Patents

Literature

32results about How to "Avoid doubling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

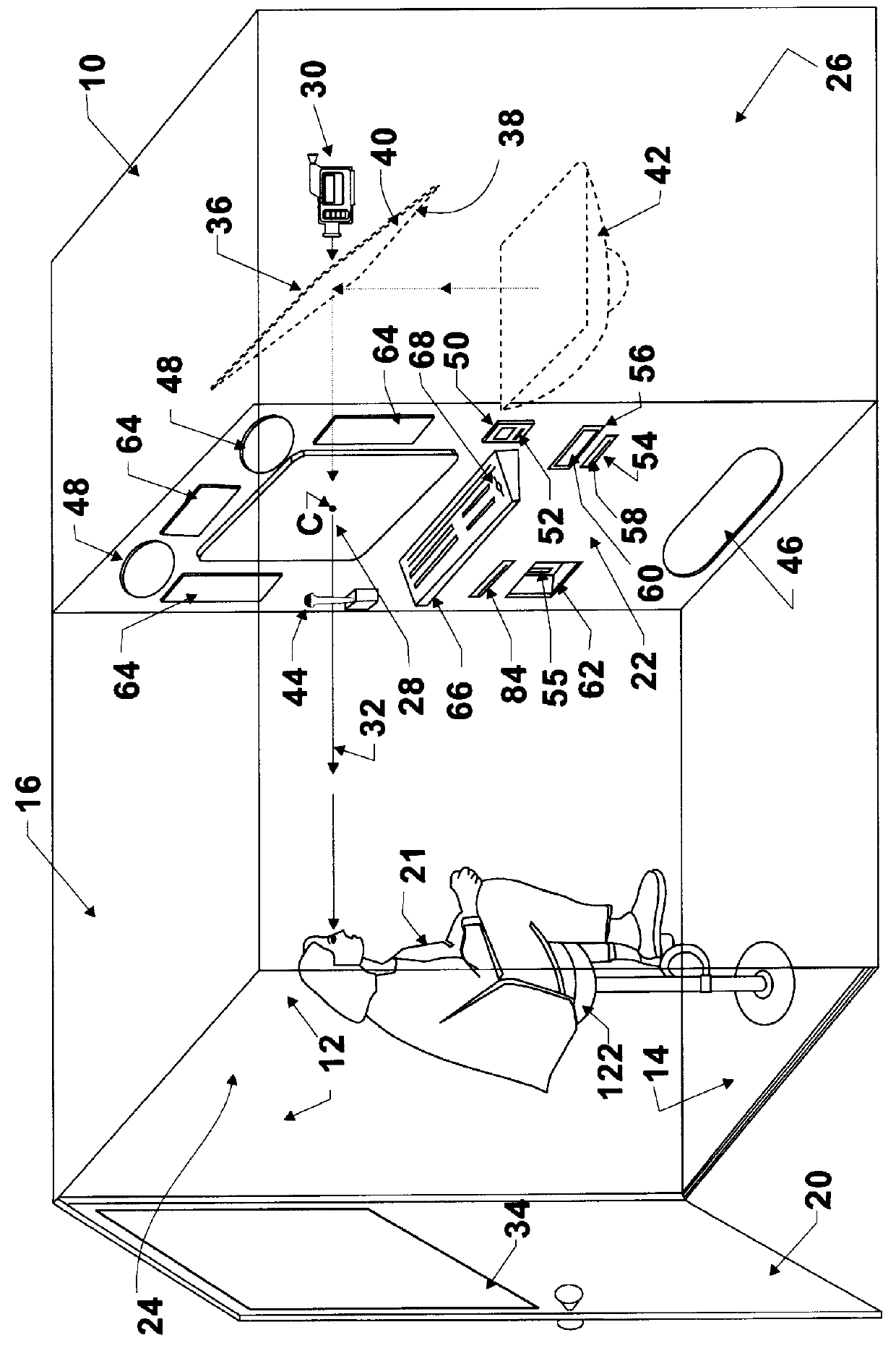

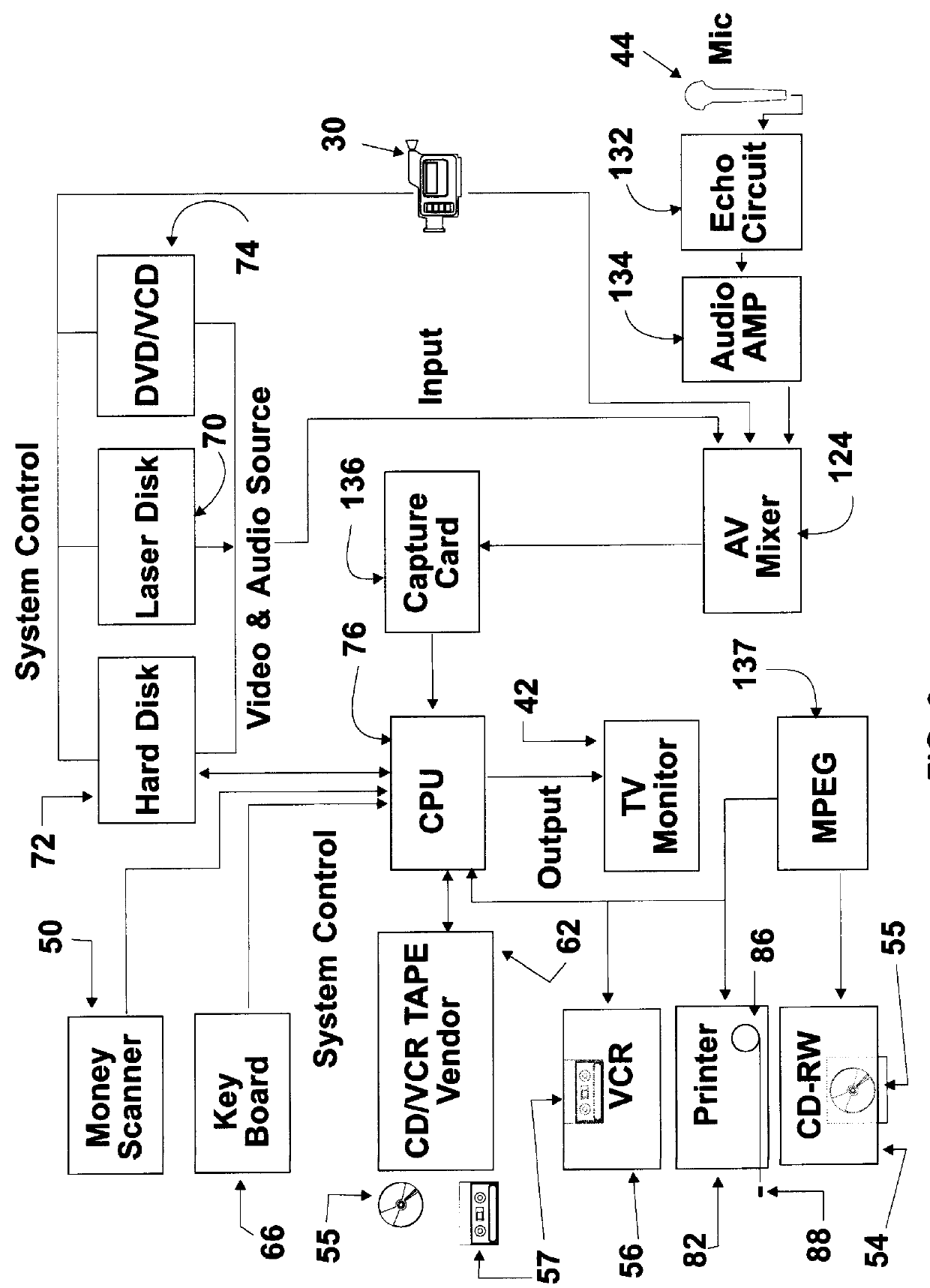

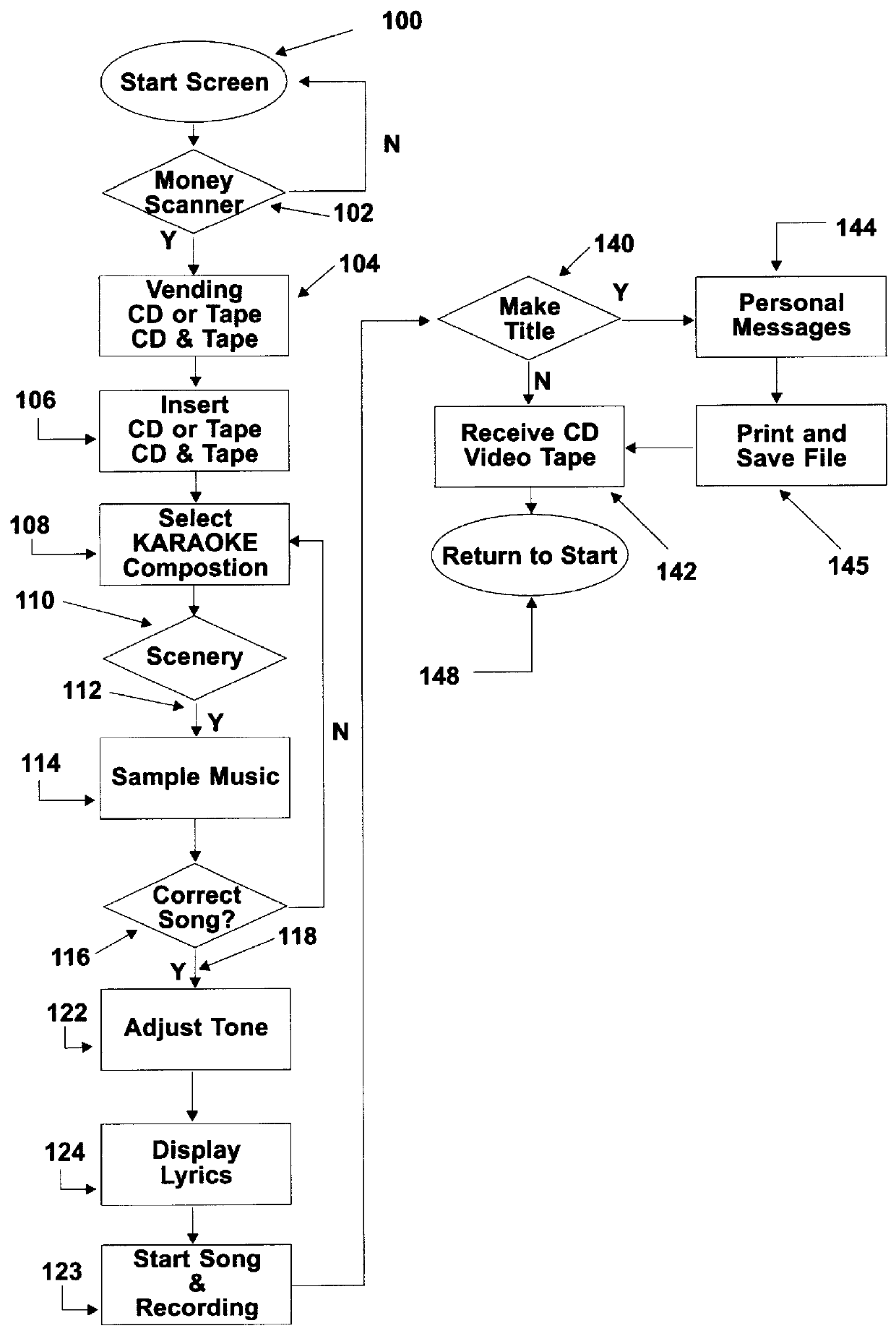

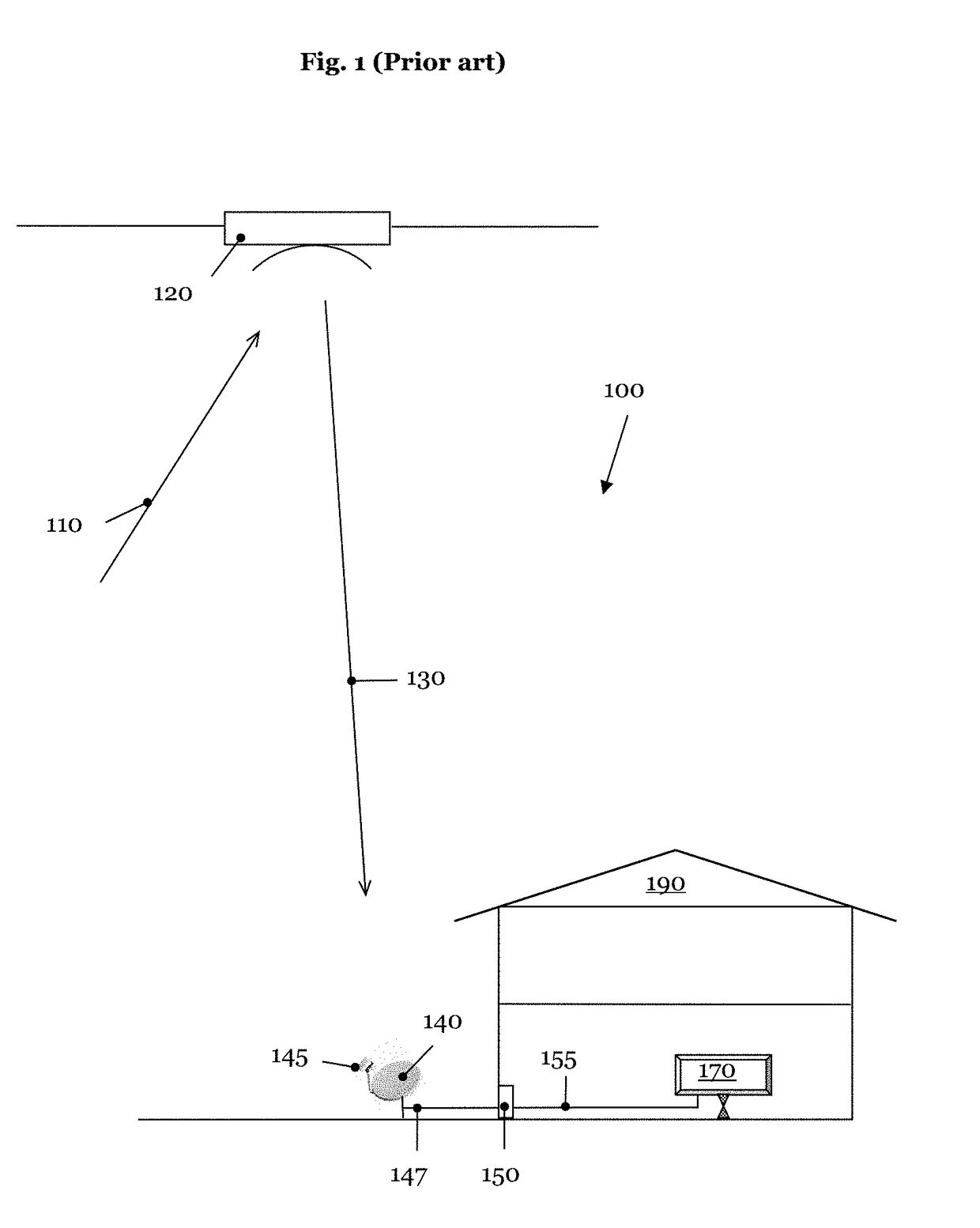

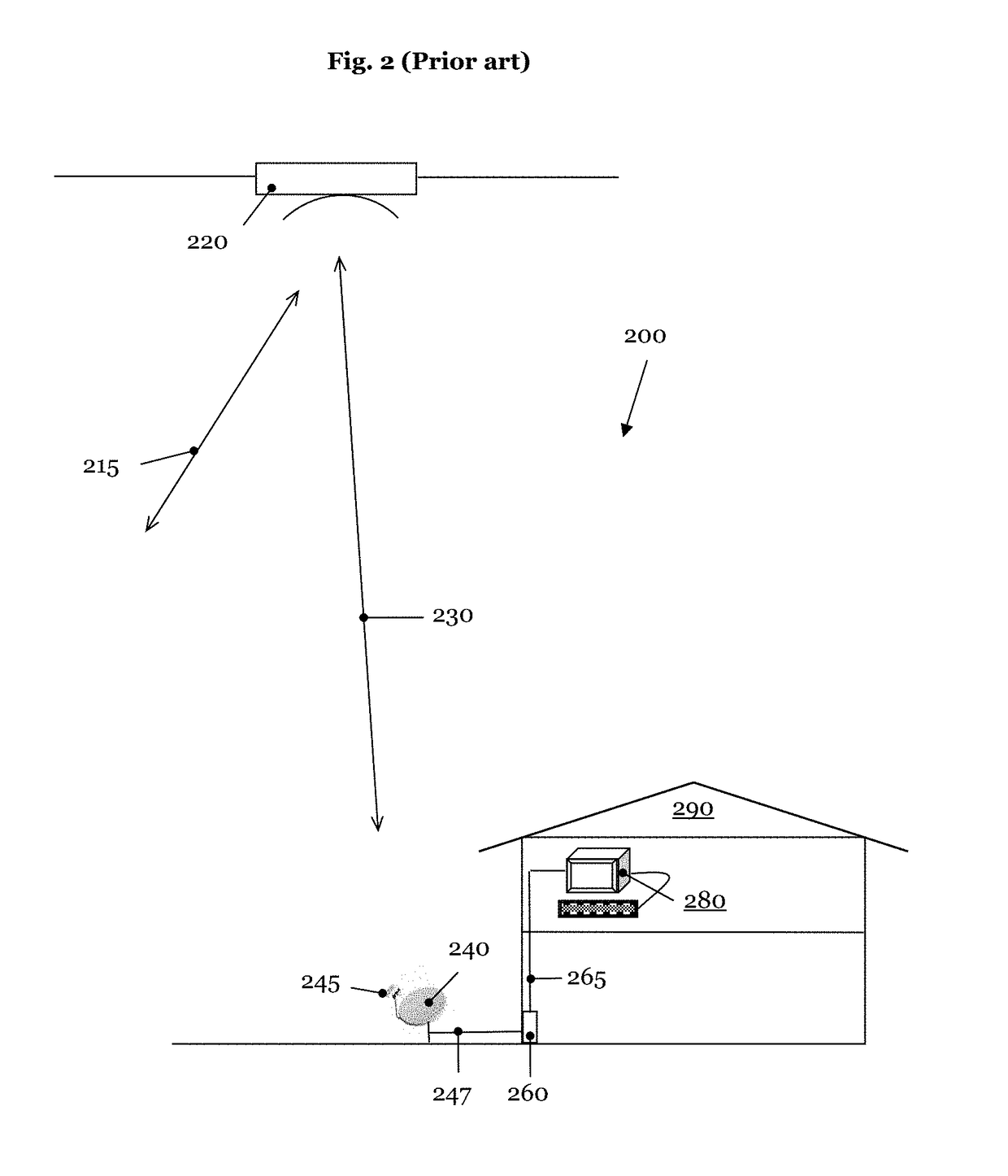

Personalized karaoke recording studio

InactiveUS6086380AMinimizes problemEasy to adaptGearworksMusical toysPersonalizationComputer graphics (images)

In a self-operated karaoke recording booth a user is provided with a selection of background scenes from which to choose and also with the option of having the lyrics of the karaoke selection displayed or suppressed. A video camera positioned at the user's eye level is located on the nonreflective side of a one-way mirror and is directed at a specified performer location through the one-way mirror, which is inclined at a forty-five degree angle relative thereto. Messages and video displays are provided to the user by a video display monitor connected to a computer that faces the reflective side of the one-way mirror and is also located at a forty-five degree angle relative thereto. The system is designed to maintain the visual focus of the performer directly into the lens of the video camera throughout the performance and to combine the video camera images with the background scene in such a way as to avoid a double exposure or phantom image of the performer against the background. The performer can choose to have the lyrics of the selected karaoke composition displayed or suppressed. If the election is for a display, the lyrics are displayed at the center of the viewing screen, directly in line with the video camera.

Owner:CHU CHIA CHEN +3

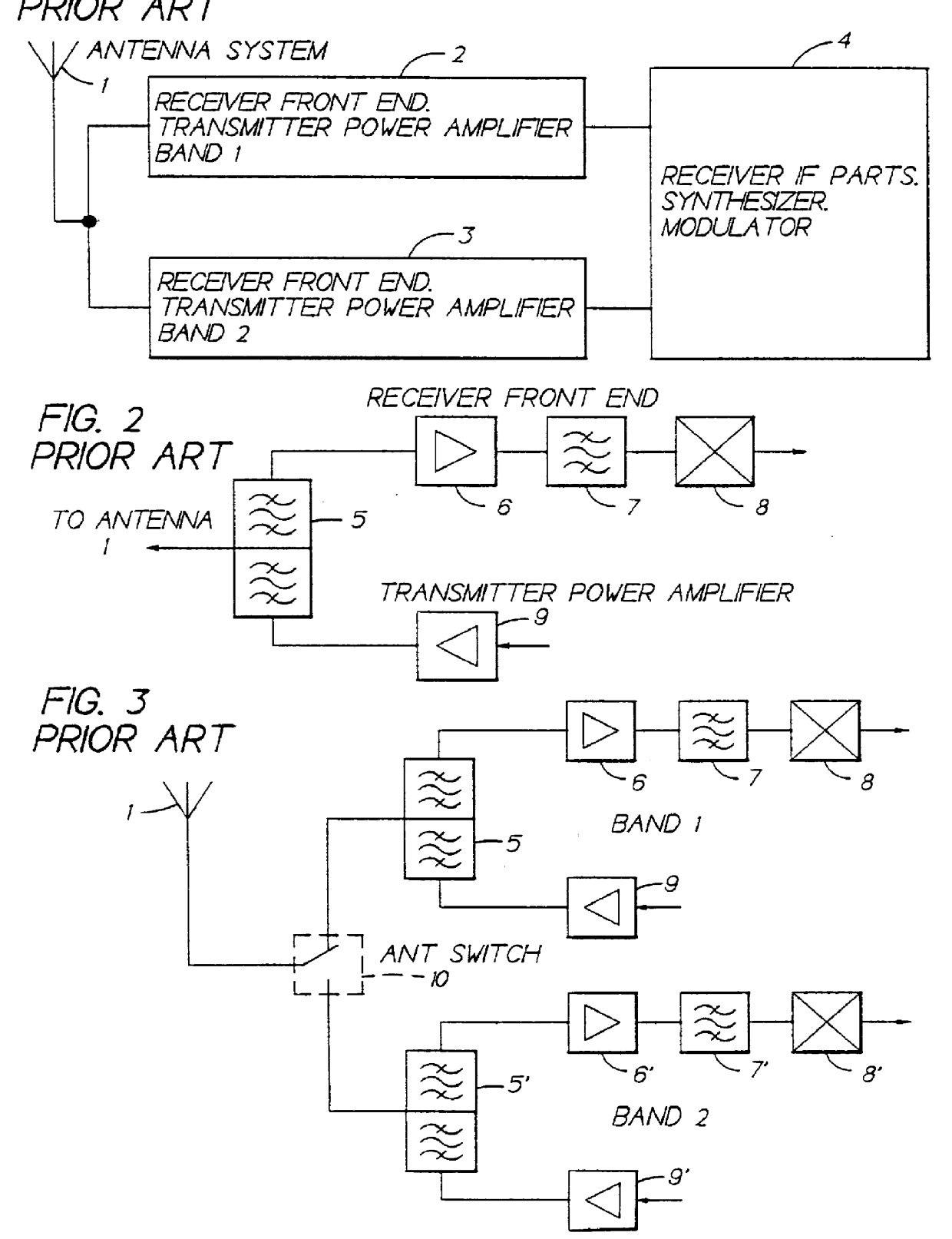

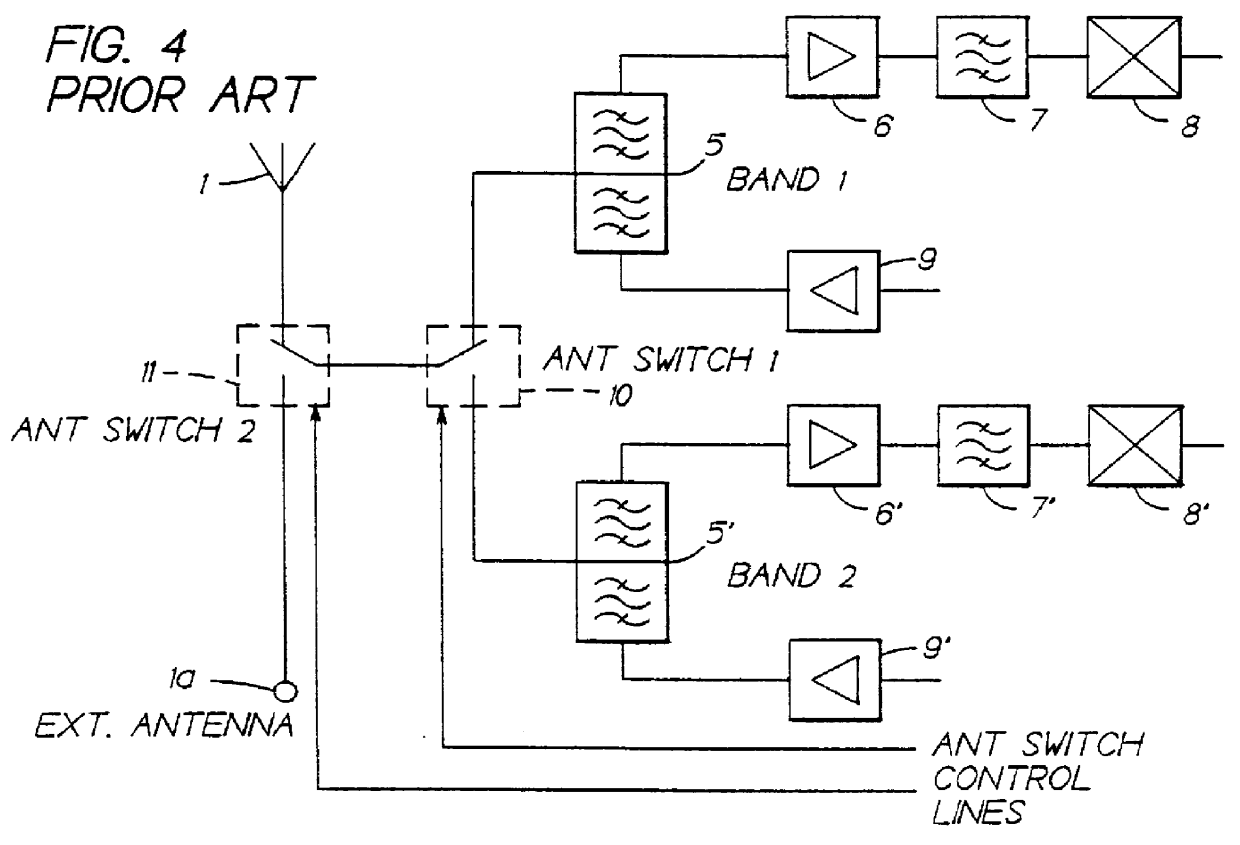

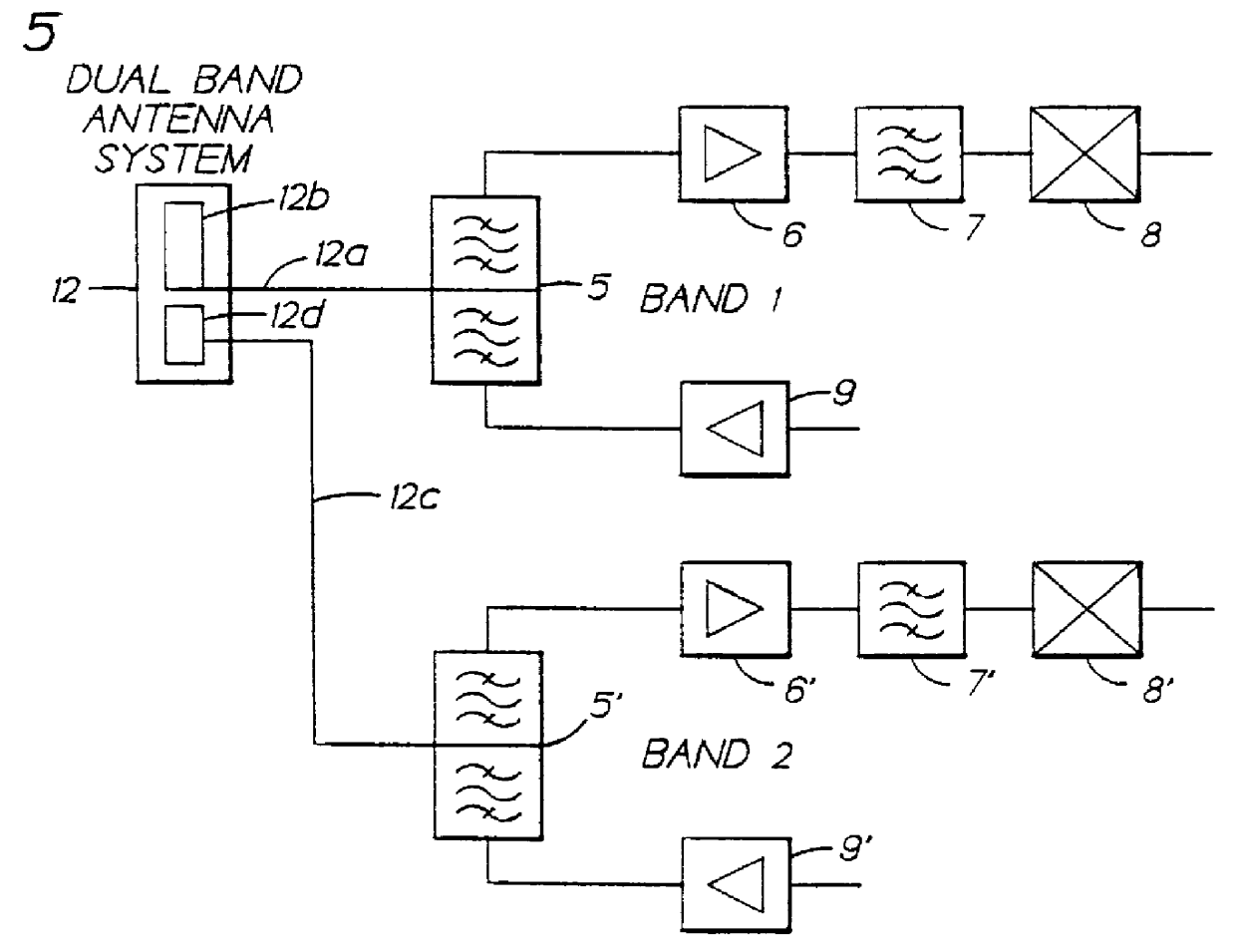

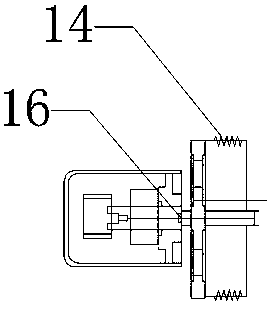

Antenna switching circuits for radio telephones

InactiveUS6115585AEliminate requirementsFunction increaseSimultaneous aerial operationsAntenna supports/mountingsTransceiverEngineering

Disclosed are various embodiments of circuitry for coupling first and second transceivers of a dual band radio telephone to integral and external antennas. The circuitry uses impedance matching lengths of transmission lines and switches arranged to provide a minimum insertion loss. Also disclosed is an embodiment for use with a single band radio telephone, such as a digital TDMA radio telephone that either transmits or receives at any given time. Also disclosed is an antenna switching arrangement for a dual band phone that eliminates a requirement for duplexers.

Owner:NOKIA MOBILE PHONES LTD

Lubricating antistatic high-performance oil for drawing production of carbon fibre

InactiveCN101280475AAvoid defectsReduce frictionMonocomponent synthetic polymer artificial filamentSynthetic polymer filament chemical after-treatmentFiberEpoxy

The invention relates to the chemical materials of the new material field, in particular to a high-performance anti-static lubricating finish oil used in the carbon fiber wire-drawing production process. The composition of the raw materials is calculated with the weight percentage. The quaternary ammonium salt type cationic surfactant of 3 to 10, the polyoxyethylene-polyoxy-propylene-polyether of 1 to 3, the ammonia modified silicone oil of 2 to 8, epoxy-modified silicone oil of 2 to 8, polyether modified silicone oil of 2 to 8, the fluoride silicon oil of 10 to 20, lauric acid polyoxyethylene ester of 1 to 3, laurinol polyoxyethylene of 1 to 3, polyoxyethylene hydrogenerated castor oil of 4 to 20, and the rest of high-purity deionized water are stirred in a reaction kettle for 3 to 5 hours with the temperature controlled within the range of 56 to 60 DEG degree, thus the finish oil product can be produced. The invention is applied in the carbon fiber wiredrawing production process, in which the finish oil is in the formation of a membrane on the monofilament surface, not only the adhesion and merging between the monofilaments can be avoided, but also the friction and wear of the fiber surface and the roller during the production process can be prevented. Therefore, the finish oil has excellent smoothness, antistatic property, collection property and self-emulsifying property as well.

Owner:李元杰

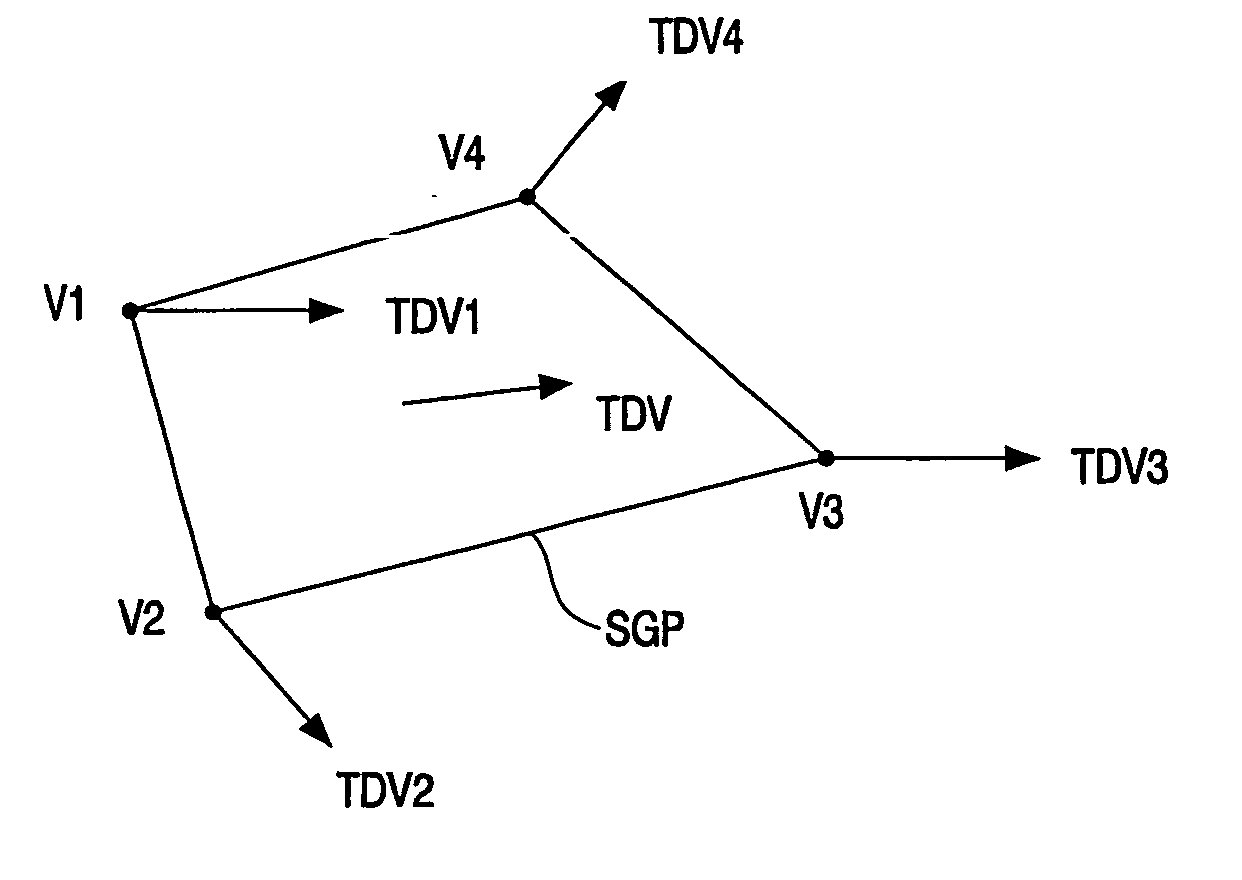

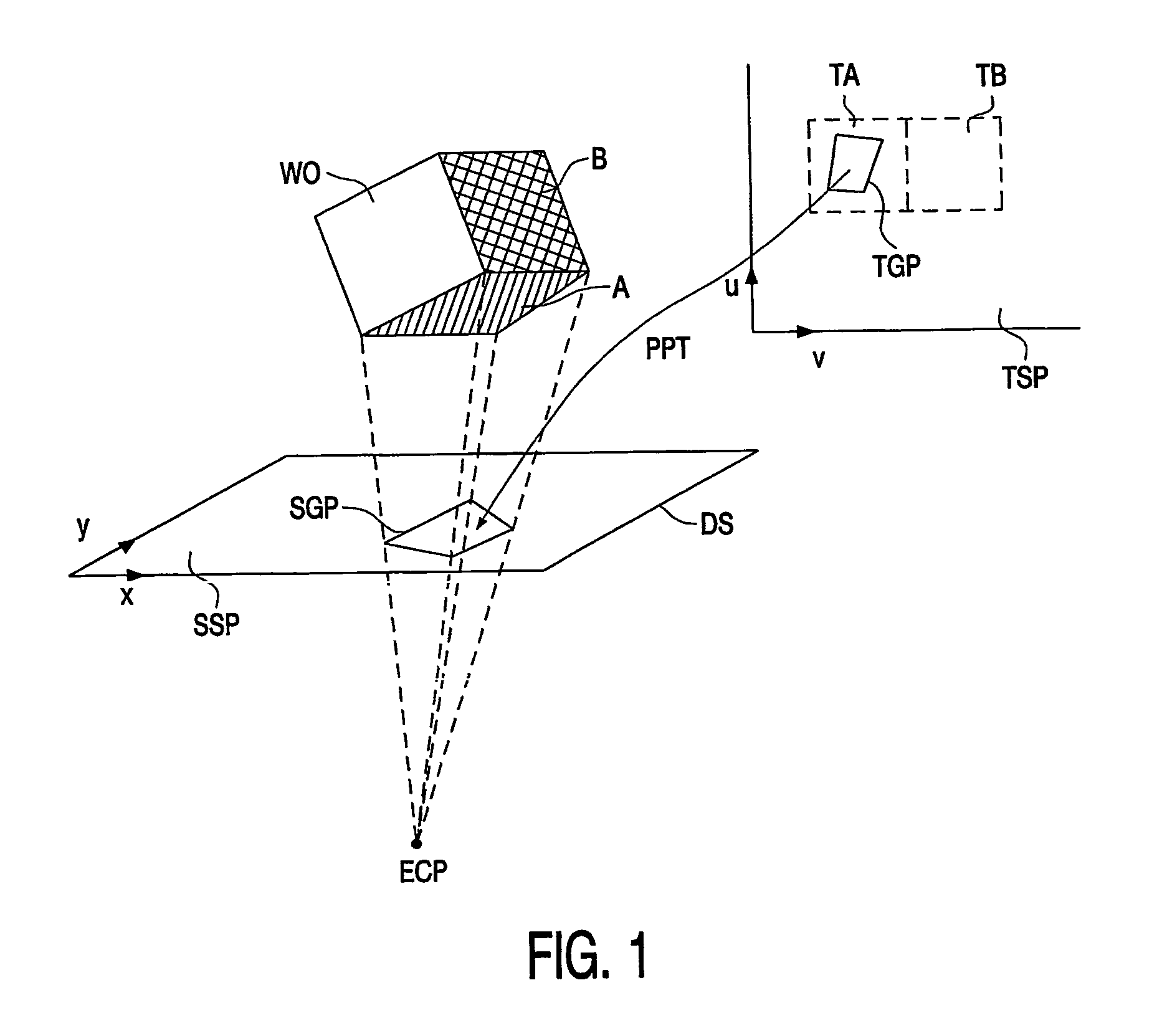

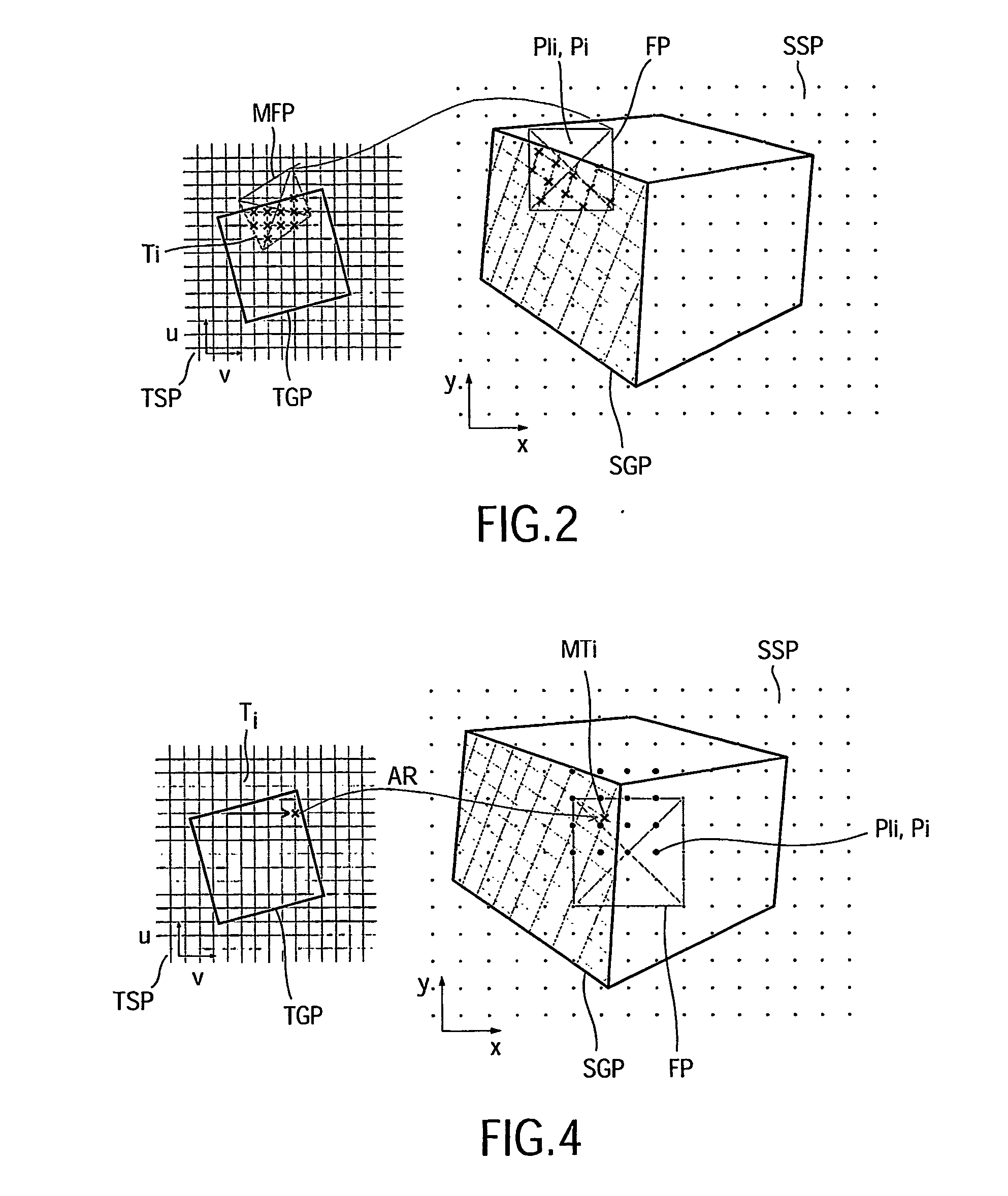

Generation of motion blur

InactiveUS20070120858A1Acceptable motion blurReduce aliasingAnimation3D-image renderingGraphicsGraphic system

In a method of generating motion blur in a 3D-graphics system, geometrical information (GI) defining a shape of a graphics primitive (GP) is received (RSS; RTS) from a 3D-application. A displacement vector (SDV; TDV) defining a direction of motion of the graphics primitive (GP) is also received from the 3D-application or is determined from the geometrical information. The graphics primitive (GP) is sampled (RSS; RTS) in the direction indicated by the displacement vector to obtain input samples (RPi), and an one dimensional spatial filtering (ODF) is performed on the input samples (RPi) to obtain temporal prefiltering.

Owner:NXP BV

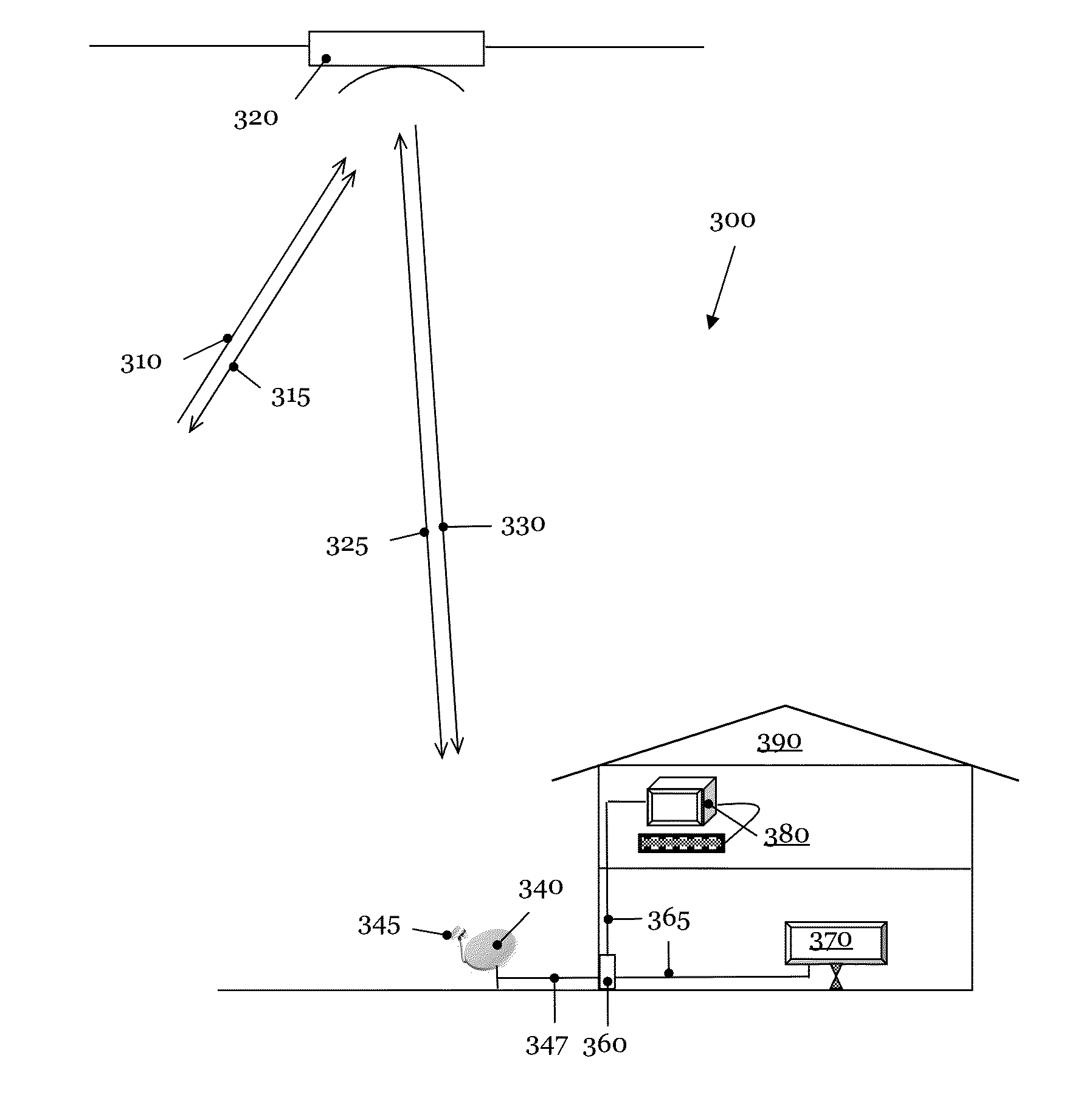

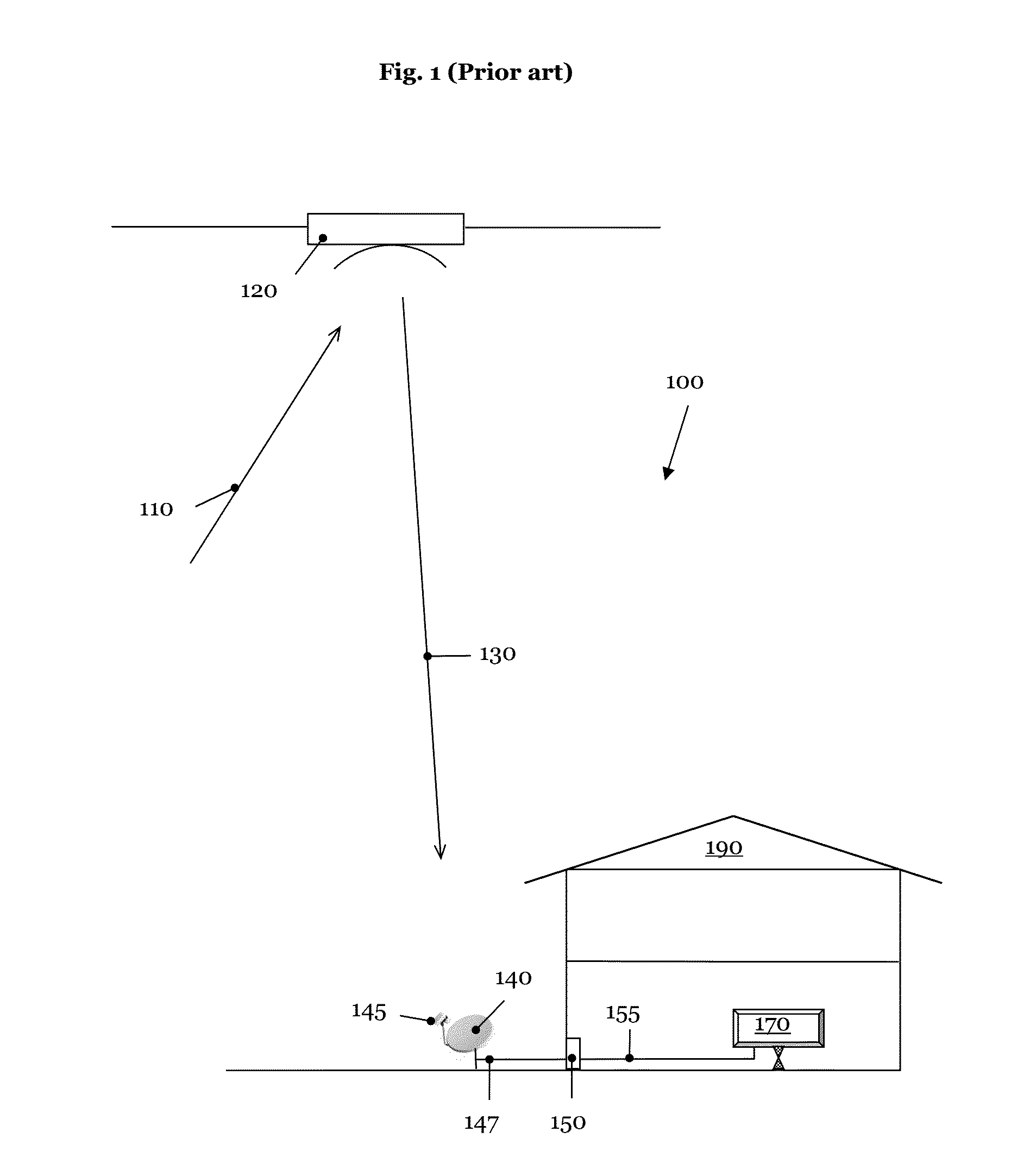

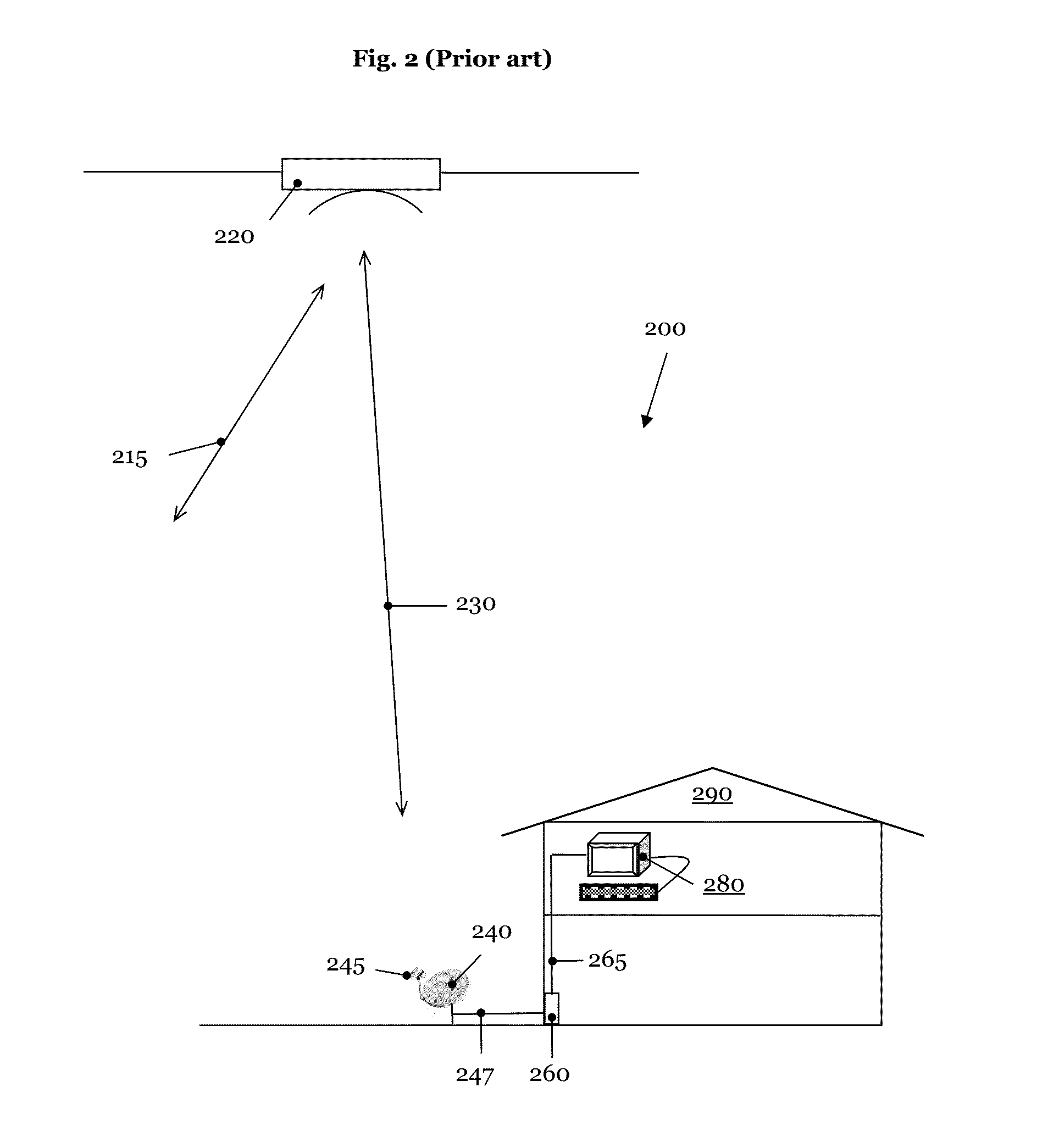

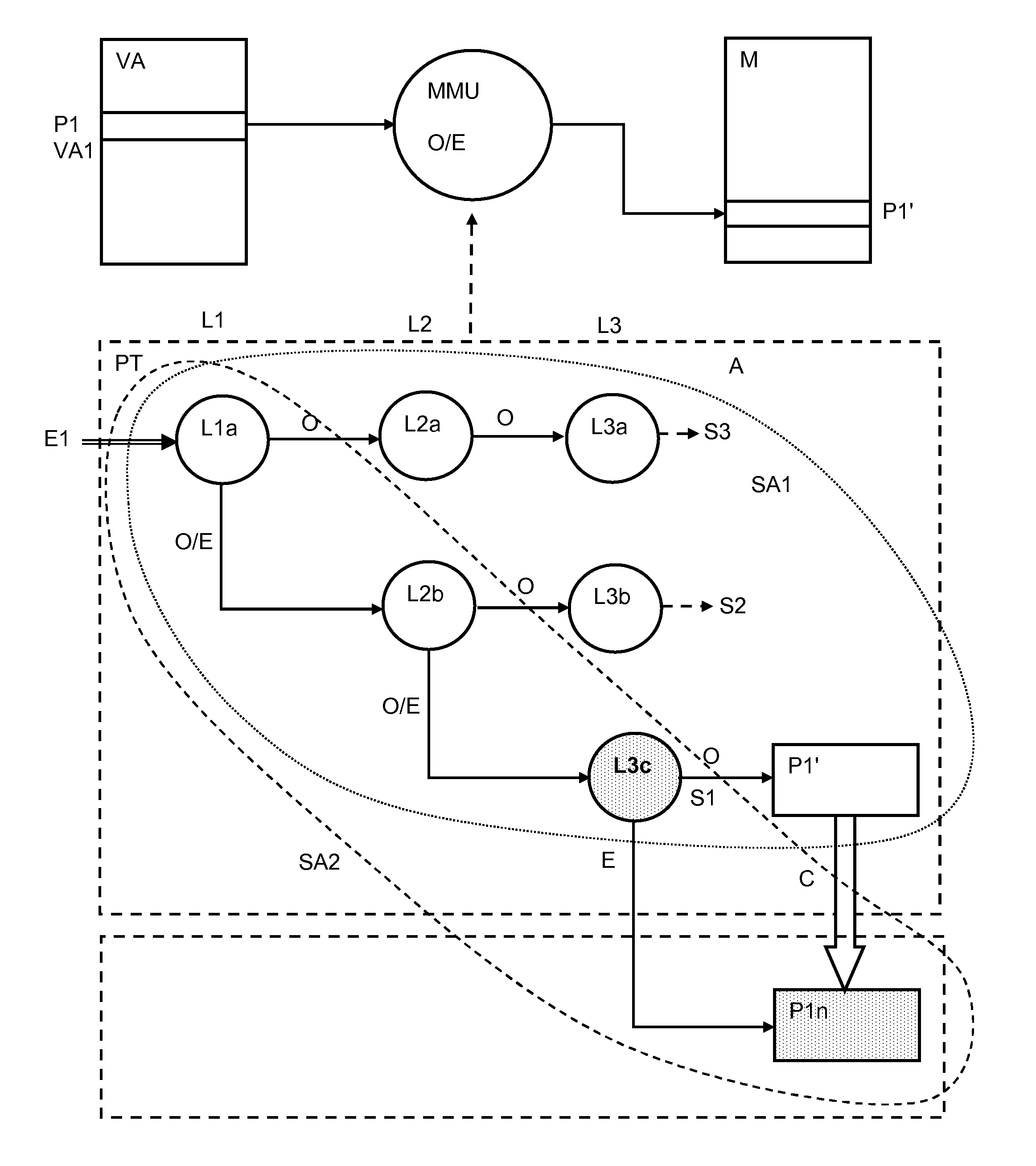

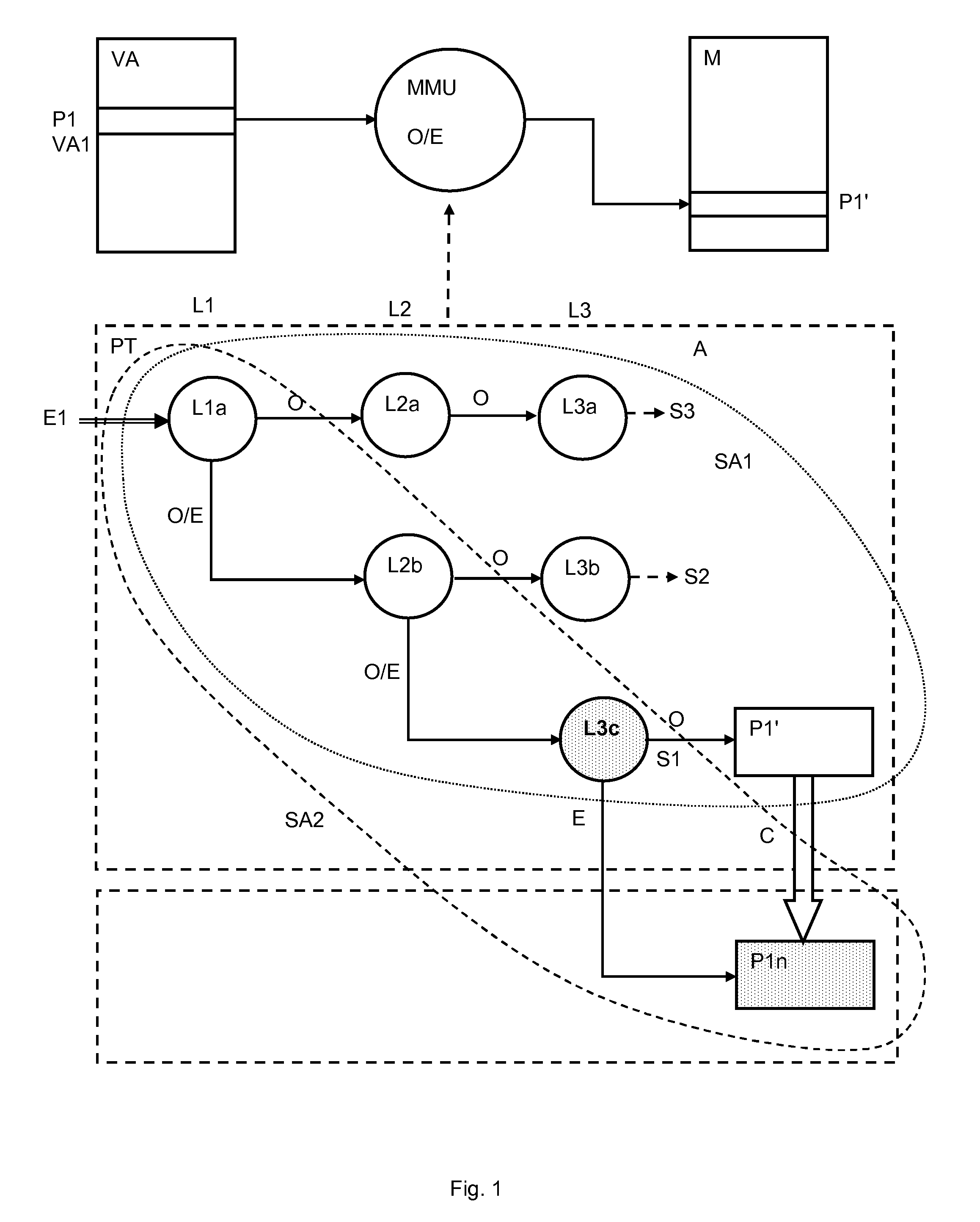

Apparatus and Method for Providing a Joint IP Data-Stream

InactiveUS20150264437A1Uniform data formatAvoid doublingGHz frequency transmissionSelective content distributionDigital dataData stream

The present invention refers to an apparatus for providing at least one joint outgoing IP data stream, the apparatus comprises: (a) at least one receiver adapted to receive a stream of digital TV data, the stream simultaneously containing digital data of a plurality of TV channels, (b) at least one transceiver adapted to receive a downlink stream of IP data and to transmit an uplink stream of IP data via a satellite link, (c) at least one processing unit adapted to convert the digital TV data received from the receiver into a first outgoing IP data stream and to convert the IP data received from the transceiver into a second outgoing IP data stream, and (d) at least one switching unit adapted to combine the first outgoing IP data stream and the second outgoing IP data stream in at least one joint outgoing IP data stream.

Owner:MX1 GMBH

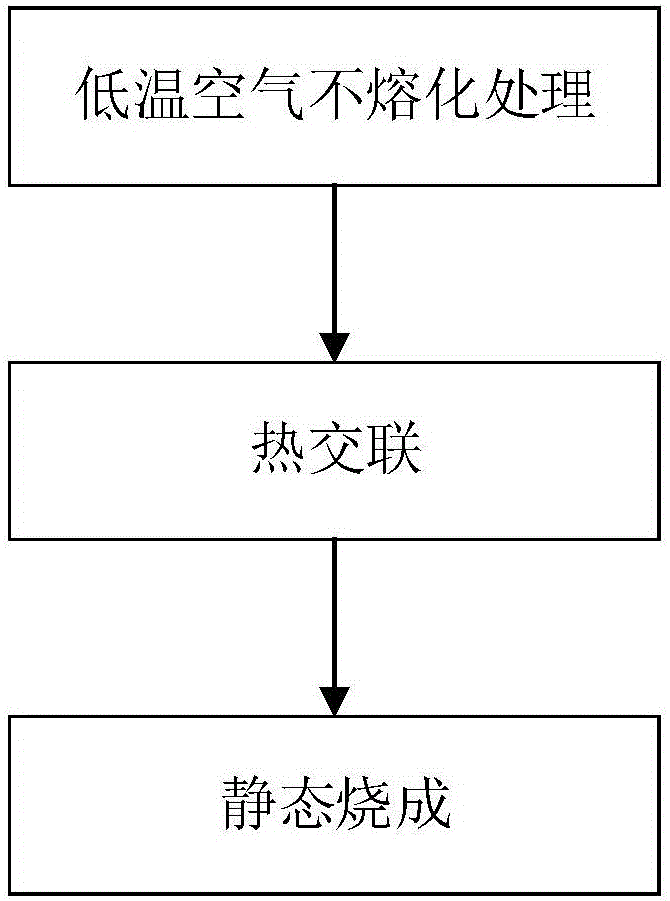

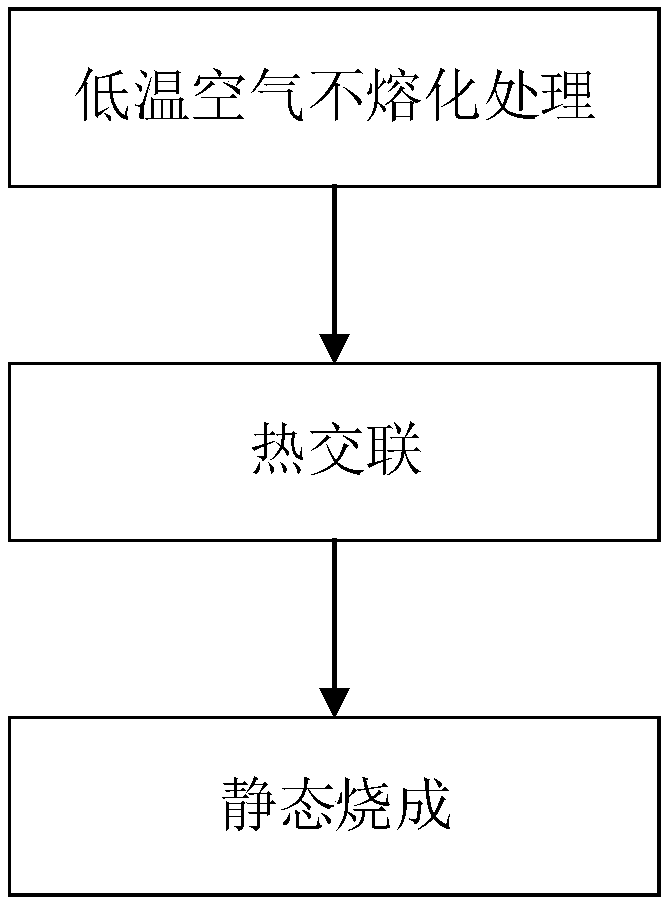

Method using air curing to prepare low-oxygen-content continuous SiC fibers

The invention provides a method using air curing to prepare low-oxygen-content continuous SiC fibers. The method has the advantages that low-temperature air curing and heat crosslinking are used in a combined manner, the heat crosslinking is added after the air curing as compared with a traditional preparation method, the problem of excessively high fiber oxygen content caused by traditional preparation method merely increasing the air curing temperature is avoided, the problem of fiber doubling caused by the direct high-temperature pyrolysis after the low-temperature air curing is also avoided, and the continuous SiC fibers with oxygen content below 10wt% and good performance are prepared.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of high modulus polyethylene fiber

InactiveCN103757735APromote crystallizationCrystallize fastArtificial filament physical treatmentMonocomponent polyolefin artificial filamentLow-density polyethyleneWater baths

The invention provides a preparation method of a high modulus polyethylene fiber. The preparation method is characterized by mixing and swelling 5-10 parts by mass of ultra-high molecular weight polyethylene, 0.5-5 parts by mass of low density polyethylene, 0.01-0.04 part by mass of spinning aid and 100 parts by mass of organic solvent; after a formed polyethylene organic solution is fully dissolved by a double-screw extruder, enabling a gel fiber extruded by a spinneret plate to enter a flash evaporation heating zone heated by water vapor, and carrying out quick flash evaporation on the organic solvent in the gel fiber to form a solid protofilament; after shock cooling of the solid protofilament in a water bath, carrying out hot stretching by heating with water vapor more than 60 times, thus preparing the high modulus polyethylene fiber in a fibrillated net structure. The preparation method has the beneficial effects that a proper amount of low density polyethylene is added, the solid protofilament is subjected to shock cooling in the water bath, and meanwhile, the water vapor is used as a heating and protecting medium to shorten the preparation cycle, thus reducing the production cost and improving the fiber quality.

Owner:JIANGSU SHENTAI SCI & TECH DEV

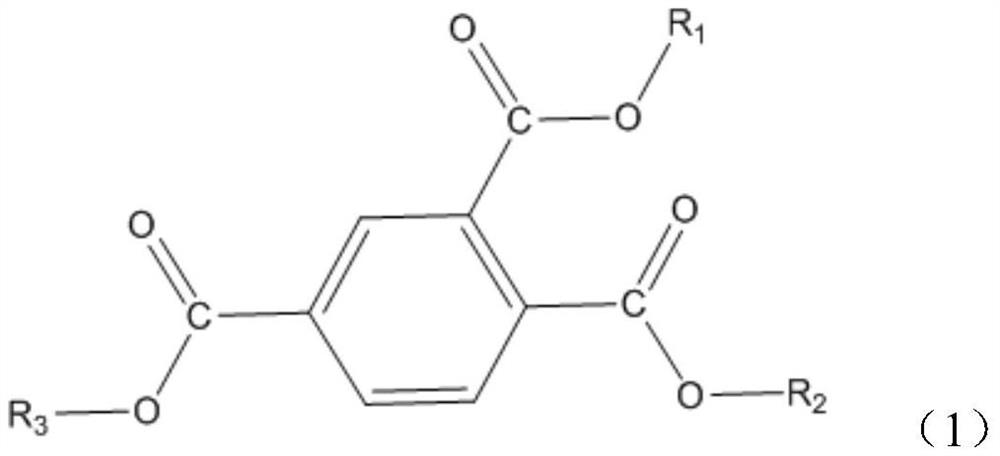

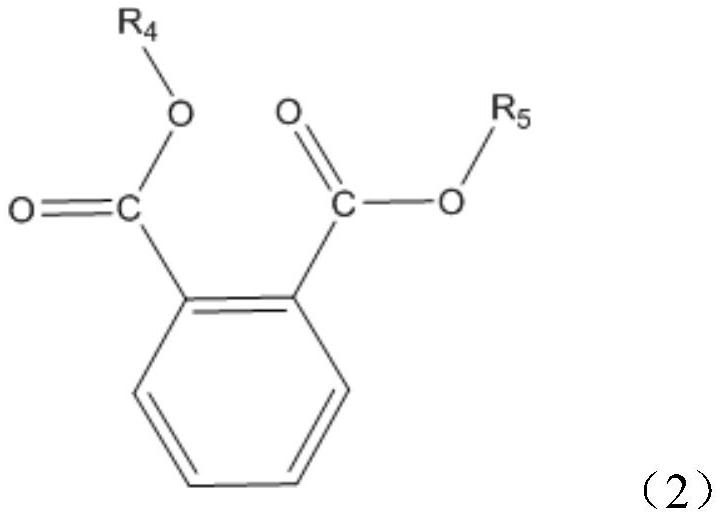

Silicon-free oiling agent for carbon fiber precursor

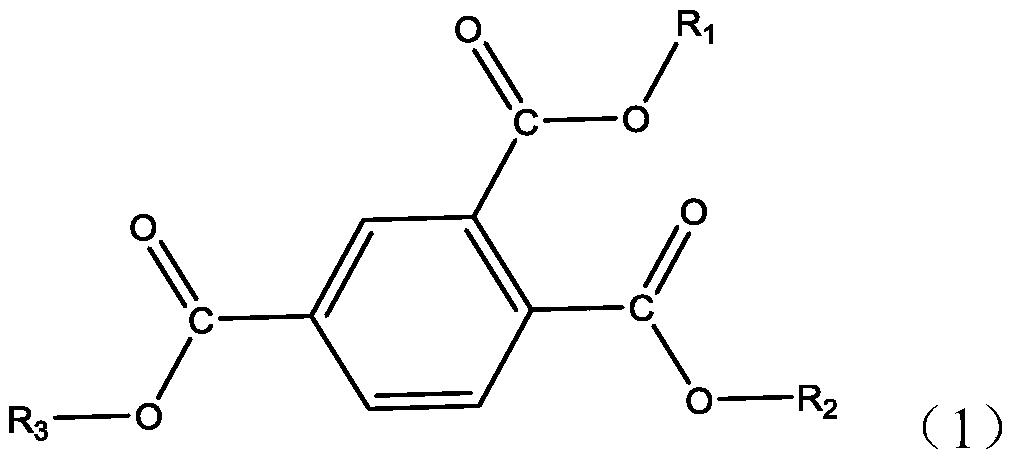

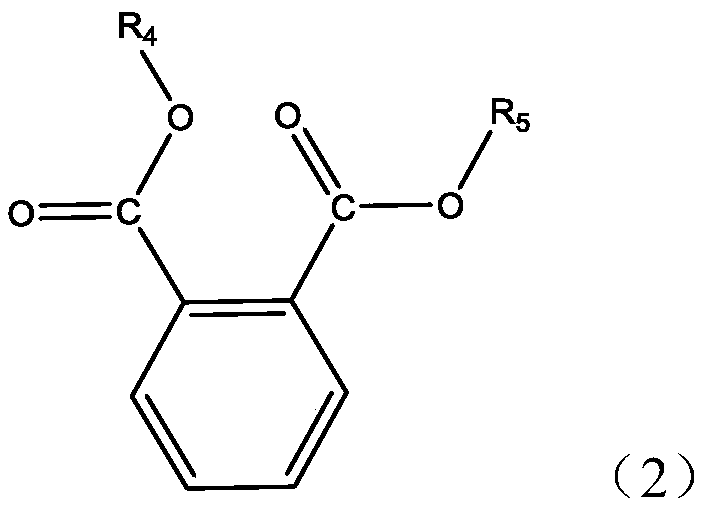

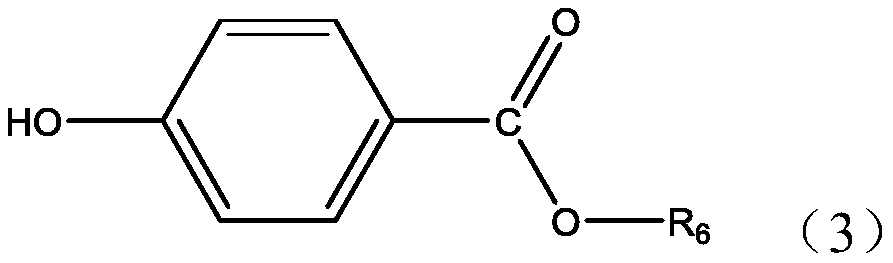

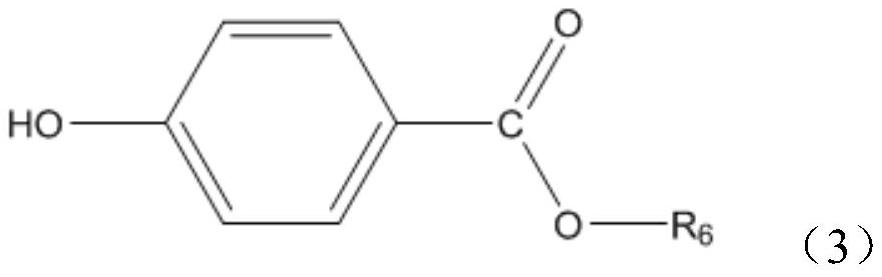

ActiveCN110670350AEnsure uniformity of qualityAvoid softeningFibre typesFibre chemical featuresBenzoic acidPolymer science

The invention discloses a silicon-free oiling agent for carbon fiber precursor. The silicon-free oiling agent comprises an aqueous emulsion prepared by dispersing aromatic ester compounds, aromatic polyoxyethylene ether and amine compounds, by the mass ratio of (50-80):(10-35):(1-5), in water; the aromatic ester compounds include one or more of benzene tricarboxylic acid esters, benzene dioctyl phthalate esters, hydroxy-benzoate esters and bisphenol ethoxide high-grade fatty acid esters; aromatic polyoxyethylene ether includes one or more of alkylphenol polyoxyethylene and bisphenol-A polyoxyethylene ether; the amine compounds include one or more of lauramide ethoxide, aliphatic long-chain quaternary ammonium; the survival rate of mass of the aromatic ester compounds is 80-98% at the temperature of 300 DEG C in the atmosphere of air, and the mass ratio of the aromatic ester compounds in involatile components of the oiling agent is 50-80%. Roll banding degree of the precursor in production can be reduced effectively, doubling and adhering of PAN filaments in the pre-oxidation process can be avoided, and the silicon-free oiling agent has certain hydrophilicity and heat resistance.

Owner:HENGSHEN

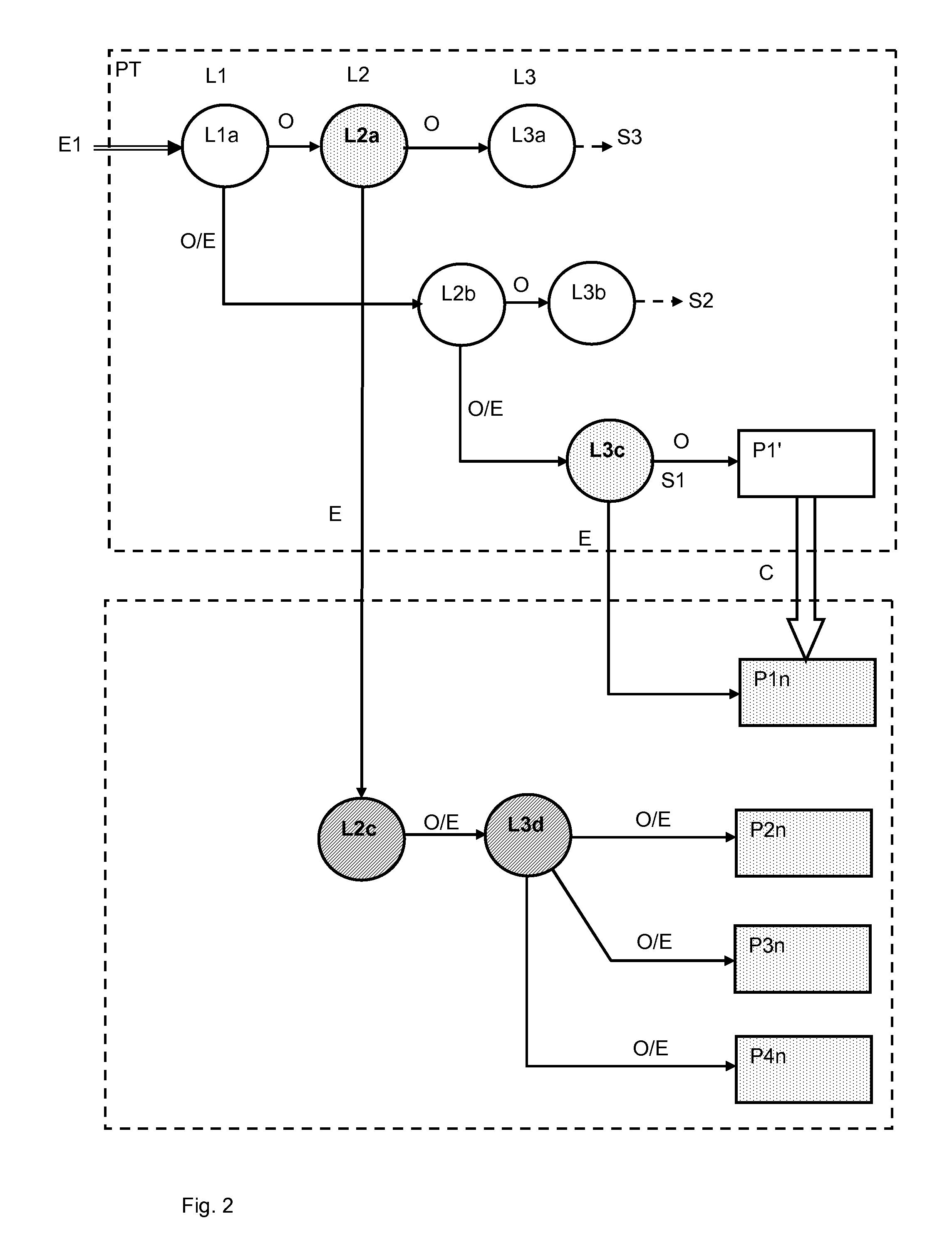

Method for updating data in memories using a memory management unit

InactiveUS8484435B2Reliably carry-outPrevent stateSoftware engineeringMemory adressing/allocation/relocationManagement unitStructure of Management Information

A method for updating, in the background, data stored in physical memories without affecting the current operations performed by the microprocessor. When the update is completely terminated, the application switches from an old version to a new version. This switching occurs by a reconfiguration of the page table during which a first sub-tree structure of pointers accessing the old version of data stored in memories is replaced by a second sub-tree structure of pointers thus allowing access to the new version of data. This update method prevents incoherent transitory states of the system as the latter works with the previous data version until the installation of the new version becomes usable. In the case of an interruption to the update process, the application can always reinitialize the update since the old version of data can be reactivated by returning to the previous configuration of the page table.

Owner:NAGRAVISION SA

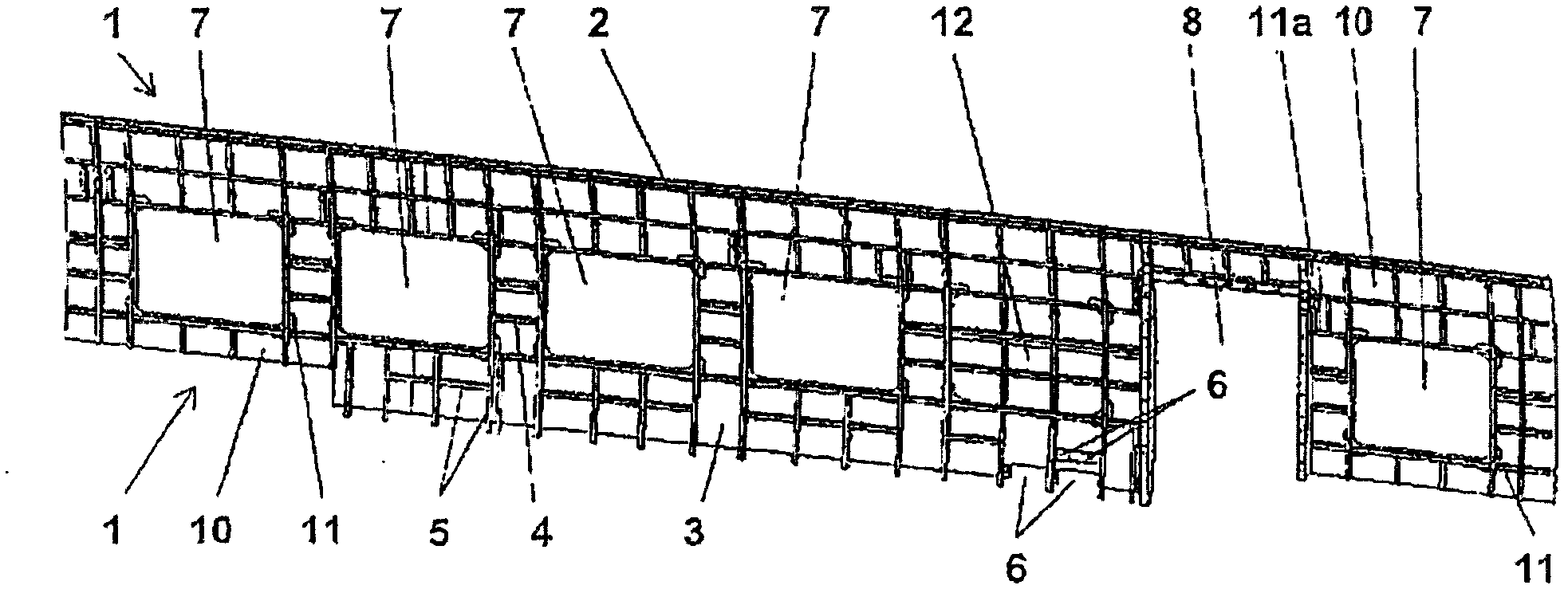

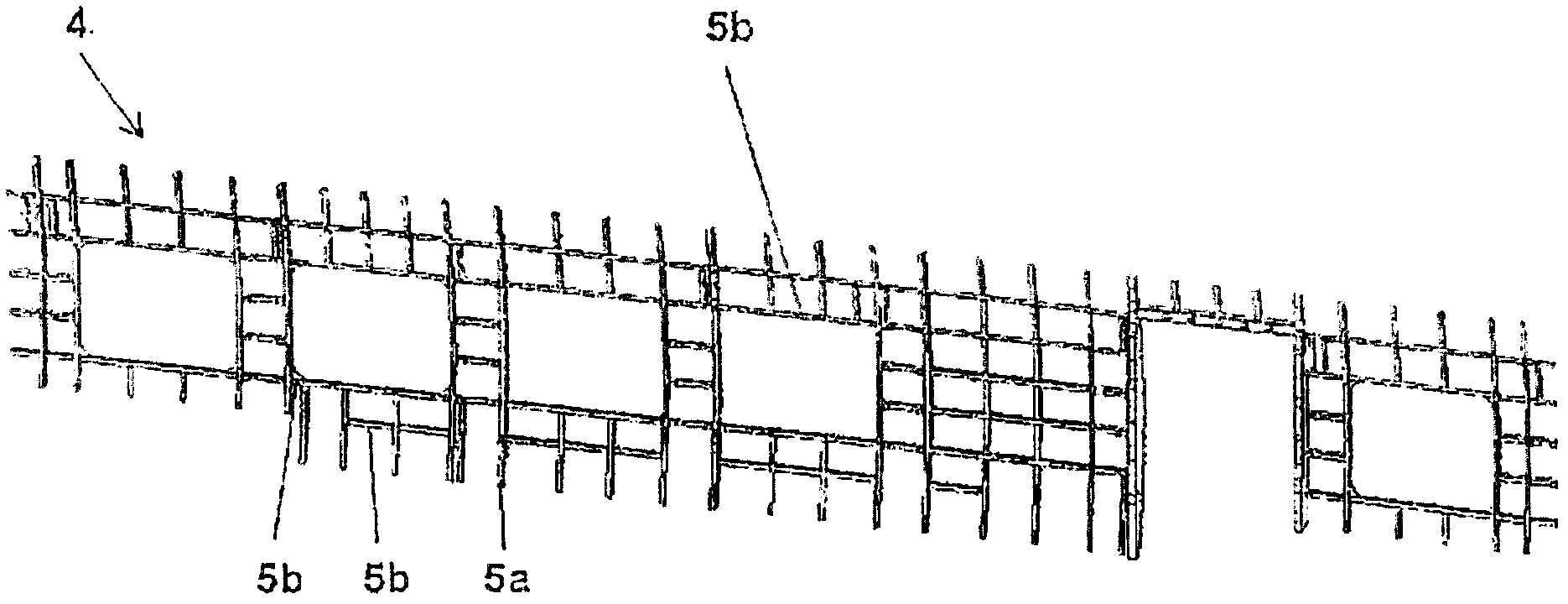

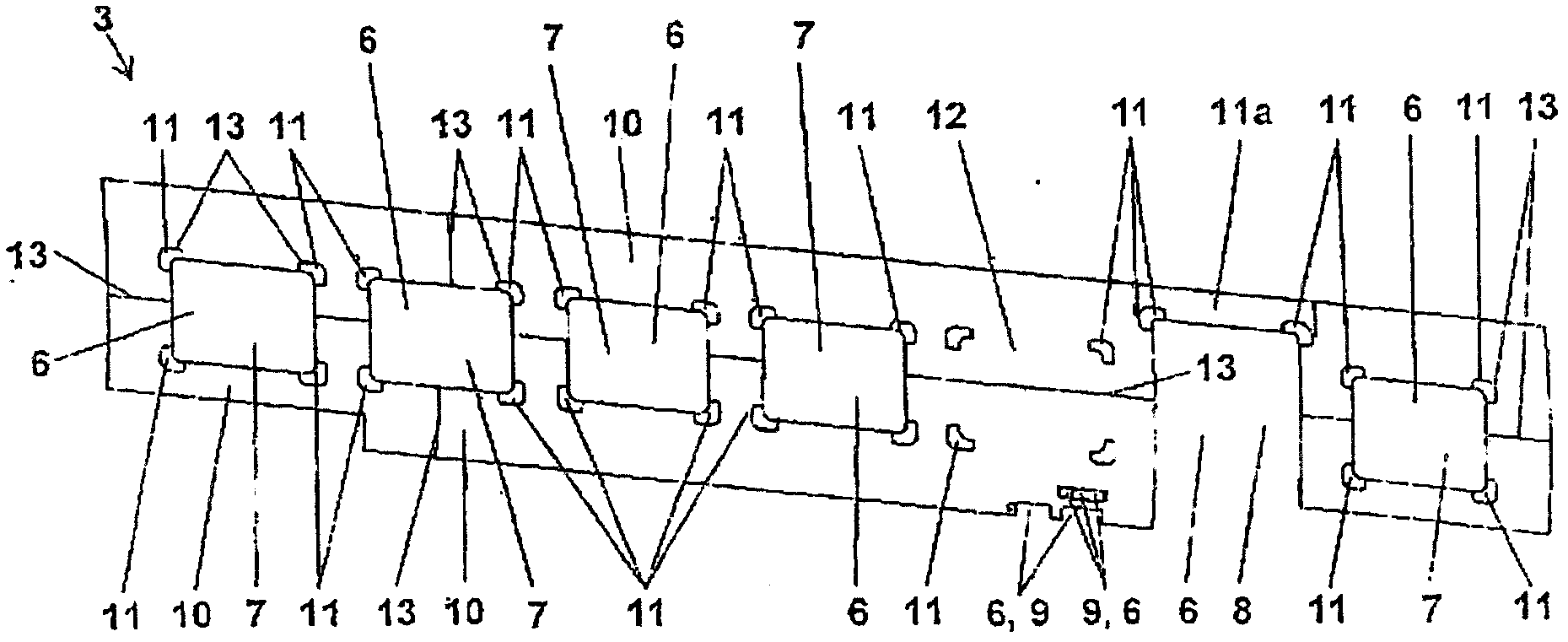

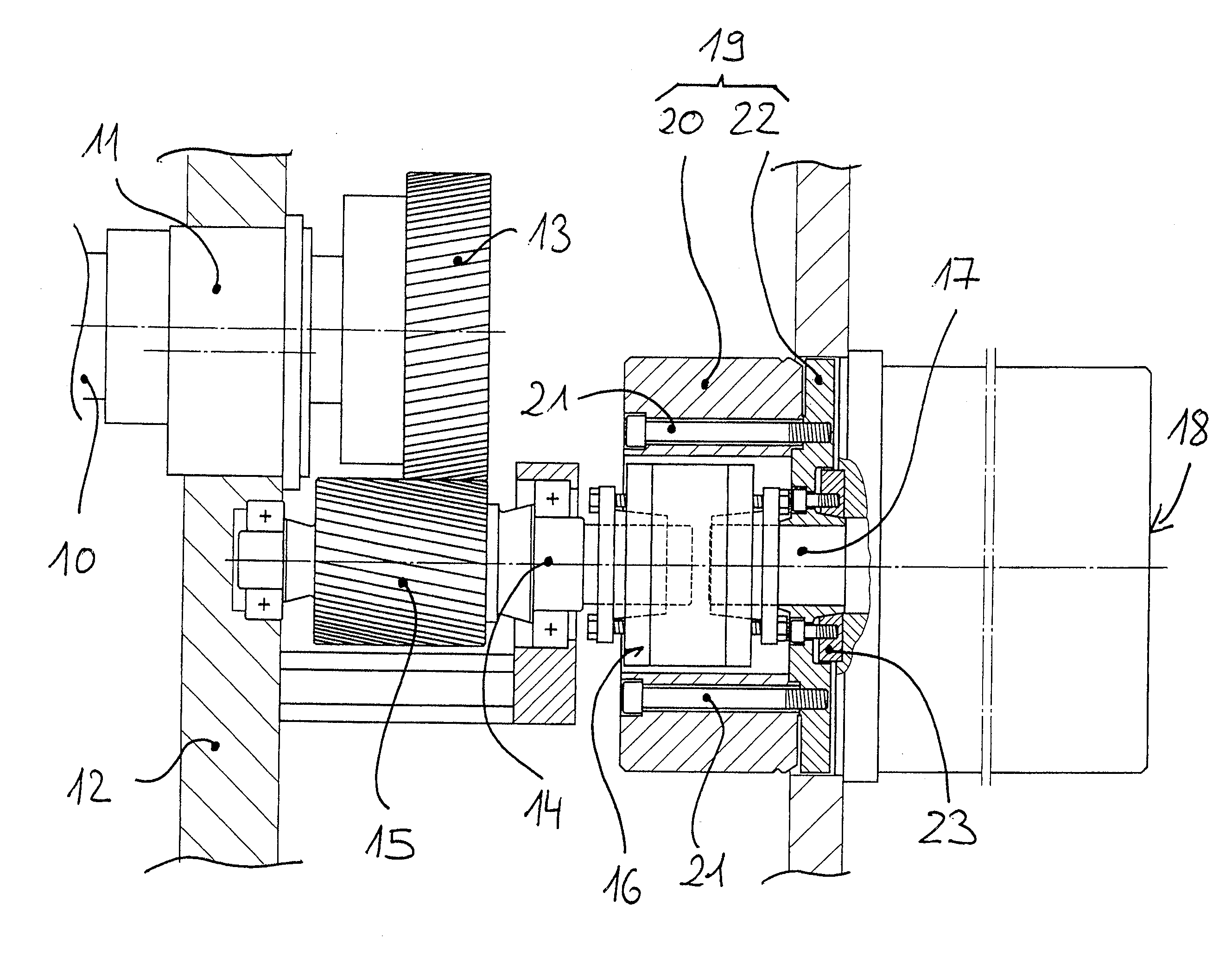

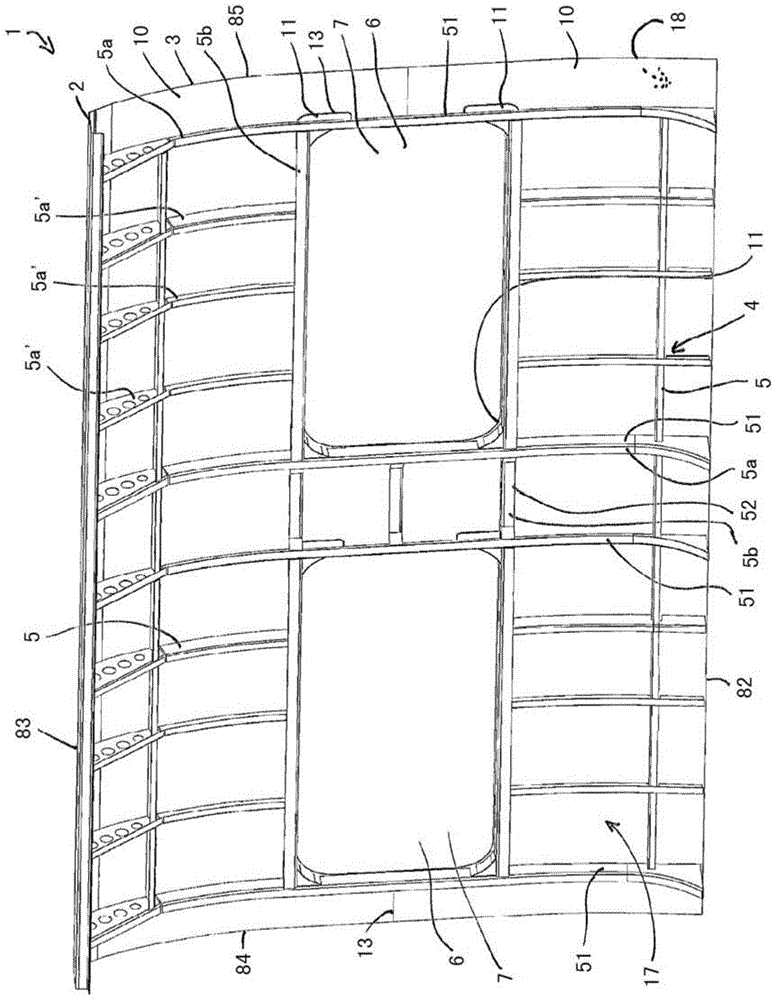

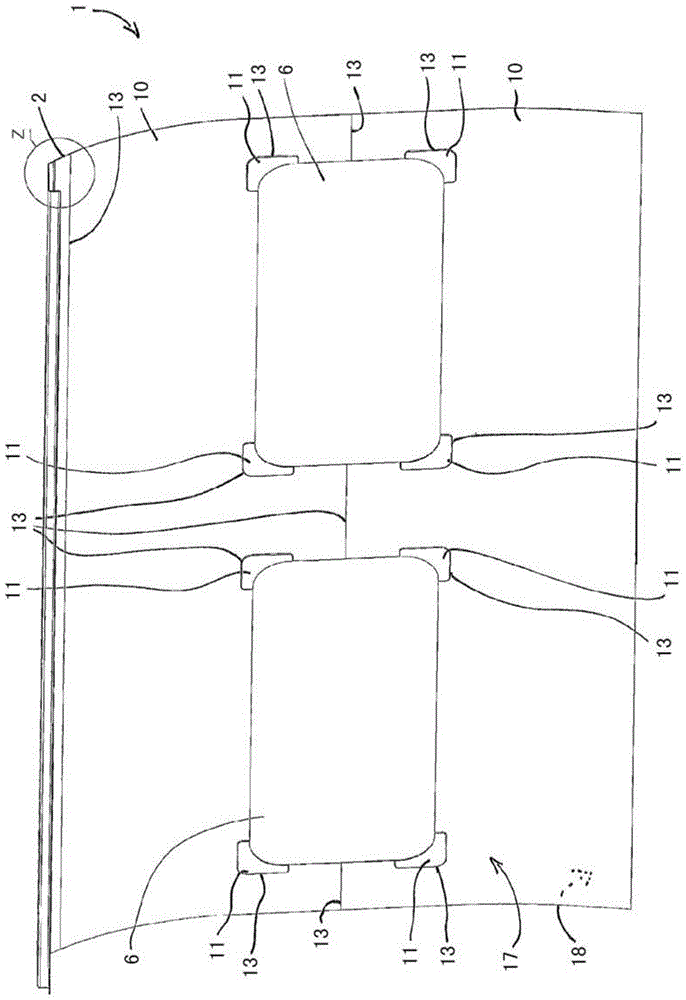

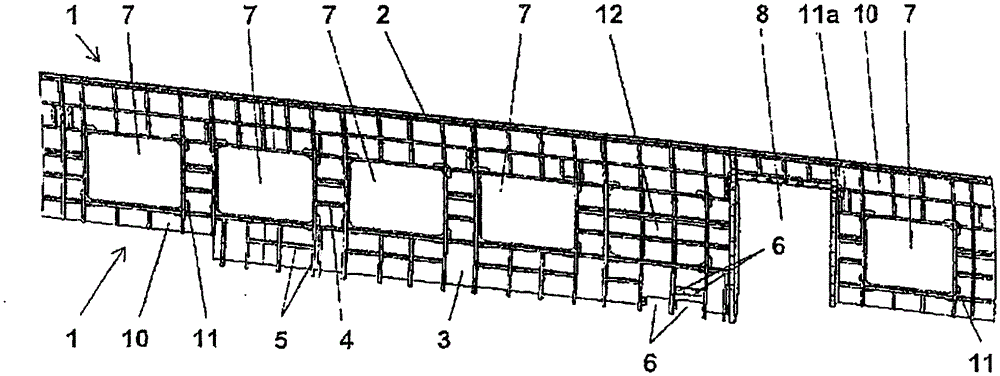

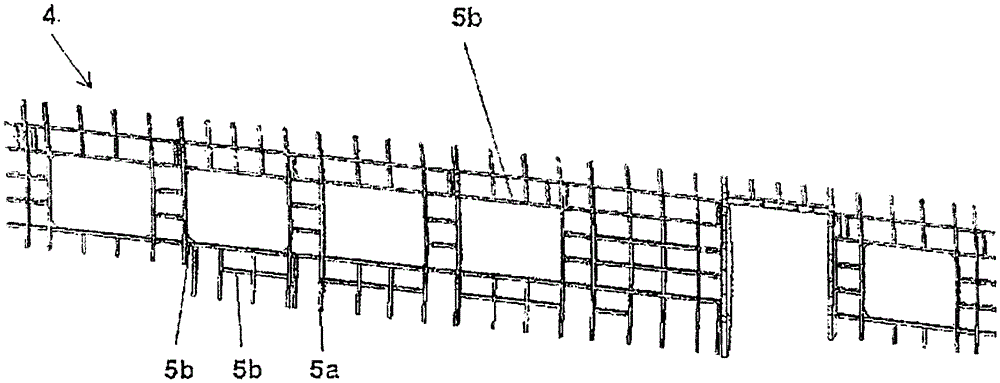

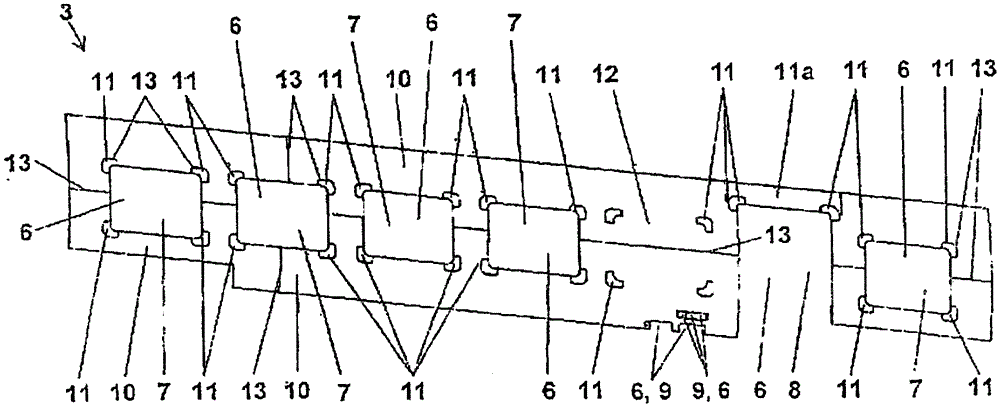

Outer wall for a railway vehicle body and method for producing same

ActiveCN103025596AHigh susceptibilityAvoid doublingRailway transportAxle-box lubricationEngineeringUltimate tensile strength

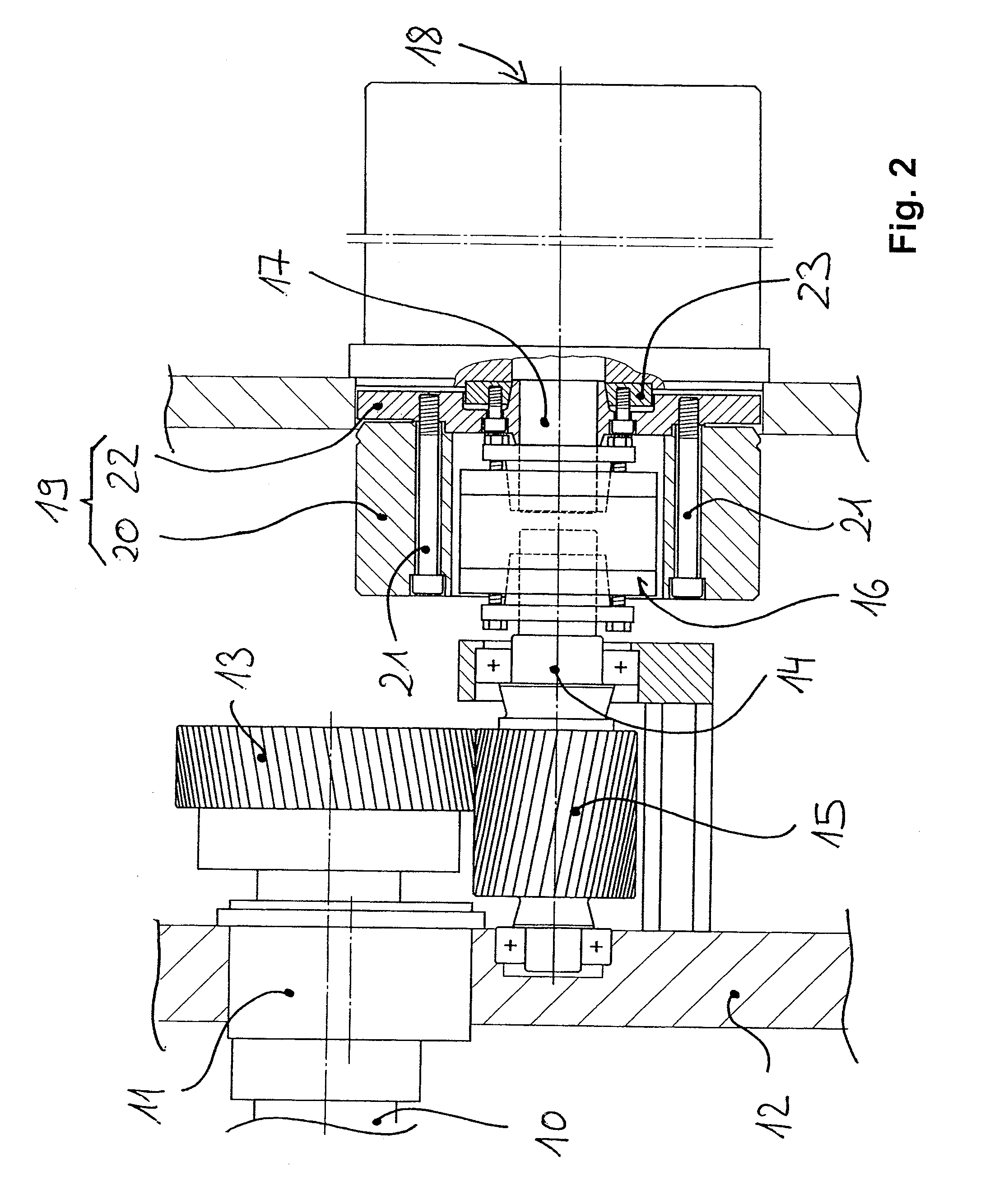

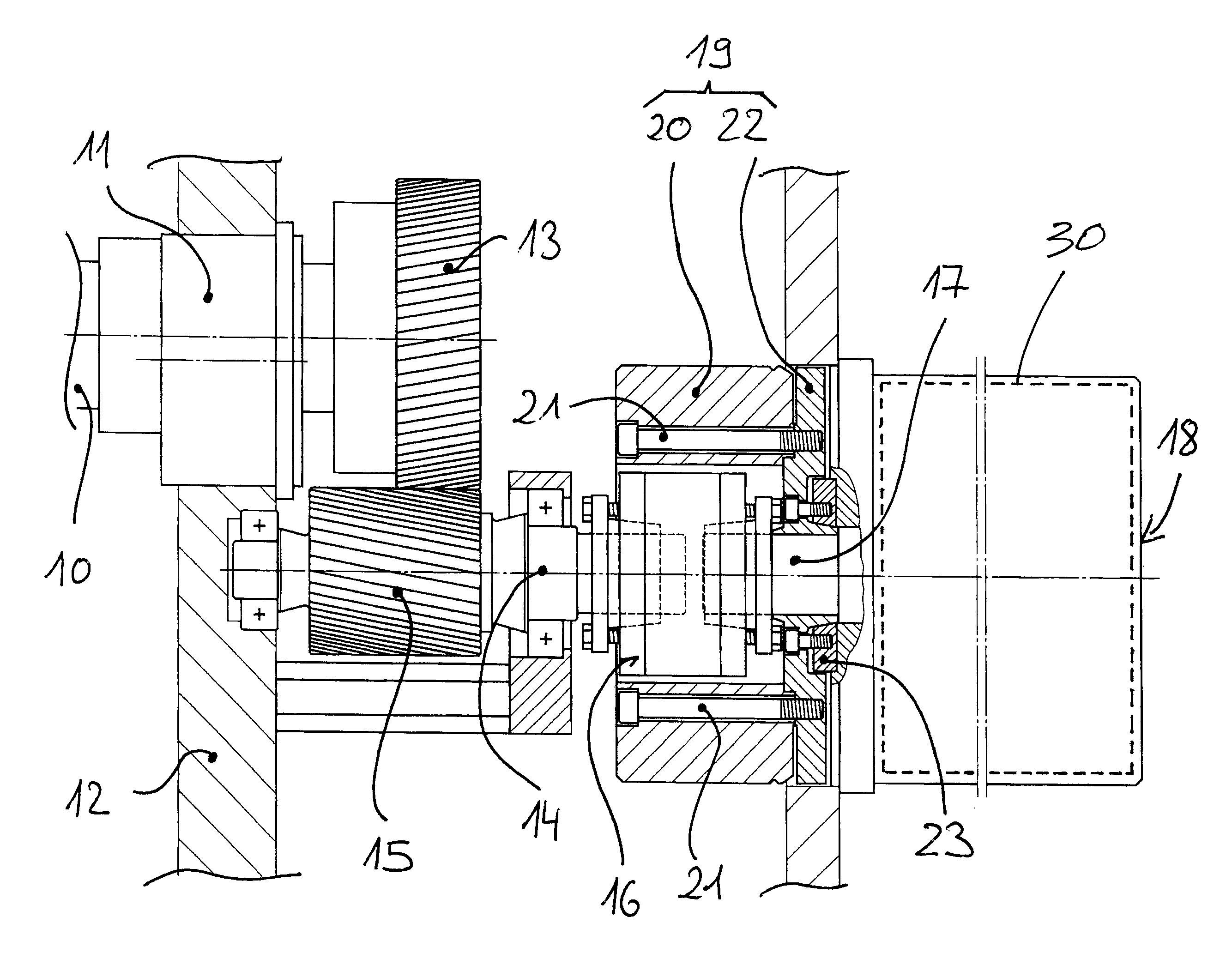

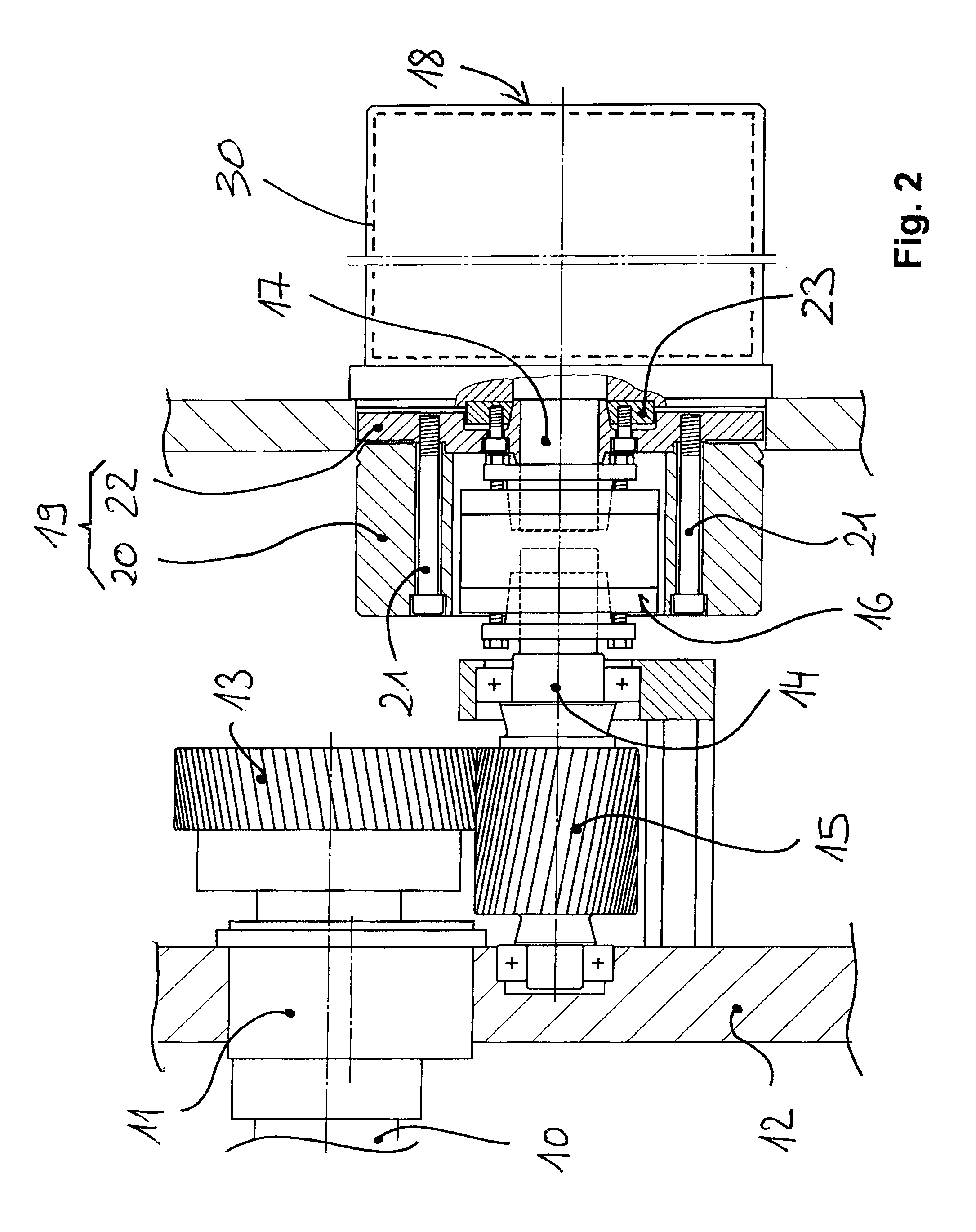

The invention relates to a method for producing an outer wall module or an outer wall (1) or a coach body of a railway vehicle, and to an outer wall, an outer wall module, and a coach body of a railway vehicle. The following steps are provided for producing an outer wall (1) or an outer wall module: assembling 2-dimensional sheet metal parts (10, 11) having different properties (15, 16) into an outer sheet metal shell (3) designed as a self-supporting thrust area module, wherein the end faces of the sheet metal parts (10, 11) are each oriented transverse to the 2-dimensional extension of the individual sheet metal parts (10, 11) abut one another and are assembled by penetrating laser weld seams (13) in such a manner that the individual sheet metal parts (10, 11) form a flush outer surface (17) on an outer face of the thrust area module, wherein the sheet metal parts (10, 11) having different properties (15, 16) comprise first sheet metal parts (10) and second sheet metal parts (11), and the second sheet metal parts (11) each comprise a greater resistance, in particular strength and / or greater material thickness (15) than the first sheet metal parts (10), and the second sheet metal parts (11) are inserted in regions of the outer sheet metal shell (3) at which increased stresses occur during operation of the railway vehicle in a coach body produced from the outer wall module or the outer wall (1), and a structure (4) is created from rib profiles (5, 5a, 5b), wherein end face butt edges (19, 20, 21) of the rib profiles (5, 5a, 5b) adjoin the inner face (17) of the outer sheet metal shell (3) by means of T-joints, and are fastened to the outer sheet metal shell (3) by means of laser weld seams (13).

Owner:BOMBARDIER TRANSPORTATION GMBH

PAN-based carbon fiber precursor oiling agent and preparation method thereof

PendingCN112796009ALower fried shredsEvenly distributedArtificial filament chemical after-treatmentEpoxyFiber

The invention relates to the technical field of spinning oil agents, in particular to a PAN-based carbon fiber precursor oil agent and a preparation method thereof. The PAN-based carbon fiber precursor oiling agent is prepared from the following components in percentage by mass of 5%-50% of amino and epoxy group modified organic silicon emulsion, 5%-35% of polyether modified organic silicon emulsion, 0.5%-10% of quaternary ammonium salt, 0.1%-5% of a wetting agent and deionized water. During preparation, the amino and epoxy group modified organic silicon emulsion and the polyether modified organic silicon emulsion are added into a variable-speed mixer according to the proportion and stirred uniformly, then the quaternary ammonium salt is added according to the proportion and stirred, finally the wetting agent and the deionized water are slowly added according to the proportion, and the materials are stirred uniformly and sub-packaged. The PAN-based carbon fiber precursor oiling agent is good in quality stability and heat resistance, adhesion and doubling of PAN precursors in the pre-oxidation process can be effectively prevented, pore defects in the high-temperature carbonization process are reduced, and the amount of broken filaments is reduced.

Owner:上海氟聚化学产品股份有限公司

Printing Unit

ActiveUS20100107913A1Improve control qualityImprove printing qualityRotary letterpress machinesRotary lithographic machinesDrive motorFlywheel

A printing unit of a printing press, such as a web press constructed as a periodical printing press, having at least one printing couple, wherein the printing couple or each printing couple comprises a form cylinder, a transfer cylinder, an inking unit, and preferably a dampening unit. A drive motor is associated with at least one printing couple, and drives the form cylinder or the transfer cylinder of a respective printing couple. In accordance with the invention, a flywheel mass is associated with at least one drive motor which drives the form cylinder or the transfer cylinder of the respective printing couple, where the flywheel mass is connected to the rotor of the respective drive motor in a torsionally rigid manner.

Owner:MANROLAND WEB SYST

Printing unit

ActiveUS8418610B2Quality is easy to controlImprove printing qualityRotary letterpress machinesRotary lithographic machinesDrive motorPrinting press

Owner:MANROLAND WEB SYST

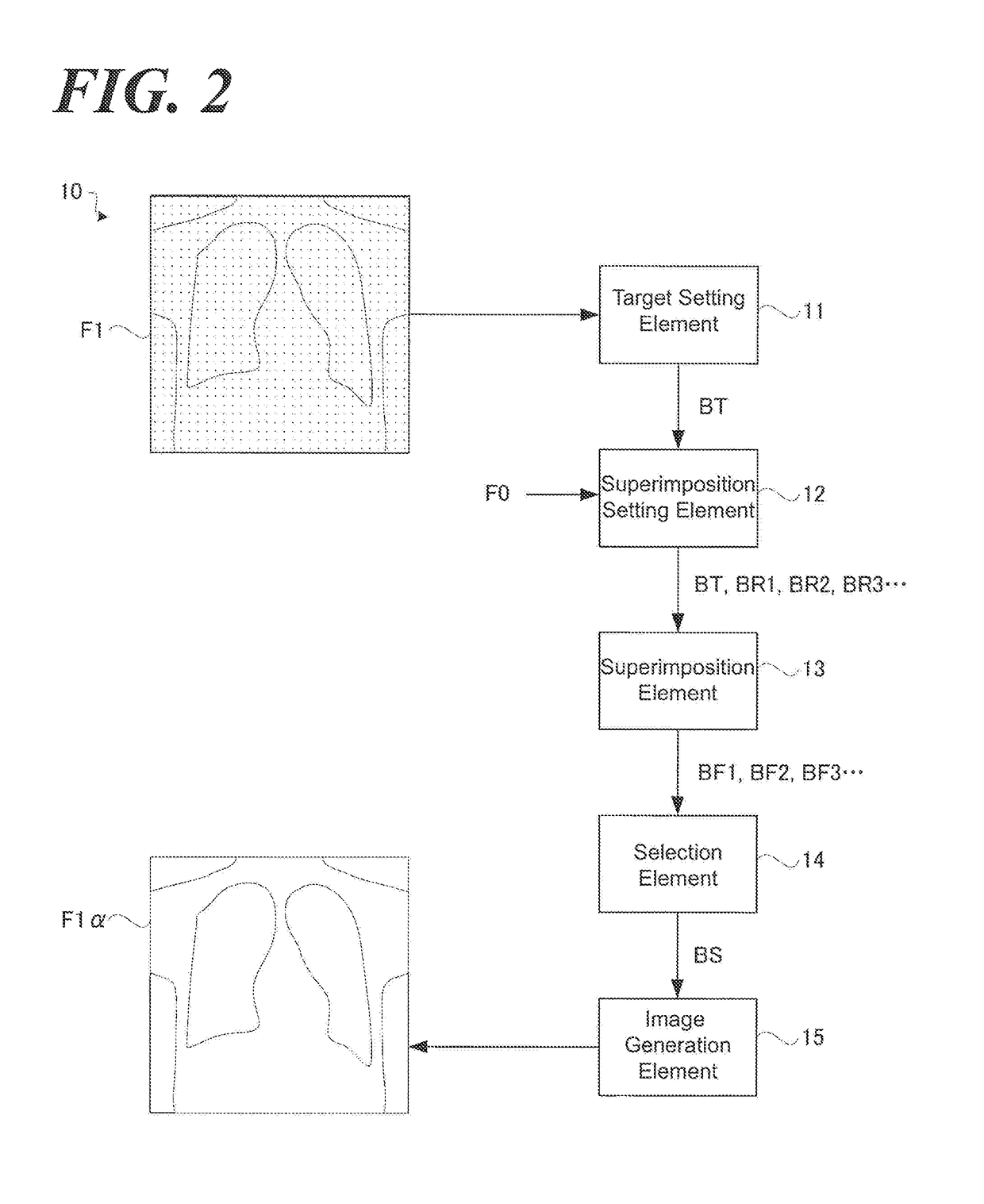

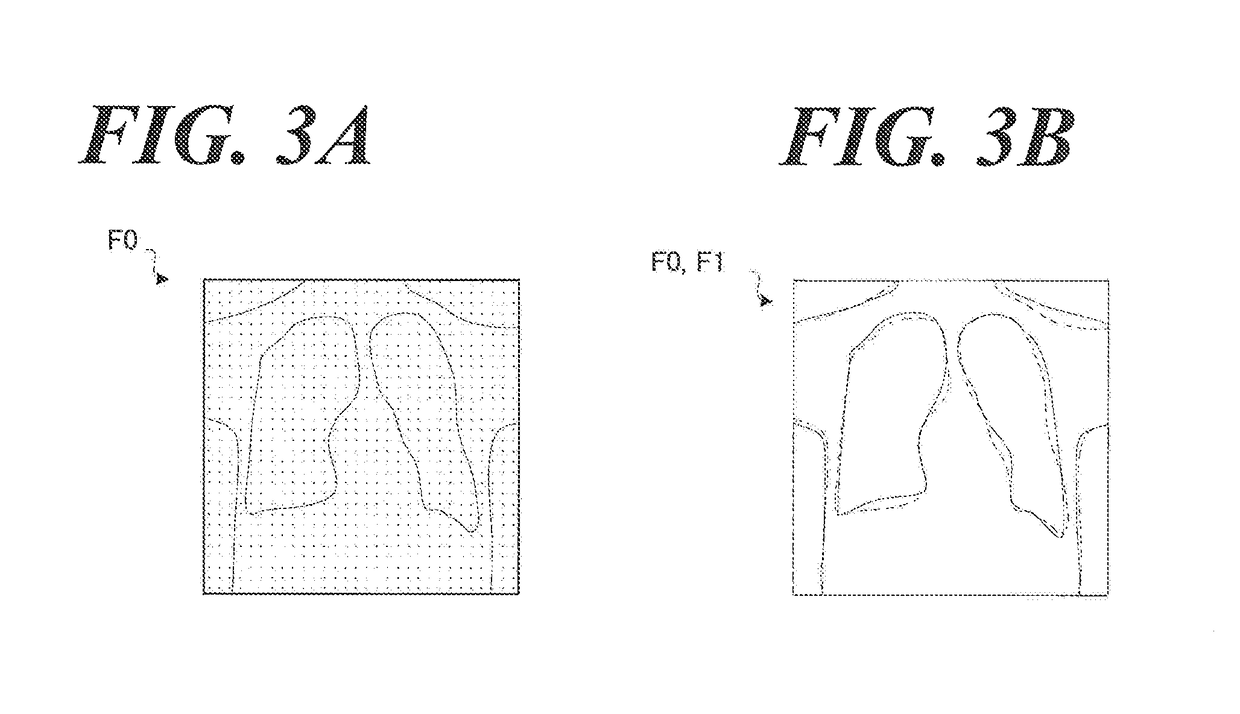

Image processing device

ActiveUS20180270401A1Reduce noiseCancel noiseTelevision system detailsImage enhancementImaging processingComputer science

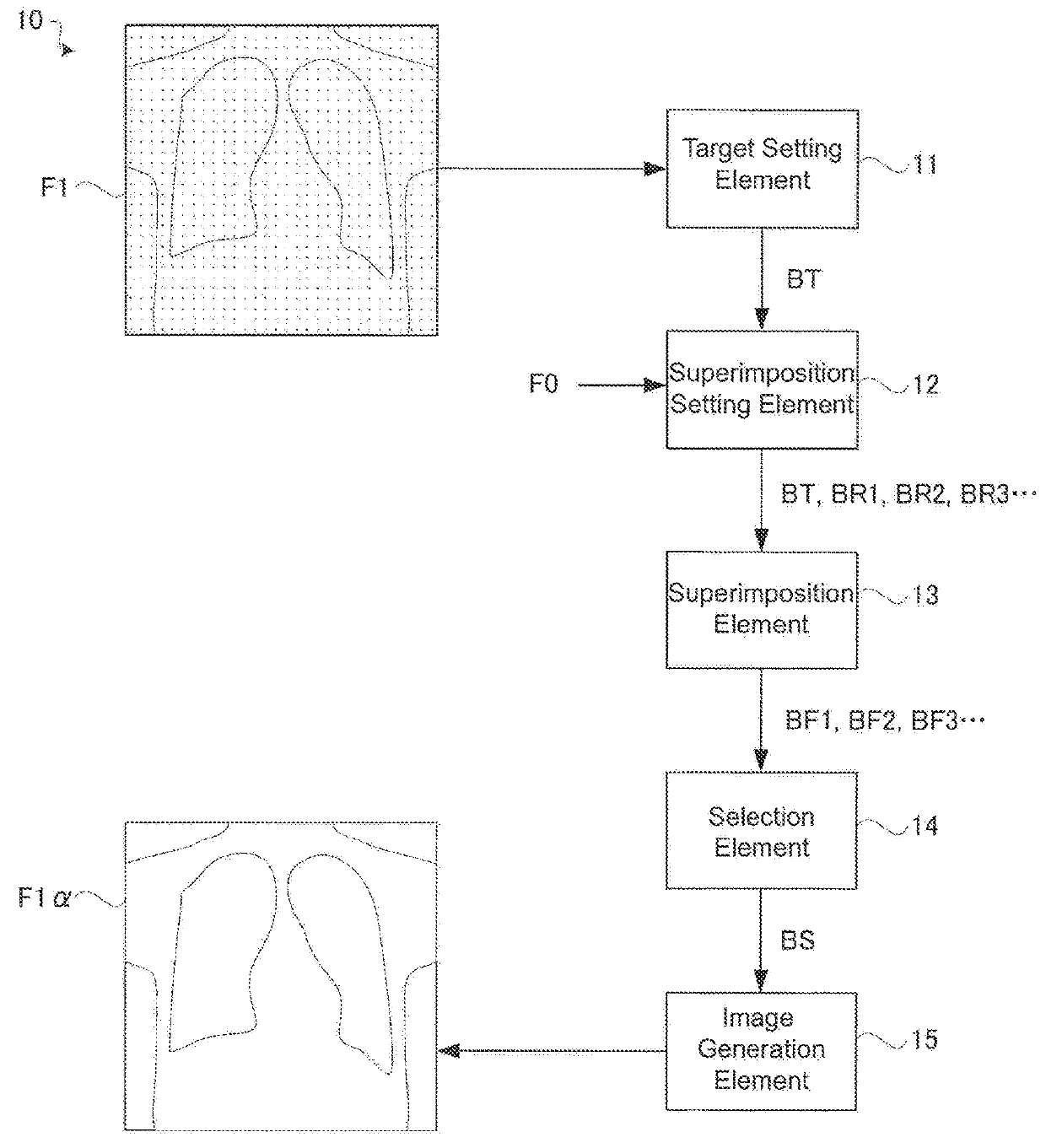

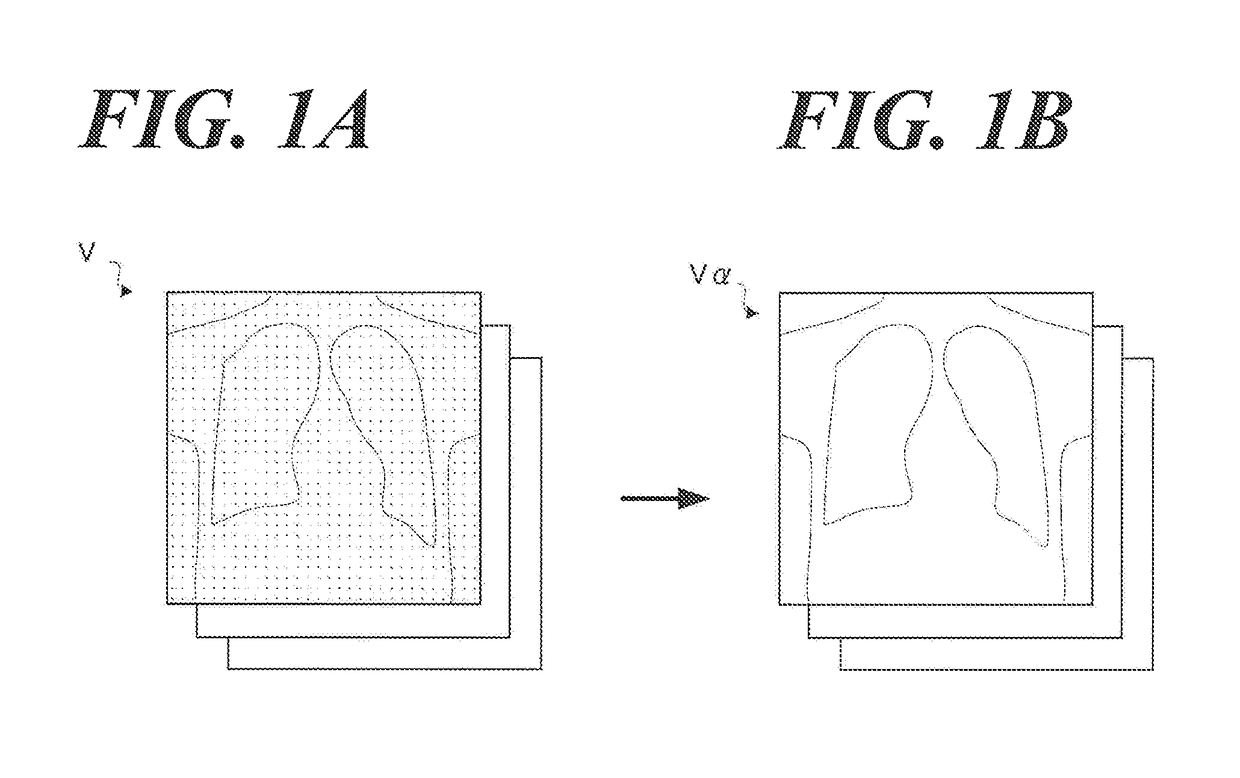

With the present invention, it is possible to provide an image processing apparatus capable of reliably removing noise, even for a live image having a poor S / N ratio. The present invention has a configuration to search for where, on a frame F0, a target block BT is reflected. When superimposing the frame F0 and a frame F1, the target block BT, which is a fragment of the frame F0, and a plurality of blocks to be superimposed, which is a fragment of the frame F1 are set, and if, from fusion blocks BF generated by superimposing the target block BT on each of the blocks to be superimposed BR, a selection block BS is selected wherein superimposed subject images most reinforce one another, it is possible to reliably suppress duplication of the subject images.

Owner:SHIMADZU CORP

Image processing device

ActiveUS10165156B2Image can be preventedAvoid doublingImage enhancementTelevision system detailsImaging processingComputer science

With the present invention, it is possible to provide an image processing apparatus capable of reliably removing noise, even for a live image having a poor S / N ratio. The present invention has a configuration to search for where, on a frame F0, a target block BT is reflected. When superimposing the frame F0 and a frame F1, the target block BT, which is a fragment of the frame F0, and a plurality of blocks to be superimposed, which is a fragment of the frame F1 are set, and if, from fusion blocks BF generated by superimposing the target block BT on each of the blocks to be superimposed BR, a selection block BS is selected wherein superimposed subject images most reinforce one another, it is possible to reliably suppress duplication of the subject images.

Owner:SHIMADZU CORP

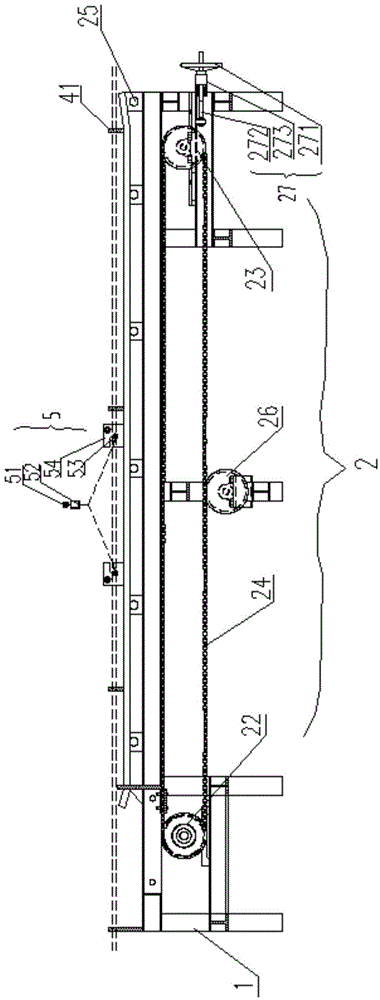

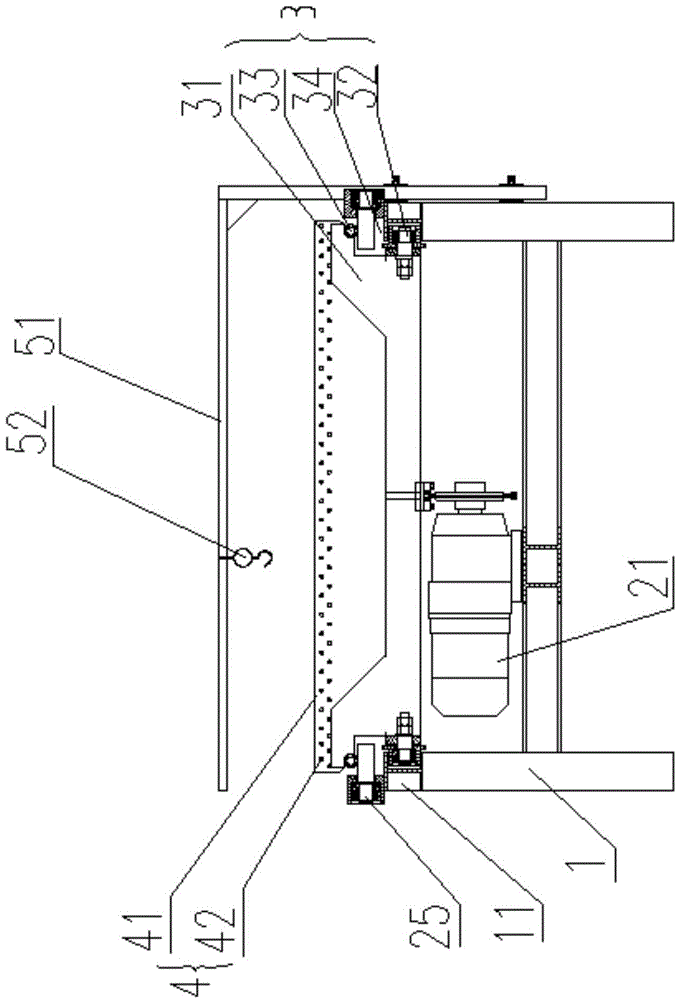

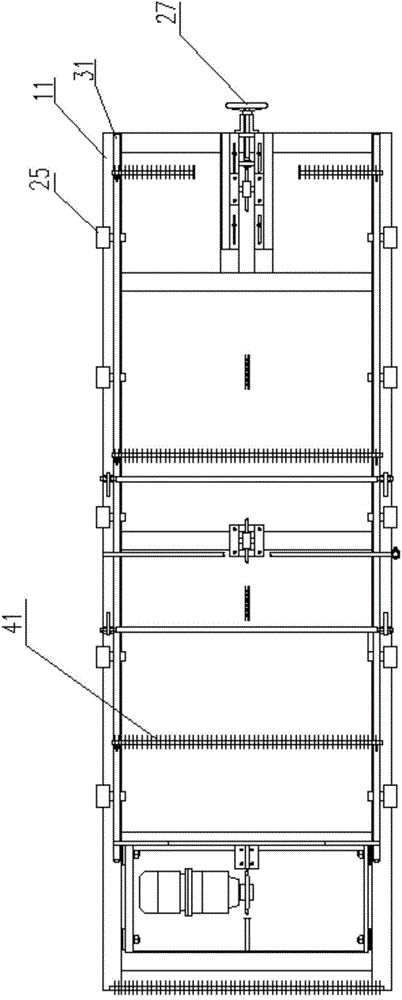

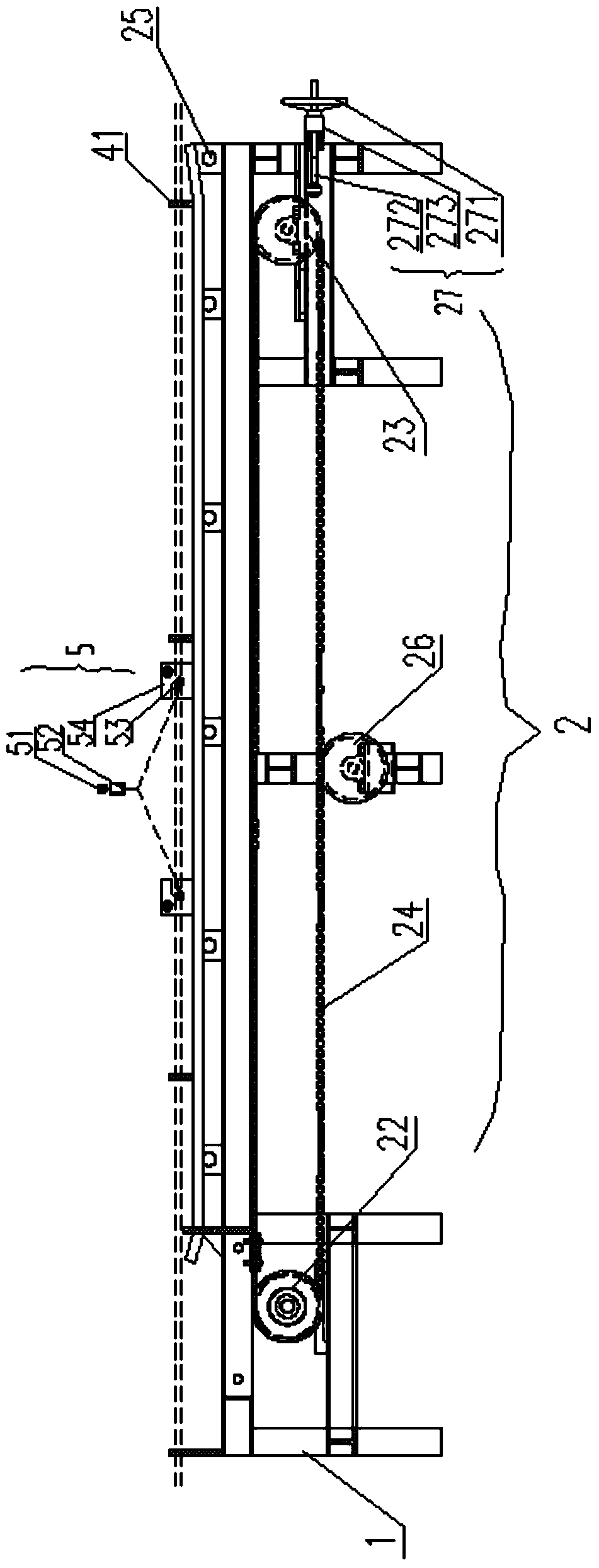

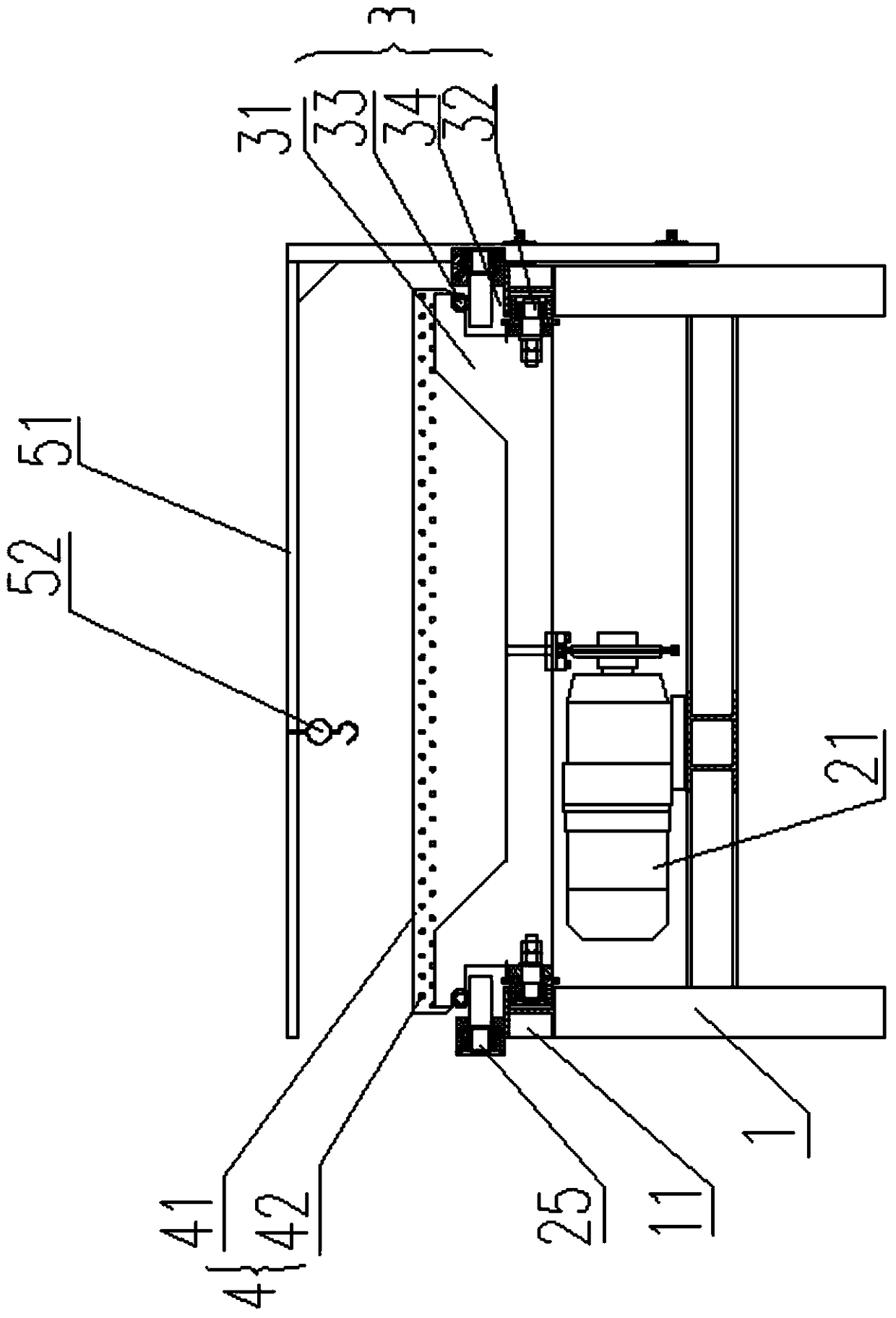

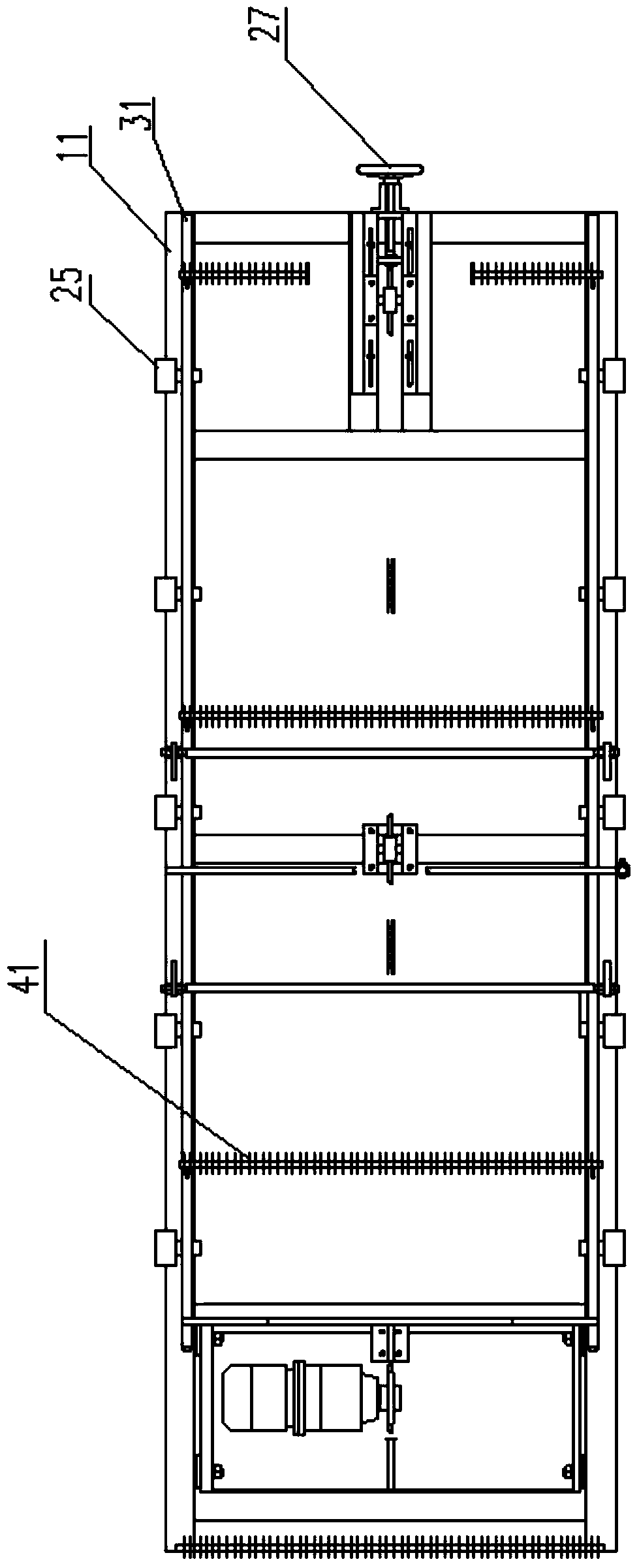

Electric steel wire separating device

InactiveCN105752741APrevent the phenomenon of threading and threadingRealize multi-layer splittingFilament handlingElectrical steelEngineering

The invention belongs to the field of steel wire production and particularly relates to an electric steel wire separating device.The electric steel wire separating device comprises a rack, a driving mechanism, a wire guiding mechanism and a wire separating mechanism, wherein the wire guiding mechanism and the wire separating mechanism are respectively arranged on the rack, the driving mechanism drives the wire guiding mechanism to move along the rack, the wire separating mechanism is installed on the wire guiding mechanism and comprises wire separating plates, and wire separating holes staggered vertically are distributed in the wire separating plates.The wire separating holes formed in the wire separating plates can separate steel wires staggered vertically and horizontally, multi-layer wire separation is achieved, the heating efficiency is improved, energy is saved, and the electric steel wire separating device is simple, easy to operate, convenient to popularize and apply and has a higher practical value.

Owner:ZHANGJIAGANG DONGHANG MACHINERY

Lubricating antistatic high-performance oil for drawing production of carbon fibre

InactiveCN101280475BAvoid defectsReduce frictionMonocomponent synthetic polymer artificial filamentSynthetic polymer filament chemical after-treatmentEpoxyFiber

The invention relates to the chemical materials of the new material field, in particular to a high-performance anti-static lubricating finish oil used in the carbon fiber wire-drawing production process. The composition of the raw materials is calculated with the weight percentage. The quaternary ammonium salt type cationic surfactant of 3 to 10, the polyoxyethylene-polyoxy-propylene-polyether of1 to 3, the ammonia modified silicone oil of 2 to 8, the epoxy-modified silicone oil of 2 to 8, the polyether modified silicone oil of 2 to 8, the fluoride silicon oil of 10 to 20, lauric acid polyoxyethylene ester of 1 to 3, the laurinol polyoxyethylene of 1 to 3, the polyoxyethylene hydrogenerated castor oil of 4 to 20, and the rest of high-purity deionized water are stirred in a reaction kettle for 3 to 5 hours with the temperature controlled within the range of 56 to 60 DEG C, thus the finish oil product can be produced. The invention is applied in the carbon fiber wiredrawing production process, in which the finish oil is in the formation of a membrane on a monofilament surface, not only the adhesion and merging between the monofilaments can be avoided, but also the friction and wear of the fiber surface with the roller during the production process can be prevented. Therefore, the finish oil has excellent smoothness, antistatic property, collection property and self-emulsifying property as well.

Owner:李元杰

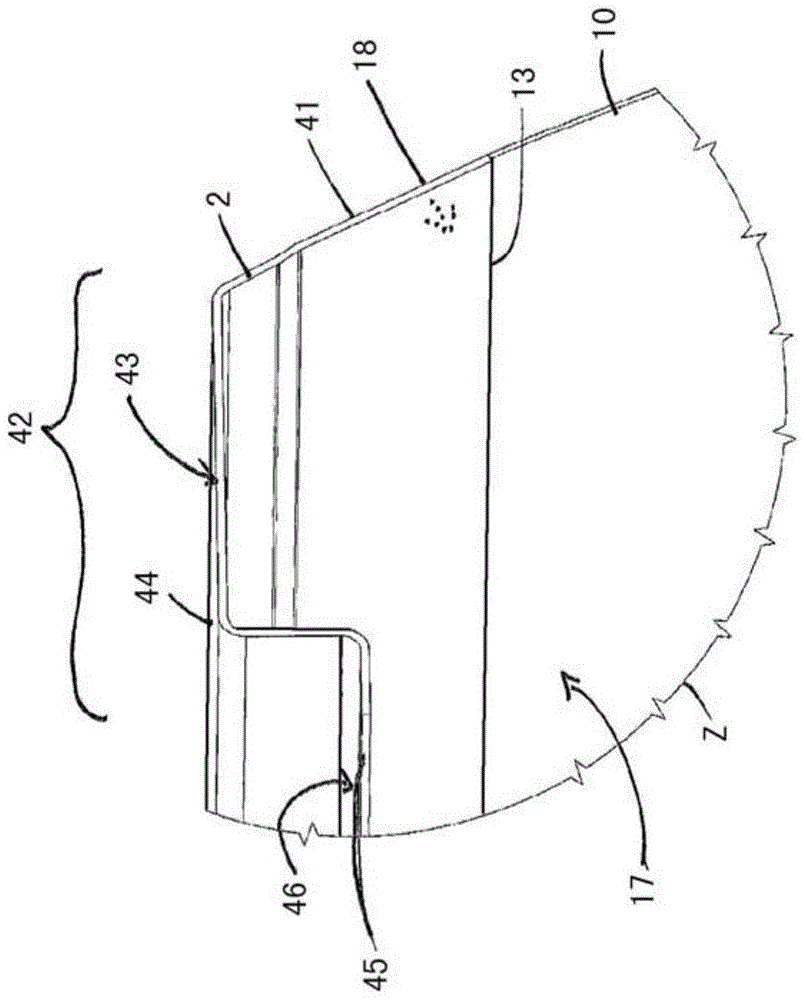

Rail vehicle blank structure and its manufacturing method

ActiveCN103534160BAvoid doublingHigh susceptibilityRailway roofsAxle-box lubricationEngineeringFlange

The invention relates to a method for manufacturing a blank structure of a rail vehicle, comprising the steps of: providing an underframe (60), producing an outer wall module (1) according to a tailor-made blank method in which the The cut metal plates ( 10 , 11 ) with different material properties are joined to each other by means of laser welding to form a side wall surface, so that the outer surface ( 18 ) of the side wall surface is produced at the butt joint without material change, and the outer wall module ( 1) the frame (4) formed by frame profiles (5, 5a, 5b) is joined to the inner side (17) of the side wall surface, and several outer wall modules (1) are joined to at least one central side wall section (81 ), wherein the outer wall modules ( 1 ) are bonded to each other to the ground by means of laser welding without offsets occurring at the joints in the outer surface ( 18 a ) of the side wall section ( 81 ), at least the middle side wall section ( 81) and optionally outer wall modules (1) configured as side wall end modules (94) and optionally end modules mounted on the chassis (60) and attached to the top elements (71, 72), wherein The step of producing the outer wall module (1) consists of joining a curved upper flange profile (2) to the side wall face, wherein the upper flange profile (2) closes the upper edge of the outer wall module and is butt-bonded to the material by means of laser welding Adjacent metal sheets (10, 11) of different properties without material abrupt changes on the outer surface (18) of the side wall, wherein the upper flange profile (2) comprises a The profile section (42) with the outer surface (18) curved towards the inner side (17) of the outer wall module (1); and in the step of joining the skeleton (4) on the inner side (17) of the side wall , 5a, 5b) with end-side abutment edges (19, 20, 21) mounted via a T-shaped abutment interface and fixed to the side wall surface including the upper flange profile via a laser weld (13) in a material-fit manner on the inside (17). Furthermore, the invention relates to the blank structure of the vehicle body and the outer wall module.

Owner:BOMBARDIER TRANSPORTATION GMBH

Low-ash polyacrylonitrile-based fiber, polyacrylonitrile-based carbon fiber and preparation method thereof

ActiveCN113373554AAvoid stickingAvoid doublingArtificial filament washing/dryingArtificial filament heat treatmentPolymer scienceCarbon fibers

The invention relates to a low-ash polyacrylonitrile-based fiber, a polyacrylonitrile-based carbon fiber and a preparation method thereof. The invention adopts the technical scheme that the preparation method of the low-ash polyacrylonitrile-based fiber comprises the following steps of oiling a fiber to be oiled to obtain an oiled fiber, wherein the swelling capacity of the fiber to be oiled is less than or equal to 80 percent, an oil agent used for oiling is prepared from crude oil and water, the concentration of the oil agent is smaller than or equal to 5 percent, a pH value of the crude oil is alkaline, the surface tension is smaller than or equal to 35 mN / m, the particle size is 200 to 400 nm, the antioxidant residue mass fraction in the air atmosphere is smaller than or equal to 10 percent, and the heat-resistant residue mass fraction in the nitrogen atmosphere is smaller than or equal to 10 percent; and carrying out drying densification treatment, steam drafting treatment and relaxation heat setting treatment on the oiled fiber to obtain the polyacrylonitrile-based fiber. According to the low-ash polyacrylonitrile-based carbon fiber, the ash content is less than or equal to 0.2 percent. According to the low-ash polyacrylonitrile-based fiber, the polyacrylonitrile-based carbon fiber and the preparation method thereof provided by the invention, the ash content of the polyacrylonitrile-based fiber and the polyacrylonitrile-based carbon fiber is mainly reduced, and broken filaments, fractured filaments, sticky filaments and doubled filaments are avoided.

Owner:山西钢科碳材料有限公司

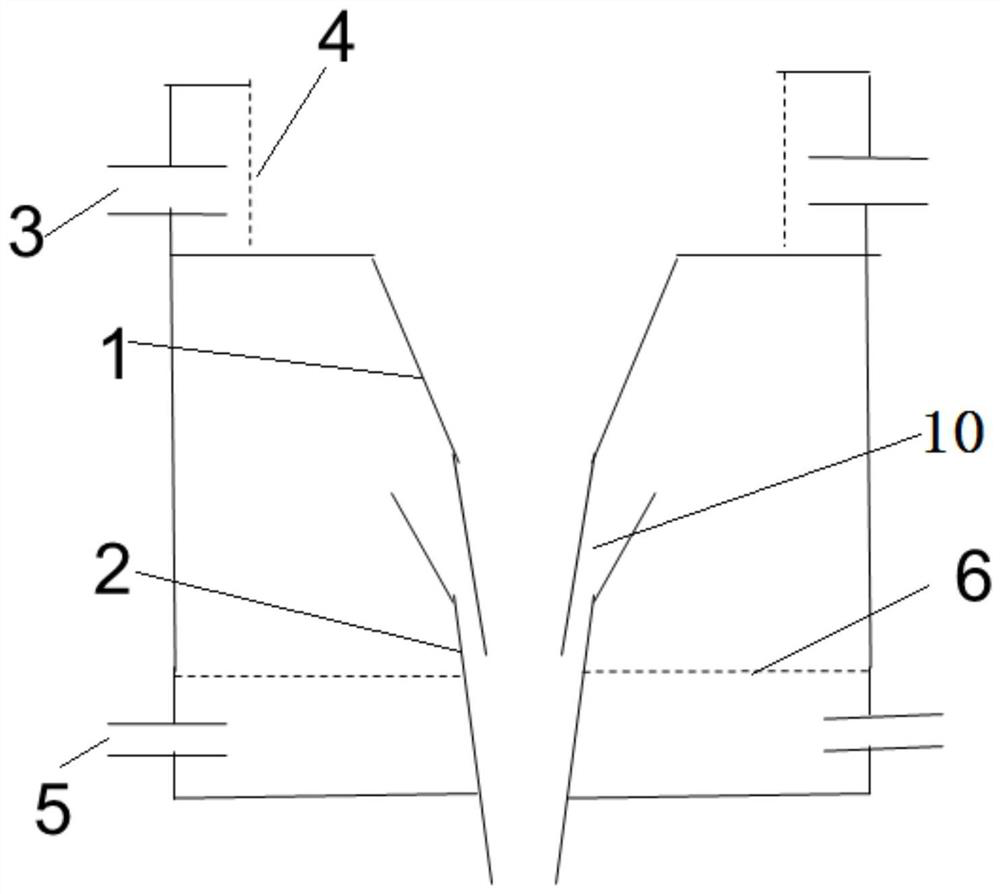

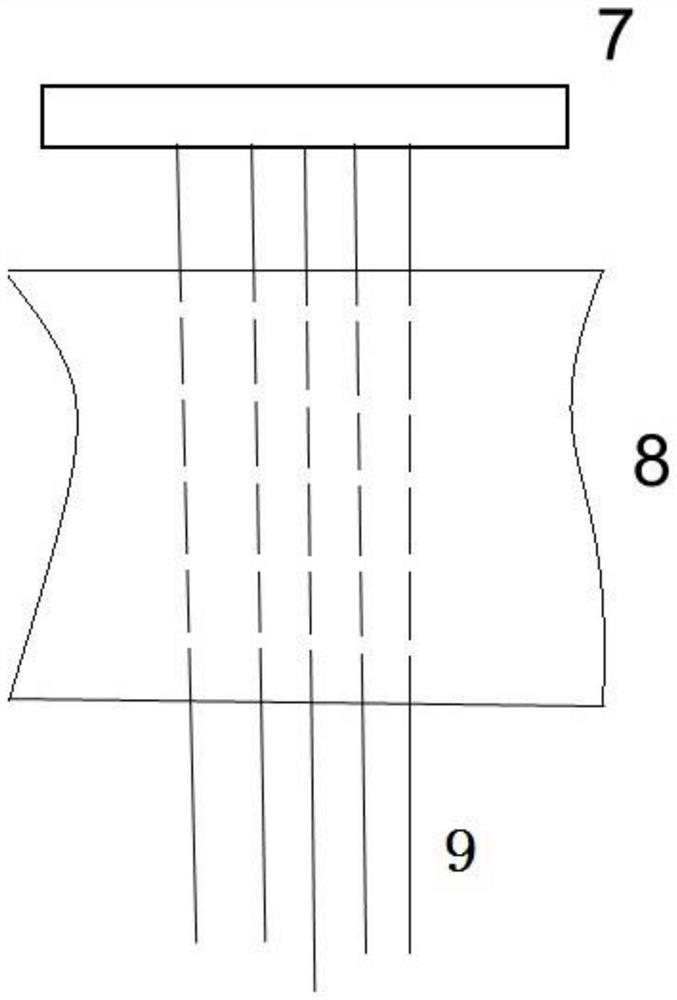

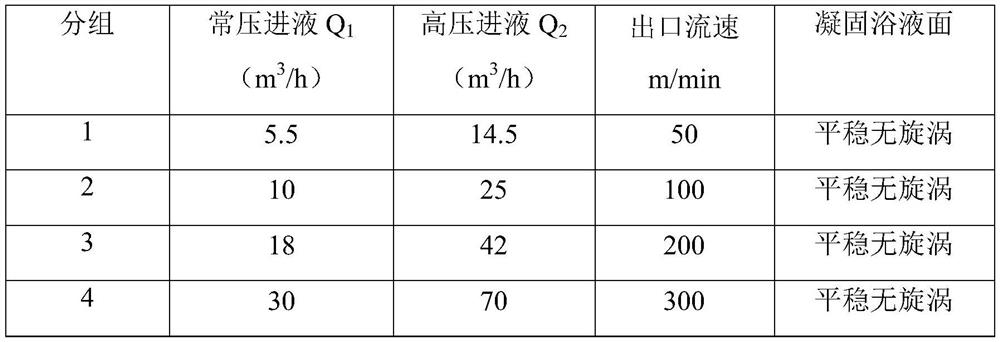

A kind of preparation method of cellulose fiber tow

ActiveCN111101215BGood mechanical propertiesGood lookingArtificial thread manufacturing machinesMonocomponent cellulose artificial filamentPolymer scienceSpinning

The invention discloses a method for preparing cellulose fiber tow, comprising: (1) mixing cellulose with an organic solvent to obtain a cellulose spinning solution; (2) extruding the cellulose spinning solution through a spinneret out, through the air gap layer, into the coagulation bath of the wide funnel, and solidify and draw in the accelerating fluid to obtain cellulose fiber tow; wherein, the length of the wide funnel in the horizontal direction is 300-2000mm. The invention utilizes a wide-width funnel to prepare Lyocell tow, and a plurality of monofilaments pass through the wide-width funnel to form a curtain, and the monofilaments are arranged in parallel without entanglement. The tow prepared by the invention has good mechanical properties and more excellent appearance, and can be used for wide-width and high-yield spinning to improve production capacity; in addition, it can also be used to prepare long-tow nonwoven materials.

Owner:CHINESE TEXTILE ACAD

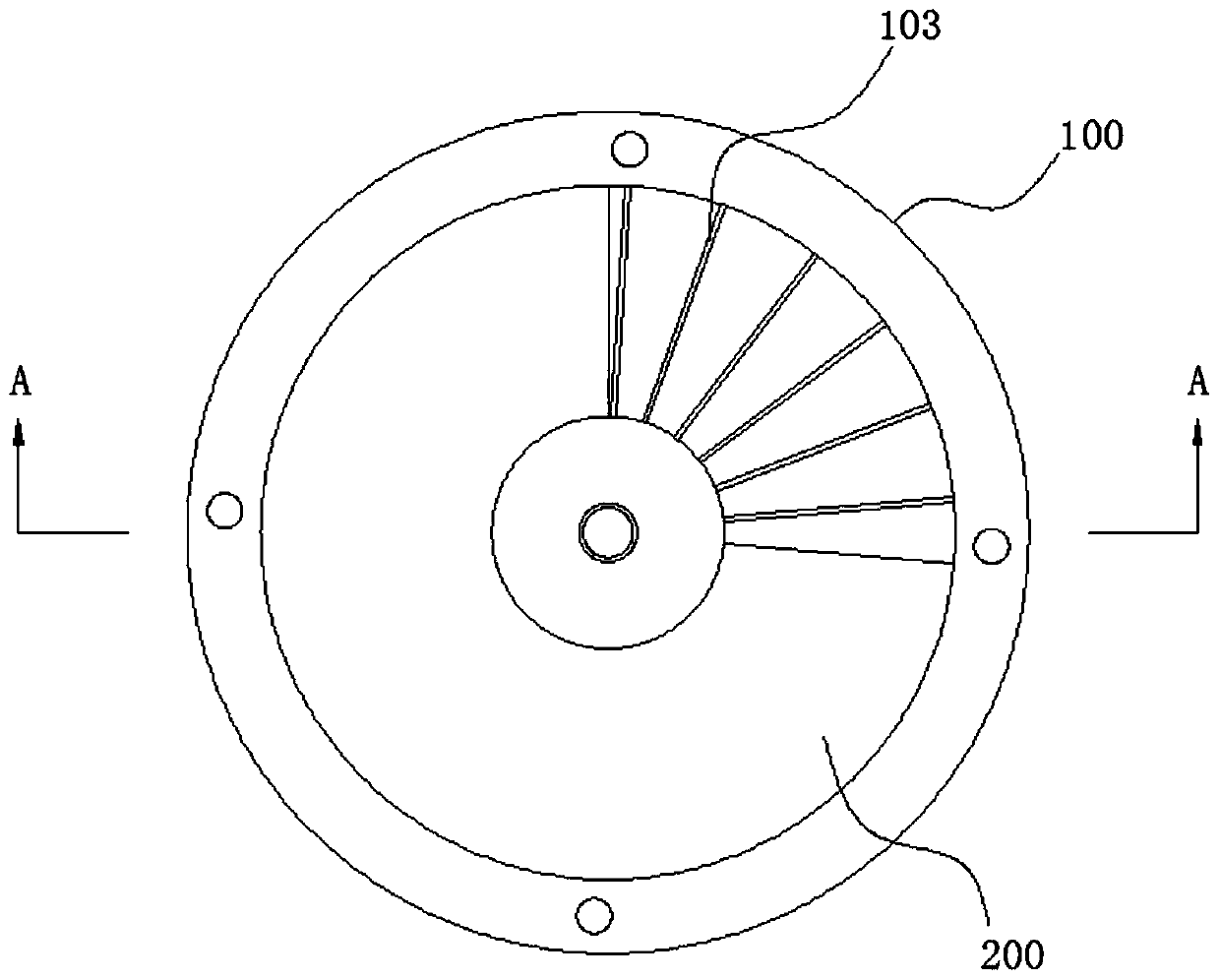

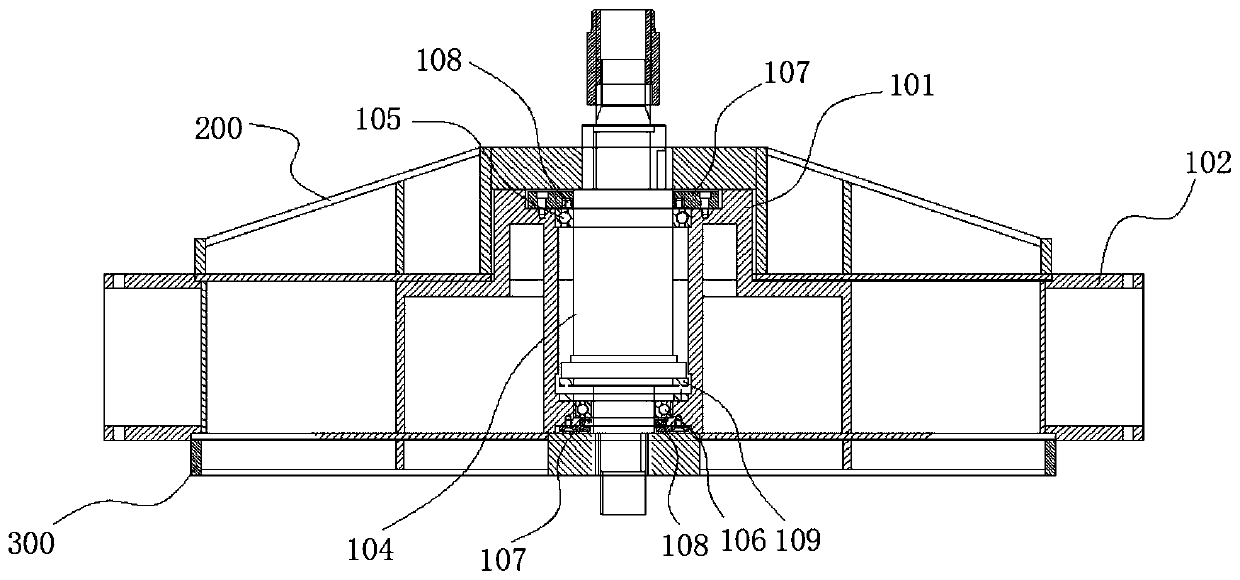

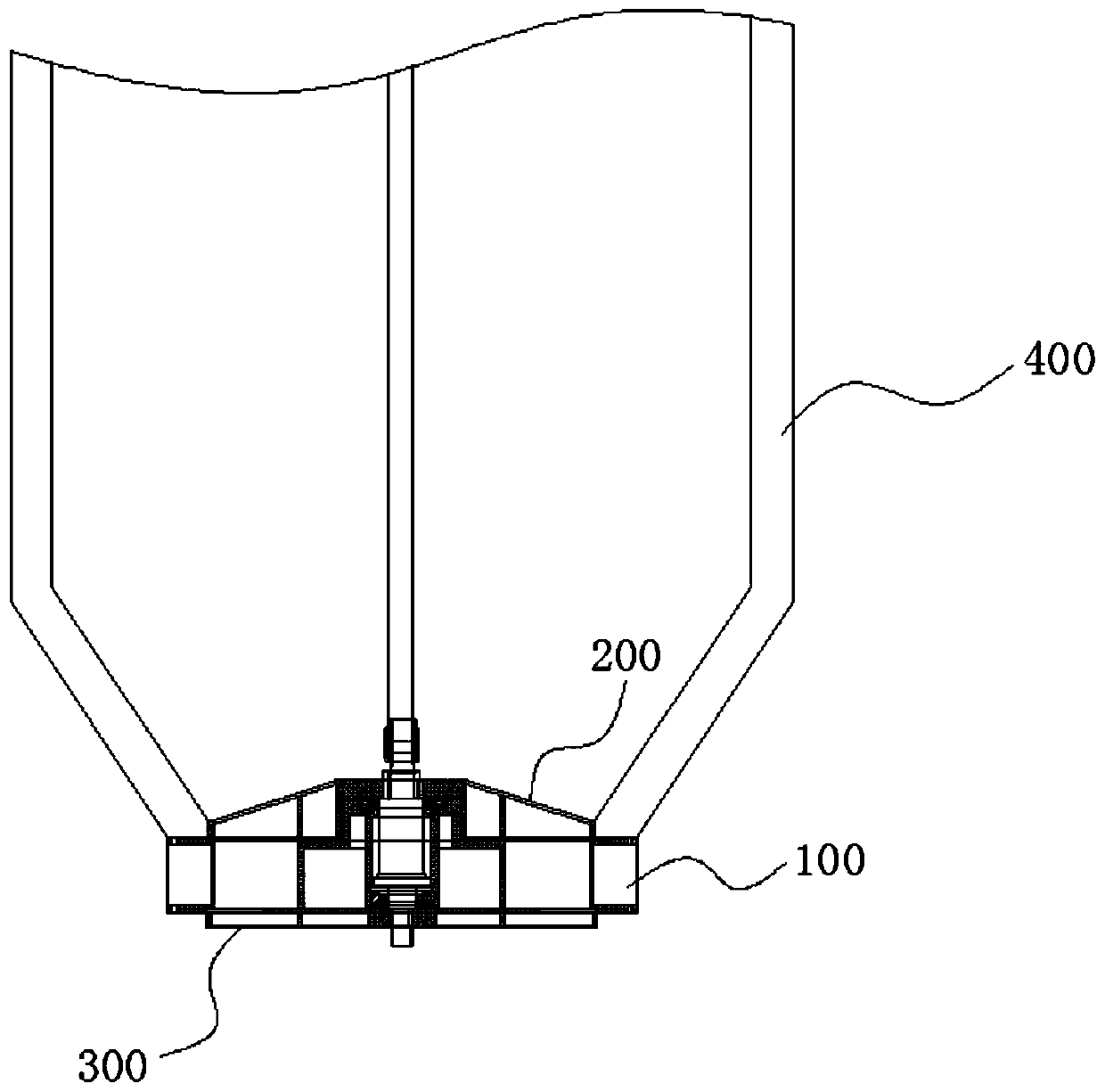

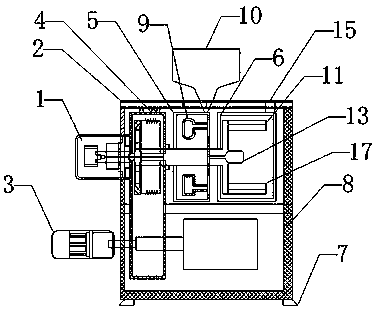

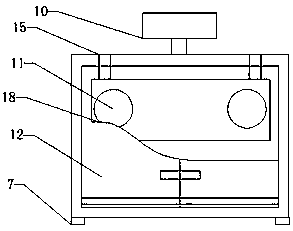

Impeller feeder for measuring bucket

The invention belongs to the technical field of construction equipment, and discloses an impeller feeder for a measuring bucket. The impeller feeder comprises a blade disk, and the blade disk comprises an inner ring, an outer ring and a blade grid ring arranged between the inner ring and the outer ring; the height of the inner ring is higher than the height of the outer ring; the outer ring is fixedly connected with a discharge port at the lower end of the measuring bucket; the inner ring is internally provided with a transmission shaft, and the two ends, located at the inner ring, of the transmission shaft are rotationally connected with the inner ring through a first bearing and a second bearing; the top of the blade disk is provided with an upper rotating baffle, the bottom of the bladedisk is provided with a lower rotating baffle, the upper rotating baffle and the lower rotating baffle are fixedly mounted on the transmission shaft, and opening holes are formed in the positions, corresponding to the blade grid ring, of the upper rotating baffle and the lower rotating baffle in a staggered manner. By means of the impeller feeder, the multiple bearings are arranged in the inner ring, multiplied changes of gaps between the upper and lower rotating baffles and the blade disk after stress due to bearing oil gaps can be effectively avoided, and the flow control accuracy of the impeller feeder is improved.

Owner:成都广维重工科技有限公司

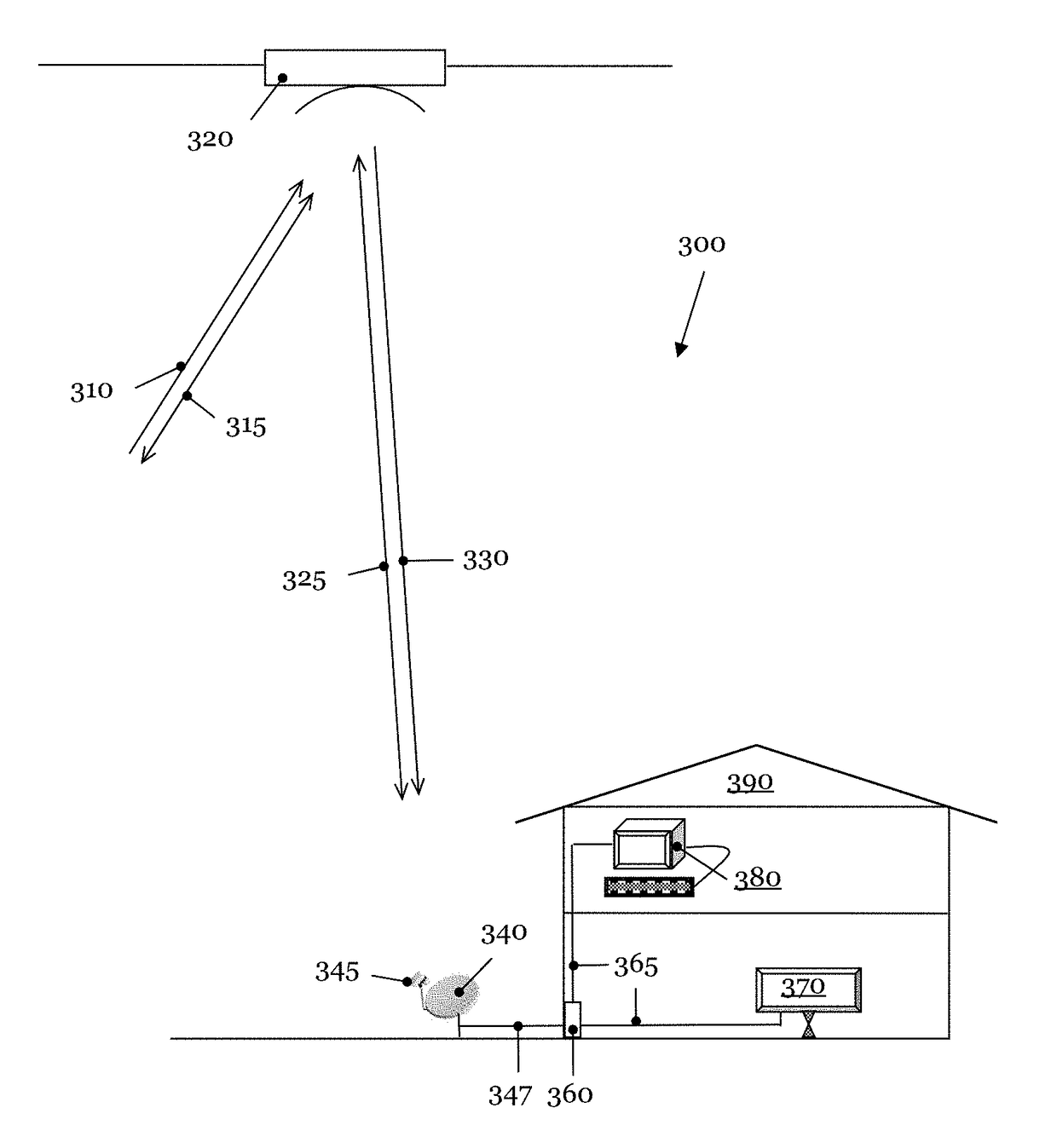

Apparatus and method for providing a joint IP data-stream

InactiveUS10051324B2Uniform data formatAvoid doublingGHz frequency transmissionSelective content distributionDigital dataData stream

The present invention refers to an apparatus for providing at least one joint outgoing IP data stream, the apparatus comprises: (a) at least one receiver adapted to receive a stream of digital TV data, the stream simultaneously containing digital data of a plurality of TV channels, (b) at least one transceiver adapted to receive a downlink stream of IP data and to transmit an uplink stream of IP data via a satellite link, (c) at least one processing unit adapted to convert the digital TV data received from the receiver into a first outgoing IP data stream and to convert the IP data received from the transceiver into a second outgoing IP data stream, and (d) at least one switching unit adapted to combine the first outgoing IP data stream and the second outgoing IP data stream in at least one joint outgoing IP data stream.

Owner:MX1 GMBH

A method for preparing continuous SIC fibers with low oxygen content without melting in air

ActiveCN106192078BImprove temperature resistanceImprove mechanical propertiesFibre chemical featuresOxygen contentSic fiber

The invention provides a method using air curing to prepare low-oxygen-content continuous SiC fibers. The method has the advantages that low-temperature air curing and heat crosslinking are used in a combined manner, the heat crosslinking is added after the air curing as compared with a traditional preparation method, the problem of excessively high fiber oxygen content caused by traditional preparation method merely increasing the air curing temperature is avoided, the problem of fiber doubling caused by the direct high-temperature pyrolysis after the low-temperature air curing is also avoided, and the continuous SiC fibers with oxygen content below 10wt% and good performance are prepared.

Owner:NAT UNIV OF DEFENSE TECH

Polyacrylonitrile-based fiber, polyacrylonitrile-based carbon fiber and preparation methods

ActiveCN113417033AHigh porosityEasy to split fiberArtificial filament heat treatmentSynthetic polymer filament chemical after-treatmentPolymer scienceCarbon fibers

The invention relates to polyacrylonitrile-based fiber, polyacrylonitrile-based carbon fiber and preparation methods of the polyacrylonitrile-based fiber and the polyacrylonitrile-based carbon fiber. The preparation method of the polyacrylonitrile-based fiber comprises the following steps of carrying out first oiling treatment on fiber to be oiled to obtain first oiled fiber; and carrying out drying densification treatment, steam drafting treatment, relaxation heat setting treatment and winding on the first oiled fiber to obtain the polyacrylonitrile-based fiber. Before the step of relaxation heat setting treatment, the fiber subjected to steam drafting treatment is subjected to second oiling treatment; and oil agents used for the first oiling treatment and the second oiling treatment are different. The polyacrylonitrile-based fiber is subjected to pre-oxidation, low-temperature carbonization and high-temperature carbonization treatment to obtain the polyacrylonitrile-based carbon fiber. The methods are mainly used for preparing high-strength and medium-modulus polyacrylonitrile-based fiber and polyacrylonitrile-based carbon fiber with excellent performance.

Owner:山西钢科碳材料有限公司

Ultrasonic atomized steam assisted double-roller carbon fiber drying and heating device

InactiveCN109682200AGuaranteed fitGuaranteed temperature uniformityHeating element materialsHeating arrangementCarbon fibersProcess engineering

The invention relates to an ultrasonic atomized steam assisted double-roller carbon fiber drying and heating device, and belongs to the technical field of drying device preparation. According to the device, a steam composite surface drying method is adopted, water is heated to form steam, then ultrasonic oscillation is performed so as to form small steam droplets and form a stable and uniform disperse system and disperse into a material drying device, the phenomena of nonuniformity and difficulty in control over the temperature of roller surfaces of the drying device in a traditional techniqueare effectively improved, the temperature and humidity of an environment field are stable and controllable, the runaway speed of water molecules in raw silk is effectively controlled by adjusting thehumidity, the phenomenon of a skin-core structure of a material is reduced, the phenomenon of brittle failure of the carbon fiber material in a preoxidation process due to the skin-core structure iseffectively improved, and oscillation dispersion is performed on the material by the ultrasonic device, so that the steam is effectively and uniformly scattered and is dispersed, and the drying efficiency and the uniform performance of the drying device are further improved.

Owner:殷连海

For rail vehicle - outer wall of carriage and manufacturing method

ActiveCN103025596BHigh susceptibilityAvoid doublingRailway transportAxle-box lubricationComputer moduleEngineering

The invention relates to a method for producing an outer wall module or an outer wall (1) or a coach body of a railway vehicle, and to an outer wall, an outer wall module, and a coach body of a railway vehicle. The following steps are provided for producing an outer wall (1) or an outer wall module: assembling 2-dimensional sheet metal parts (10, 11) having different properties (15, 16) into an outer sheet metal shell (3) designed as a self-supporting thrust area module, wherein the end faces of the sheet metal parts (10, 11) are each oriented transverse to the 2-dimensional extension of the individual sheet metal parts (10, 11) abut one another and are assembled by penetrating laser weld seams (13) in such a manner that the individual sheet metal parts (10, 11) form a flush outer surface (17) on an outer face of the thrust area module, wherein the sheet metal parts (10, 11) having different properties (15, 16) comprise first sheet metal parts (10) and second sheet metal parts (11), and the second sheet metal parts (11) each comprise a greater resistance, in particular strength and / or greater material thickness (15) than the first sheet metal parts (10), and the second sheet metal parts (11) are inserted in regions of the outer sheet metal shell (3) at which increased stresses occur during operation of the railway vehicle in a coach body produced from the outer wall module or the outer wall (1), and a structure (4) is created from rib profiles (5, 5a, 5b), wherein end face butt edges (19, 20, 21) of the rib profiles (5, 5a, 5b) adjoin the inner face (17) of the outer sheet metal shell (3) by means of T-joints, and are fastened to the outer sheet metal shell (3) by means of laser weld seams (13).

Owner:BOMBARDIER TRANSPORTATION GMBH

Electric wire splitting device for steel wire

InactiveCN105752741BPrevent the phenomenon of threading and threadingRealize multi-layer splittingFilament handlingElectrical steelEngineering

The invention belongs to the field of steel wire production and particularly relates to an electric steel wire separating device.The electric steel wire separating device comprises a rack, a driving mechanism, a wire guiding mechanism and a wire separating mechanism, wherein the wire guiding mechanism and the wire separating mechanism are respectively arranged on the rack, the driving mechanism drives the wire guiding mechanism to move along the rack, the wire separating mechanism is installed on the wire guiding mechanism and comprises wire separating plates, and wire separating holes staggered vertically are distributed in the wire separating plates.The wire separating holes formed in the wire separating plates can separate steel wires staggered vertically and horizontally, multi-layer wire separation is achieved, the heating efficiency is improved, energy is saved, and the electric steel wire separating device is simple, easy to operate, convenient to popularize and apply and has a higher practical value.

Owner:ZHANGJIAGANG DONGHANG MACHINERY

A kind of preparation method of water-soluble nonwoven fabric based on polyvinyl alcohol and polyethylene oxide

ActiveCN106222885BReduce hydrogen bondingLow melting pointArtificial filament heat treatmentMelt spinning methodsFiberPolymer science

The invention relates to a preparation method of a water-soluble non-woven fabric based on polyvinyl alcohol and polyethylene oxide and belongs to the technical field of textile chemical fibers. The high-fluffiness water-soluble non-woven fabric with a three-leaf structure is prepared through commixing and abnormal-shape spinning of the polyvinyl alcohol and the polyethylene oxide, online net forming and hot rolling. The non-woven fabric can be applied to the fields of clothing and home textiles, medical treatment and health care and the like. The preparation method has the advantages of simplicity, no pollution, low cost, wide applicable range and high application value.

Owner:大连天马可溶制品有限公司

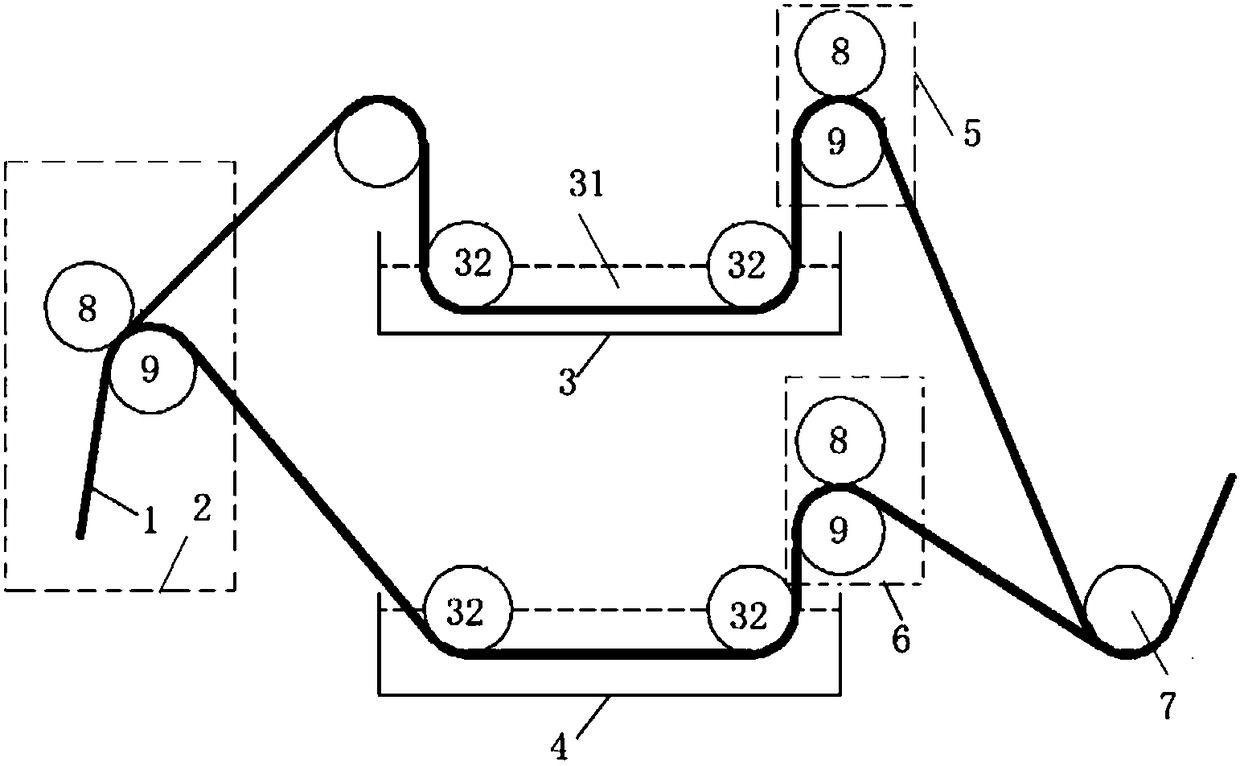

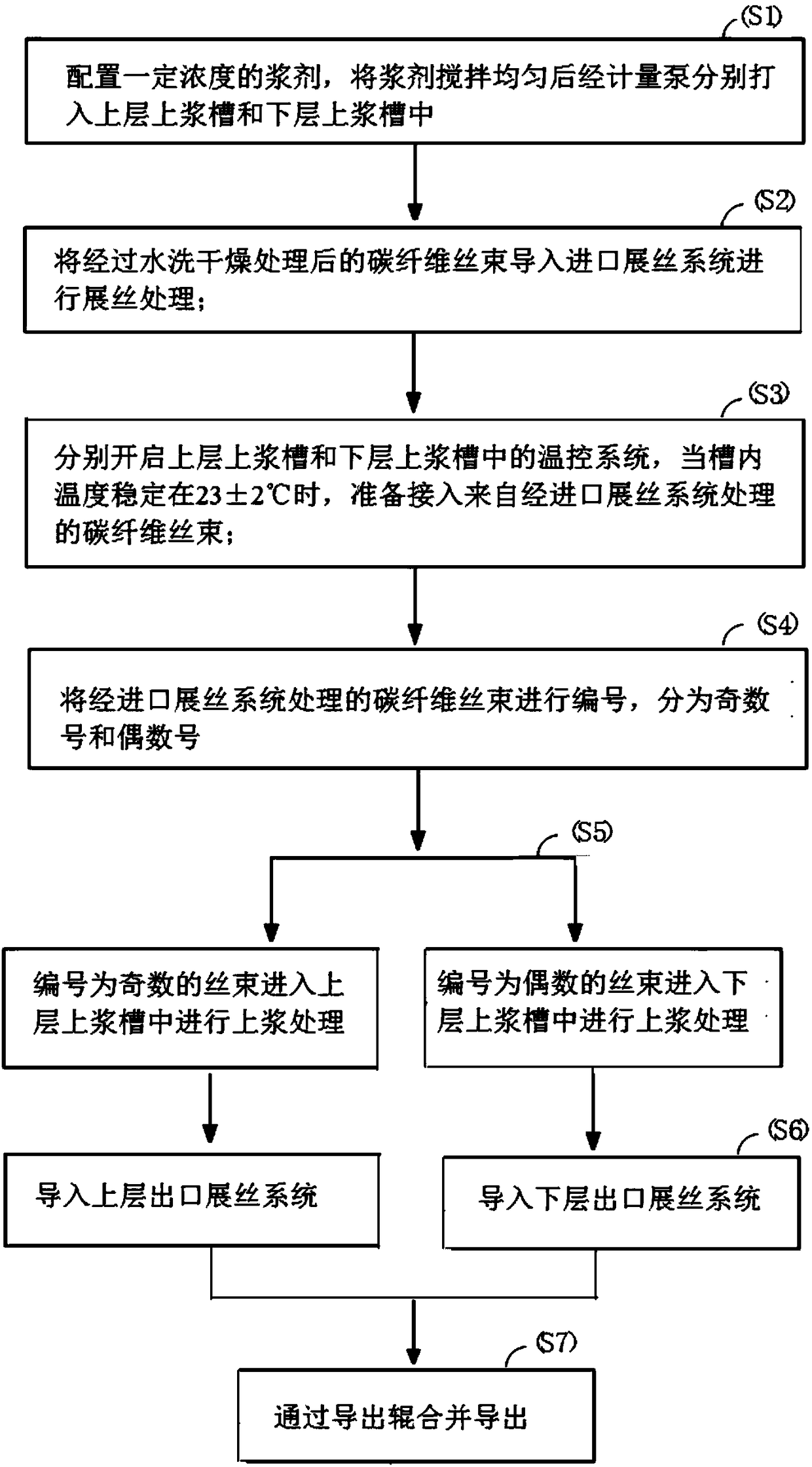

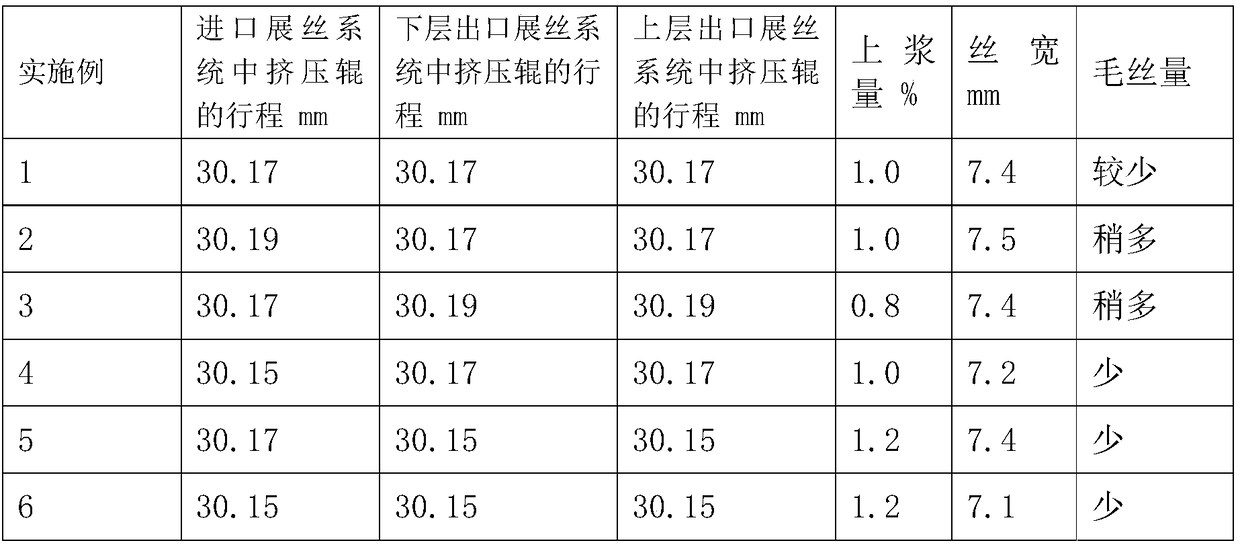

Sizing and sizing systems and sizing processes for carbon fibers

ActiveCN107475945BReasonable structural designSave spaceLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsTemperature controlFiber

The invention discloses a novel sizing and shaping system for carbon fibers and a sizing technology. The sizing and shaping system comprises an upper layer sizing tank, a lower layer sizing tank, an inlet filament stretching system, an upper layer outlet filament stretching system and a lower outlet filament stretching system, wherein the upper layer sizing tank comprises a first temperature control system with a jacket, and two stainless steel polished rollers; the lower layer sizing tank is distributed in the vertical direction of the upper layer sizing tank, and the lower layer sizing tank comprises a second temperature control system with a jacket, and two stainless steel polished rollers; an inlet of the upper layer sizing tank and an inlet of the lower layer sizing tank are jointly connected with the inlet filament stretching system; the upper layer outlet filament stretching system is connected with an outlet of the upper layer sizing tank; the lower layer outlet filament stretching system is connected with an outlet of the lower layer sizing tank; the inlet filament stretching system, the upper layer outlet filament stretching system and the lower layer outlet filament stretching system each comprise two parallel supporting rollers, and bearings at the two ends of every two supporting rollers are arranged in same slide ways respectively. According to the sizing and sizing system and the sizing technology, adhesion of adjacent carbon filaments is avoided, so that the consistency of the width and sizing amount of the carbon fiber filaments is greatly improved.

Owner:ZHONG AN XIN TECH CO LTD

A kind of silicone-free oil agent for carbon fiber precursor

ActiveCN110670350BEnsure uniformity of qualityAvoid softeningFibre typesFibre chemical featuresBenzoic acidFiber

The invention discloses a silicone-free oil agent for carbon fiber precursors, which comprises aromatic ester compounds, aromatic polyoxyethylene ethers, and amine compounds dispersed in water at a mass ratio of 50-80:10-35:1-5. Aqueous emulsion; aromatic ester compounds include one or more of trimellitates, phthalates, hydroxybenzoates and ethoxylated bisphenol higher fatty acid esters; aromatic polyoxyethylene ethers include alkyl One or more of phenol polyoxyethylene ethers and bisphenol A polyoxyethylene ethers; amine compounds include one or more of ethoxylated lauramides and aliphatic long-chain quaternary ammonium salts; and aromatic ester compounds in the air The mass residual rate at 300°C under the atmosphere is 80-98%, and the mass ratio in the non-volatile components of the oil agent is 50-80%. It can effectively reduce the sticking degree of the raw silk during the production process, prevent the PAN monofilament from sticking to each other during the pre-oxidation process, and has a certain degree of hydrophilicity and heat resistance.

Owner:HENGSHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com