A backlight front assembly system and method

A technology for assembling systems and backlight sources, applied in chemical instruments and methods, packaging, laminating devices, etc., can solve problems such as low efficiency, low production efficiency of manual patching, and poor consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

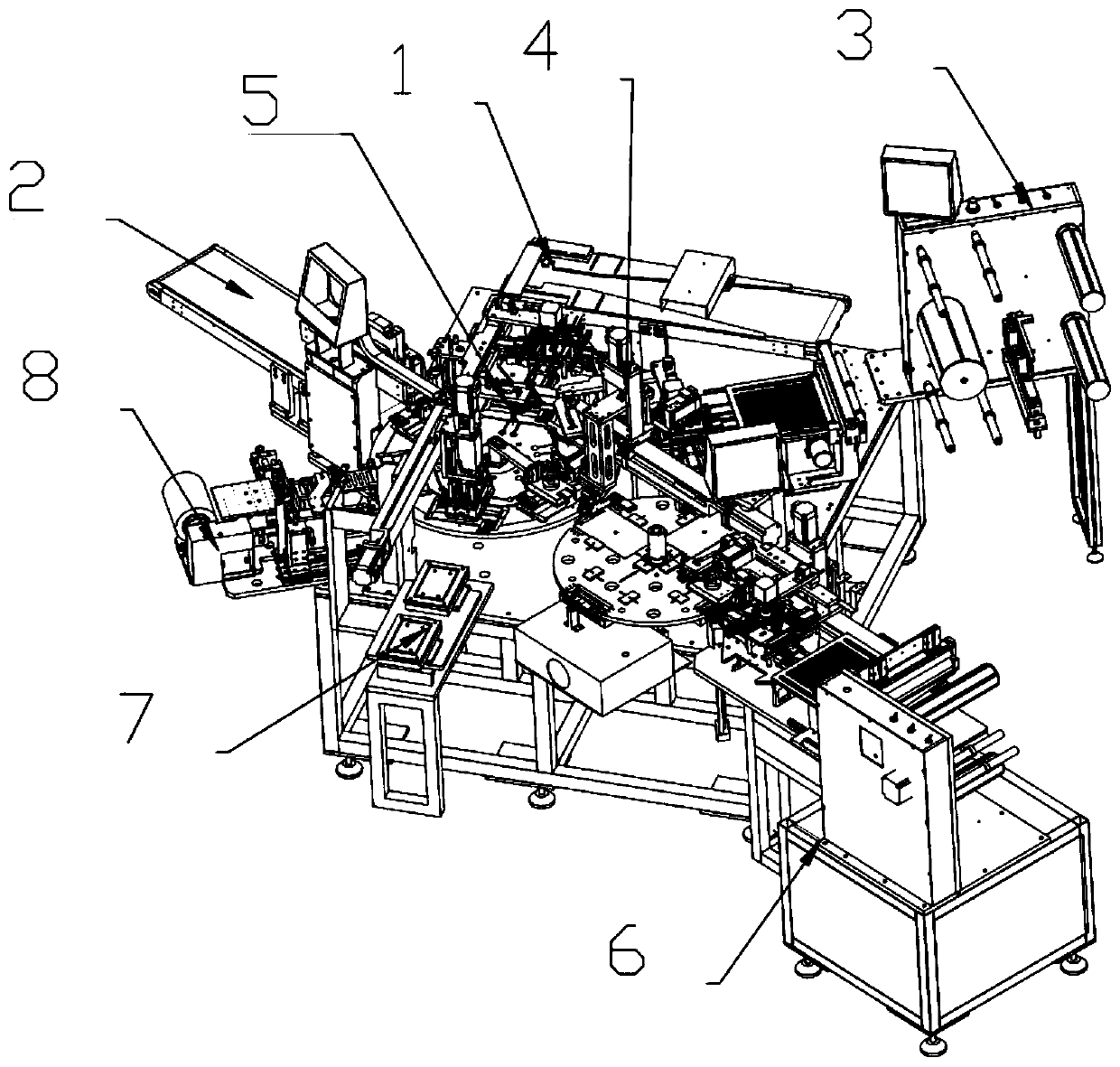

[0096] Such as Figure 1 to Figure 10 As shown, a backlight front assembly system is characterized in that it includes a base on which a main disk 5, a feeding conveyor belt 1, a feeding conveyor belt 2, a reflective sheet attaching device, and a light guide plate are arranged. Inserting and attaching and FPC attaching pressing device, glue frame device and protective film attaching device;

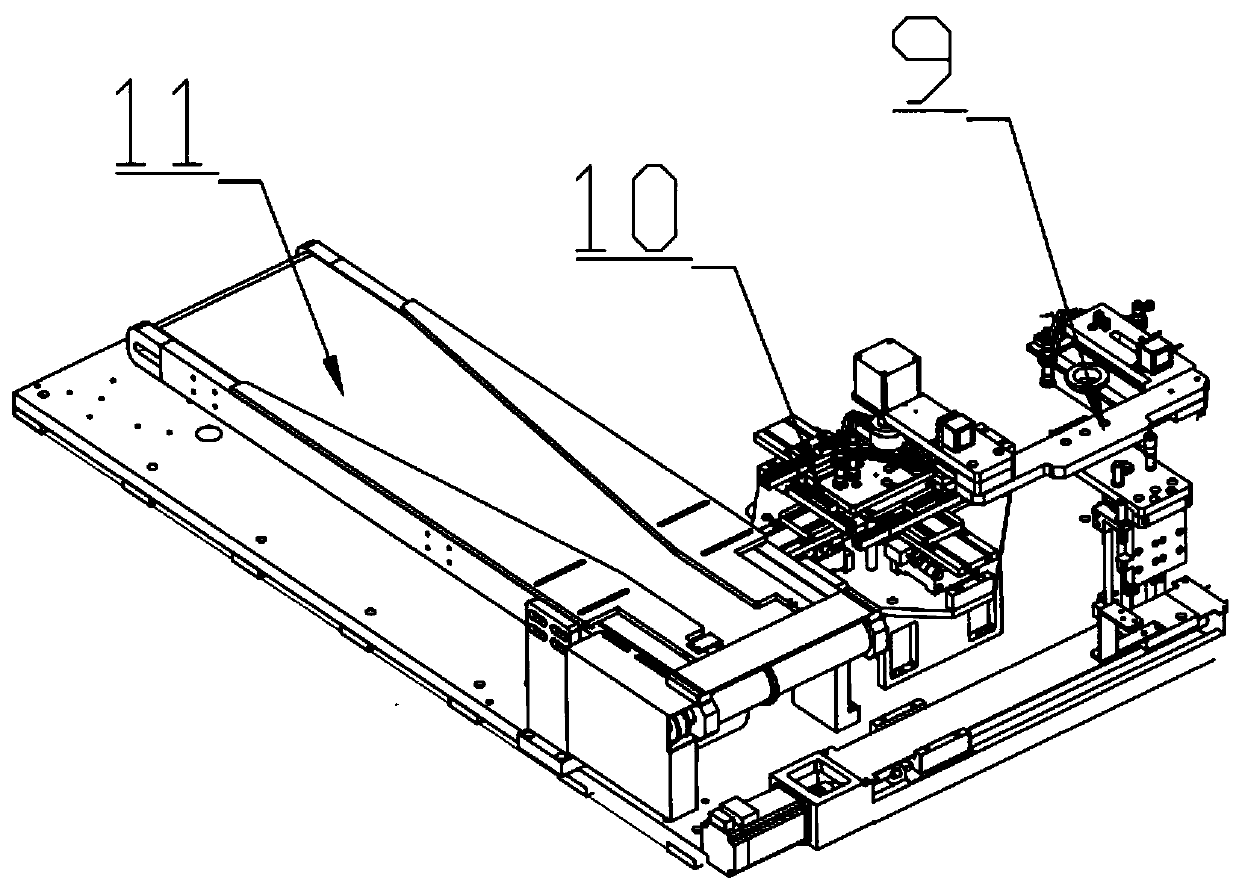

[0097] The feeding conveyor belt is provided with a feeding X-axis manipulator 9 and a feeding correction structure 10. The feeding X-axis manipulator can grab the iron frame of the incoming material and place the iron frame on the feeding correction structure. The feeding X-axis manipulator Used to move the calibrated iron frame to the main disc jig;

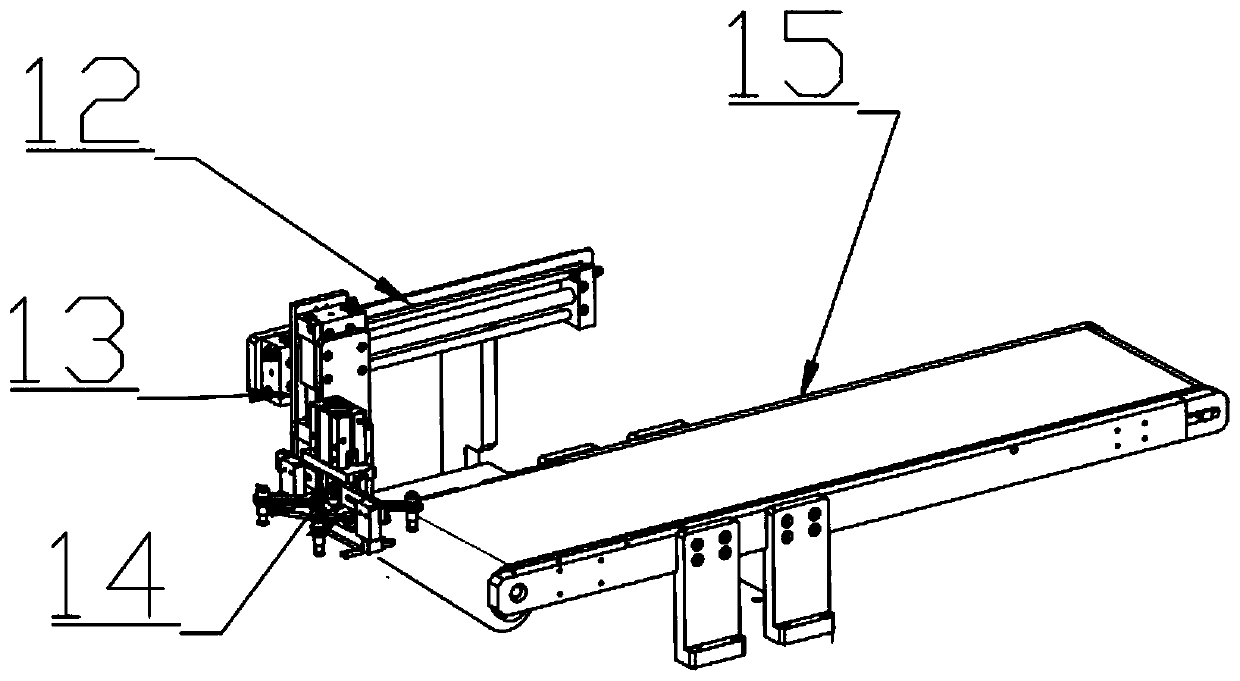

[0098] Described blanking conveyer belt is provided with blanking X-axis traverse rodless cylinder 2, blanking Z-axis rodless cylinder 13, grabber (the block that catches product is called grabber) retrieving cylinder 14, blanking conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com