Material identification equipment and control method of material identification equipment

A technology for identification and materials, applied in the field of material identification equipment and the control of material identification equipment, can solve the problems of manual damage to the identification code, confusion in scanning and identification, low work efficiency, etc., and achieve good attachment quality, accurate identification, and work efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

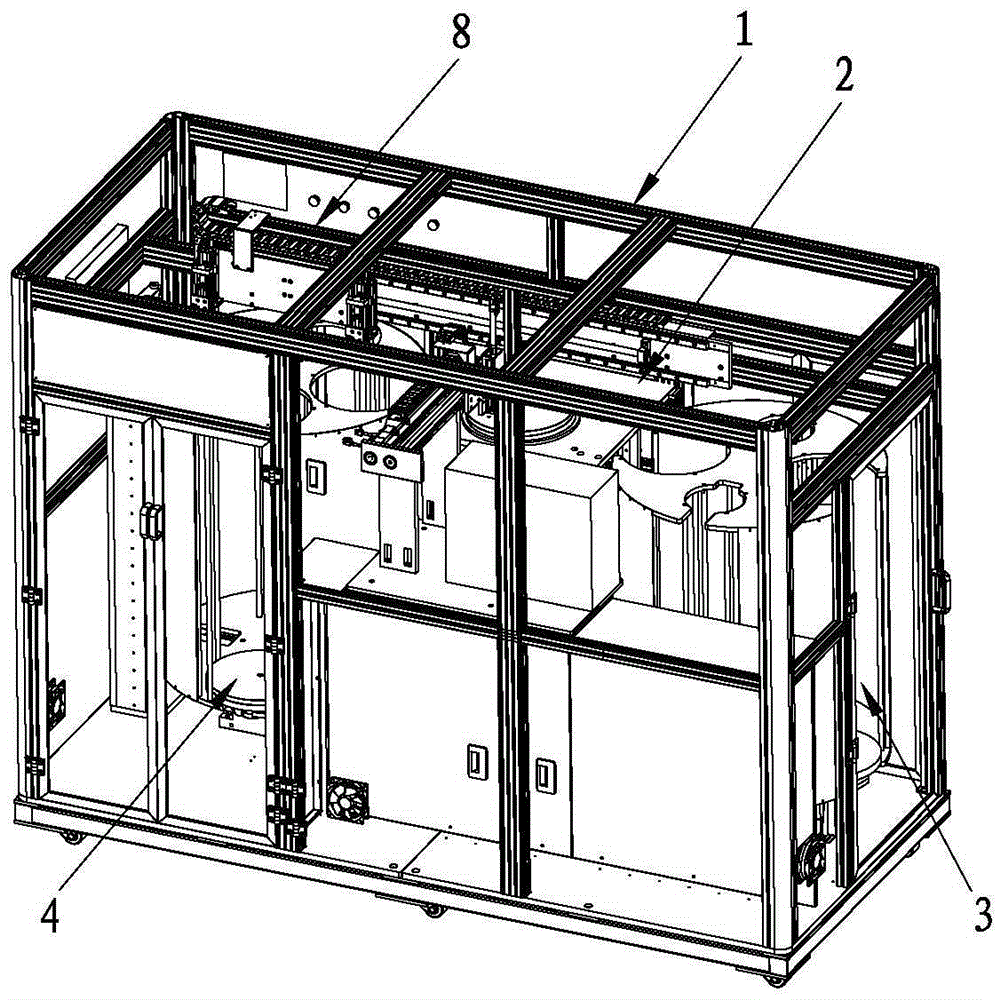

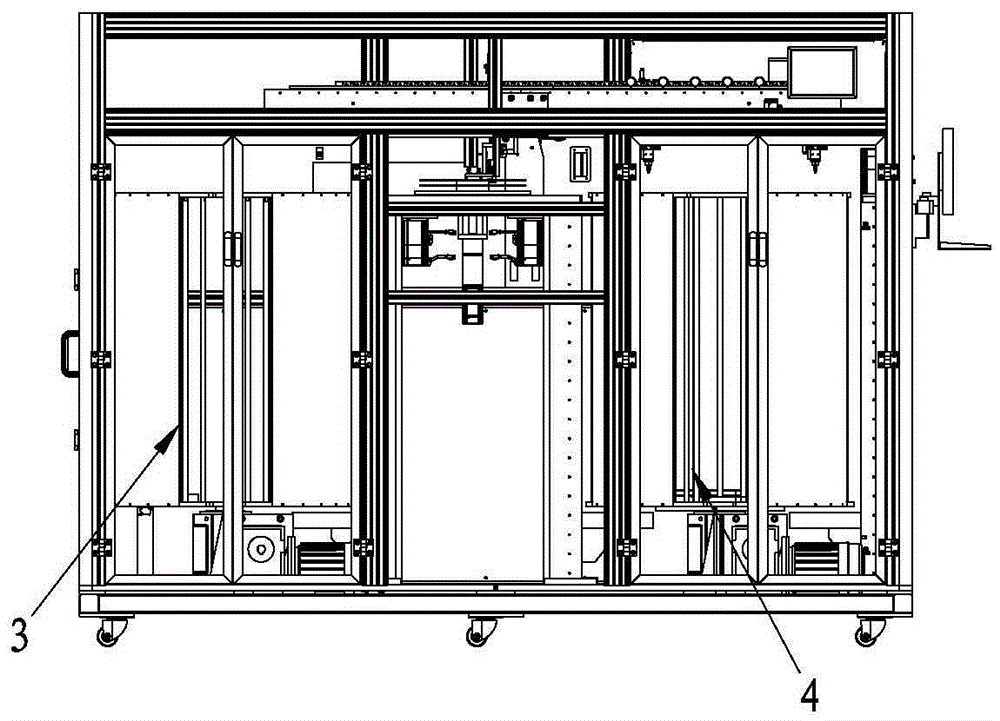

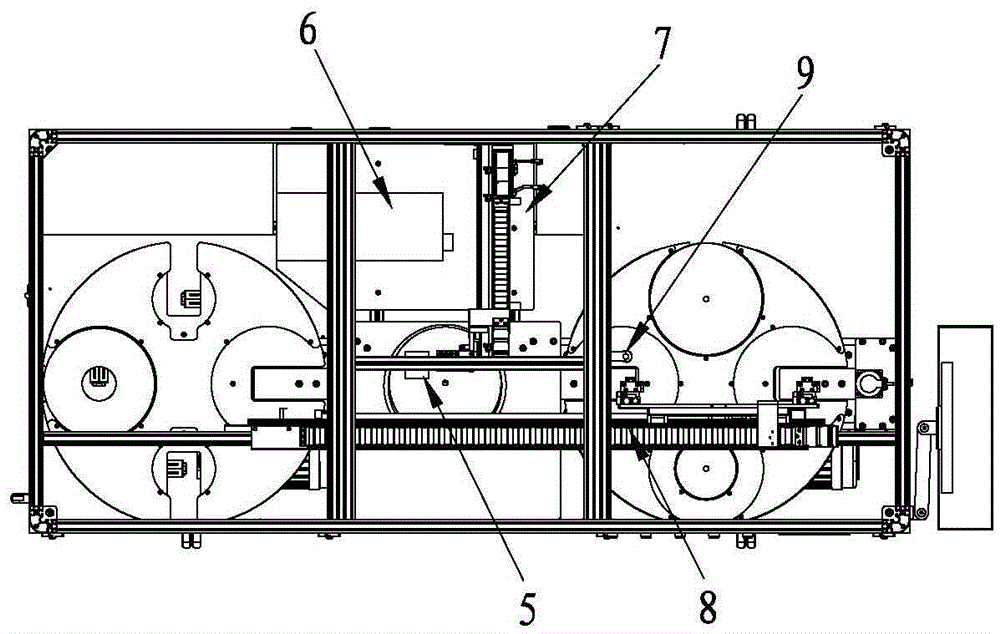

[0050] see Figure 1 to Figure 8, a material identification device, comprising a support frame 1, the support frame 1 is provided with a working platform 2, one side of the working platform 2 is provided with a feeding device 3, and the other side of the working platform 2 is provided with an unloading A material device 4, the top of the working platform 2 is provided with a scanning device 5 for obtaining the identification information of the tray, and the support frame 1 is also provided with a printing device 6, which acquires the identification of the printing device 6 and attaches the identification to the tray The attaching device 7 further includes a conveying device 8 for transferring the tray of the loading device 3 to the working platform 2 and sending the tray of the working platform 2 to the unloading device 4 . When the material identification equipment is working, a number of trays are first installed on the feeding device 3, and then the trays are automatically ...

Embodiment 2

[0064] see Figure 9 , the difference between this embodiment and Embodiment 1 is that the conveying device 8 includes a first linear module 88 and a second linear module 89, and the first linear module 88 is connected with a The material tray of the device 3 is transferred to the first manipulator 85 of the working platform 2 , and the second linear module 89 is connected to the second manipulator 86 for sending the material tray of the working platform 2 to the unloading device 4 . When loading is required, the first linear module 88 drives the first manipulator 85 to move back, the first manipulator 85 acquires the tray and sends the tray to the working platform 2, and when unloading, the second The linear module 89 moves back and drives the second manipulator 86 to obtain the material tray on the working platform 2, and then send the working material tray with the new logo to the unloading device 4. The first linear module and the second linear module 89 are controlled in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com