For rail vehicle - outer wall of carriage and manufacturing method

A technology for rail vehicles, carriages, applied in the field of outer walls and manufacturing for rail vehicles-carriage, can solve the problems of influence, unfavorable external appearance and surface characteristics of planar elements, etc., to achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

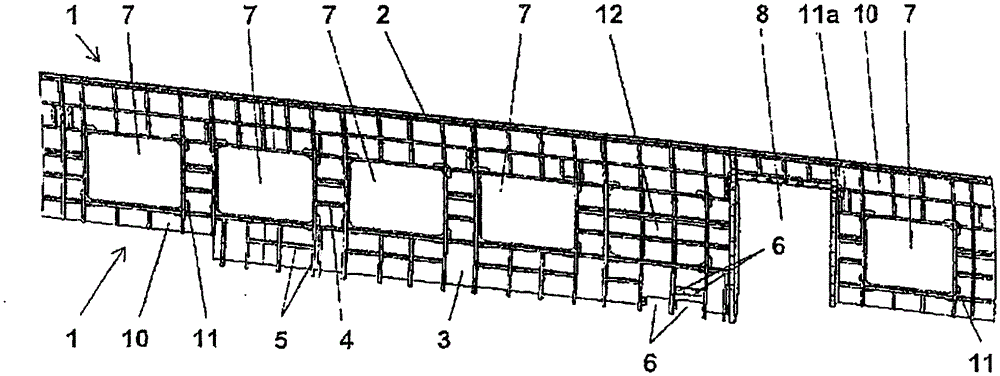

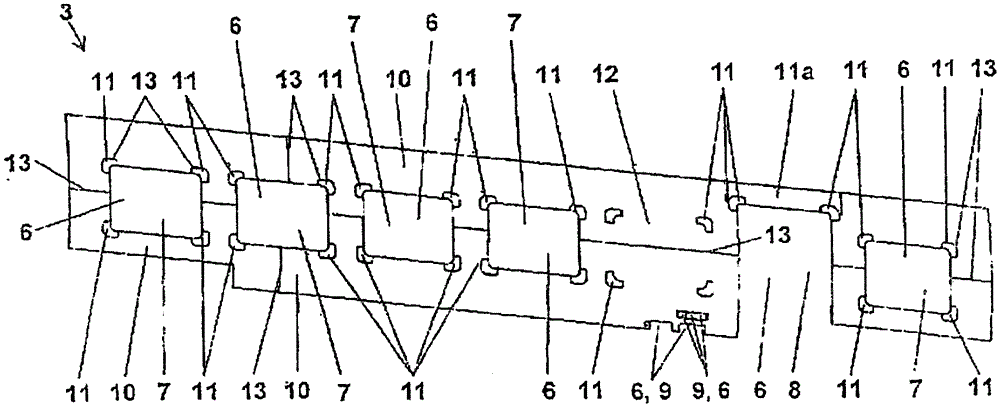

[0044] exist figure 1 In FIG. 2 , an outer wall 1 is schematically shown, which is fastened to a continuous end carrier 2 extending in the longitudinal direction of a car body of a rail vehicle, which is configured as an upper truss. The outer wall 1 comprises an outer panel 3 made of sheets of different material thickness. exist figure 1 A frame 4 consisting of frame profiles 5 is fastened to the inner side of the outer panel shown in . Functional openings 6 in the form of windows 7 , door openings 8 and supply and connection openings 9 are formed in the outer panel 3 , which forms a smooth outer surface on the outside (below the plane of the drawing). The outer panel 3 is designed as a self-supporting shear zone. The frame 4 serves only or mainly to reinforce the shear zone.

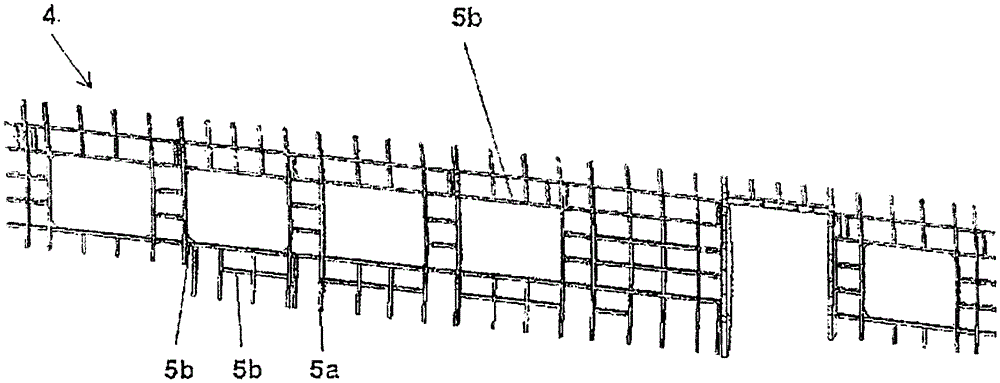

[0045] exist figure 2 is schematically shown according to figure 1 The outer panel of the outer wall 1. A first sheet metal 10 of a first material thickness and a second sheet metal 11 , 11 a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com