Microcrystalline glass polishing process

A technology of glass-ceramic and process, which is applied in the field of polishing treatment, can solve problems such as difficulty in controlling the roughness of the glass, affecting the overall flatness of the glass, and uneven stress distribution, so as to shorten the polishing process time, shorten the production time, and reduce the roughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

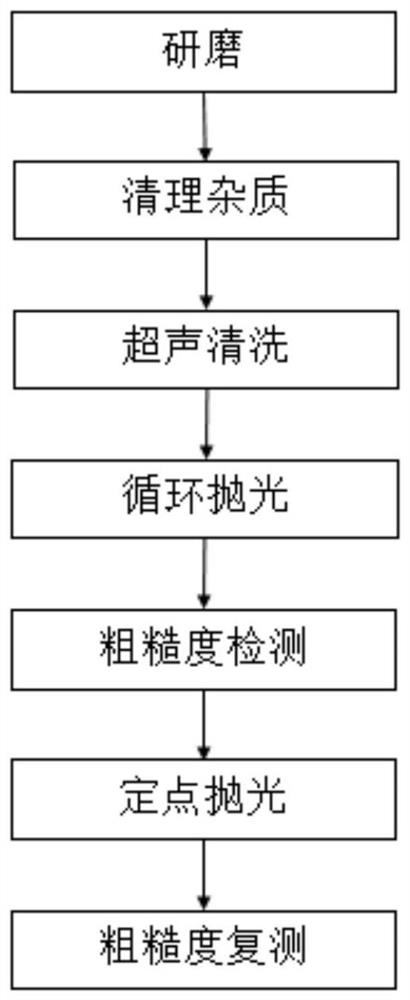

[0033] like figure 1 Shown, a kind of crystallized glass polishing process of the present invention comprises the following steps:

[0034] S1. Use a grinder to grind the 0.900mm glass-ceramic sheet refined by the engraving machine to a thickness of 0.725mm, and remove the cutting line marks on the surface of the glass-ceramic.

[0035] S2. Cleaning up impurities on the glass-ceramics: repeatedly washing the prepared glass-ceramics sheet with pure water to remove visible foreign matter on the surface.

[0036] S3. Insert the glass sheet into the shelf, place it in the ultrasonic cleaning machine, and clean it. The ultrasonic cleaning parameters are shown in the following table:

[0037]

[0038] S4. Preparation of polishing liquid: Accurately weigh 25KG of small-sized polishing powder, then slowly add the polishing powder to 25-35KG of clear water while stirring, and add it to the liquid storage tank of the polishing machine after stirring evenly .

[0039] S5. Polishing...

Embodiment 2

[0064] The invention provides a glass-ceramics polishing process, comprising the following steps:

[0065] S1. Grind the 0.900mm glass-ceramic sheet refined by Jingdiao machine to a thickness of 0.725mm with a grinder;

[0066] S2. Cleaning up impurities on the glass-ceramics: repeatedly washing the prepared glass-ceramics sheet with pure water to remove visible foreign matter on the surface.

[0067] S3. Insert the glass sheet into the shelf, place it in the ultrasonic cleaning machine, and clean it. The ultrasonic cleaning parameters are shown in the following table:

[0068]

[0069] S4. Accurately weigh 25KG of polishing powder with a particle size of 25-30nm, then slowly add the polishing powder into 30KG of clear water while stirring, and add it to the liquid storage tank of the polishing machine after stirring evenly.

[0070] S5. Polishing: the cleaned glass-ceramic sheet is placed in the grinding chassis of the polishing machine, the polishing powder is injected i...

Embodiment 3

[0095] A glass-ceramic polishing process of the present invention comprises the following steps:

[0096] S1. Grind the 0.900mm glass-ceramic sheet refined by Jingdiao machine to a thickness of 0.725mm with a grinder;

[0097] S2. Cleaning up impurities on the glass-ceramics: repeatedly washing the prepared glass-ceramics sheet with pure water to remove visible foreign matter on the surface.

[0098] S3. Insert the glass sheet into the shelf, place it in the ultrasonic cleaning machine, and clean it. The ultrasonic cleaning parameters are shown in the following table:

[0099]

[0100] S4. Accurately weigh 25KG of polishing powder with a particle size of 25-30nm, then slowly add the polishing powder into 25KG of clear water while stirring, and add it to the liquid storage tank of the polishing machine after stirring evenly.

[0101] S5. Polishing: the cleaned glass-ceramic sheet is placed in the grinding chassis of the polishing machine, the polishing powder is injected in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com