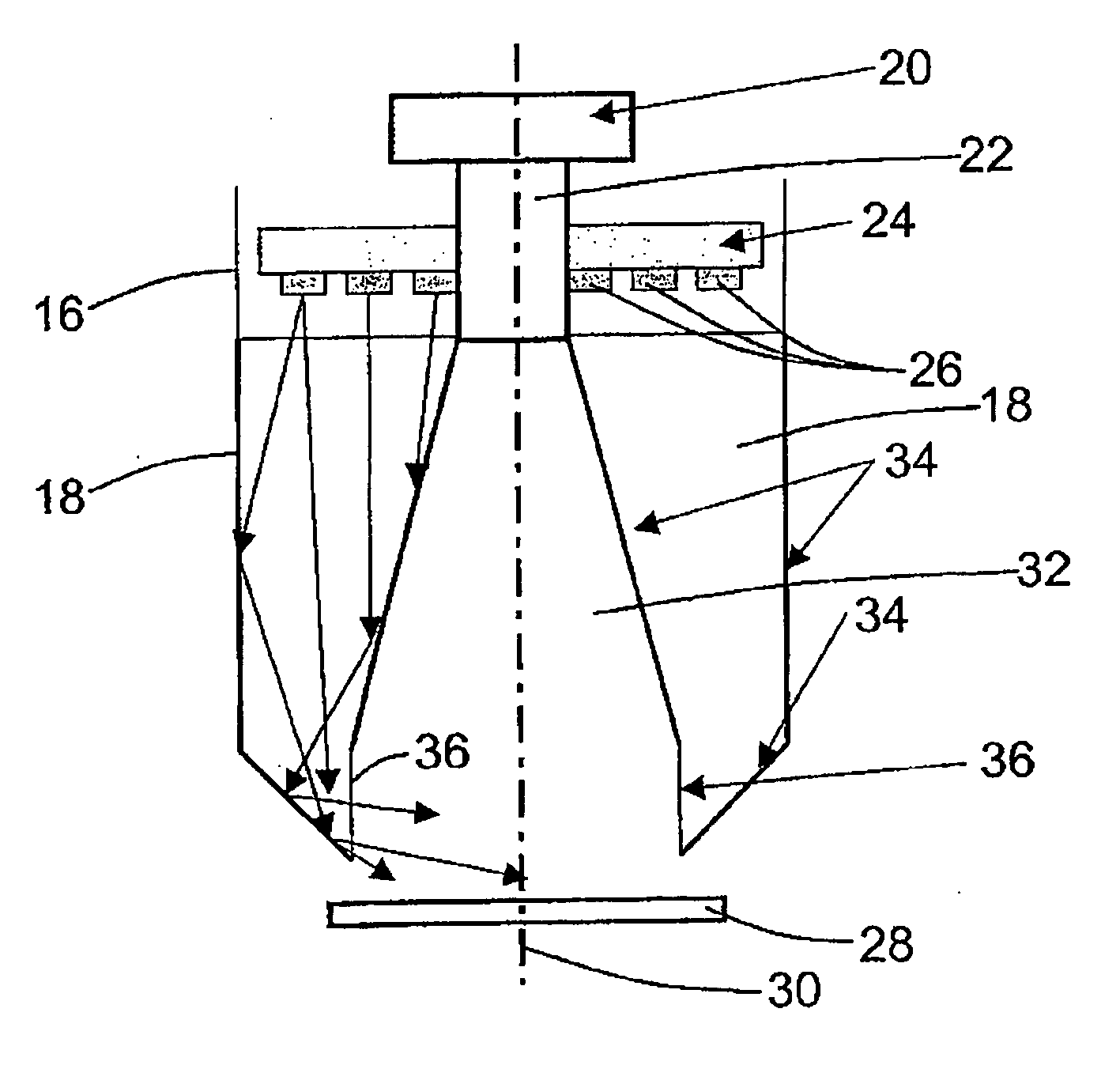

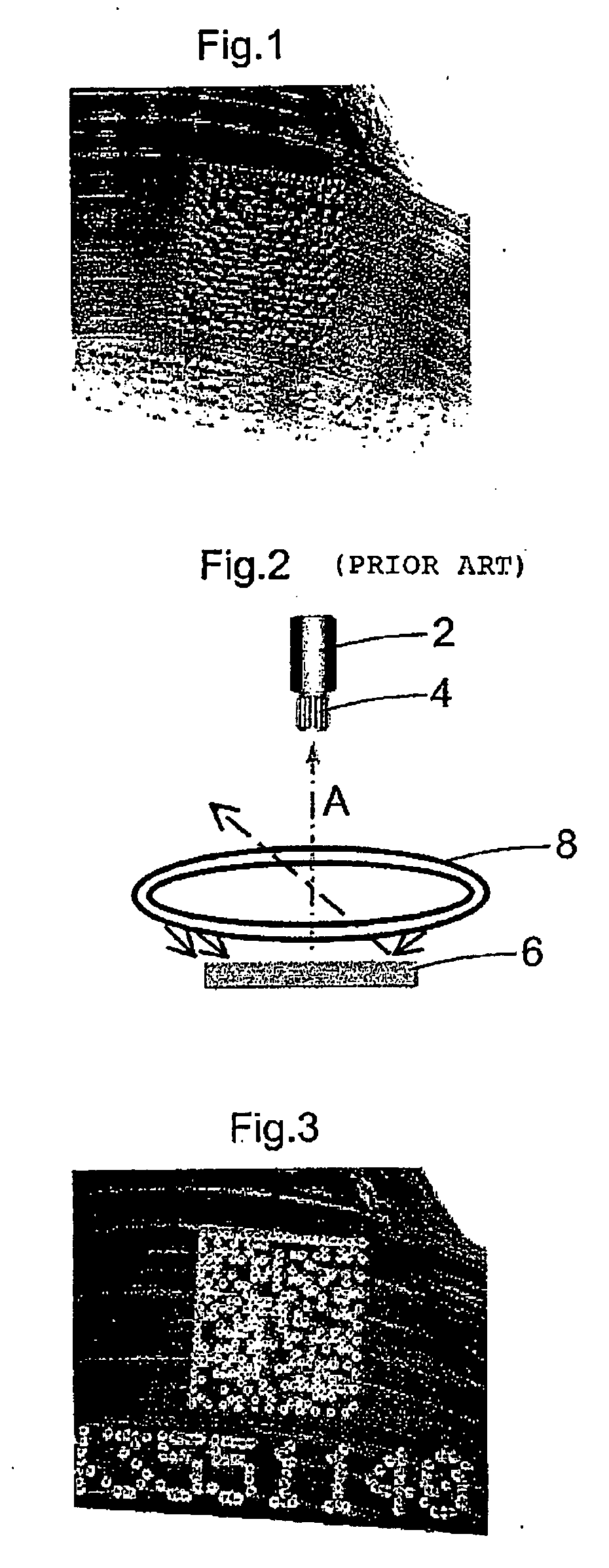

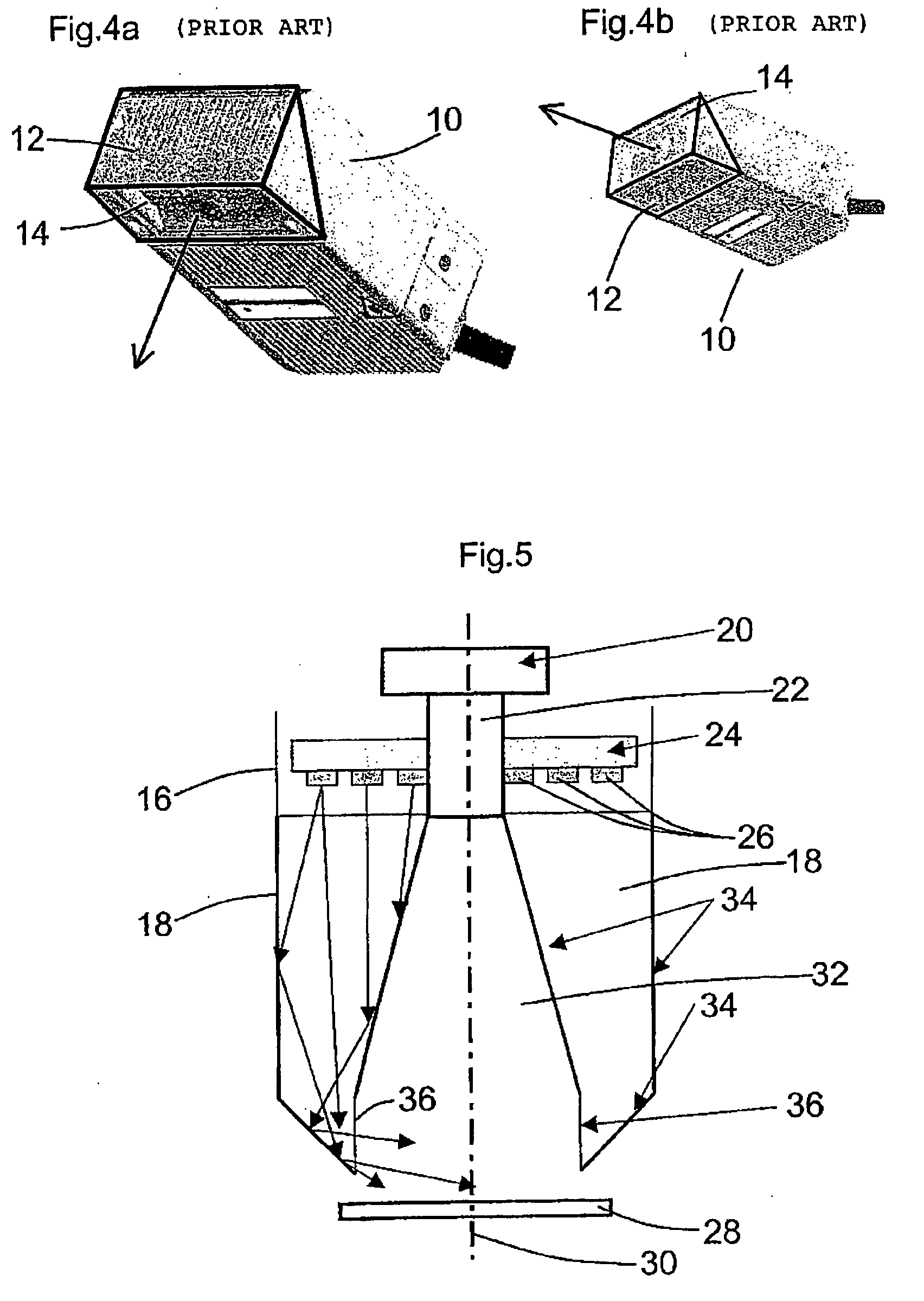

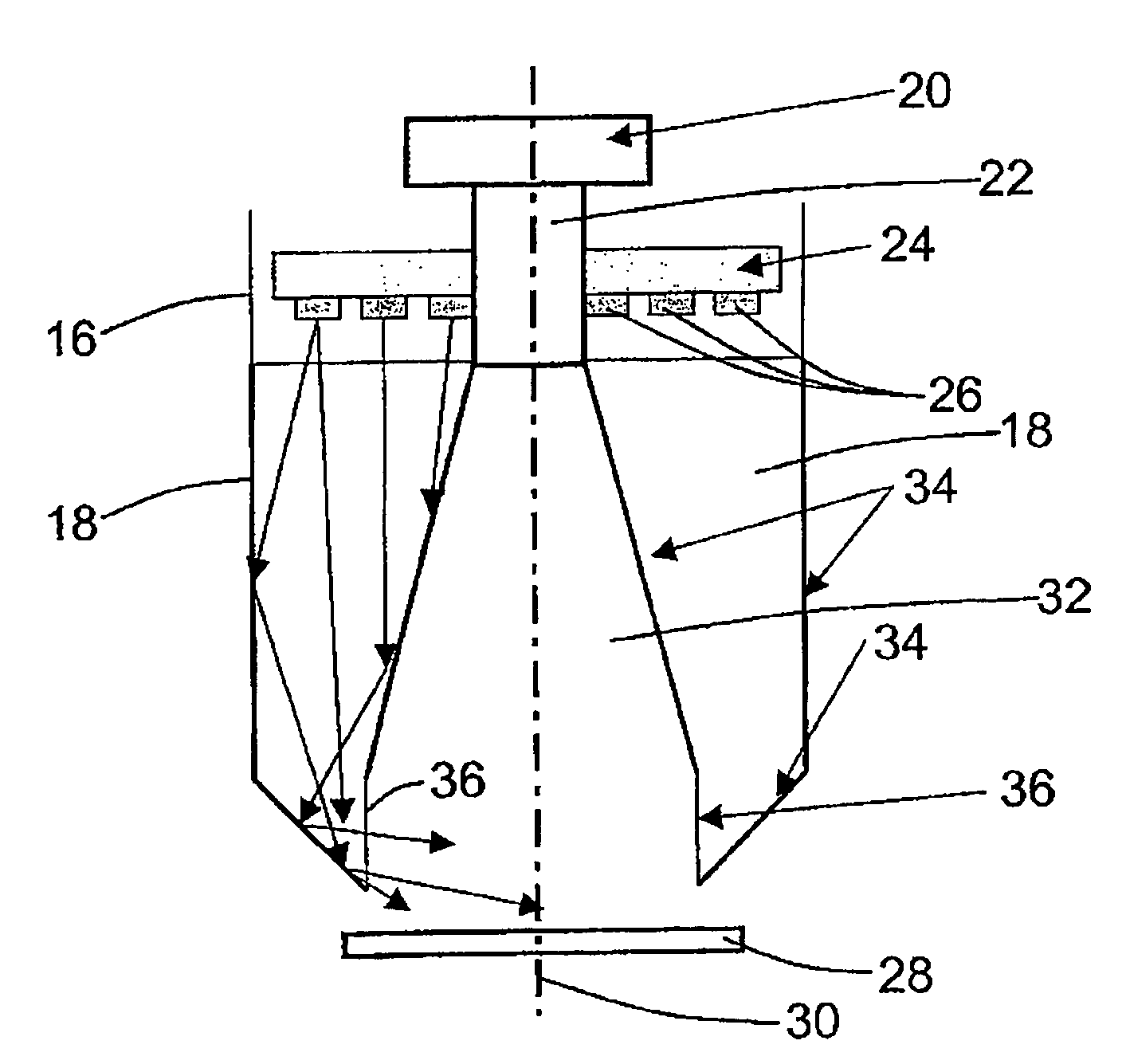

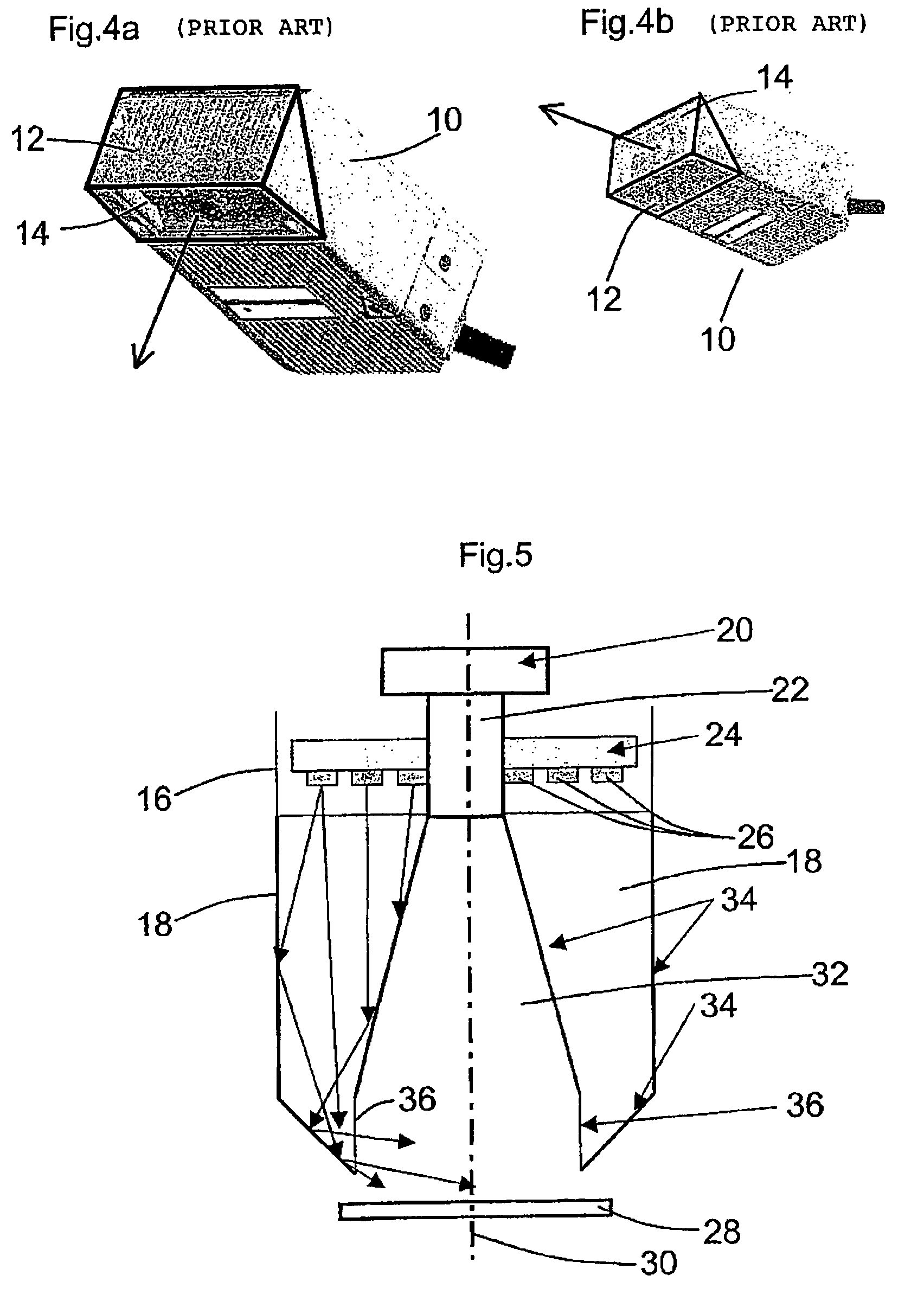

Code reader

ActiveUS20060175409A1Improve reliabilityReduces total economic effortCharacter and pattern recognitionSensing by electromagnetic radiationOptoelectronicsDepth of field

A code reader comprising an integrated light source for the illumination of a reading region, a sensor matrix and an optical receiving system positioned in front of the latter, wherein the light emergence surface of the light source is located in or closely in front of the depth of field zone of the optical receiving system.

Owner:SICK AG

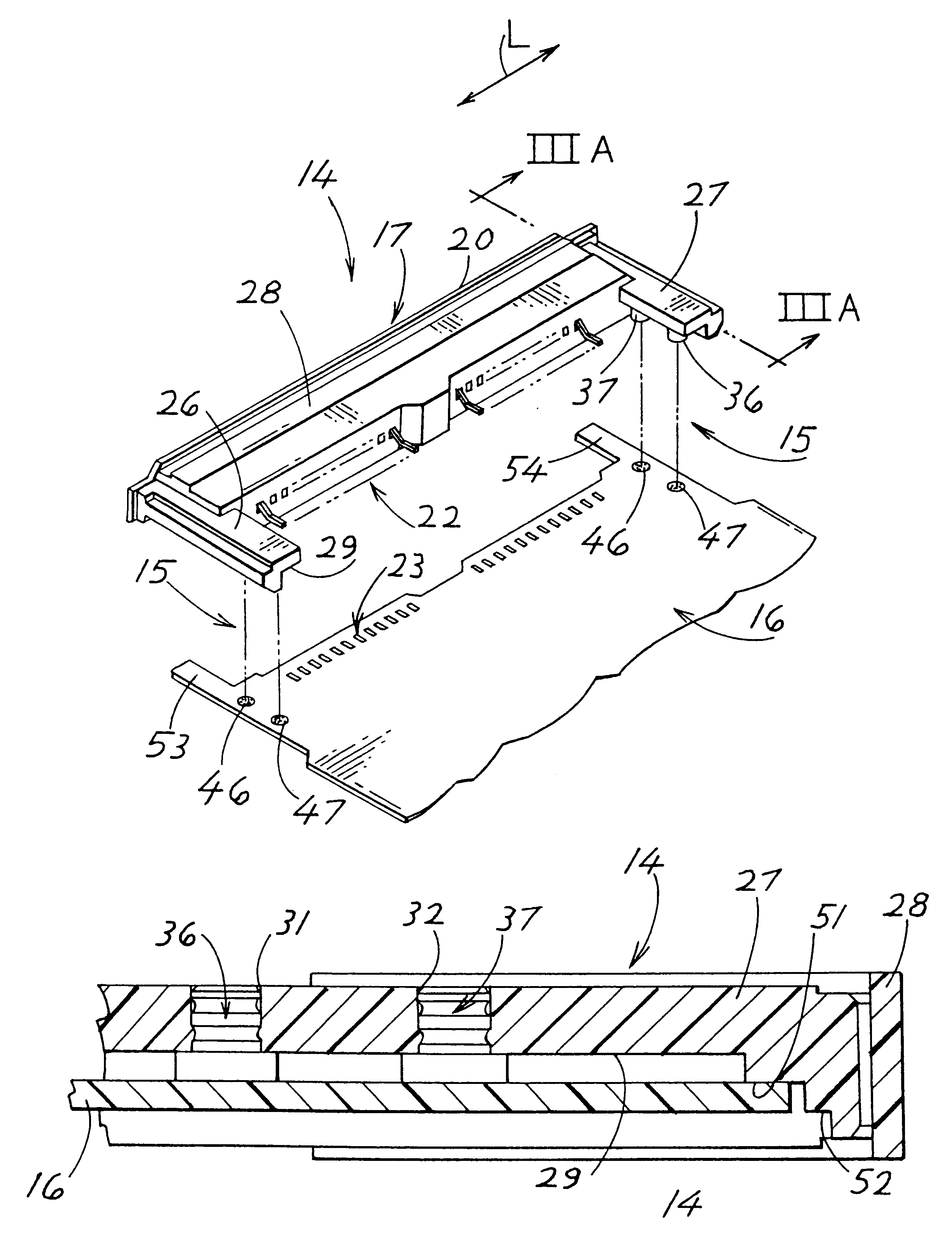

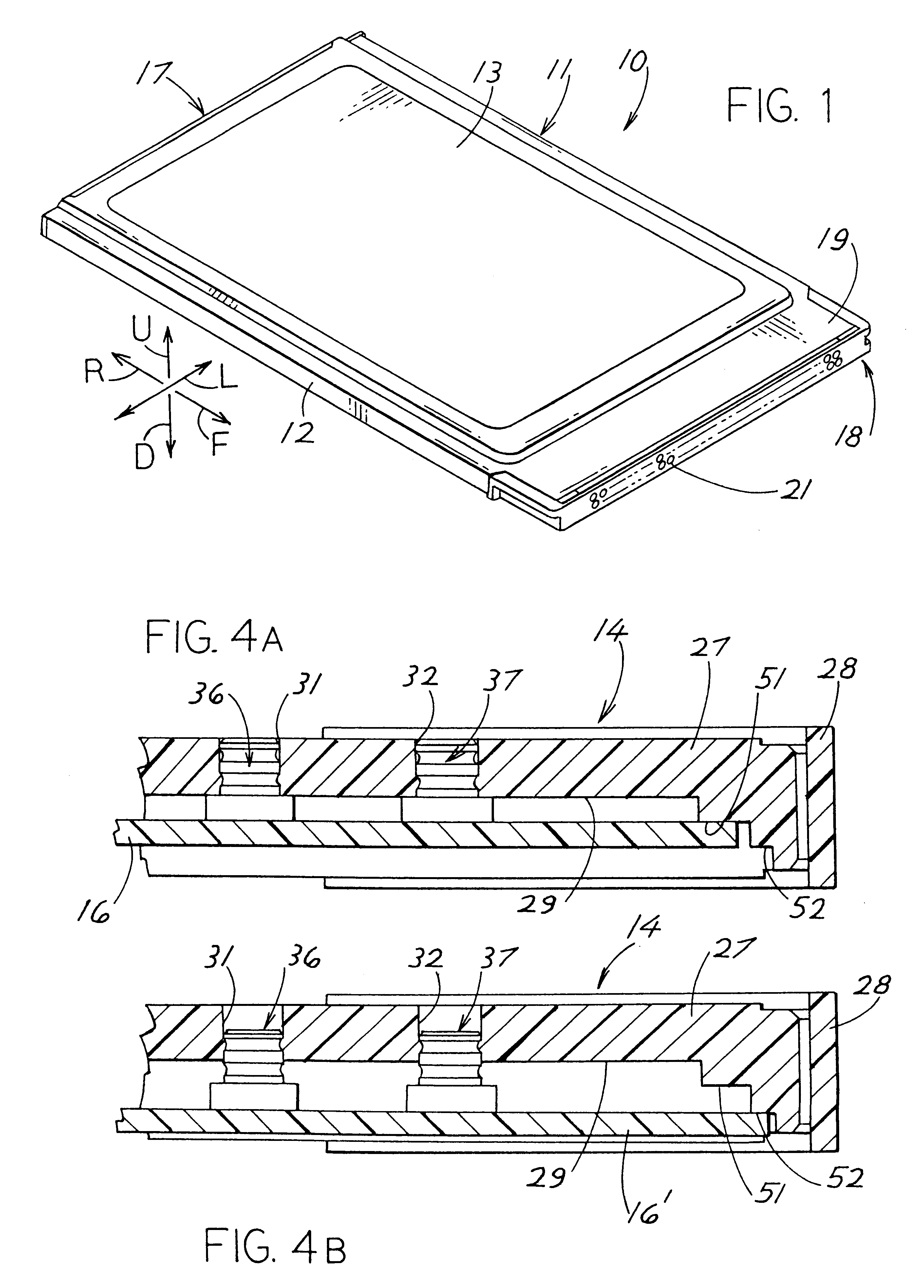

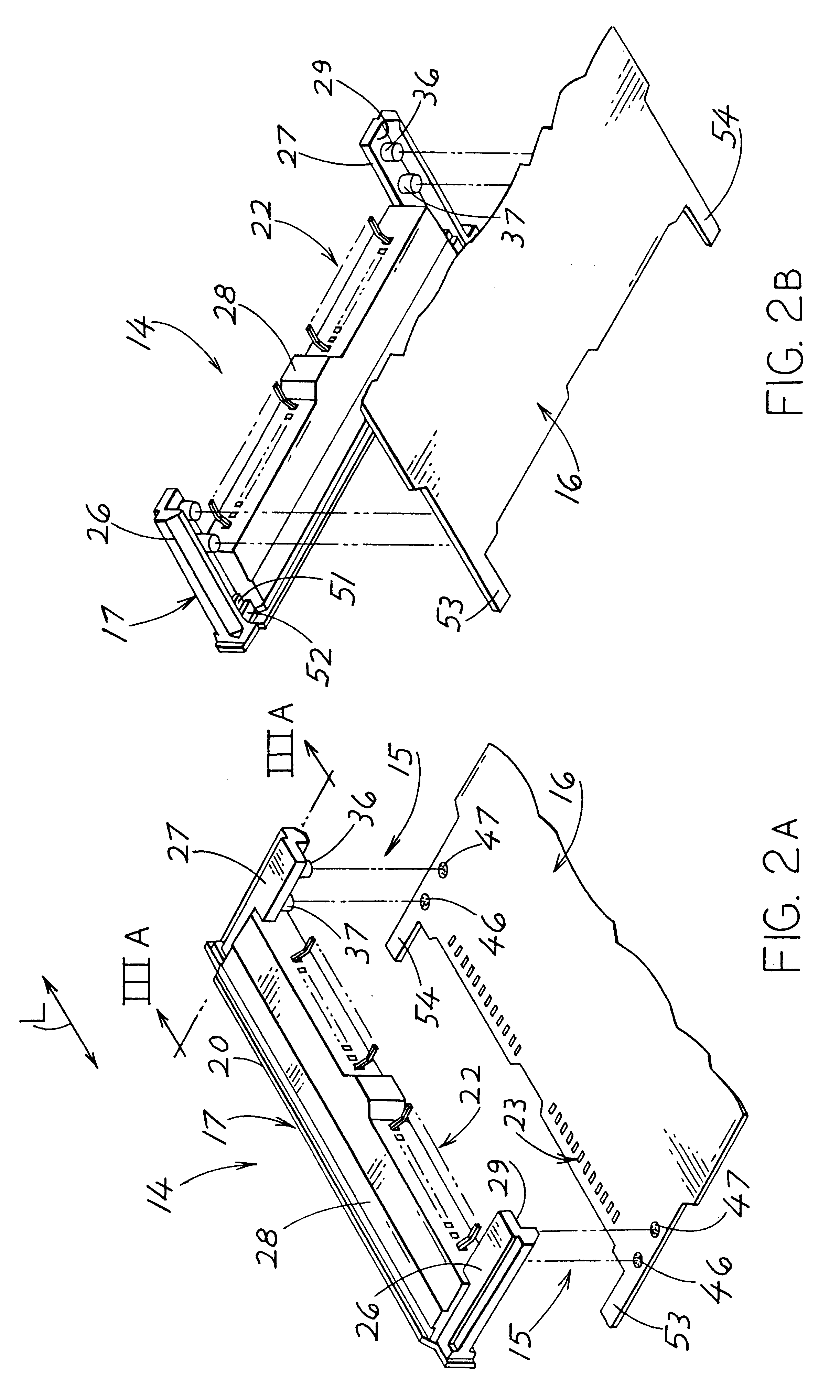

Connection assembly of printed-circuit board and connector and an electronic-equipment plug-in card provided with same

InactiveUS6307753B1Easy to produceAssembly precisionPrinted circuit assemblingIncadescent body mountings/supportSolderingPrinted circuit board

In a connection assembly (15) of printed-circuit board and connector, a printed-circuit board (16) and a connector (17) can be fixed positionally accurately in relation to one another by means of position holders (36, 37) provided on the connector (17). The position holders are constituted of soldering pins (36, 37) and the printed-circuit board (16) is provided with soldering pads (46, 47) which can be connected to the opposing soldering pins (36, 37) by soldering. There is provided in this manner a connection assembly (15) of printed-circuit board and connector in which the positionally accurate fixing of a printed-circuit board (16) and a connector (17) is more easily produced and more precisely assembled than has been possible to date.

Owner:ITT CANNON

Code reader

ActiveUS7510120B2Improve reliabilityReduces total economic effortSensing by electromagnetic radiationOptoelectronicsDepth of field

A code reader comprising an integrated light source for the illumination of a reading region, a sensor matrix and an optical receiving system positioned in front of the latter, wherein the light emergence surface of the light source is located in or closely in front of the depth of field zone of the optical receiving system.

Owner:SICK AG

Clamping apparatus with a clamping chuck and a work piece carrier releasably connectable thereto

Owner:EROWA

Stator Blade for a Turbomachine which is Exposable to Axial Throughflow, and also Stator Blade Arrangement for It

InactiveUS20110052397A1Easy to insertHinders provisionPropellersRotary propellersEngineeringMechanical engineering

A stator blade and a stator blade arrangement for a turbomachine which is exposable to axial throughflow is provided. Each stator blade is retained via a fixed clamping in a circumferential groove. For the fixed clamping, provision is made on one side of the blade root for a shaped piece with a threaded hole into which a tensioning screw, which is supported on the bottom of the circumferential groove, may be screwed.

Owner:SIEMENS AG

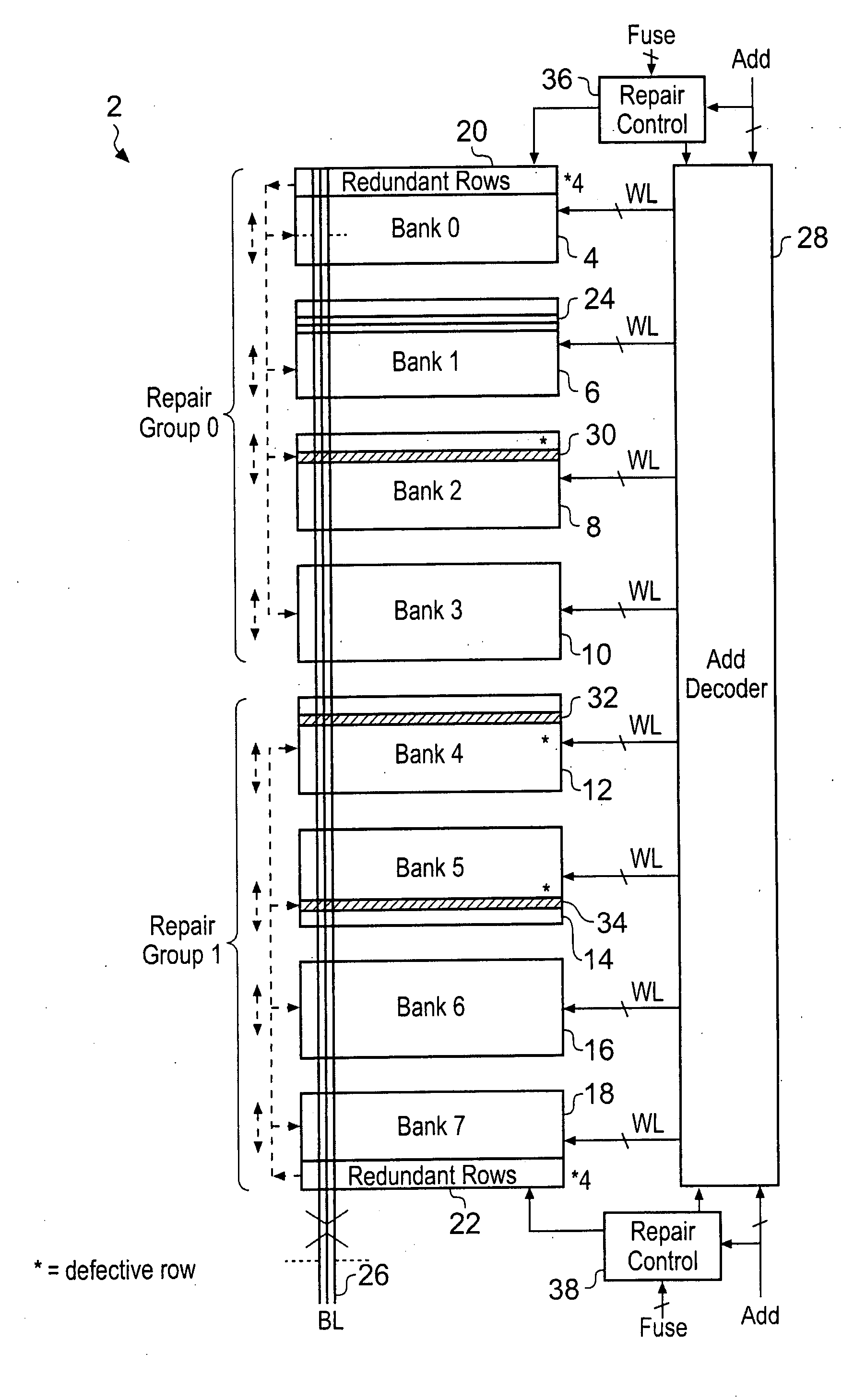

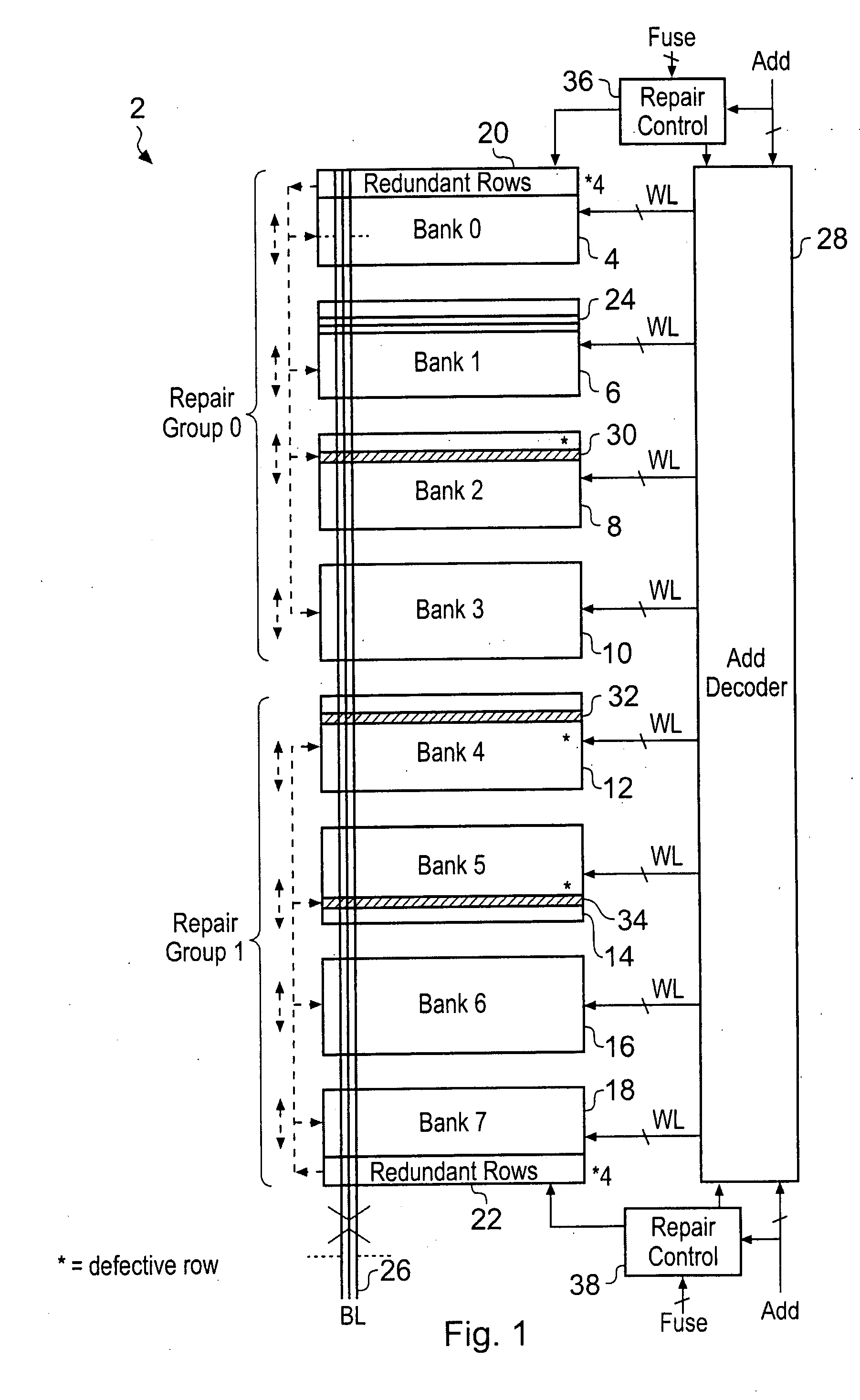

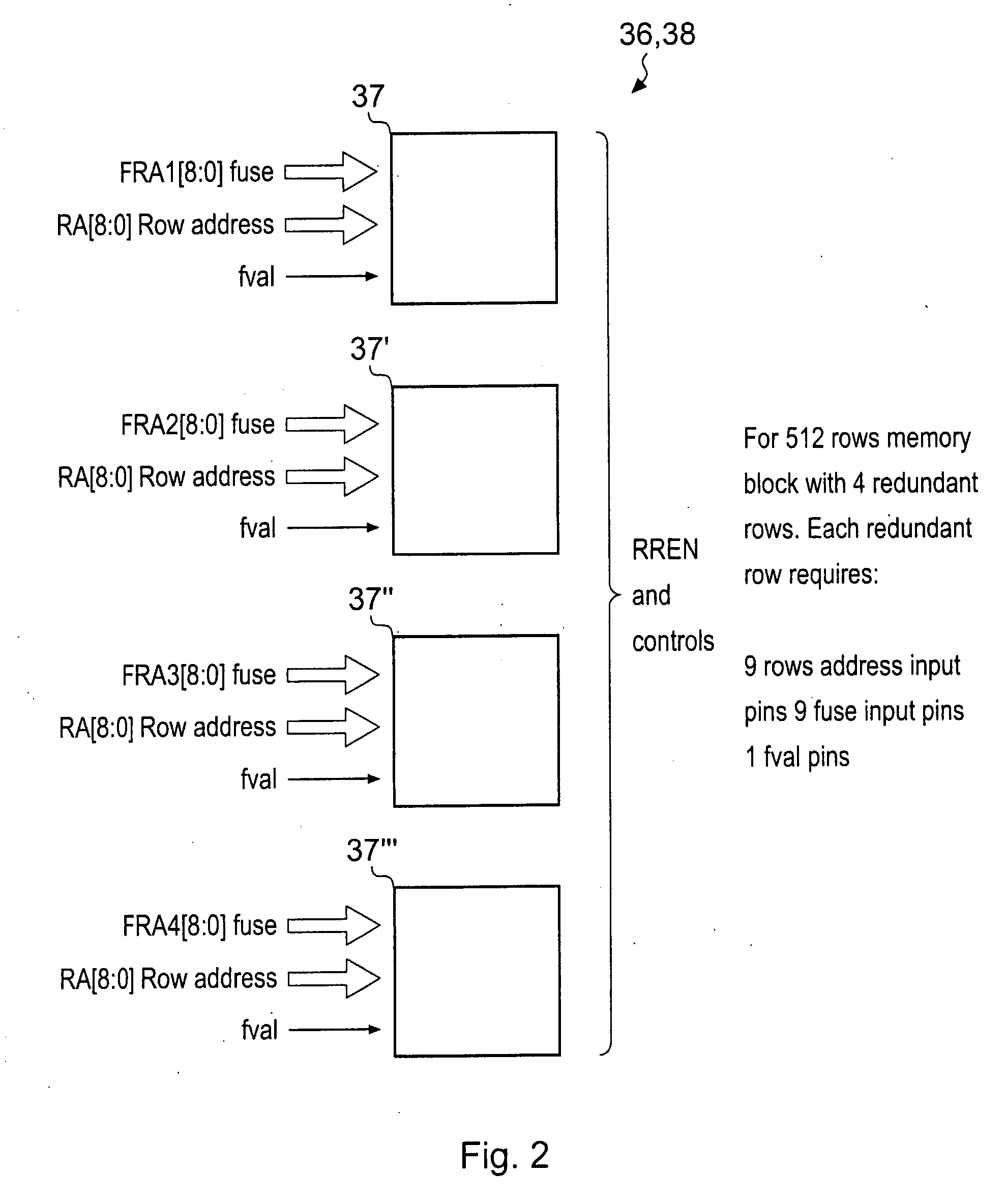

Redundancy architecture for an integrated circuit memory

ActiveUS20080259701A1Increase widthConveniently disposedRead-only memoriesDigital storageMultiplexingBit line

An integrated circuit memory 2 is described having multiple memory banks 4, 6, 8, 10, 12, 14, 16, 18 which are grouped into repair groups Group0, Group1. One of the memory banks 4, 18 is provided with redundant rows 20, 22 which can be used to substitute for a defective row 30, 32, 34 found within any of the memory banks within the common repair group concerned. Redundant columns of memory cells 60, 62 are also provided and these may be substituted for defective columns 66, 68 by multiplexing circuitry 56, 58. This multiplexing circuitry shifts the bit lines which are selected to form part of a bit group to access a given data bit by an amount less than the multiplexing width being supported by that multiplexing circuitry 56, 58 thereby reducing the number of redundant columns which need be provided.

Owner:ARM LTD

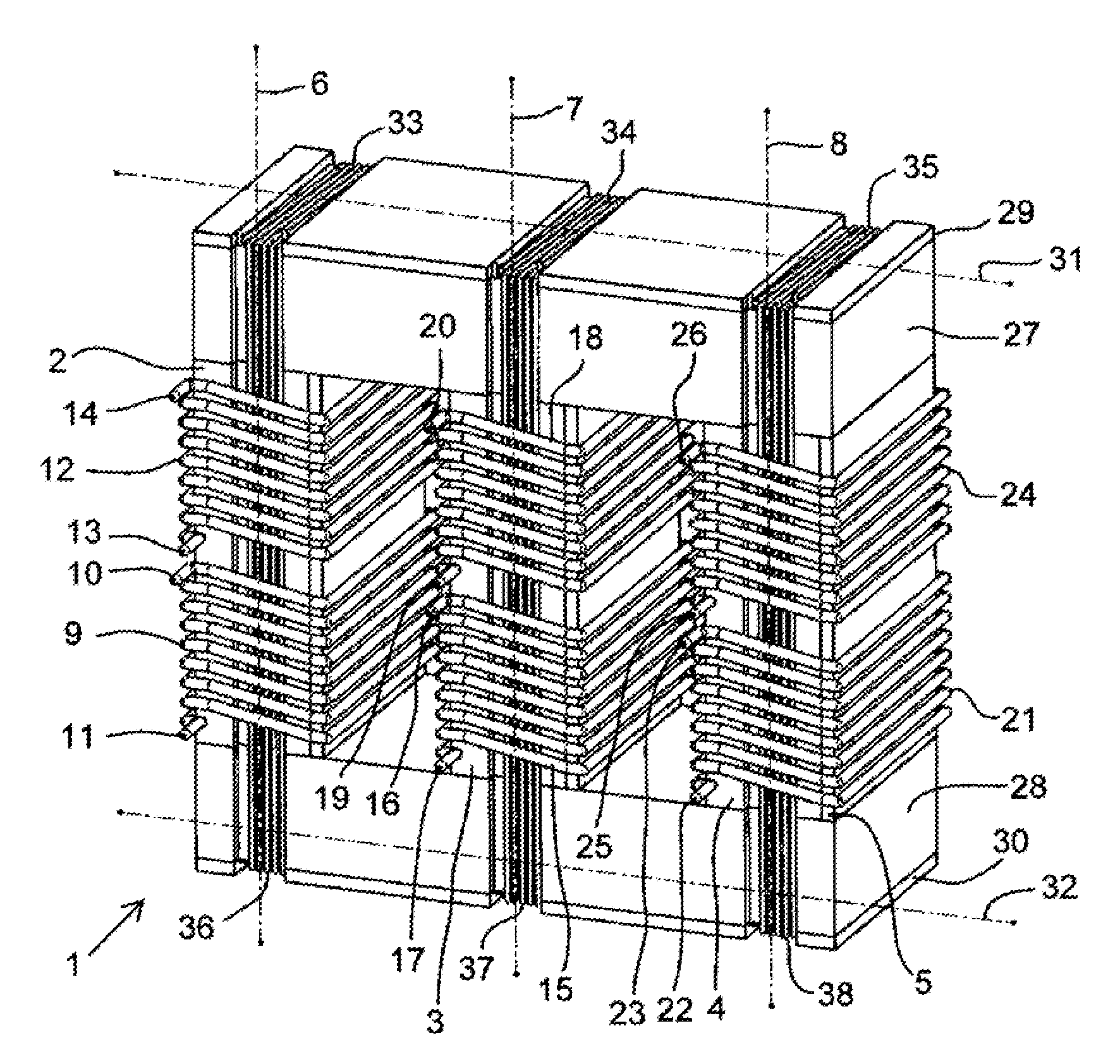

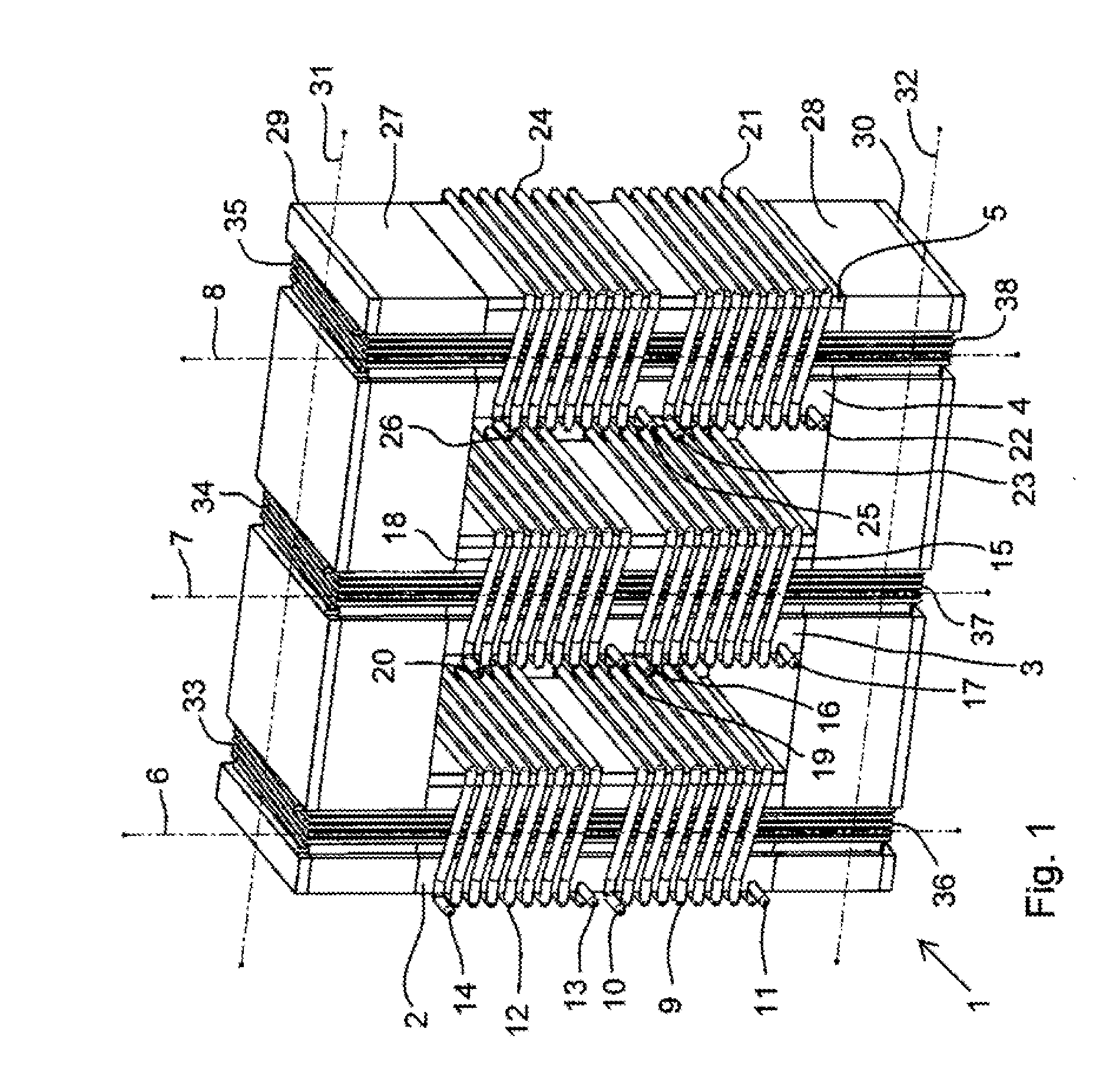

Transformer

InactiveUS20130009737A1Electrical discharge can be preventedControl outputConversion without intermediate conversion to dcVariable inductancesTransformerEngineering

A polyphase transformer (1) comprising at least a first leg (2, 51) and a second leg (3, 52) of a magnetic material is described. The transformer comprises a single core with legs (2-4, 51-53) and yokes (27, 28, 54, 55). A primary winding (9, 15, 21, 56, 60, 62) is arranged on each one of the legs (2-4, 51-53) arranged to produce primary magnetic fields in the legs (2-4, 51-53), a secondary winding (12, 18, 24, 59, 61, 63) is arranged on each one of the legs (2-4, 51-53). The winding axis of the primary winding (9, 15, 21, 56, 60, 62) and the winding axis of the secondary winding (12, 18, 24, 59, 61, 63) are essentially parallel to each other on each one of the legs (2-4, 51-53). The transformer (1) also comprises at least one control winding (33-35, 45-47, 48, 49, 73-75) arranged to produce magnetic fields in each one of the legs (2-4, 51-53) being essentially orthogonal to the primary magnetic fields in the legs (2-4, 51-53).

Owner:VETCO GRAY SCANDINAVIA

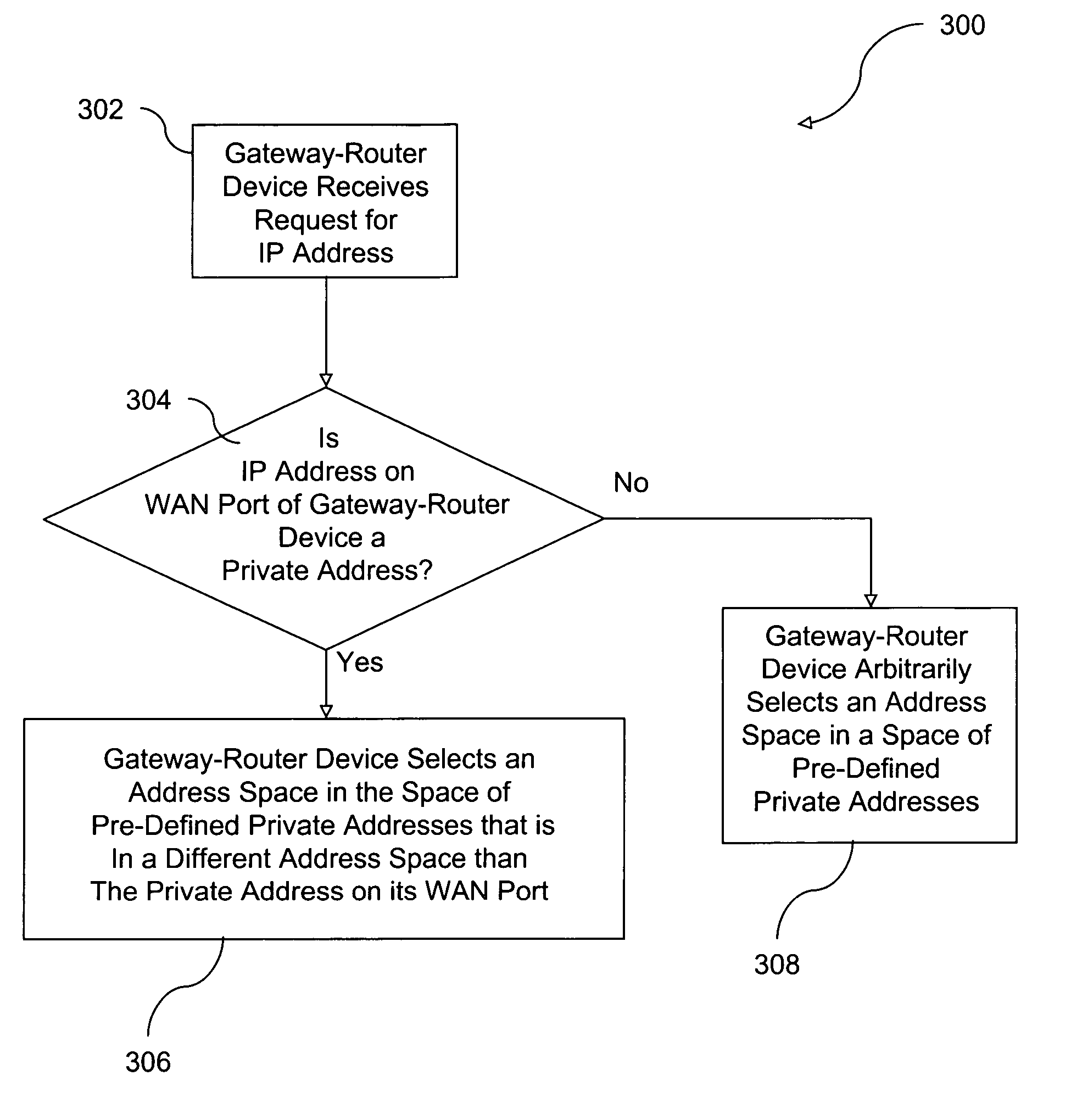

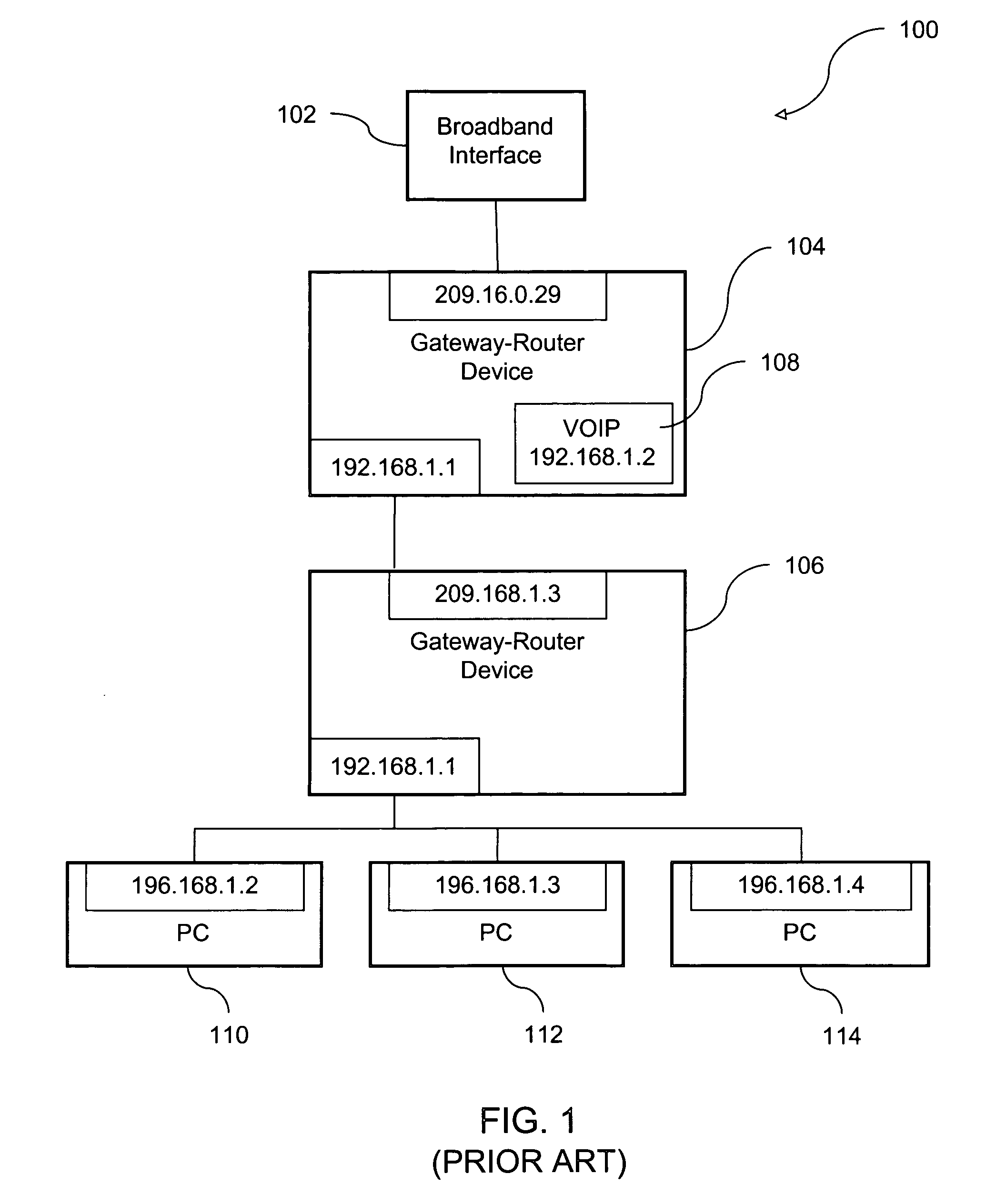

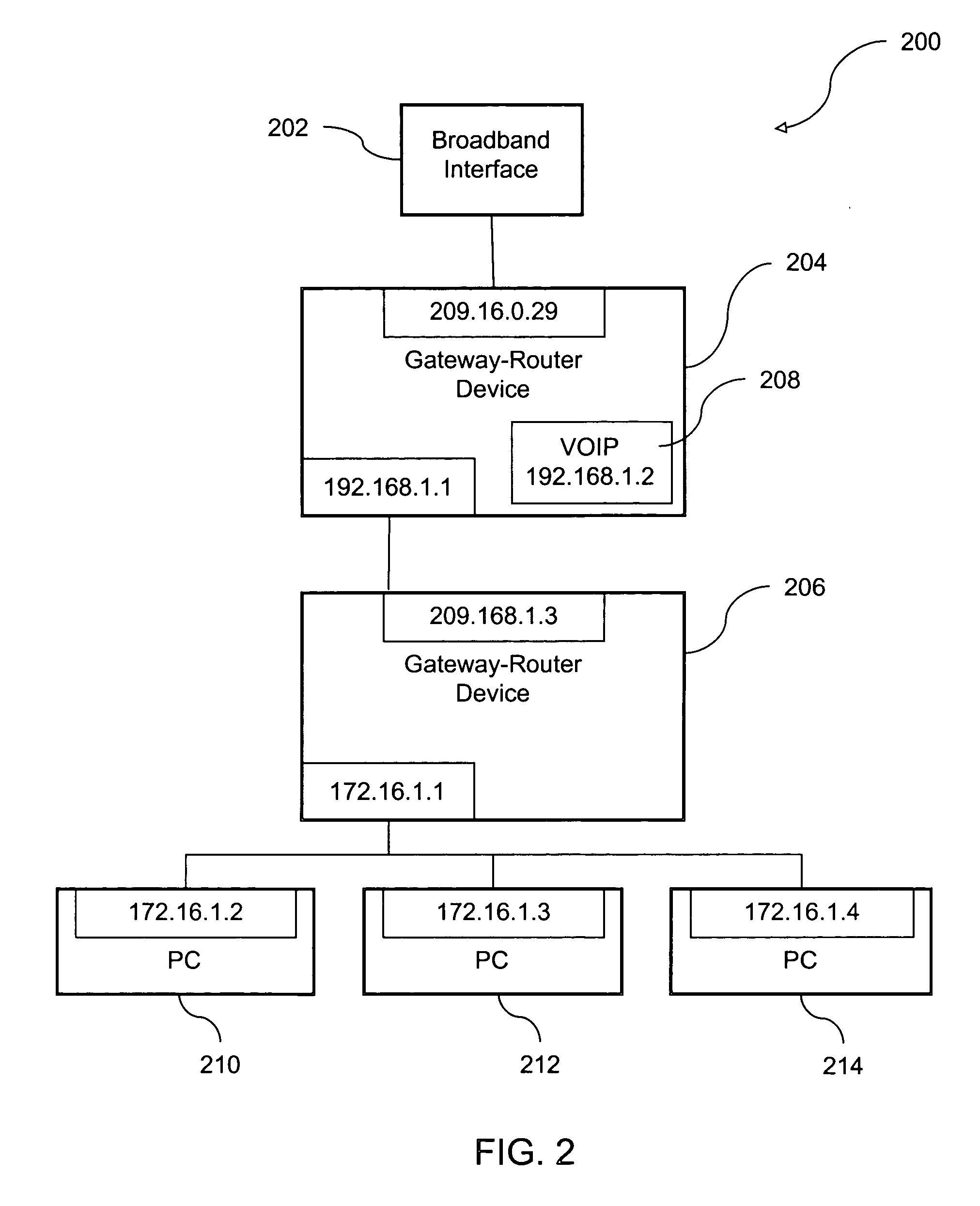

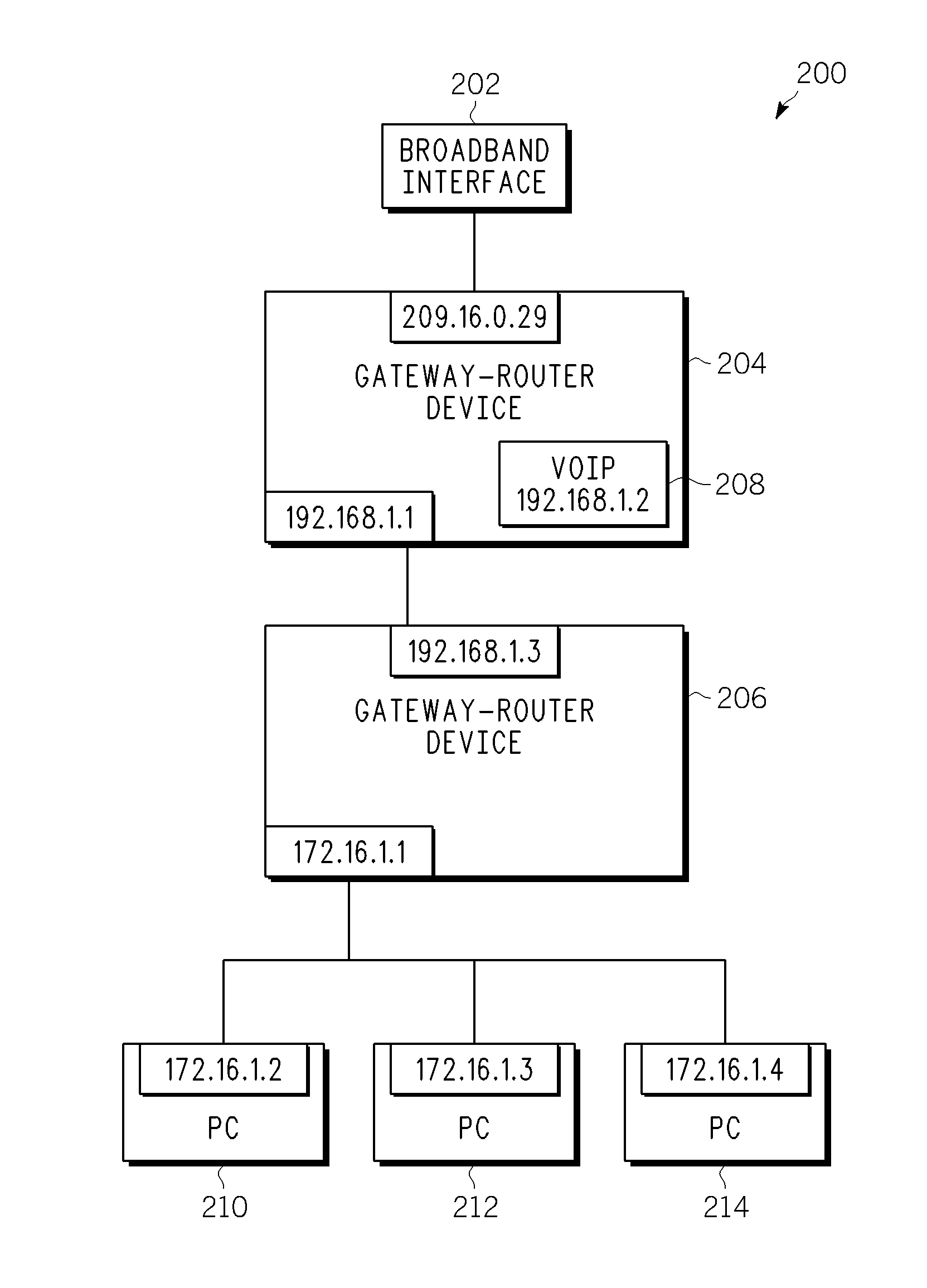

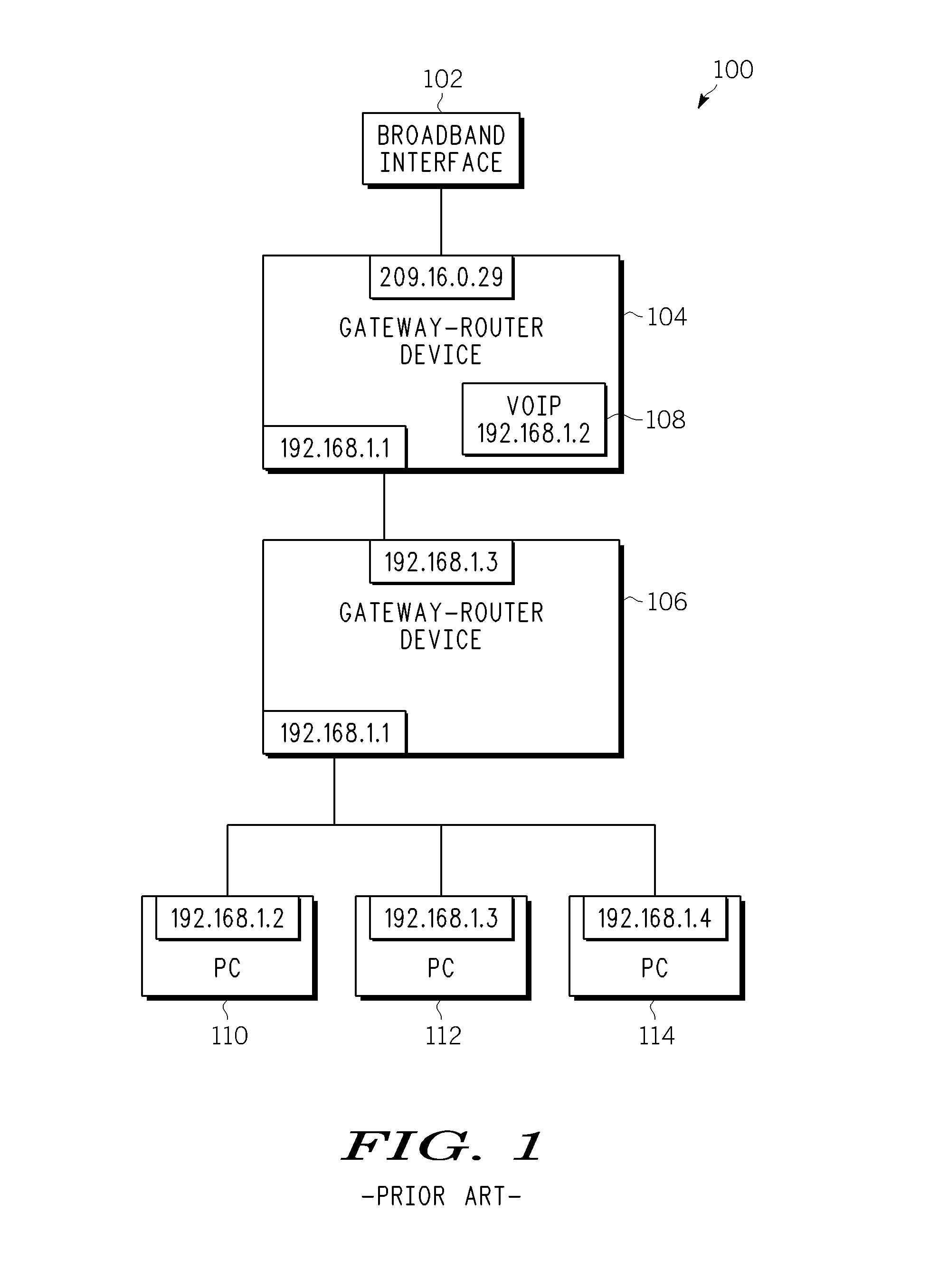

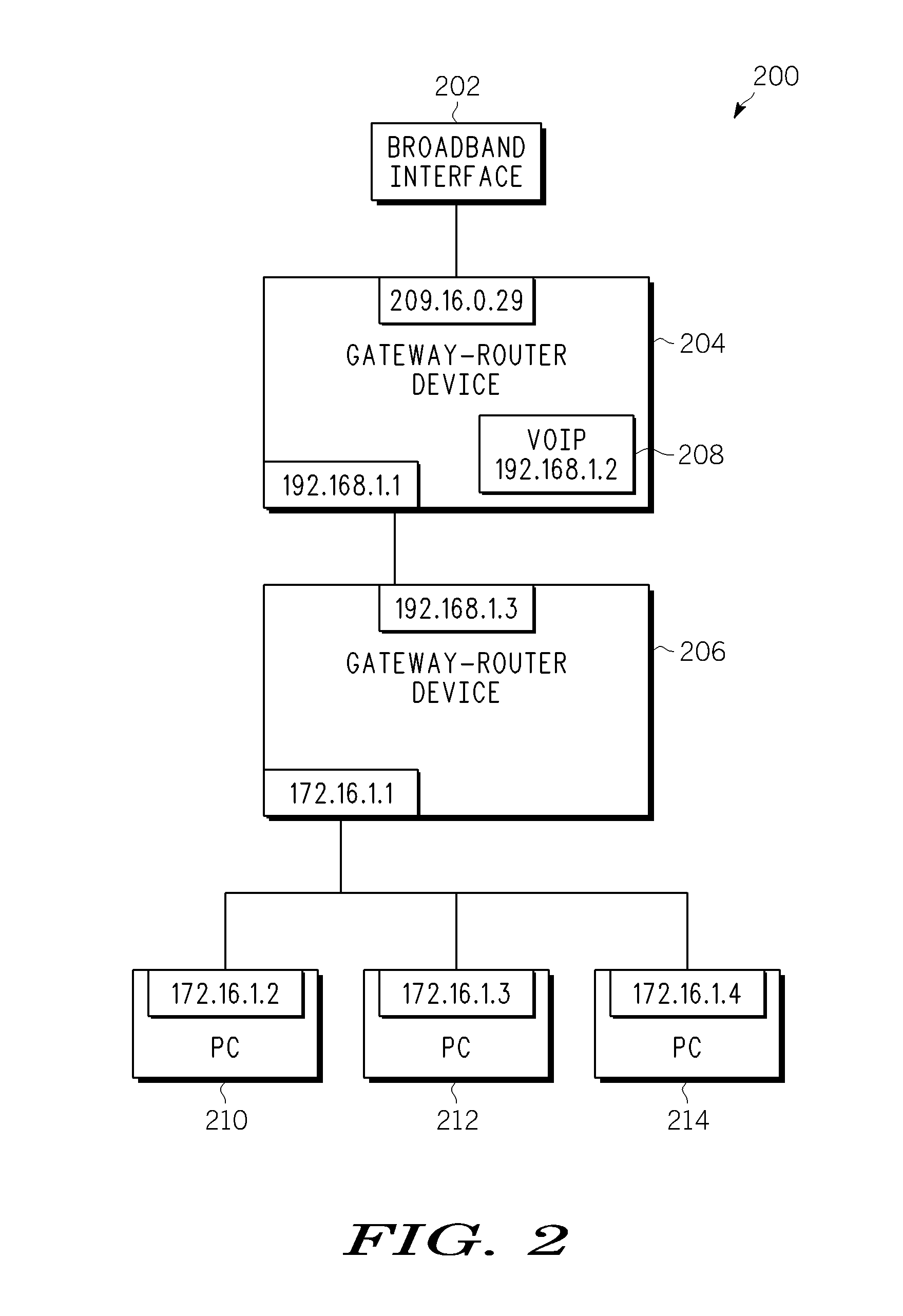

Device, system, and method for automatically determining an appropriate LAN IP address range in a multi-router network environment

InactiveUS20060114835A1Eliminate conflictAvoid network conflictError preventionFrequency-division multiplex detailsPrivate addressNetwork topology

A device, system and method which provides for automatic selection of an alternative private address space by a gateway-router device which is given a private address on its WAN port is disclosed. The present invention provides for a device, system, and method wherein, in a given network topology, if a gateway-router device is given an IP address on its WAN port that is in a private address space then such gateway-router device will automatically select an alternative private address space to use for its DHCP server that will provision addresses to devices interconnected to its LAN port. The above inventive technique eliminates any conflict in private address provisioning.

Owner:GOOGLE TECH HLDG LLC

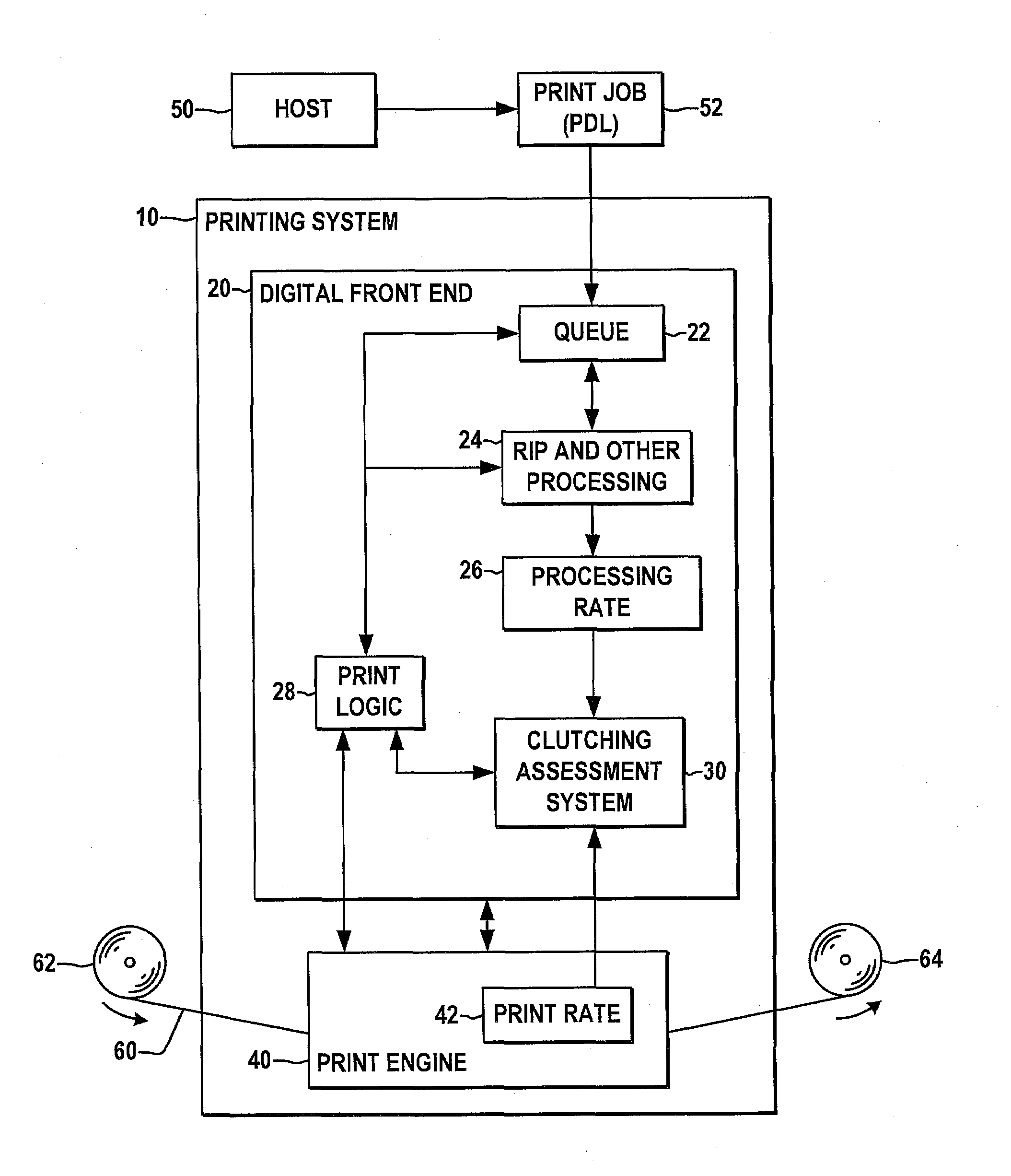

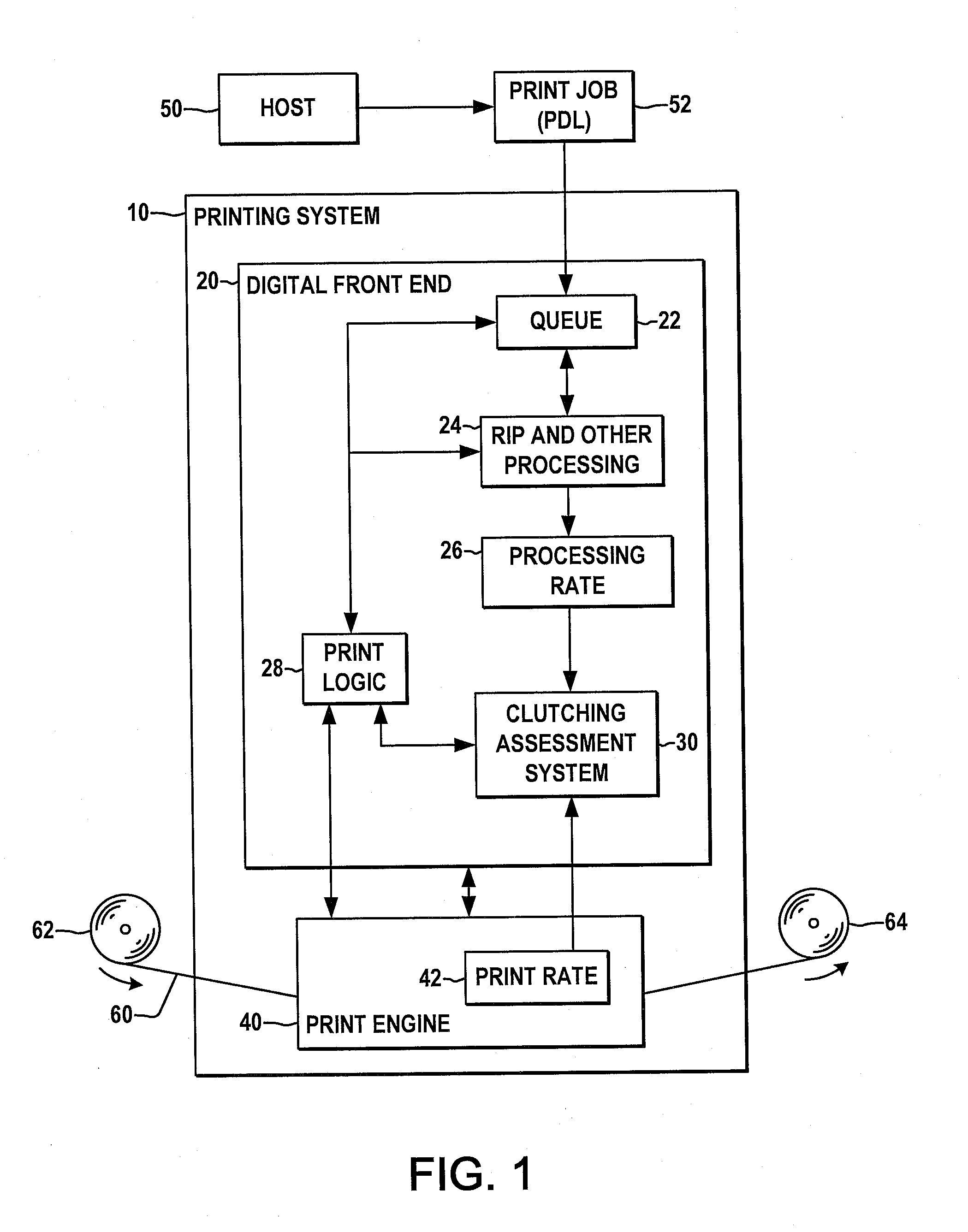

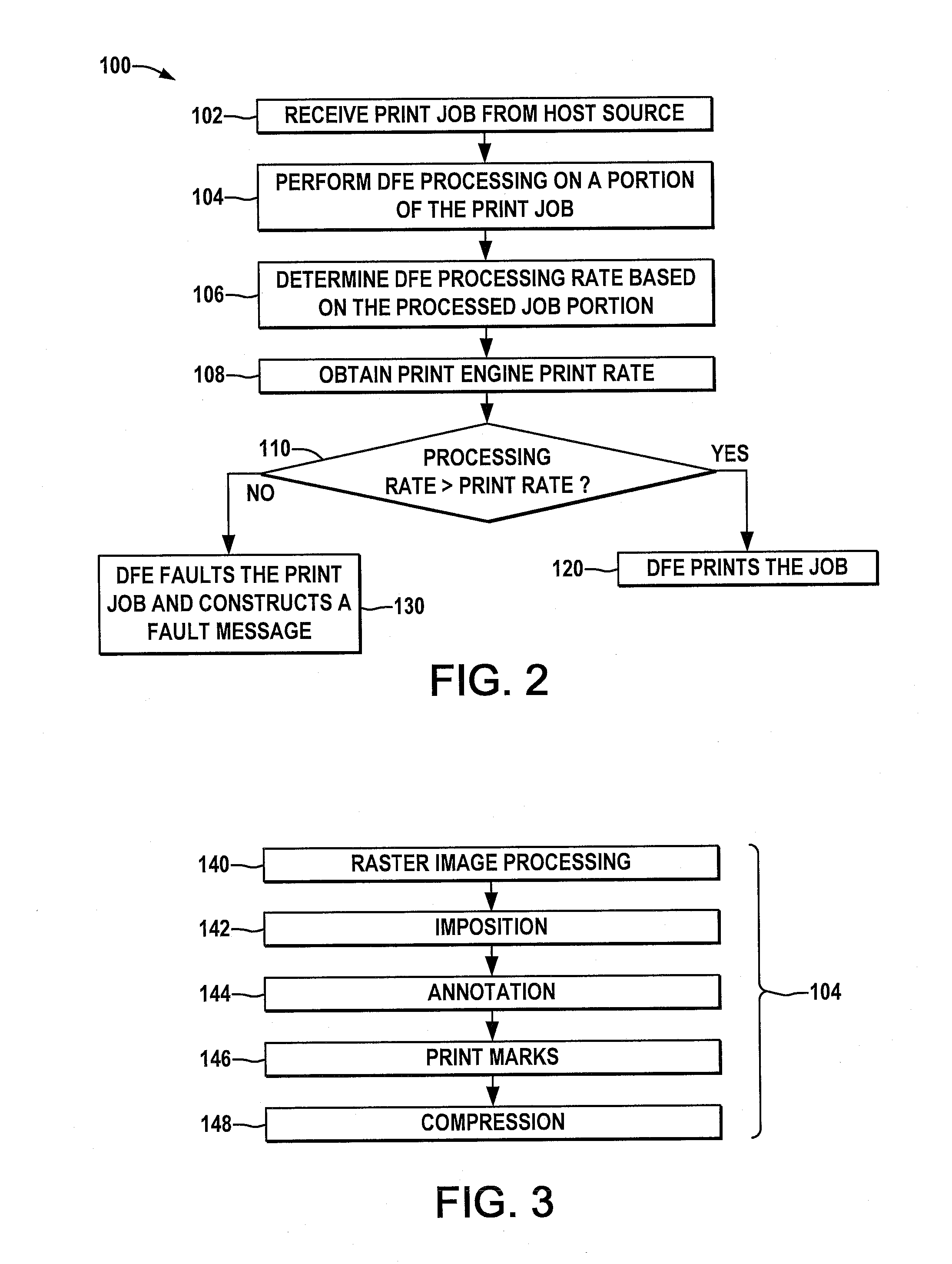

System and method for mitigating printer clutching

ActiveUS20080130035A1Hinders provisionDigitally marking record carriersDigital computer detailsComputer science

Systems and methods are presented for assessing whether a print job is likely to result in print system clutching by actual or modeled processing of a portion of the print job according to assessed processing rate information and to the print rate of a print engine, and selectively refraining from printing the job based on the comparison of the processing rate information and the print rate.

Owner:XEROX CORP

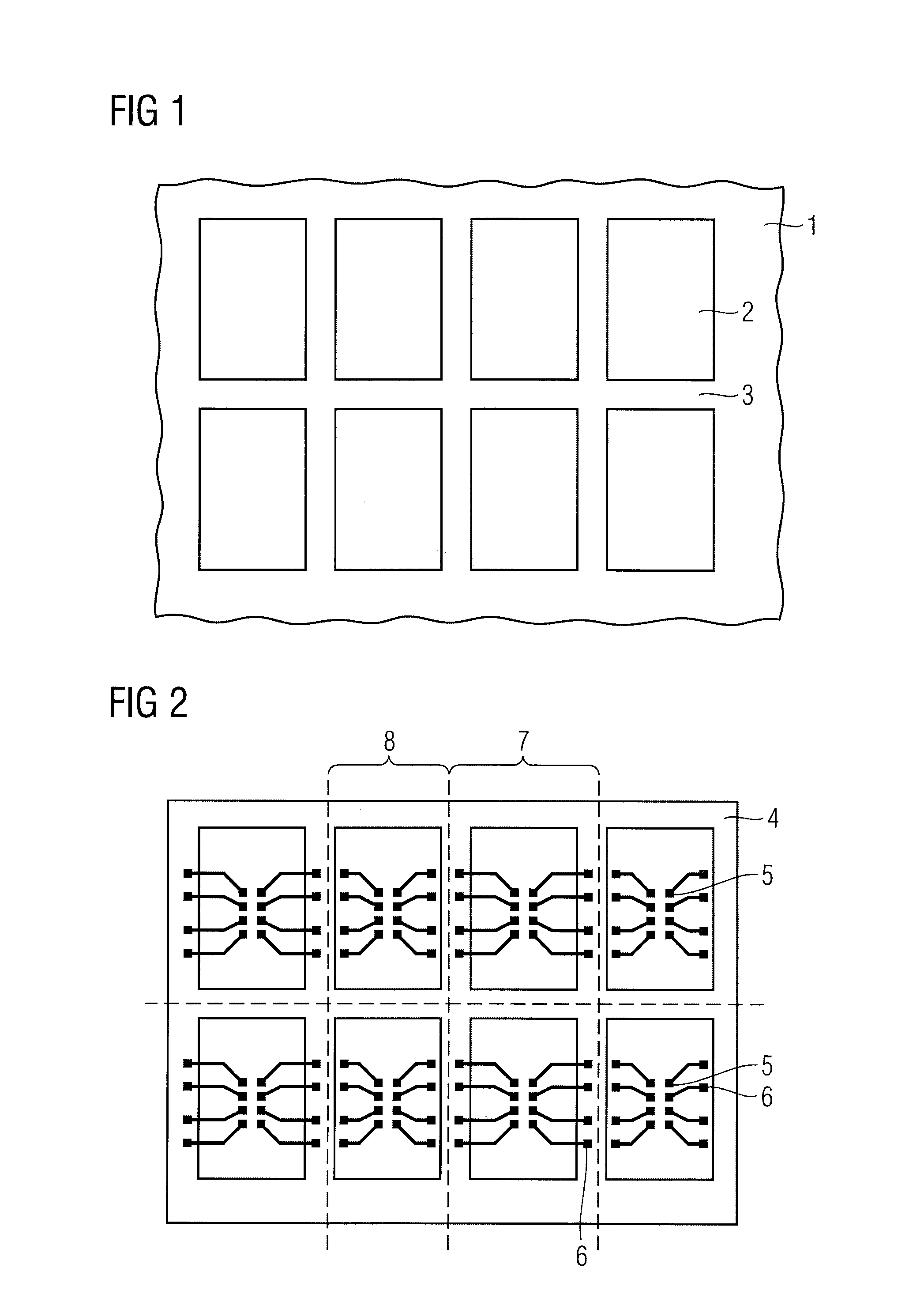

Method for producing chip stacks and chip stacks formed by integrated devices

InactiveUS7271026B2Hinders provisionEasy to manufactureSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerContact pad

The method of the present invention relates to a method for producing a chip stack comprising the steps of manufacturing at least a first and a second integrated structure on a single substrate, an area of the first integrated structure and an area of the second integrated structure adjoining a respective first and second kerf area; providing a first redistribution layer on the first integrated structure on the substrate, said first redistribution layer at least partially extending beyond the area of the first integrated structure into the first kerf area, thereby forming a first integrated device area, wherein a first contact pad is arranged on the first redistribution layer in a first contacting area overlapping the first kerf area; providing a second redistribution layer on a second integrated structure on the substrate, including a second contact pad, thereby forming a second integrated device area; separating the first and second integrated device areas along a separation line defined by at least one of the boundaries of the first integrated device area and the second integrated device area, resulting in separated first and second integrated devices; and stacking the second integrated device on the first integrated device so that the first contacting pattern is uncovered by the second integrated device.

Owner:POLARIS INNOVATIONS LTD

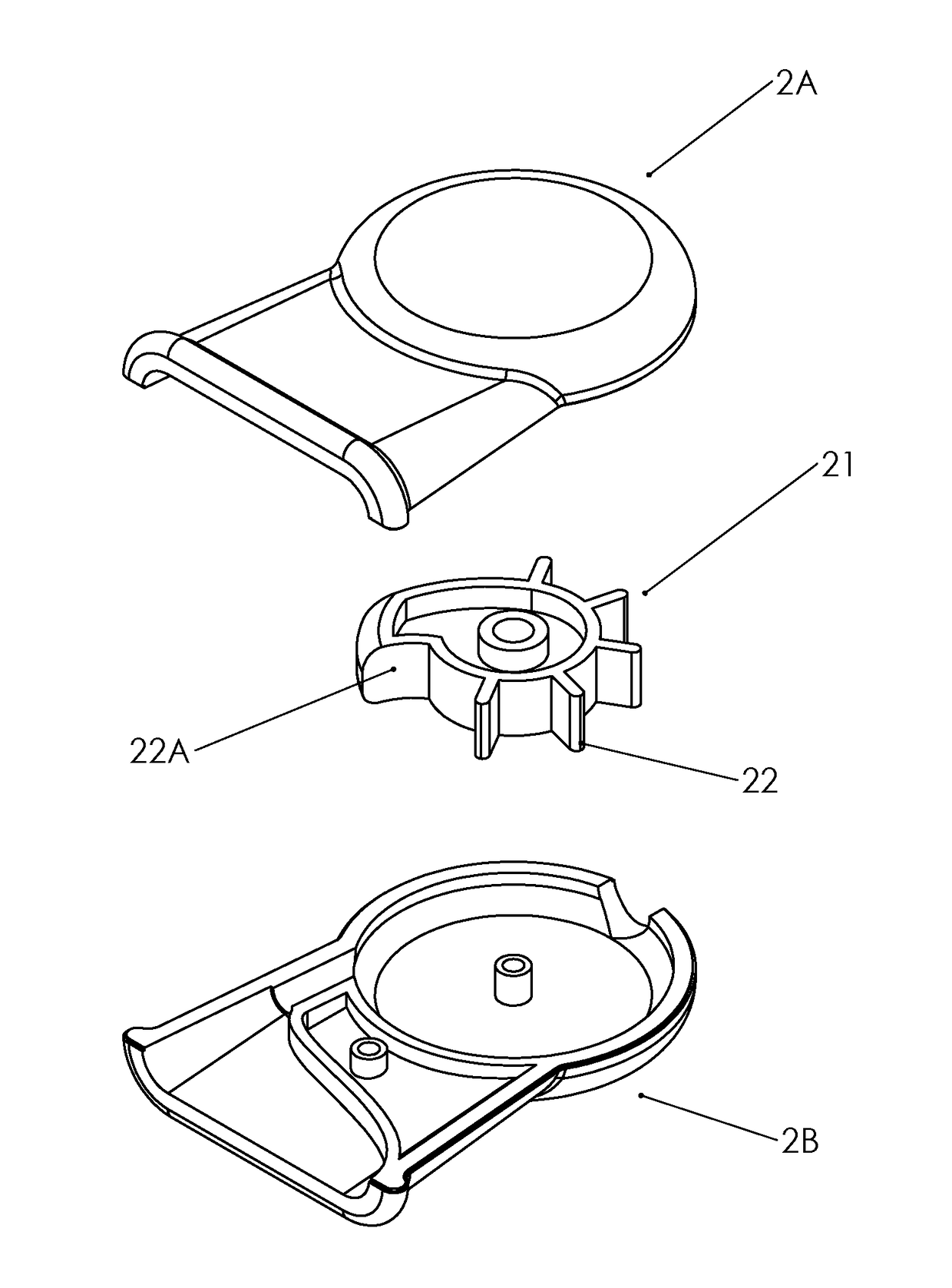

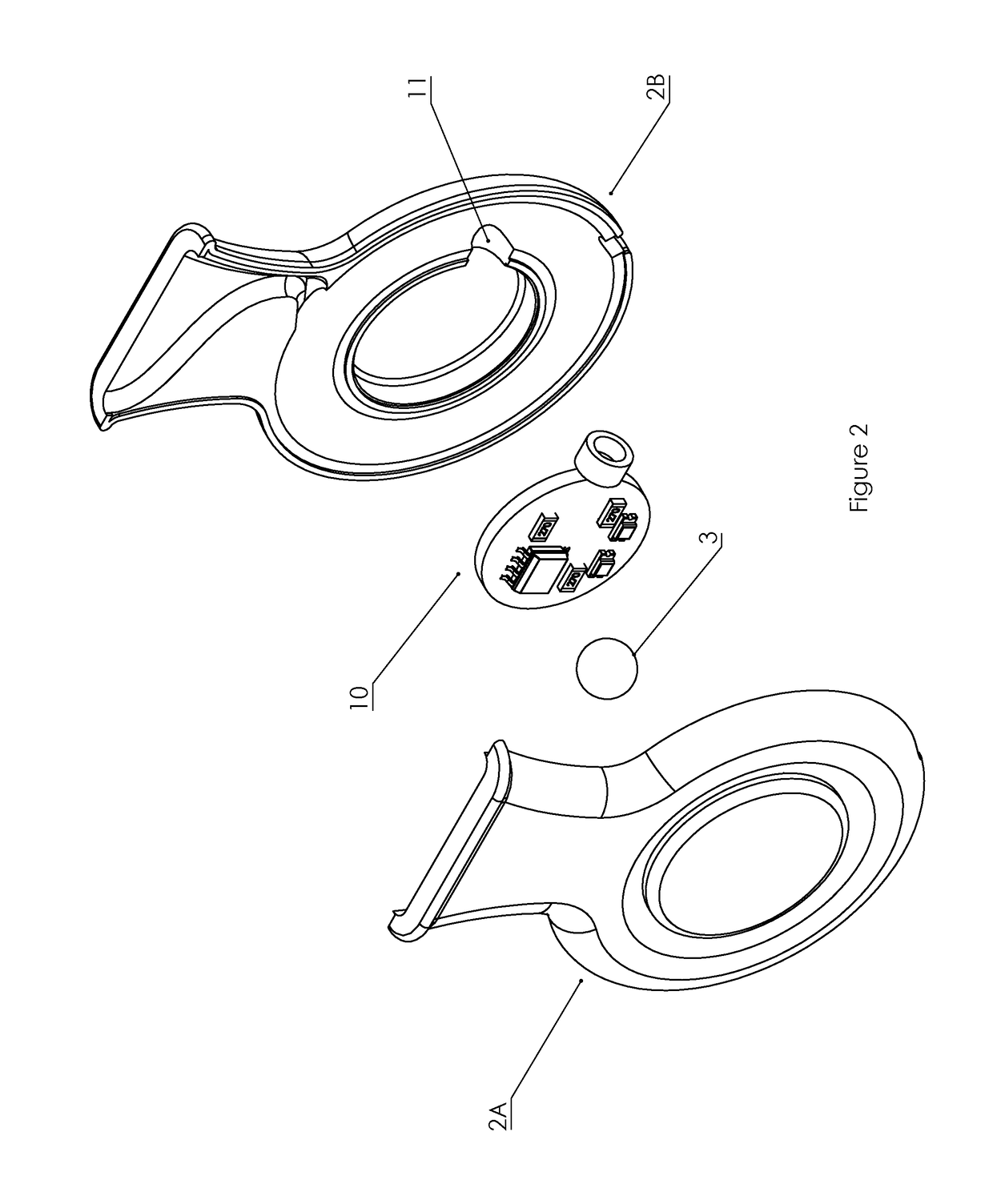

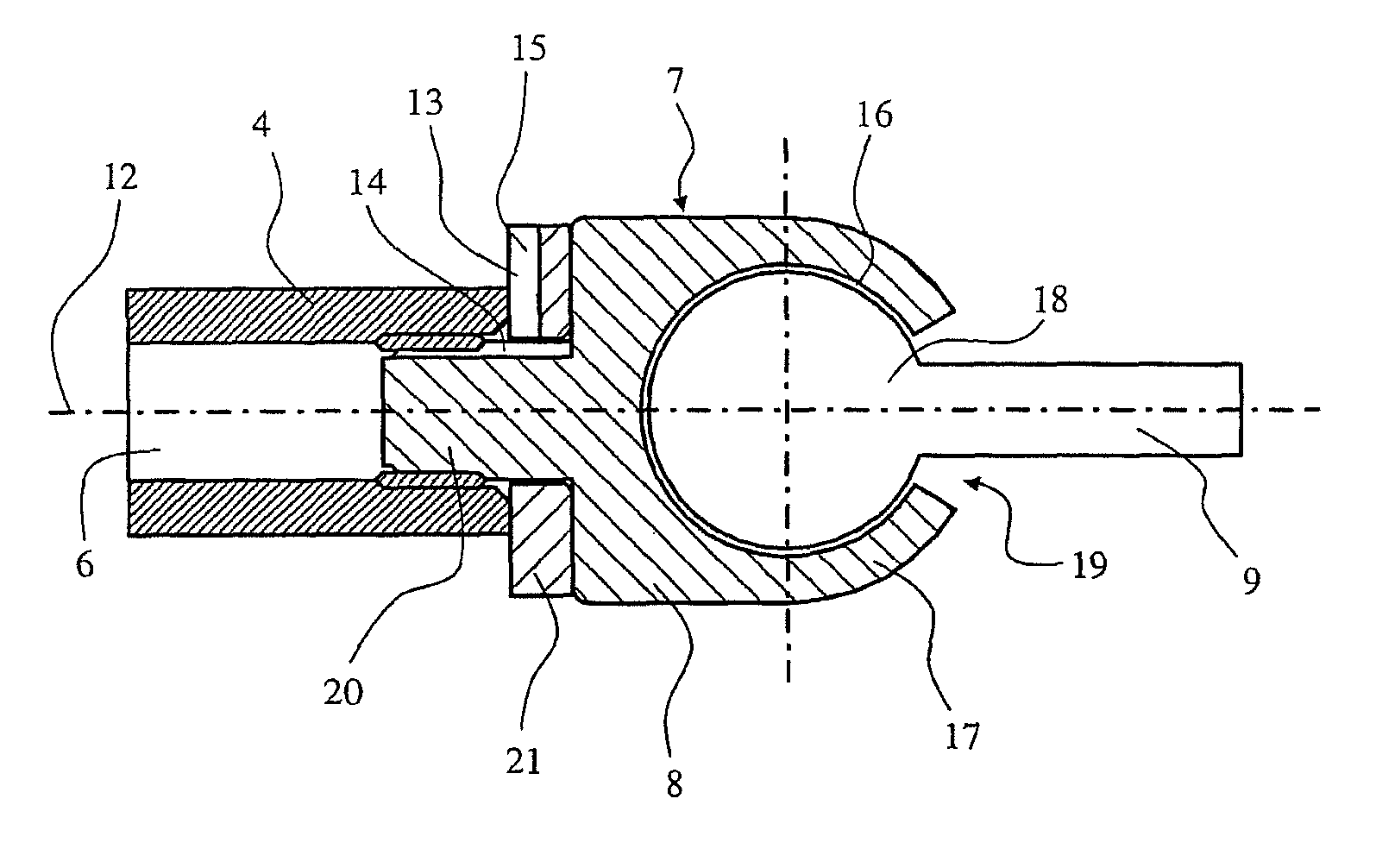

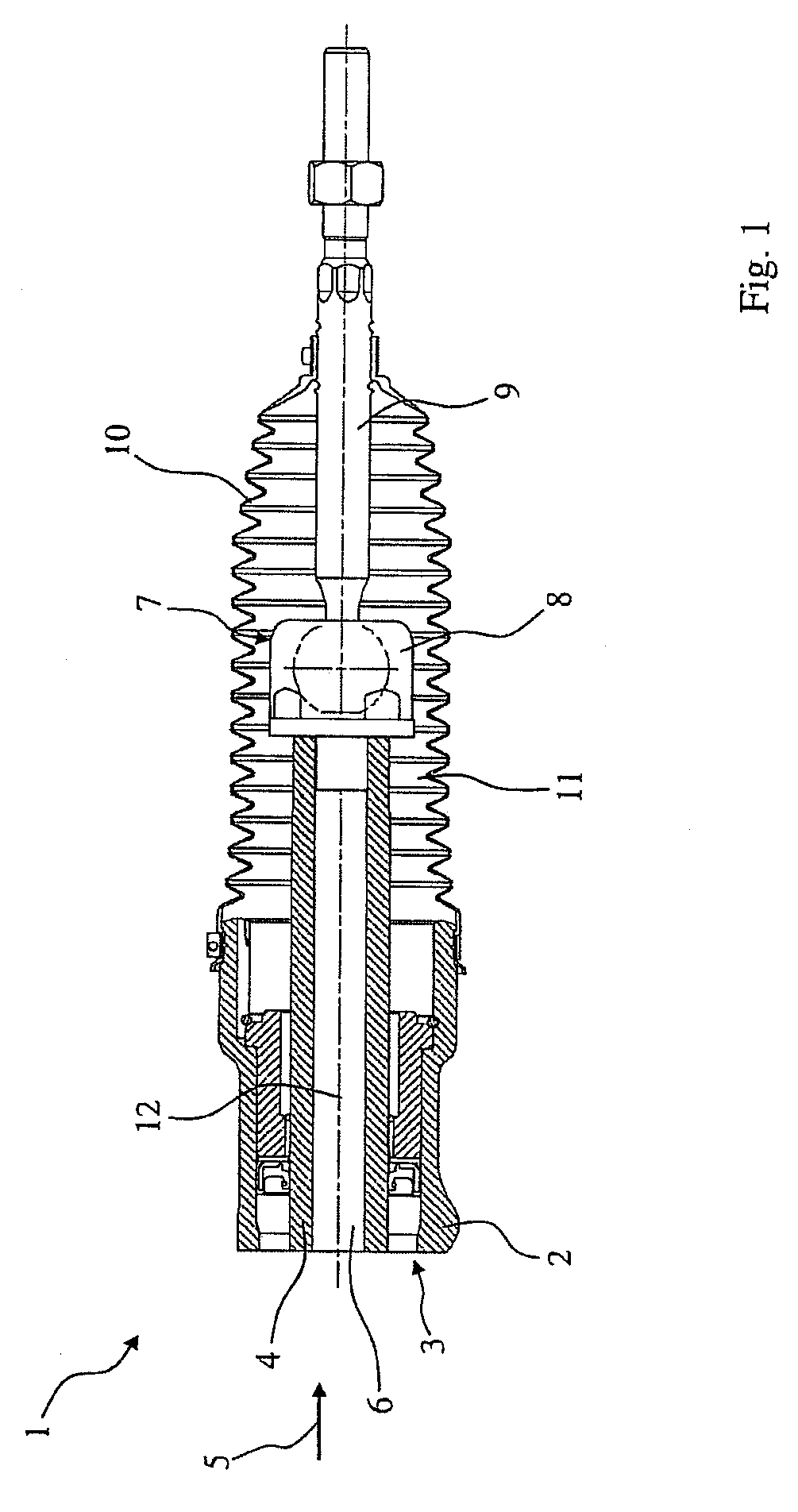

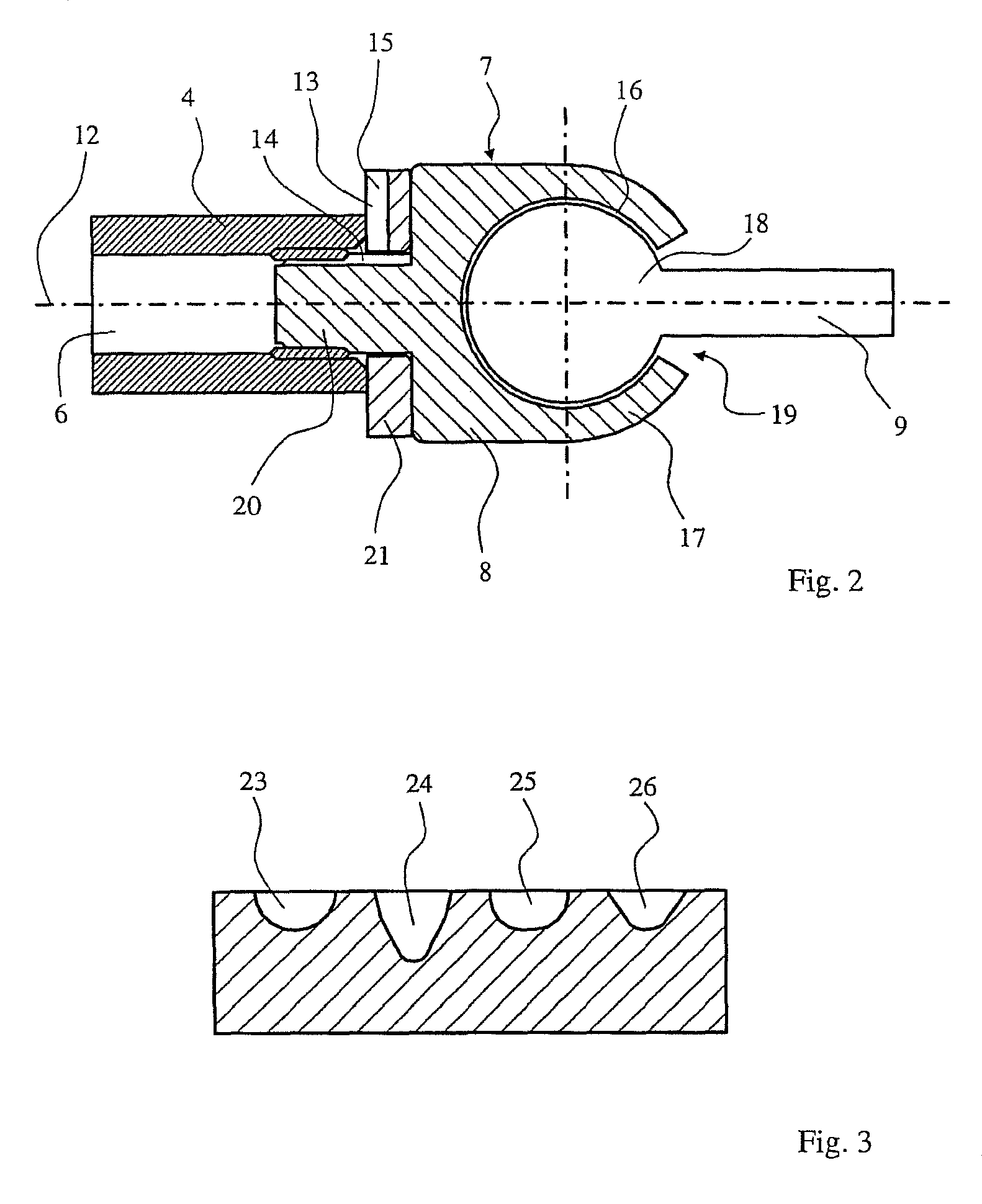

Positive exhalation pressure device

ActiveUS20170173282A1Easy to changeEliminate riskRespiratorsMedical devicesEngineeringDuring expiration

A positive exhalation pressure device (1) is described. The device (1) comprises a housing (2) having an annular chamber (5), a chamber inlet (6) configured to permit air into the chamber, a chamber outlet (7) configured to permit air out of the chamber, and a mouthpiece (8) in fluid communication with the chamber inlet. A movable body such as a ball (3) is disposed in the housing within the annular chamber and configured to revolve around the annular chamber in response to flow of air through the chamber from the chamber inlet to the chamber outlet. The movable body is configured to at least partially block the chamber outlet as it revolves around the annular chamber causing cyclical fluctuations in airflow resistance.

Owner:SOLOPEP LTD

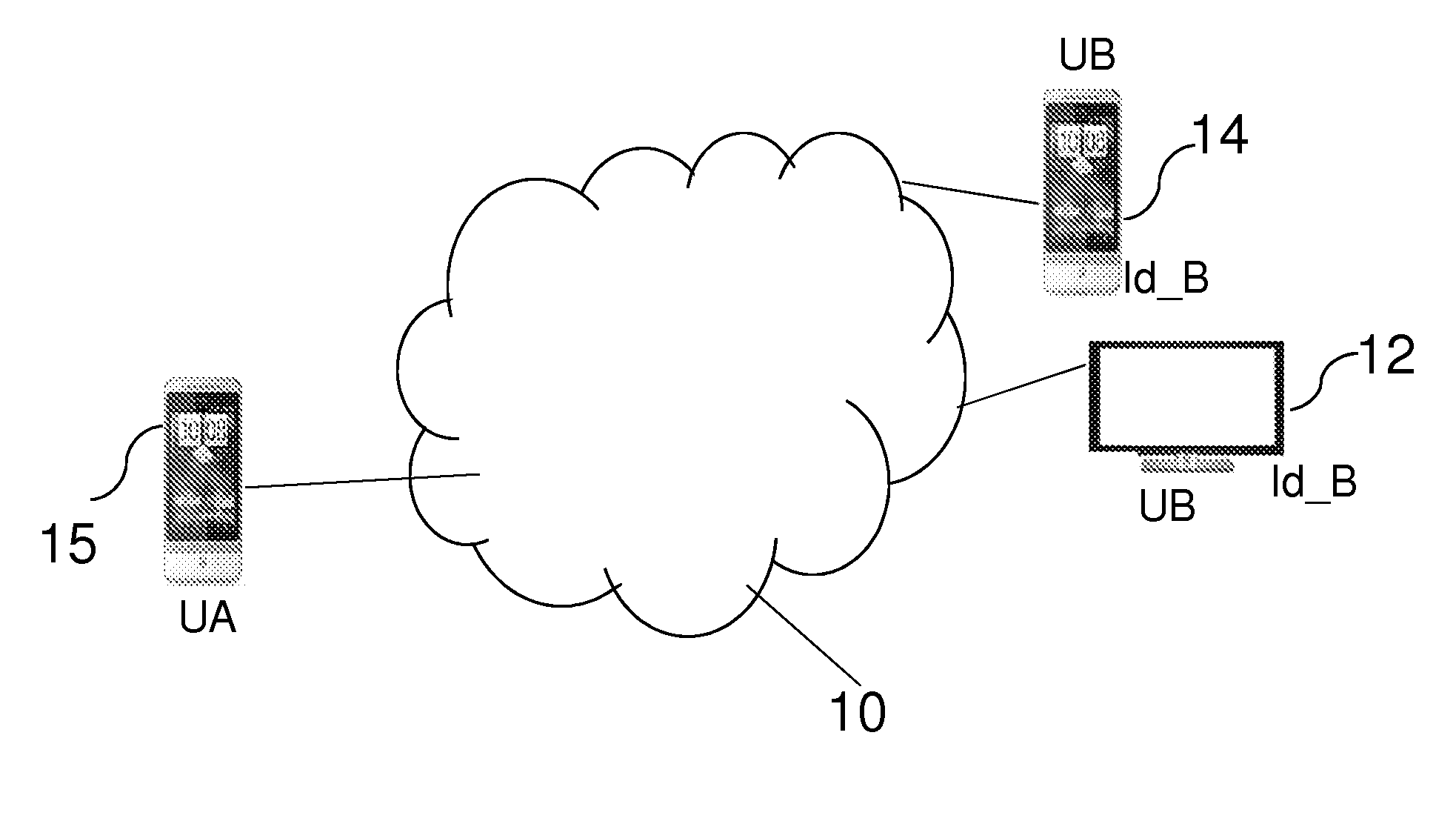

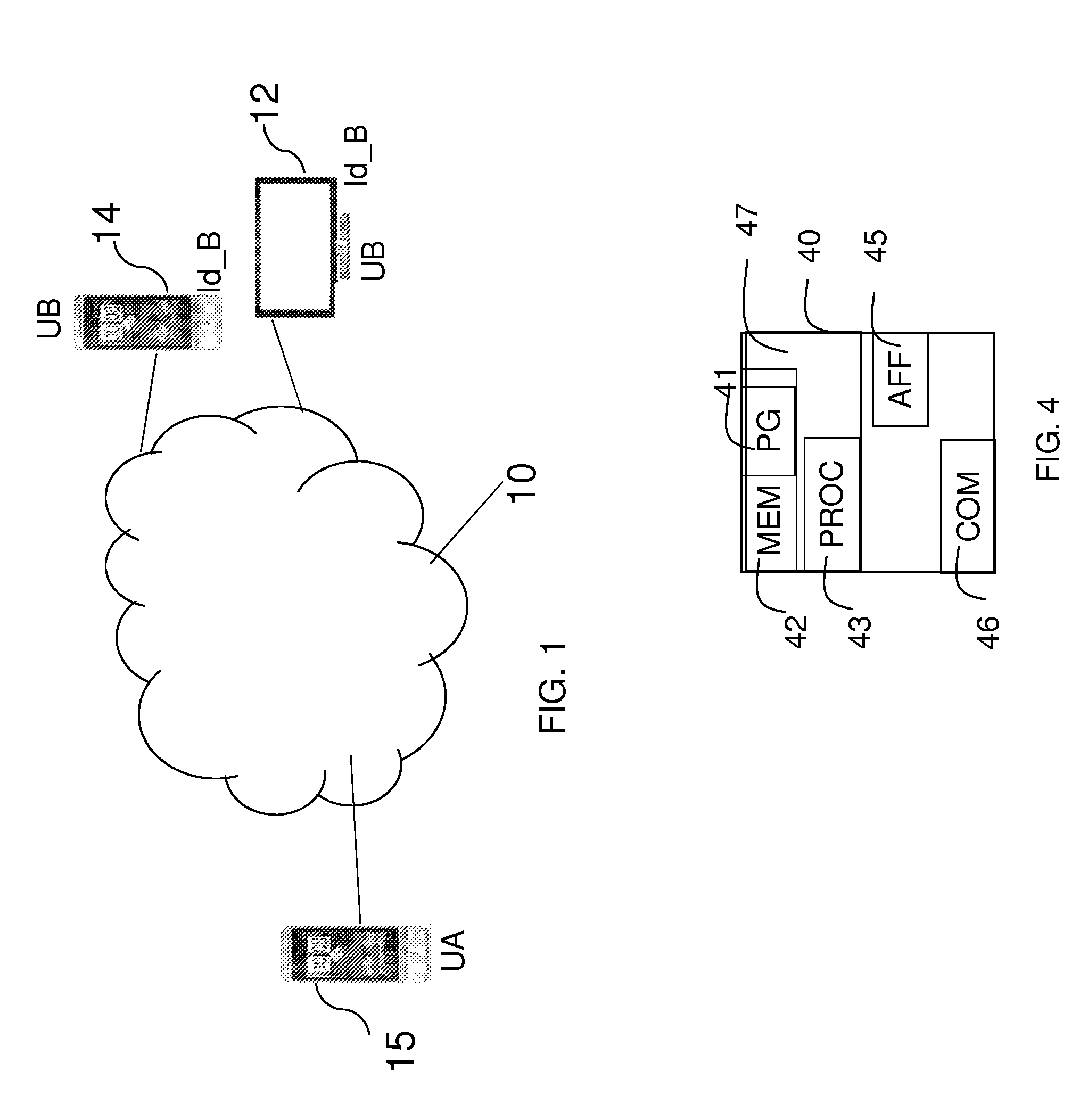

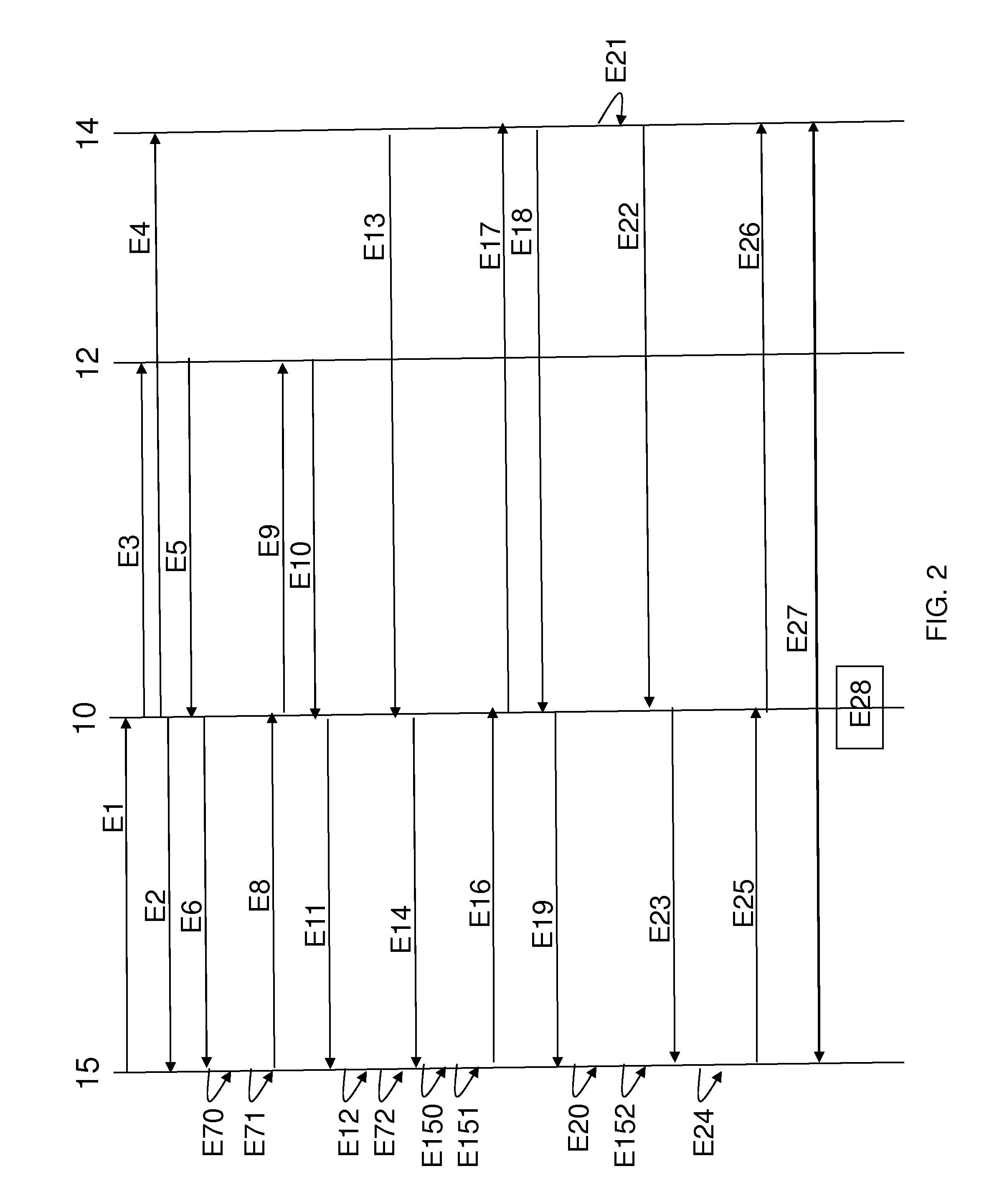

Method and device for establishing a communication

ActiveUS20150163838A1Hinders provisionConnection managementWireless commuication servicesTelecommunications

Owner:ORANGE SA (FR)

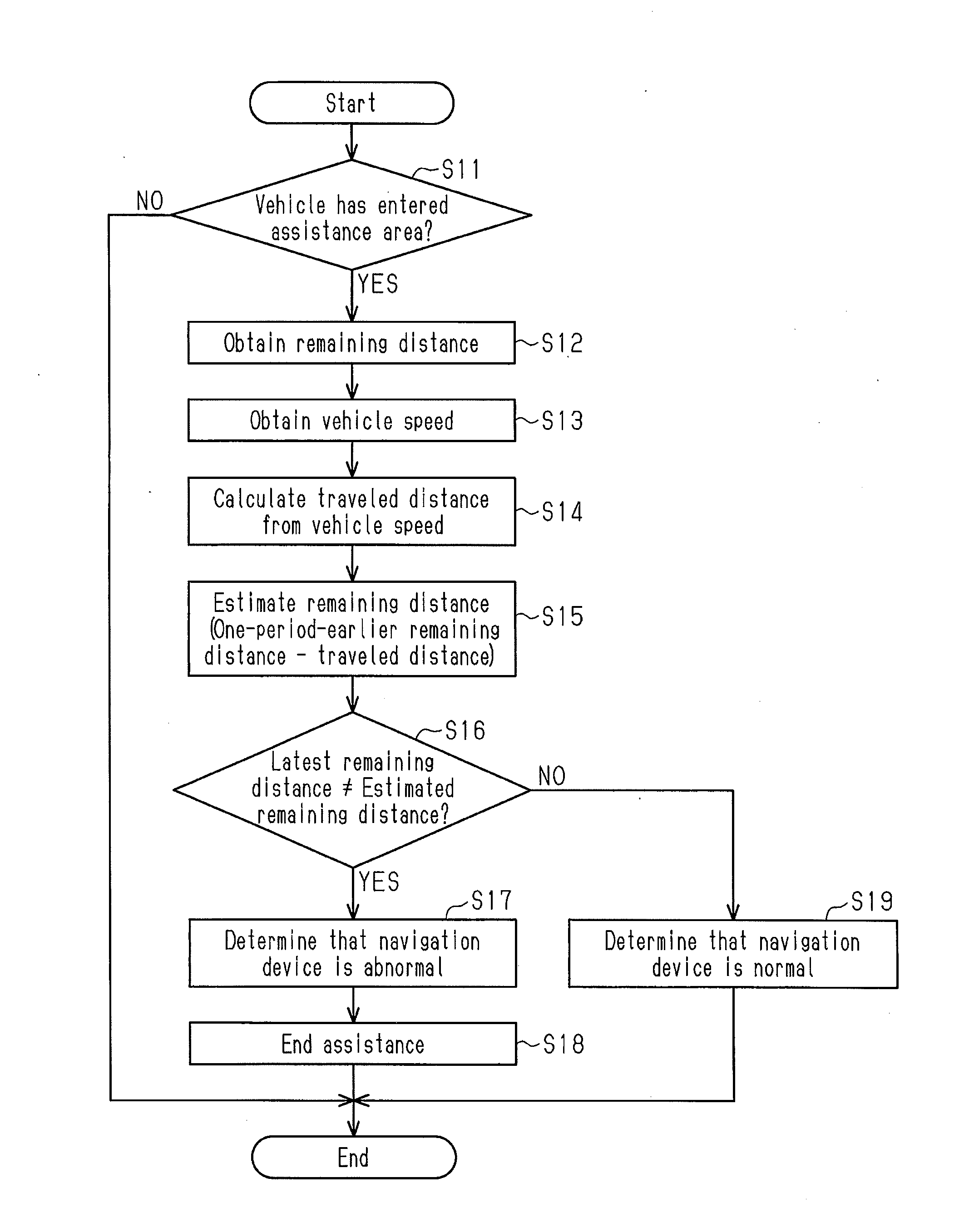

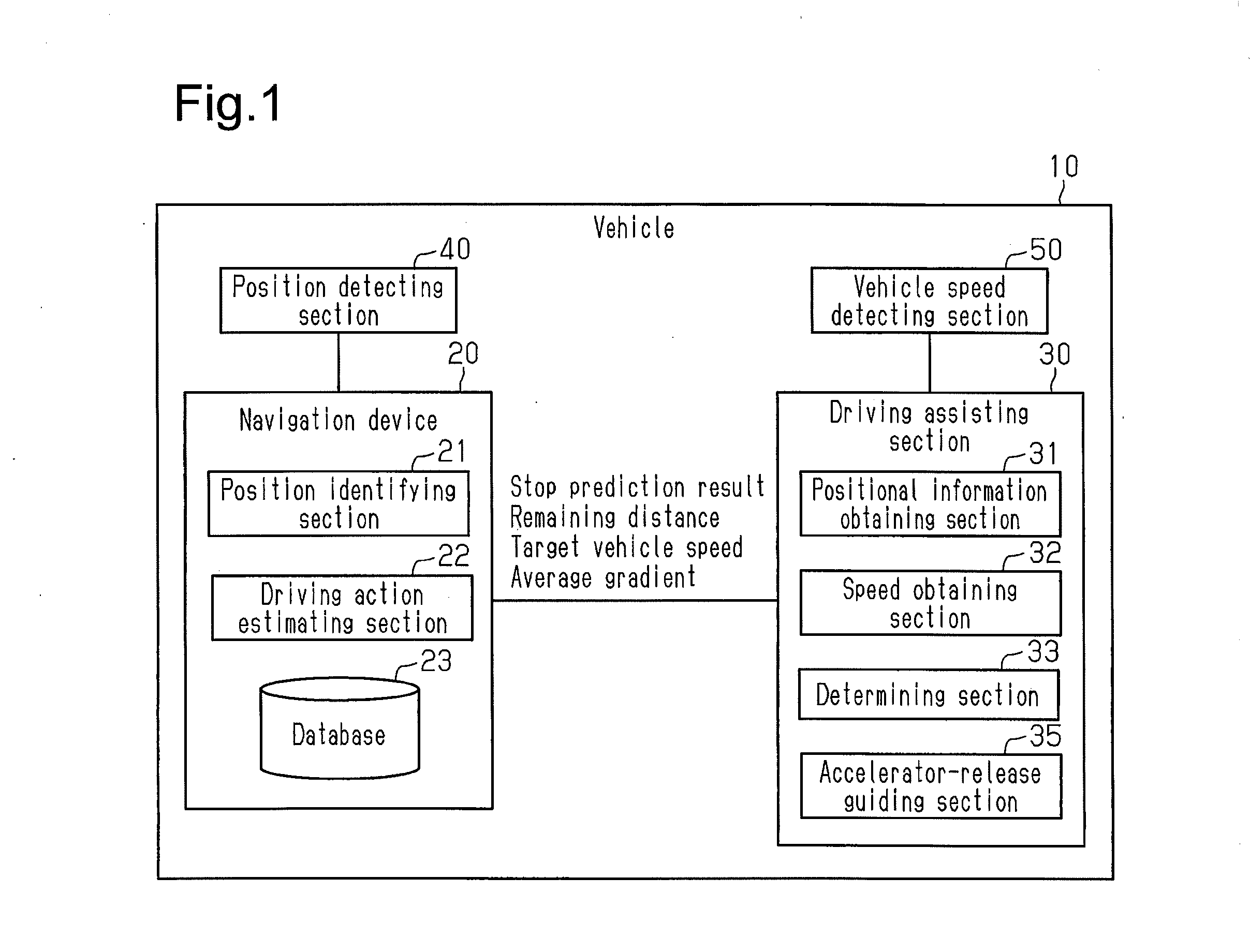

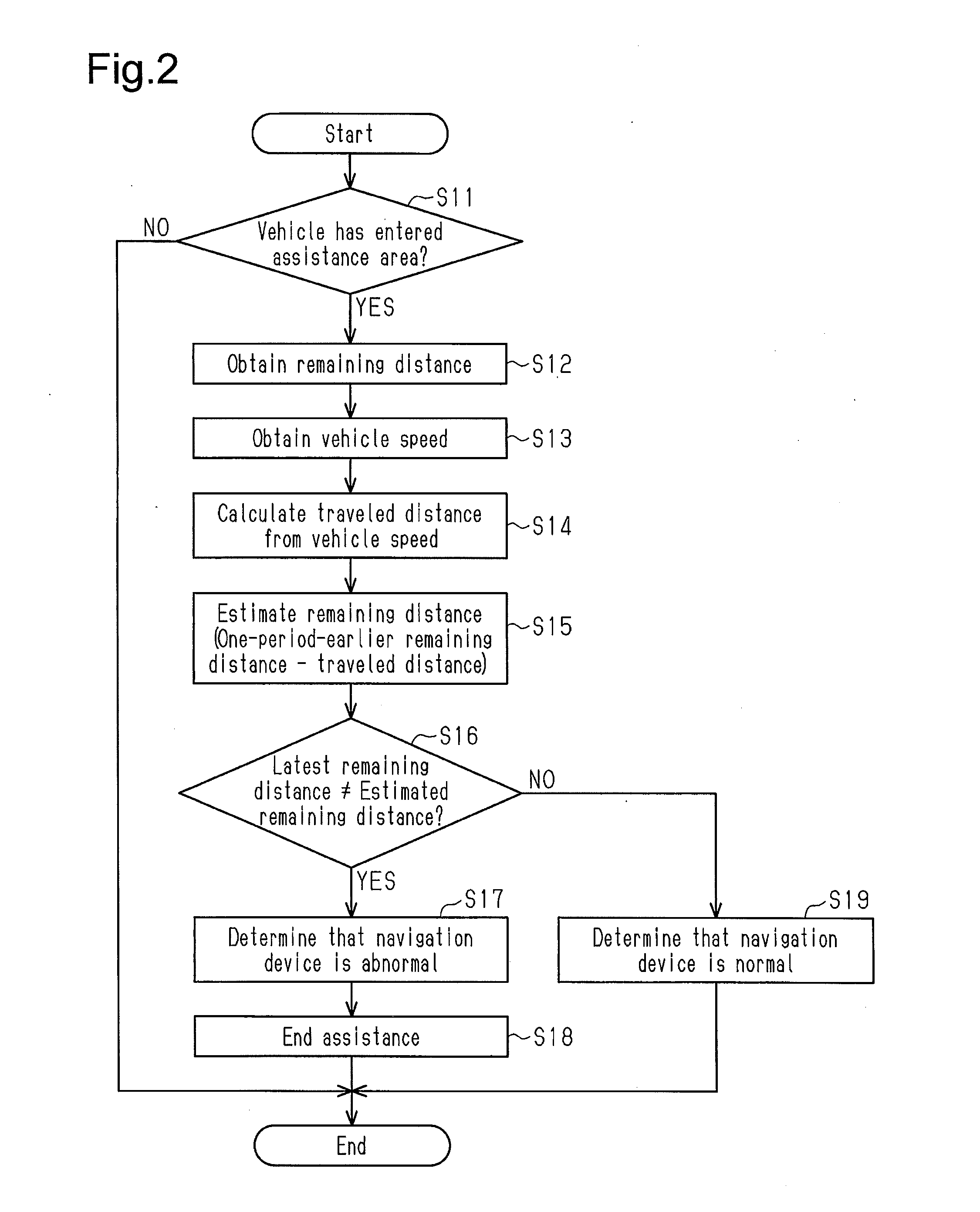

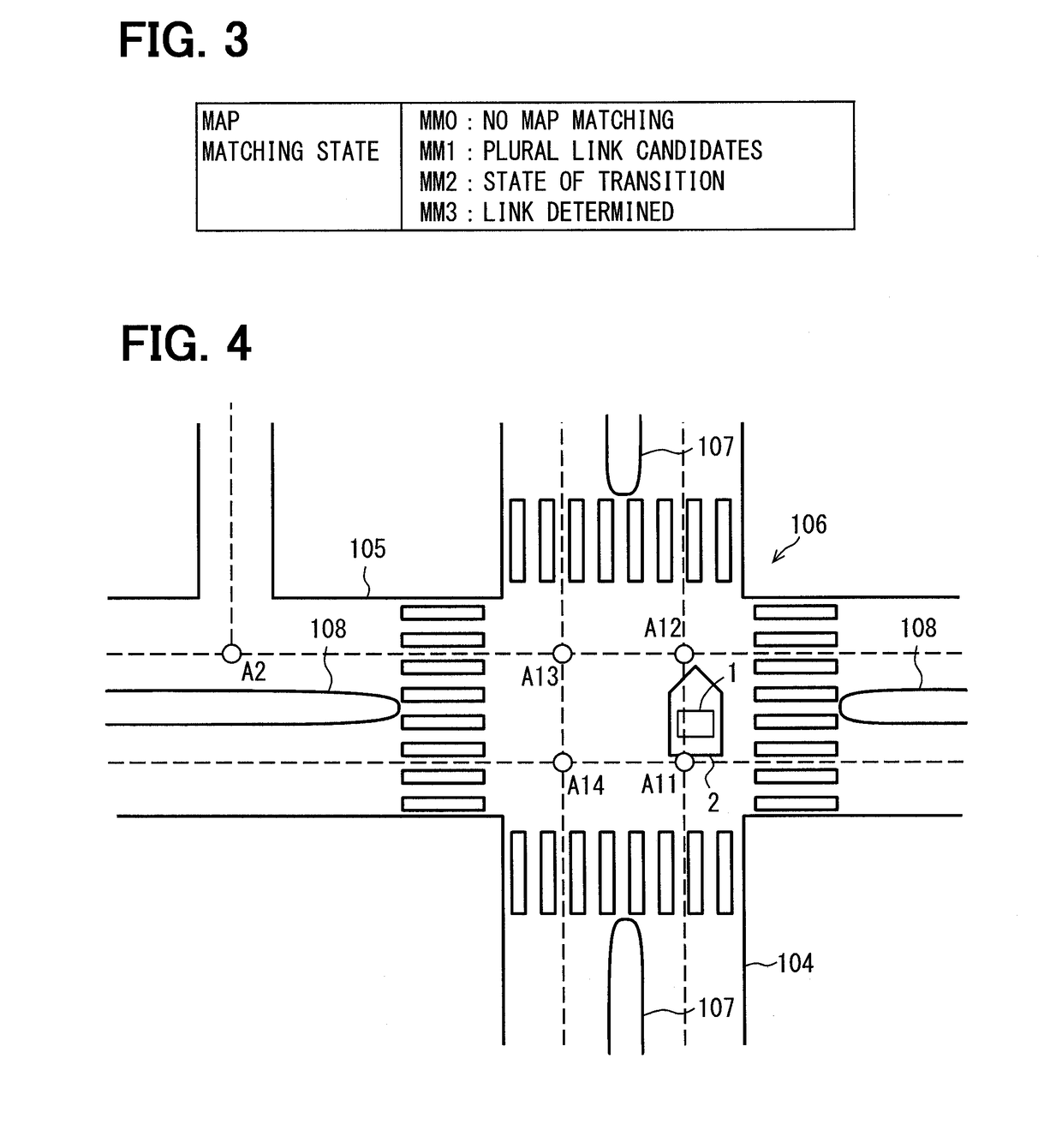

Vehicle information-processing device

InactiveUS20160091315A1Efficiently determinedHinders provisionInstruments for road network navigationNavigation by speed/acceleration measurementsInformation processingSimulation

Owner:TOYOTA JIDOSHA KK

Method for codec negotiation and selection

ActiveUS8374587B2Improve coordinationEasy to operateNetwork traffic/resource managementSpecial service for subscribersCall setup

A method of modifying a call setup message for a call from a first terminal to a second terminal, the call setup message being sent from the first terminal to a network node via an intermediate node which handles at least some signaling or traffic associated with the call, wherein the network node is responsible for negotiating call setup requirements for the call to the second terminal, the method comprising the steps of: intercepting the call setup message at the intermediate node; identifying one or more preferences or capabilities associated with the intermediate node which may impact the way in which the intermediate node can handle signaling or traffic associated with the call; modifying the call setup message based on information relating to said preferences or capabilities; and sending the modified call setup message to the network node, in order that the node can effect said negotiations based on the modified message.

Owner:TELEFON AB LM ERICSSON (PUBL)

Joint arrangement for a vehicle

ActiveUS8348541B2Design is limitedPrevent surfaceSteering linkagesToothed gearingsInterior spaceEngineering

Owner:ZF FRIEDRICHSHAFEN AG

Device. system, and method for automatically determining an appropriate LAN IP address range in a multi-router network environment

InactiveUS7512138B2Hinders provisionEliminate conflictError preventionTransmission systemsIp addressPrivate address

A device, system and method which provides for automatic selection of an alternative private address space by a gateway-router device which is given a private address on its WAN port is disclosed. The present invention provides for a device, system, and method wherein, in a given network topology, if a gateway-router device is given an IP address on its WAN port that is in a private address space then such gateway-router device will automatically select an alternative private address space to use for its DHCP server that will provision addresses to devices interconnected to its LAN port. The above inventive technique eliminates any conflict in private address provisioning.

Owner:GOOGLE TECHNOLOGY HOLDINGS LLC

Lens and method for manufacturing same

ActiveUS20120140340A1Hinders provisionStable arrangementOptical articlesMountingsOptoelectronicsLens plate

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

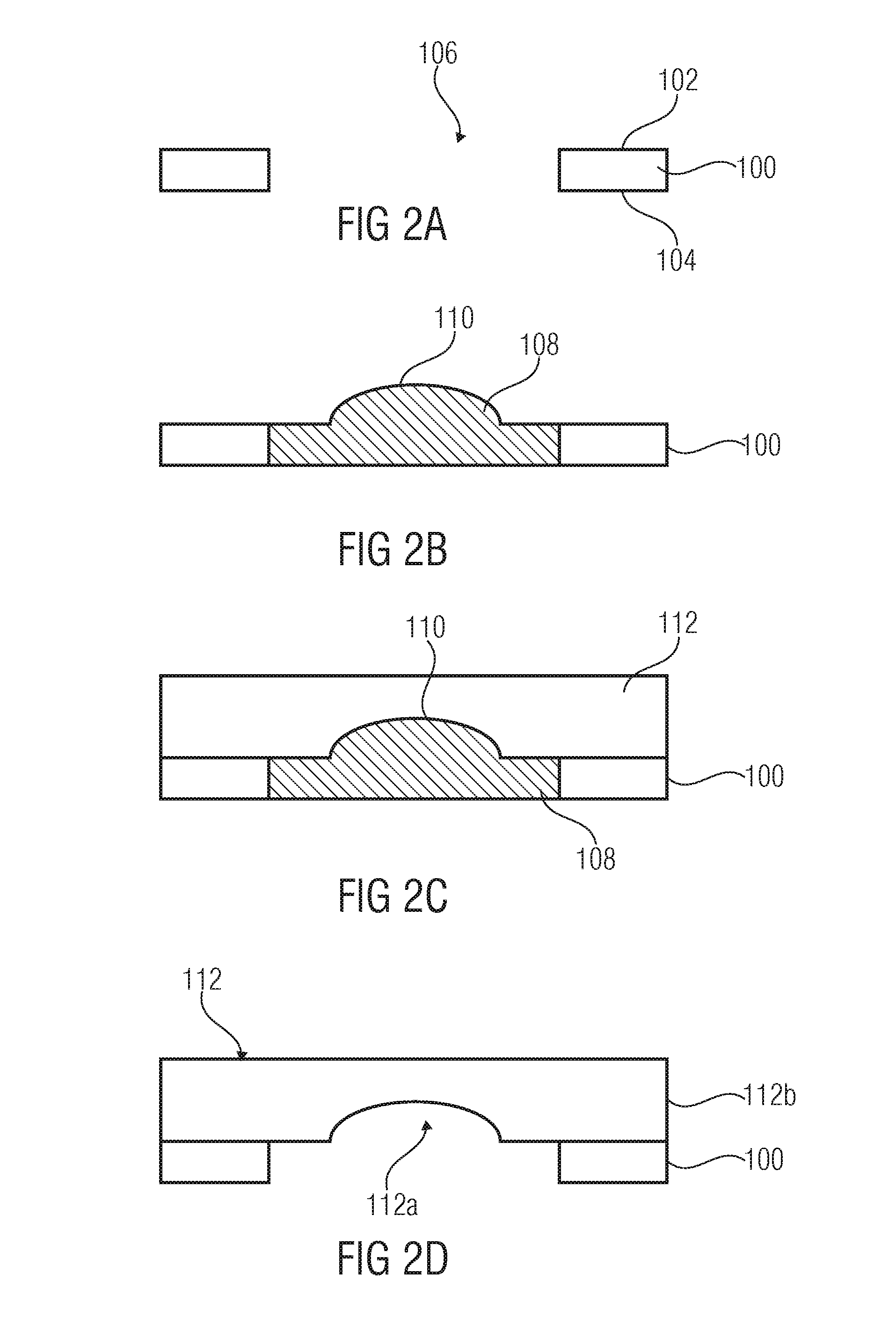

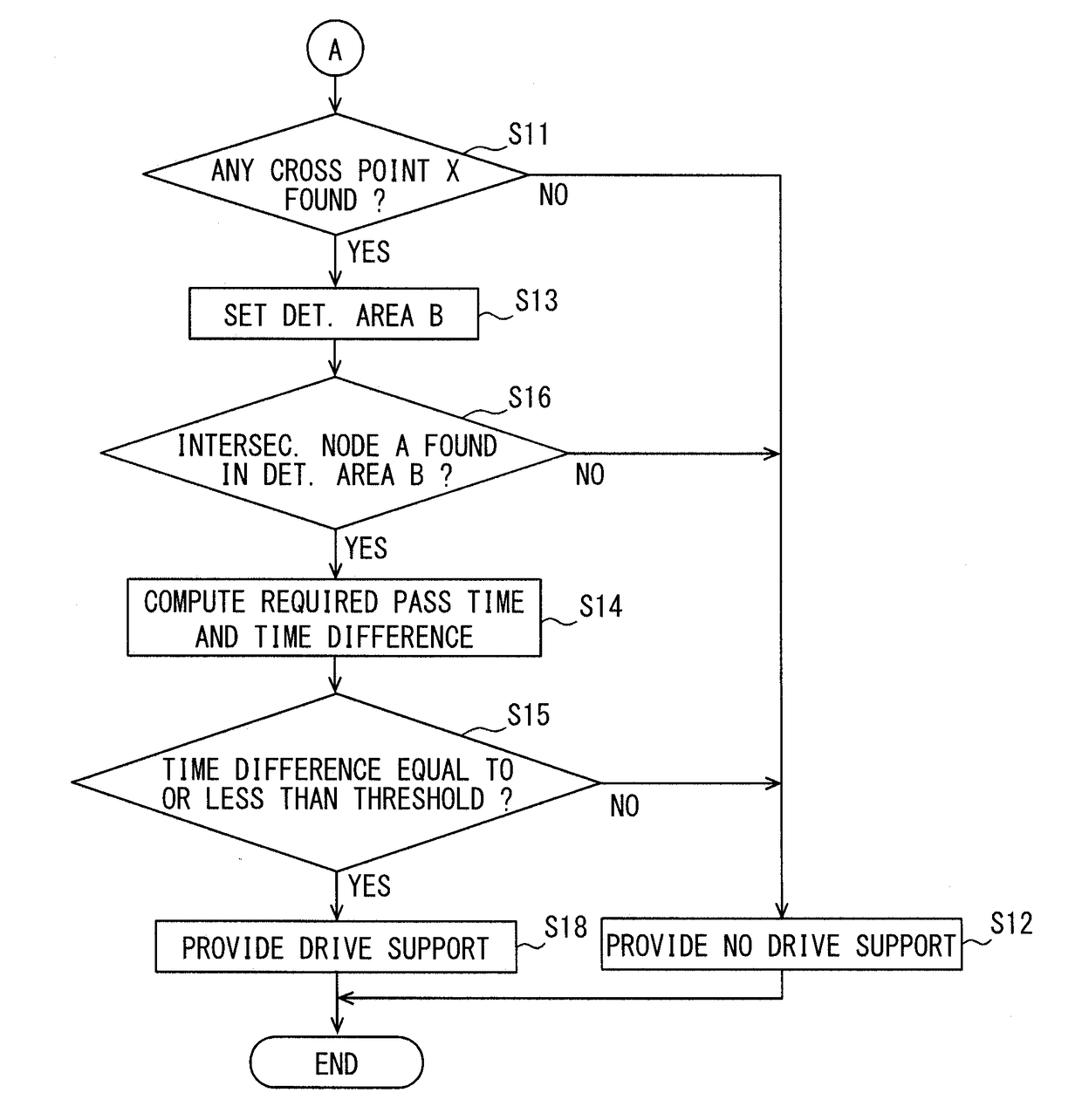

Drive support apparatus

ActiveUS20170206787A1Prevents provisionPreventing lack of supportInstruments for road network navigationParticular environment based servicesMap matchingReal-time computing

A drive support apparatus includes: a reliability determiner determining a reliability of a map matching, an area definer defining a determination area to include a cross point between a self-vehicle predicted path and a nearby vehicle predicted path, an intersection node finder determining an intersection node in a travel direction of the self-vehicle based on a high map matching reliability, and a node determiner determining whether the intersection node is found in the determination area. When no intersection node is found in the determination area, a drive support level is suppressed, and when the reliability is low, drive support is provided depending on whether the cross point between the self-vehicle predicted path and the other vehicle predicted path is found. Thus, lack of the drive support in a support-required situation is prevented, while preventing a provision of an unnecessary drive support.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com