Intelligent monitoring system for wind power blade assembly mold

An intelligent monitoring system and technology for wind turbine blades, applied in household components, household appliances, other household appliances, etc., can solve the problems of online monitoring of mold clamping gap and mold clamping dislocation, lack of real-time feedback of molds, etc., so as to improve monitoring efficiency and reduce Labor cost, reduce the effect of trial and error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

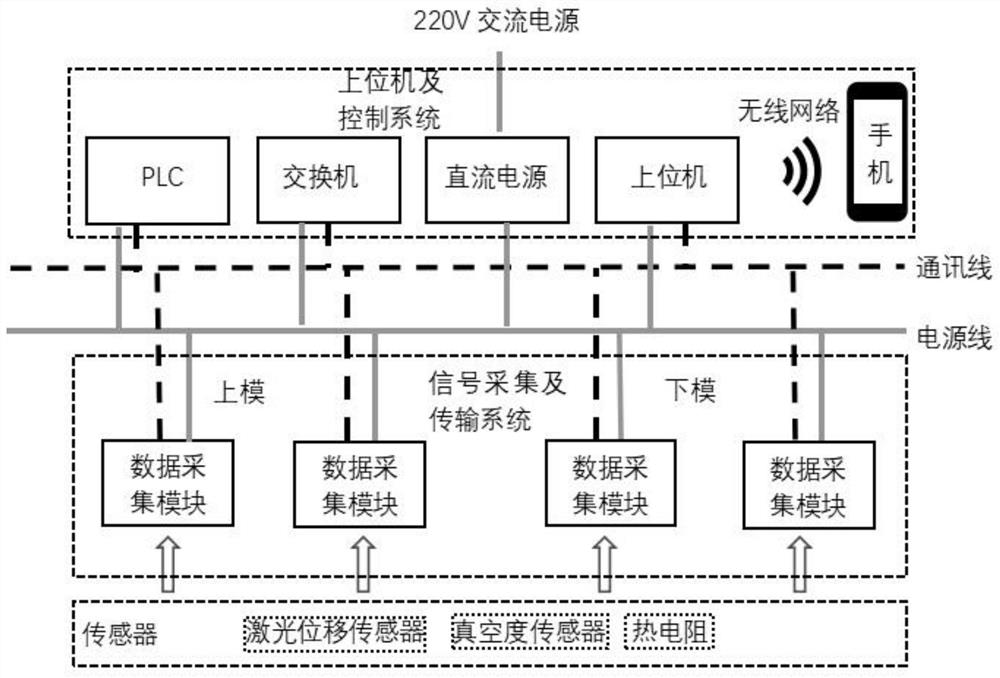

[0052] Such as figure 1 As shown, the intelligent monitoring system for wind turbine blade component molds in a preferred embodiment of the present invention mainly includes three parts, namely sensors, signal acquisition and transmission systems, and control systems.

[0053] In this embodiment, a wind power blade mold is taken as an example for illustration.

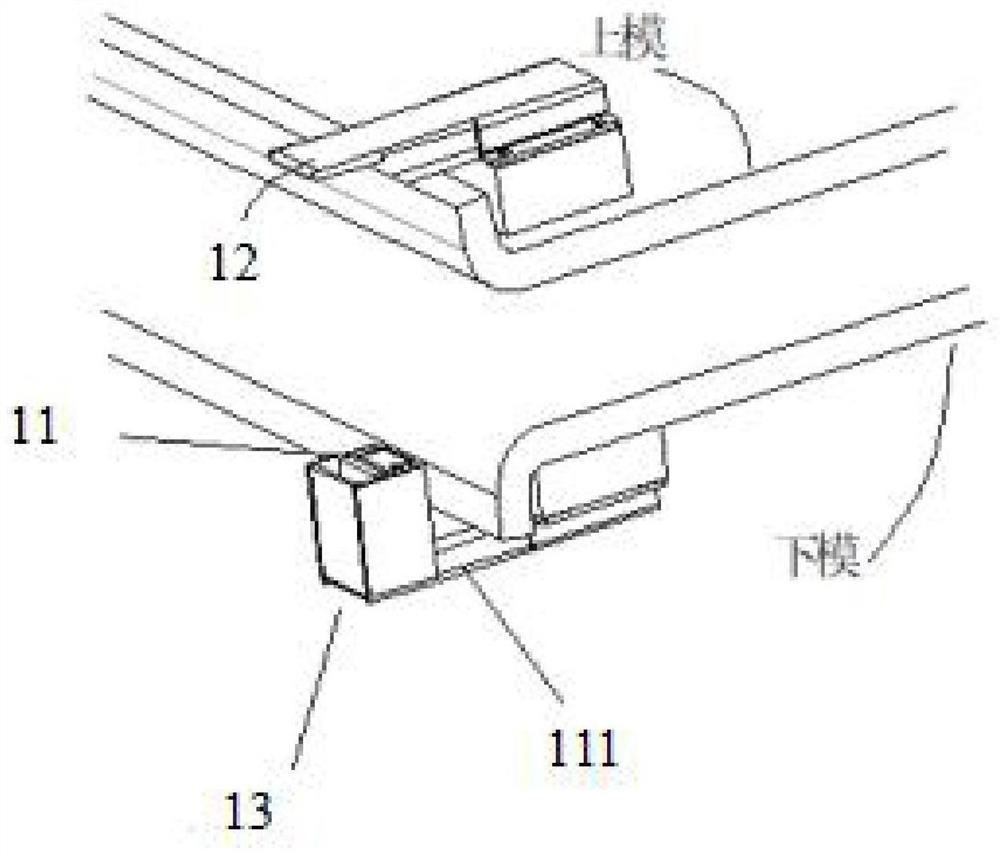

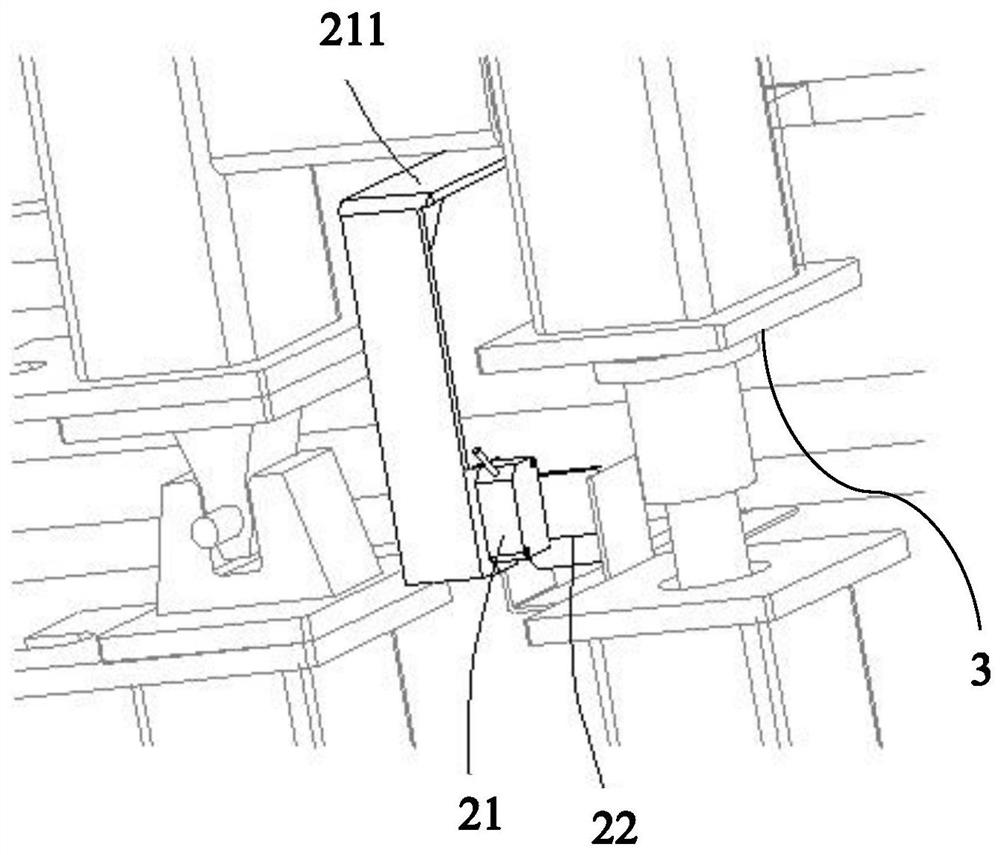

[0054] Sensors include vacuum sensors, temperature sensors, and laser displacement sensors. Among them, there are multiple vacuum sensors, which are respectively installed on the vacuum pipes at the rear edge of the upper mold and the rear edge of the lower mold, and can measure the vacuum degrees at multiple positions on the front edge and the rear edge of the mold except the vacuum pipes. The temperature sensor includes multiple thermal resistors pre-buried on the PS surface and SS surface of the mold. The thermal resistors are evenly distributed on the entire surface of the PS surface and SS surface of the mold, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com