Method for preparing electrode plate by dry rolling

A technology for preparing electrodes and dry rolls, which is applied in the field of lithium ions, can solve the problems of grain dropping, sticking rolls, broken belts, etc., achieve uniform thickness, reduce process equipment, and avoid uneven thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

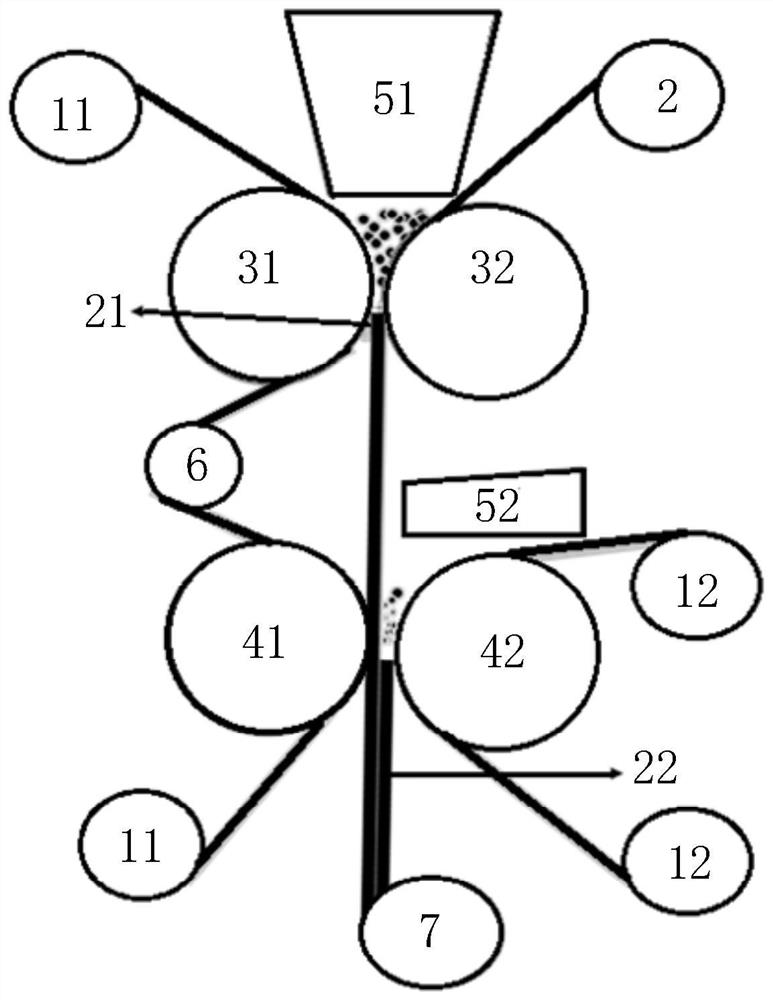

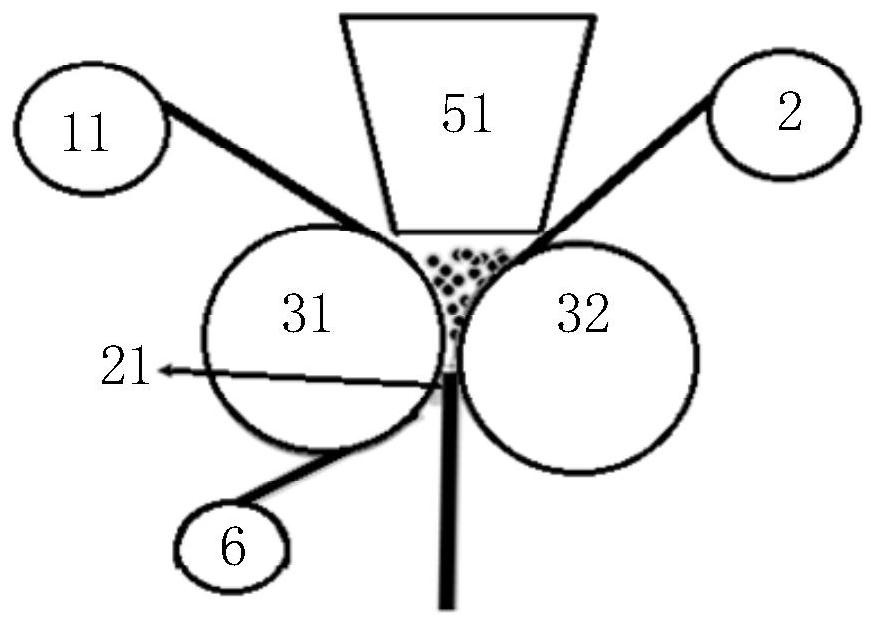

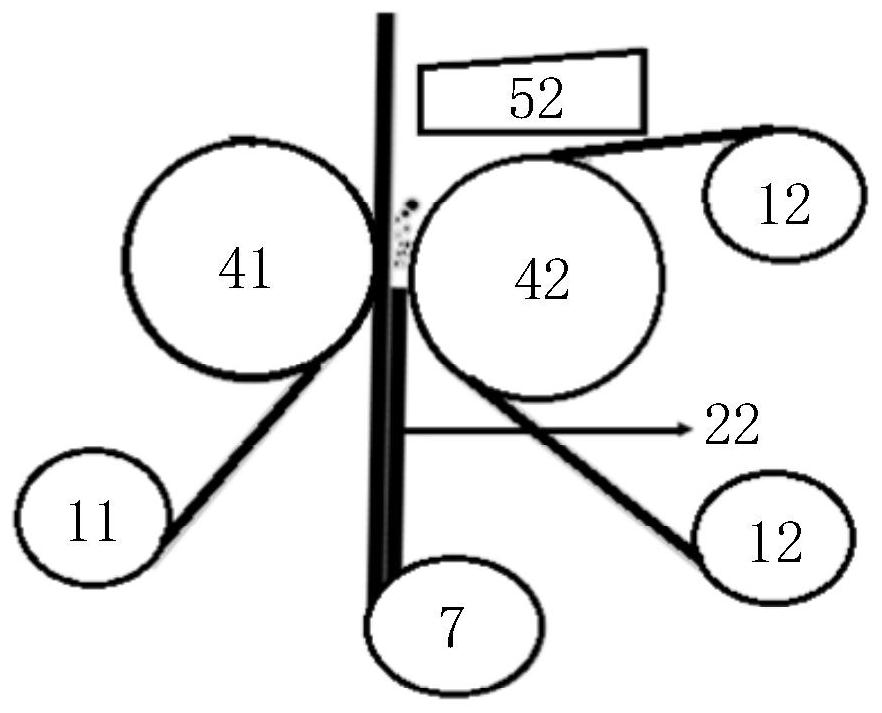

[0103] combine figure 1 , this embodiment is used to illustrate the method for preparing an electrode sheet by dry rolling of the present invention.

[0104] The first powder used in this embodiment 1 is the same as the second powder, which is a mixture of high nickel ternary positive electrode material, sodium carboxymethyl cellulose and Ketjen black (high nickel ternary positive electrode material, carboxymethyl fiber The weight ratio of plain sodium to Ketjen black is 85:7:8), and the average particle size is 10 μm. It is pre-mixed until it is fibrous and then added to the feeding bin; the first film material and the second film material are both PET film, foil Aluminum foil with a thickness of 14 μm was selected as the material.

[0105] The specific preparation method is:

[0106] (1) The first film material 11 (3m / min) and the foil material (5m / min) are unwound, and at the same time pass vertically between the opposite first rollers (specifically vertical rollers 31, 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com