A method for preparing continuous SIC fibers with low oxygen content without melting in air

A low oxygen content, fiber technology, applied in the direction of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of reduced fiber mechanical strength, high equipment requirements, and harsh conditions for the preparation of continuous SiC fibers with low oxygen content, so as to reduce oxygen content, The effect of low preparation cost and easy realization of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

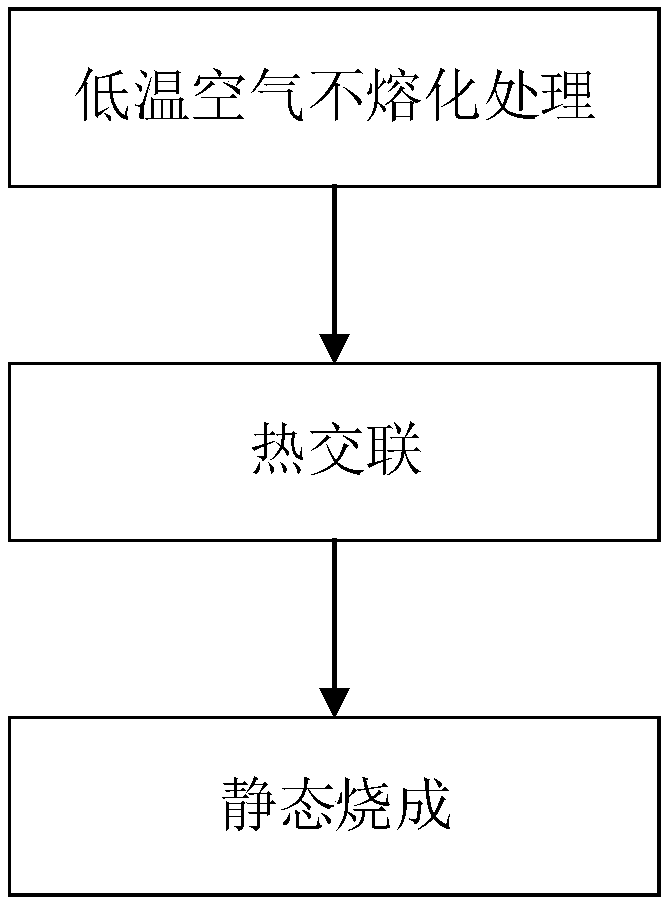

Method used

Image

Examples

Embodiment 1

[0047] (1) PCS polymer (softening point is 223°C, number average molecular weight is 1.76×10 3 g / mol, molecular weight distribution coefficient is 3.43) is placed in the melting cylinder of the melt spinning device, heated to 360 ° C under the protection of an inert atmosphere, and after it is completely melted into a uniform melt, under the pressure of 300 ° C and 0.5 MPa , and draw and spin at a speed of 450m / min to obtain a whole tube of PCS fibrils with an average diameter of 12um, 1000 pieces / bundle, and a continuous length of 500m.

[0048] (2) Place the whole cylinder of PCS fibrils in an air infusible treatment device for infusibility treatment, raise to 100°C for 1 hour and keep the temperature for 2 hours, then raise the temperature to 160°C at a temperature increase rate of 5°C / hour, and at 160°C After holding for 5 hours, the temperature was lowered to room temperature to obtain non-melting fibers.

[0049] (3) The whole cylinder of infusible fibers is placed in a...

Embodiment 2

[0053] The entire cylinder of PCS fibrils obtained in the step (1) of Example 1 was placed in an air infusible treatment device for infusibility treatment, raised to 100 °C for 1 hour and kept for 2 hours, and then increased to 10 °C / hour at a heating rate. 170°C, incubating at 170°C for 2 hours and then cooling to room temperature to obtain infusible fibers. The whole cylinder of infusible fibers was placed in a graphite furnace, protected by nitrogen gas, raised to 100°C for 1 hour and kept for 1 hour, raised to 500°C at a heating rate of 60°C / hour, and then increased at a temperature of 120°C / hour. The speed was increased to 1200°C, and the temperature was kept for 0.5 hours to obtain continuous SiC fibers with low oxygen content.

[0054] The Si content of the SiC fiber prepared in this example is 56.23wt%, the C content is 33.09wt%, the O content is 7.18wt%, the average diameter is 11.9um, the tensile strength is 2.30GPa, and the Young's modulus is 202GPa.

[0055] The f...

Embodiment 3

[0057] The whole cylinder of PCS fibrils obtained in the step (1) of Example 1 was placed in an air infusible treatment device for infusibility treatment, raised to 100 °C for 1 hour and kept for 3 hours, and then increased to 15 °C / hour at a heating rate. 180°C, incubating at 180°C for 0.5 hours and then lowering to room temperature to obtain non-melting fibers. The whole cylinder of infusible fibers was placed in a graphite furnace, protected by argon gas, raised to 100 °C for 1 hour and kept at The heating rate was increased to 1100°C, and the temperature was maintained for 2 hours to obtain continuous SiC fibers with low oxygen content.

[0058] The SiC fiber prepared in this example has a Si content of 56.35wt%, a C content of 32.34wt%, an O content of 9.21wt%, an average diameter of 12.3um, a tensile strength of 2.22GPa, and a Young's modulus of 201GPa.

[0059] The fiber was kept at 1400°C in nitrogen for 1 hour and then lowered to room temperature, and the strength re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com