Mute steam blow through valve

A technology for blowing off valves and steam, which is applied to valve details, valve devices, and valve operation/release devices, etc. It can solve the problems of the original cut-off valve such as large blowing noise, and achieve long service life, good sealing performance, and high interaction. transsexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

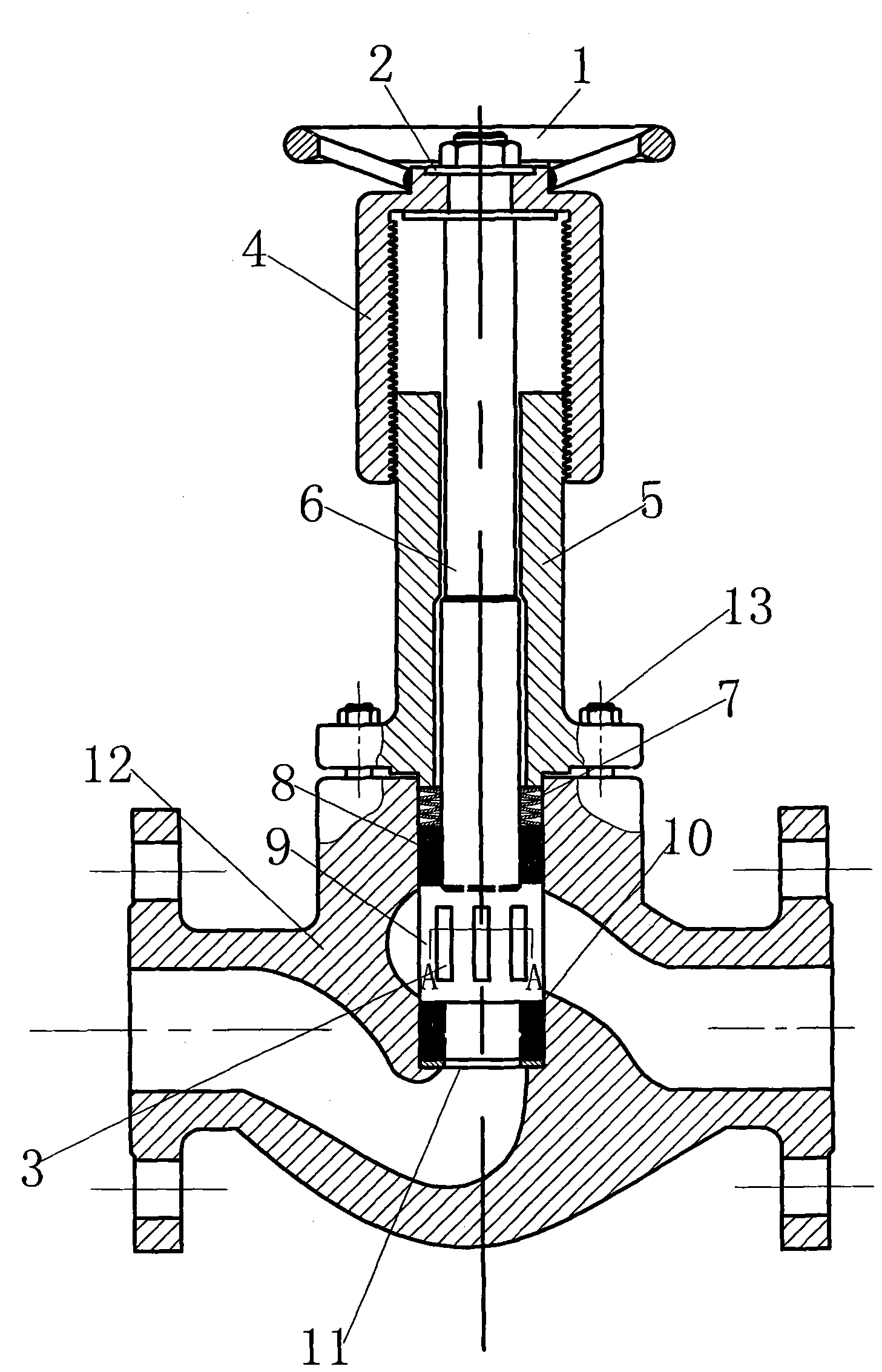

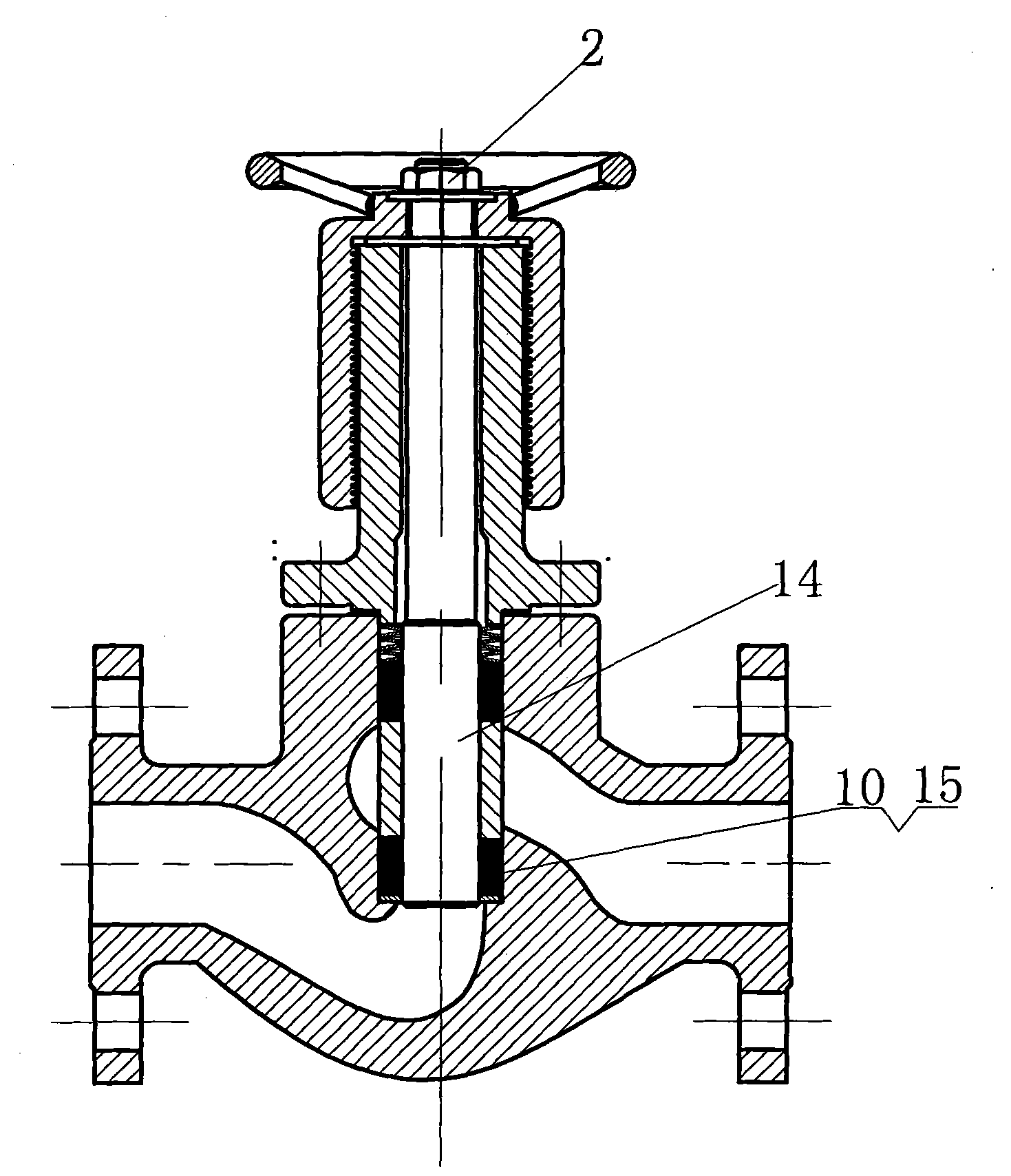

[0016] A silent steam blow-off valve, including a valve body 13, a hand wheel 1, a valve stem 6, a valve core 14, a valve stem cap 4, a gland 5 and a double seal assembly, at the lower port of the valve cavity 15 in the middle of the valve body 12 A washer 11 is provided;

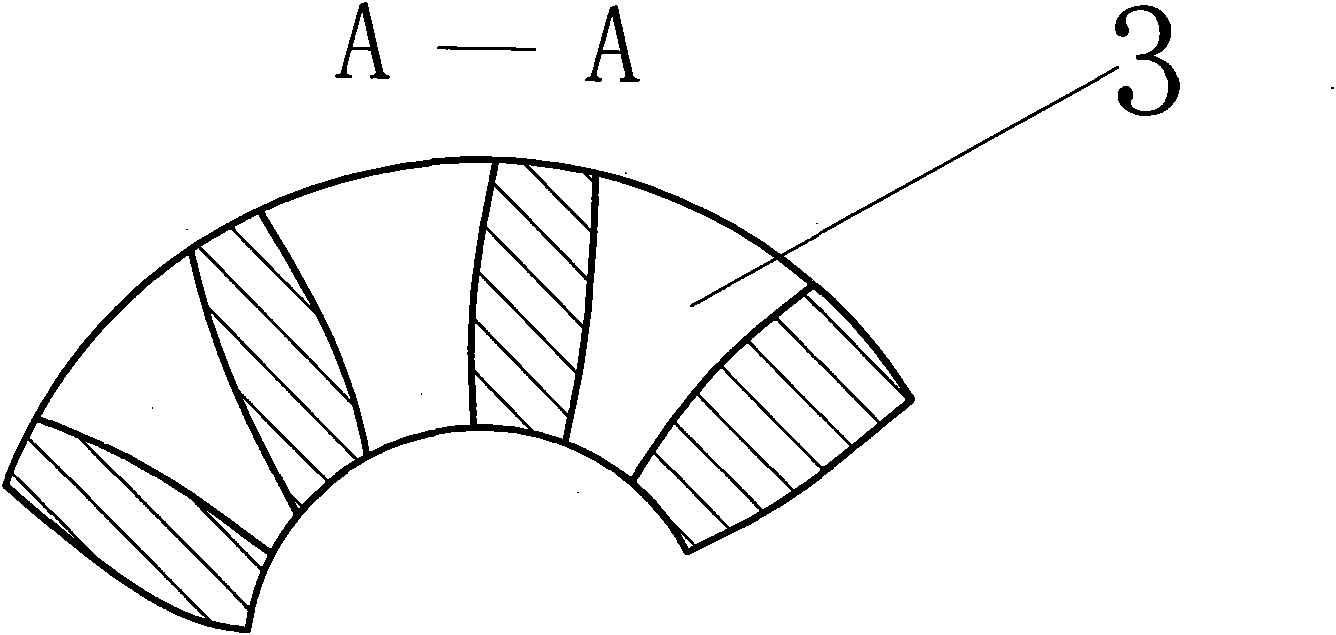

[0017] The double seal assembly consists of a disc spring 7, a graphite stainless steel upper sealing ring 8, a valve core sleeve 9 and a graphite stainless steel lower sealing ring 10, which are sequentially fitted on the valve core 14 and then loaded into the valve cavity 15 in the middle of the valve body 12; Graphite stainless steel lower sealing ring 10 and graphite stainless steel upper sealing ring 8 are closely matched with the inner wall of the valve cavity 15 in the middle of the valve body 12 respectively; the gland 5 is set on the valve stem 6, and the cover is fixed on the valve body 12 through bolts 13; The lower end surface of the graphite stainless steel lower sealing ring 10 abuts against t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com