Carsette turning over and positioning device

A positioning device and cassette technology, applied in the direction of support structure installation, electrical components, electrical components, etc., can solve the problems of fragments, cassette positioning errors, long time, etc., to prevent a large number of fragments, reduce production costs, and increase output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

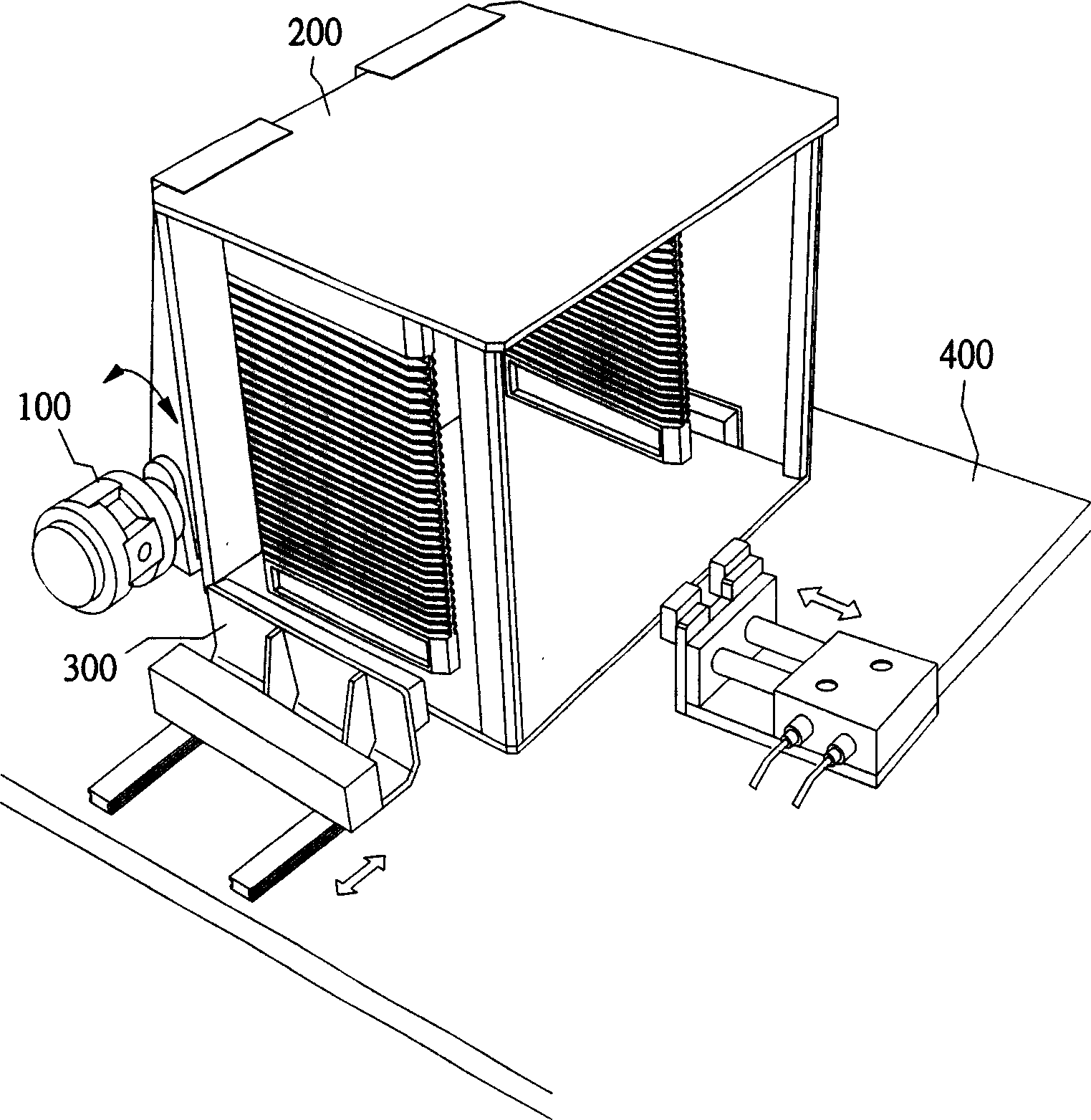

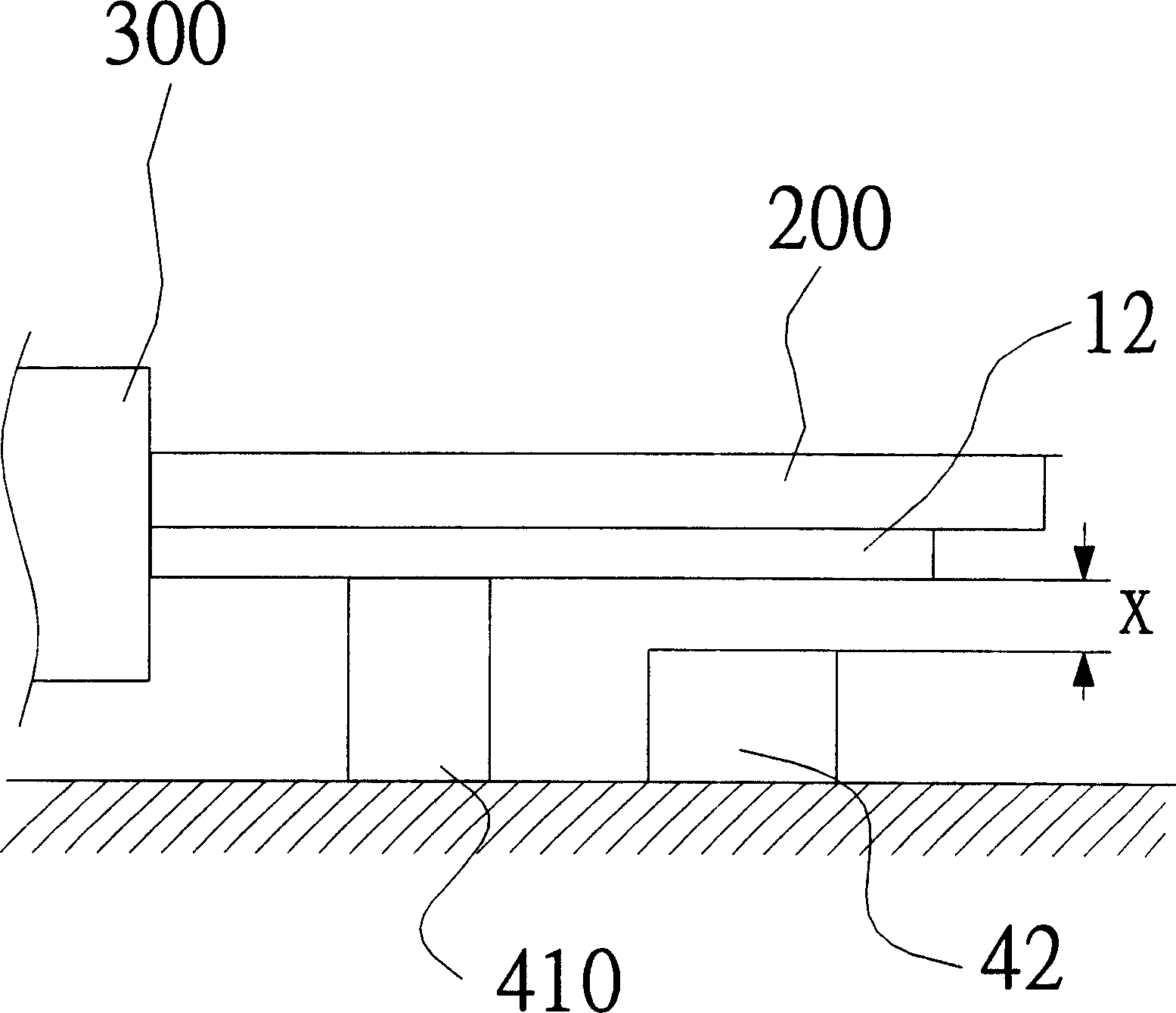

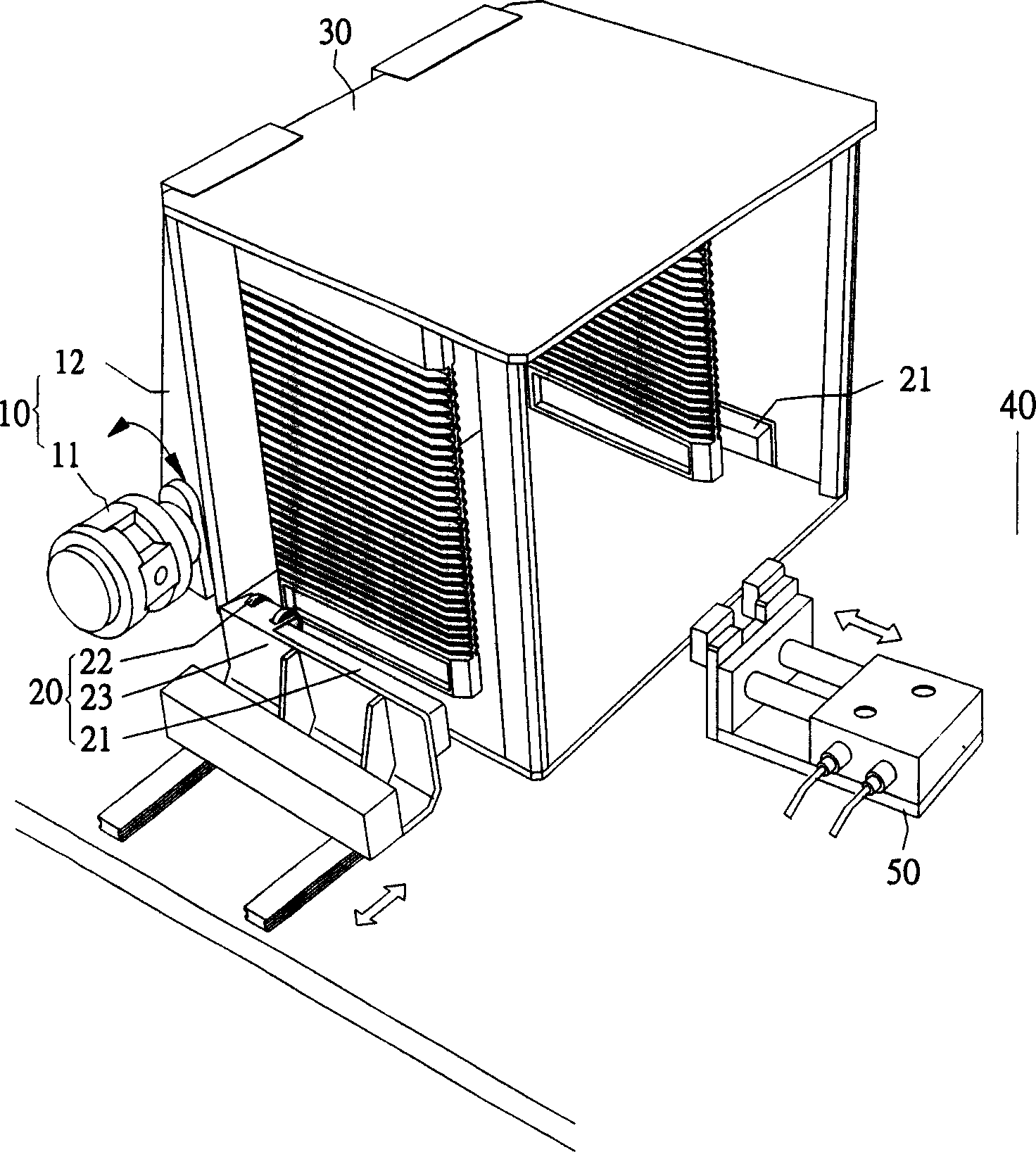

[0028] Please refer to image 3 , image 3 It is a perspective view of a cassette flipping positioning device according to a preferred embodiment of the present invention. The cassette flipping and positioning device of the present invention includes a flipping unit 10 and a mobile positioning unit 20 . In this preferred embodiment, the turning unit 10 is located on the bottom side of the cassette to be turned over. The turning unit 10 is composed of a coupling 11 driven by a servo motor and an L-shaped support base 12. The coupling 11 can drive and support The base 12 makes the surface of the supporting base 12 that was originally parallel to the reference platform 40 become perpendicular to the reference platform 40 , and the surface that was originally perpendicular to the reference platform 40 is turned to be parallel to the reference platform 40 . The support base 12 can clamp the cassette, preventing the cassette 30 from falling when turning over. The mobile positioni...

Embodiment 2

[0030]The structure and actuation method of this embodiment are roughly the same as those in Embodiment 1. It includes an overturn unit and a mobile positioning unit. The overturn unit is located on the bottom side of the cassette to be overturned. The supporting base is composed of the supporting base, and the coupling can drive the supporting base, so that the surface of the supporting base originally parallel to the reference platform becomes perpendicular to the reference platform, and the surface originally perpendicular to the reference platform becomes parallel to the reference platform. Supports the base and holds the cassette to prevent the cassette from falling during flipping. The mobile positioning unit is located on both sides of the reversed cassette, and has a base 61, a positioning element 64 and a rolling element 62, wherein the rolling element 62 and the positioning element 64 are fixed on the base 61, and the rolling element 62 protrudes from the Between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com