Explosion-proof blanket

An explosion-proof cover and leak-proof technology, applied in blasting, defense, reactive armor, etc., can solve the problems of poor explosive protection ability, poor shock wave unloading ability, leakage of fragments at the bottom of the explosion fence, etc., to achieve good protection effect, unloading Strong ability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

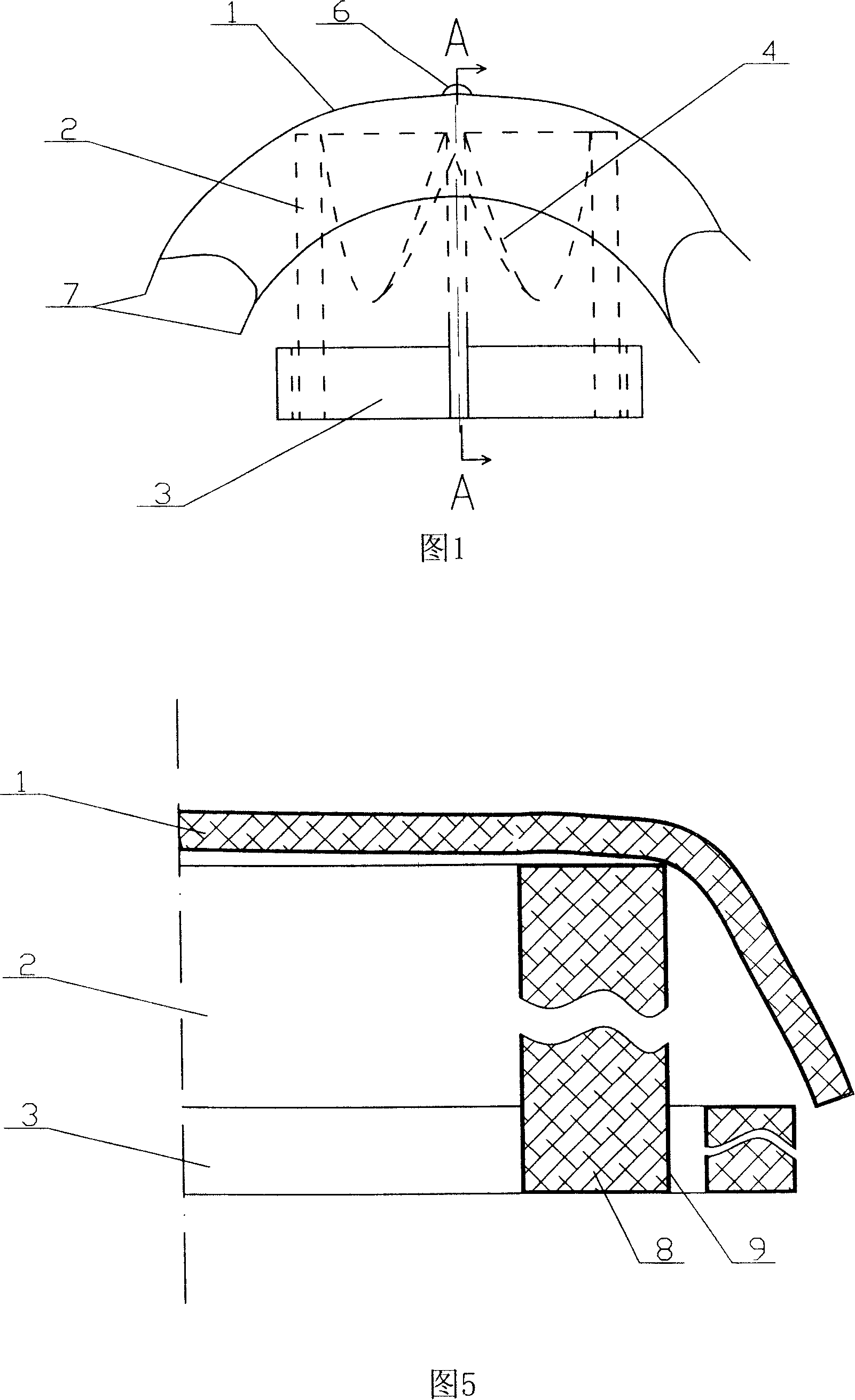

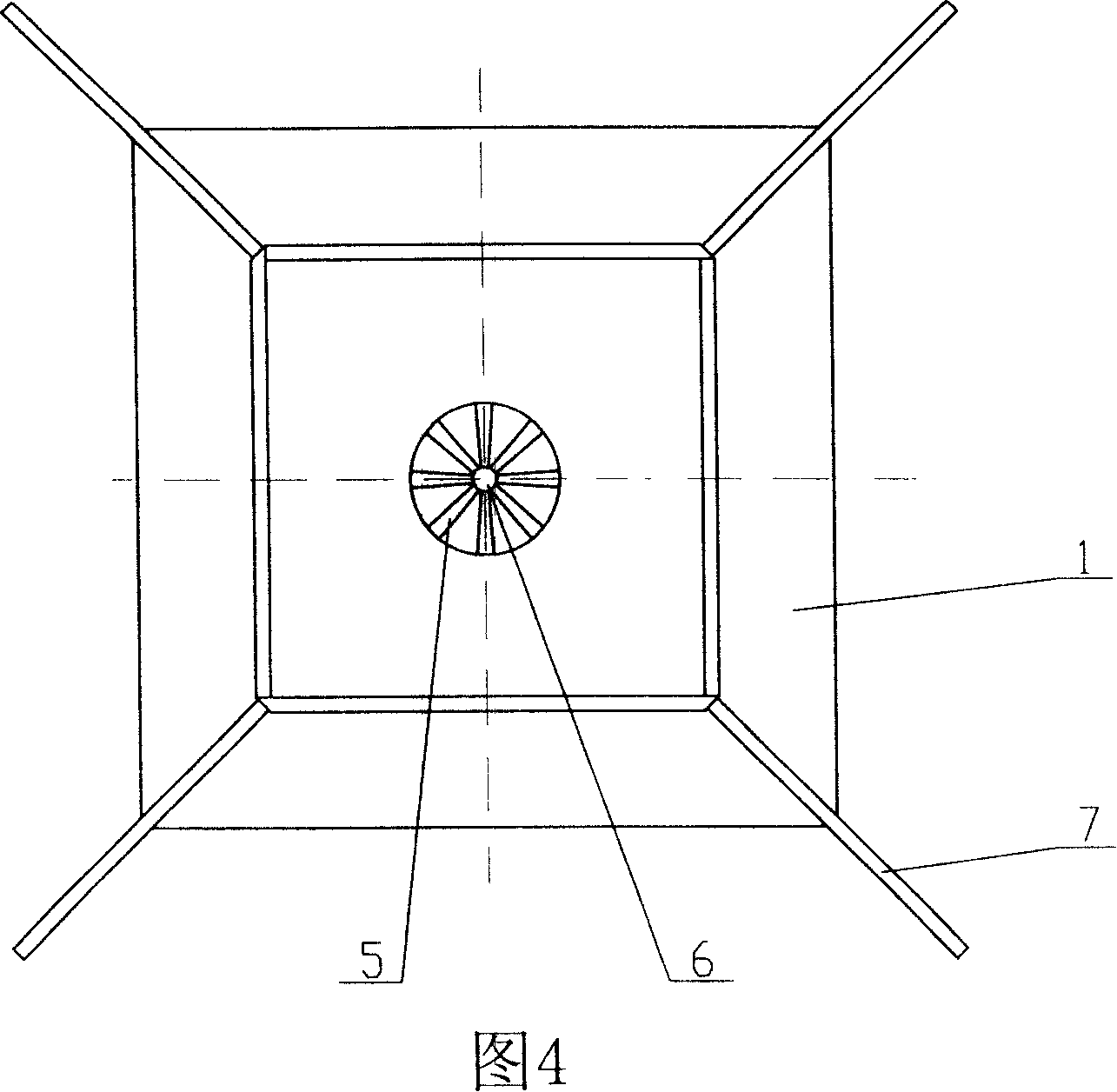

[0024] Please refer to Fig. 1, the product of the present invention is made up of explosion-proof cover blanket 1, explosion-proof fence 2, leak-proof fence 3, position-limiting hand strap 4, connecting round buckle 6, and cover blanket handle 7. Wherein, an explosion-proof blanket 1 is covered on the explosion-proof fence 2, and a leak-proof fence 3 is looped outside the bottom of the explosion-proof fence 2, and the explosion-proof fence 2 moves axially in the leak-proof fence 3, and is limited by a connecting belt 4 One end of the connection belt 4 is connected to the leak-proof fence 3, and the other end is connected to the explosion-proof fence 2; the explosion-proof fence 2 is a through-hole cylindrical structure.

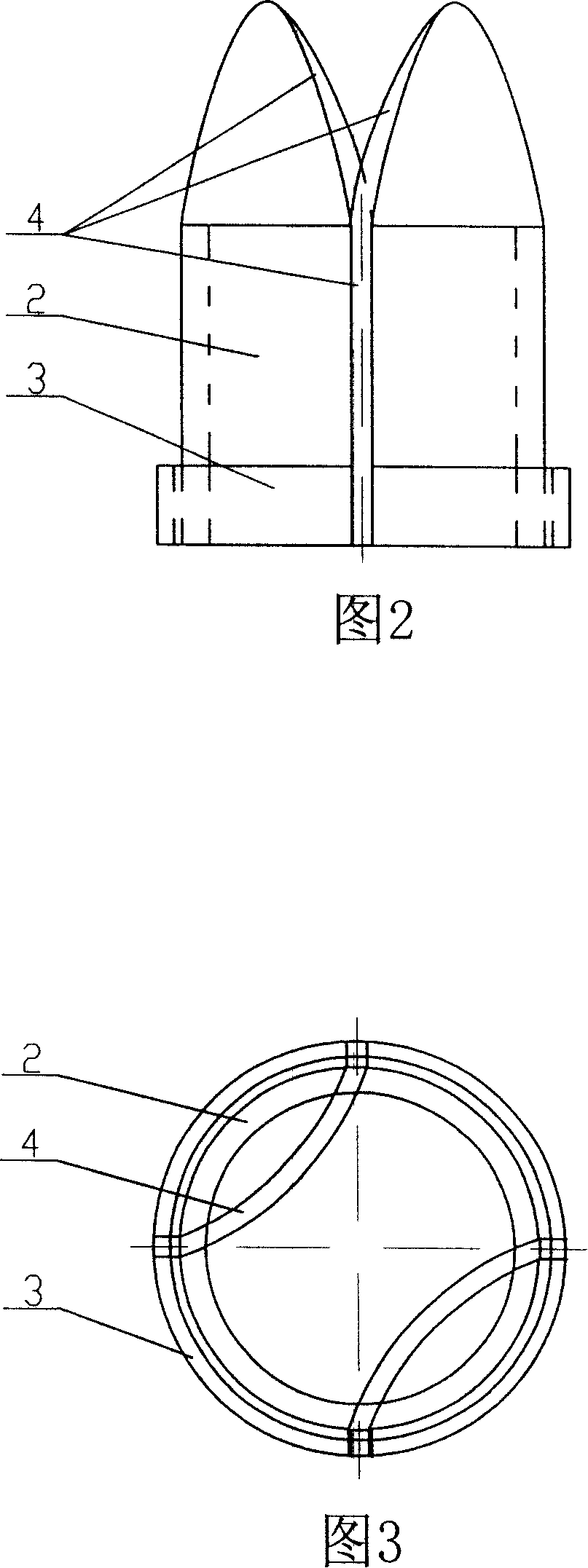

[0025] It can be further seen from FIG. 2 and FIG. 3 that the connecting belt 4 extends out of the explosion-proof fence 2 after passing through the leakage-proof fence 3 and the explosion-proof fence 2 from bottom to top. Two adjacent protruding parts are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com