Battery winding mechanism for tab detection

A detection mechanism and battery roll technology, applied in the field of lithium-ion batteries, can solve the problems of short circuit of the winding core, inability to use detection instruments to detect the folding of the positive and negative electrode tabs, and entering the market, so as to achieve accurate judgment and reduce the leakage of the tabs. Check the effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

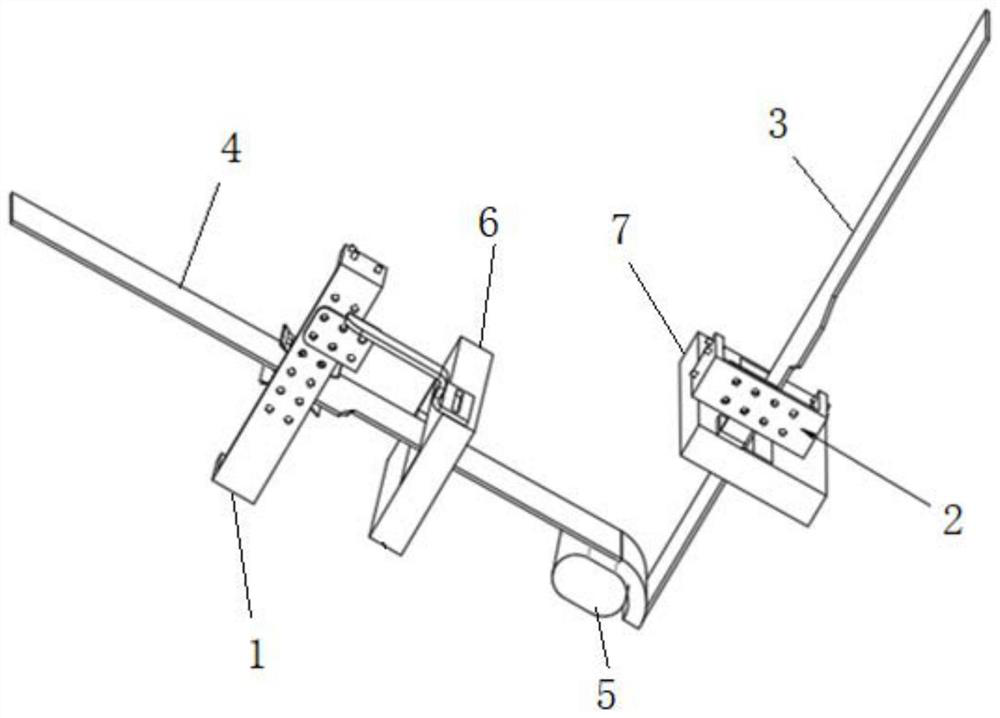

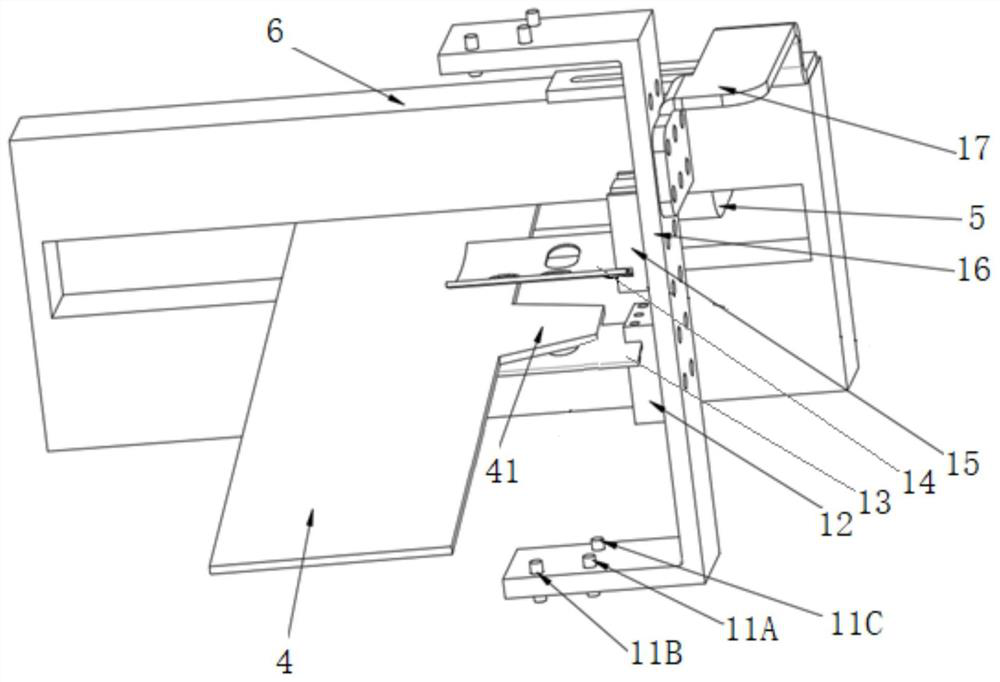

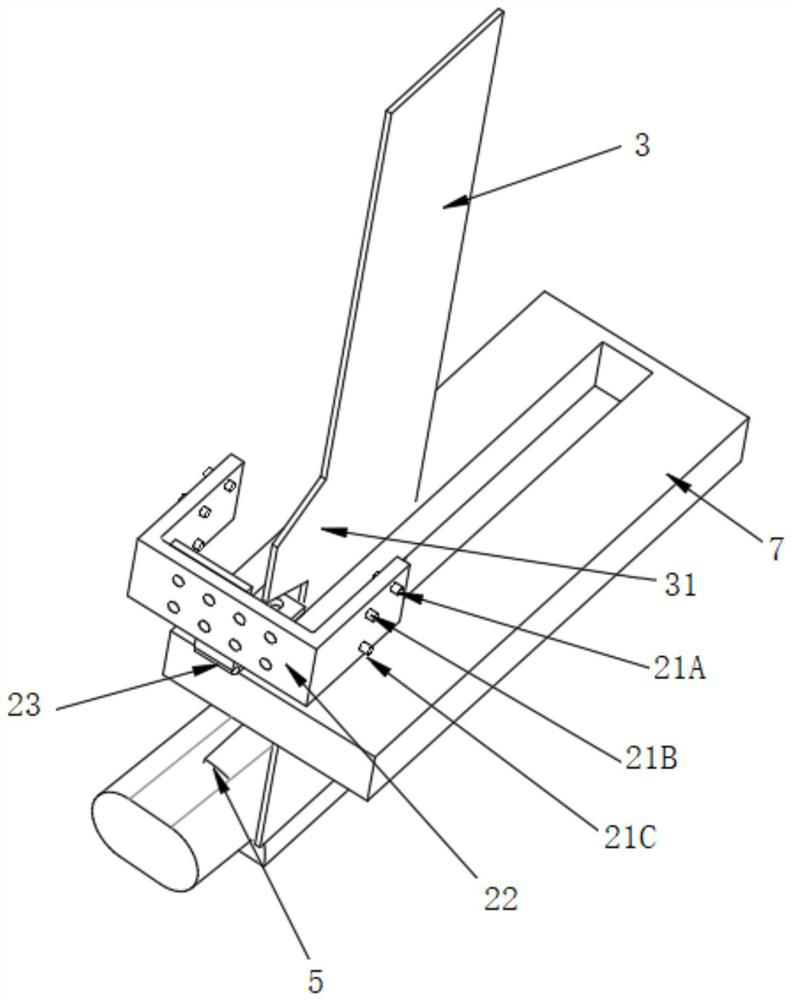

[0026] Such as Figure 1-3 As shown, a battery winding mechanism for tab detection includes a winding needle 5 for winding the positive electrode sheet 3 and the negative electrode sheet 4 into a wound battery, and a positive electrode cutter 7 and a negative electrode cutter for cutting the positive and negative electrode sheets. Knife 6, the front end of the positive electrode cutter 7 is connected with a positive electrode detection mechanism 2 for detecting the positive electrode tab 31 of the positive electrode sheet 3 turning over, and the positive electrode detection mechanism 2 includes a positive electrode frame 22 and a second opposite sensor; The positive electrode piece 3 vertically passes through the positive electrode detection mechanism 2, the positive electrode cutter 7 and the winding needle 5 in turn, and then is wound. That is, if the sound beam or signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com