Double-screw pump provided with elastic lining layer

A twin-screw pump and screw technology, applied in the direction of pumps, rotary piston pumps, rotary piston machines, etc., can solve the problems of restricting the comprehensive mechanical performance of pumps, increasing production and manufacturing costs, and limiting application fields, so as to improve the comprehensive mechanical performance , Reduce machining accuracy, broaden the adaptability and the effect of application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the drawings as follows:

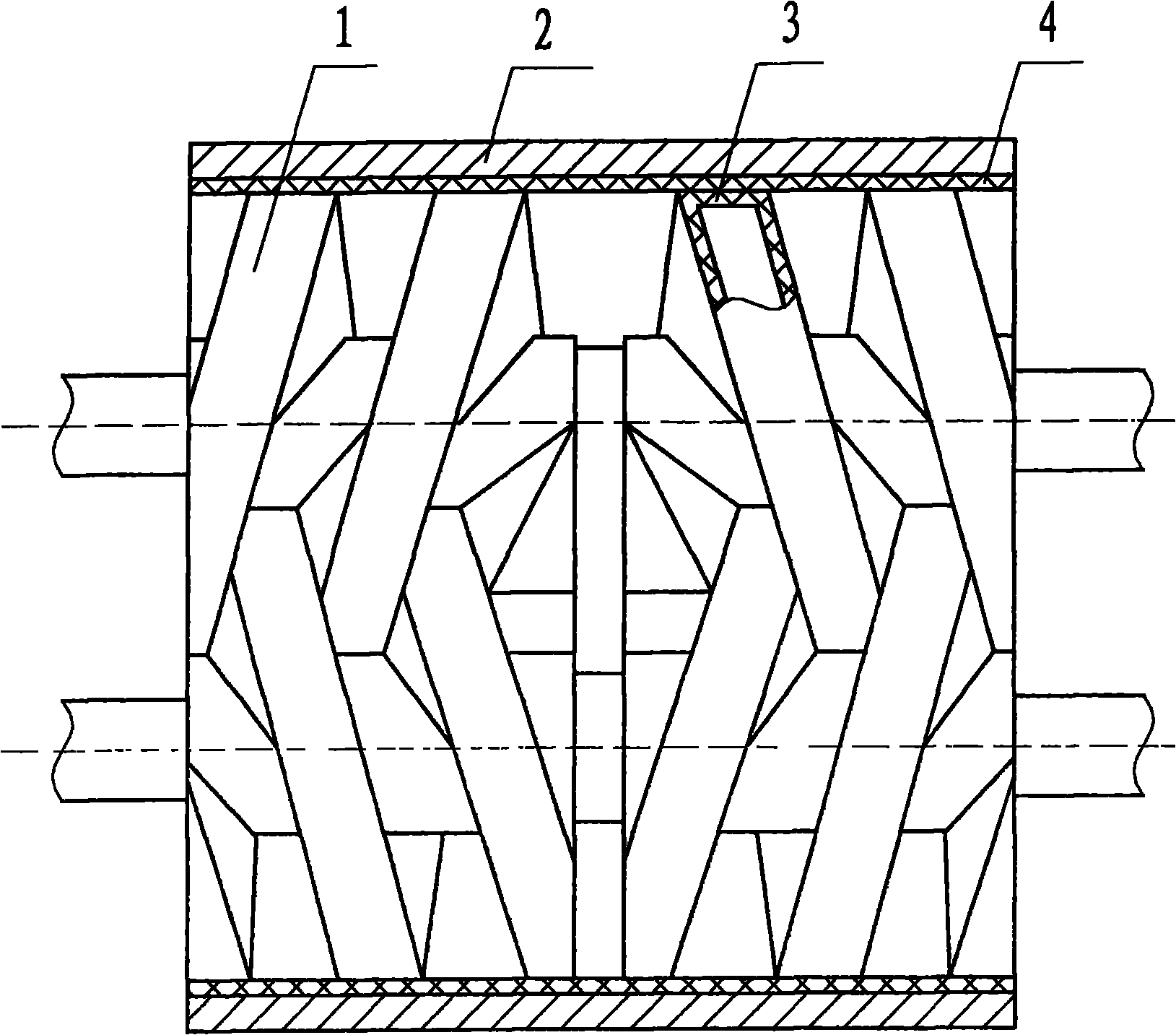

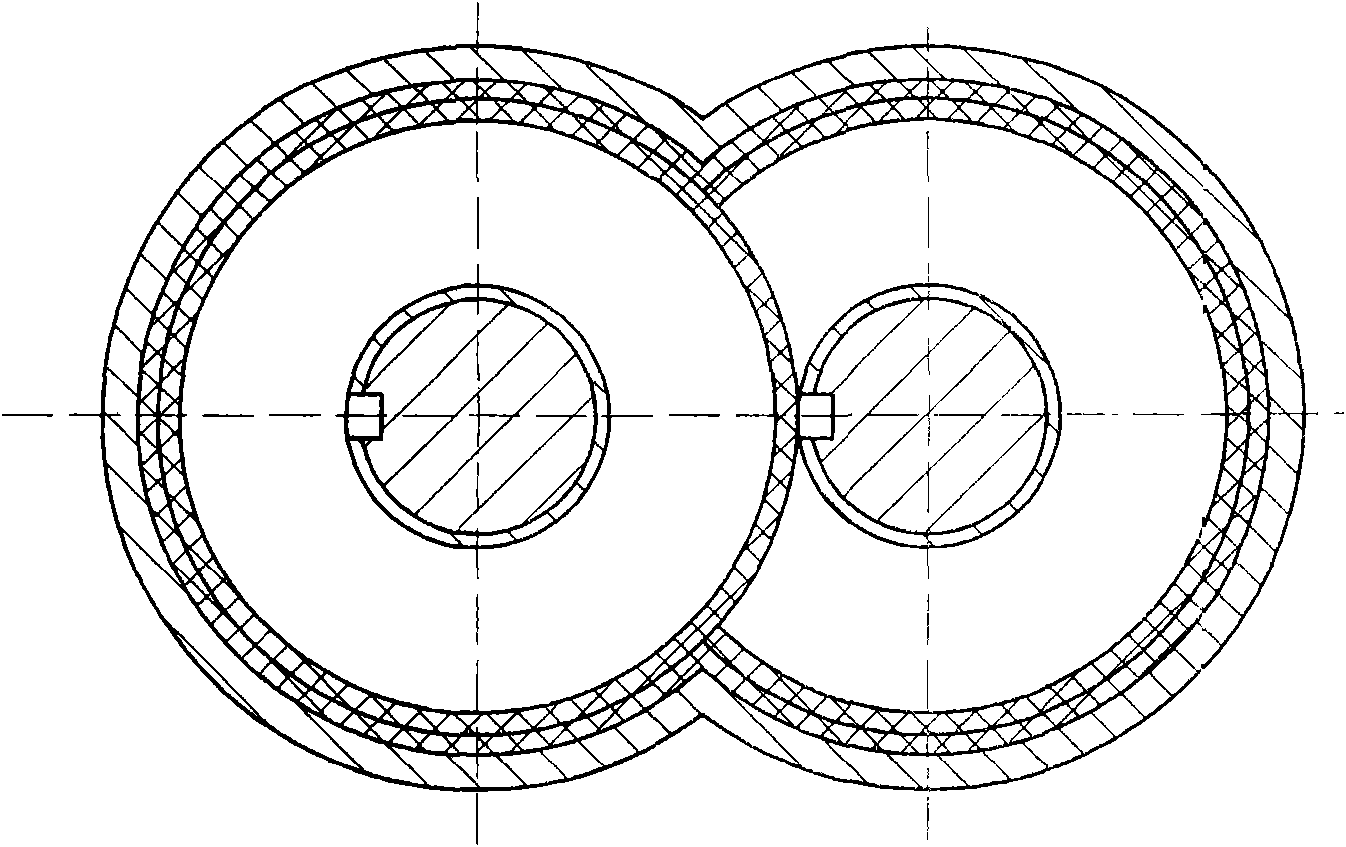

[0012] figure 1 , figure 2 It is a schematic diagram of the structure of the twin screw pump with elastic lining of the present invention. The present invention can be implemented in the following ways: using existing machining technology, rough machining the screw or pump sleeve under the premise of reducing machining accuracy, or even using casting technology, For example, with precision casting technology, the screw (1) or the blank of the pump sleeve (2) is made, and then a mold or other existing technology is used to line the screw (1) with a layer of elastic body (3) on the surface of the screw. (2) The inner surface of the pump sleeve is lined with elastomer (4). The elastomer material can be rubber, elastic plastic, or other elastic composite materials.

[0013] Whether each screw and between the screw and the pump sleeve of the twin screw pump involved in the tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com