Thin film absorption device

A technology of thin film adsorption and adsorption discs, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve good adsorption effects, improved wear, and reasonable design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

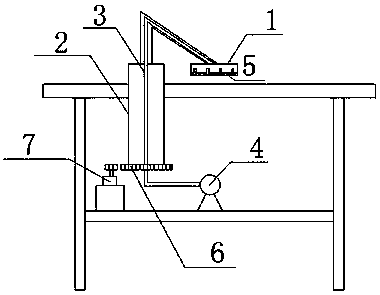

[0015] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0016] like figure 1 As shown, a thin film adsorption device includes an adsorption disk 1, which is installed on a rotating seat 2. The adsorption disk 1 is conical, and an air extraction pipeline 3 is installed in the adsorption disk 1. There is a hollow space inside the rotating seat 2. cavity, the air suction line 3 passes through the cavity and is connected to the negative pressure device 4, and the rotating seat 2 is driven by a drive motor 7.

[0017] The negative pressure device 4 in this embodiment adopts an air extractor, which is used to extract air to generate negative pressure, thereby absorbing the film, and adopts the air extractor to provide negative pressure, which is easy to install and use.

[0018] In this embodiment, there are several small holes on the adsorption disk 1, and a layer of flexible medium layer 5 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com