Base plate transfer device

A conveying device and substrate technology, applied in glass manufacturing equipment, glass transportation equipment, manufacturing tools, etc., can solve problems such as limited effect, delayed production, and inability to detect edge defects of glass substrates, saving space and avoiding pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

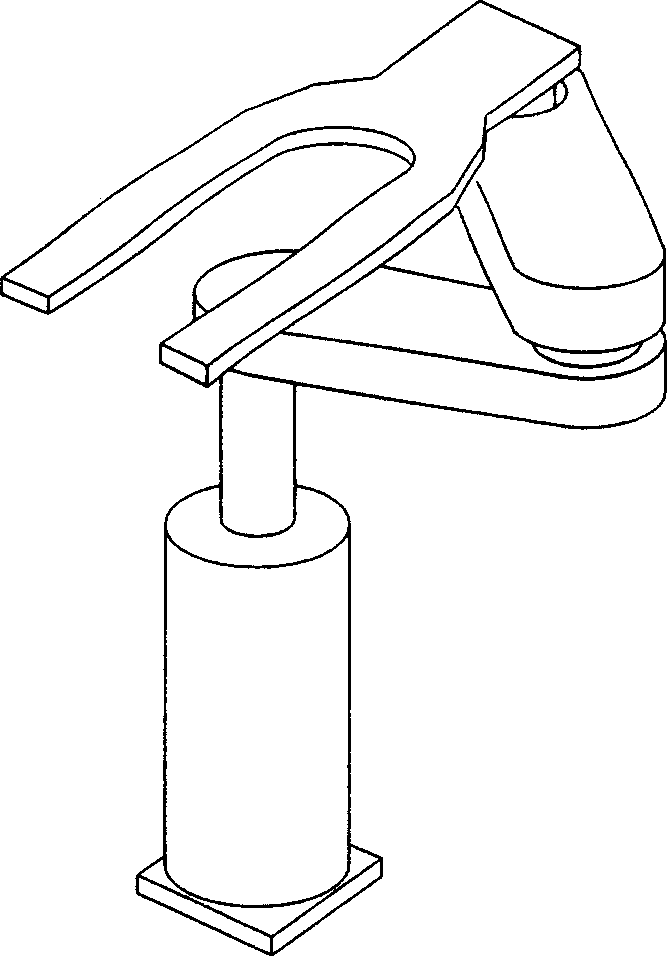

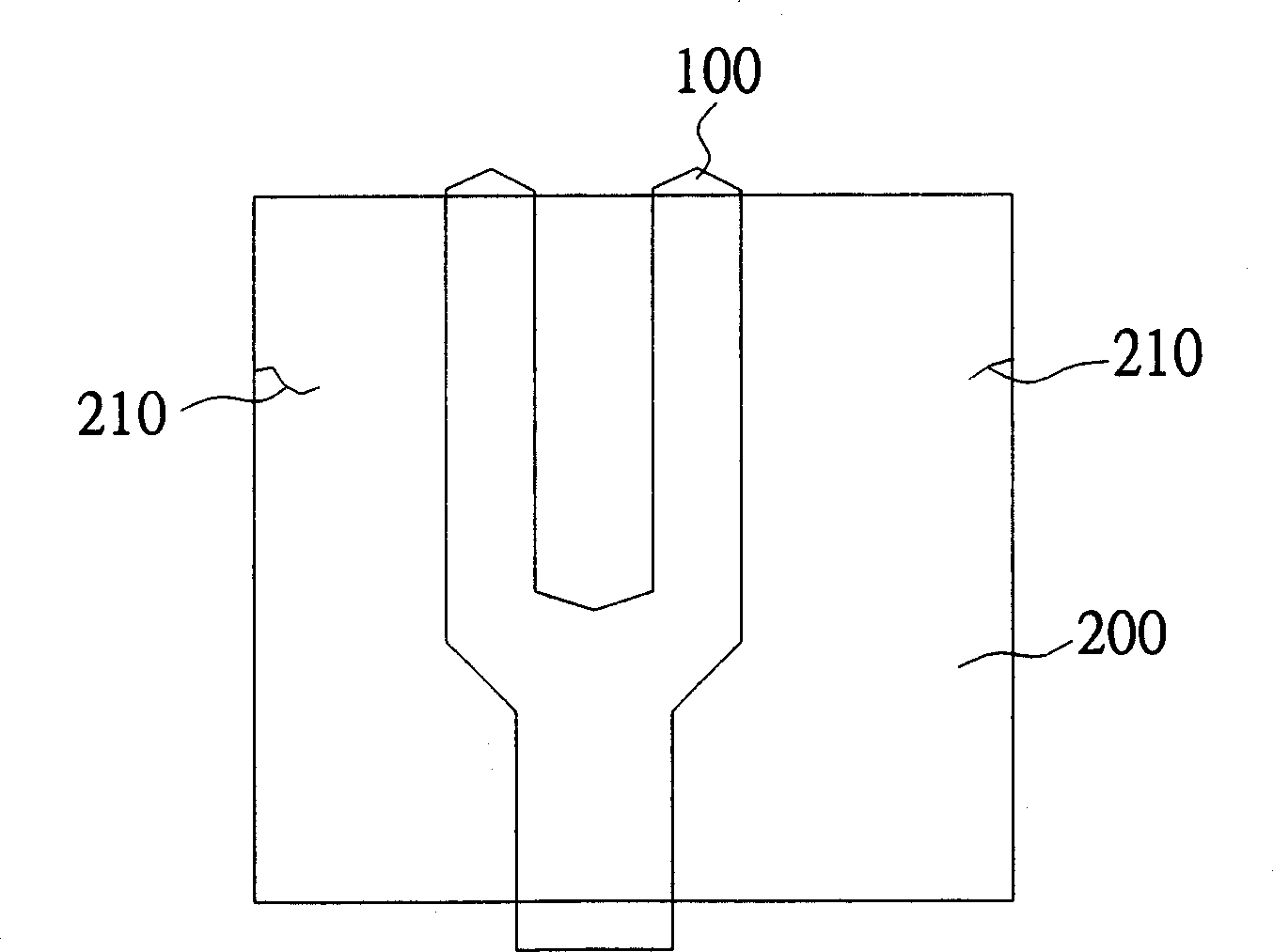

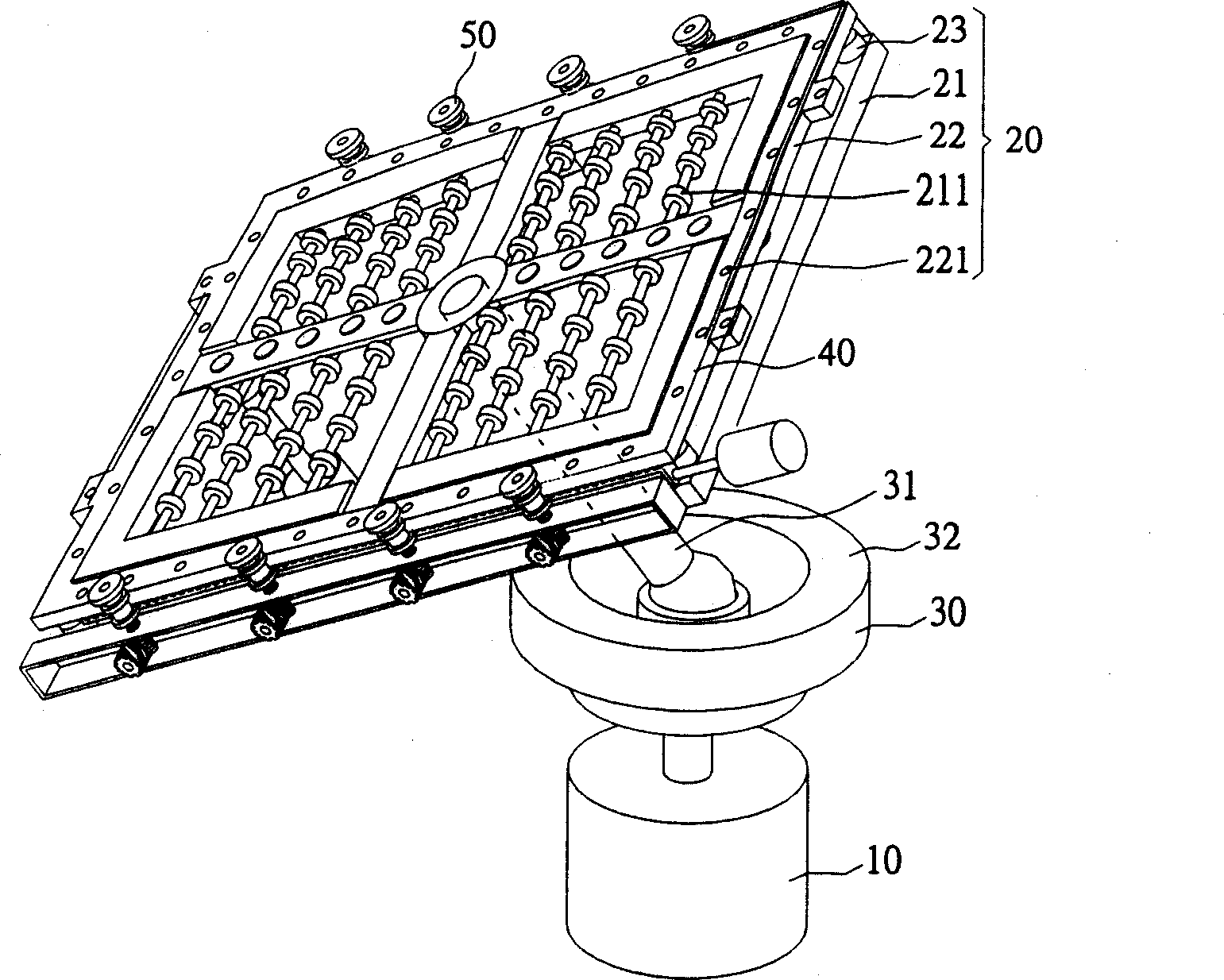

[0031] Please refer to figure 2 , figure 2 It is an assembled perspective view of a preferred embodiment of the substrate transfer device of the present invention. The substrate transfer device of the present invention includes a base 10 , a substrate carrying unit 20 and a rotating shaft unit 30 . In this preferred embodiment, the base 10 can be a movable base, so that the substrate transfer device of the present invention can be moved to a desired position arbitrarily, or further used to transfer the substrate. The rotating shaft unit 30 has a supporting shaft 31 and a rotating shaft seat 32 . The lower end of the supporting shaft 31 is pivotally connected to the rotating shaft seat 32 to support and adjust the inclination direction and angle of the substrate carrying unit 20 . The rotating shaft seat 32 is fixed on the base 10 for supporting and controlling the rotation of the supporting shaft 31 to indirectly control the inclination direction and angle of the substrate...

Embodiment 2

[0034] Please refer to FIG. 4 . FIG. 4 is an exploded perspective view of a substrate carrying unit according to another preferred embodiment of the present invention. The structure of this preferred embodiment is roughly the same as that of Embodiment 1. The substrate carrying unit 60 includes a carrying base 61 connected to the support shaft 31, several supporting elements 611 located on the surface of the carrying base 61, and a carrying top seat located on the upper side of the supporting element 611. 62. At least one telescopic element 63 sandwiched between the bearing top seat 62 and the bearing base 61, and several positioning elements 64, the difference is that the supporting element 611 of this preferred embodiment is a leg (pin), which The stretchable element 63 can be adjusted to pass through the carrying top seat 62 to support the substrate. Similarly, several vacuum suction nozzles 621 are provided on the surface of the carrier top 62 for absorbing and detecting t...

Embodiment 3

[0037] Please refer to FIG. 5 . FIG. 5 is an exploded perspective view of a substrate carrying unit according to another preferred embodiment of the present invention. The structure of this preferred embodiment is roughly the same as that of Embodiment 2. The substrate carrying unit 70 includes a carrying base 71 connected to the support shaft 31, a carrying top seat 72 located on the upper side of the carrying base 71, and several supporting elements located on the surface of the carrying base 71. 711, at least one floating support element 721 installed inside the bearing top seat 72 in a floating manner, at least one telescopic element 73 sandwiched between the bearing top seat 72 and the bearing base 71, and several positioning elements 74, and The difference is that the supporting element 711 of this preferred embodiment is a protruding rod, which can be moved up and down by the adjustment of the telescopic element 73 to push the floating supporting element 721, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com