Extra-high voltage transformer maintenance operation device and maintenance method

A technology of operating devices and transformers, applied in the direction of switchgear, electrical components, etc., can solve the problems of difficult operation, failure to solve the safety problems of high-voltage transformers, and complicated installation of maintenance work platforms, so as to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

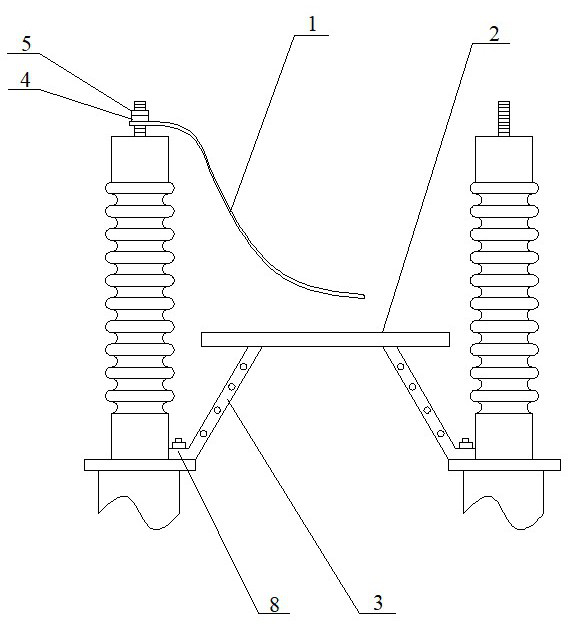

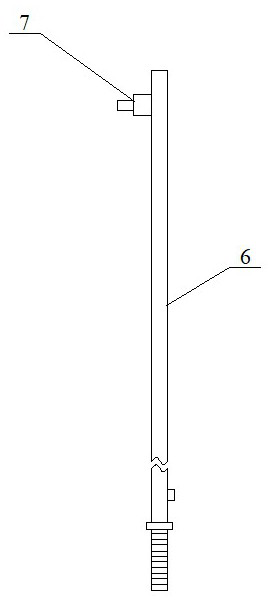

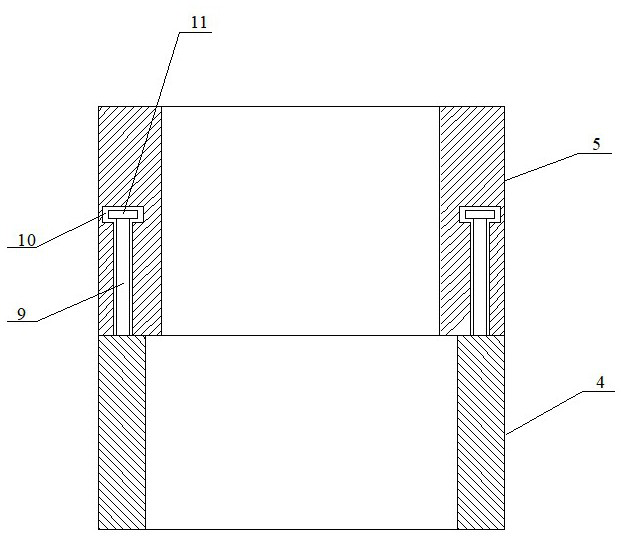

[0033] Such as Figure 1~2 As shown, a UHV transformer inspection and maintenance operation device includes a safety belt suspension mechanism fixed on the top bolt of the transformer, and an inspection and maintenance operation platform arranged on the panel of the transformer low-voltage bushing rising seat; the safety belt suspension mechanism includes a safety belt 1. The connecting piece arranged on the upper end of the safety belt 1, and the installation assembly for installing the connecting piece on the top bolt of the transformer; the maintenance work platform includes a support plate 2, a ladder 3 and an installation base, and the support Both sides of the plate 2 are provided with the ladders 3, and the lower parts of the two ladders 3 are provided with installation bases, and the two installation bases are respectively connected to the panels of the two transformer low-voltage bushing risers by bolts.

[0034] Specifically, the upper end of the safety belt 1 is pro...

Embodiment 2

[0041] Such as Figure 1~3 As shown, a UHV transformer inspection and maintenance operation device includes a safety belt suspension mechanism fixed on the top bolt of the transformer, and an inspection and maintenance operation platform arranged on the panel of the transformer low-voltage bushing rising seat; the safety belt suspension mechanism includes a safety belt 1. The connecting piece arranged on the upper end of the safety belt 1, and the installation assembly for installing the connecting piece on the top bolt of the transformer; the maintenance work platform includes a support plate 2, a ladder 3 and an installation base, and the support Both sides of the plate 2 are provided with the ladders 3, and the lower parts of the two ladders 3 are provided with installation bases, and the two installation bases are respectively connected to the panels of the two transformer low-voltage bushing risers by bolts.

[0042] Specifically, the upper end of the safety belt 1 is pro...

Embodiment 3

[0049] Such as Figure 1~5 As shown, the UHV transformer maintenance operation device of the embodiment of the present invention is different from the first and second embodiments in that: the support plate 2 includes two angle steels 12, and a plurality of angle steels 12 are arranged between the two angle steels. The connecting rods 13, and the folding plates arranged on the plurality of connecting rods 13, one end of the folding plates is hinged to the two angle steels.

[0050] The folding plate includes a first plate body 14, a second plate body 15 and a third plate body 16 which are sequentially hinged, the first plate body 14 is hinged to the two angle steels 12, and the bottom of the second plate body 15 is arranged The two folded legs 17, the first plate body 14 and the lower part of the third plate body 16 are all provided with pads, which are used to be at the same height as the second plate body.

[0051] The folding legs are spring double legs, and one spring dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com