Split type concentric water distributor suitable for scaling well and separate injection process

A split-type, water distributor technology, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of reducing operating costs, high costs, and the need to remove oil pipes, and achieves high operating efficiency, reducing The effect of water injection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

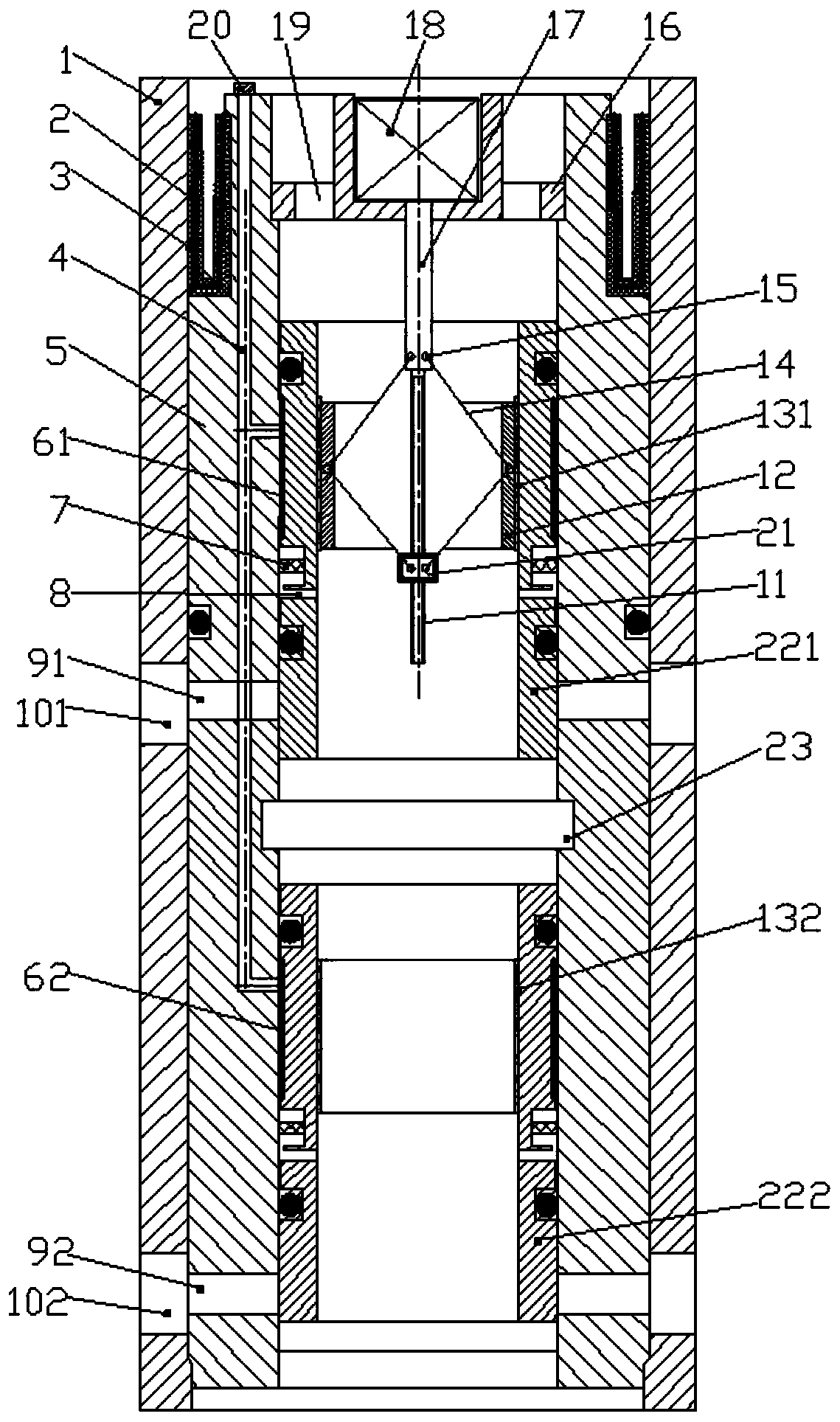

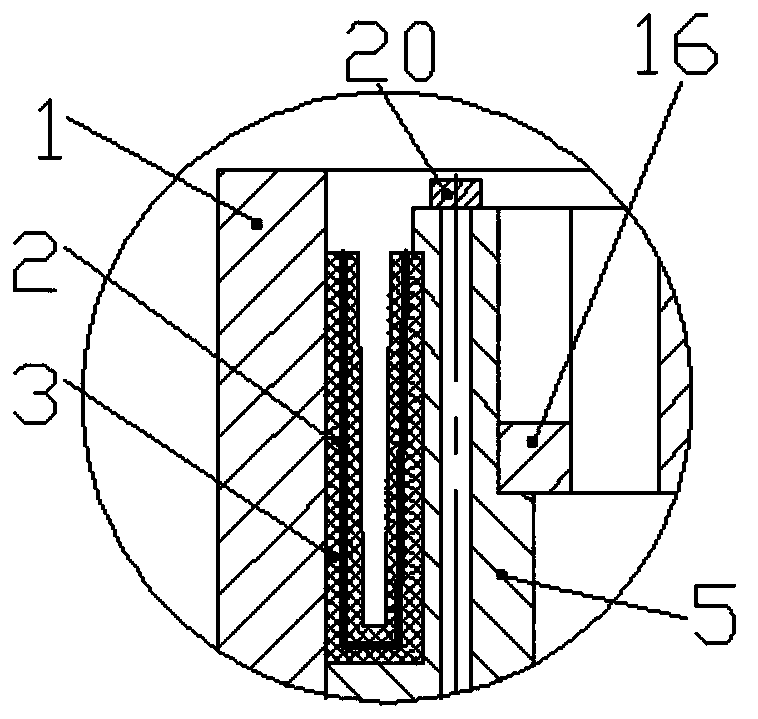

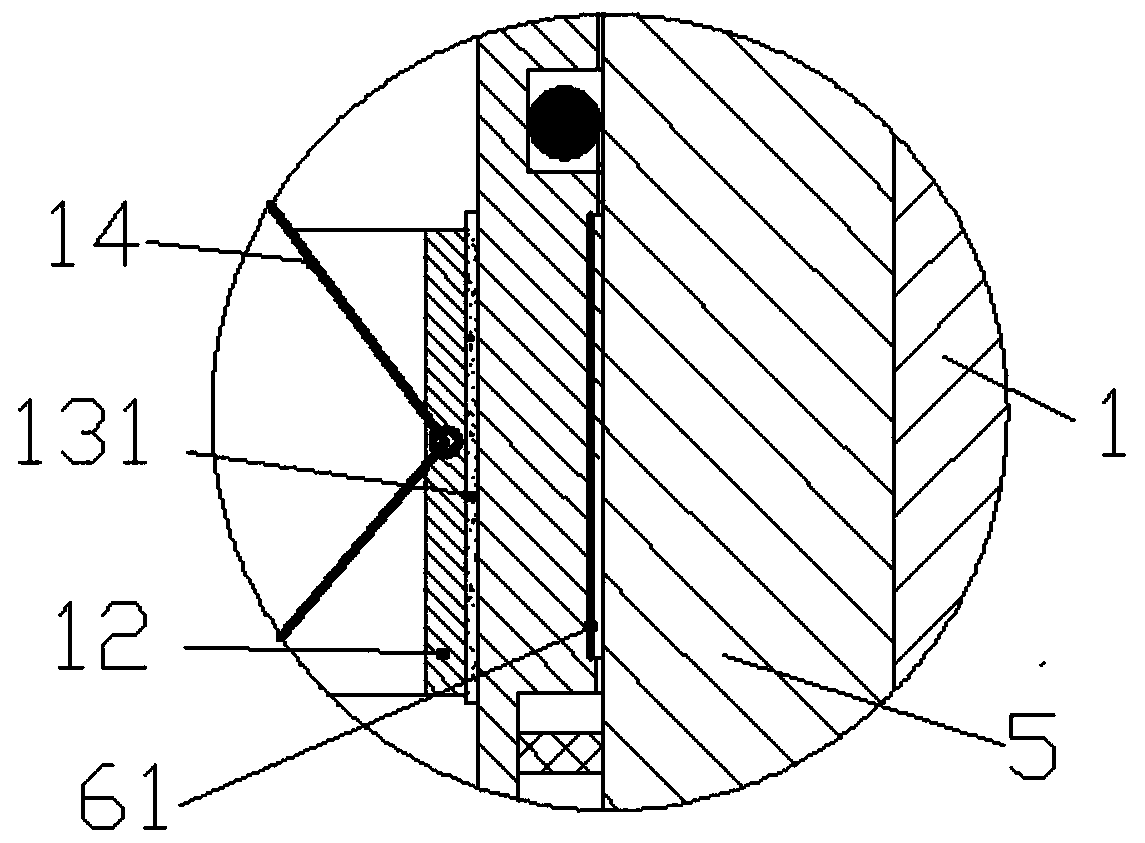

[0024] The present invention will be further described below in conjunction with implementation and accompanying drawings.

[0025] Such as Figure 1-4 As shown, the present invention is a split-type concentric water distributor suitable for fouling wells, including a working cylinder 1, a core body 5 installed in the working cylinder 1, and a core body 5 installed in the core body 5 Adjusting mechanism, the working cylinder 1 and the core body 5 are respectively radially provided with a first-level water injection hole 101 and a second-level water injection hole 102, a first-level core water nozzle 91 and a second-level core water nozzle 92, and the core The body 5 is provided with a rubber seal 3 that is close to the working cylinder 1, and the rubber seal 3 is provided with a grooved steel sheet 2. When the water is injected, the high-pressure water and the grooved steel sheet 2 can ensure that the rubber seal 3 is tightly sealed. Paste on the mandrel 1 and the core body 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com