Force loading system for detecting mechanical property of robot and system adjusting method

The technology of loading system and robot is applied in the field of force loading system and system adjustment for detecting mechanical properties of robots, which can solve the problems of cumbersome operation, low precision and low measurement efficiency, and achieves high adjustment efficiency, convenient work flow, and easy operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

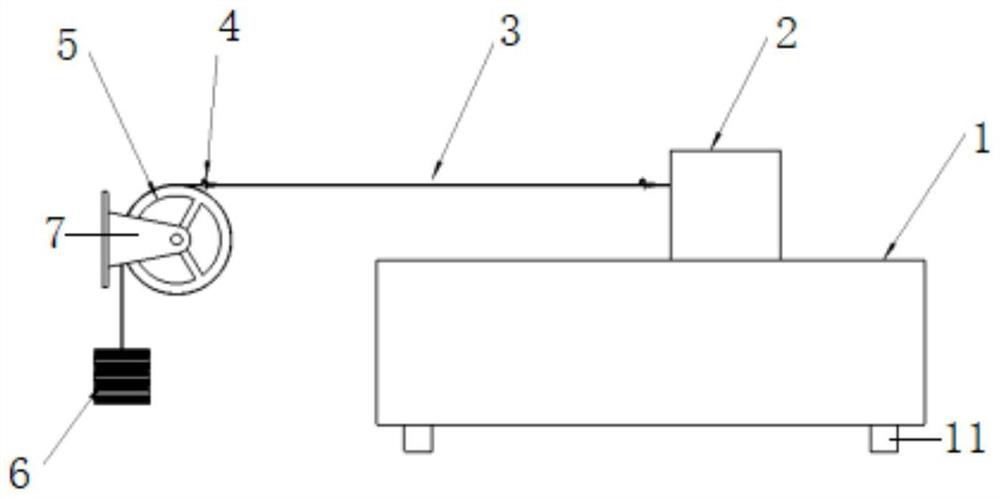

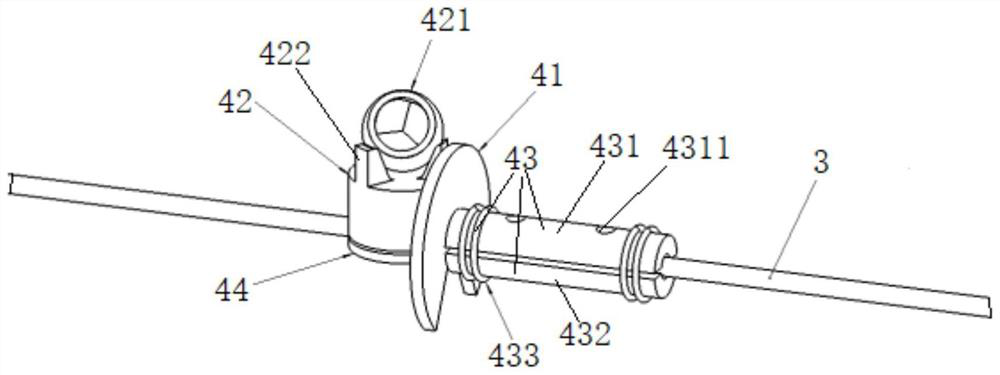

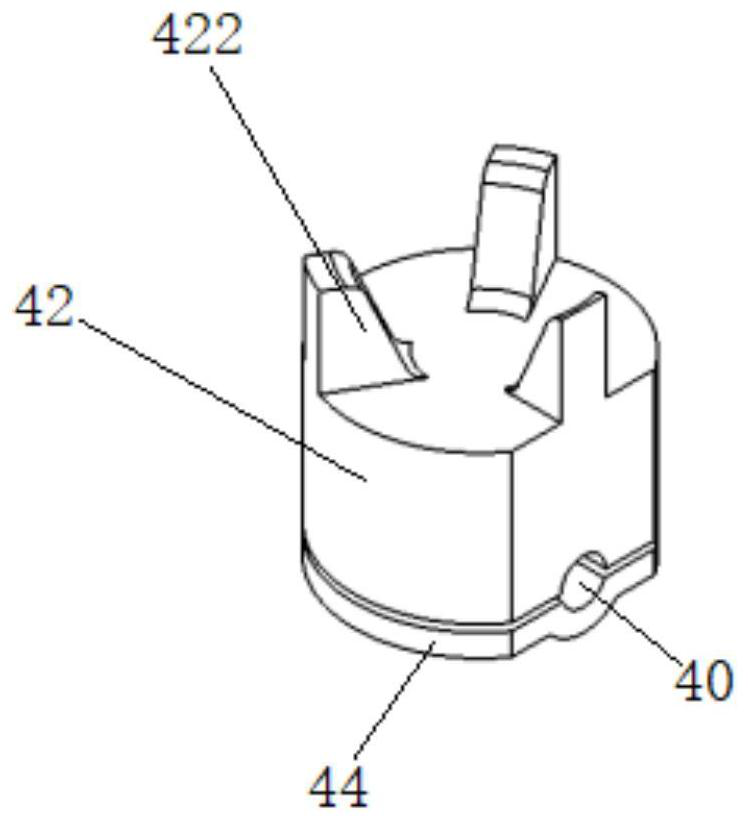

[0047] Such as figure 1 The illustrated embodiment is a force loading system for detecting the mechanical properties of a robot, comprising a rectangular support platform 1 extending laterally on the upper surface, and four support feet 11 respectively arranged at 4 corners of the lower surface of the support platform, The force-bearing cube 2 arranged on the right part of the upper surface of the support platform, the rope 3 connected to the force-bearing cube at the right end, the target ball seat tooling 4 arranged on the rope, the pulley 5 used to support the left part of the rope, and the rope connected to the left end of the rope Weight 6; the ground is provided with a moving mechanism 7 for driving the shaft of the pulley to move vertically and forward and backward; the bottom of each support foot is provided with a height adjustment bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com