Leakage detection device and leakage detection method for lithium ion battery

A lithium-ion battery and battery technology, applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of laser instability, explosion, effective screening, etc., and achieve reduction Detect the risk of missed judgment, improve the detection efficiency, and improve the effect of screening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

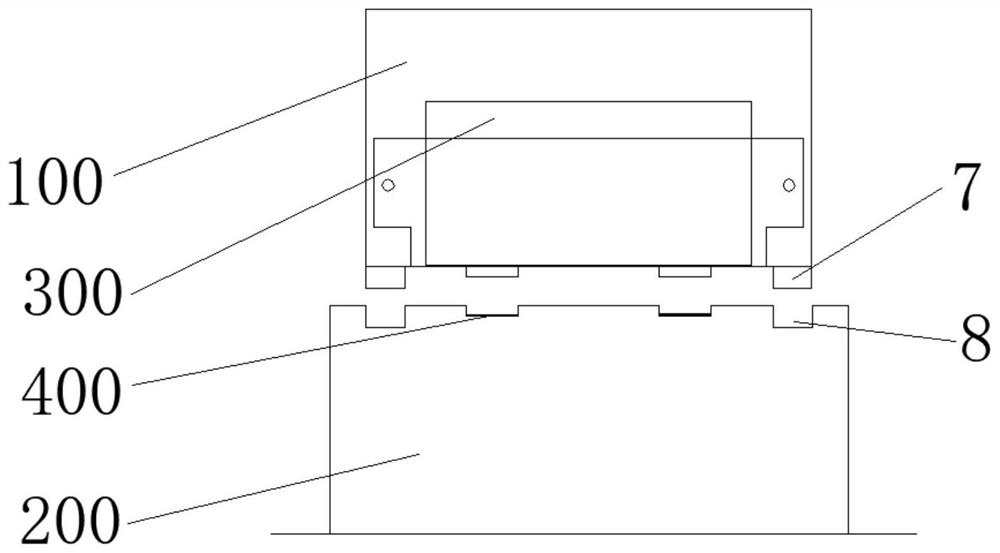

[0048] Please refer to figure 1 As shown, the leak detection device for a lithium ion battery includes a loading tray structure 100 on which a battery 300 is loaded, and the loading tray structure 100 is detachably mounted on a test platform 200 .

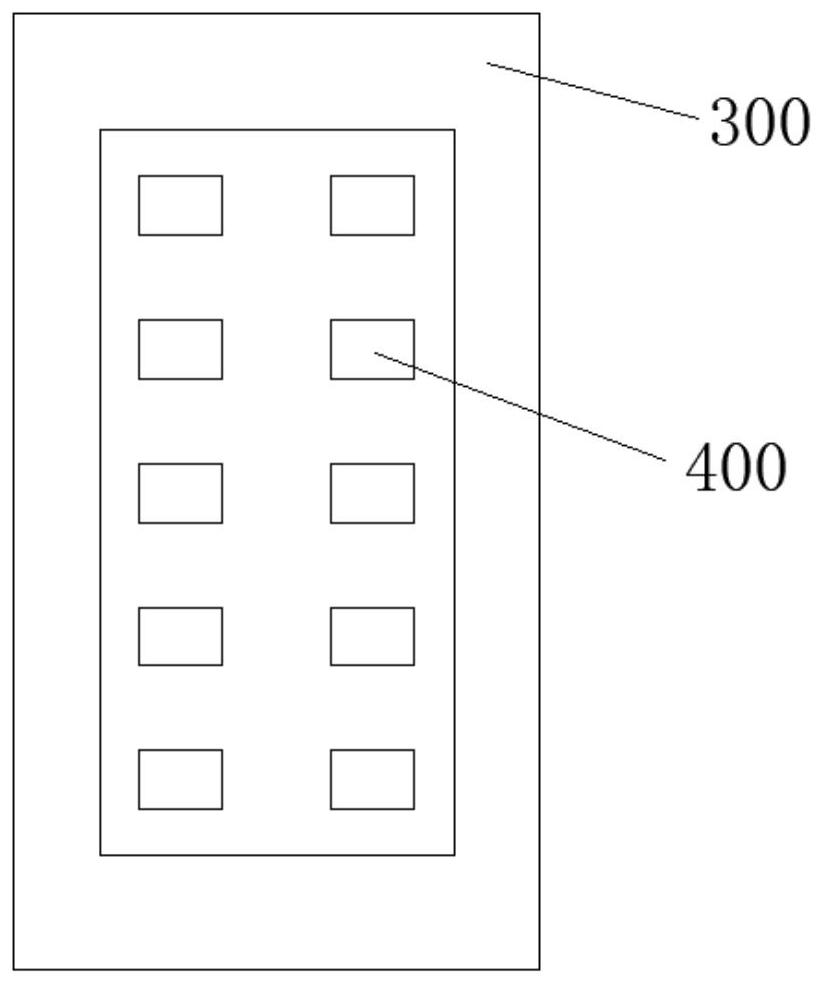

[0049] Such as image 3As shown, the test platform 200 is provided with a test hole corresponding to the battery, and a test paper 400 is provided in the test hole. The loading tray structure 100 loaded with the battery 300 is installed forward or turned over and installed on the test platform 200, so that the battery 300 is turned upside down and in contact with the test paper 400 and closely adhered to it. The test paper 400 detects whether the welding seam of the battery 300 has leakage holes Leakage of electrolyte.

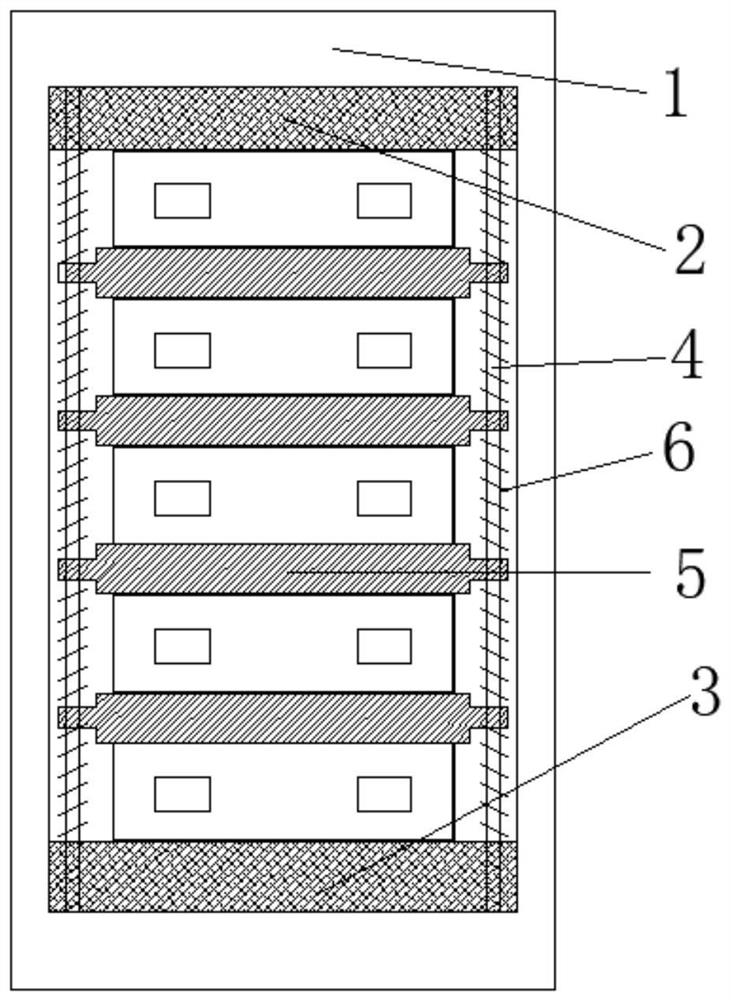

[0050] In one embodiment of the present invention, as image 3 As shown, the loading tray structure 100 includes a loading tray 1 , and a clamping assembly is provided on the loading tray 1 , and the clamping as...

Embodiment 2

[0060] This specific embodiment provides a leak detection method for a lithium-ion battery. By using the leak detection device in Example 1, the lithium-ion battery is installed upside down on the loading tray structure 100, and then the loading tray structure 100 is installed forward on the test The detection on the platform 200 specifically includes the following steps:

[0061] S1. Install several batteries 300 upside down on the loading tray structure 100 in sequence.

[0062] Specifically:

[0063] Firstly, turn several batteries 300 upside down in turn by the manipulator, so that the poles of the batteries 300 are placed downwards at the loading and buffering station;

[0064] Secondly, the inverted battery 300 is sequentially grasped by the manipulator and placed in the clamping area formed by the adjacent clamping blocks 5;

[0065] Again, the inserting block 3 is clamped by the manipulator and installed on the loading tray 1, so that the clamping block 5 clamps the ...

Embodiment 3

[0076] This specific embodiment provides a leak detection method for a lithium-ion battery. By adopting the leak detection device of Embodiment 1, the difference between this embodiment and Embodiment 2 is that this embodiment uses the lithium-ion battery forward (pole upward direction) on the loading tray structure 100, and then install the loading tray structure 100 on the test platform 200 for testing after turning over the loading tray structure 100, which specifically includes the following steps:

[0077] S1. Install several batteries 300 on the loading tray structure 100 sequentially in the forward direction (the poles of the batteries are upward).

[0078] Specifically:

[0079] Firstly, the battery 300 is grabbed and placed in the clamping area formed by the adjacent clamping blocks 5 sequentially by the manipulator;

[0080] Again, the inserting block 3 is clamped by the manipulator and installed on the loading tray 1, so that the clamping block 5 clamps the battery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com