Packaging box for liquid crystal display panel assemblies

A liquid crystal display panel and packaging box technology, applied in the field of packaging, can solve problems such as broken pieces, damaged flexible circuit boards, and inability to provide positioning buffers, and achieve the effects of preventing pulling, avoiding broken pieces, and protecting lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

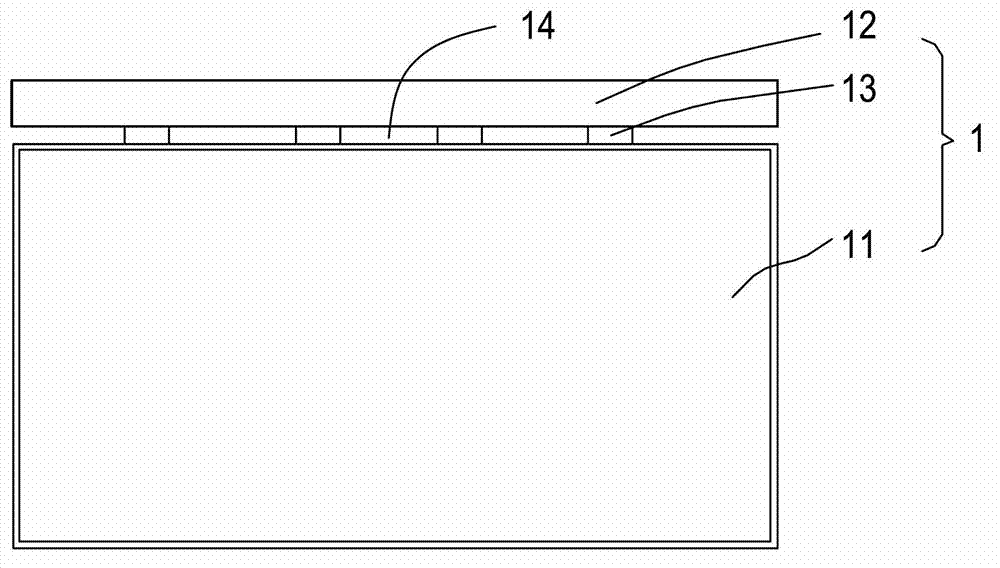

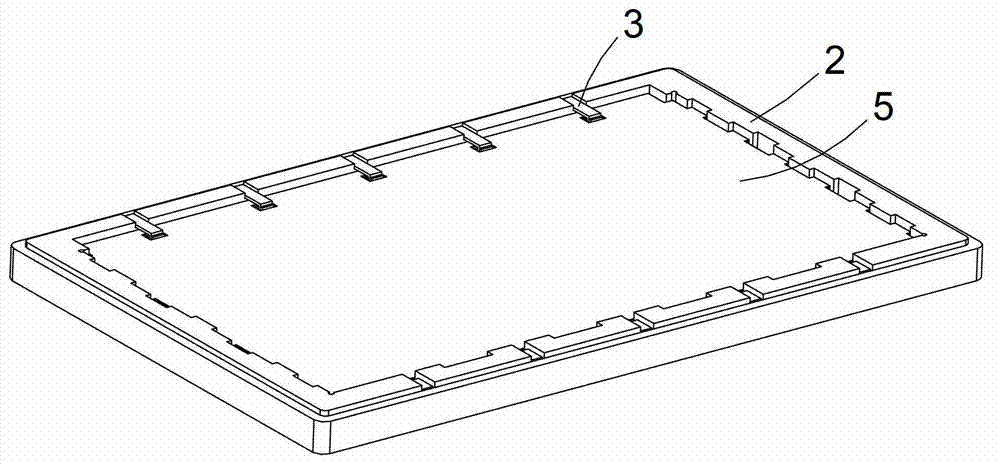

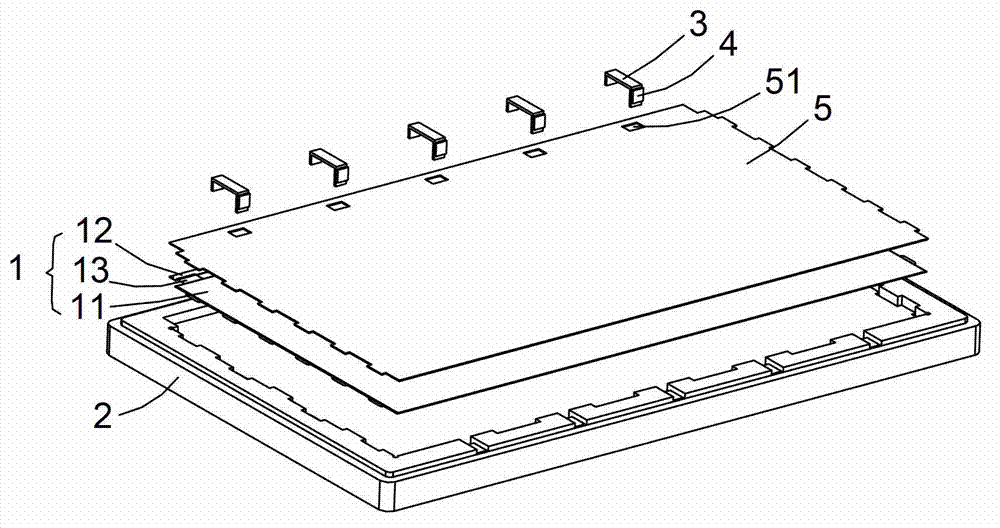

[0025] The invention discloses a packaging box for a liquid crystal display panel assembly, which is used for packaging such as figure 1 The shown liquid crystal display panel assembly 1, as the first embodiment of the packaging box of the present invention, is as Figure 2 to Figure 5 As shown, the packing box includes a box body 2, the side wall of the box body 2 is provided with a card slot 21, and the packing box also includes a holding member 3, and the holding member 3 includes a first arm 31, The second arm 32 and the connecting portion 33 for connecting the first arm 31 and the second arm 32, the clamping member 3 is a U-shaped structure, and the first arm 31 and the second arm 32 of the clamping member straddle the circuit The board 12, the first arm 31 is inserted into the card slot 21, and the second arm 32 is inserted into the notch 14 on the liquid crystal display panel assembly.

[0026] In this embodiment, the number of the holding members 3 is multiple, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com