Patents

Literature

138results about How to "Avoid Fragments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

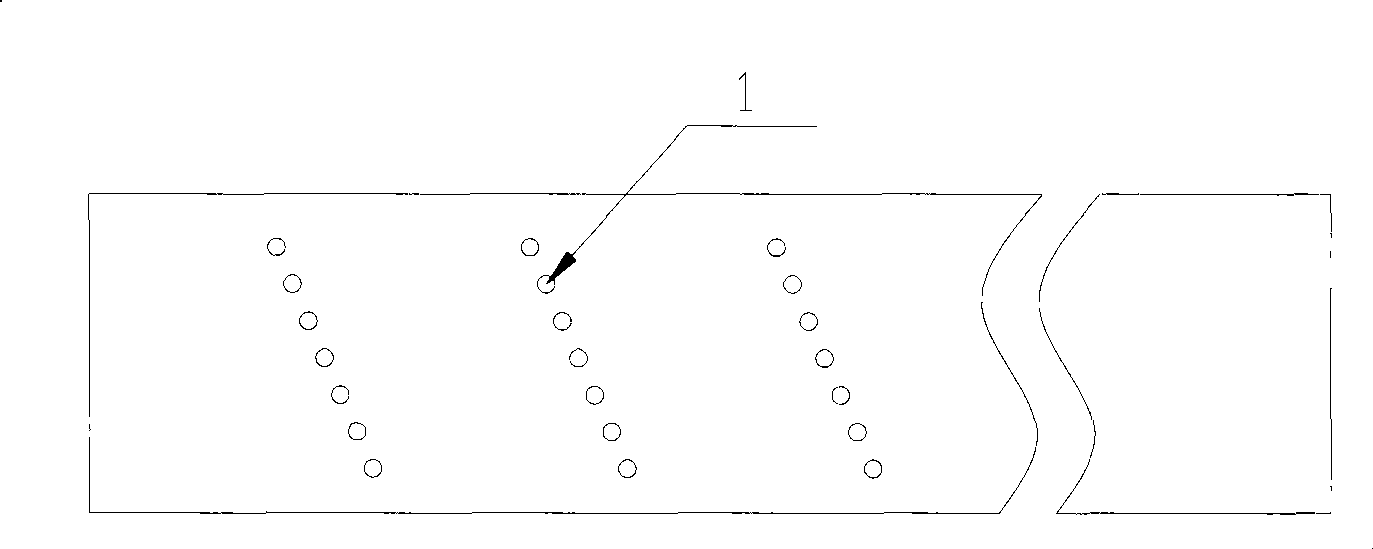

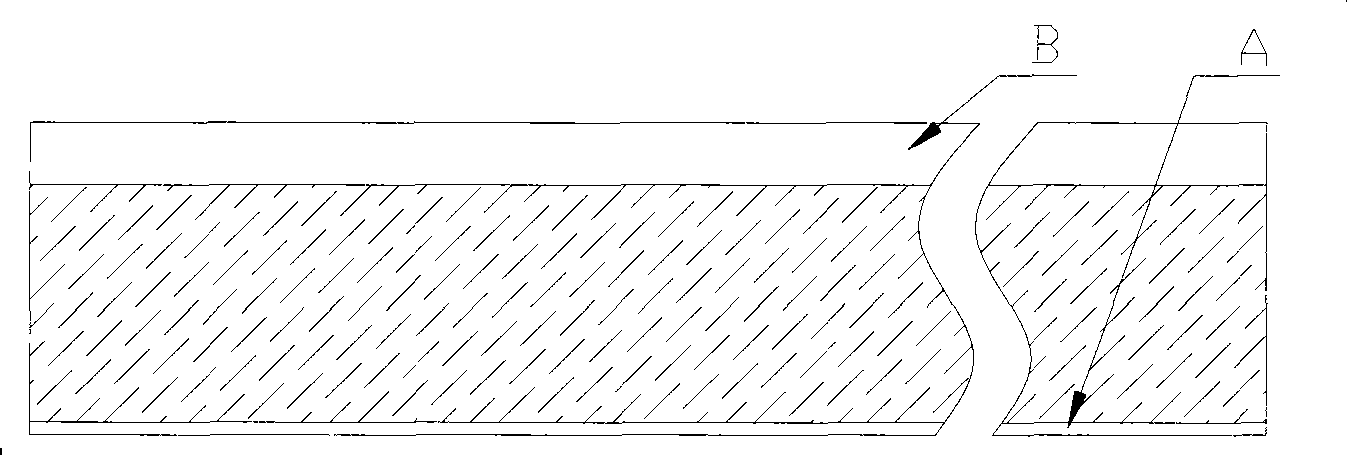

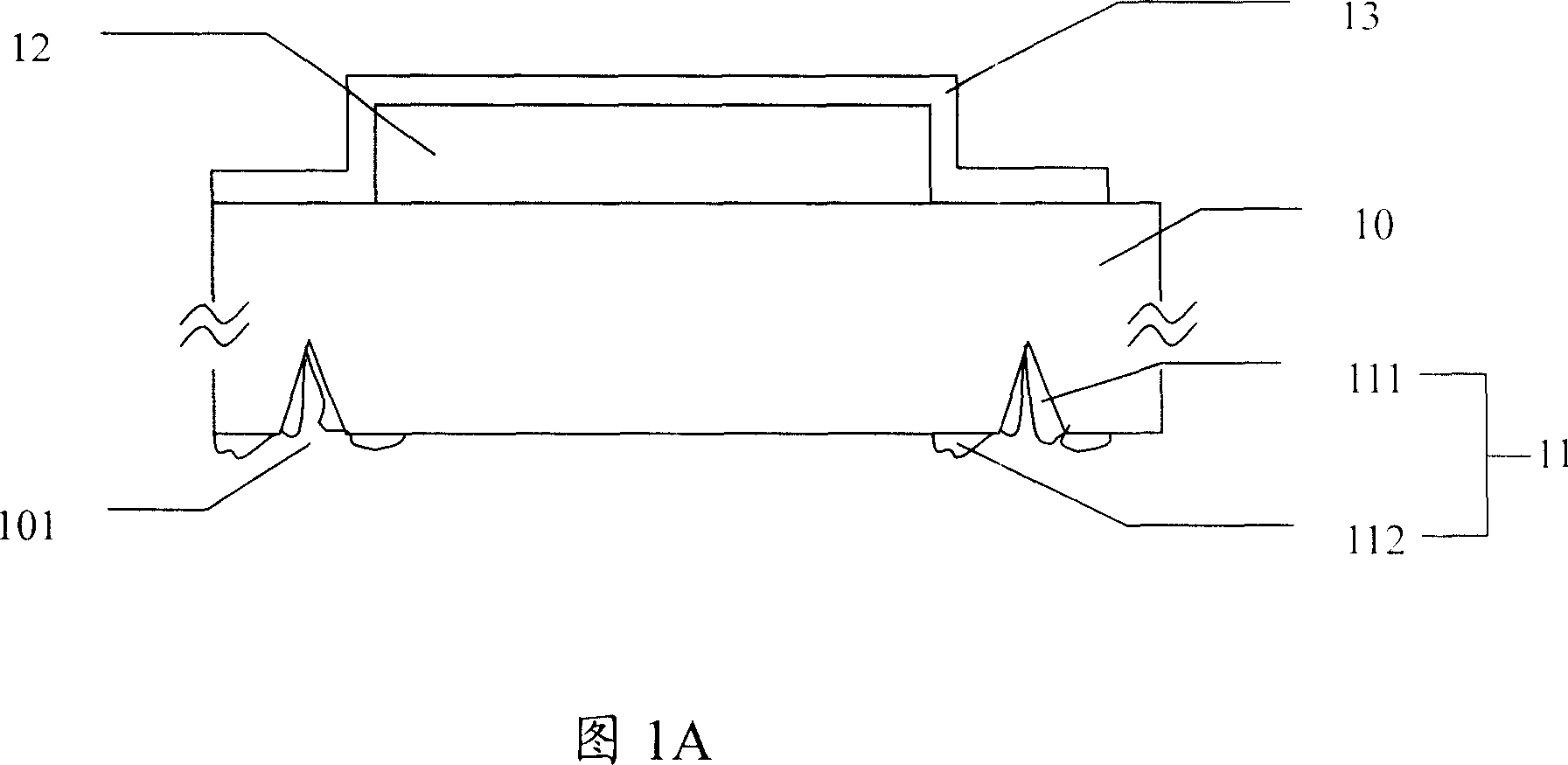

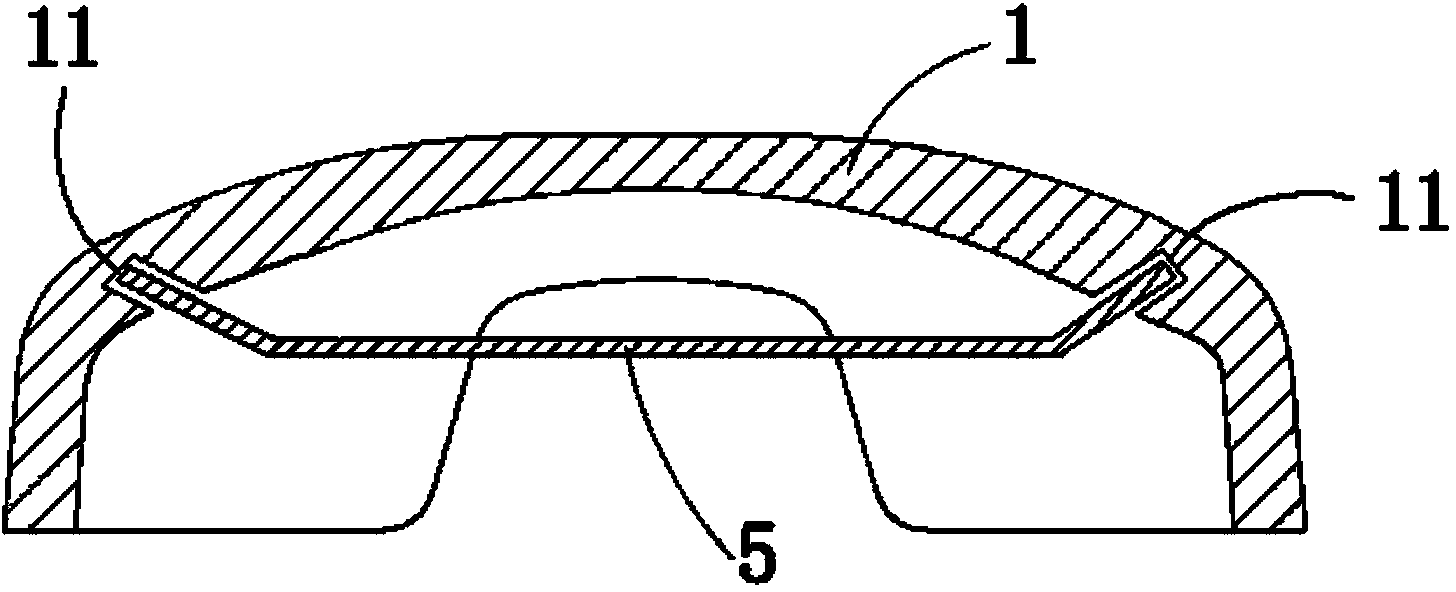

Lithium battery current collecting body, high capacity cylindrical lithium ionic cell and preparation

InactiveCN101364644AAvoid breakingReliable contactFinal product manufactureElectrode carriers/collectorsCurrent collectorLithium electrode

The invention discloses a current collector of a lithium ion battery, wherein stress dispersing holes are formed on the current collector. The invention further discloses a high-capacity cylindrical lithium ion battery including the current collector, and the preparation method thereof. The prepared lithium ion battery has the advantages of high capacity and higher safety performance.

Owner:SHENZHEN BAK BATTERY CO LTD

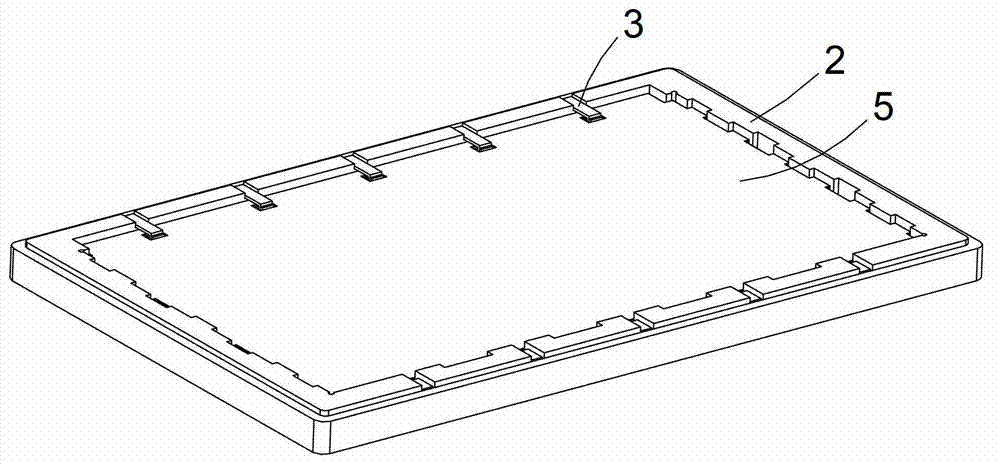

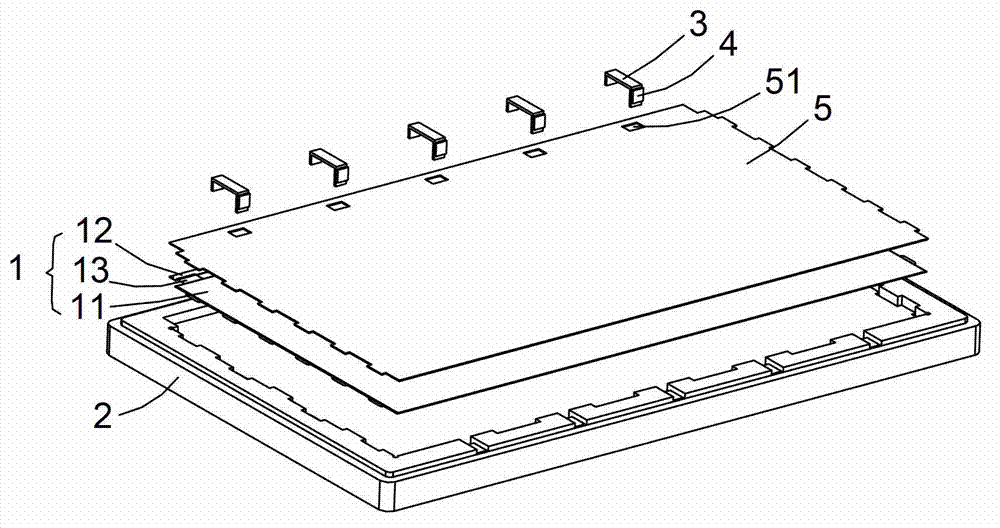

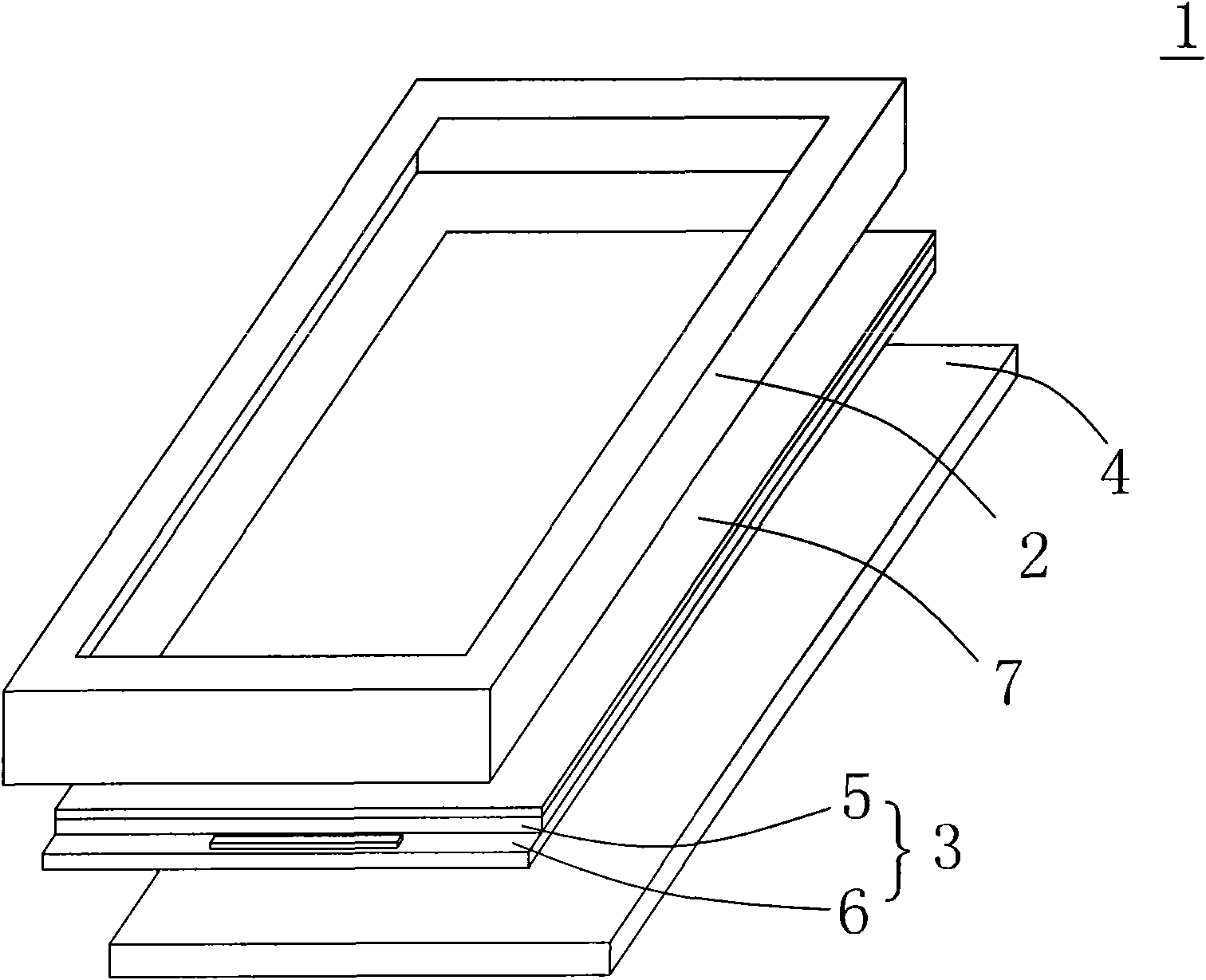

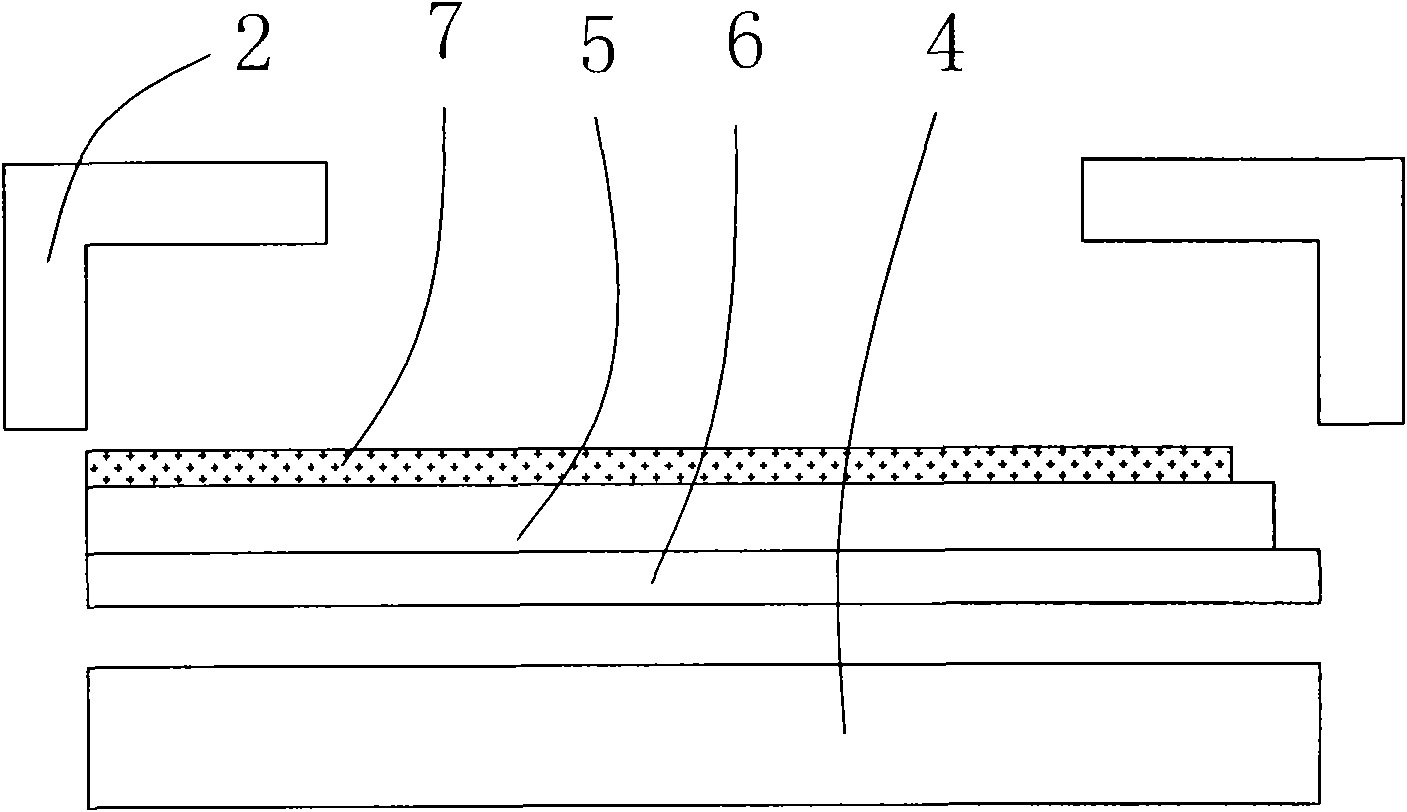

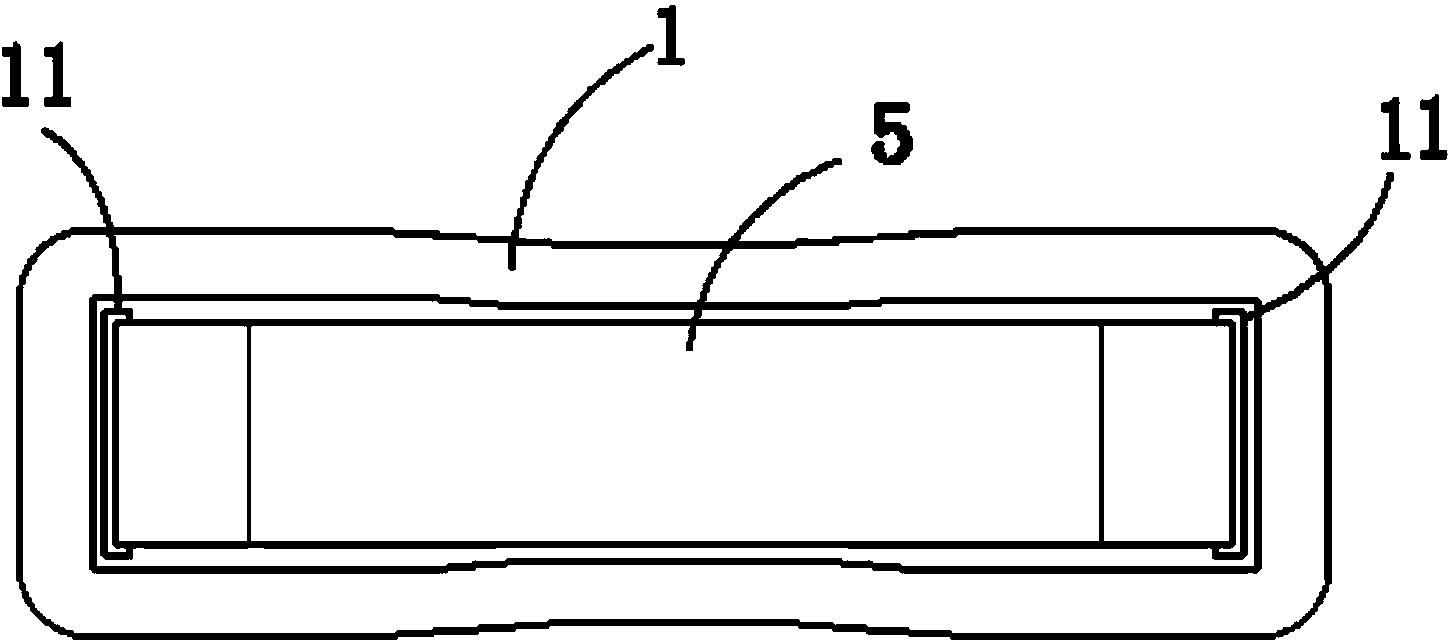

Packaging box for liquid crystal display panel assemblies

InactiveCN102897436AAvoid pullingReduce displacementContainers to prevent mechanical damageDamagable goods packagingLiquid-crystal displayFlexible circuits

The invention relates to the field of packaging, and specifically relates to a packaging box for liquid crystal display panel assemblies. The packaging box comprises a box body, the side wall of the box body is provided with a clamp slot, the packaging box also comprises a clamping component, the clamping component comprises a first arm, a second arm and a connecting part, the connecting part is used for connecting the first arm and the second arm, the first arm is inserted in the clamp slot, and the second arm is inserted in a gap on a liquid crystal display panel assembly. The first arm is inserted in the clamp slot on the side wall of the box body, so that the clamping component is fixed simply; the second arm is inserted in a gap on a liquid crystal display panel assembly, so that the second arm can achieve an effect of positioning the flexible circuit board side of a liquid crystal display panel, and the other three sides of the liquid crystal display panel are positioned through the side wall of the box body, so that the liquid crystal display panel is completely positioned in the horizontal direction.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

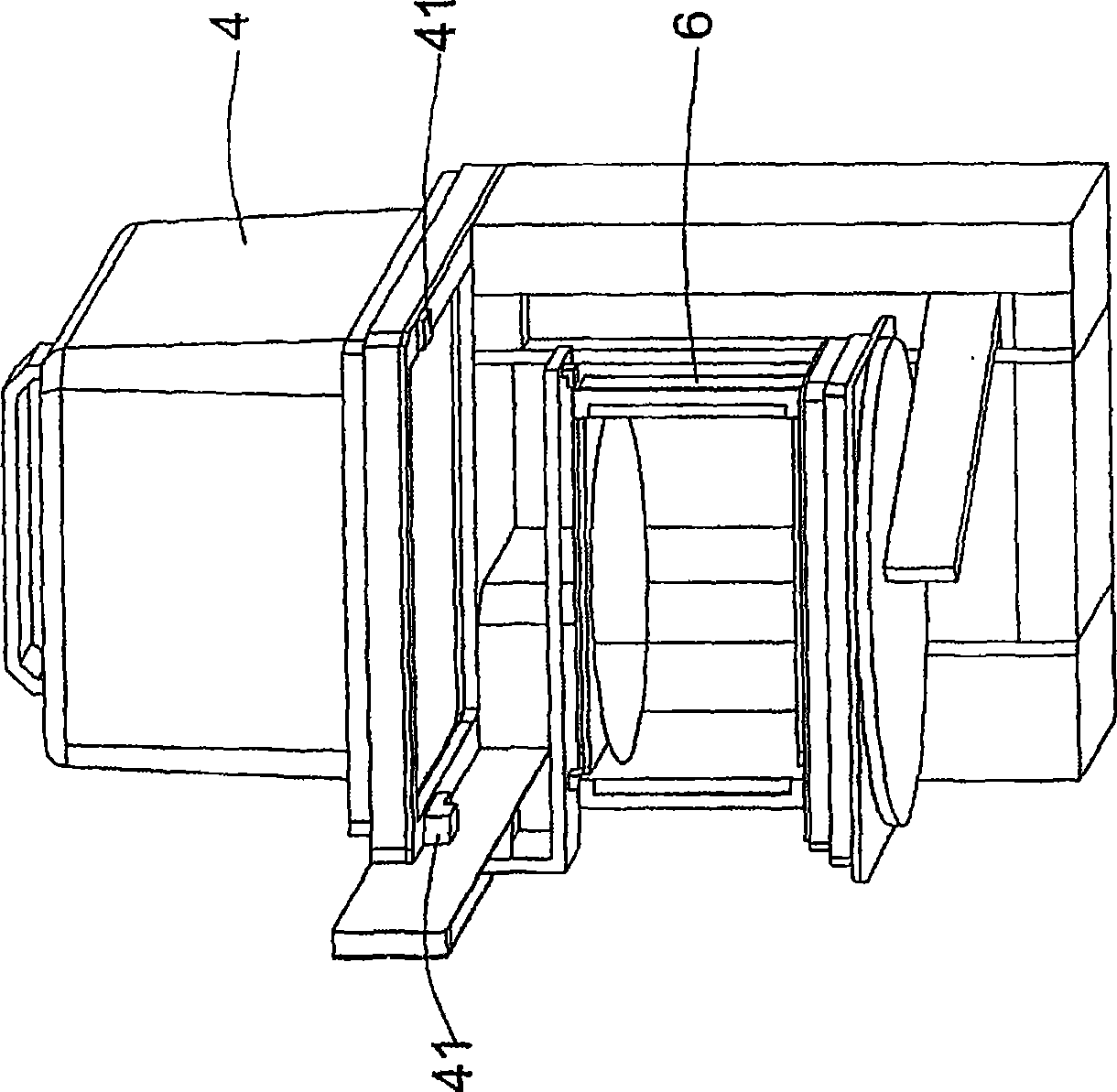

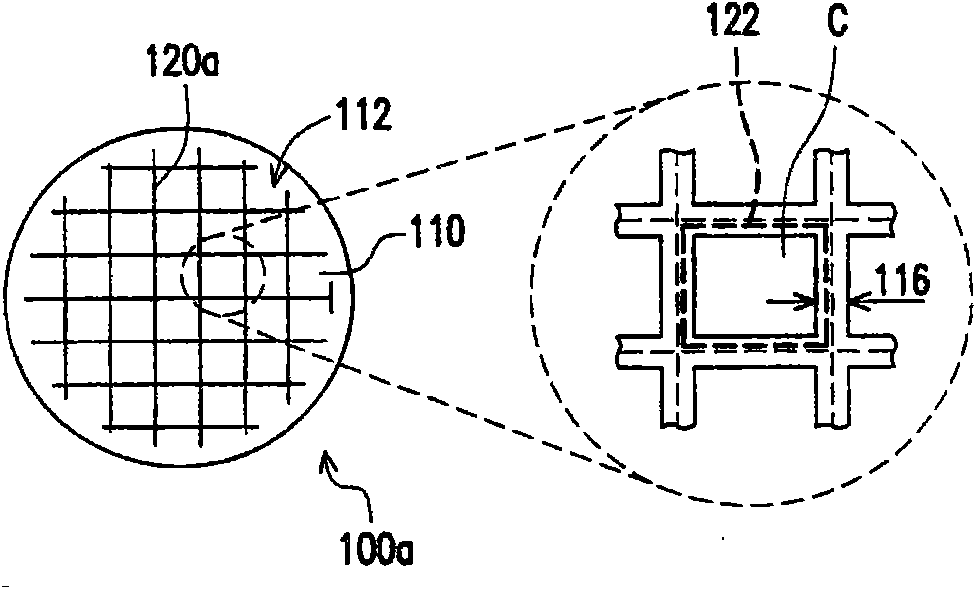

Wafer raising platform and wafer test machine

InactiveCN101477961AAvoid FragmentsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingDevice formEngineering

The invention relates to a wafer lifting platform. The wafer lifting platform comprises a first containing zone and a second containing zone, a driver module, a sensing device and a control device, wherein, at least a wafer cassette is arranged in the first containing zone, and the wafer cassette comprises an opening to allow a boat for bearing a wafer to be moved to the second containing zone from the wafer cassette; the driver module is used for providing the position lifting for the boat; the control device is used for receiving signals sent by the sensing device and controlling the motion of the wafer lifting platform according to the signals; the wafer lifting platform is characterized in that the sensing area of the sensing device forms at least a datum plane in the second containing zone, the datum plane is close to the periphery of the wafer and is perpendicular to the plane of the wafer; and when the position of the wafer in the boat is shifted and the wafer forms influence with the datum plane to trigger the sensing device, the control device stops the operation of the wafer lifting platform.

Owner:KING YUAN ELECTRONICS

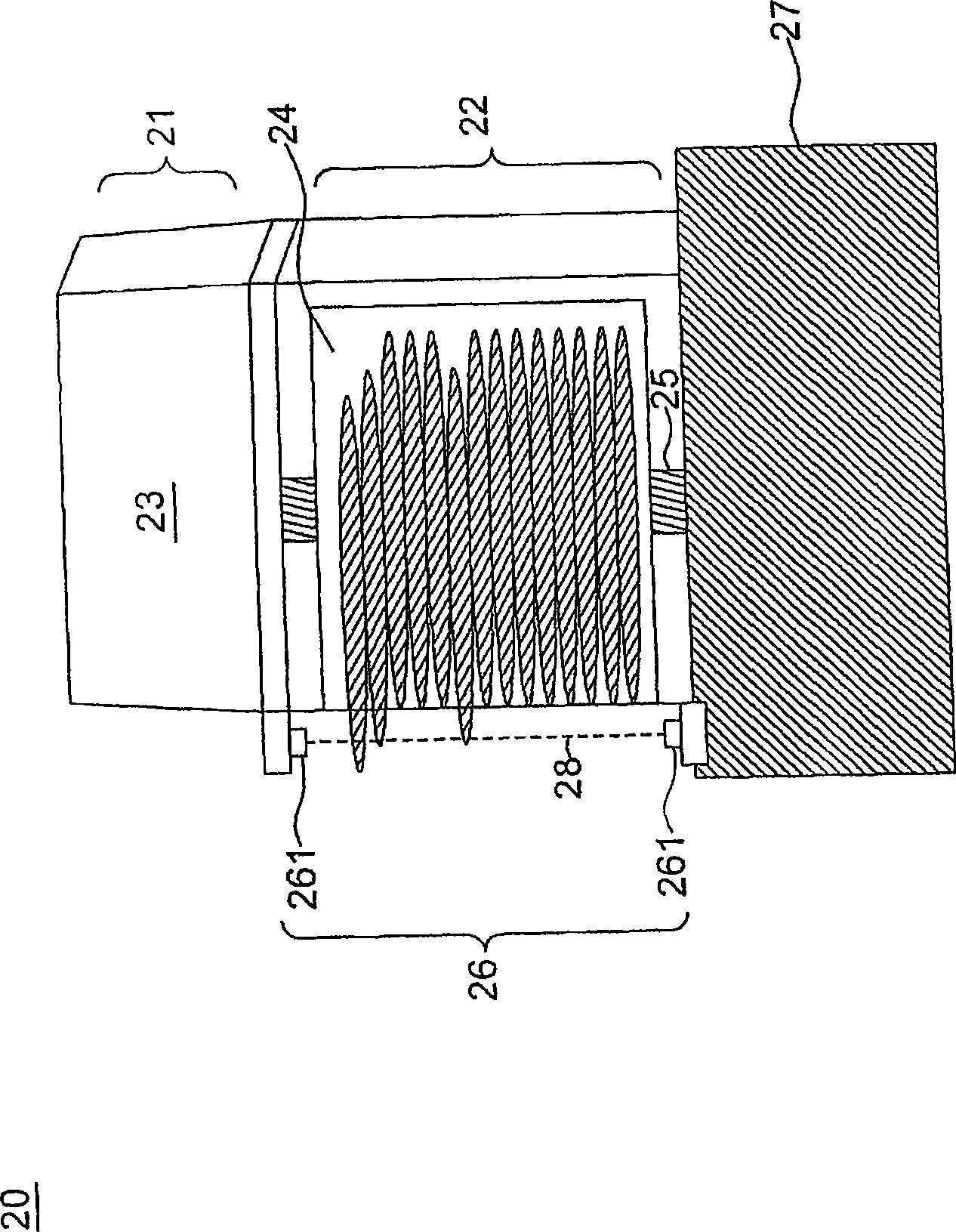

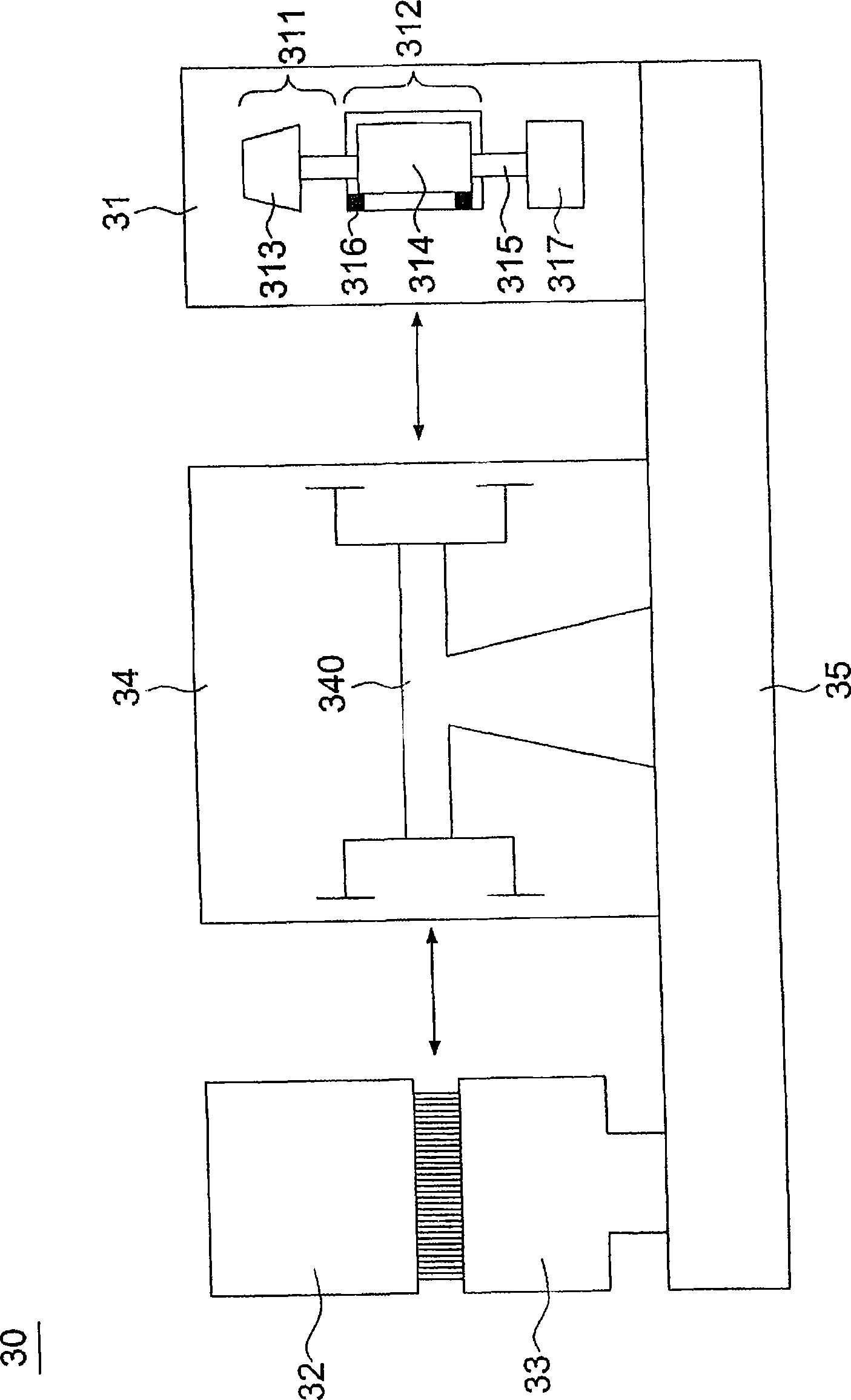

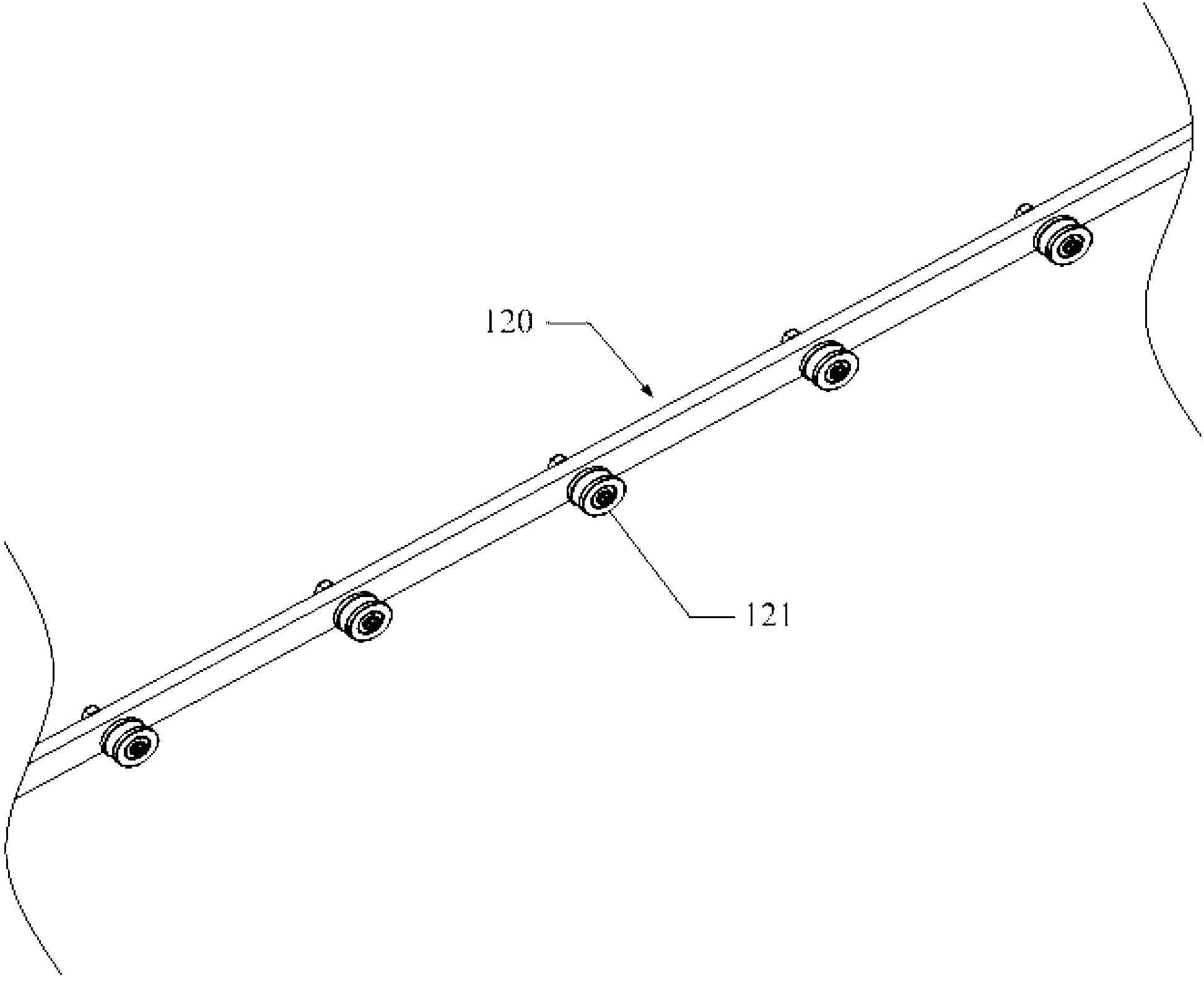

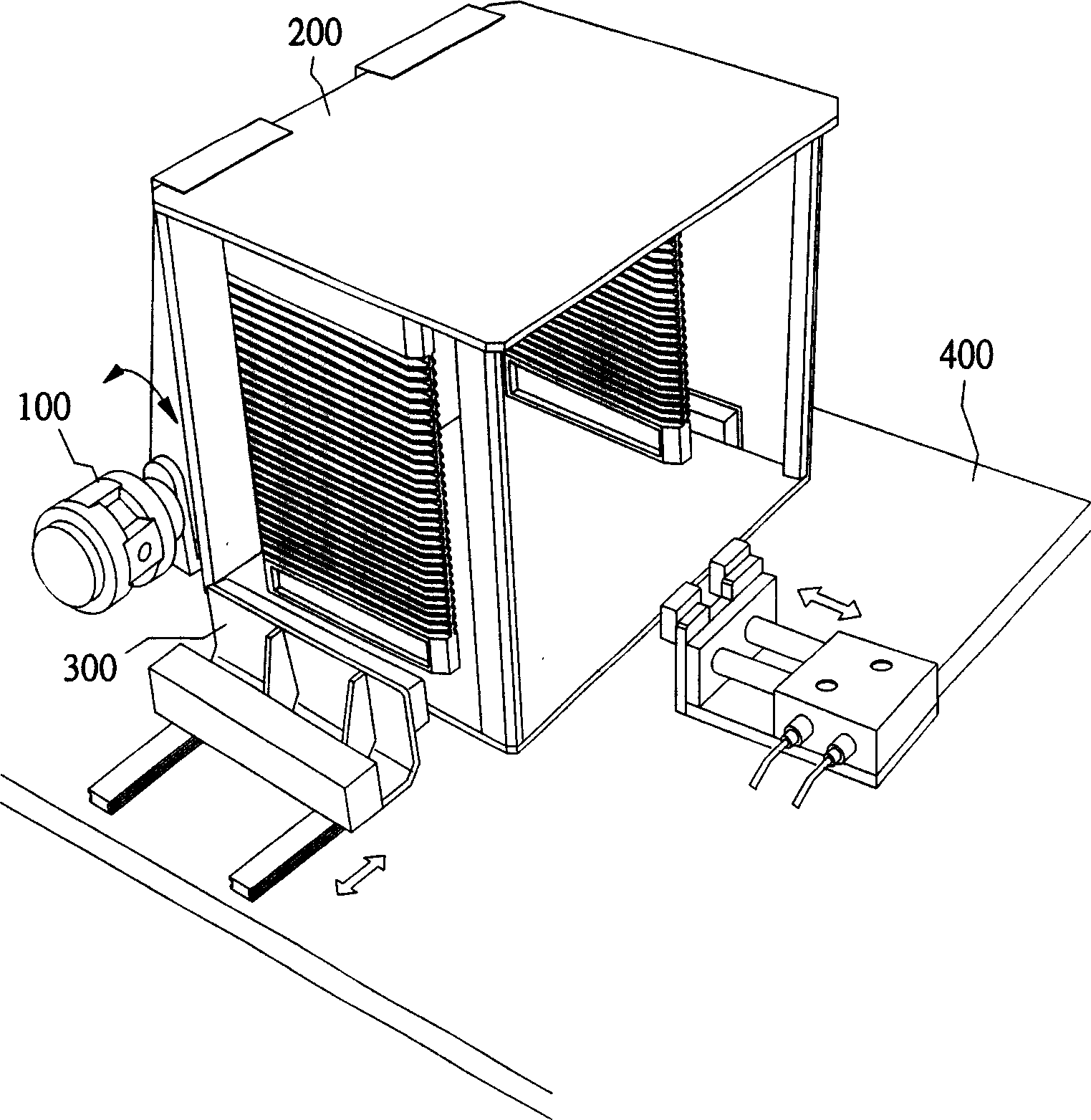

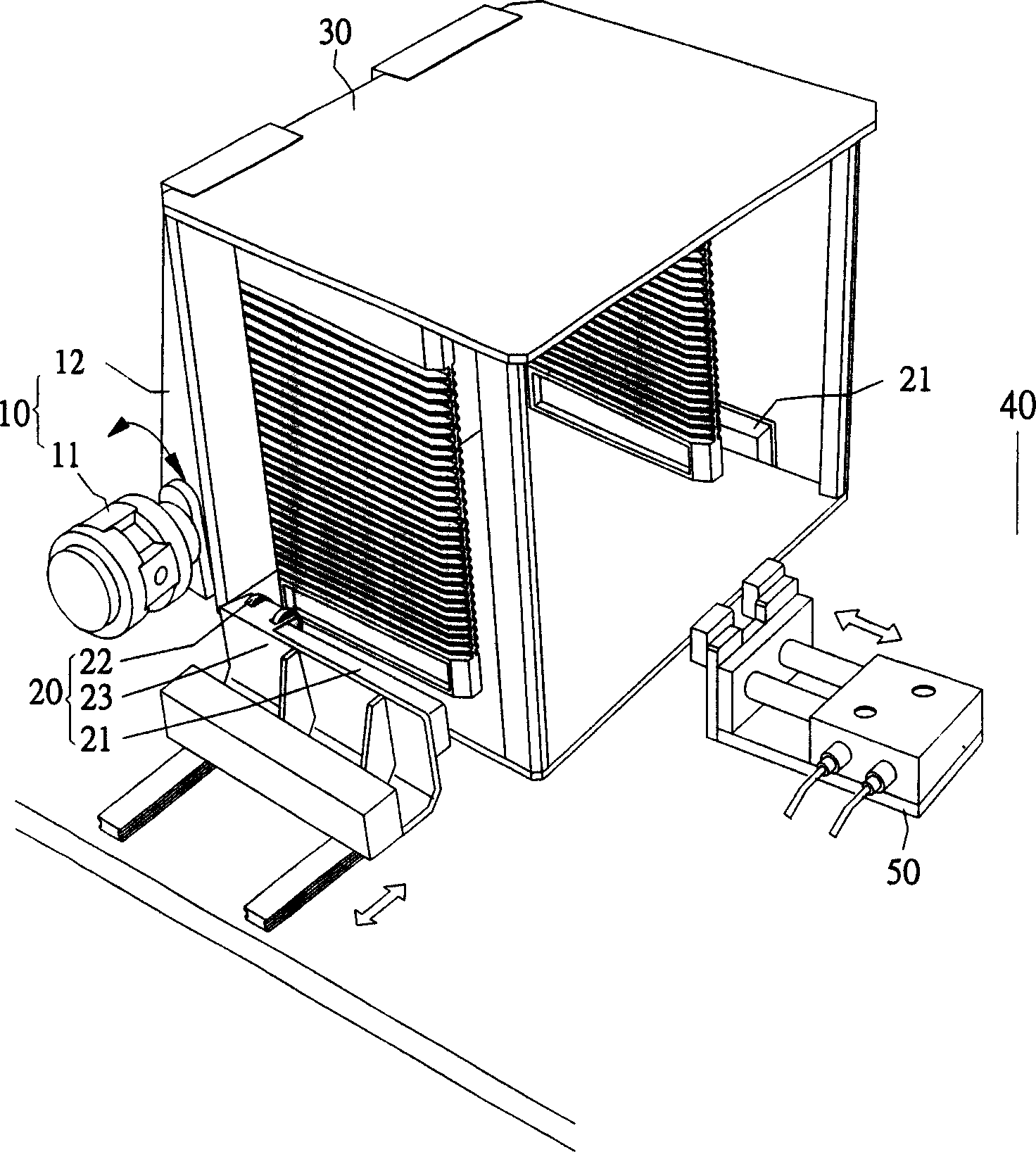

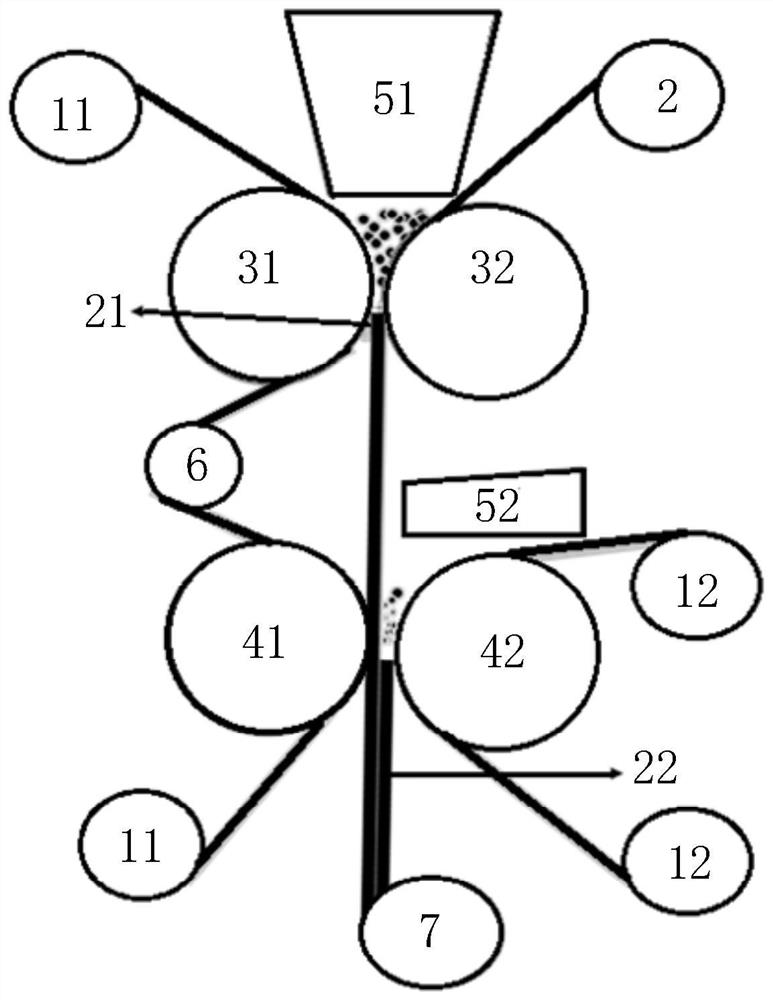

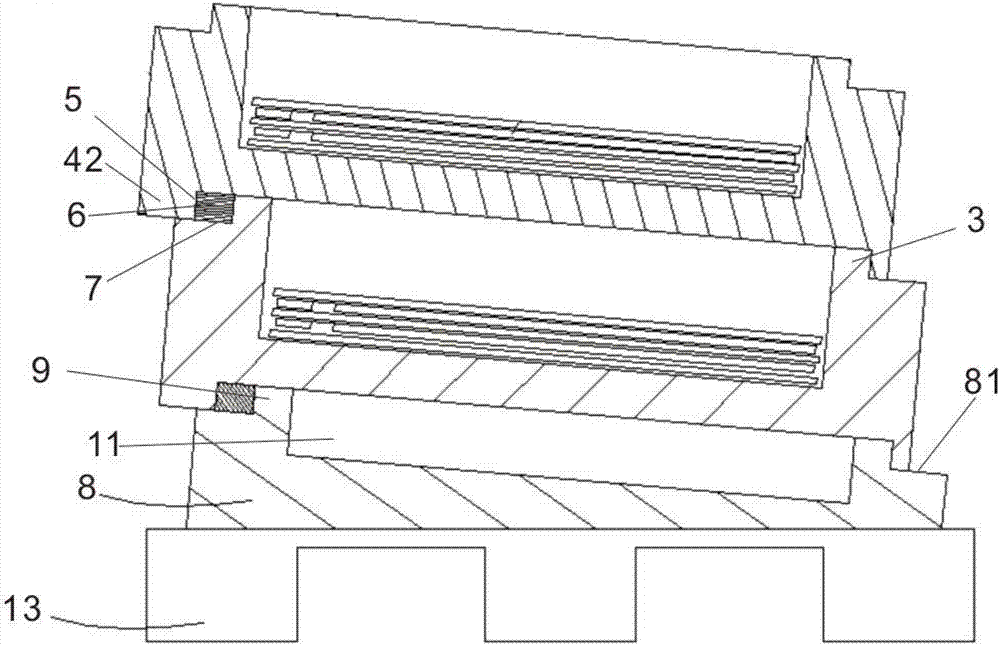

Magnetron sputtering coating system

ActiveCN103820762ALow plating resistanceMeet the coating process requirementsVacuum evaporation coatingSputtering coatingCoating systemOn cells

The invention relates to a magnetron sputtering coating system, comprising a linearly arranged slice entering chamber, a first buffer chamber, a first transition chamber, a sputtering coating chamber, a second transition chamber, a second buffer chamber and a slice discharging chamber, wherein the sputtering coating chamber comprises a first direct current sputtering chamber, a second direct current sputtering chamber, a third direct current sputtering chamber and a fourth direct current sputtering chamber which are connected successively. The first direct current sputtering chamber is connected to the first transition chamber; the fourth direct current sputtering chamber is connected to the second transition chamber; the first direct current sputtering chamber is provided with two first cathode targets; the second direct current sputtering chamber is provided with two second cathode targets; the third direct current sputtering chamber is provided with two third cathode targets; and the fourth direct current sputtering chamber is provided with two fourth cathode targets. By using the magnetron sputtering coating system for coating, fragment rate can be effectively reduced; coating of the film with relatively low sheet resistance can be facilitated; process requirements of on-cell coating are met; and production yield is increased.

Owner:WGTECH JIANGXI

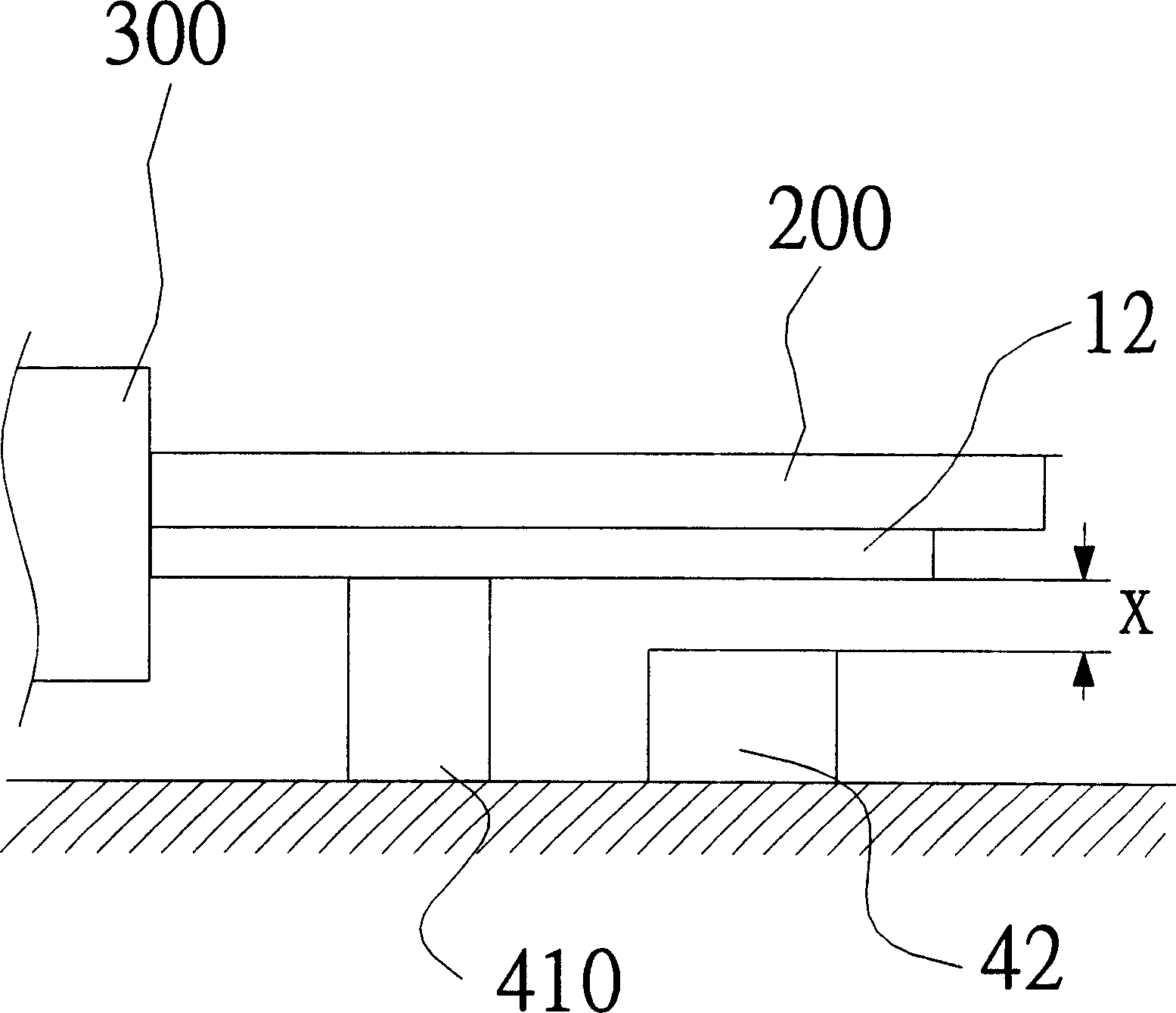

Wafer transfer method and device

InactiveCN102376608AAvoid FragmentsImprove stabilityConveyor partsEngineeringElectrical and Electronics engineering

The invention relates to a wafer transfer method and device. The method comprises the following steps of: detecting whether a wafer deviates from a designated position; and stopping transferring the wafer when the wafer deviates from the designated position. According to the invention, before the wafer is transferred, whether the wafer deviates from the designated position is detected, and when the wafer deviates from the designated position, a wafer storing and lifting device is stopped transferring the wafer, thereby avoiding the problem of wafer fragment because the wafer deviating from the designated position is continued to be transferred, further improving the stability and safety of wafer transfer, reducing the fragment percent and greatly saving cost.

Owner:CSMC TECH FAB1 +1

Wafer thinning method

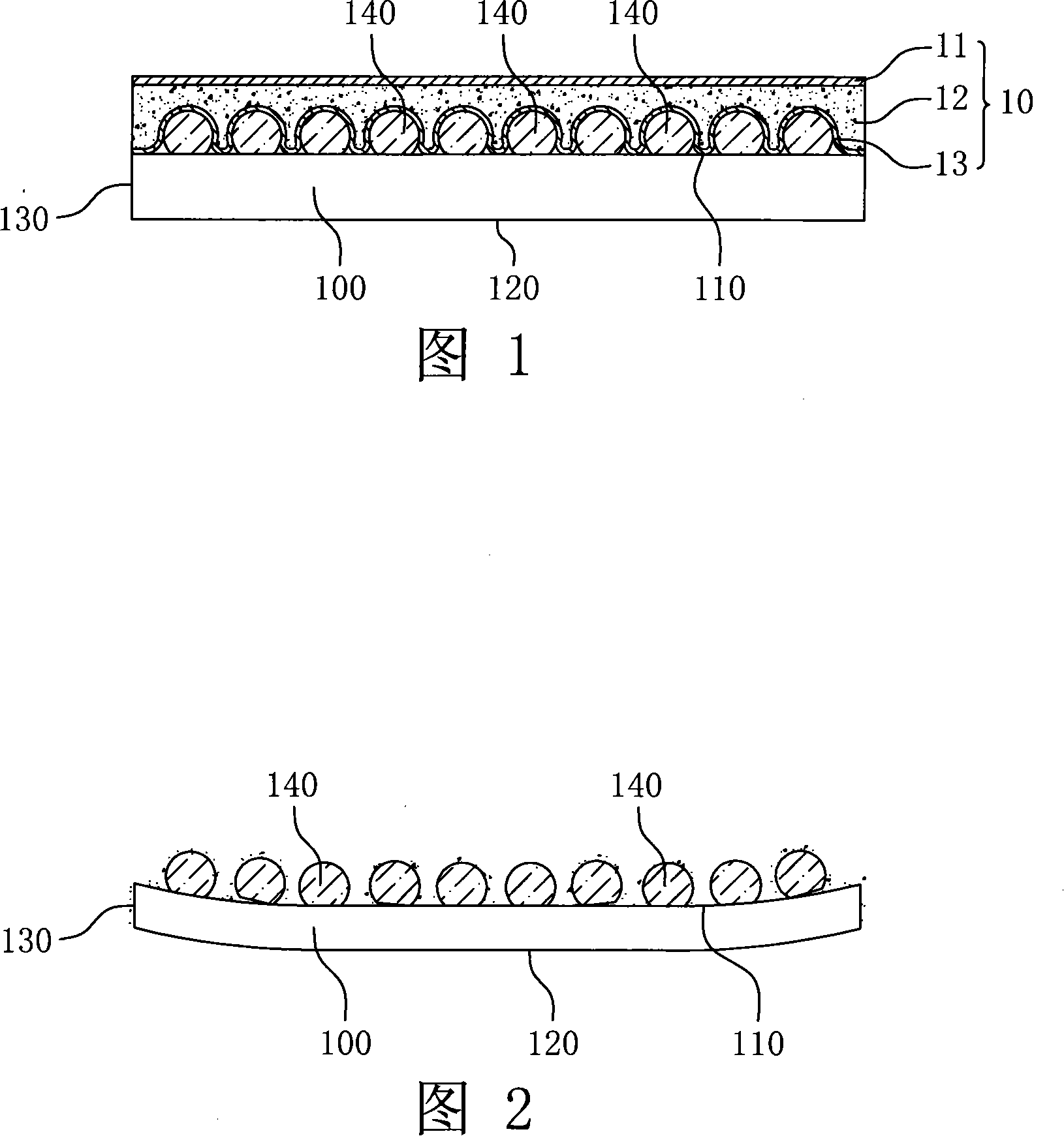

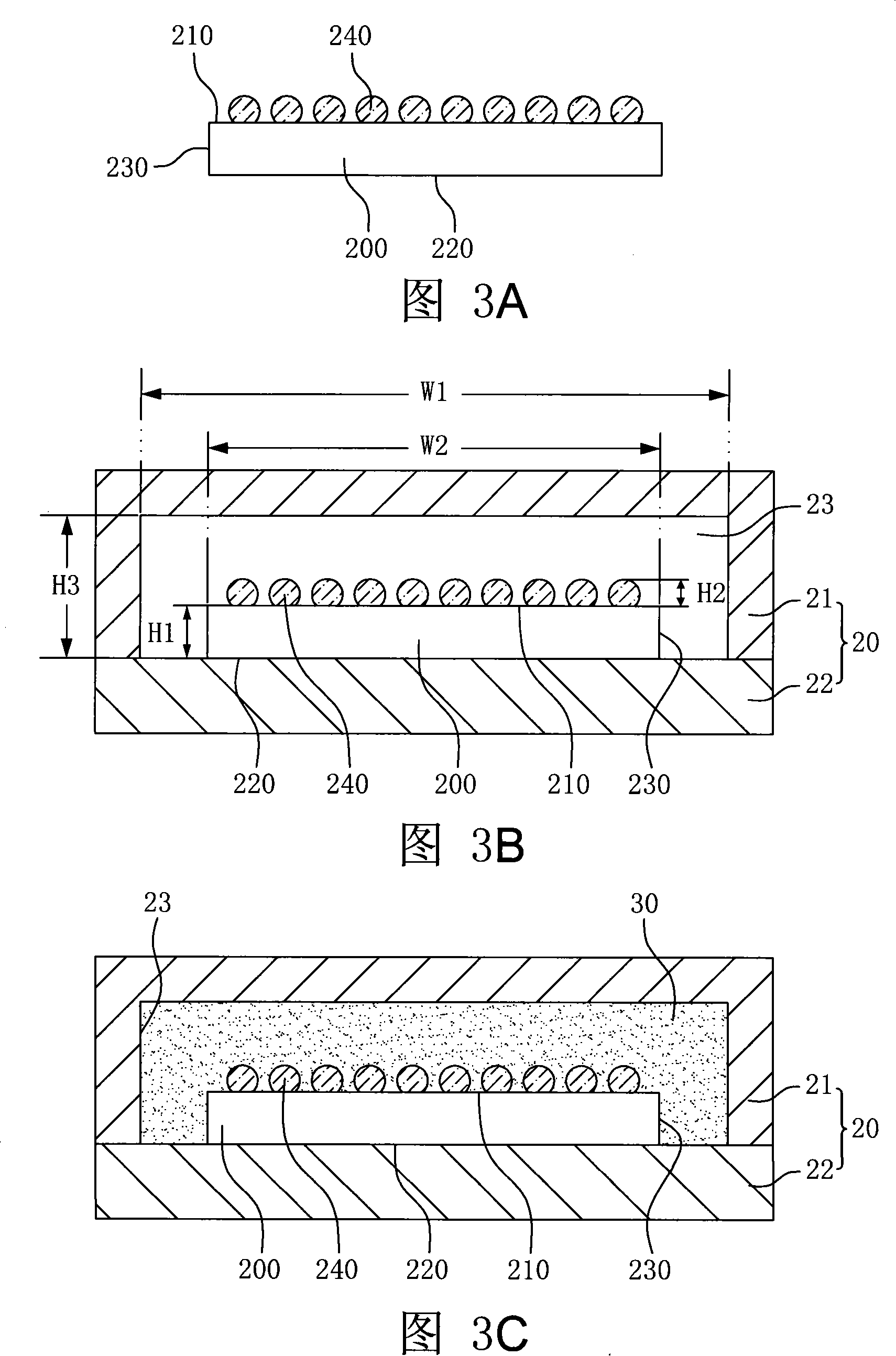

ActiveCN101150059AAvoid warpingAvoid FragmentsSemiconductor/solid-state device manufacturingEngineeringWafer thinning

This invention relates to a method for getting wafers thinner including: providing a wafer with an active side and a back, setting several hump elements on the active side and putting the wafer in a die and forming a macromolecular material in the die to cover the active side of the wafer at least, solidifying the macromolecular material and removing the die, grinding the back of the wafer to get the wafer thinner, finally, removing the material to expose the active side of the wafer and the hump elements on it, which utilizes the die to enable the macromolecular material to cover the active side of the wafer and wrap the hump elements, in this way, stress generated in grinding the wafer is distributed on the wafer uniformly so as to avoid warp, break, crack of the wafer or peel off of the hump elements.

Owner:ADVANCED SEMICON ENG INC

Method for cooperative office by using task tree mode

InactiveCN106803165ARealize classified and hierarchical managementAvoid fragmentsOffice automationResourcesTask completionDecomposition

The invention discloses a method for cooperative office by using a task tree mode. The method comprises the following steps of: setting a project or an affair as a general task and setting a specific description of the general task; decomposing the general task into first-class sub-tasks, setting the specific descriptions of the first-class sub-tasks, and assigning the first-class sub-tasks to corresponding first-class sub-task executors; enabling the first-class sub-task executors to decompose the first-class sub-tasks into second-class sub-tasks which are assigned to corresponding second-class sub-task executors; continuing the decomposition and the assignment until the last-class task executors; enabling the respective-class task executors to submit the tasks to a task reviewer after accomplishing the tasks, enabling the task reviewer to determine a score x based on the completion quality of the tasks, and enabling a system to determine an efficiency score z based on the completion efficiency of the tasks and to determine a final score A based on x and z. By using the method, a manager may monitor a job schedule in real time, the executors may timely accept the work tasks and feeds back work conditions to facilitate the changes of the job schedule and the task allocation.

Owner:贵州一马科技有限公司 +1

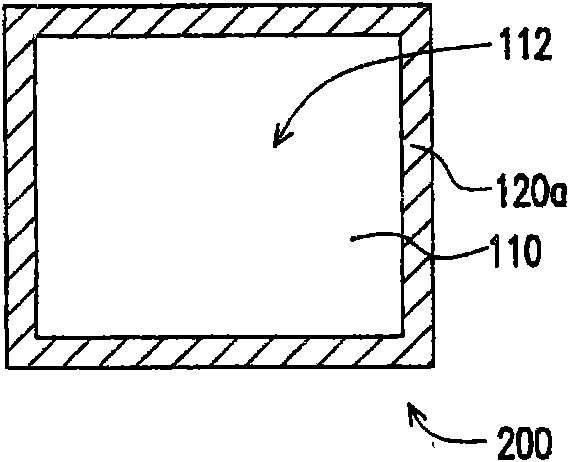

Base plate transfer device

Owner:AU OPTRONICS CORP

Substrate optical detection method and apparatus

InactiveCN101408572AAvoid FragmentsAvoid microcracksContactless testingContactless circuit testingArray data structureInductor

The invention relates to an optical detection method and a device thereof which are used for detecting the defects of a substrate. The optical detection device comprises an optical unit used for generating a light source to radiate the substrate and a plurality of groups of receiving inductor units of more than one dimension used for receiving an image generated by the radiated substrate, wherein, the light wave of the image contains a specific wavelength section as well as an image capture processing unit for capturing the image.

Owner:DELTA ELECTRONICS INC

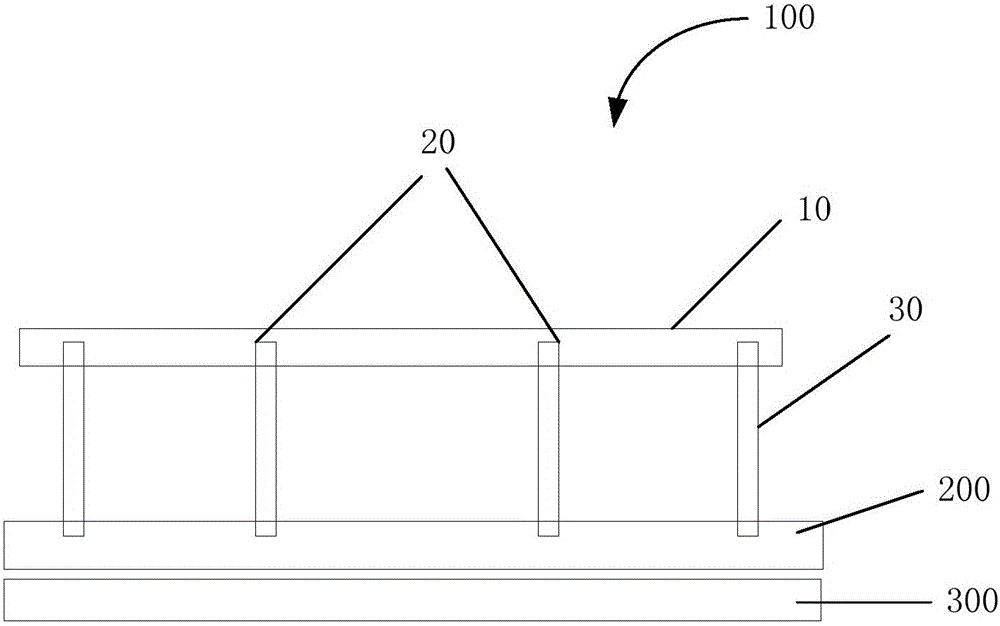

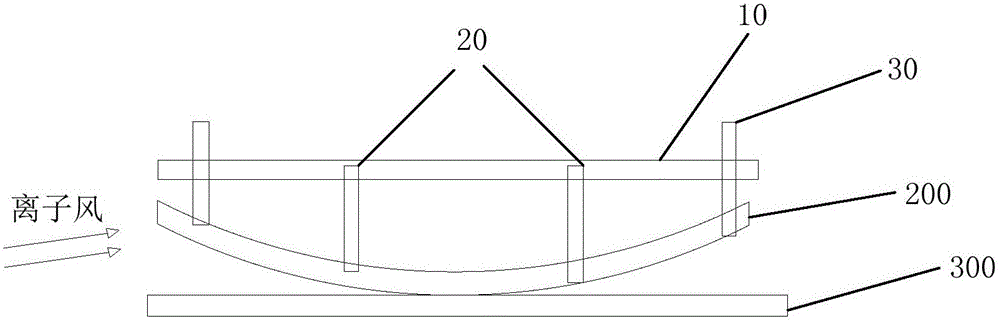

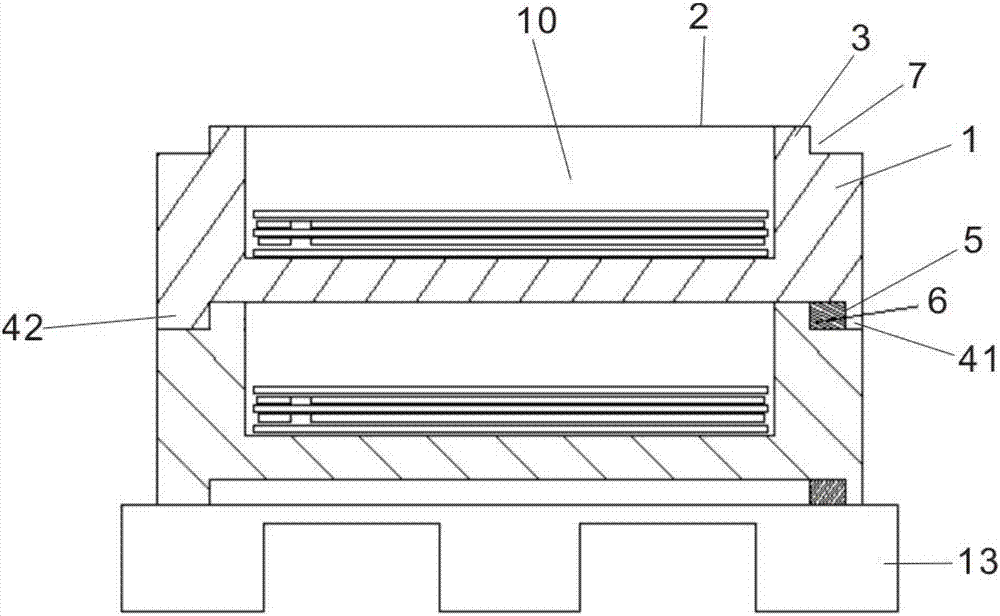

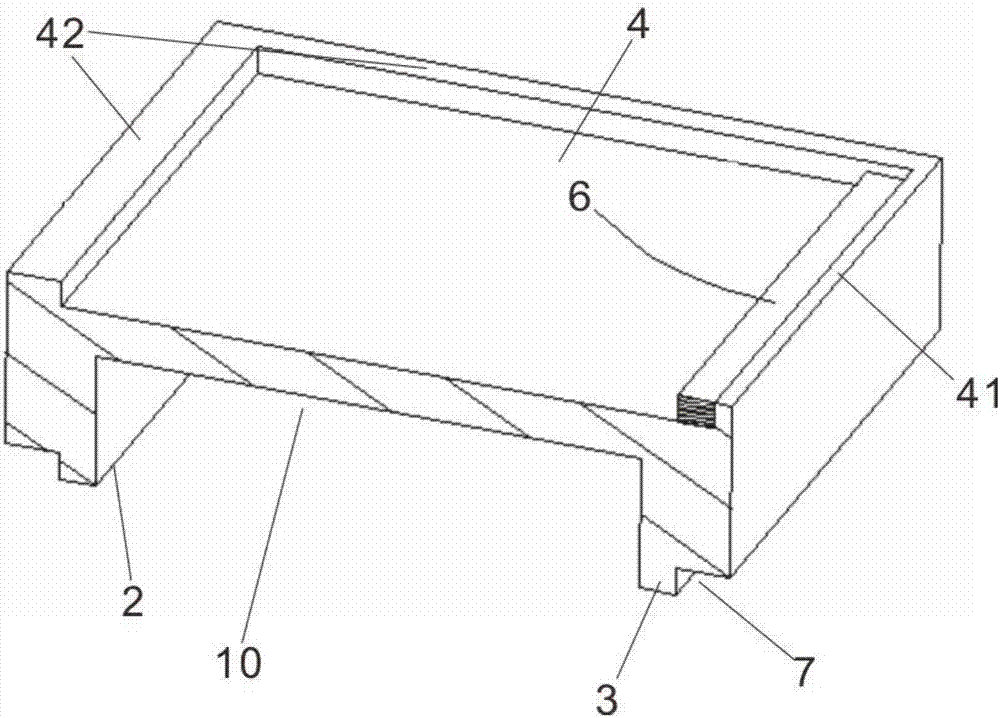

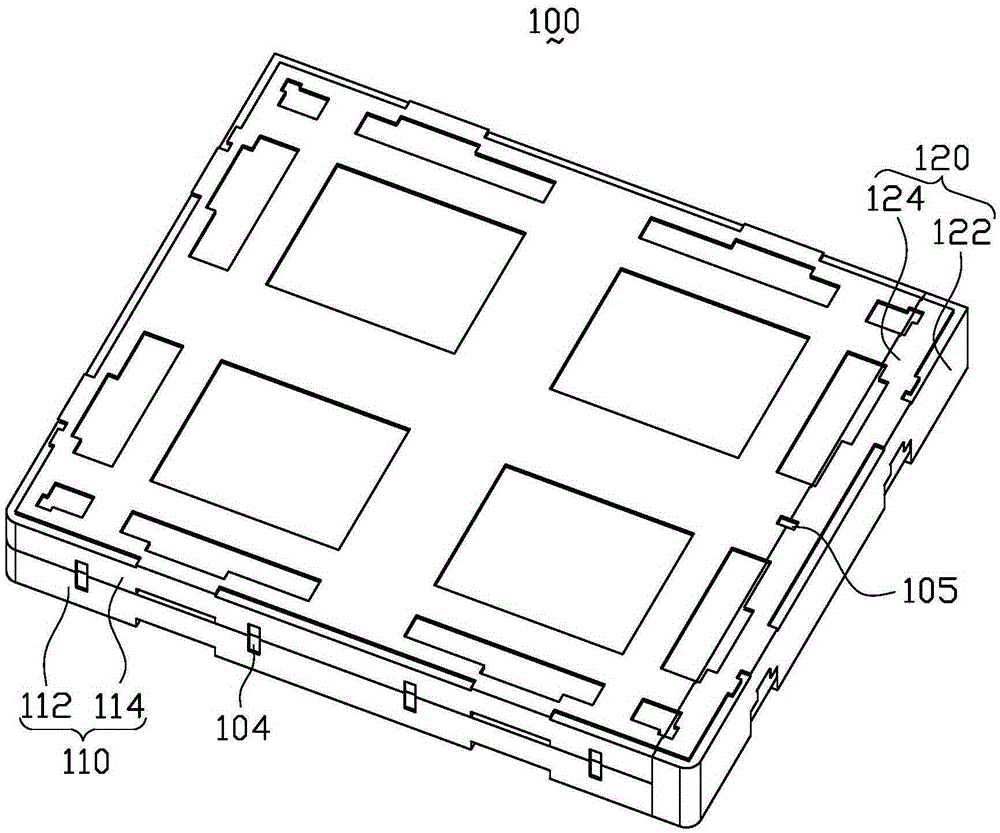

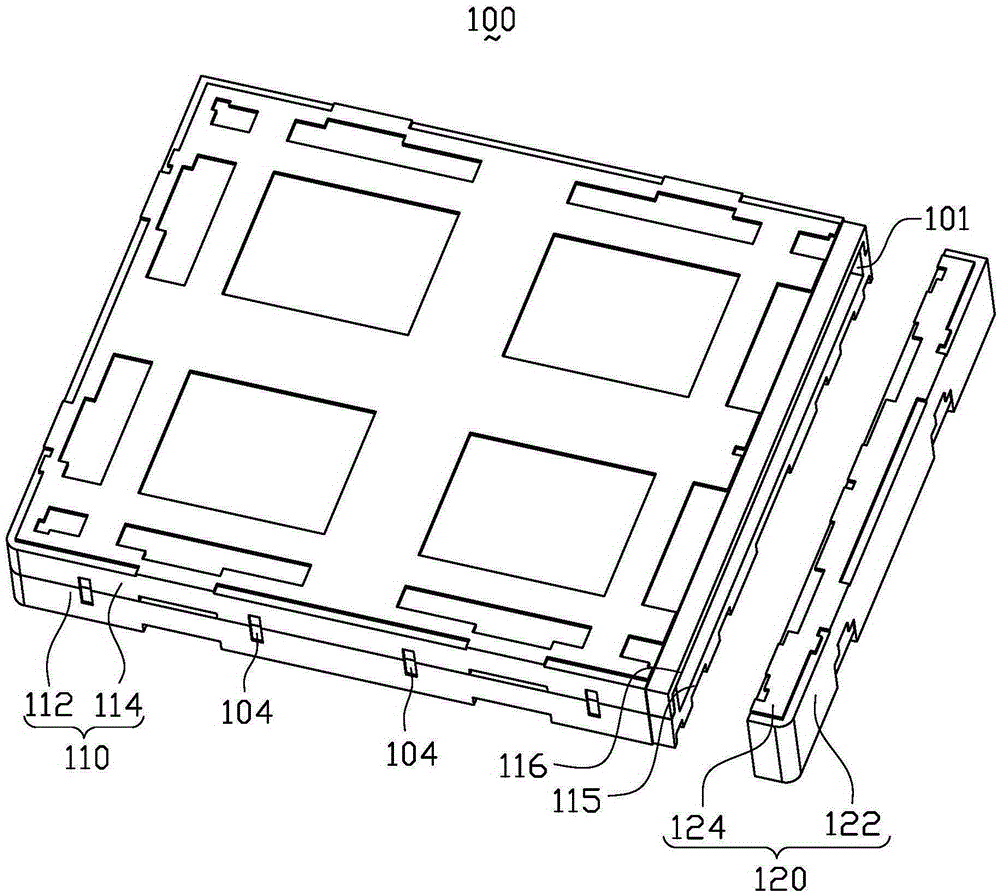

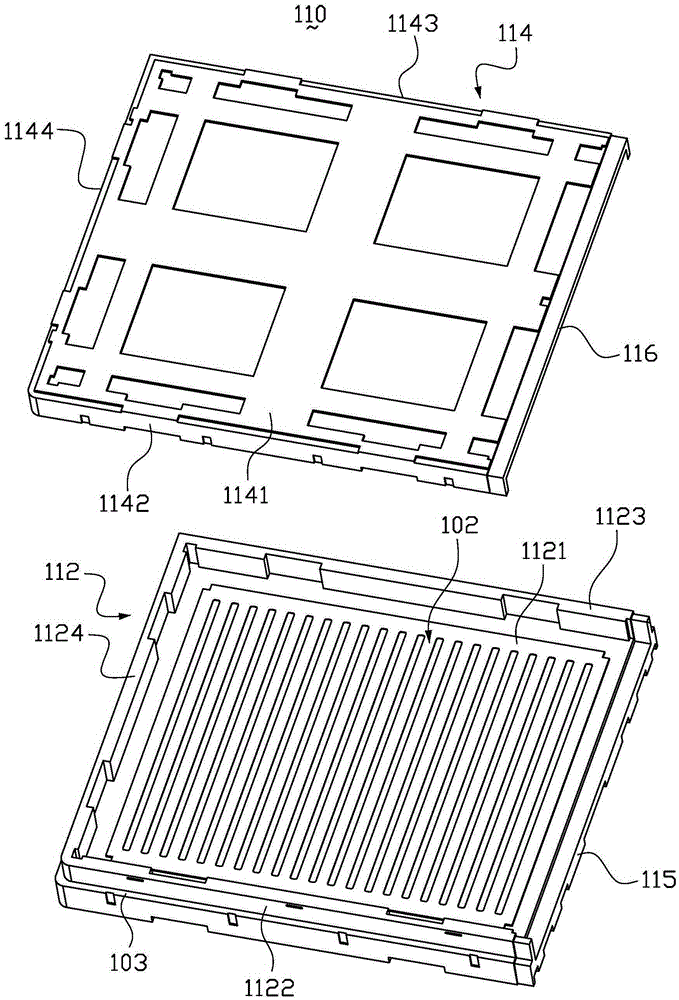

Conveying jig of liquid crystal display panel

ActiveCN103213768AIncrease the support pointReduce vibration amplitudeRigid containersDamagable goods packagingLiquid-crystal displayLiquid crystal

The invention discloses a conveying jig of a liquid crystal display panel. The conveying jig of the liquid crystal display panel comprises a drawer cage and a tray, wherein the tray is used for accommodating the liquid crystal display panel, supporting pieces are respectively arranged on two opposite lateral walls of the drawer cage, and the tray is placed on the supporting pieces. According to the conveying jig of the liquid crystal display panel, a smooth supporting surface is provided for the liquid crystal display panel, the number of supporting points of the liquid crystal display panel is increased, vibration amplitude can be reduced when the liquid crystal display panel is conveyed, deformation or fracture of the liquid crystal display panel can be effectively avoided, force only needs to be applied to the tray when the liquid crystal display panel is placed into or taken out of the jig, and the situation of the fracture of the liquid crystal display panel caused by improper force applying when the liquid crystal display panel is placed into or taken out of the jig is effectively avoided.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

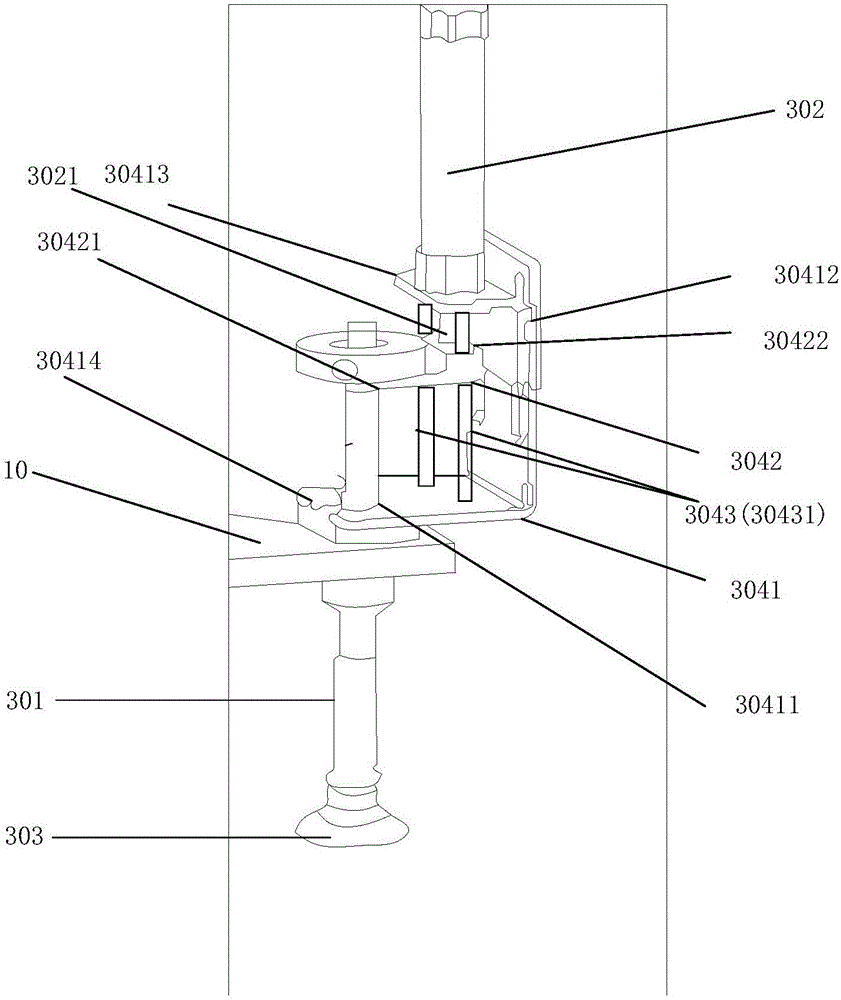

Mechanical arm

ActiveCN105858202AEasy to separateAdsorption is easy to controlConveyorsGripping headsRobotic armEngineering

The invention discloses a mechanical arm. The mechanical arm comprises a moving arm, a first adsorption device and a second adsorption device. The moving arm is horizontally arranged and moves in the horizontal direction or vertical direction to be away from or close to a first object to be adsorbed, and the first object is in tight contact with a panel; the first adsorption device is fixedly arranged on the moving arm and used for adsorbing the non-edge of the first object in contact with the first adsorption device under the vacuum effect; and the second adsorption device is movably arranged on the edge position of the moving arm, can vertically move in the vertical direction, is used for adsorbing the edge of the first object in contact with the second adsorption device under the vacuum effect, and can vertically move to enable the edge of the first object to be adsorbed, so that the edge of the first object is separated from the panel. Through the manner, adhesive force between the first object and the panel can be reduced, and it is ensured that the first object and the panel are separated very easily.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

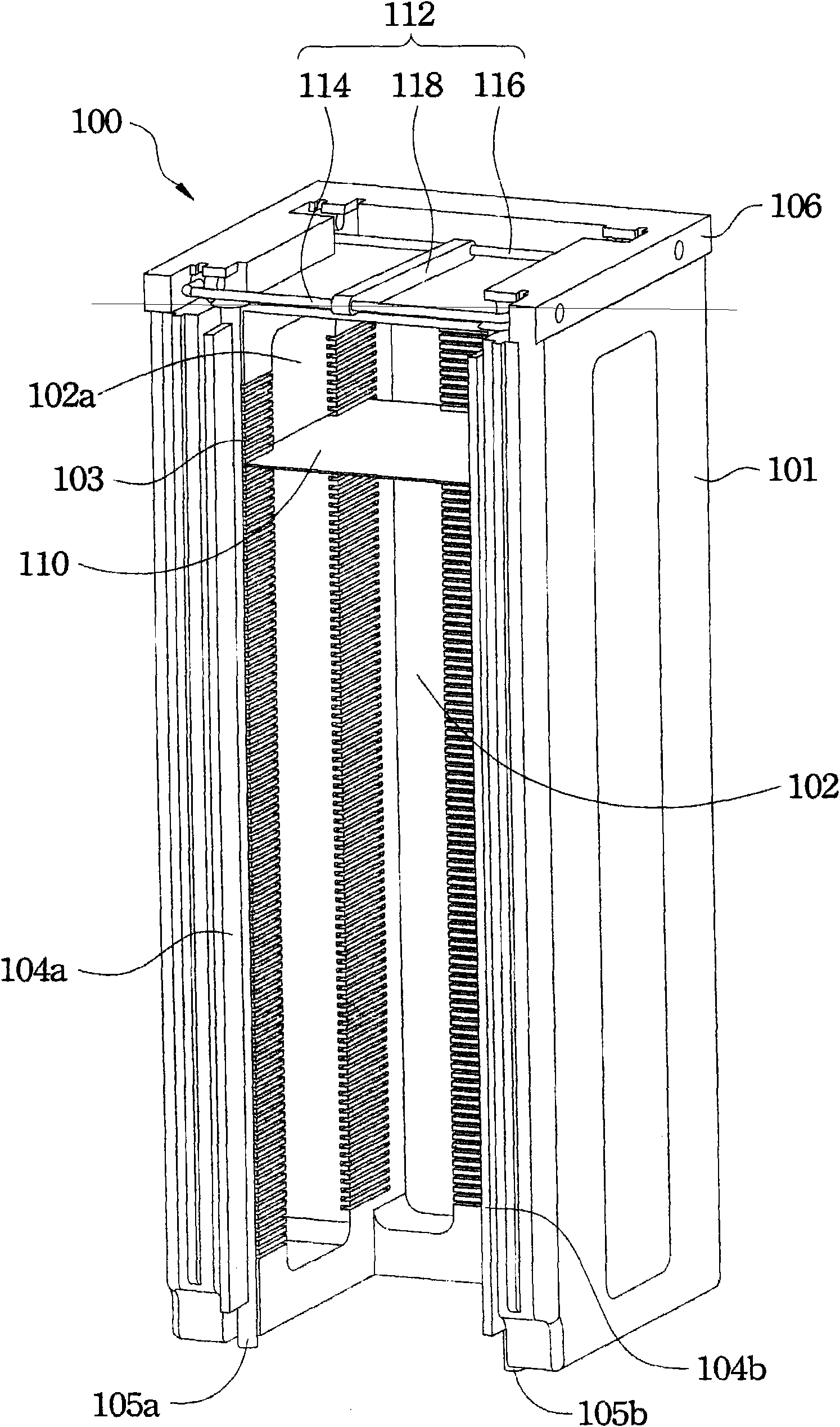

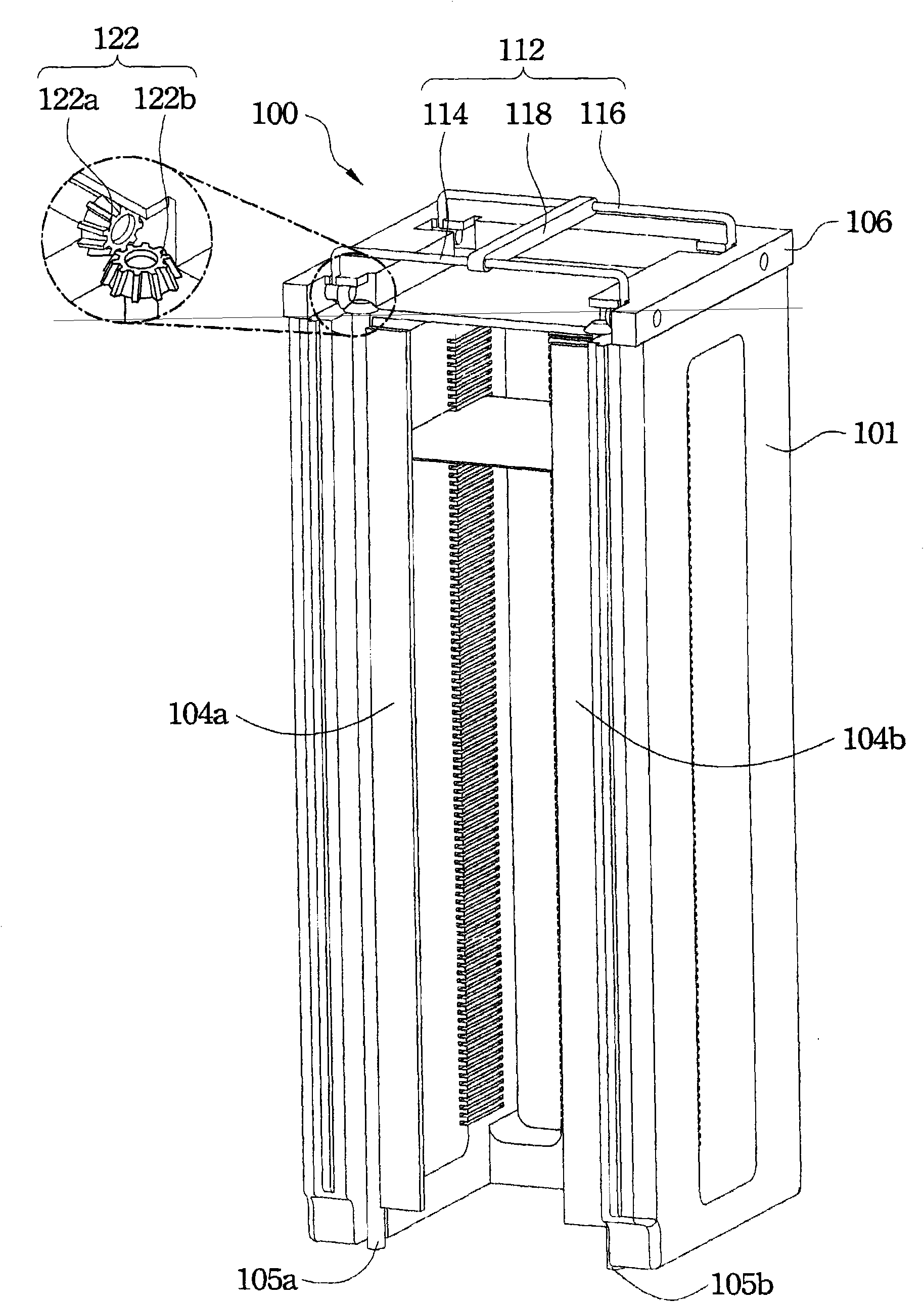

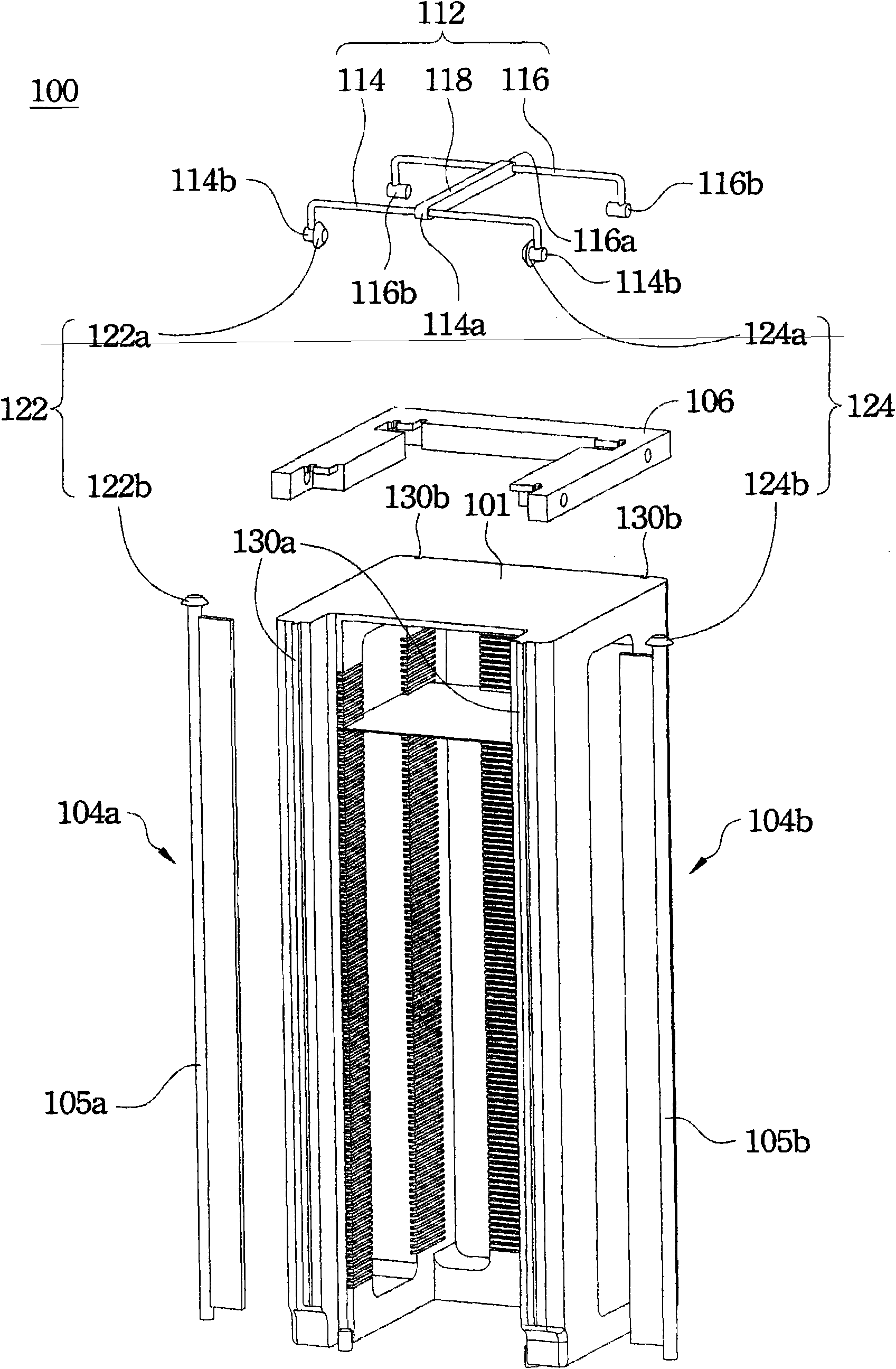

Storage box

InactiveCN102152908AImprove shipping efficiencyAvoid FragmentsLidsContainers to prevent mechanical damageGear wheelFixed frame

A storage box includes a box body, two door leaves, a fixed frame, a handle portion and two pairs of gears, wherein the box body has an accommodating space, of which the inner wall is provided with a plurality of slots for accommodating base materials, and each door leaf has an opening for a door shaft to be pivoted into the accommodating space. The handle portion includes a first U-shaped member, a second U-shaped member and a handle, wherein both ends of the first U-shaped member are respectively pivoted onto the fixed frame and are near the opening of the accommodating space, both ends of the second U-shaped member are respectively pivoted onto the fixed frame, and both ends of the handle are respectively pivoted onto the first U-shaped member and the second U-shaped member. Each pair of gears has two gear assemblies respectively situated at the end of the door shaft and the end of the first U-shaped member. Two gear assemblies are orthogonally connected, so that the two door leaves are driven to rotate when the first U-shaped member is rotated.

Owner:AU OPTRONICS CORP

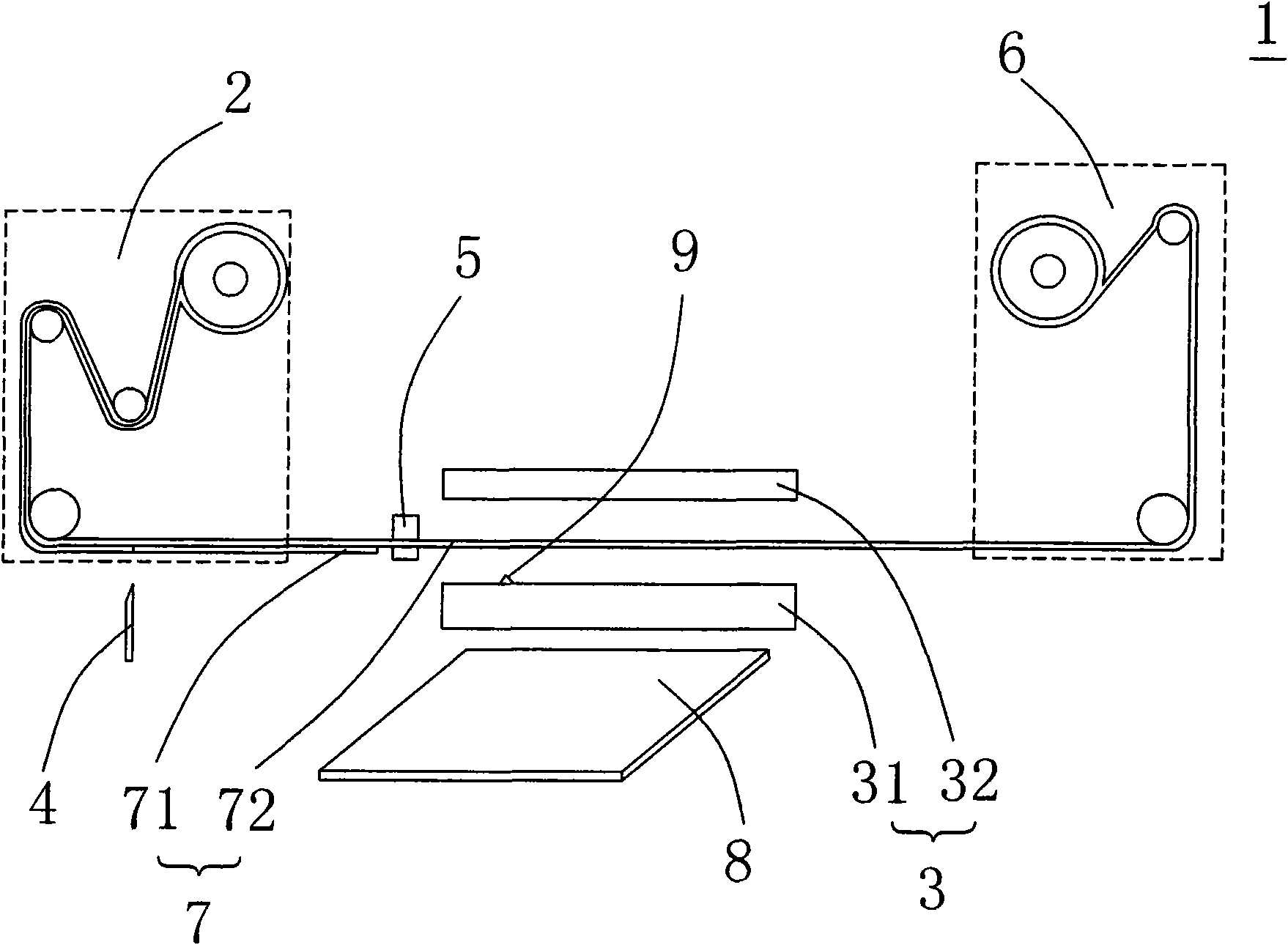

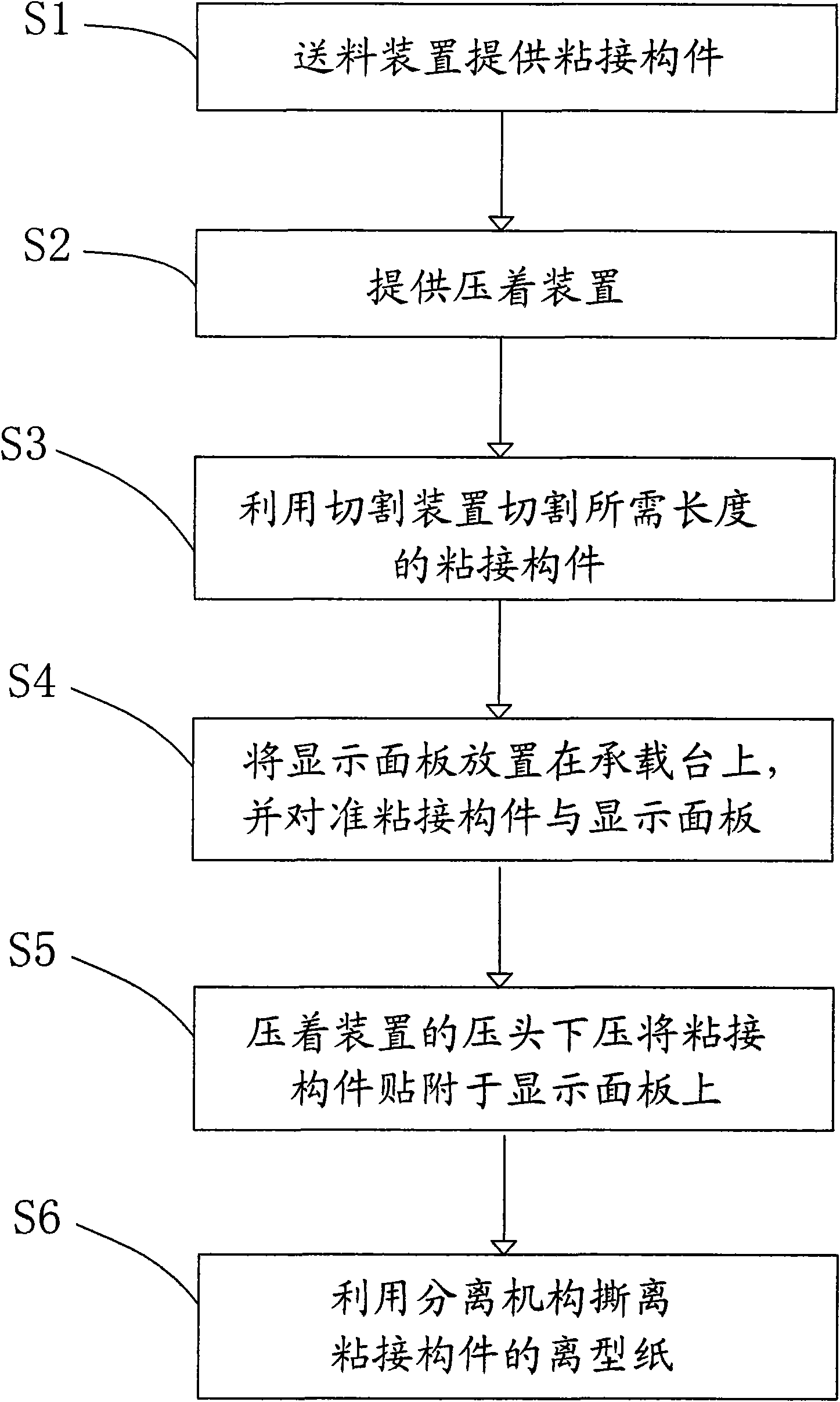

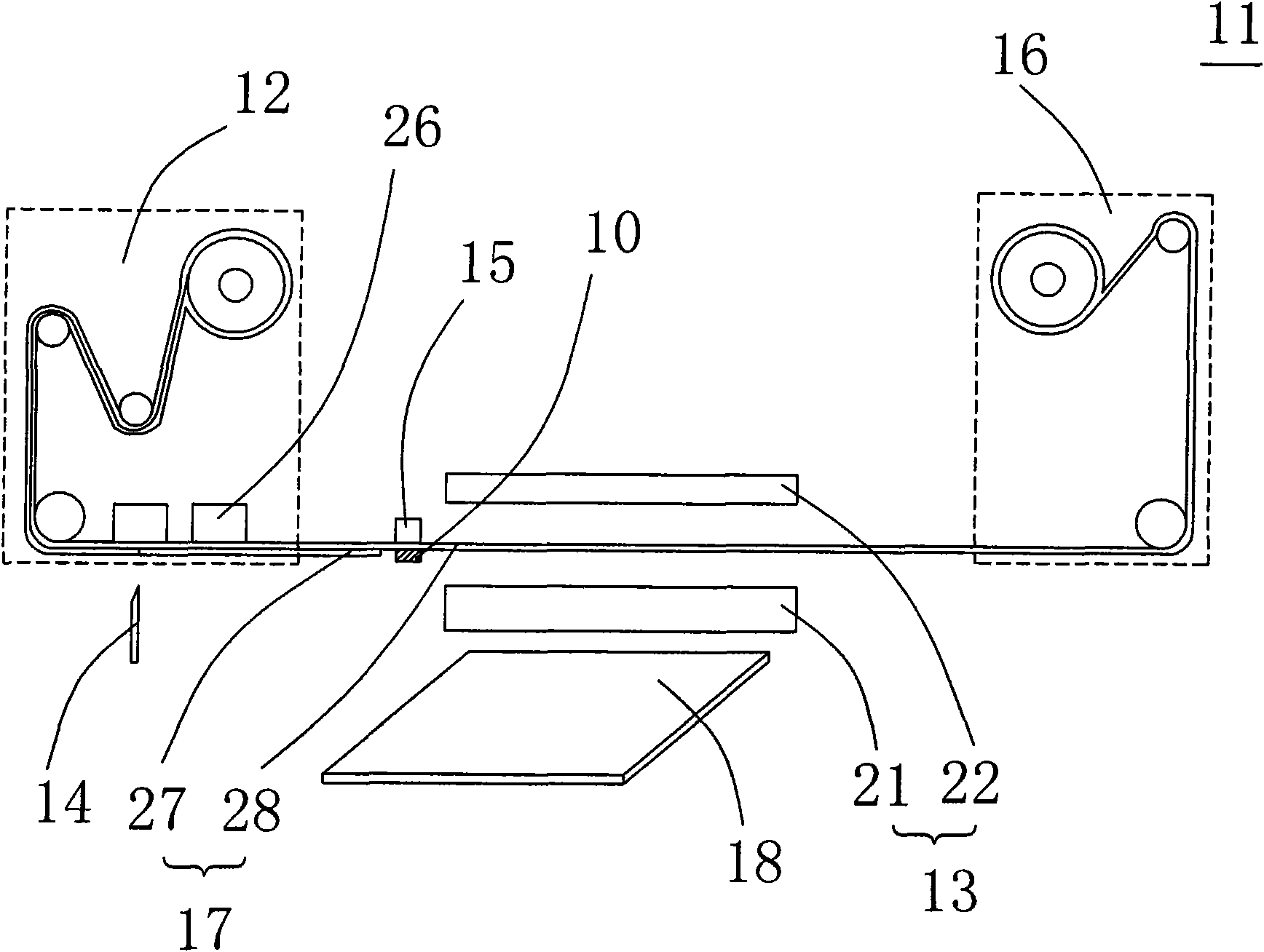

Anisotropies conductor film (ACF) attaching device and attaching method

InactiveCN101995677AReal-time detectionAvoid FragmentsLaminationLamination apparatusForeign matterAnisotropic conductive film

The invention provides an anisotropies conductor film (ACF) attaching device and an attaching method, which is used for attaching ACFs to a display panel. The attaching device comprises a pressure device, a separation device and a sensing device, wherein the pressing device comprises a plummer and a pressure head; the display panel is arranged on the plummer; the pressure head is arranged above the plummer and used for attaching adhesive components to the display panel, wherein the adhesive components comprise ACFs and release papers; the separation device moves relative to the plummer and is used for removing the release papers from the adhesive components adhered to the display panel; and the sensing device is arranged on the separation device, moves together with the separation device and is used for sensing whether foreign matters exist on the plummer.

Owner:AU OPTRONICS (XIAMEN) CORP +1

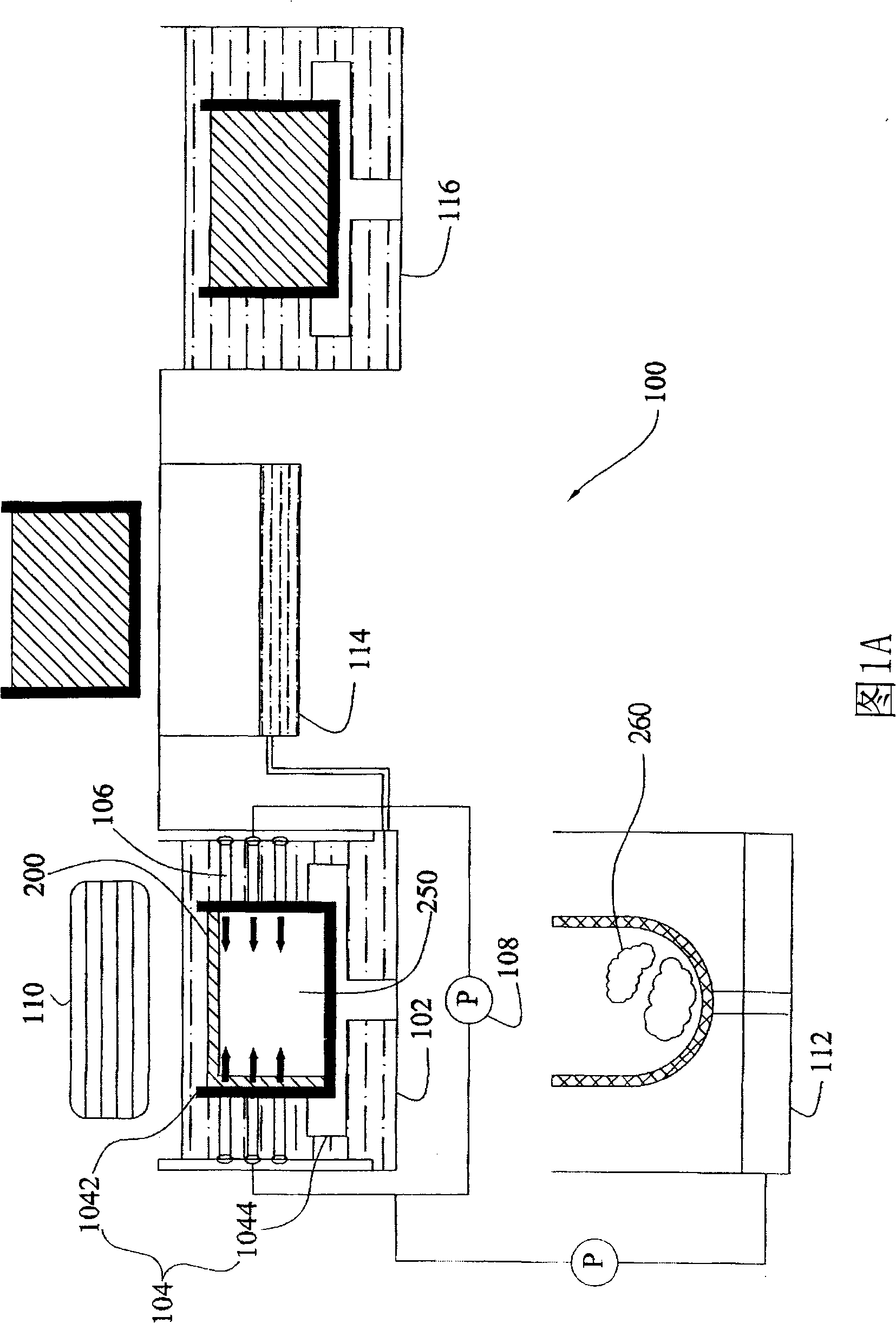

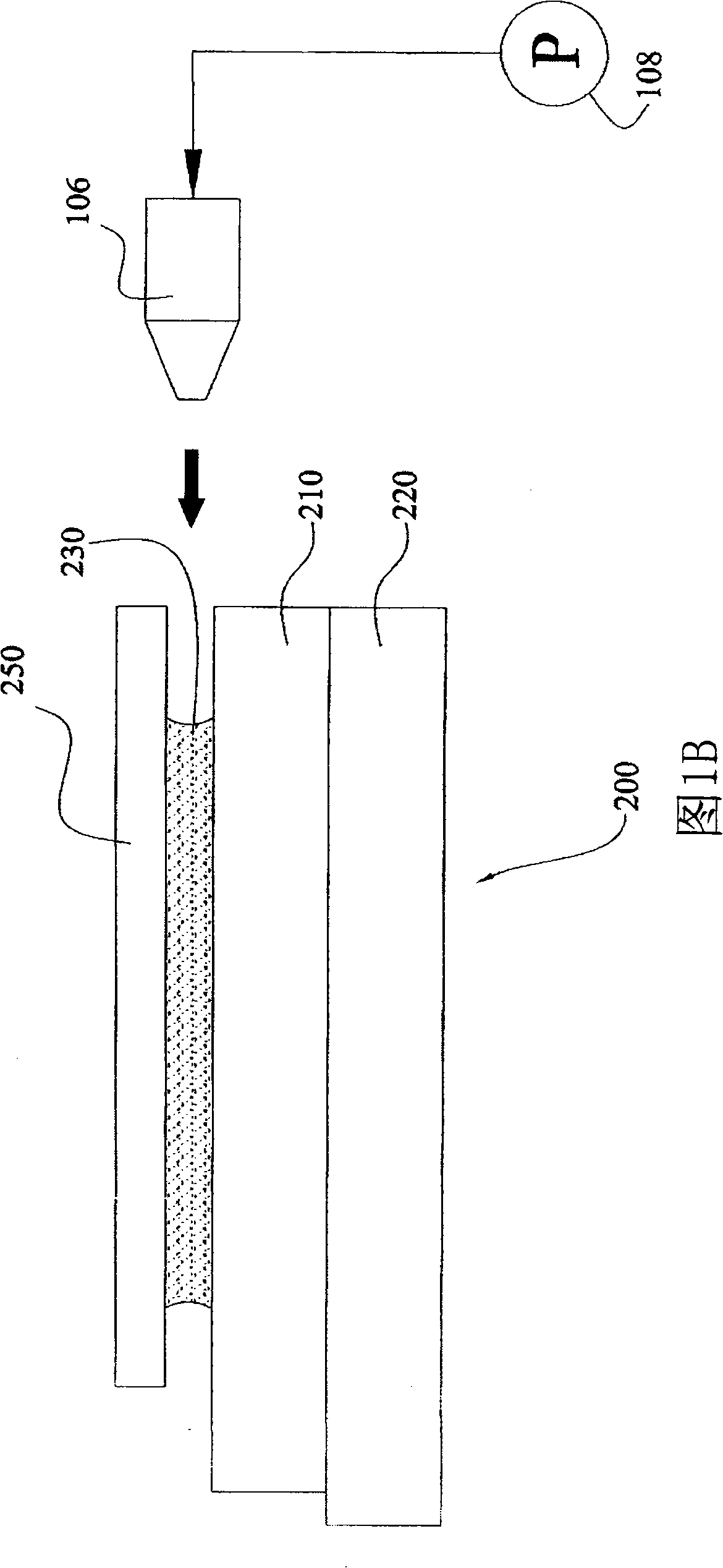

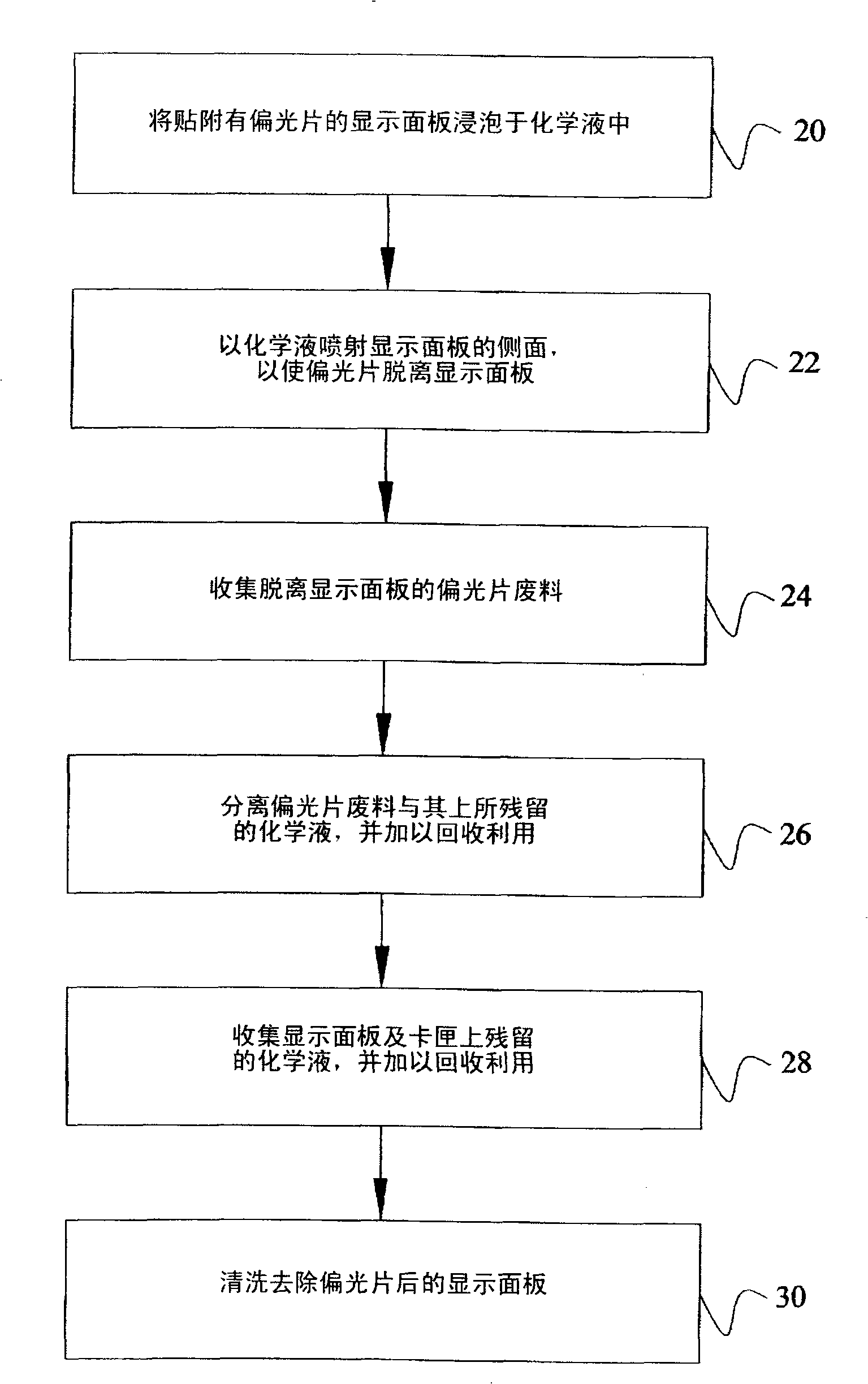

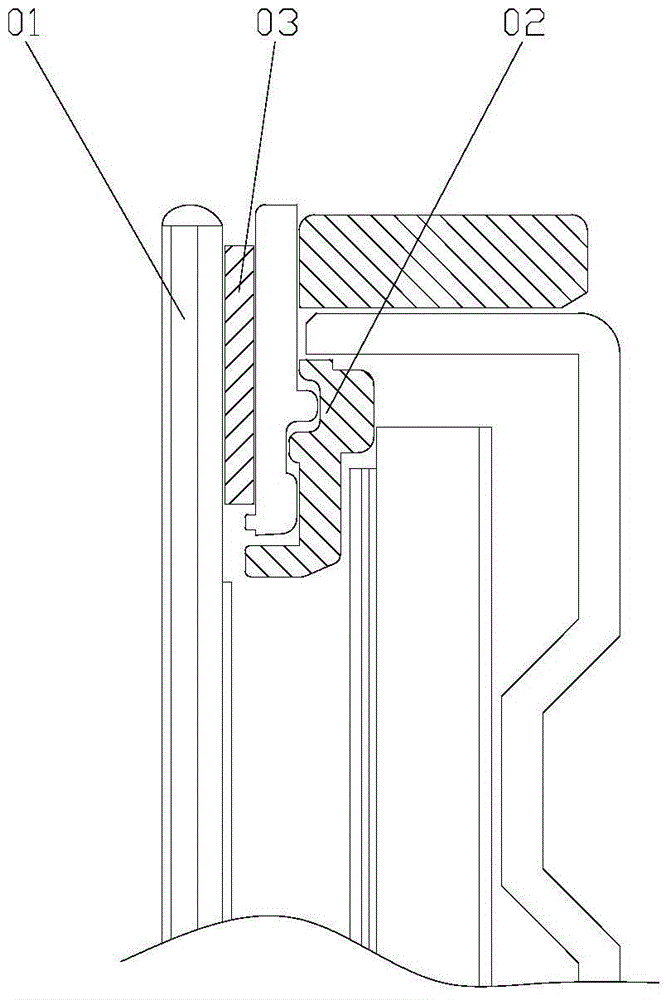

Removing device and removing method for polarizer

The invention discloses a removal device for a polarizer and a method thereof, wherein, a surface to be processed is provided with at least one display panel of the polarizer. The polarizer is attached on at least one glass substrate of the display panel by a colloid. The removal device for the polarizer comprises a membrane removing groove which contains chemical solution, a bearing unit which is arranged in the membrane removing groove for bearing the display panel, and a plurality of ejectors which are arranged in the membrane removing groove for ejecting the chemical solution to the sides of the display panel. The removal device for the polarizer and the method of the invention can lead the polarizer on the display panel to be processed, which are particularly applied to the display panel with a thinned glass substrate, thereby effectively avoiding the fragment occurrence of the display panel.

Owner:AU OPTRONICS CORP

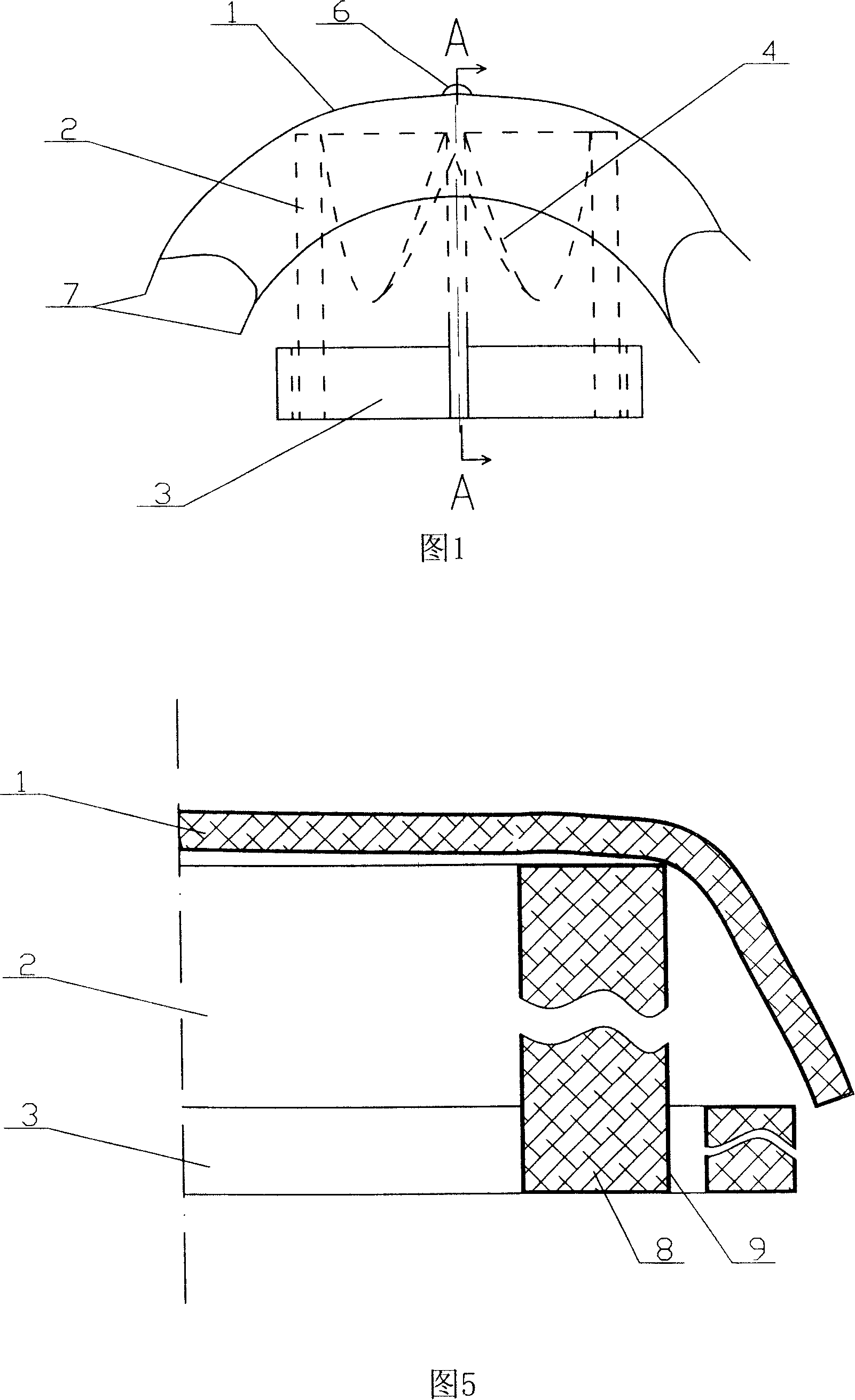

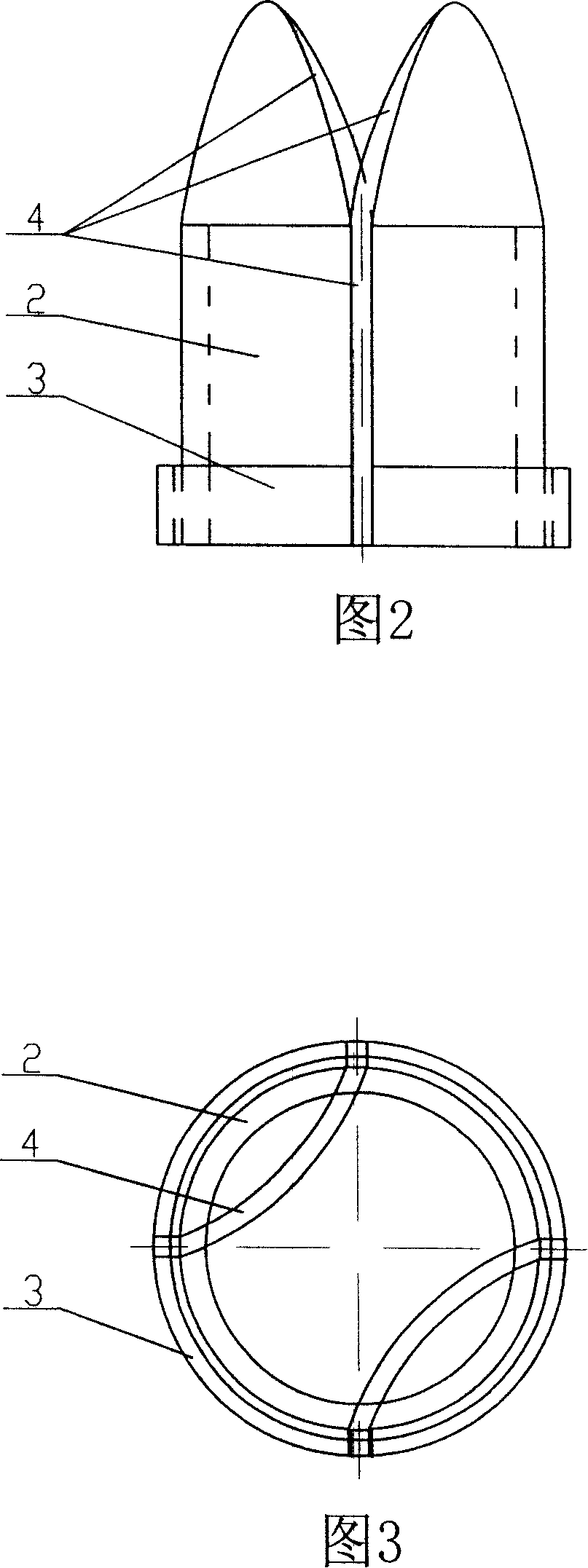

Explosion-proof blanket

InactiveCN101149244AEvenly distributedEasy to carryReactive armourDynamic armourEngineeringMechanical engineering

This invention relates to an anti-explosion blanket. The anti-explosion rail is covered with anti-explosion blanket. The anti-explosion rail is through-hole cylinder structure. The bottom of the said anti-explosion rail is covered with leak protection rail. The said anti-explosion rail moves in axial direction inside of the leak protection rail and is limited by connecting belt. One end of the said connecting belt connects to the leak protection rail. The other end connects to the anti-explosion rail. Unloading gaps are opened in the middle of the said anti-explosion blanket. One end of all the unloading gaps lead to the center of the blanket and are bonded together through connecting round buckle. The other end of all the said unloading gaps open out and form irradiation structure. This invention is convenient and has strong unloading capability. It has good protection effect in close distance.

Owner:CHONGQING JINGUAN NEW TECH DEV

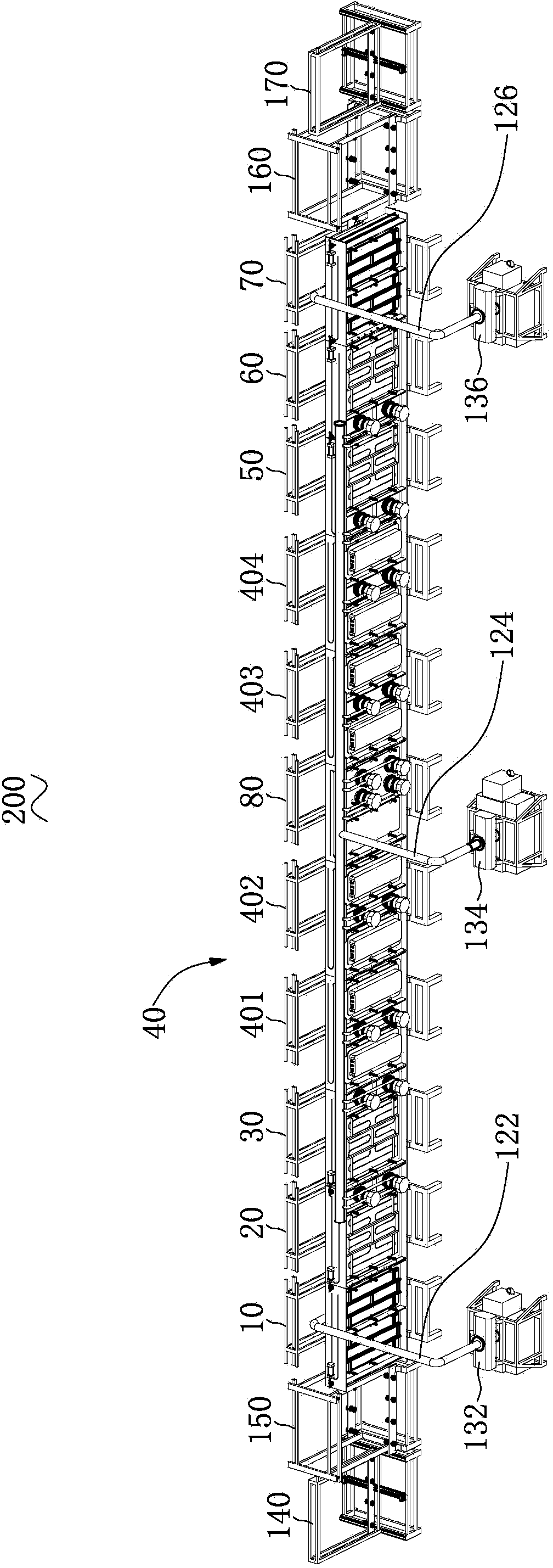

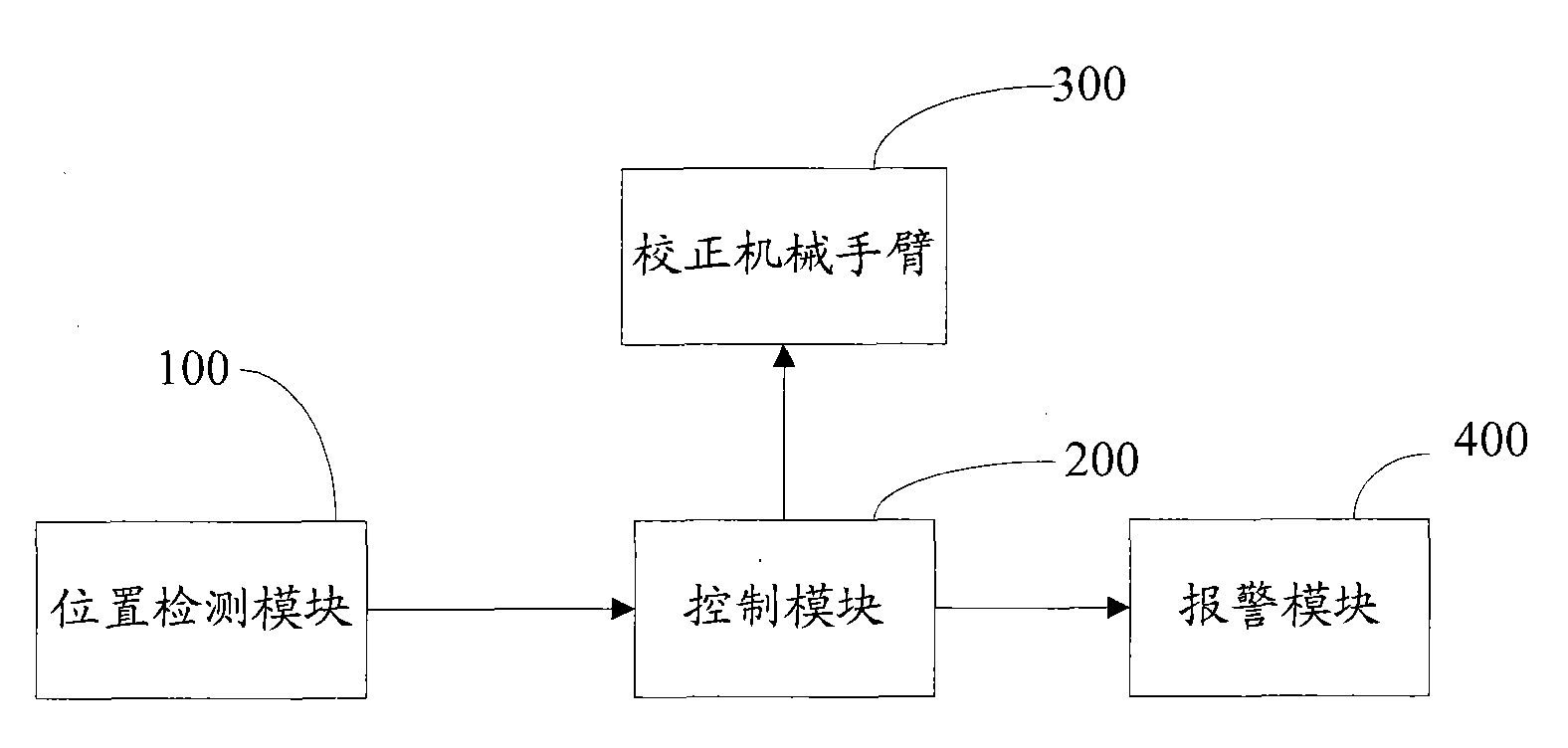

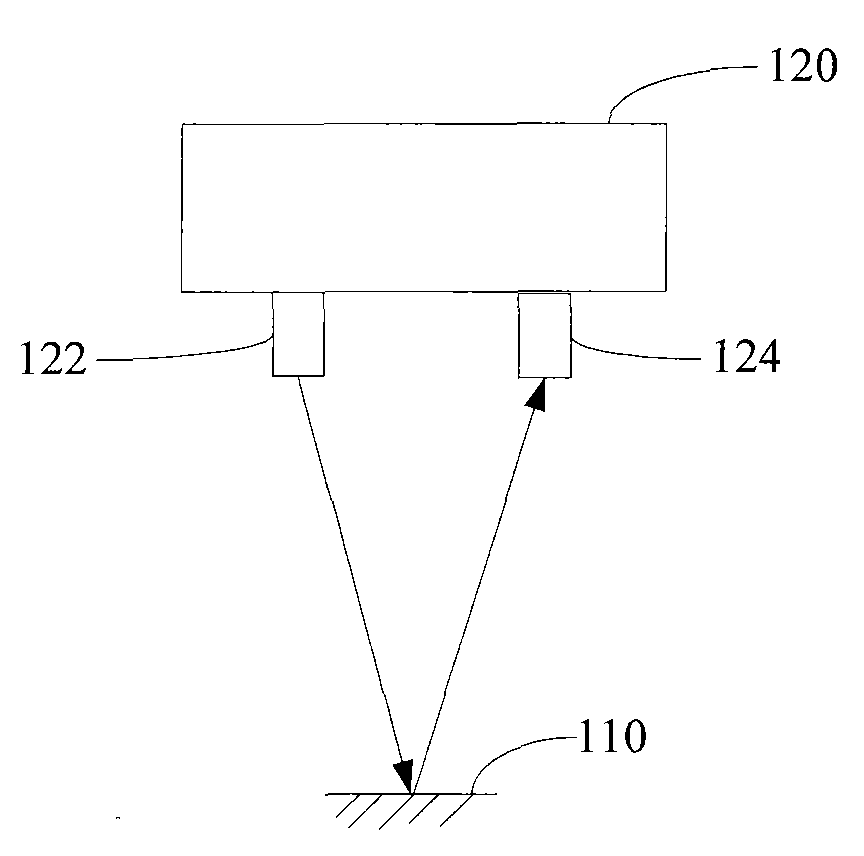

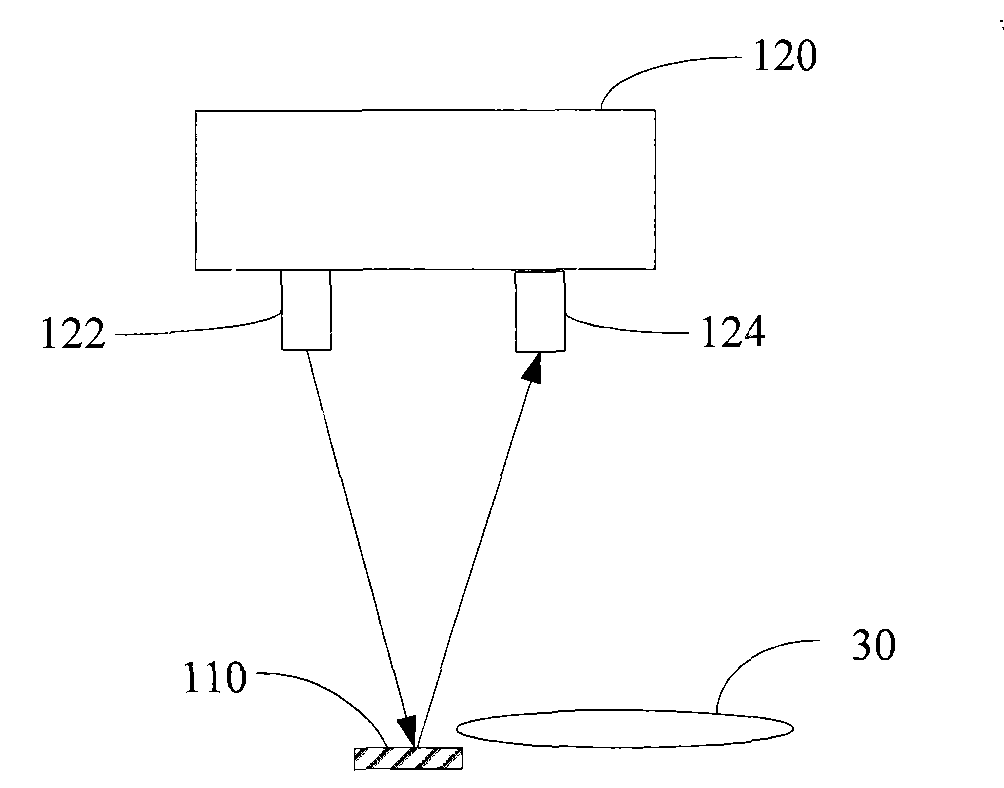

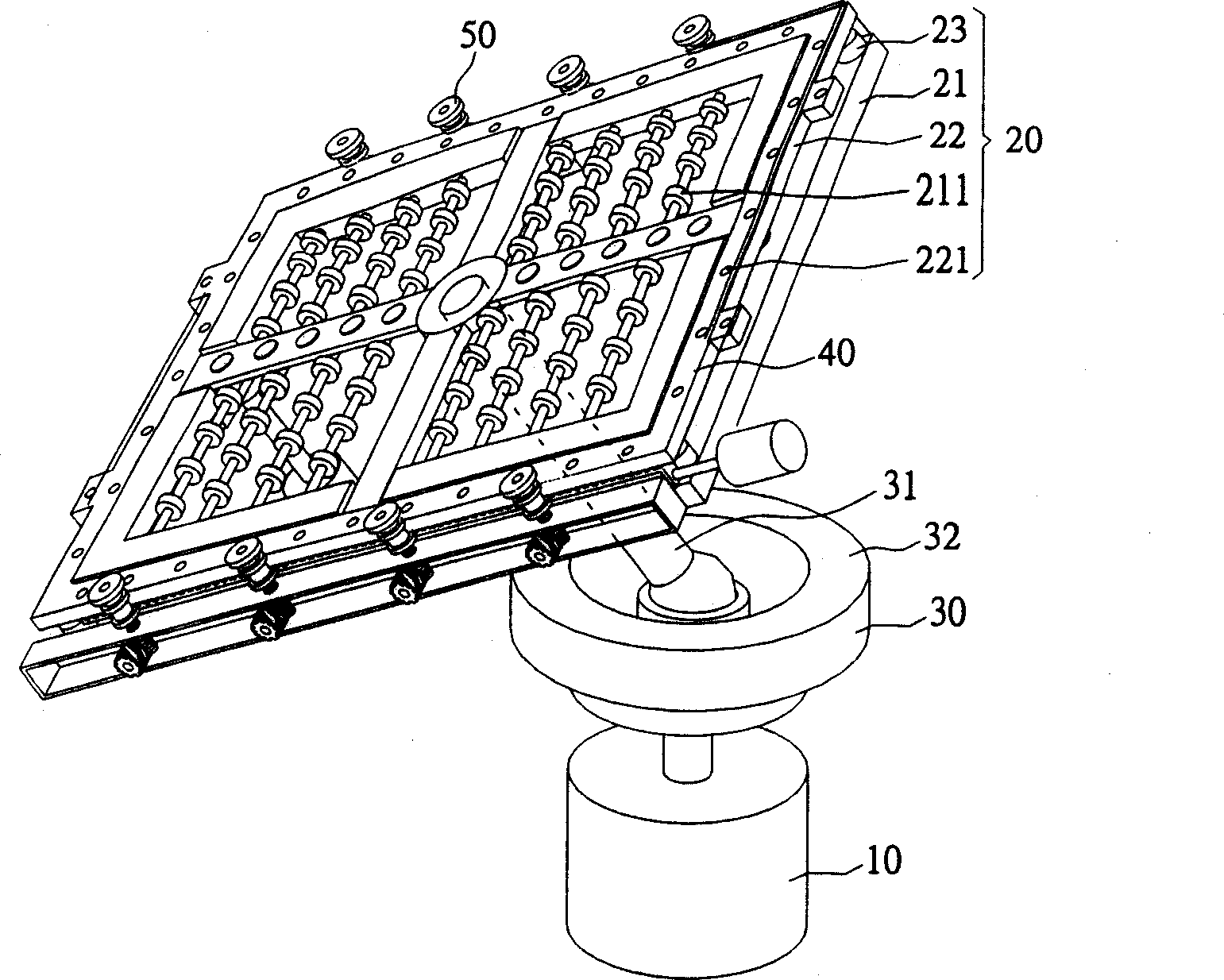

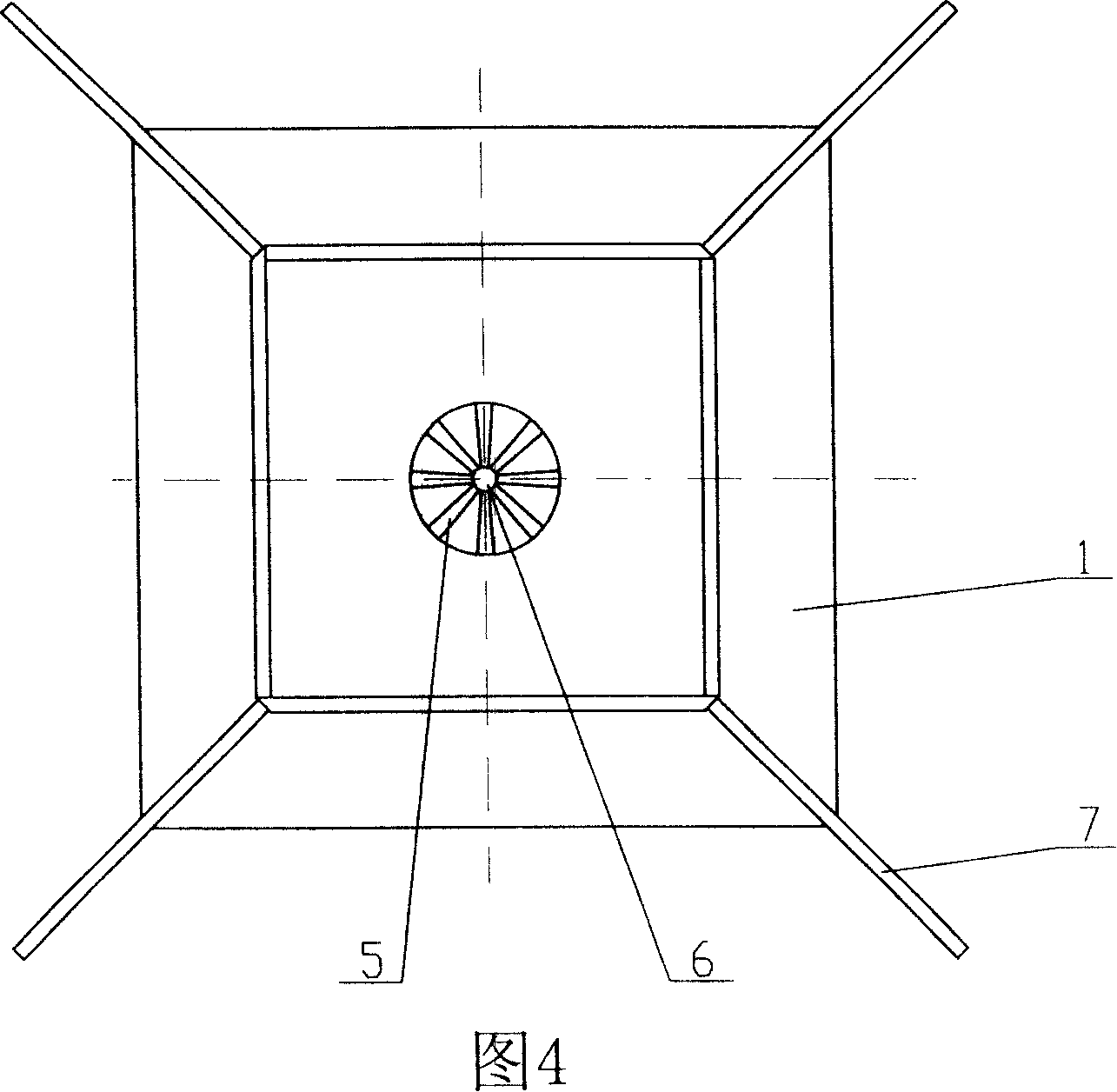

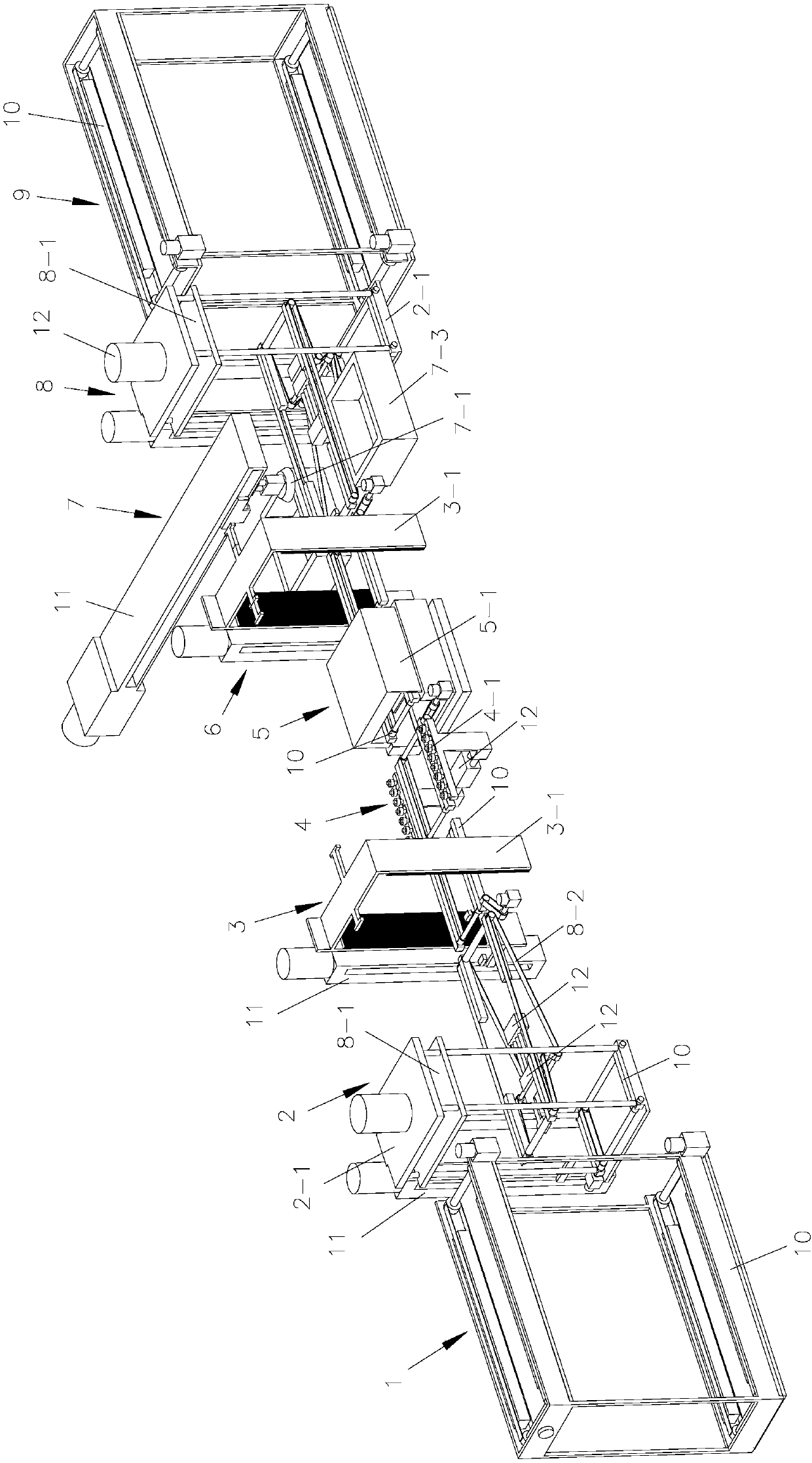

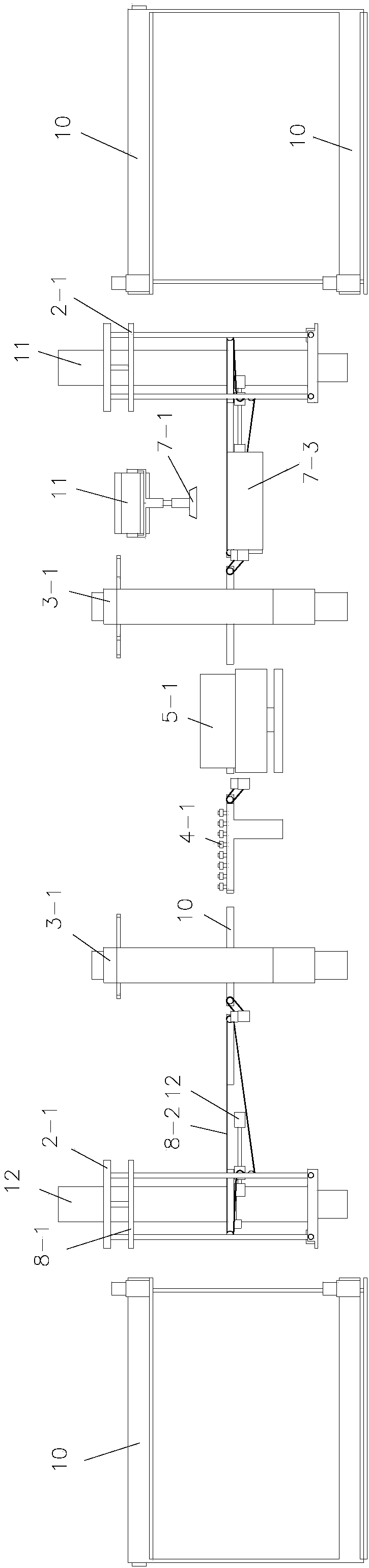

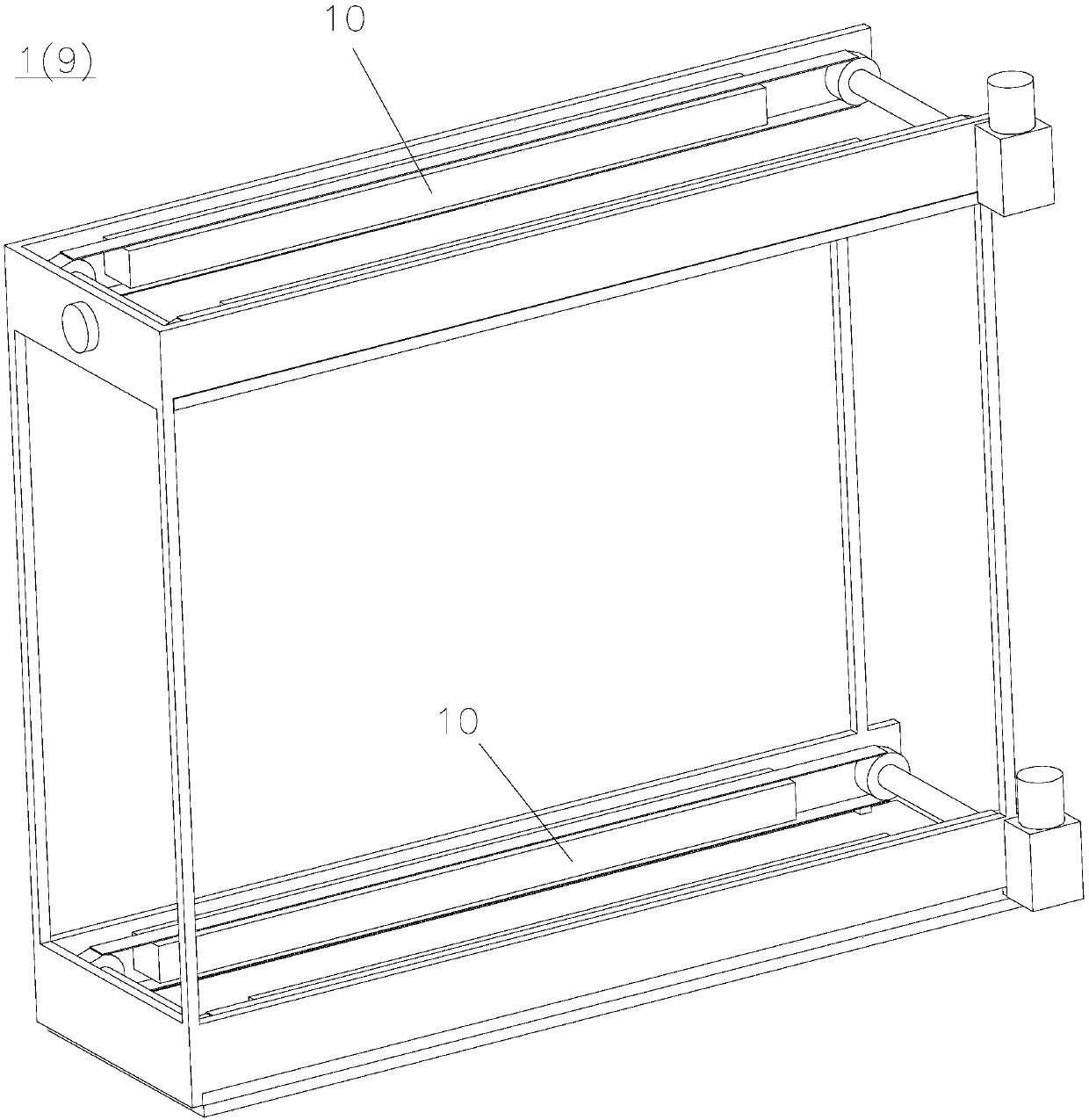

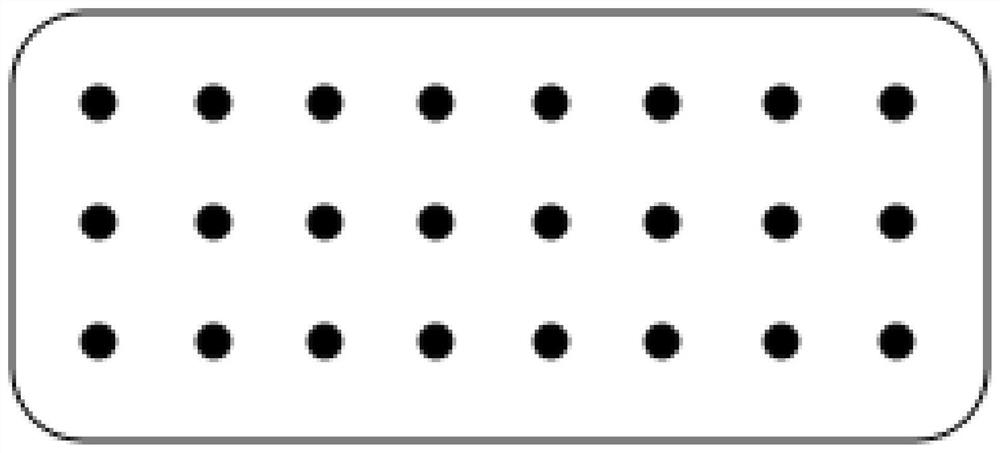

Automatic square resistance measuring equipment

ActiveCN107591342AAvoid pollutionAvoid FragmentsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingTest efficiencyLower limit

The invention relates to automatic square resistance measuring equipment. A flower basket filled with silicon wafers is controlled to be conveyed to a discharging region from a feeding region througha control part, the silicon wafers inside the flower basket are discharged one by one and conveyed to a first cache region in the discharging region, the silicon wafers are conveyed to a correction region in the first cache region, the silicon wafers are conveyed to a test region after being corrected to carry out square resistance testing in the correction region, the silicon wafers after squareresistance testing are conveyed to a second cache region, through the control of the control part, after setting standard comparison and splitting in a splitting region, the silicon wafers exceeding set standard upper limit and exceeding set standard lower limit are separated out, the silicon wafers of which the square resistance testing result is in a normal range are conveyed to the feeding region, the silicon wafers are placed onto the flower basket through the feeding region, and finally the flower basket filled with the silicon wafers is conveyed out through the discharging region. The problems of pollution, fragmenting and scratching caused by manual wafer taking and wafer testing are effectively avoided; and the square resistance of the silicon wafers is automatically tested, so that the testing efficiency is greatly improved, and bath inspection can be completed.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

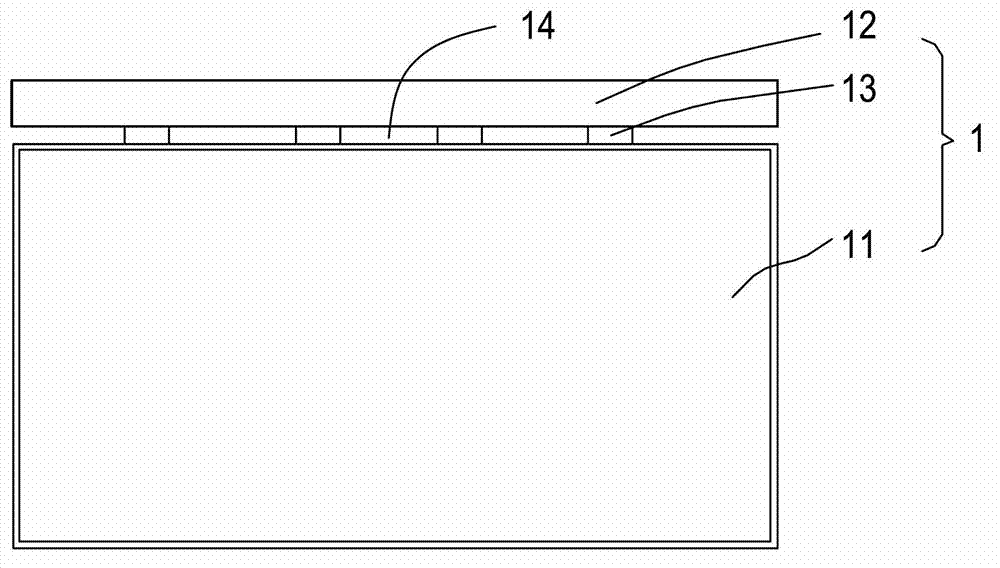

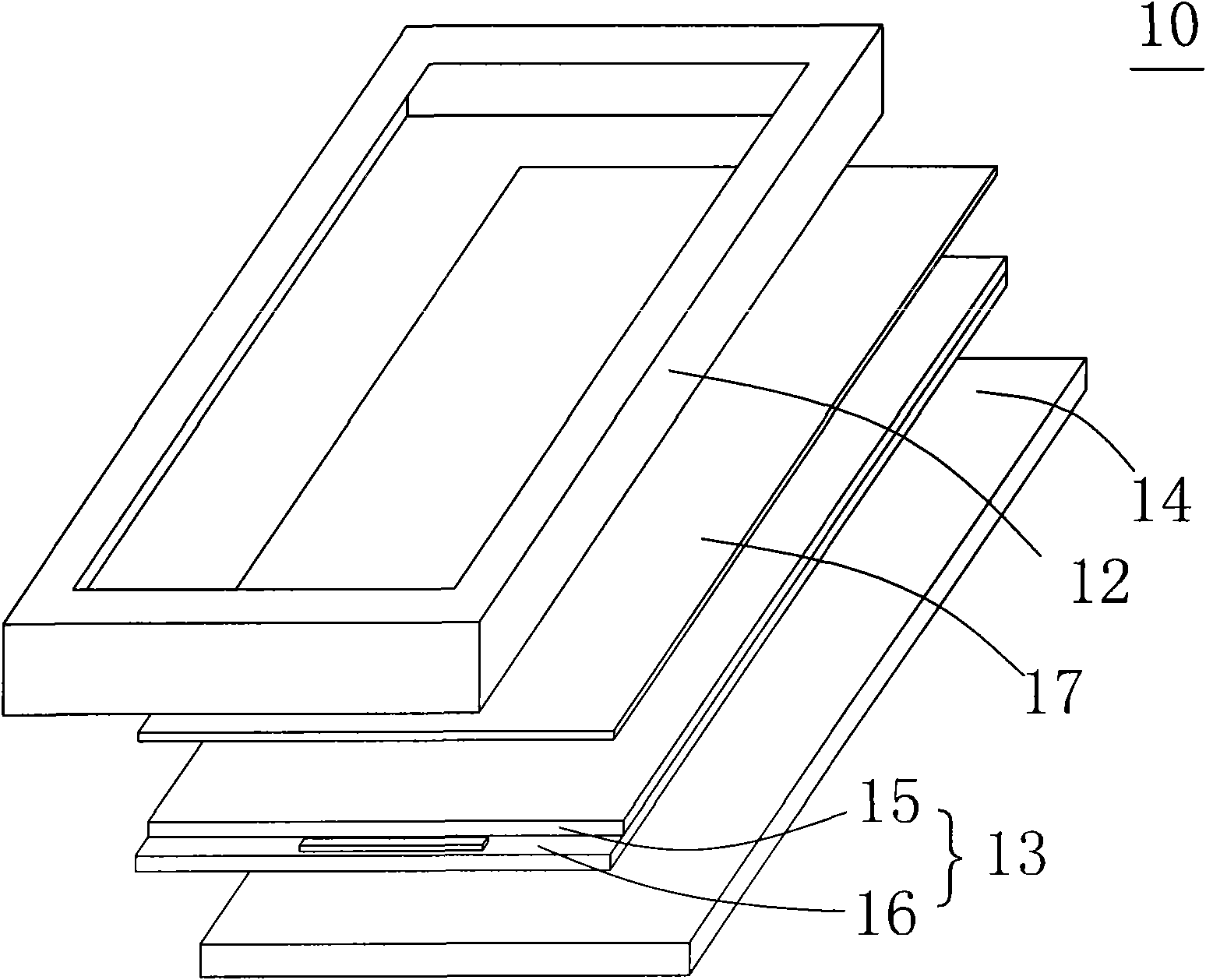

Display module and assembling method thereof

InactiveCN101666928AAvoid problems such as bright and dark spotsAvoid FragmentsStatic indicating devicesNon-linear opticsEngineeringPolarizer

The invention provides a display module and an assembling method thereof. The display module comprises a display panel, a front frame and a first polarizer film, wherein the display panel comprises afirst base plate and a second base plate which are arranged oppositely; the front frame is arranged at one side of the first base plate corresponding to the second base plate and is provided with a first surface and a second surface which are arranged oppositely, and the second surface of the front frame faces the display panel; and the first polarizer film is fixedly arranged on the front frame and is provided with a third surface and a fourth surface which are arranged oppositely, and the third surface faces the display panel.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

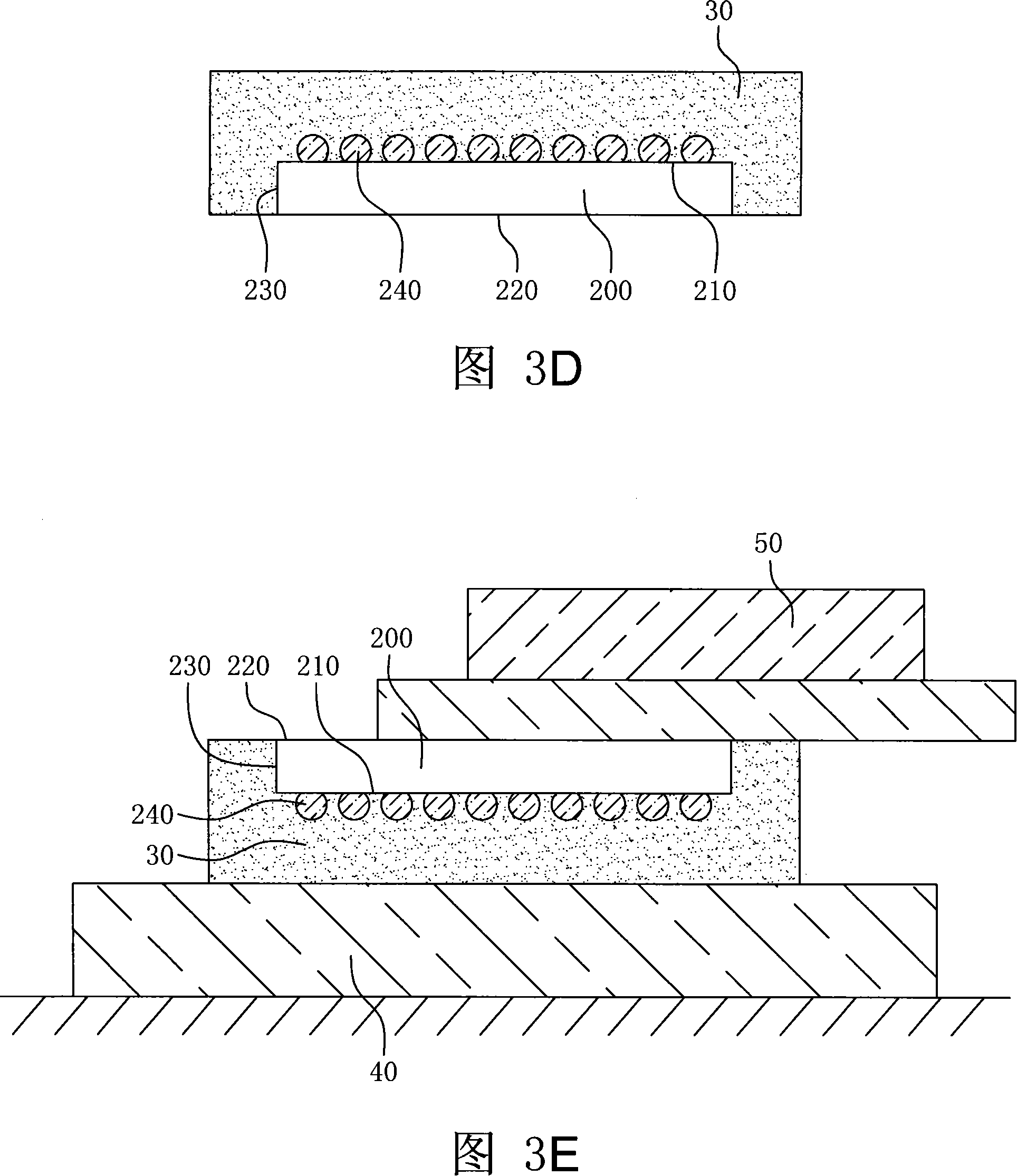

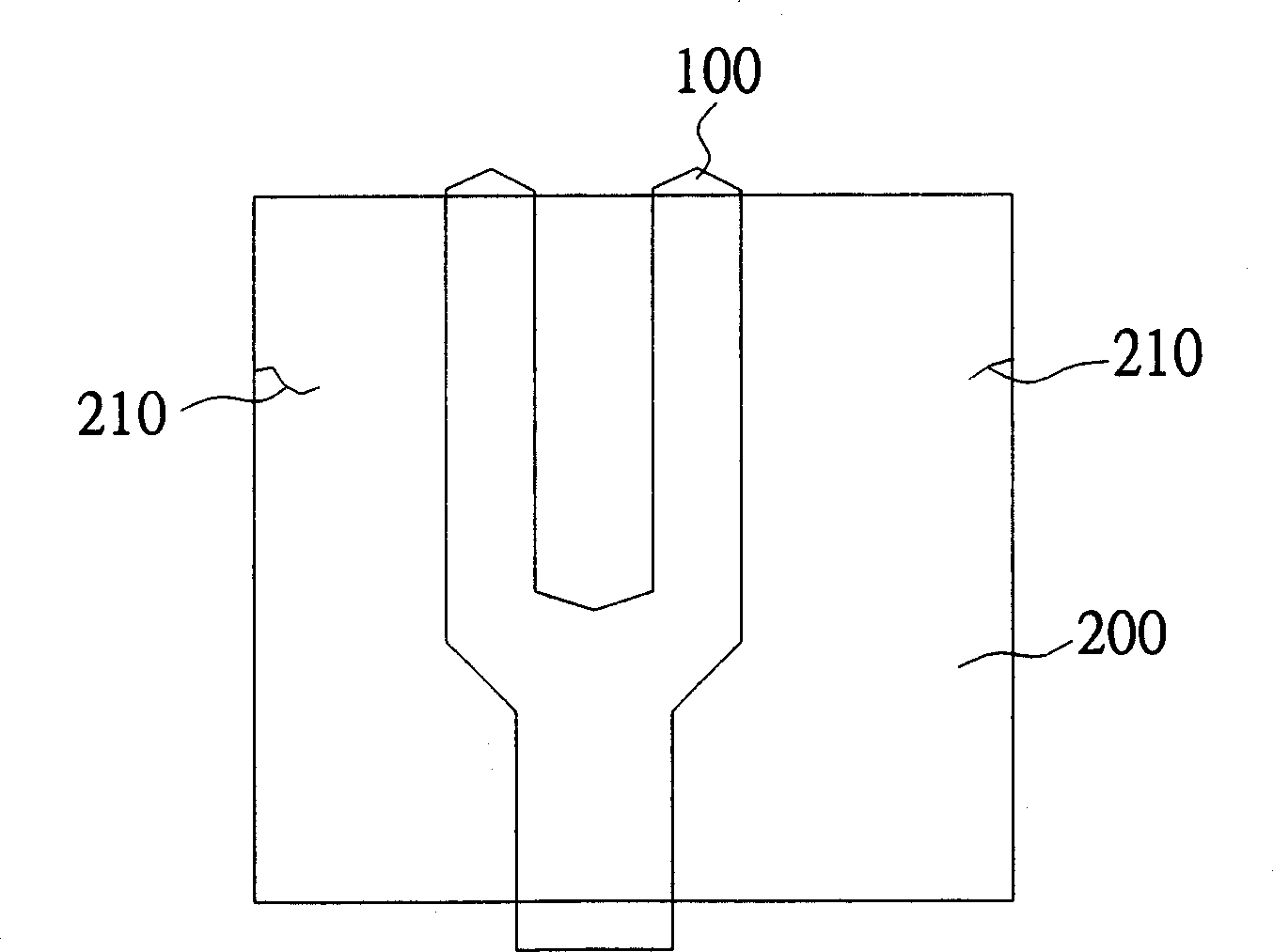

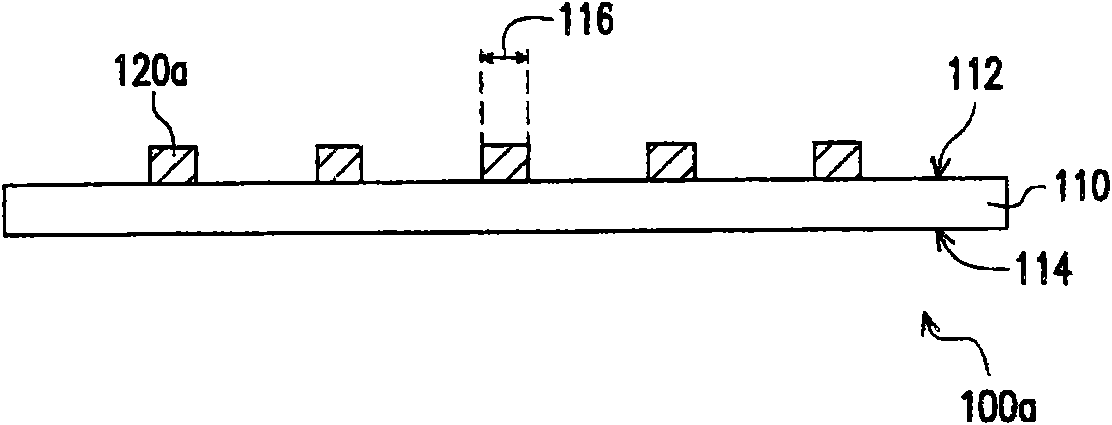

Chip structure, wafer structure and chip fabrication technique

ActiveCN101853819ATo prevent fragmentationAvoid FragmentsSemiconductor/solid-state device detailsSolid-state devicesEngineeringChip fabrication

The invention relates to a chip structure, a wafer structure and a chip fabrication technique, wherein the chip structure comprises a substrate and a stress-buffering layer. The substrate is provided with a first surface and a second surface opposite from the first surface. The stress-buffering layer is arranged around the substrate, and is at least positioned on one of the first and the second surfaces of the substrate.

Owner:ADVANCED SEMICON ENG INC

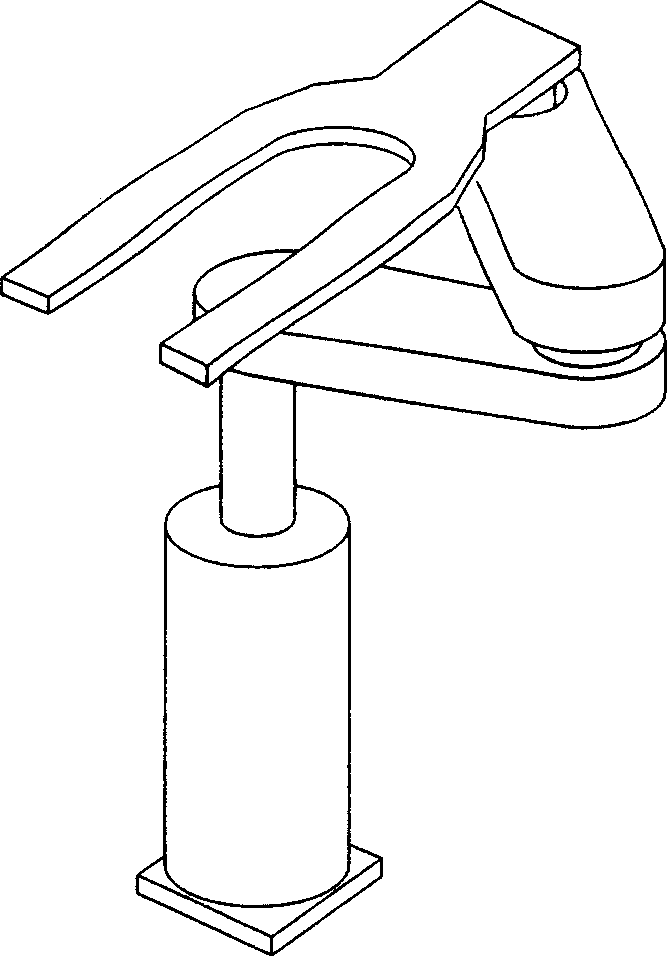

Carsette turning over and positioning device

InactiveCN1646001AHigh precisionAvoid FragmentsSupport structure mountingElectrical componentsEngineeringMechanical engineering

The invention is used in rotating a cartridge, and then fixing it. It consists of: a rotating unit located at one side of the cartridge used in rotating the cartridge; a base; movable locating unit containing a locating unit and a rolling component located at one side of rotated cartridge, and the locating component and rolling component are fixed on the base; the rolling component is pops out from the place between locating component and cartridge, used in providing positioning in vertical direction for the rotated cartridge; the location component provides the positioning in horizontal direction for the rotated cartridge.

Owner:AU OPTRONICS CORP

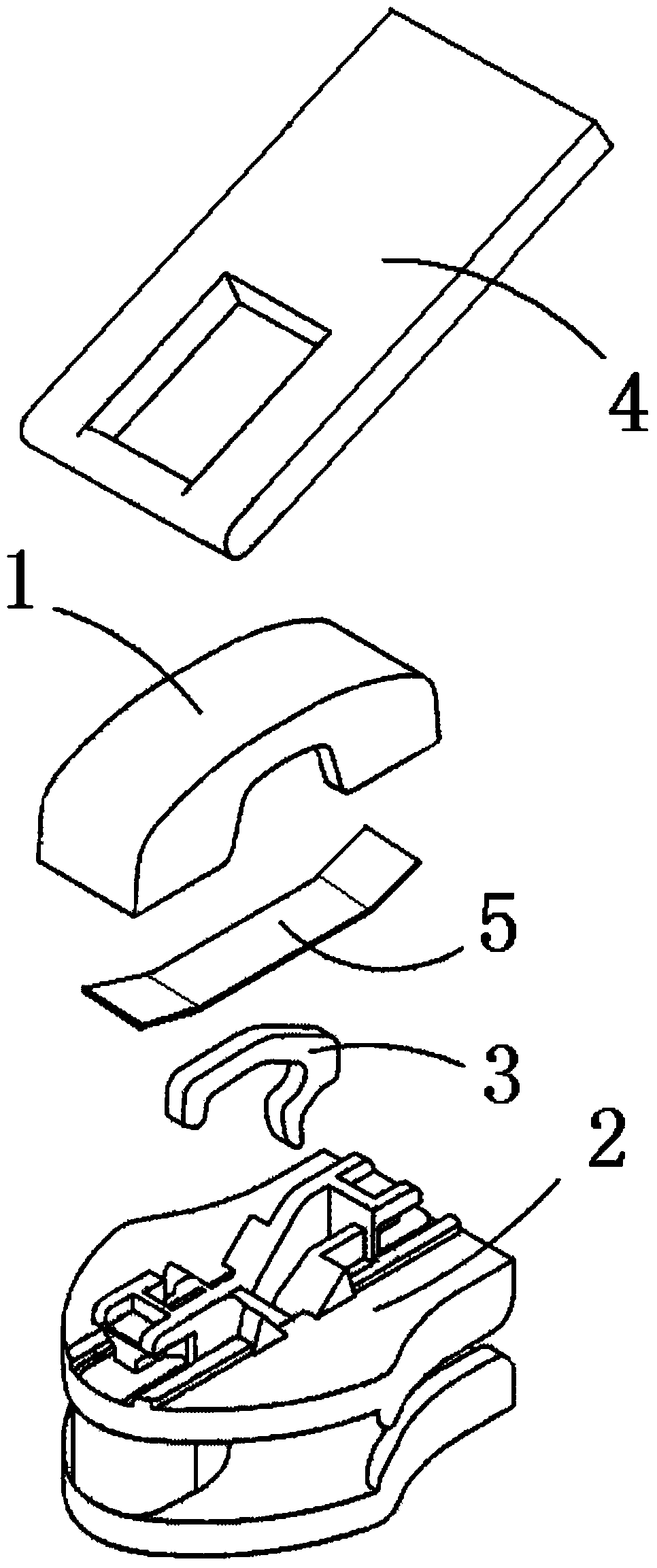

Self-locking zipper puller

The invention discloses a self-locking zipper puller. The zipper puller comprises a slider body, a cap, a shrapnel, a hook and a pulling piece; the cap is buckled on the slider body; the shrapnel is arranged at the top part of the cap through a limiting device; the upper surface of an upper flange of the slider body is provided with a locating device and a cap buckling base of the hook; one end of the hook is located on the locating device; the hook, the shrapnel and the cap penetrate through a rectangular opening of the pulling piece; the lower surface of the shrapnel leans against the upper edge of the hook; the shape of the shrapnel is that the middle part is a flat plate and the two ends are tilted upwards in an obtuse angle. According to the self-locking zipper puller provided by the invention, the production process of the shrapnel and the cap is simple, the elasticity of the shrapnel is moderate, and the contact effect is good, so that the false lock and the insecure lock can be effectively avoided, and the technical effects of light in lifting the crotch and sensitive in making the crotch can be realized. The self-locking zipper puller is made of the conventional raw materials of the industry, and has the advantages of low cost and reliable locking.

Owner:施国荣

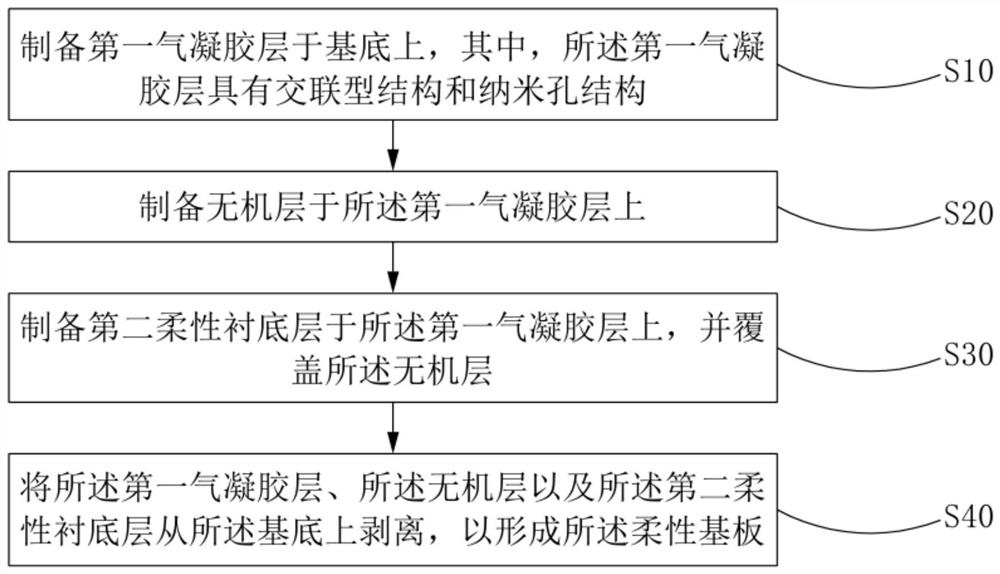

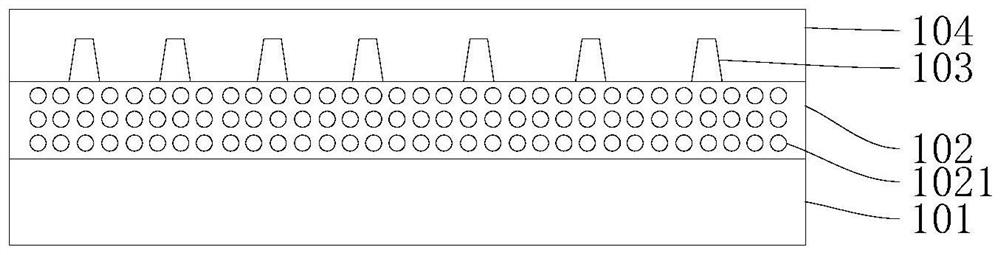

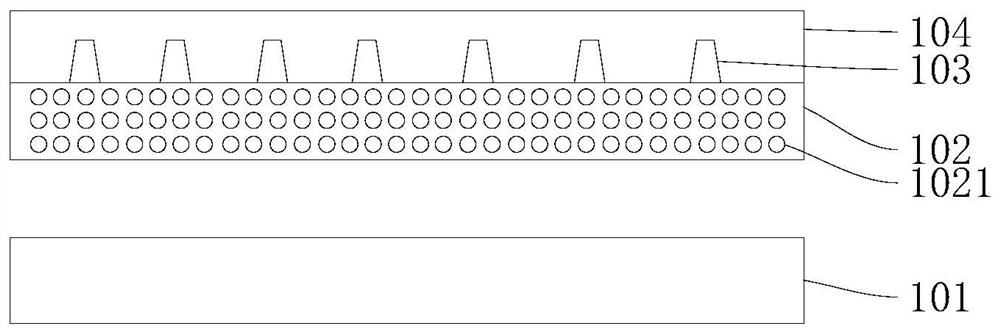

Flexible substrate, manufacturing method thereof and flexible display device

ActiveCN112071796AImprove bending performanceImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingNanoholeEngineering

The invention discloses a flexible substrate, a manufacturing method thereof and a flexible display device. The method comprises the following steps: S10, preparing a first aerogel layer on a substrate, wherein the first aerogel layer is provided with a cross-linked structure and a nanopore structure; S20, preparing an inorganic layer on the first aerogel layer; S30, preparing a second flexible substrate layer on the first aerogel layer, and covering the inorganic layer; and S40, stripping the first aerogel layer, the inorganic layer and the second flexible substrate layer from the base to form the flexible substrate. Compared with the prior art, the manufacturing method prevents the flexible substrate from being folded and broken in the stripping process, the product yield is improved, and the bending performance and stability of the flexible substrate are further improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

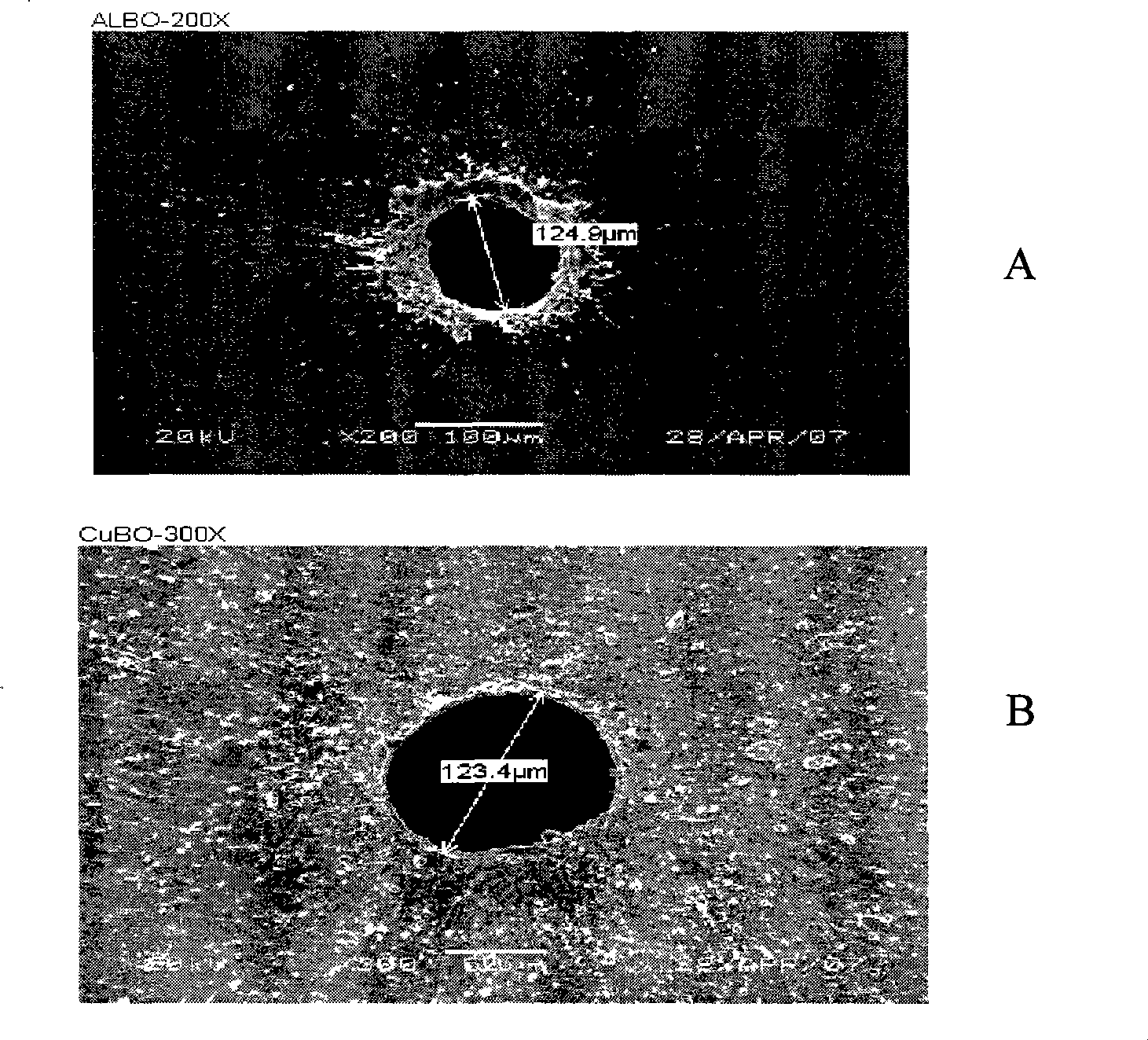

Corrosion method for germanium substrate sheet of solar battery

InactiveCN103233228AHigh strengthReduce breakage rateFinal product manufactureSemiconductor devicesHydrogen NitrateElectrical battery

The invention discloses a corrosion method for germanium substrate sheet of solar battery, comprising the following steps of: preparing No.1 corrosion liquid medicine by 1200-1300ml of pure water and 140-150ml of hydrofluoric acid with mass concentration of 48-50%, orderly placing the germanium sheet in a clamping plug, showering the clamping plug with the pure water and then dipping the clamping plug into the No.1 corrosion liquid medicine, shaking the clamping plug, after corroding the germanium sheet for 7-10 seconds, taking out the germanium sheet, quickly placing the germanium sheet into a pure water tank for washing, and showering the germanium sheet with the pure water; preparing a No.2 corrosion liquid medicine by 150-160ml of glacial acetic acid with mass concentration of not less than 99.7%, 3-5ml of bromine water with mass concentration of 99.5% and 250-260ml of hydrogen nitrate with mass concentration of 98%; dipping the clamping plug with the germanium sheet into the No.2 corrosion liquid medicine, shaking the clamping plug, taking out the germanium sheet after corroding for 20-30 seconds, placing the germanium sheet into the pure water tank for washing, showering the germanium sheet with the pure water, and finally, placing the clamping plug and the germanium sheet into a flowing water tank. By corrosion according to the method provided by the invention, the strength of the germanium sheet is enhanced, the strength is more than 18bf, and the breakage rate of the germanium sheet is greatly reduced.

Owner:中锗科技有限公司

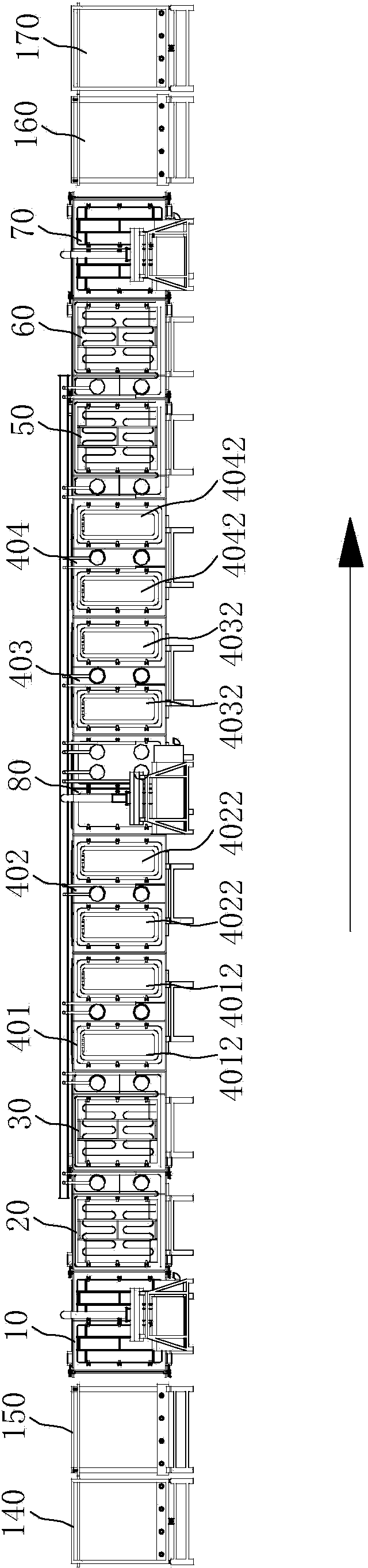

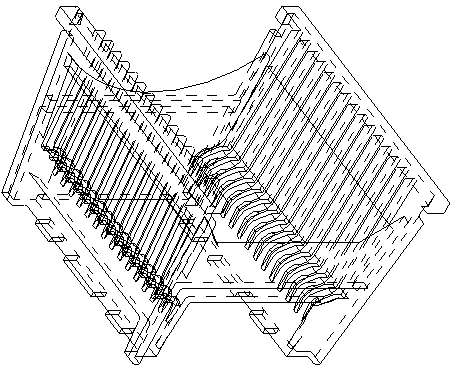

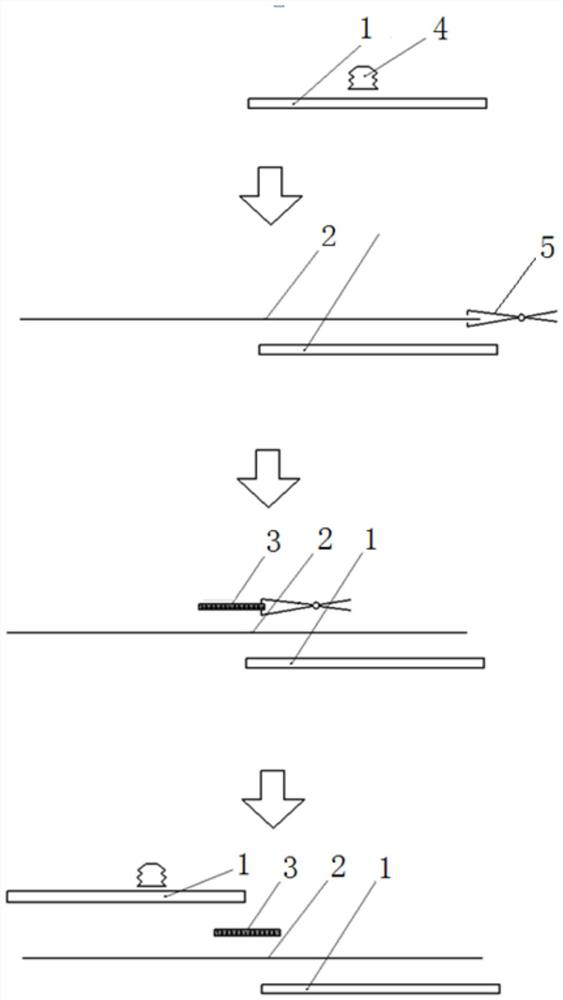

Battery string production method

ActiveCN112038434AAvoid crackingAvoid FragmentsFinal product manufactureSemiconductor devicesElectrical batteryMechanical engineering

The invention discloses a battery string production method which comprises the following steps of stacking and fixing a plurality of solder strip groups and a plurality of battery pieces together, andarranging flexible pieces between the end parts, stacked on the solder strip groups, of the battery pieces and the solder strip groups; stacking the solder strip groups, the battery pieces and the flexible pieces together according to a preset stacking mode, and then welding and fixing the stacked solder strip groups, battery pieces and flexible pieces together; or, stacking and welding the solder strip group and the battery piece together, inserting the flexible pieces between the end parts of the battery pieces and the solder strip groups, and heating and welding the flexible pieces; or, fixing the flexible pieces on the solder strip groups, and then stacking and welding the solder strip groups fixed with the flexible pieces and the battery pieces. According to the technical scheme provided by the invention, the problems of subfissure and breakage of the battery pieces in the battery string production process can be effectively prevented.

Owner:WUXI AUTOWELL TECH

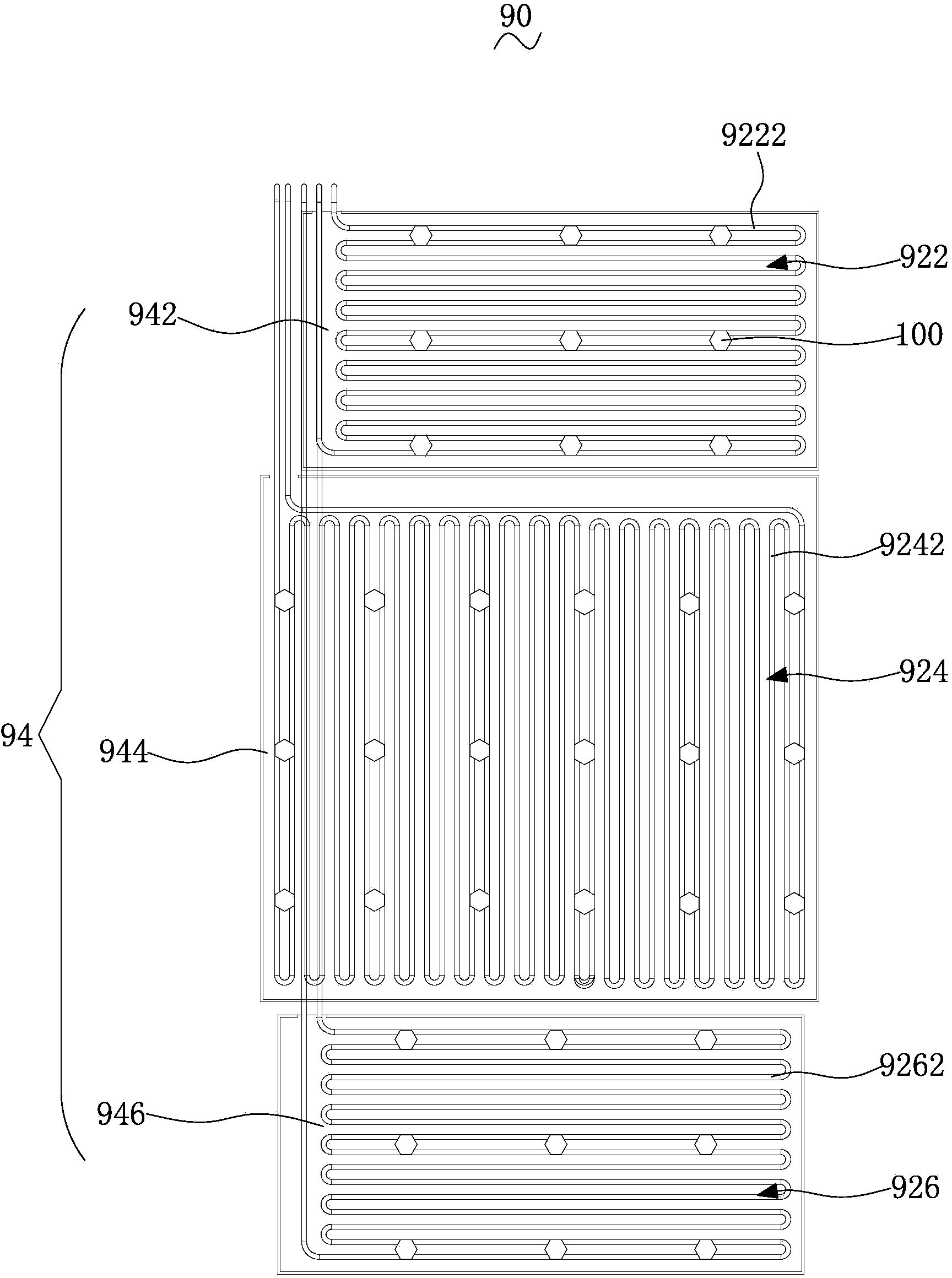

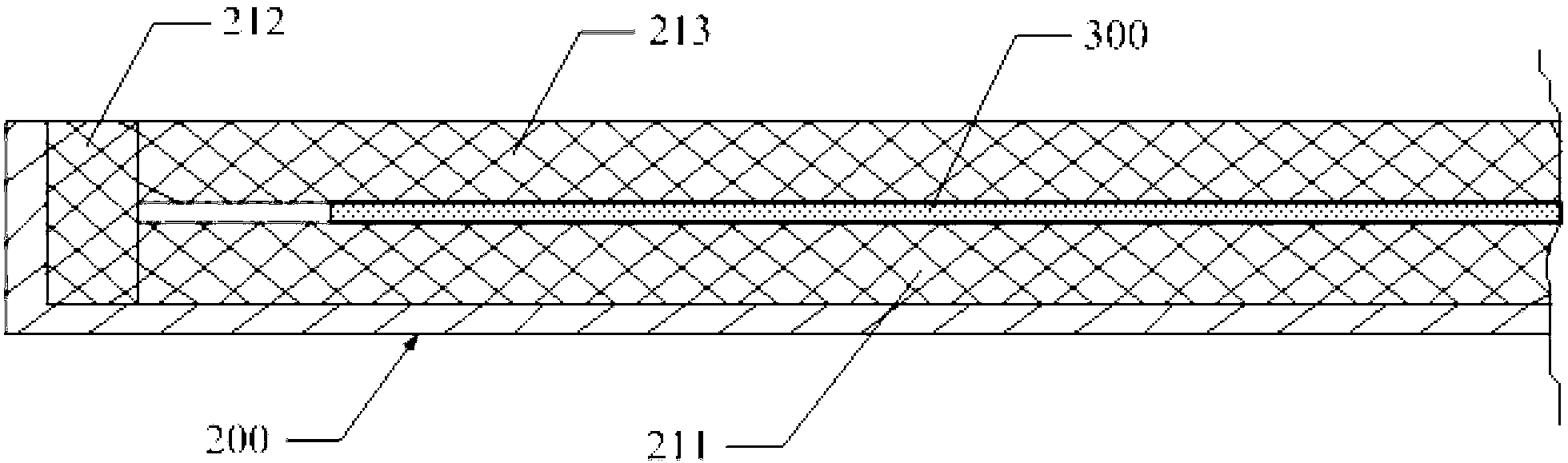

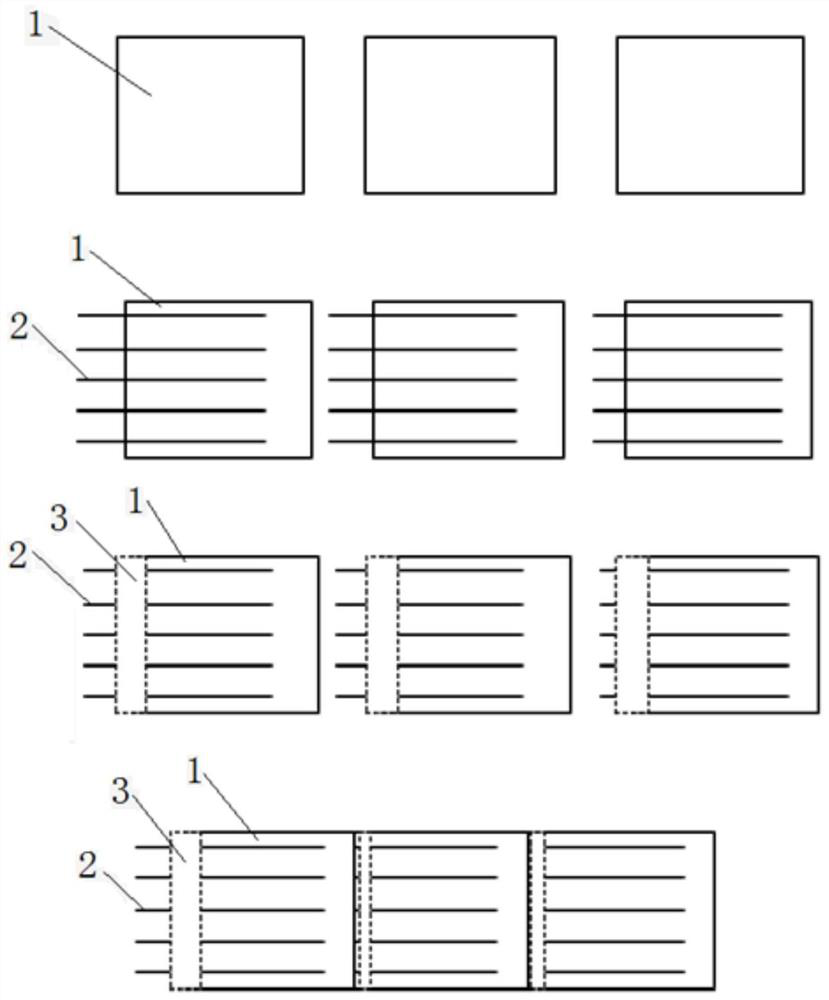

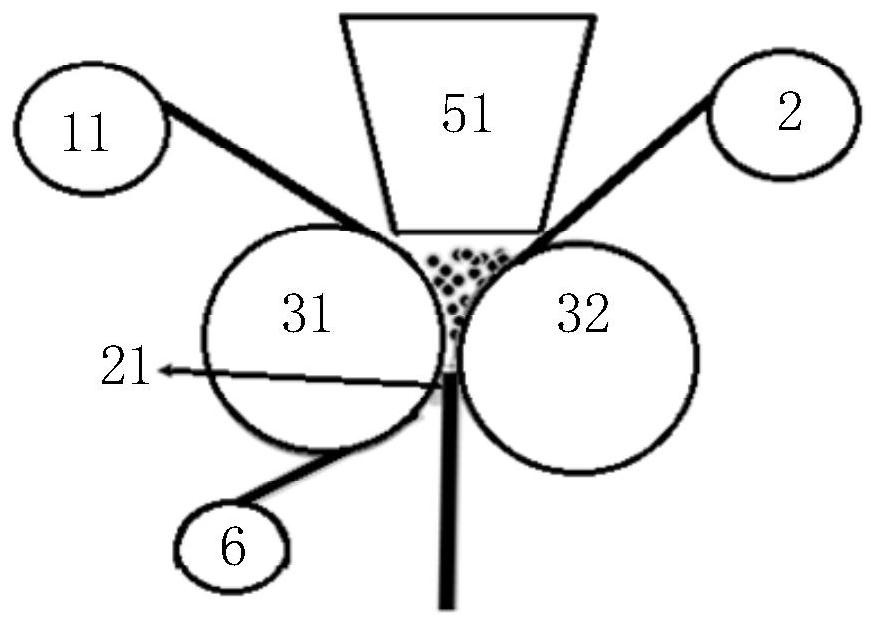

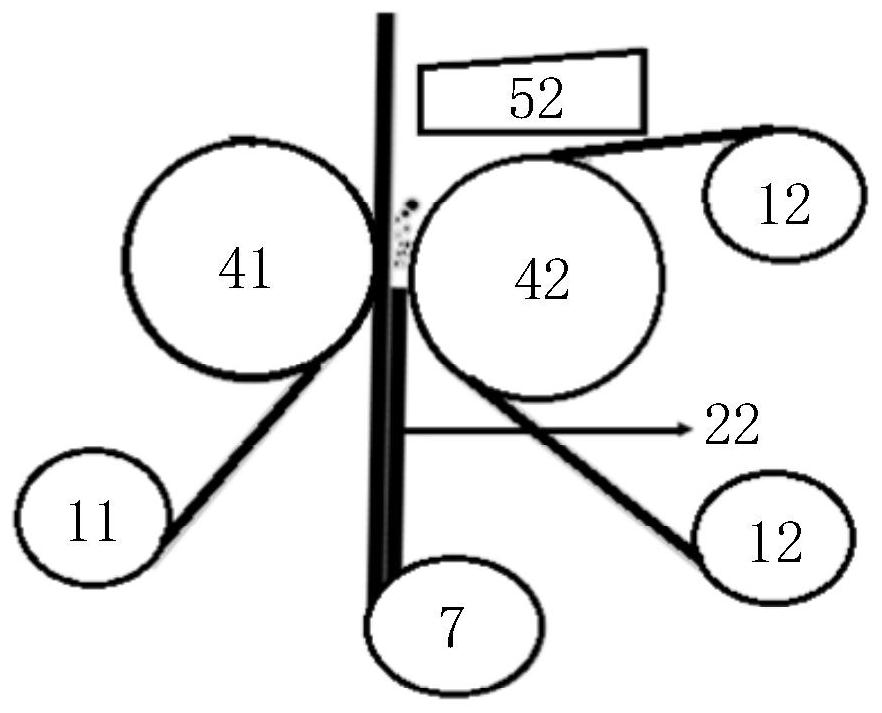

Method for preparing electrode plate by dry rolling

ActiveCN112802987AAvoid uniformityAvoid fragmentsElectrode rolling/calenderingProcess equipmentComposite material

The invention relates to the technical field of lithium ions, and discloses a method for preparing an electrode plate through dry rolling. The method comprises the following steps: (1) enabling a first membrane material and a foil material to simultaneously pass through a space between opposite first rollers, adding first powder into a gap between the first membrane material and the foil material, carrying out first rolling, and forming a first powder material tabletting layer on one side surface of the foil material; (2) enabling the first membrane material, the second membrane material and the foil material with the first powder tabletting layer to simultaneously pass through opposite second rollers, adding second powder into a gap between the second membrane material and the other side surface of the foil material, carrying out second rolling, and forming a second powder tabletting layer on the other side surface of the foil material; and 3) separating the first membrane material and the second membrane material from the side surface of the foil material to obtain the electrode plate. According to the method, double-sided simultaneous rolling and laminating flaking can be realized, the process flow is simplified, the process equipment is reduced, and the electrode plate with uniform thickness can be continuously prepared.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

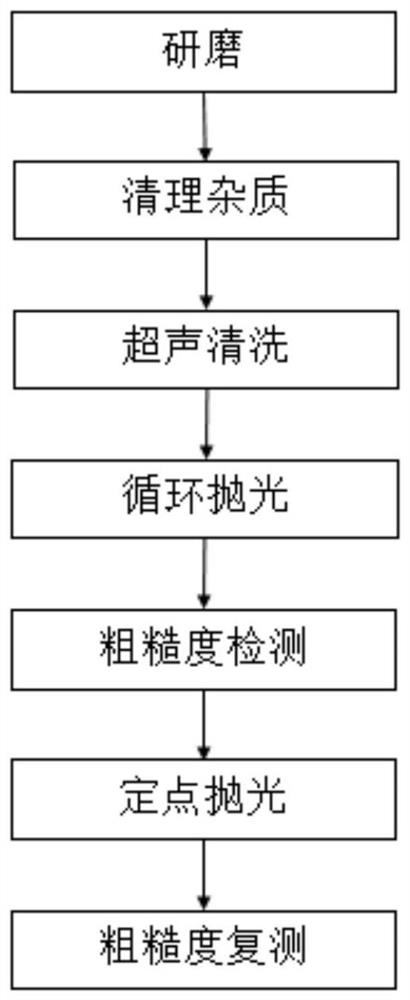

Microcrystalline glass polishing process

The invention relates to a microcrystalline glass polishing process. The process comprises the following steps: step 1, grinding and thinning the surface of microcrystalline glass to remove cutting line marks on the surface of the microcrystalline glass; step 2, carrying out impurity removal on the ground microcrystalline glass; step 3, carrying out ultrasonic cleaning on the microcrystalline glass subjected to impurity removal; step 4, polishing the microcrystalline glass subjected to ultrasonic cleaning; step 5, detecting roughness of the polished microcrystalline glass, and carrying out fixed-point polishing according to the roughness difference; and step 6, detecting the roughness of the microcrystalline glass subjected to fixed-point polishing again, if the microcrystalline glass is unqualified, executing the step 5 to carry out fixed-point polishing again, and if the microcrystalline glass is qualified, obtaining the polished microcrystalline glass. The glass can be ground in a targeted manner by combining a polishing process, so that in the produced microcrystalline glass, the roughness is reduced, the flatness is improved, the original production time is shortened, the production cost is reduced, and the production benefits of manufacturers are improved.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

Baseboard steering mechanism, baseboard transmitting device and wet equipment

The invention provides a baseboard steering mechanism, a baseboard transmitting device and wet equipment. The baseboard steering mechanism comprises a adjustment-side guide wheel and a fixing-side guide wheel which are oppositely arranged on two sides of a transmitting baseboard, and each of the adjustment-side guide wheel and the fixing-side guide wheel comprises a first roller capable of movingin position and a second roller with fixed position. The adjustment-side guide wheel serving as an adjusting part is used for correcting position offset of the baseboard in motion and cannot lead to fragment of the baseboard, the fixing-side guide wheel serving as a fixing part is used for controlling the position offset of the baseboard in motion, and abnormal occurrence of the existing wet equipment in fragment of the baseboard, equipment downtime and the like due to different in position setting of the guide wheels can be avoided.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

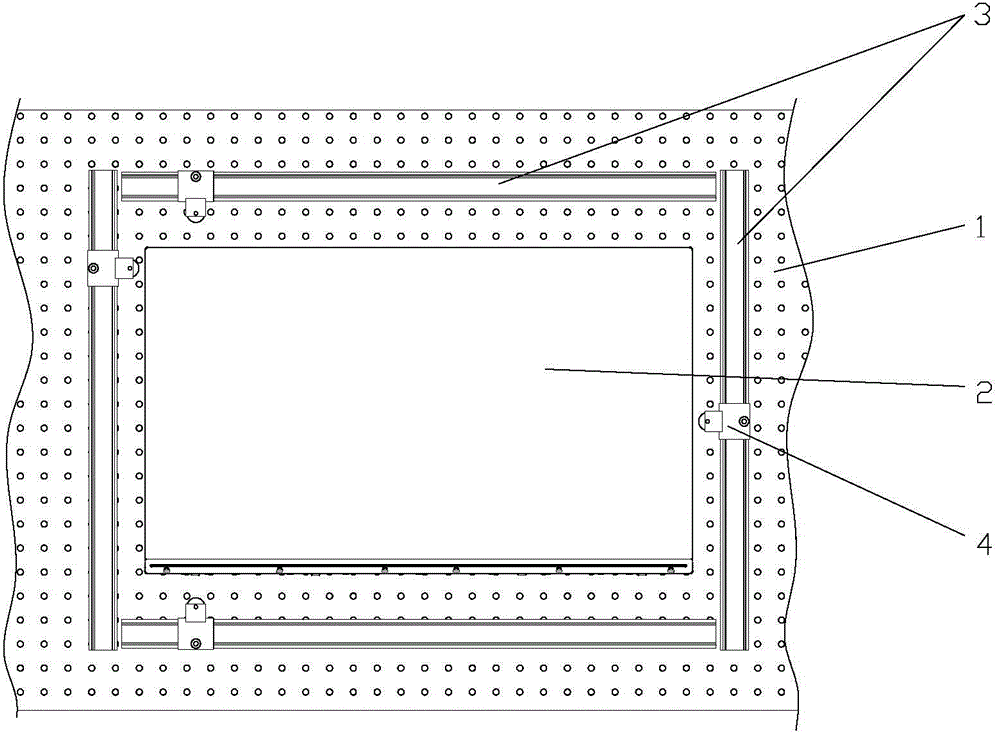

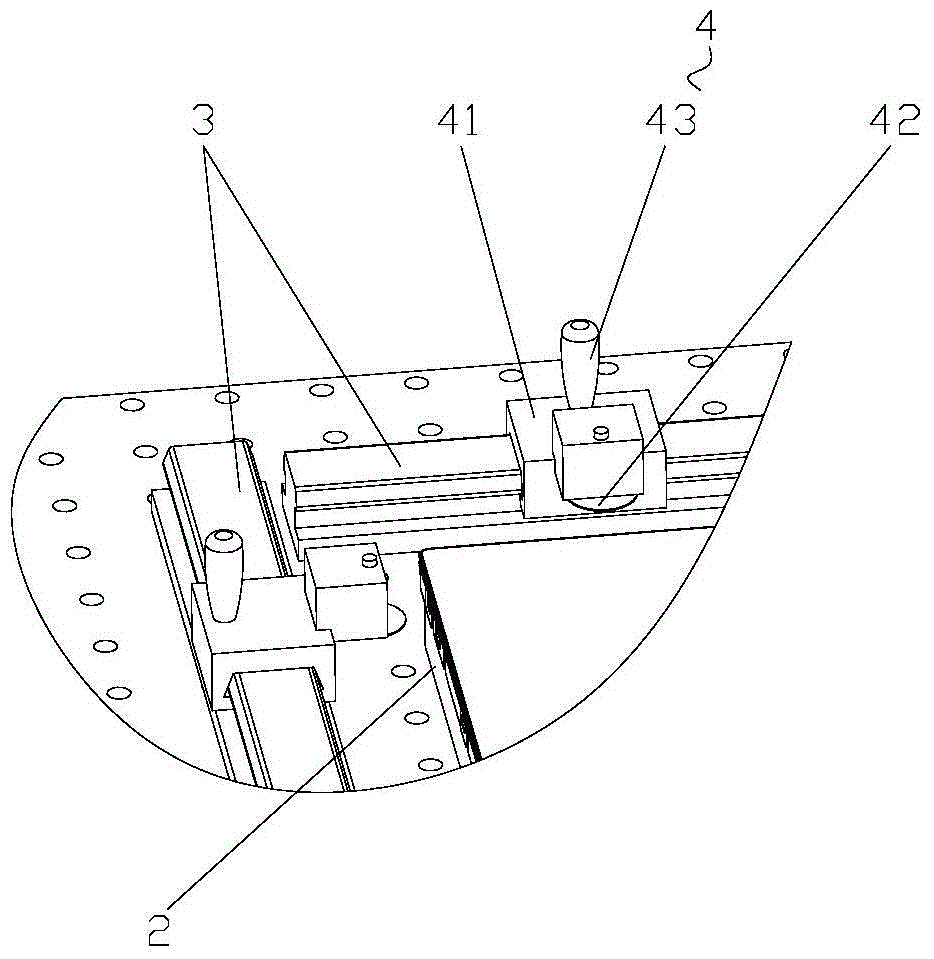

Tool for cutting double-sided adhesive tape between liquid crystal display panel and glue frame

InactiveCN104526725AGuaranteed flatnessAvoid FragmentsMetal working apparatusLiquid-crystal displayLiquid crystal

The invention discloses a tool for cutting a double-sided adhesive tape between a liquid crystal display panel and a glue frame. The tool comprises a baseplate and a glue frame positioning plate, wherein the glue frame positioning plate is fixed on the baseplate; the glue frame bonded with the liquid crystal display panel is coated and positioned on the glue frame positioning plate; slide rails are respectively arranged on the baseplate corresponding to four side edges of the glue frame positioning plate; cutting knives are respectively arranged on the slide rails; blades of the cutting knives face to the glue frame positioning plate; and when the cutting knives slide along with the slide rails, the blades of the cutting knives cut off the double-sided adhesive tape between the liquid crystal display panel and the glue frame. The tool uses the cutting knives for cutting off the double-sided adhesive tape between the liquid crystal display panel and the glue frame, and guarantees the cutting smoothness in quick cutting to prevent the liquid crystal display panel from being broken.

Owner:L&T DISPLAY TECH FUJIAN

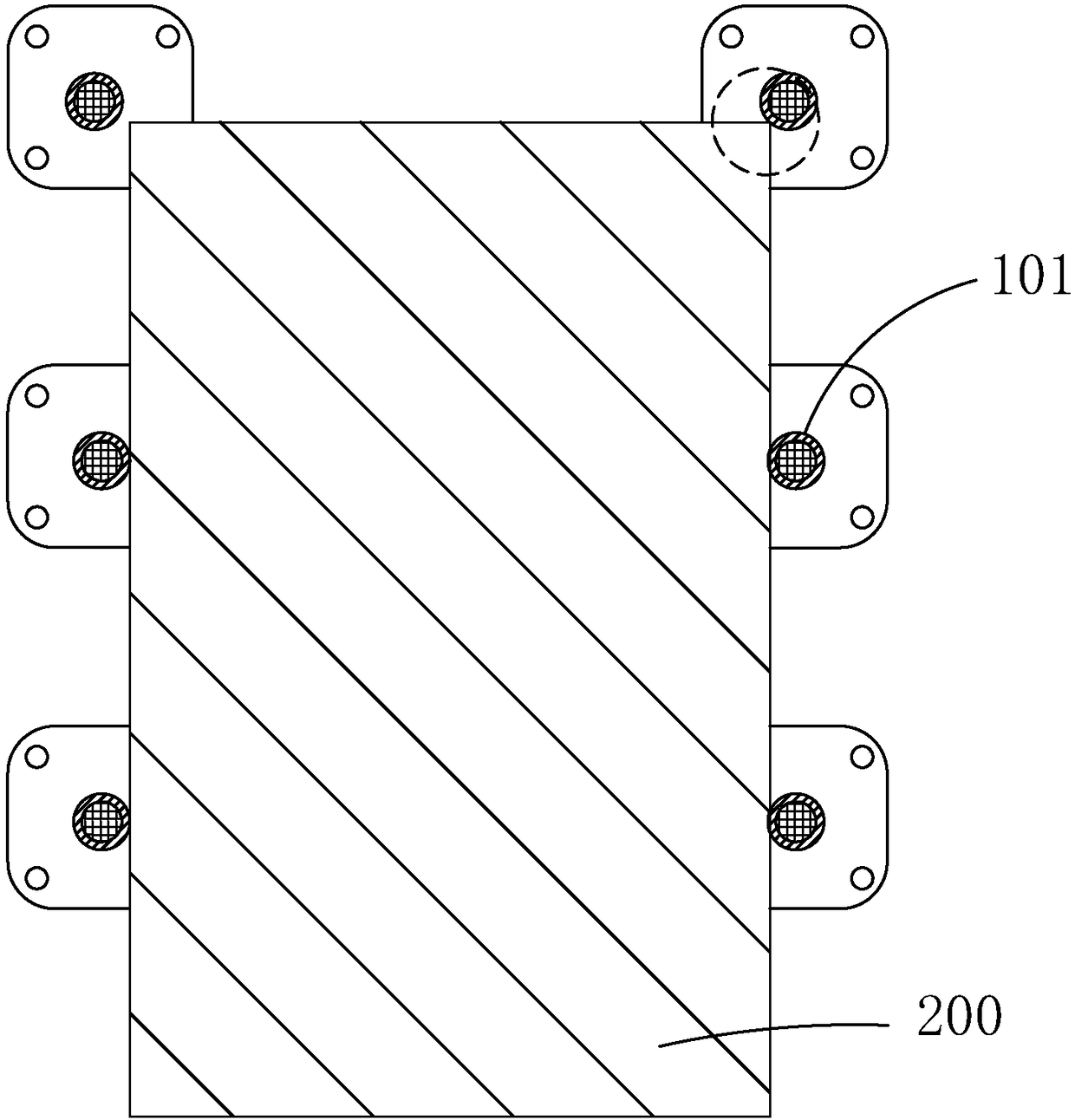

Packaging box

ActiveCN107572095AImprove reliabilityReduce impact forceRigid containersExternal fittingsLiquid-crystal displayEngineering

The invention provides a packaging box which comprises a base and a plurality of box bodies, wherein the box bodies can be piled on one another; accommodating cavities used for the loading of a liquidcrystal display are formed in the box bodies; each box body is provided with an opening, and the opening communicates with the corresponding accommodating cavity; a circle of a first bump is arrangedon the edge of each opening; a first groove is formed in the bottom of each box body; the section of the base is wedge-shaped, and then an inclined surface is formed on the surface of the upper end of the base; a second bump is arranged on the inclined surface; and when being sequentially piled on the base, the box bodies are all arranged in an inclined manner. Compared with the prior art, the packaging box has the advantages that through the arrangement of a layer of the wedge-shaped base at the bottom end of the piled box bodies, the box bodies are all arranged in an inclined manner after being piled on one another, so that the impact force between the side, positioned at a COF circuit board, of the liquid crystal display and the box bodies can be reduced during transportation, the problem that the liquid crystal display is broken can be avoided, and the reliability of box bodies can be improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

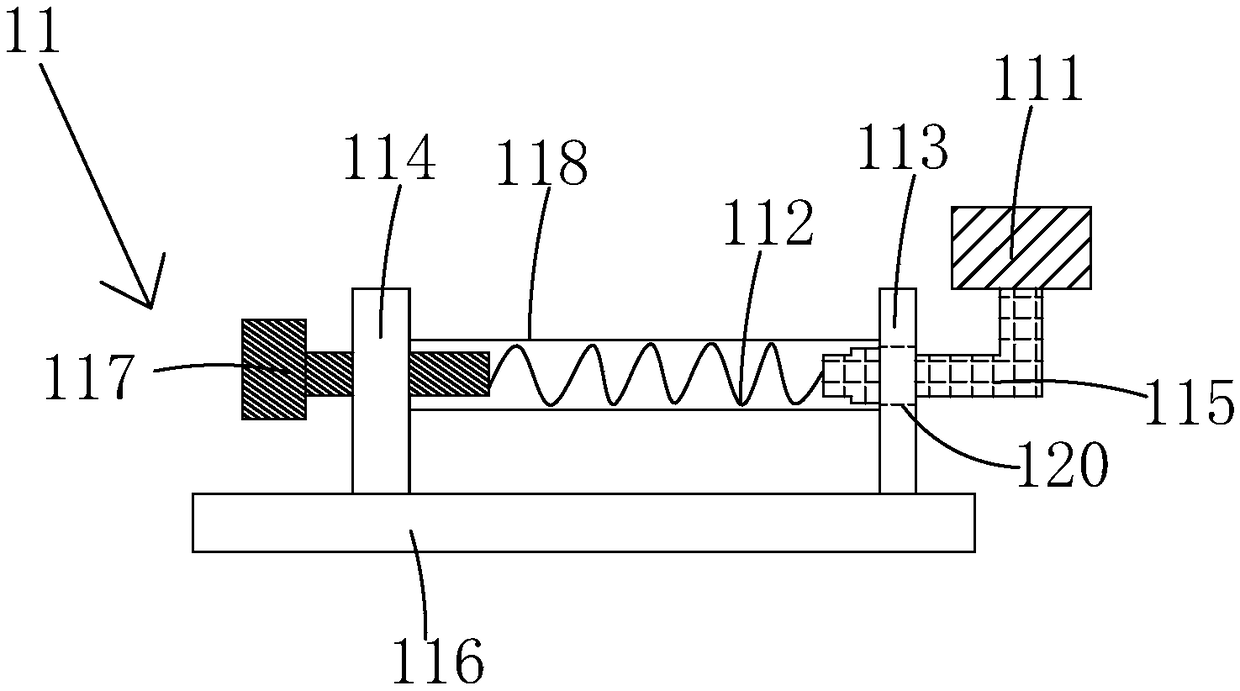

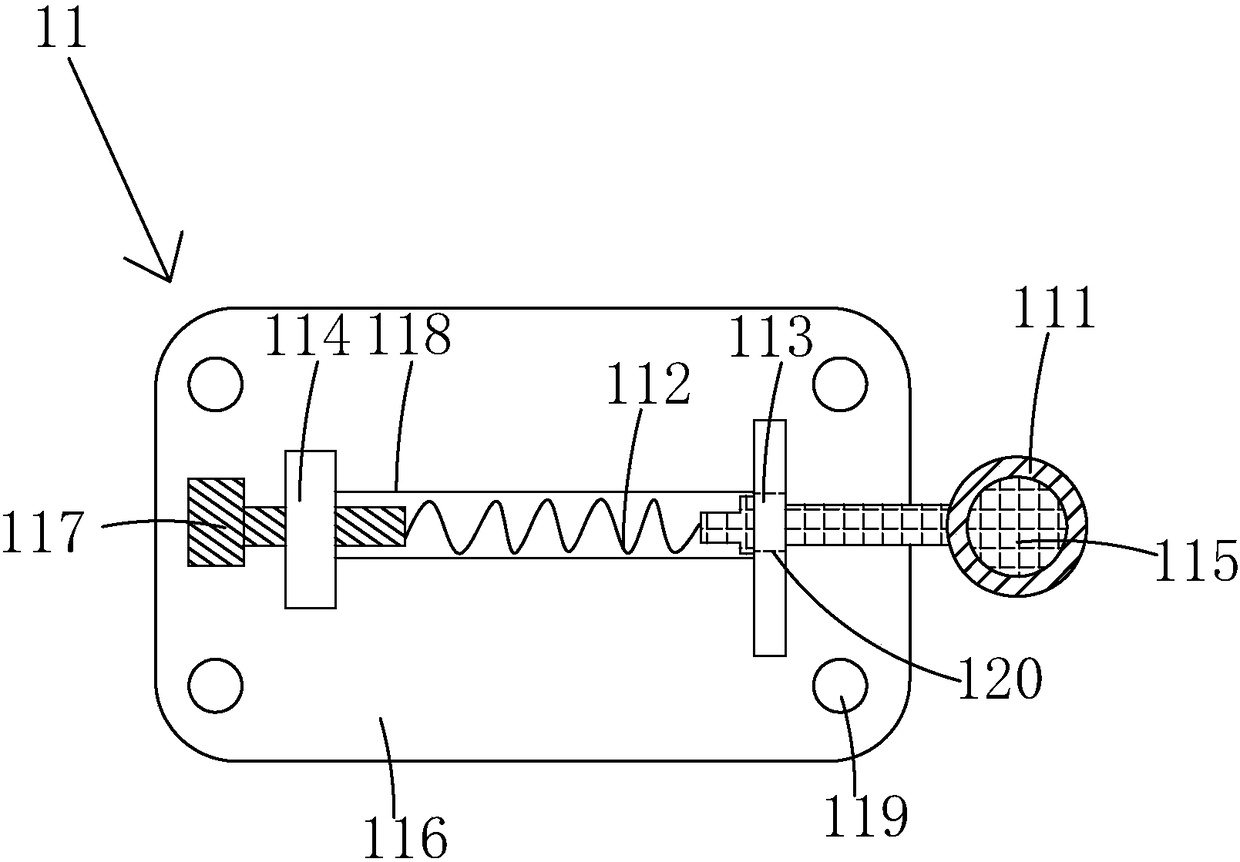

Packaging box structure and glass substrate encapsulating method

The invention relates to a packaging box structure which comprises a box body, a box cover and a lock assembly, wherein the box body comprises a first box body part and a second box body part which are arranged oppositely, the first box body part and the second box body part are spliced to form the box body, the lock assembly used for locking and fixing the first box body part and the second box body part is arranged between the first box body part and the second box body part, the locking assembly is detachably connected with the first box body part and the second box body part, the box cover is buckled on the opening of the box body, the locking assembly used for locking and fixing the box body and the box cover is arranged between the box body and the box cover, and the locking assembly is detachably connected with the box body and the box cover. The packaging box structure disclosed by the invention can prevent fragments of a glass substrate, is convenient to take the glass substrate, can improve the working efficiency and is convenient for counting the quantity of the glass substrate. The invention further relates to a glass substrate encapsulating method.

Owner:KUSN INFOVISION OPTOELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com