Processing system of toothbrushes and using method of processing system

A processing system and toothbrush technology, applied to other household appliances, applications, household components, etc., can solve the problems of decreased integrity and reliability, extremely high requirements for matching accuracy, small processing volume in a single batch, etc., and achieve good processing results. , The effect of low matching precision requirements and large processing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

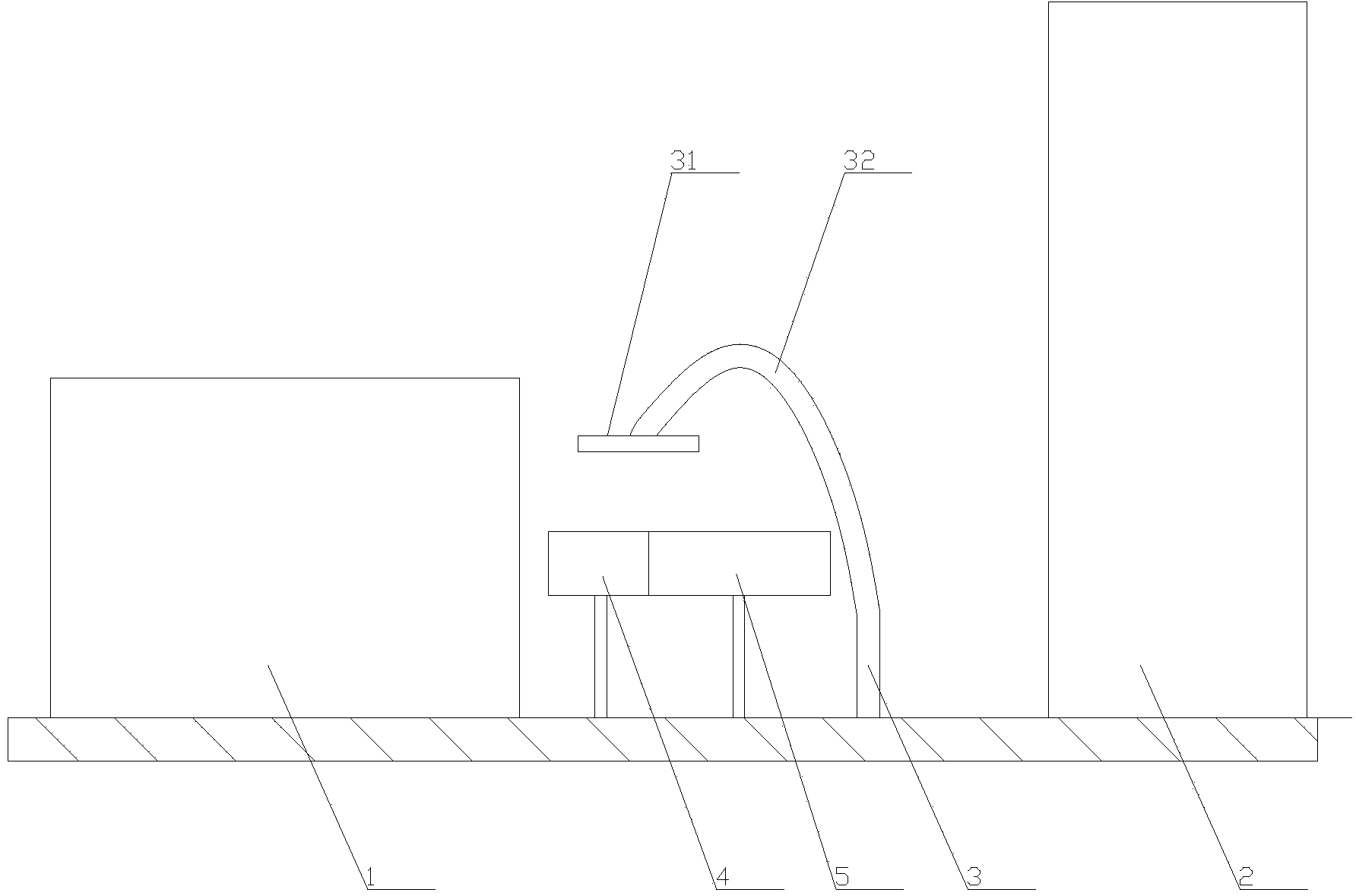

[0068] The present invention as Figure 1-17 as shown,

[0069] The toothbrush includes a body and an overcoating body, the body includes a head and a handle, and the overcoating body is wrapped outside the handle; the processing system includes a molding injection molding machine 1 and an overmolding injection molding machine 2, through which Forming Injection molding machine 1 injection-molding the body, through the encapsulation injection molding machine 2 to encapsulate the body multiple times (secondary encapsulation can be performed after one molding, if the encapsulation body is composed of multiple colors or multiple special parts, Then, after the second encapsulation, encapsulation can be carried out three times, four times or even multiple times); the processing system also includes a transfer mechanism 3;

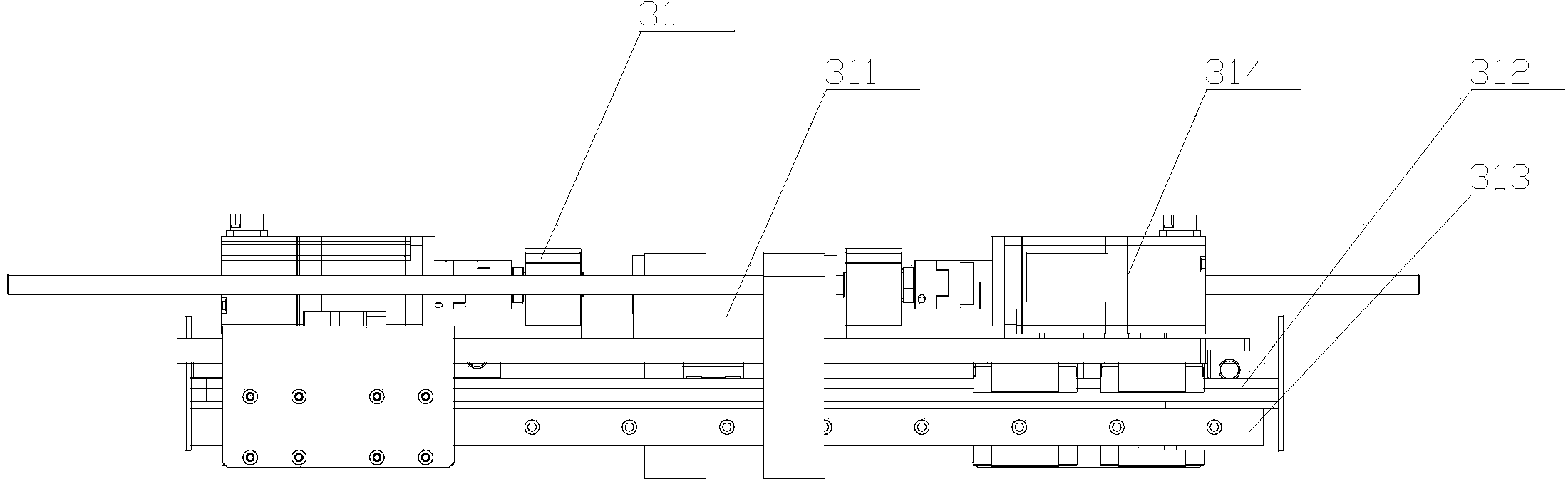

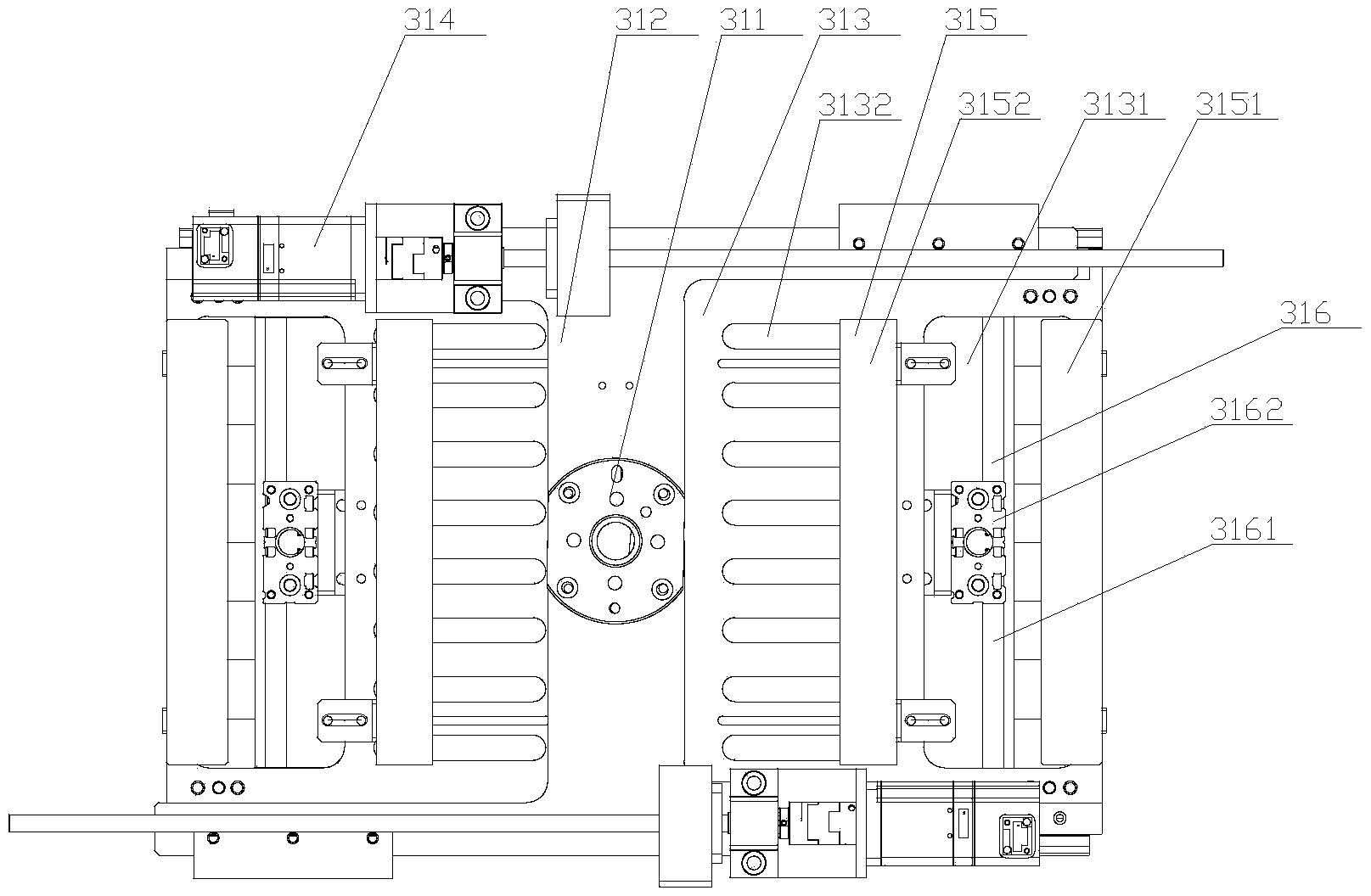

[0070] The transfer mechanism 3 includes a mechanical arm 32 (in this case, a six-axis multi-joint robot is currently used) and a grabbing device 31. One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com