A kind of preparation method of cellulose fiber tow

A cellulose fiber and cellulose technology, applied in the field of spinning, can solve the problems of poor spinning stability, affecting spinning output, doubling and breaking of filaments, avoiding doubling, excellent appearance and uniform speed. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a method for preparing cellulose fiber tow, the specific steps are as follows:

[0049] (1) After mixing cellulose pulp with a degree of polymerization of 600 and NMMO aqueous solution, it is swollen and dissolved to prepare a transparent solution, and then filtered and defoamed to obtain a cellulose spinning solution. The cellulose concentration of the spinning solution is 8 wt%, and the temperature of the spinning solution is 100°C.

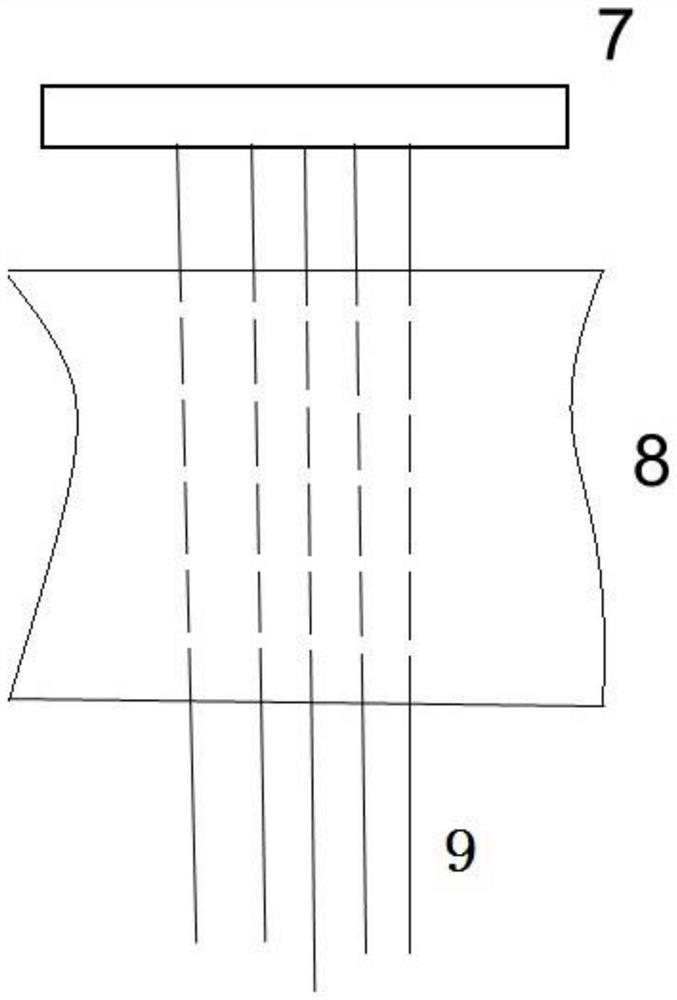

[0050] (2) The spinning liquid is metered by a metering pump, enters the spinning box, and extrudes a fine spinning stream from the spinneret hole of the spinneret, and the extrusion speed is 10m / min. The temperature of the spinning box is 95° C., and the number of holes in the spinneret is 10,000.

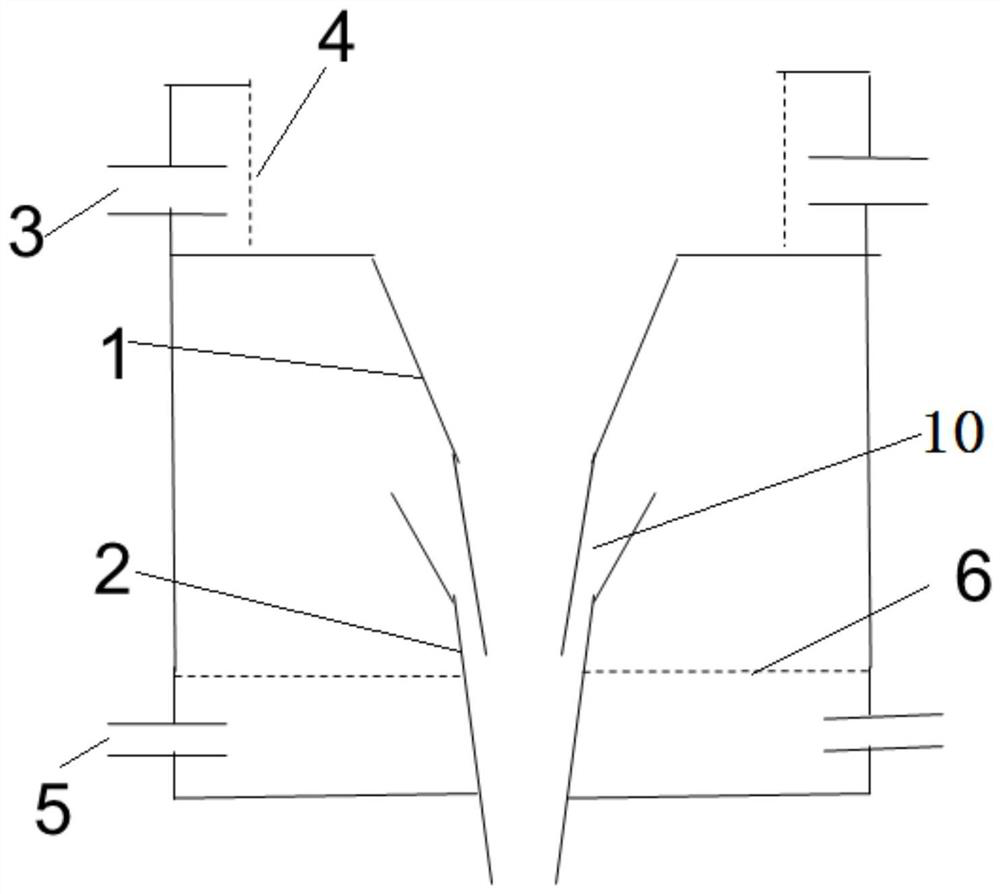

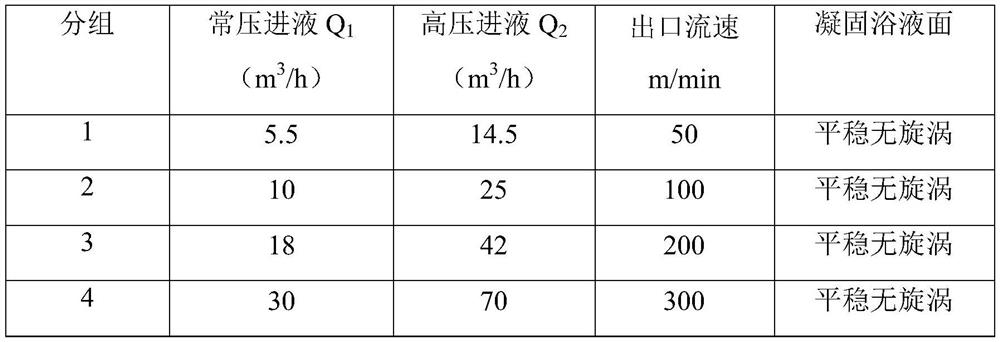

[0051] (3) The obtained fine spinning stream, after passing through an air gap with a height of 20 mm, enters the wide funnel for solidification and drafting to obtain cellulose fiber tow.

[0052] The width of the...

Embodiment 2

[0054] This embodiment provides a method for preparing cellulose fiber tow, the specific steps are as follows:

[0055] (1) After mixing cellulose pulp with a degree of polymerization of 600 and NMMO aqueous solution, it is swollen and dissolved to prepare a transparent solution, and then filtered and defoamed to obtain a cellulose spinning solution. The cellulose concentration of the spinning solution is 6 wt%, and the temperature of the spinning solution is 95°C.

[0056] (2) The spinning liquid is metered by a metering pump, enters the spinning box, and extrudes a fine spinning stream from the spinneret hole of the spinneret, and the extrusion speed is 10m / min. The temperature of the spinning box is 95° C., and the number of holes in the spinneret is 25,000.

[0057] (3) The obtained fine spinning stream, after passing through an air gap with a height of 20 mm, enters the wide funnel for solidification and drafting to obtain cellulose fiber tow.

[0058] The width of the ...

Embodiment 3

[0060] This embodiment provides a method for preparing cellulose fiber tow, the specific steps are as follows:

[0061] (1) After mixing cellulose pulp with a degree of polymerization of 600 and NMMO aqueous solution, it is swollen and dissolved to prepare a transparent solution, and then filtered and defoamed to obtain a cellulose spinning solution. The cellulose concentration of the spinning solution was 18 wt%, and the temperature of the spinning solution was 110°C.

[0062] (2) The spinning liquid is metered by a metering pump, enters the spinning box, and extrudes a fine spinning stream from the spinneret hole of the spinneret, and the extrusion speed is 10m / min. The temperature of the spinning box is 95° C., and the number of holes in the spinneret is 5000.

[0063] (3) The obtained fine spinning stream, after passing through an air gap with a height of 20 mm, enters the wide funnel for solidification and drafting to obtain cellulose fiber tow.

[0064] The width of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com