Method for producing luminous element with high-illuminating effect

A light-emitting element and manufacturing method technology, which is applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problems such as the inability to effectively remove alumina slag, and achieve the effects of avoiding fragmentation problems, increasing yield, and improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

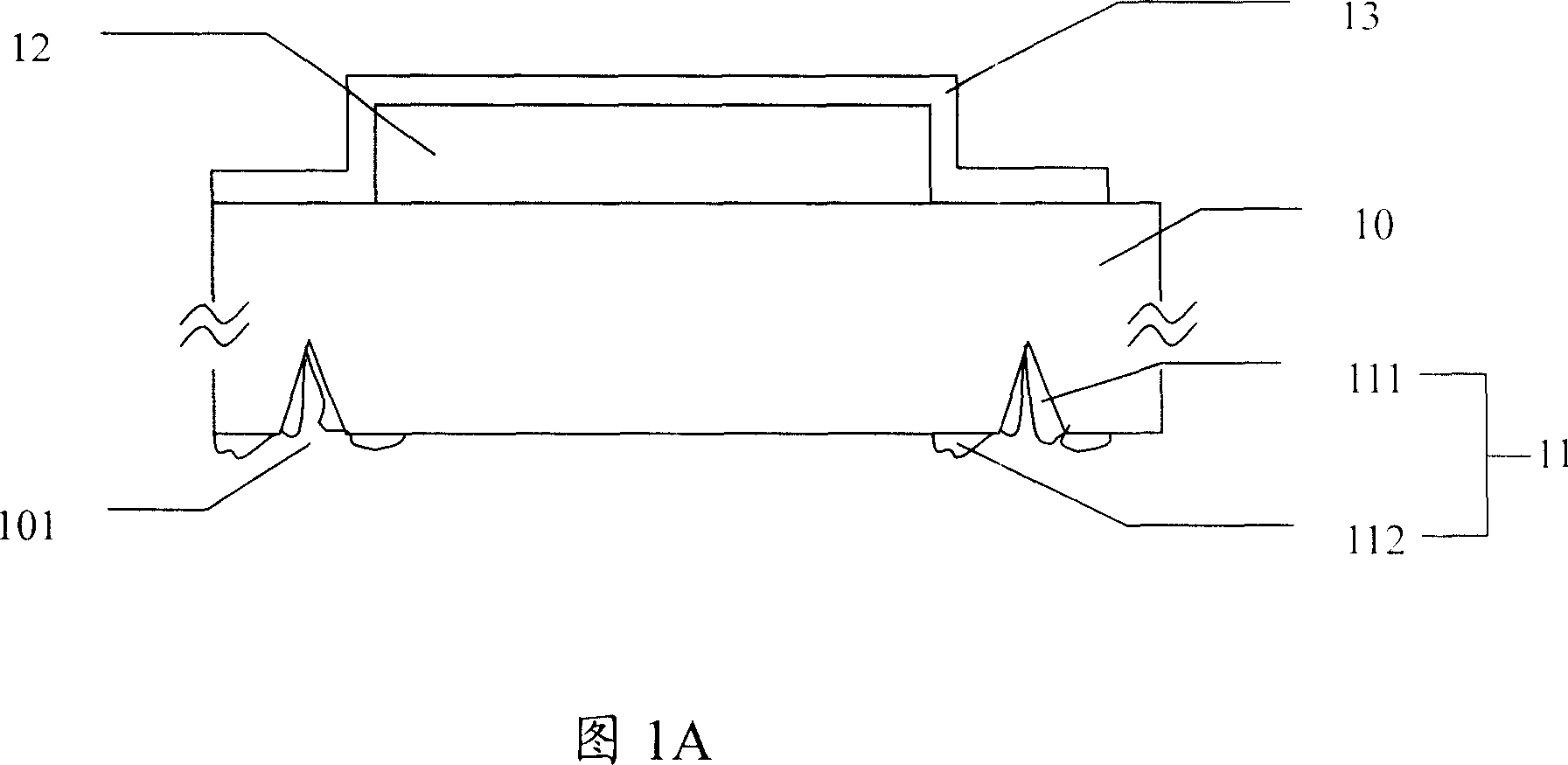

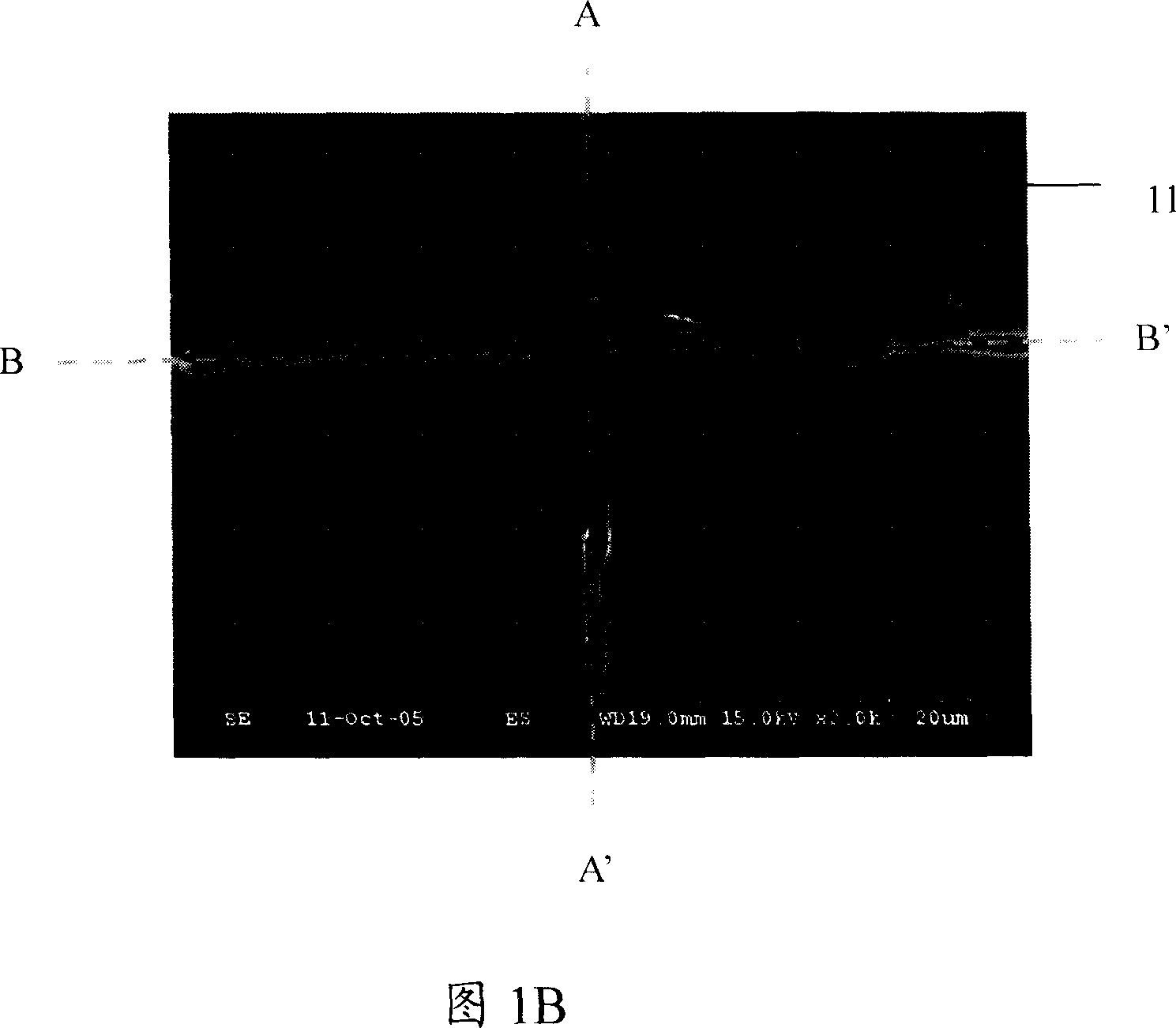

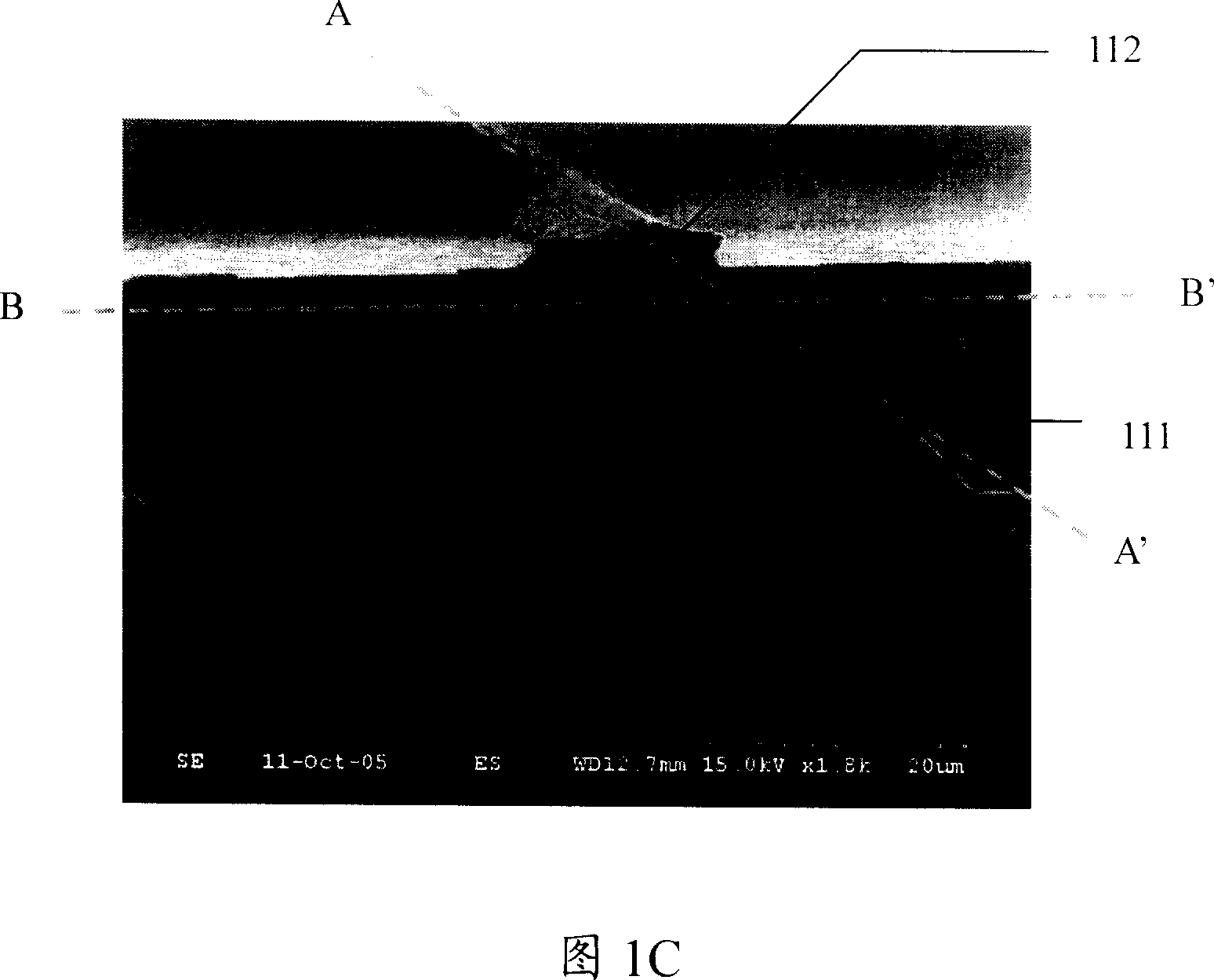

[0031] Please refer to FIGS. 1A-1C , according to a method for manufacturing a high-luminous-efficiency light-emitting element 1 according to a preferred embodiment of the present invention, the steps include on the first surface of a substrate 10 with a first upper surface and a first lower surface. A light-emitting stack 12 is formed on the surface, wherein the light-emitting stack includes a second upper surface and a second lower surface, and the second lower surface faces the substrate 10, and a first layer is coated on the second upper surface of the light-emitting stack. a protective layer 13, cutting the light-emitting element 1 with a laser beam from the lower surface of the substrate, and placing the light-emitting element 1 with the first protective layer 13 in a heated acidic solution for a period of time, passing through the hot acidic solution, By-products are removed. In the process of laser beam cutting the light-emitting element in this embodiment, the laser b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com