Lithium battery current collecting body, high capacity cylindrical lithium ionic cell and preparation

A lithium-ion battery and current collector technology, applied in the field of high-capacity cylindrical lithium-ion batteries, can solve the problems of difficult automation, difficult process control, hidden dangers of battery cell safety, etc., to facilitate high-efficiency production, avoid explosive reactions, The effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Cell size: shell diameter 50mm, total height 420mm, pole group height 363mm, nominal capacity: 50Ah.

[0046] The positive active material is LiFe coated with 5% carbon 0.99 Nb 0.01 PO 4 , 4 parts of PVDF (grade: Solvay 7200) are used as the adhesive, and 3 parts of carbon black are used as the conductive agent.

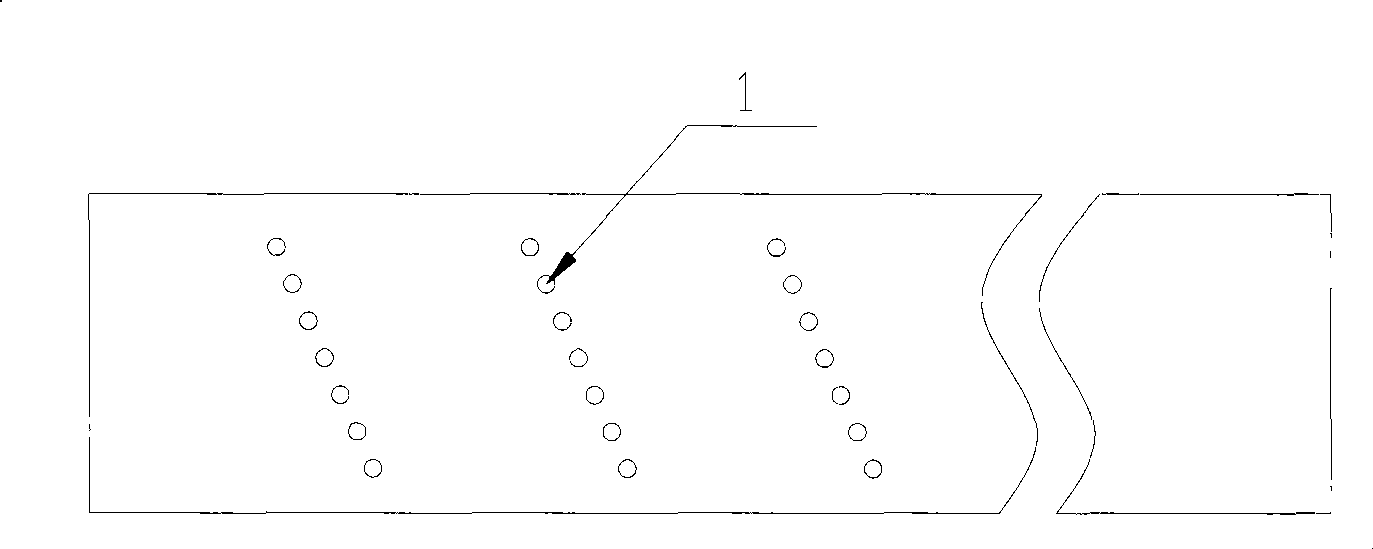

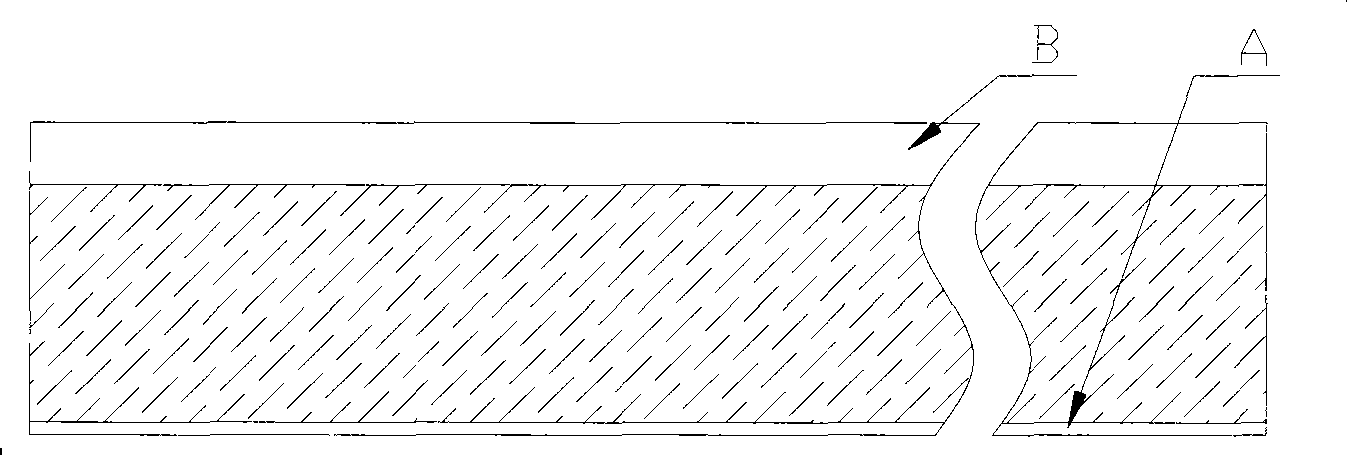

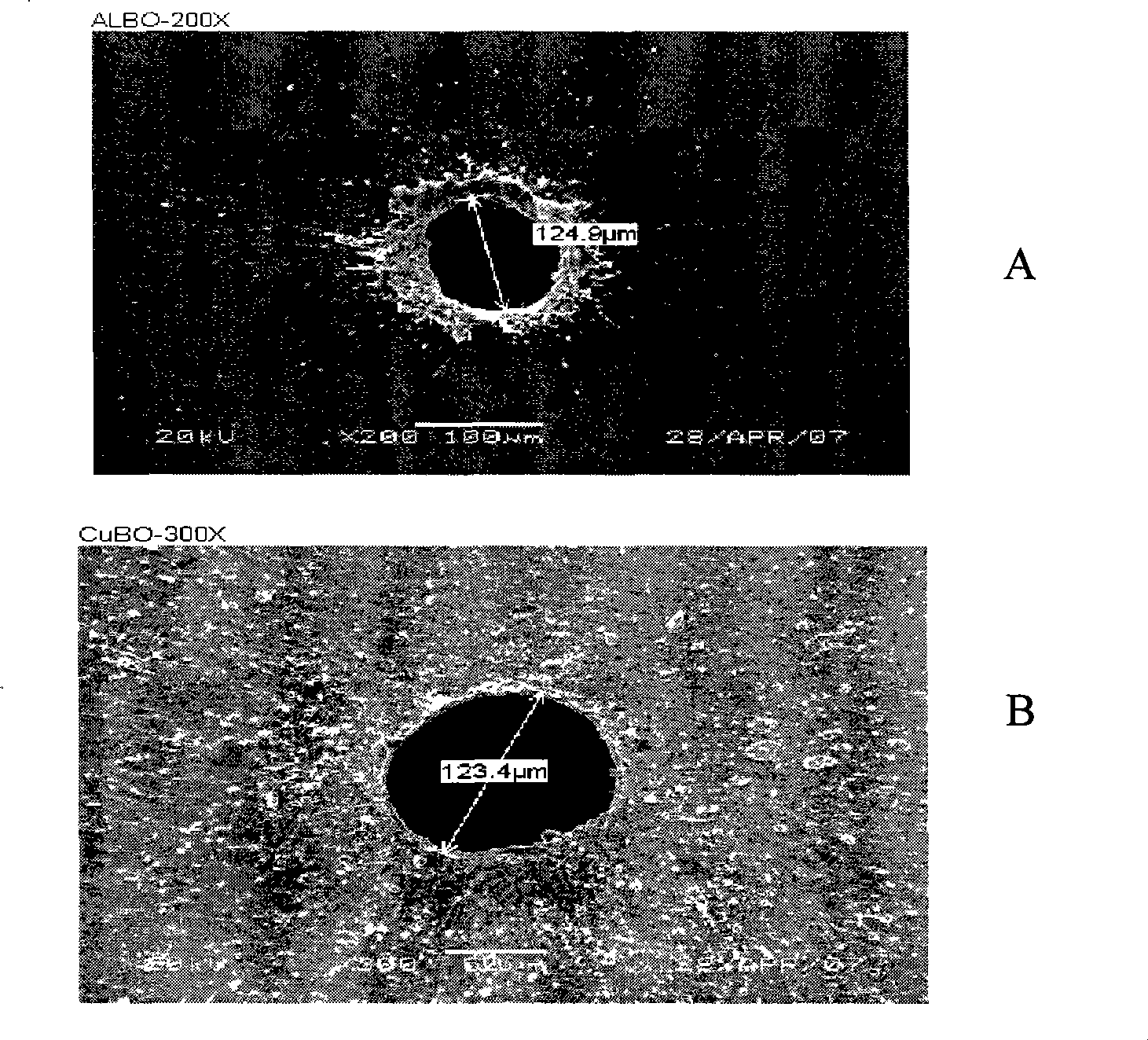

[0047] The positive electrode current collector is made of aluminum foil with a thickness of 20 microns. The width of the aluminum foil current collector is 354mm. A row of stress dispersion holes are punched on the aluminum foil every 360mm by laser drilling technology. The hole spacing is 0.5mm. The center line of the hole and the edge of the foil form an angle of 45 degrees. When continuously coating the positive electrode slurry, control the strip-shaped empty foil A with a width of 2mm on one side of the aluminum foil, and the strip-shaped empty foil B with a width of 18mm on the other side. B After the positive pole piece is rolled, ultrasonically wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com