Patents

Literature

285results about "Contactless testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

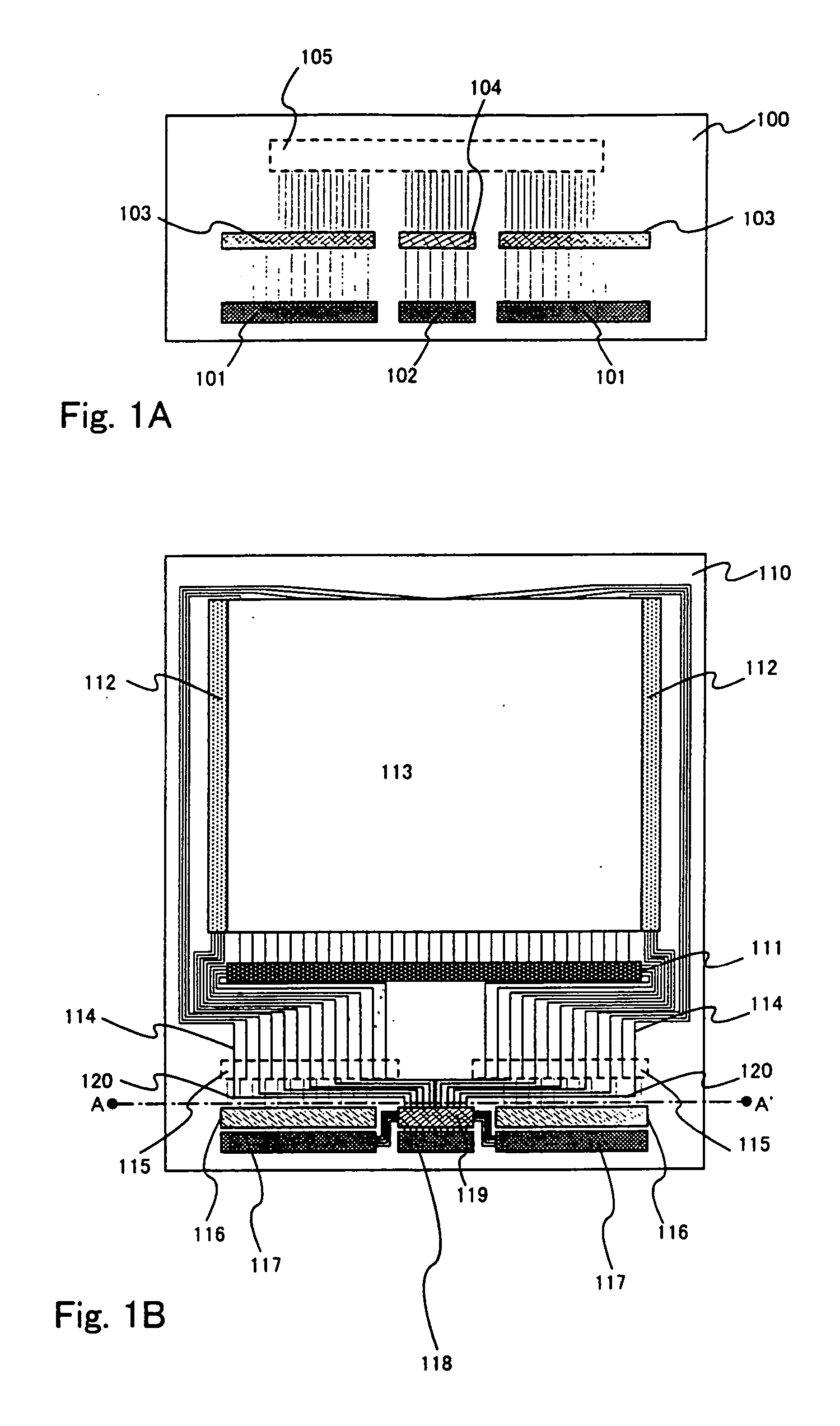

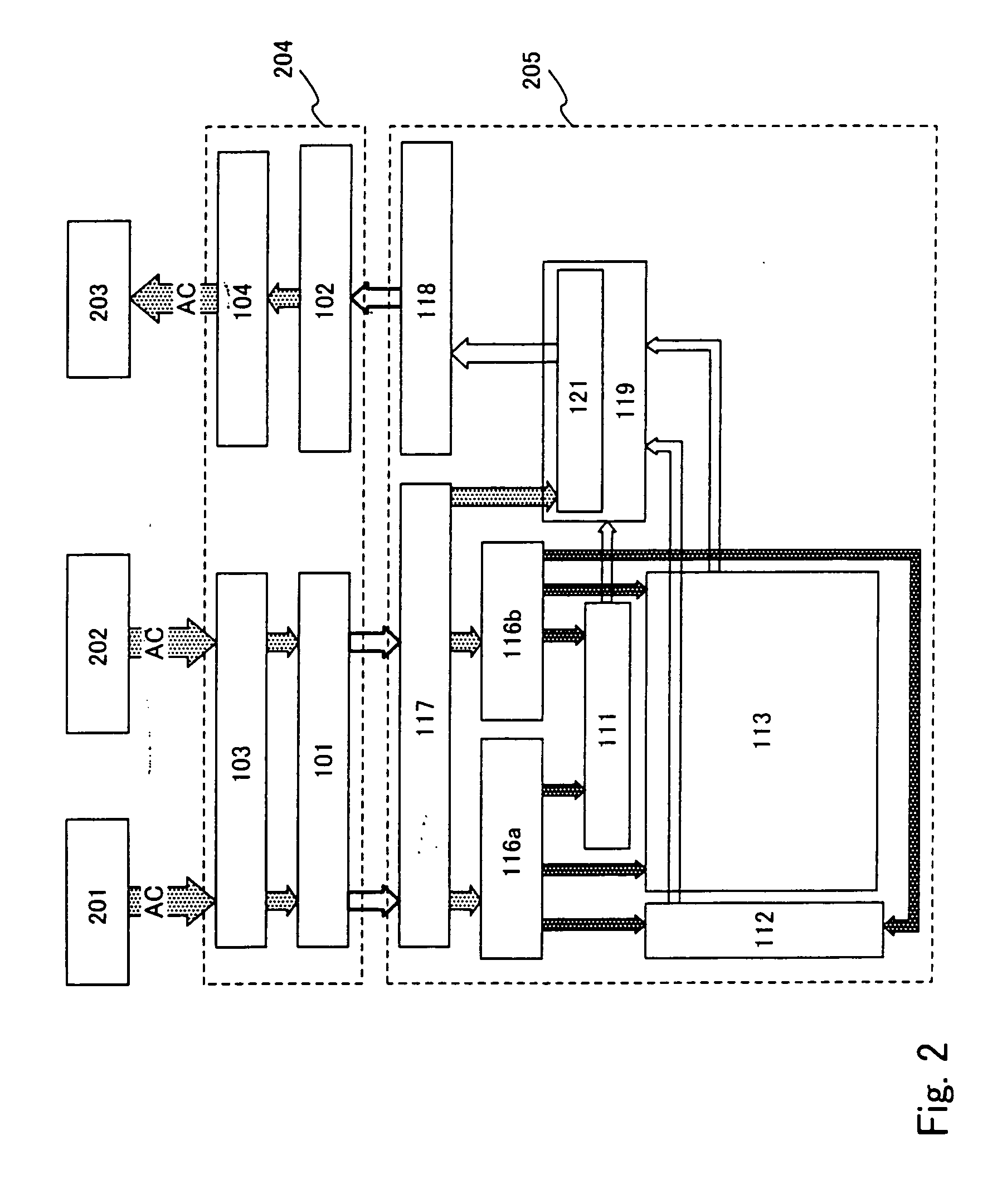

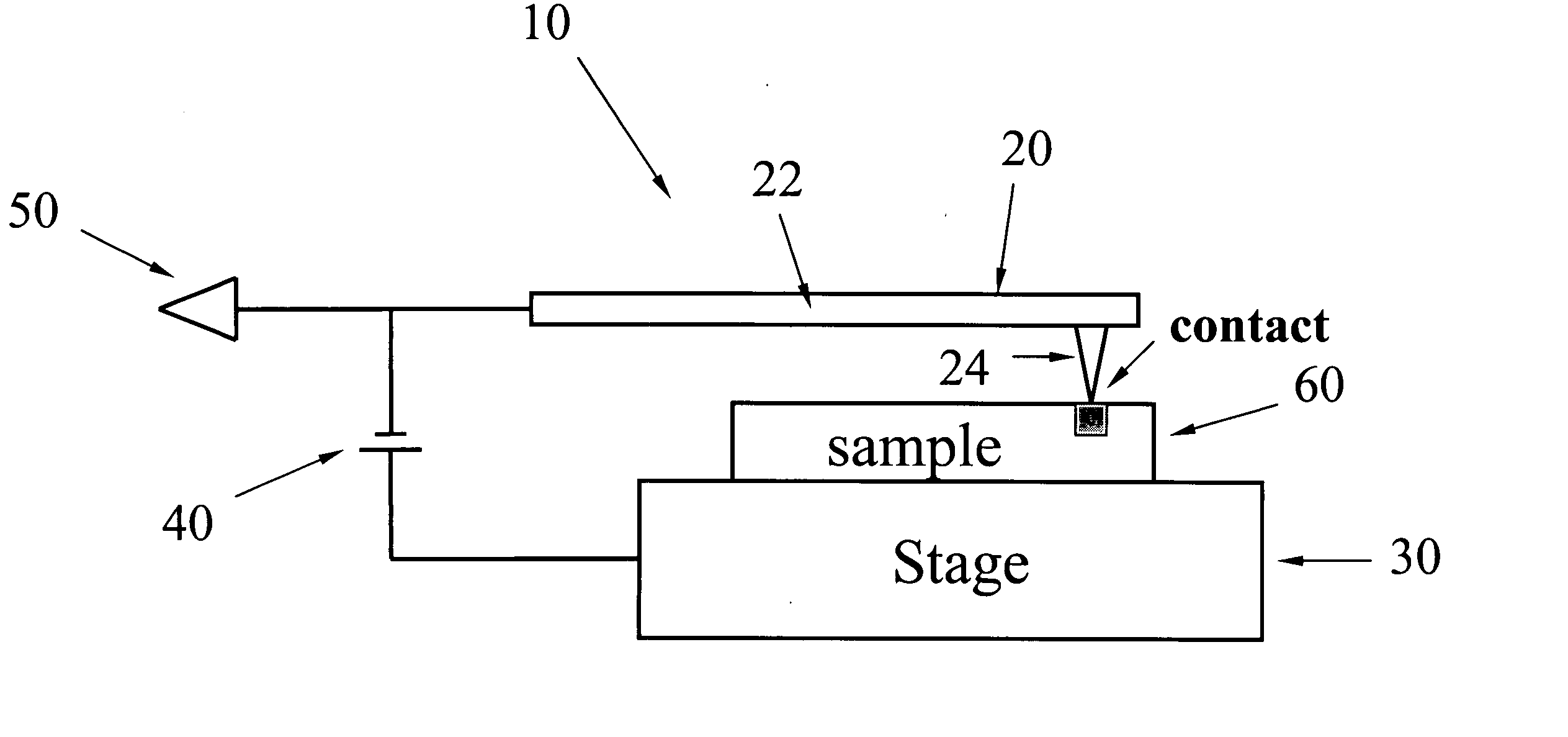

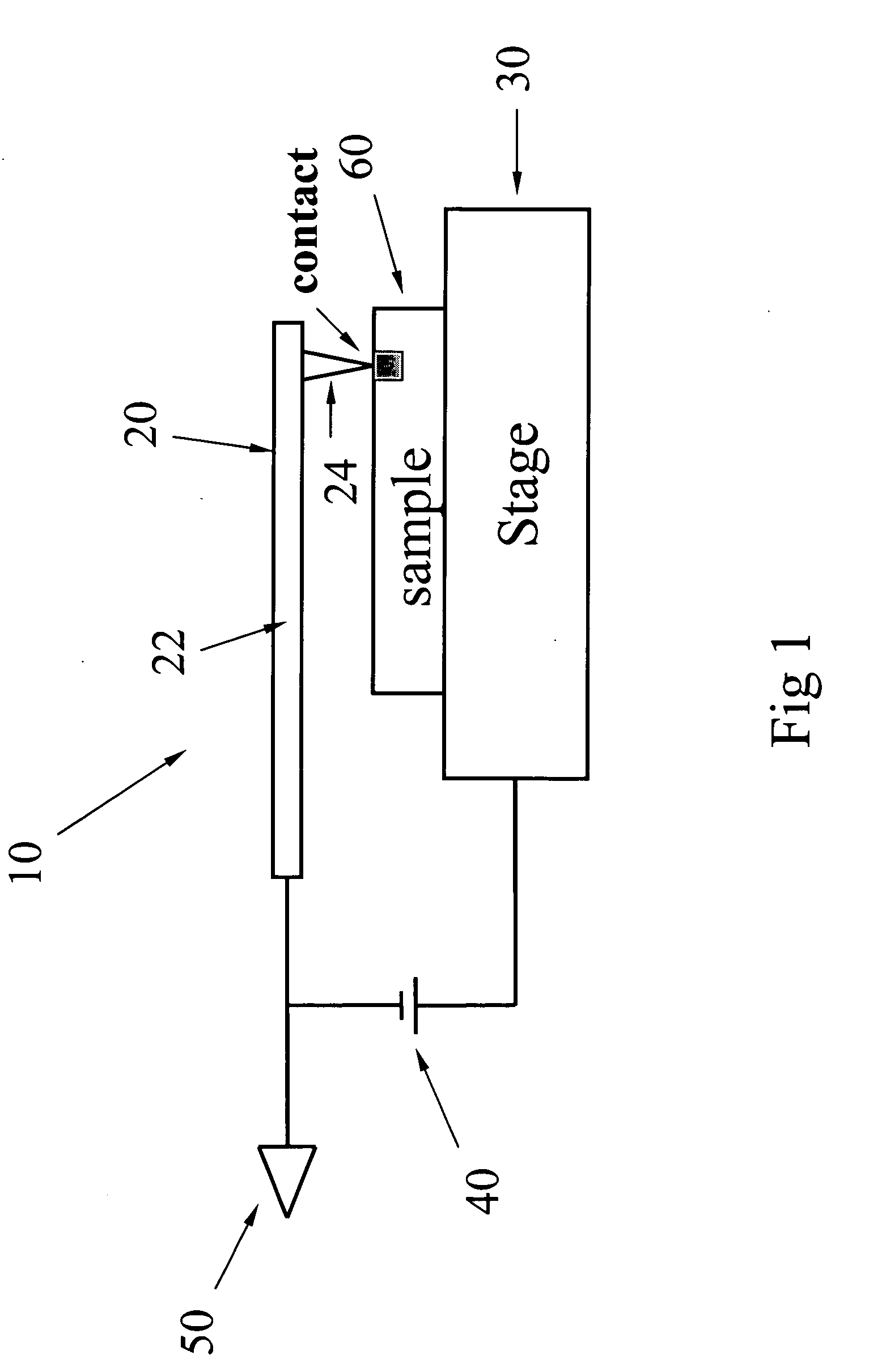

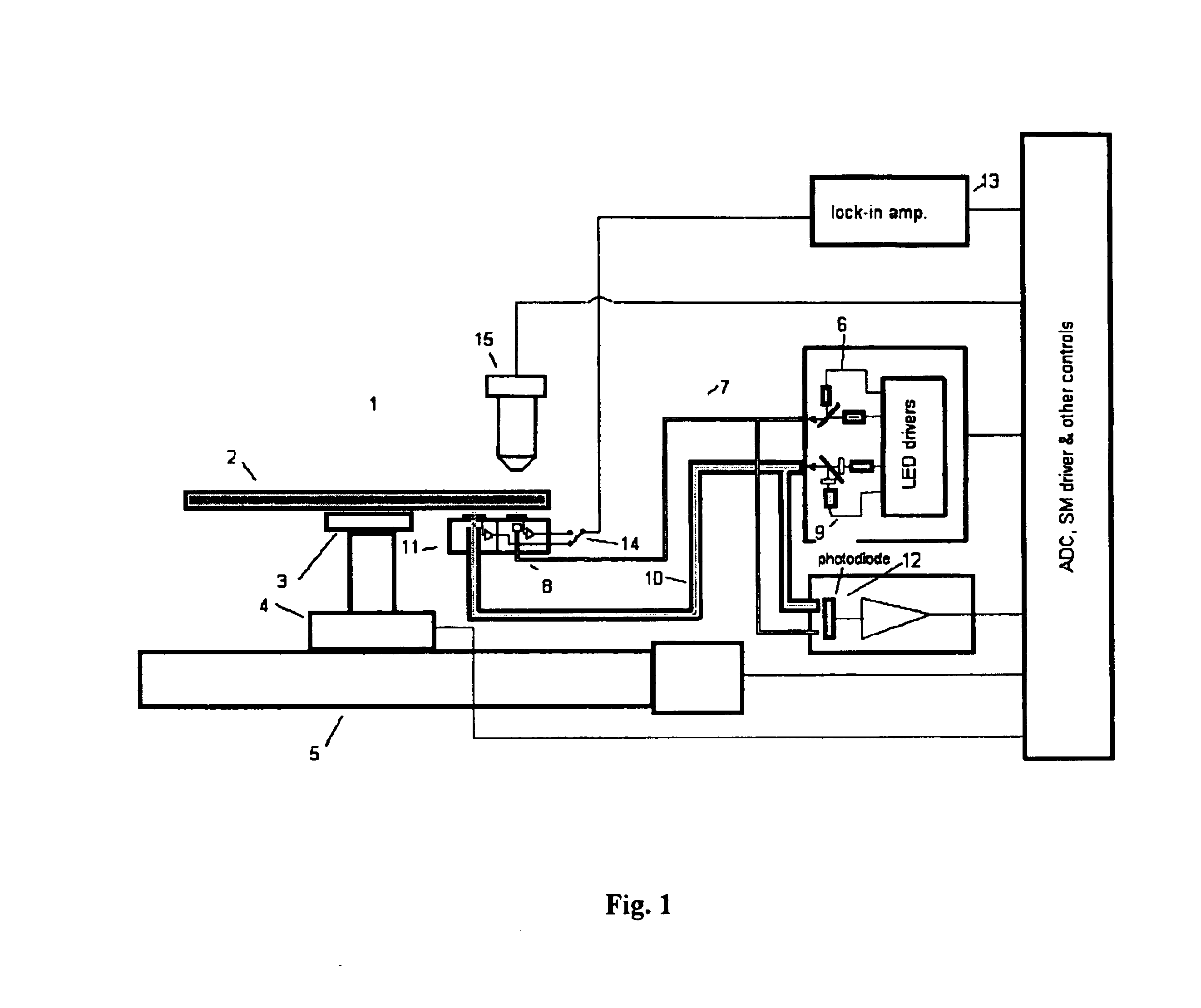

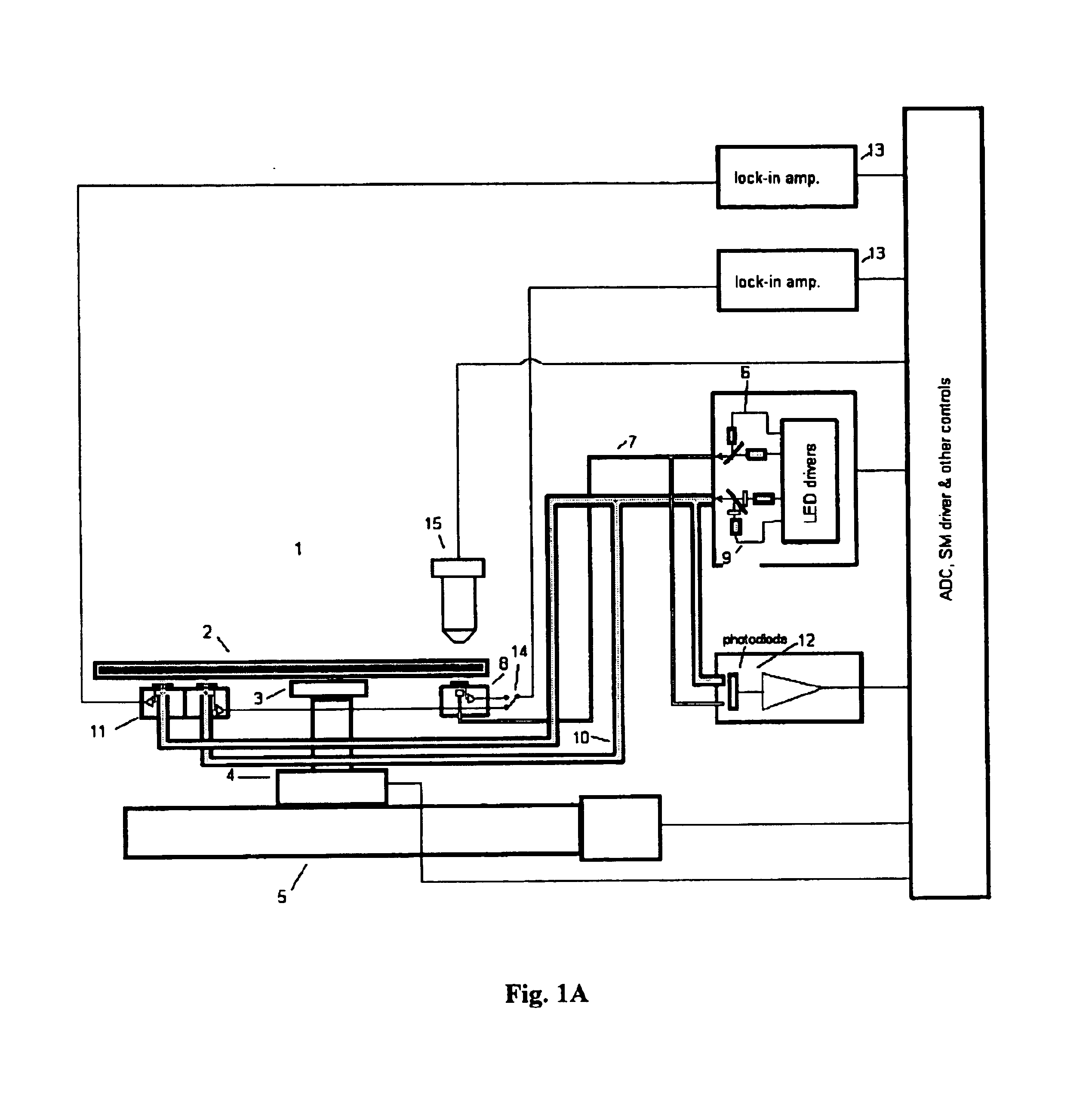

Measuring method, inspection method, inspection device, semiconductor device, method of manufacturing a semiconductor device, and method of manufacturing an element substrate

InactiveUS6891391B2Easy to checkSimplify inspection stepsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingSemiconductorSignal processing

An inspection method which simplifies an inspection step by eliminating the need to set probes on wiring or probe terminals, and an inspection device for performing the inspection step. A voltage is applied to each of inspected circuits or circuit elements to operate the same. Signal processing is performed on an output from each inspected circuit or circuit element during operation to form a signal (operation information signal) including information on the operating condition of the circuit or the circuit element. The operation information signal is amplified and the amplitude of an alternating current voltage separately input is modulated with the amplified operation information signal. The voltage of the modulated alternating current is read in a non-contact manner to determine whether the corresponding circuit or circuit element is non-defective or defective.

Owner:SEMICON ENERGY LAB CO LTD

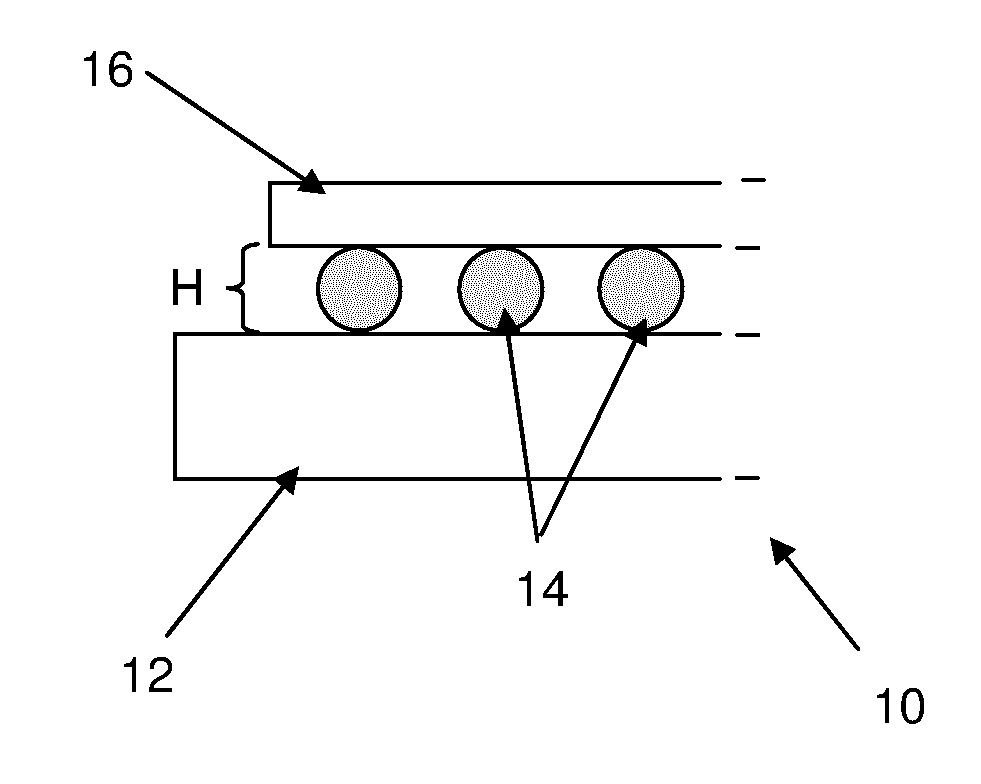

Multidimensional Structural Access

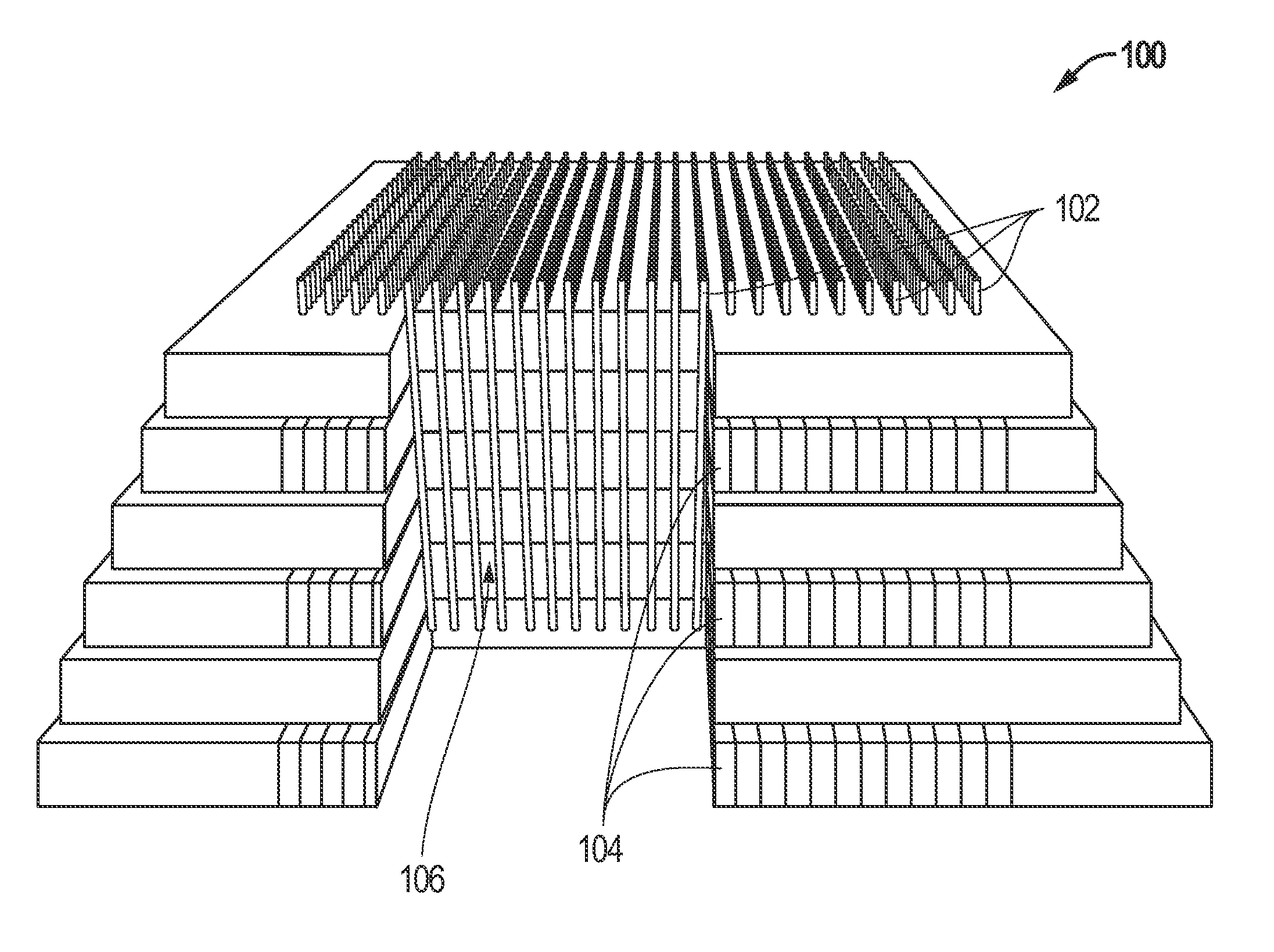

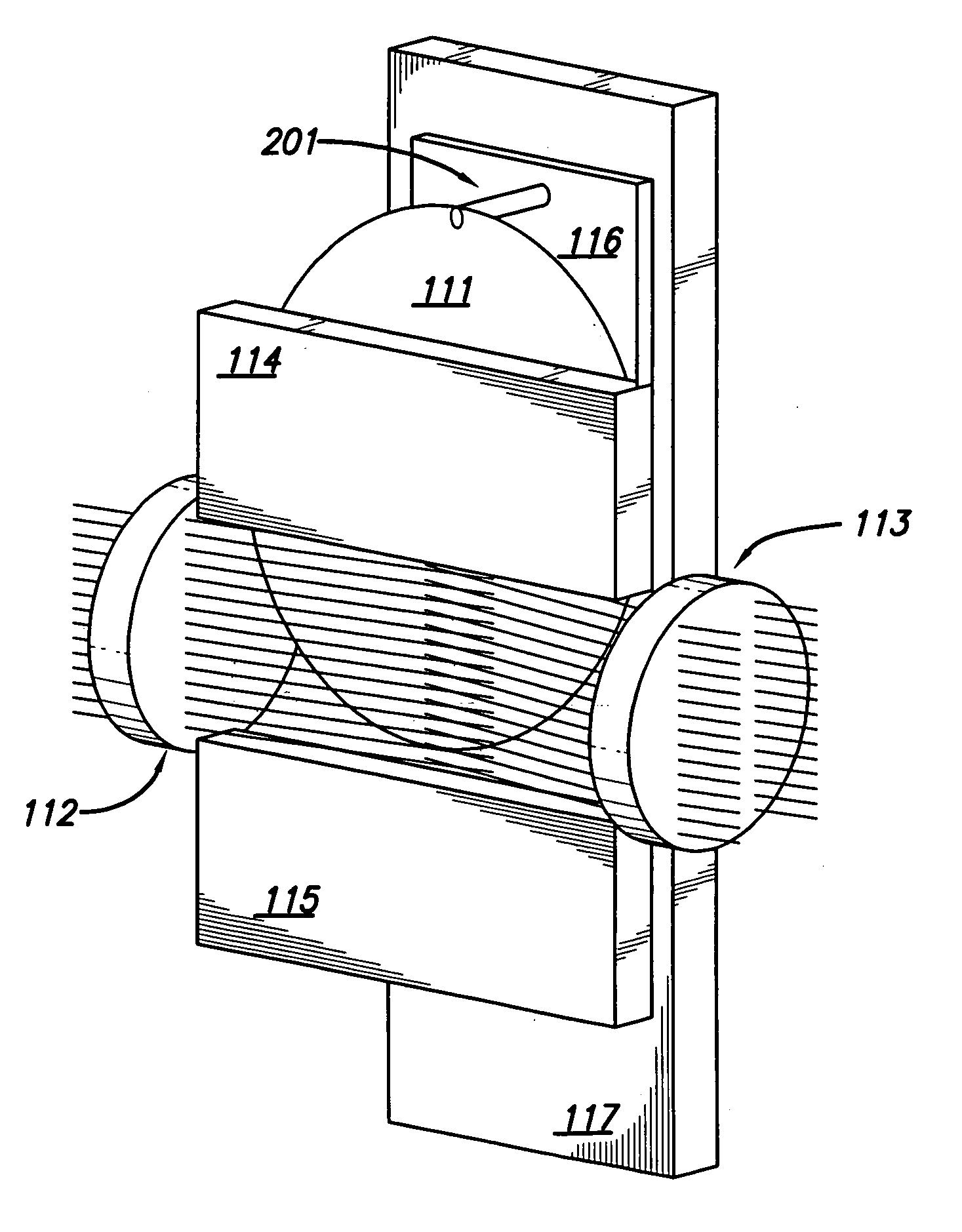

ActiveUS20150260784A1Minimizing damageSemiconductor/solid-state device testing/measurementElectric discharge tubesElectrical conductorNon orthogonal

Multiple planes within the sample are exposed from a single perspective for contact by an electrical probe. The sample can be milled at a non-orthogonal angle to expose different layers as sloped surfaces. The sloped edges of multiple, parallel conductor planes provide access to the multiple levels from above. The planes can be accessed, for example, for contacting with an electrical probe for applying or sensing a voltage. The level of an exposed layer to be contacted can be identified, for example, by counting down the exposed layers from the sample surface, since the non-orthogonal mill makes all layers visible from above. Alternatively, the sample can be milled orthogonally to the surface, and then tilted and / or rotated to provide access to multiple levels of the device. The milling is preferably performed away from the region of interest, to provide electrical access to the region while minimizing damage to the region.

Owner:FEI CO

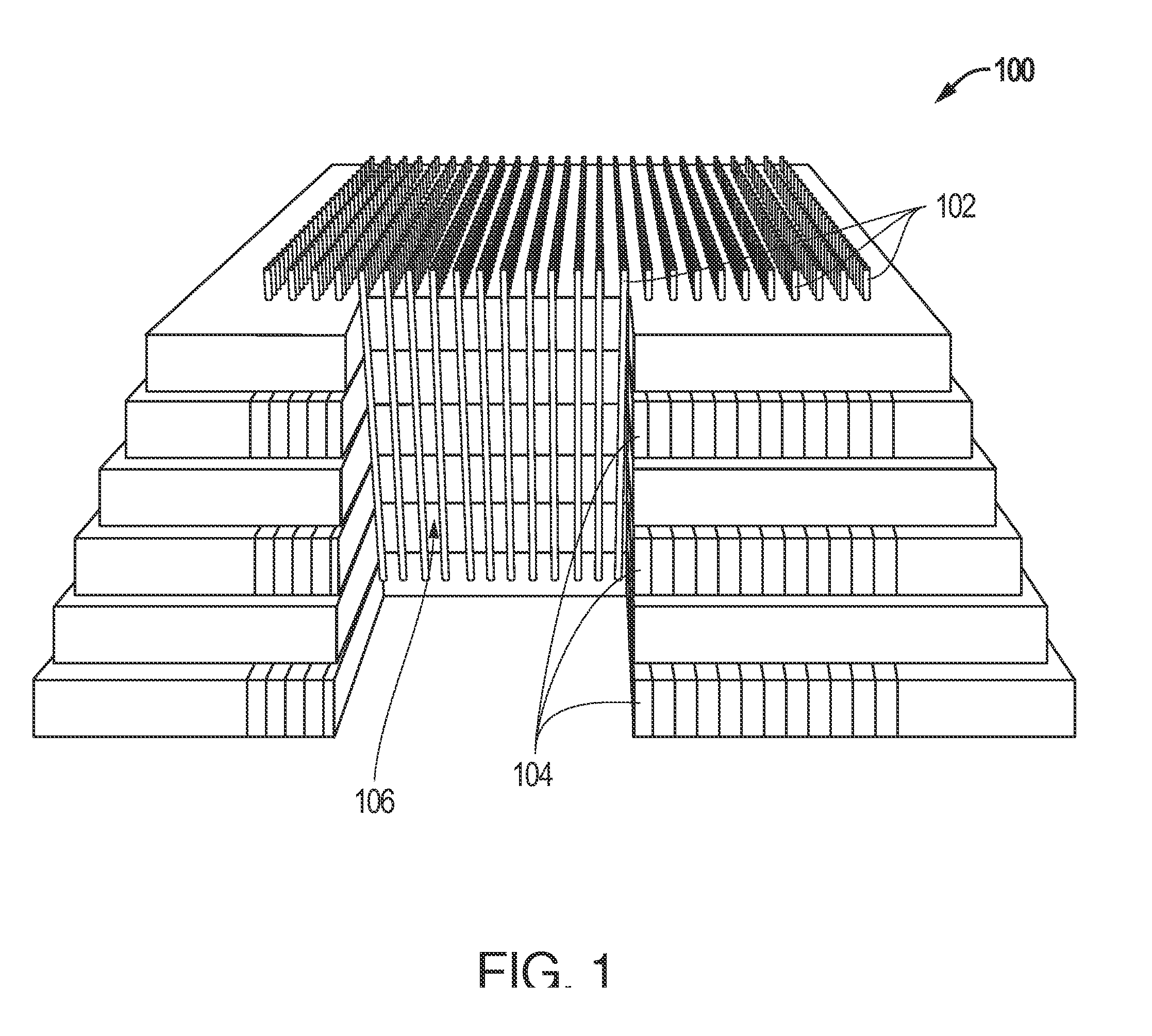

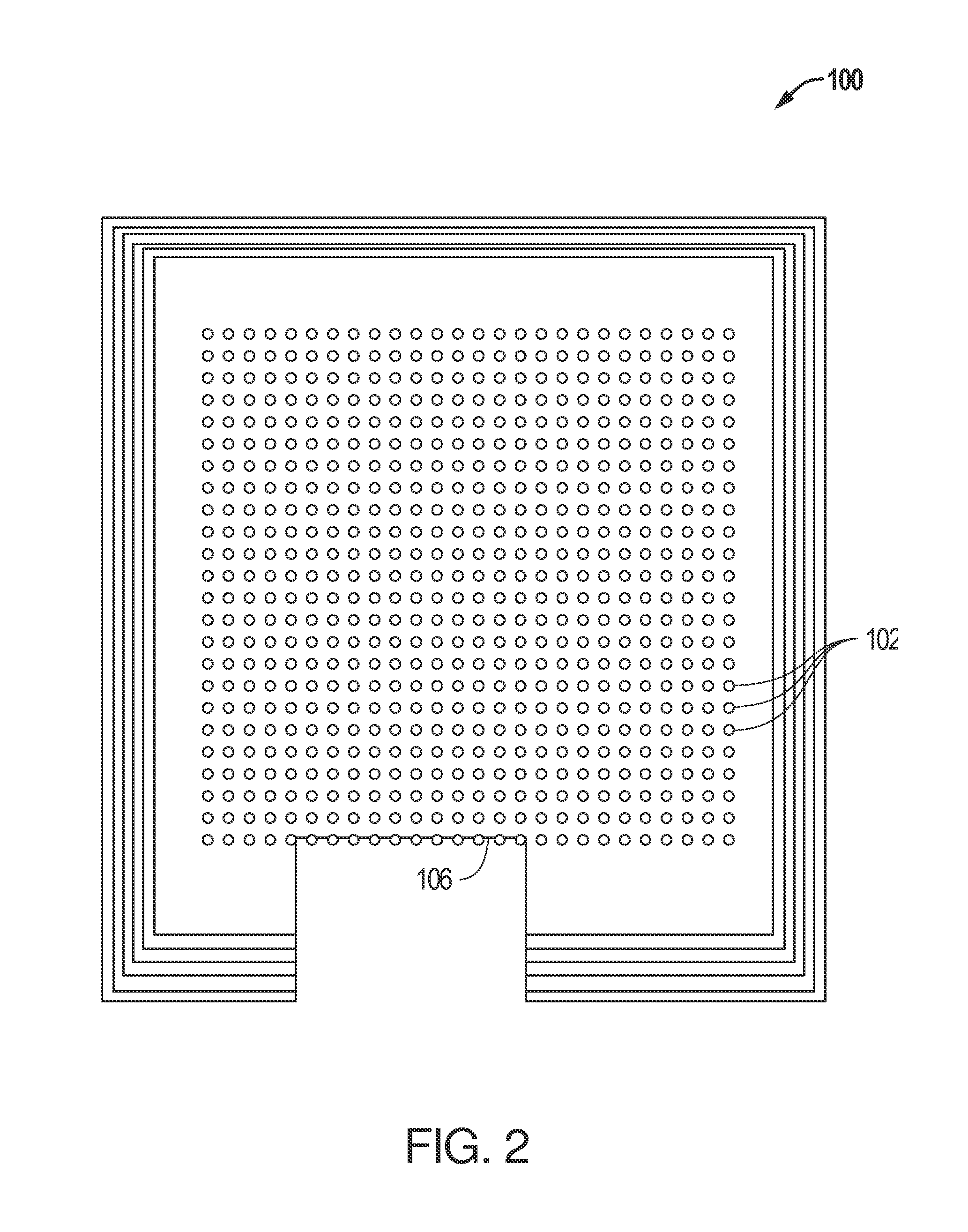

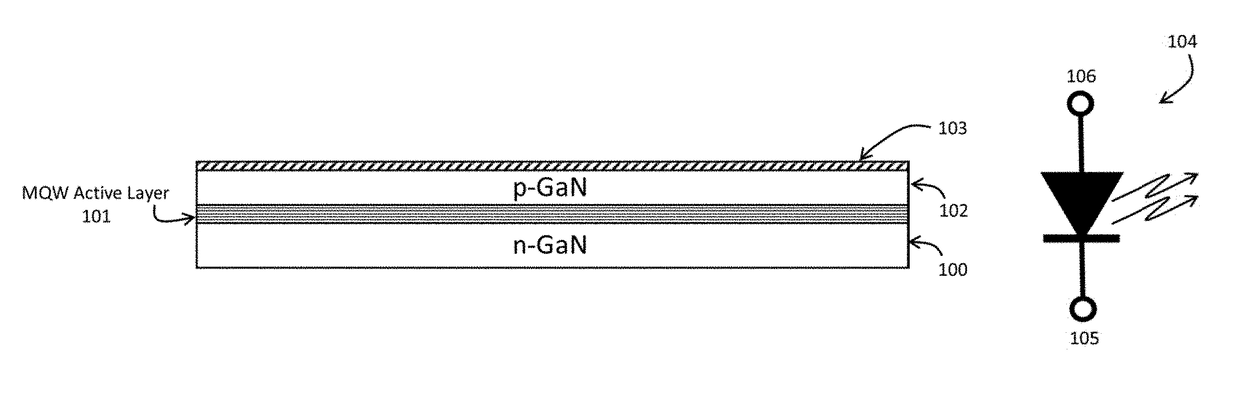

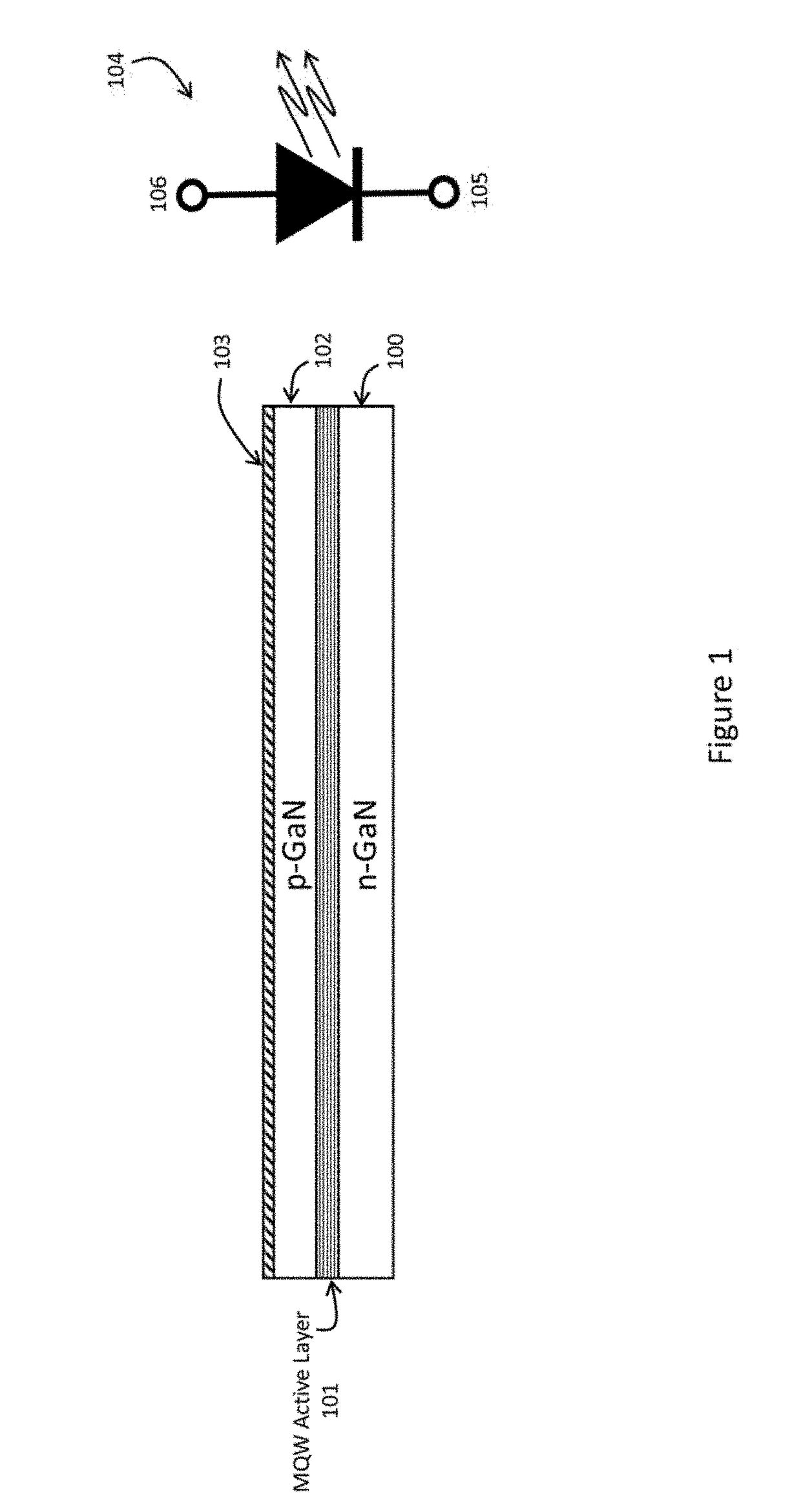

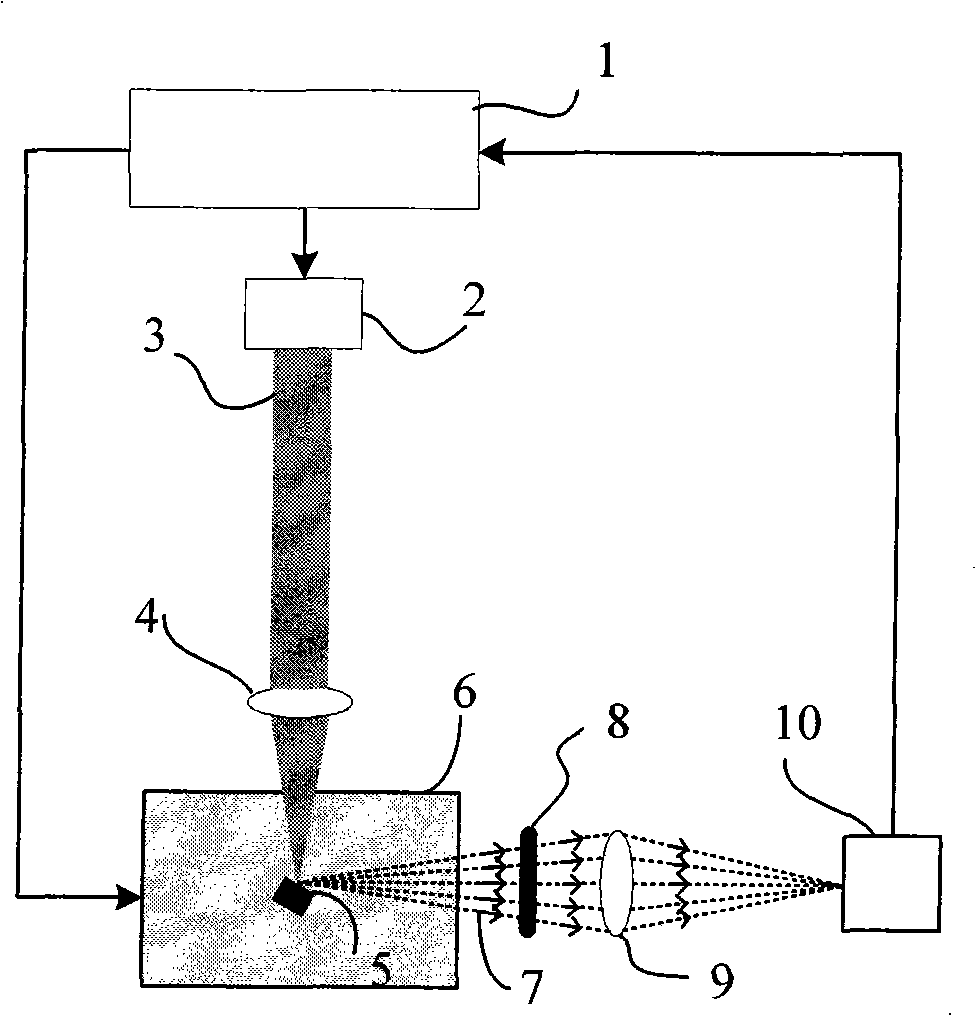

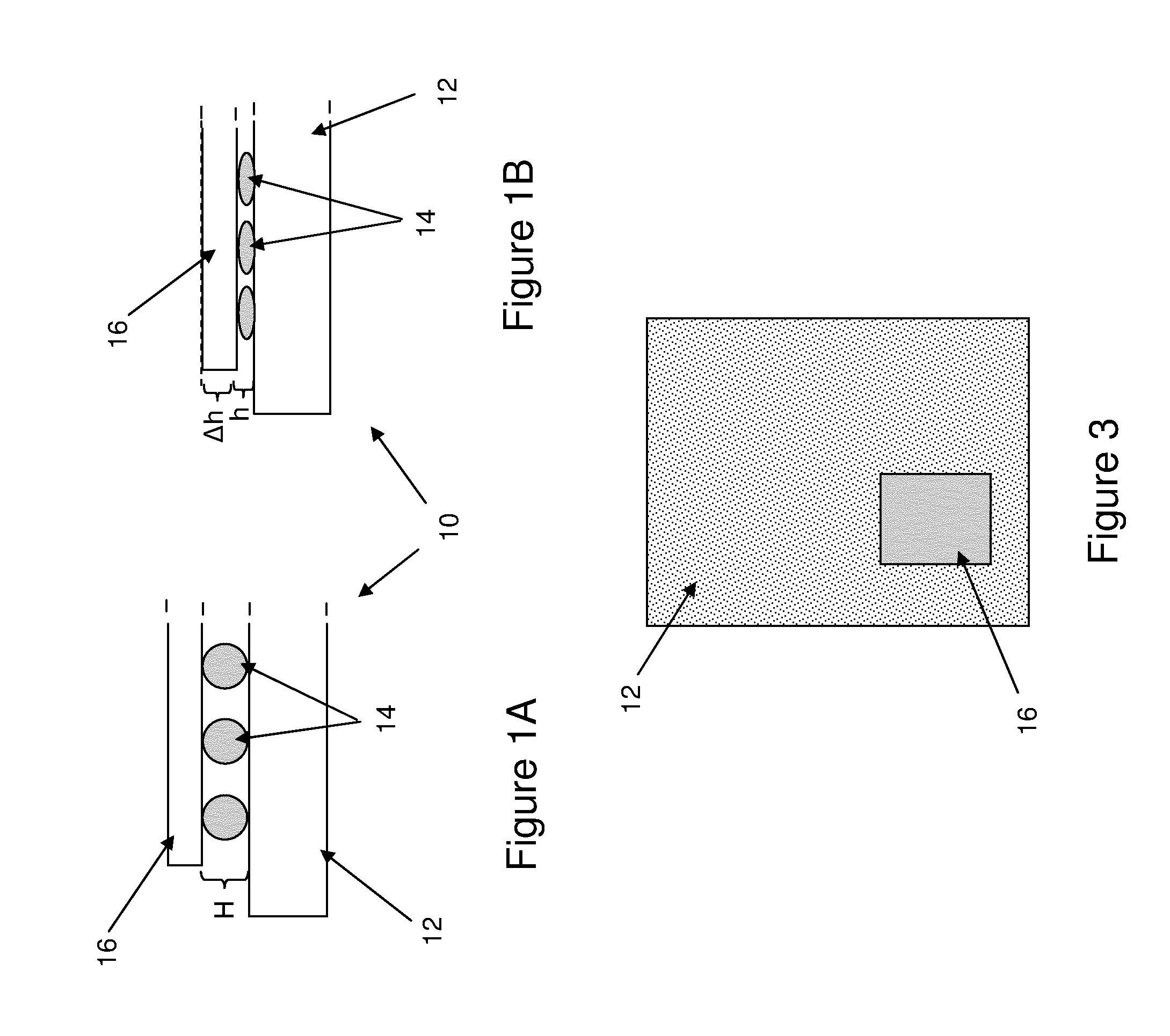

Light emitting diode (LED) test apparatus and method of manufacture

ActiveUS20180259570A1Charge coupling efficiencyEfficient Functional TestingSemiconductor/solid-state device testing/measurementDiode testingElectricityQuantum efficiency

Embodiments relate to functional test methods useful for fabricating products containing Light Emitting Diode (LED) structures. In particular, LED arrays are functionally tested by injecting current via a displacement current coupling device using a field plate comprising of an electrode and insulator placed in close proximity to the LED array. A controlled voltage waveform is then applied to the field plate electrode to excite the LED devices in parallel for high-throughput. A camera records the individual light emission resulting from the electrical excitation to yield a function test of a plurality of LED devices. Changing the voltage conditions can excite the LEDs at differing current density levels to functionally measure external quantum efficiency and other important device functional parameters.

Owner:APPLE INC

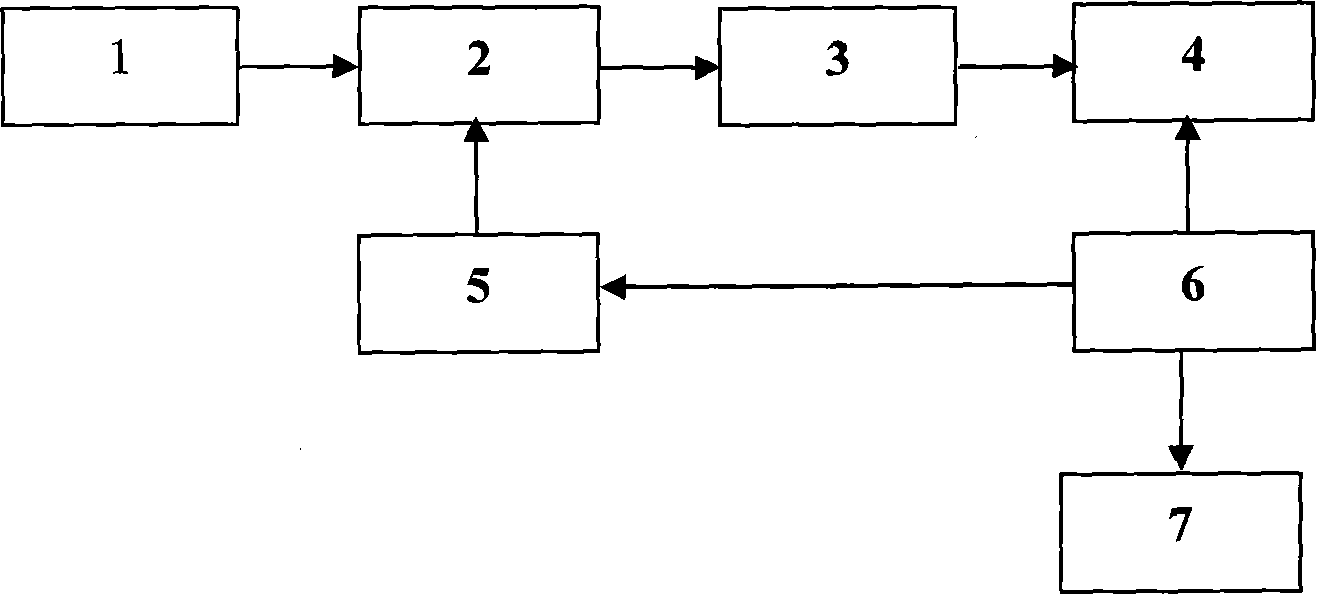

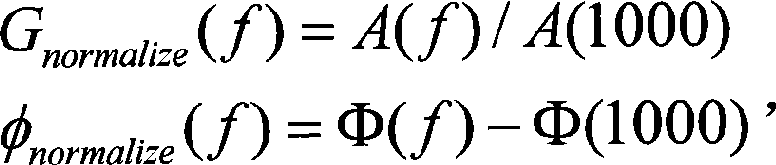

Photoelectric detector amplitude versus frequency character test method for optical fiber peg-top

InactiveCN101126784AAccurate Frequency CharacteristicsAccurately obtain frequency characteristicsSagnac effect gyrometersContactless testingGyroscopePhotodetector

The utility model discloses a method for testing the frequency properties of the photoelectric detector used for fiber optic gyroscopes. A signal generator produces sinusoidal signals and adds the signal to a light intensity modulator to carry out sinusoidal modulation on the optical power of the optical signal from the fiber source in order to produce an optical signal with sinusoidal components. The measured photodetector converts the modulated optical signal into an electrical signal and samples the electric signal by means of high-speed data acquisition card, then conducts narrowband filter and signal processing over the collected samples and calculates the corresponding frequency response. The frequency sequence pre-selected by a numerical control system changes the frequency at which the sine wave generator (NC) system sends out signals , tests a series of frequency point responses, which can be combined into an amplitude frequency response curve of the measured photodetector, and the curve is transmitted to the terminal computer for displaying and storage. By controlling all the test processes by numerical control system, the utility model has the advantages of automatic measurement, fast testing speed, high testing precision, and therefore is suitable for carefully weighing the photodetector frequency performance in the whole operating frequency range.

Owner:ZHEJIANG UNIV

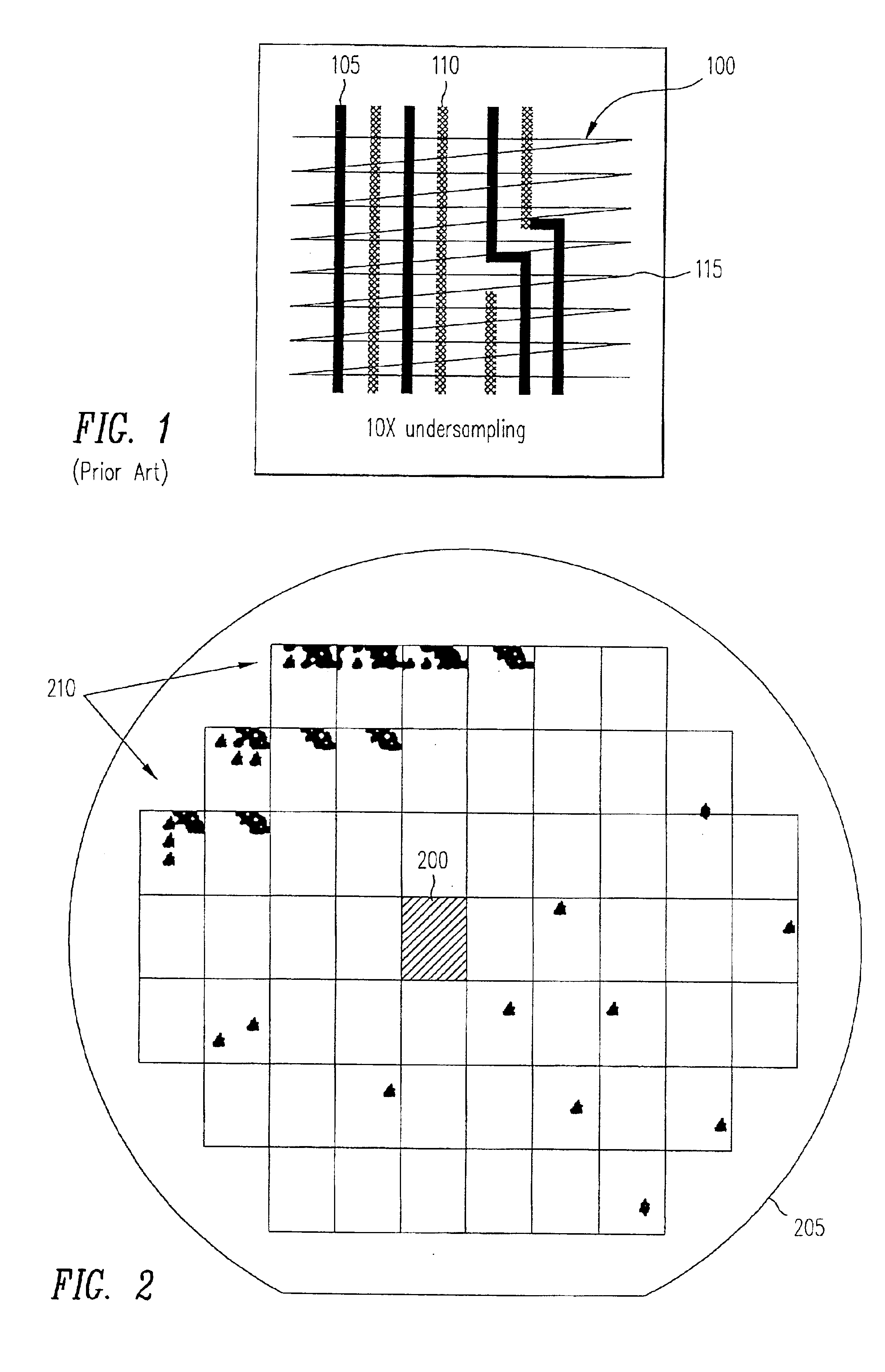

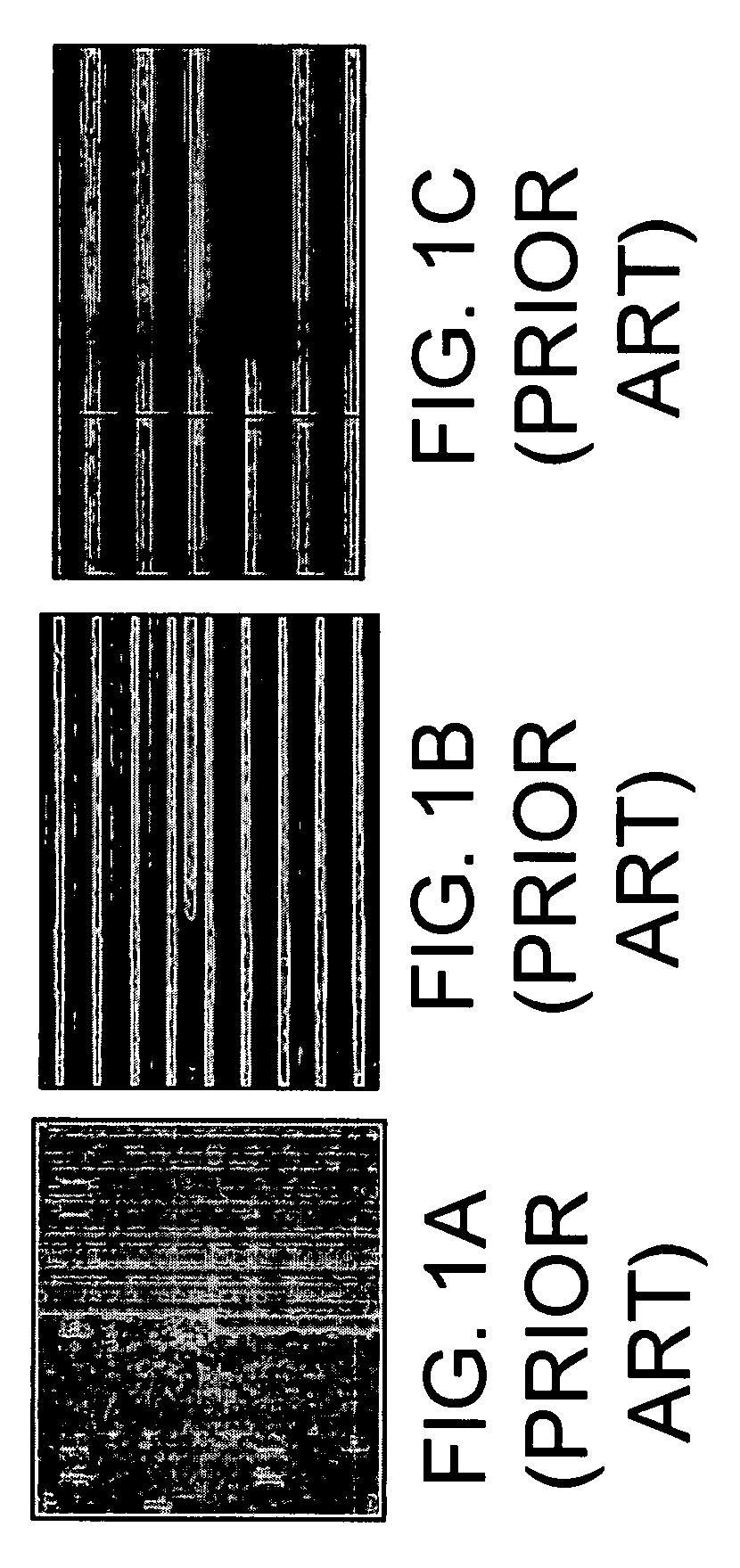

Detection of defects in patterned substrates

InactiveUS20050200841A1Image analysisSemiconductor/solid-state device testing/measurementImage resolutionPatterned substrate

One embodiment of the present invention is a method of detecting defects in a patterned substrate, including: (a) positioning a charged-particle-beam optical column relative to a patterned substrate, the charged-particle-beam optical column having a field of view (FOV) with a substantially uniform resolution over the FOV; (b) operating the charged-particle-beam optical column to acquire images of a region of the patterned substrate lying within the FOV by scanning the charged-particle beam over the patterned substrate; and (c) comparing the acquired images to a reference to identify defects in the patterned substrate.

Owner:APPLIED MATERIALS INC

Methods for inspecting semiconductor wafers

InactiveUS20150168303A1Provide usageSimple methodContactless testingFluorescence/phosphorescenceSemiconductor materialsPhotoluminescence

Methods and systems are presented for analysing semiconductor materials as they progress along a production line, using photoluminescence images acquired using line-scanning techniques. The photoluminescence images can be analysed to obtain spatially resolved information on one or more properties of said material, such as lateral charge carrier transport, defects and the presence of cracks. In one preferred embodiment the methods and systems are used to obtain series resistance images of silicon photovoltaic cells without making electrical contact with the sample cell.

Owner:BT IMAGING PTY LTD

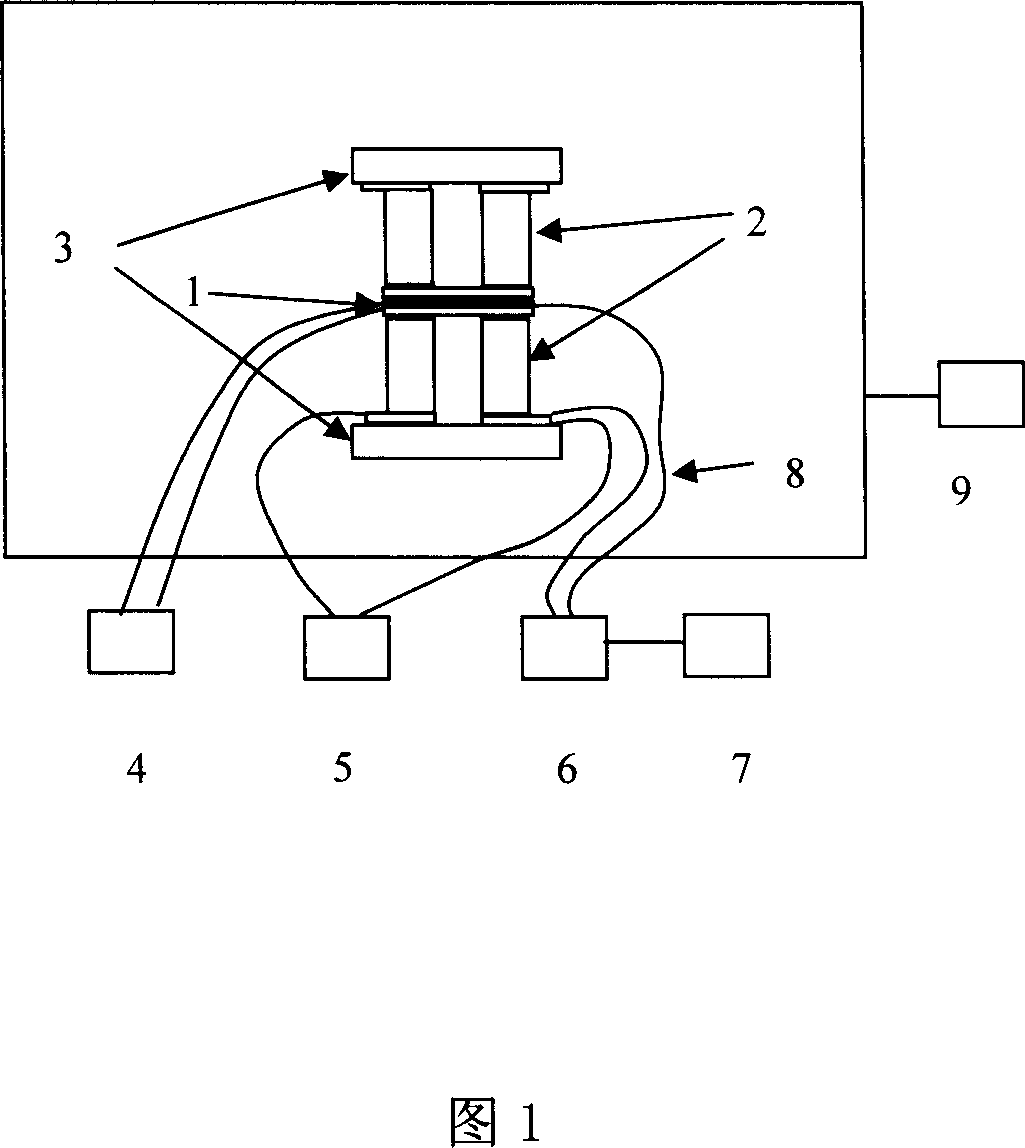

Thermoelectric power generating component performance measuring device and method thereof

ActiveCN1975448AAvoid lostSimple structureSemiconductor/solid-state device testing/measurementThermoelectric device manufacture/treatmentPresent methodMeasurement device

The invention relates to a detection device and the method for the thermoelectric electric power generation performance. The detection device is made up of the thermal resource, the cooling end, the DC, the standard load resistance, the multicenter data collector, the computer ,the thermocouple and the vacuum pump. The method is to install the two thermoelectric power generation devices between the thermal resource and the cooling end at the same time, the output of which is connected with the standard load resistance, so it can get the output power by changing the standard load resistance which contrasts to the input power to get the energy conversion efficiency. The invention can avoid the heat loss of the input measurement system by using the double detection symmetrical thermal resource, comparing to the present method, the device has the simple structure and high efficiency, and also it can detect the energy conversion efficiency directly.

Owner:中科西卡思(苏州)科技发展有限公司

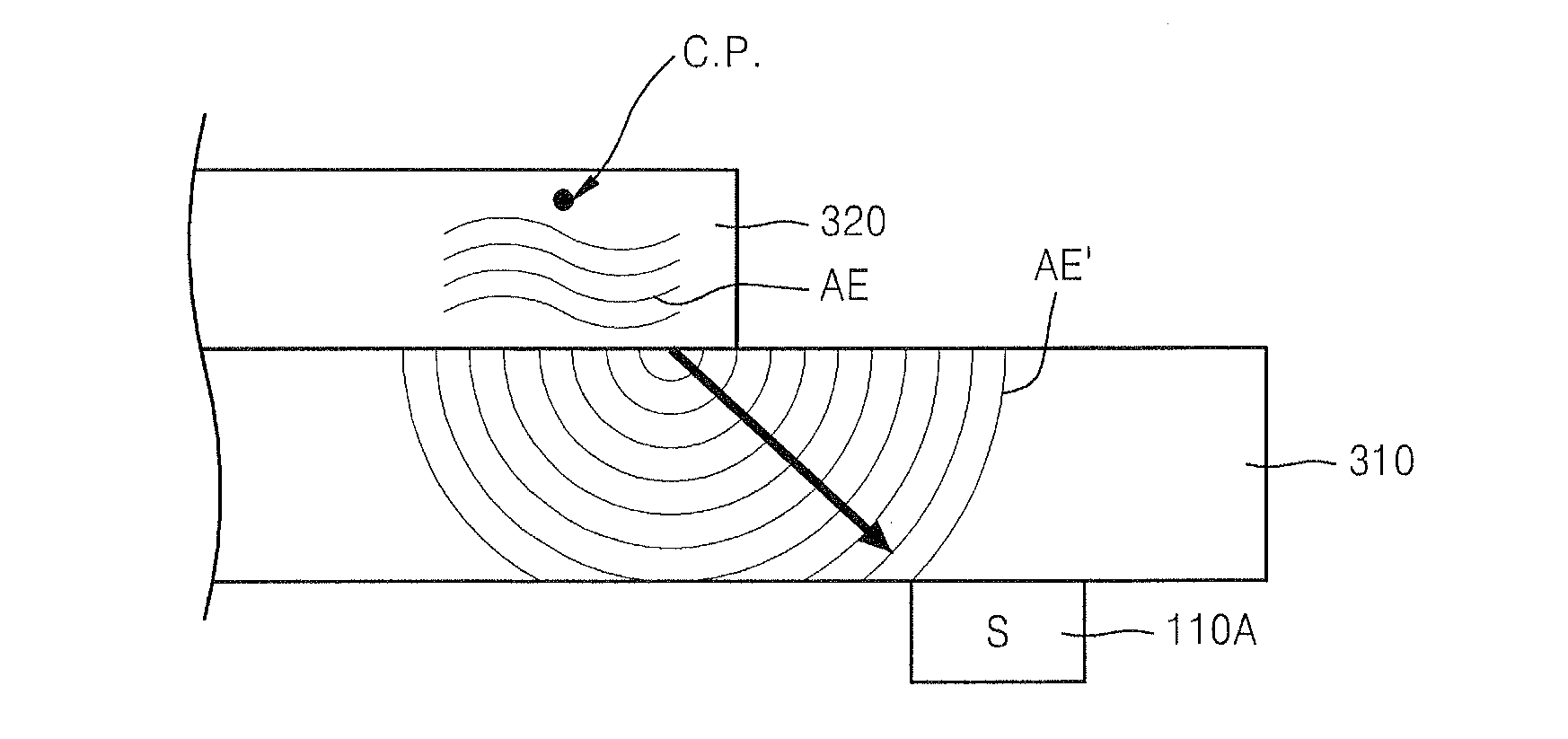

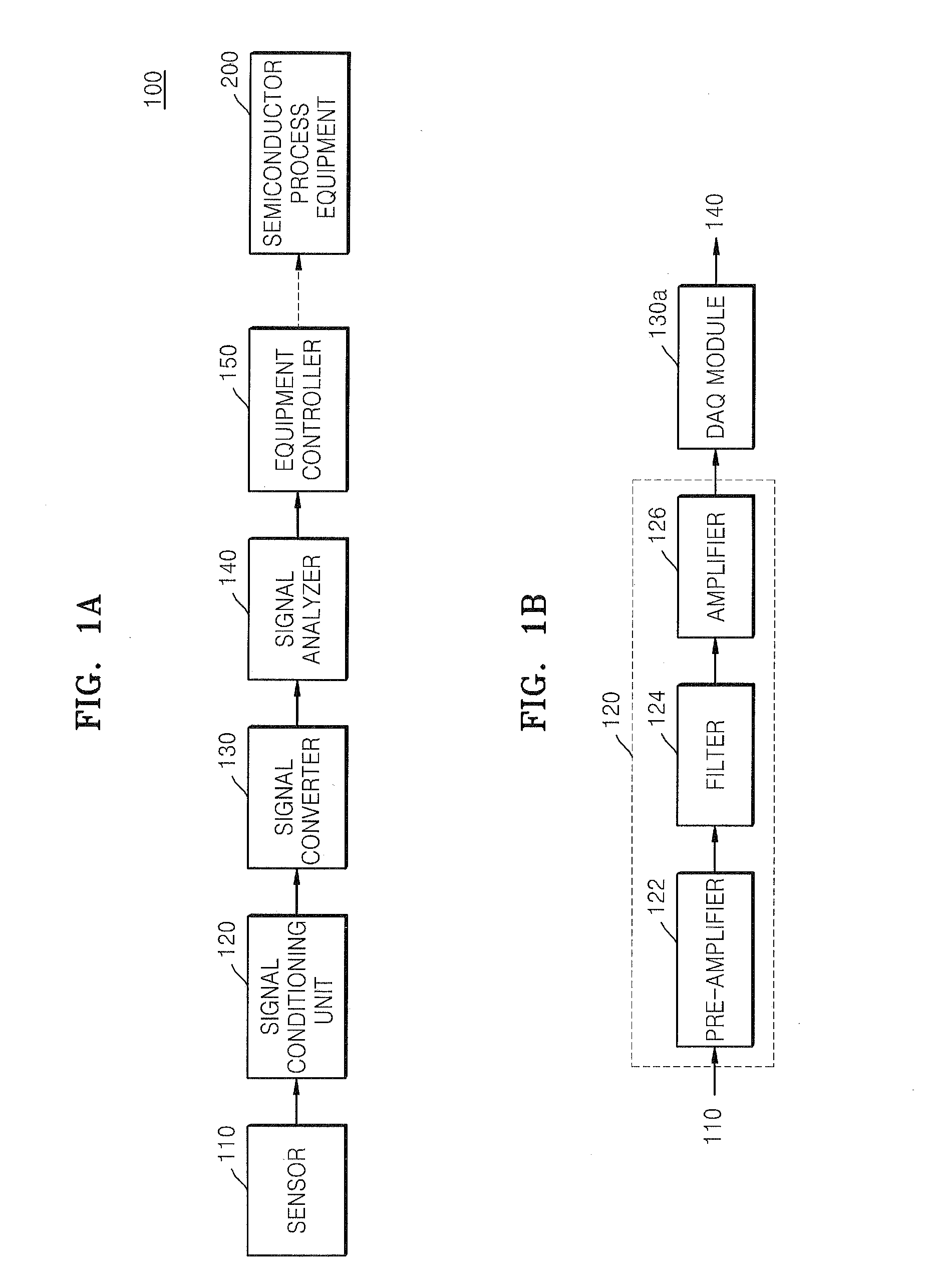

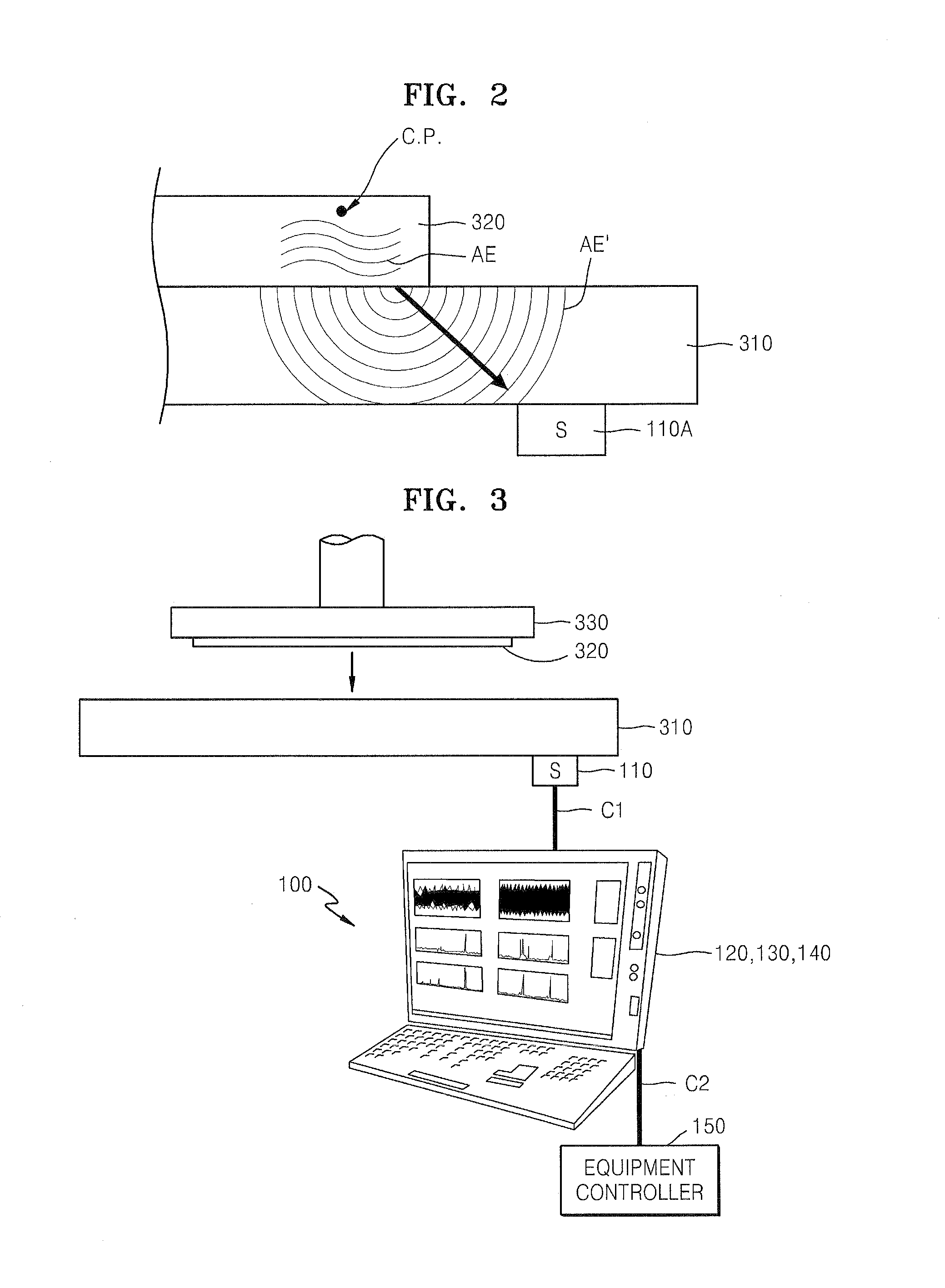

Apparatus and method of detecting a defect of a semiconductor device

InactiveUS20140208850A1Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesProcess equipmentDevice material

A semiconductor device defect detecting apparatus including: a sensor disposed on semiconductor process equipment, the sensor configured to detect a signal emitted from a semiconductor device in contact with the semiconductor process equipment; and a signal analyzer configured to determine whether the semiconductor device is defective based on the detected signal in a predetermined frequency range.

Owner:SAMSUNG ELECTRONICS CO LTD

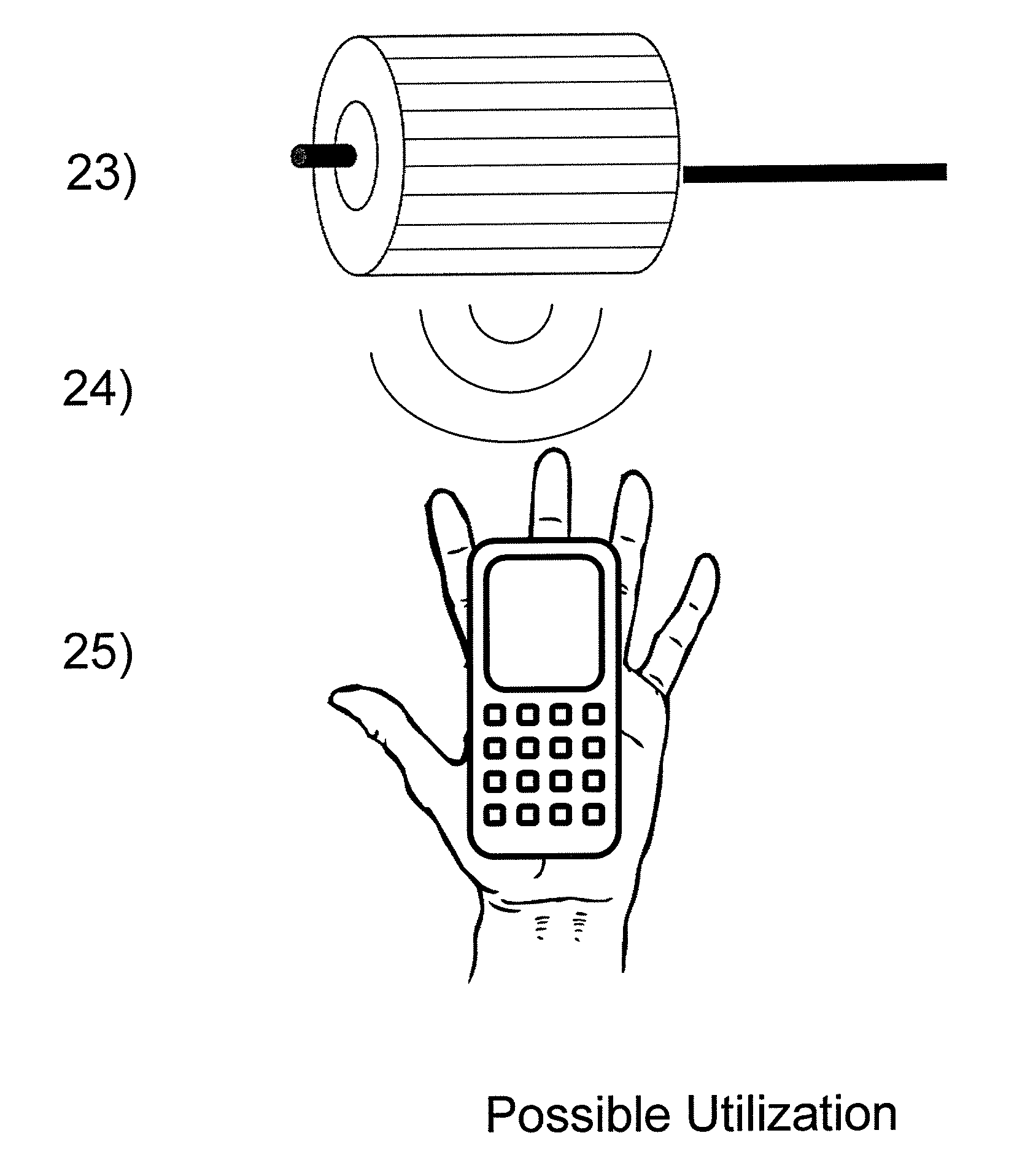

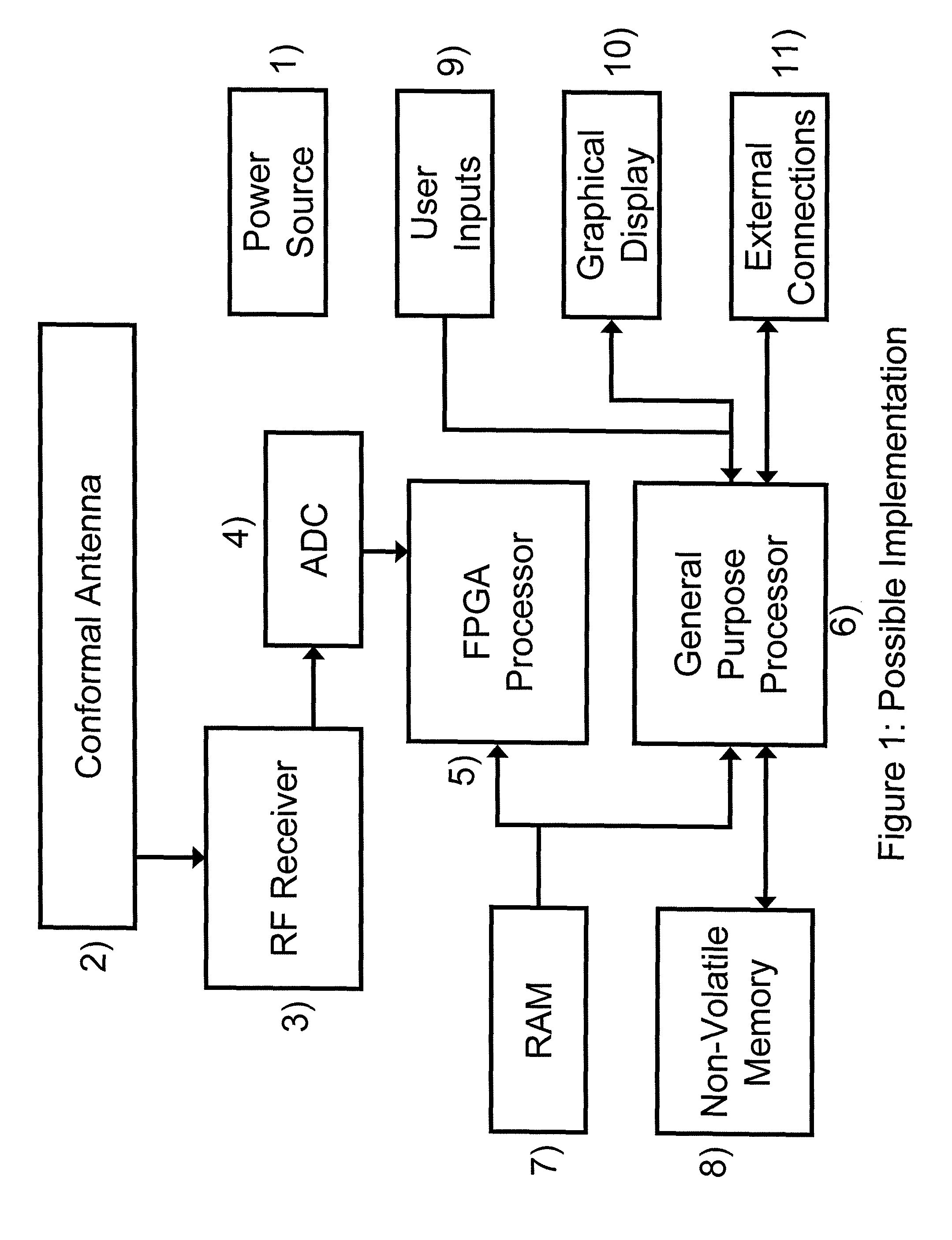

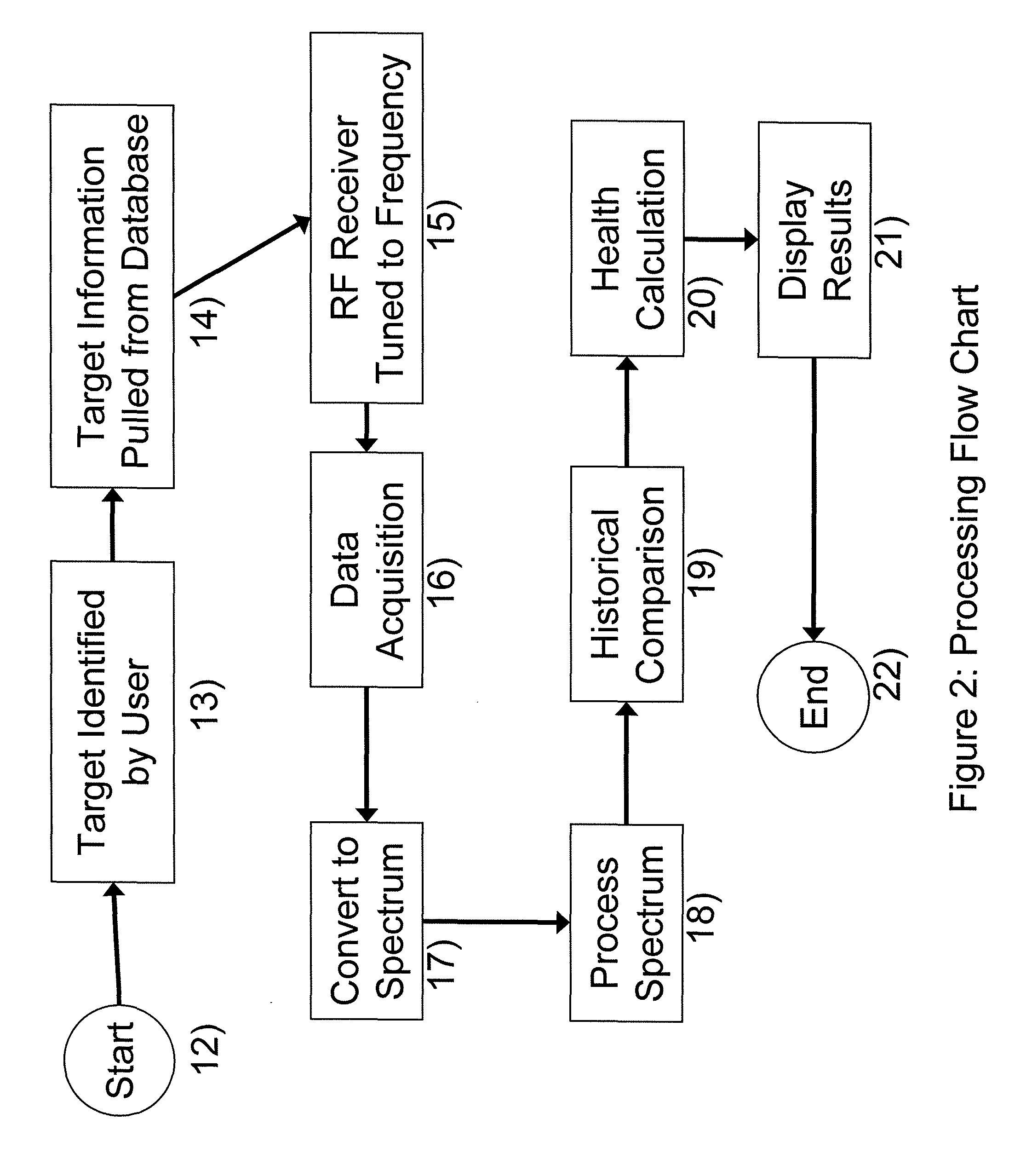

Advance manufacturing monitoring and diagnostic tool

ActiveUS8643539B2Easily employedEasy accessElectric winding testingTransformers testingElectricityElectrical devices

The current invention relates to a monitoring and analysis device and a method for monitoring and analysis that utilizes the unintended electromagnetic emissions of electrically powered systems. The present invention monitors electrical devices by taking detailed measurements of the electromagnetic fields emitted by any component or system utilizing electricity. The measurements will be analyzed to both record a baseline score for future measurements and to be used in detailed analysis to determine the status of the analyzed system or component.

Owner:NOKOMIS

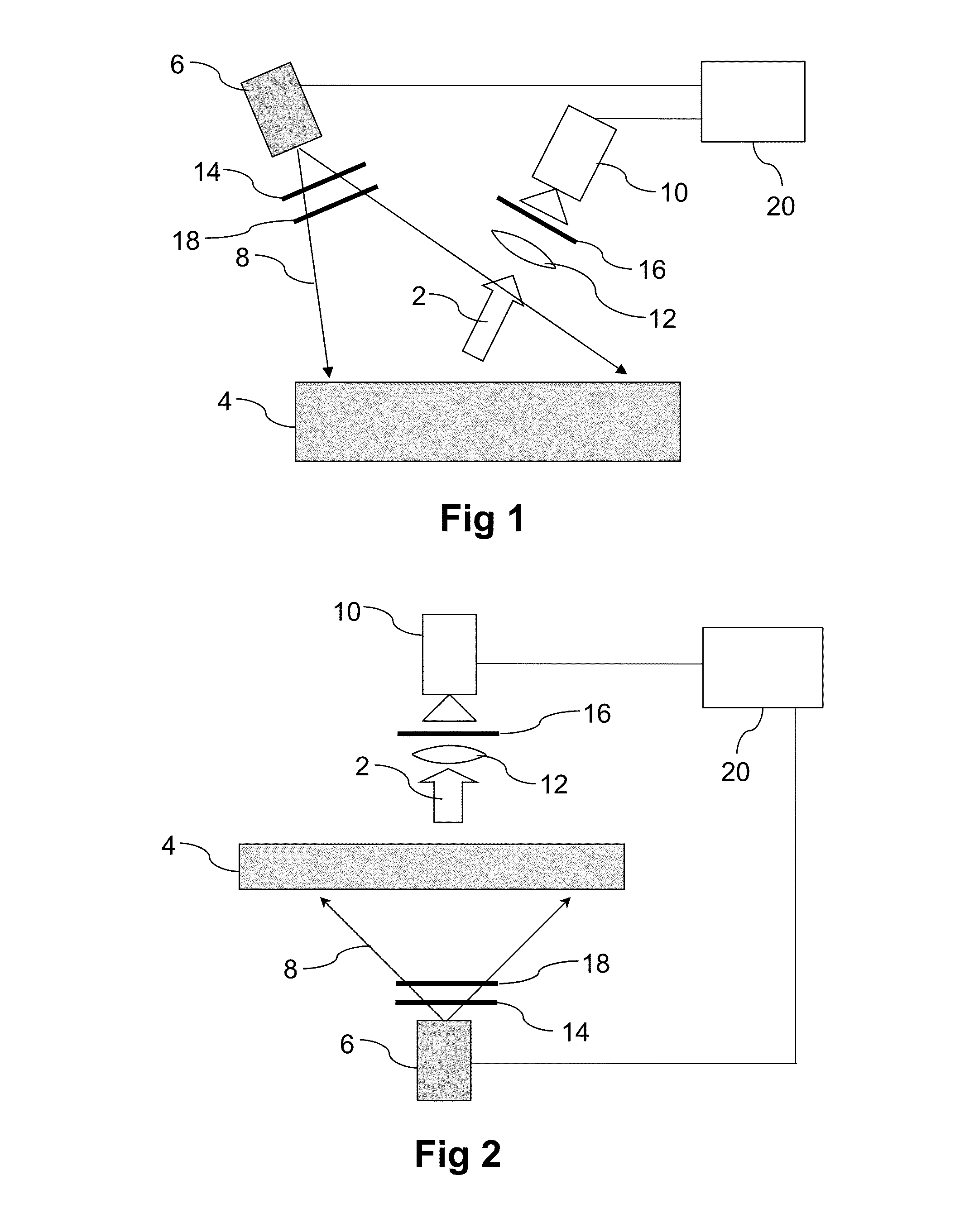

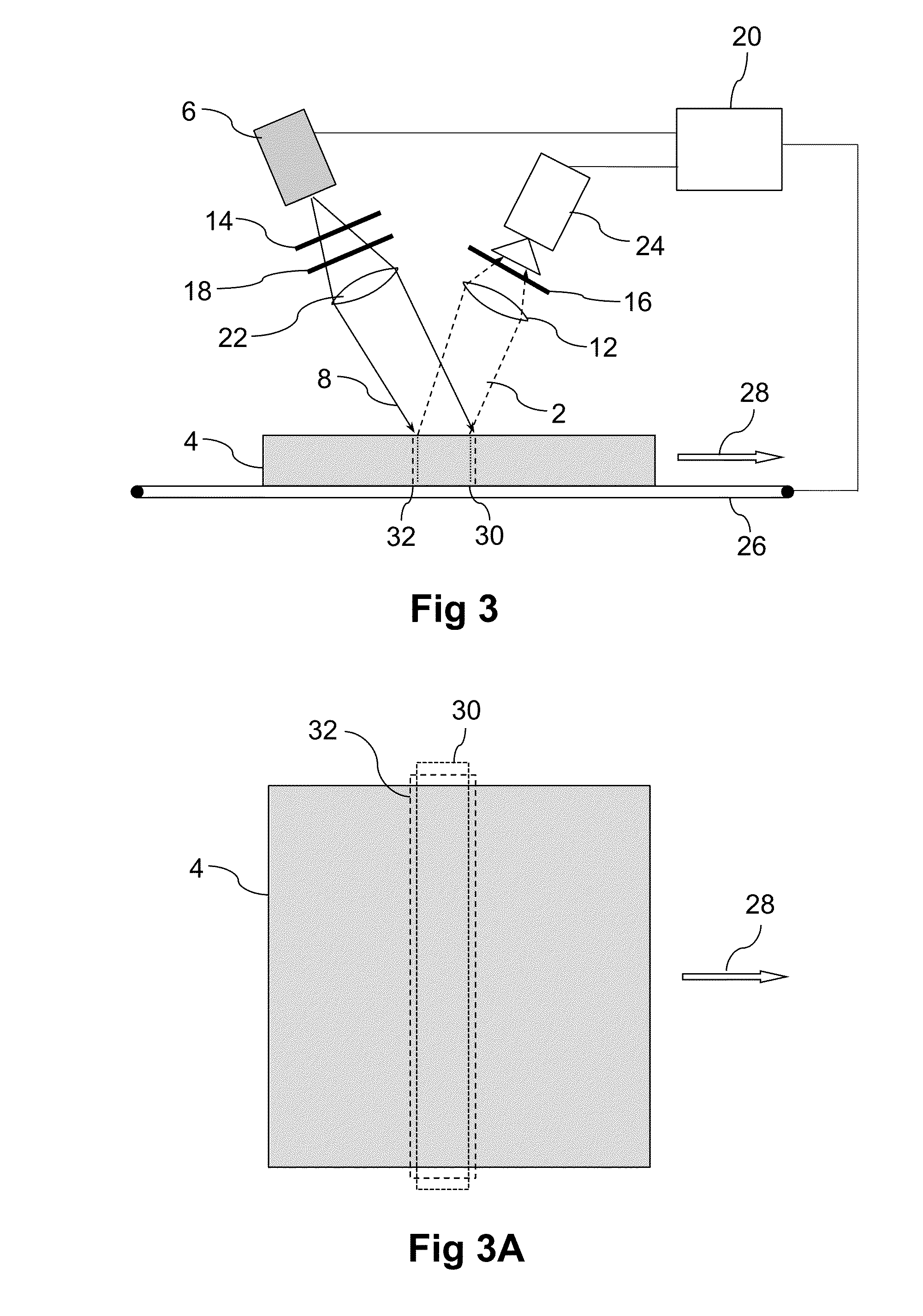

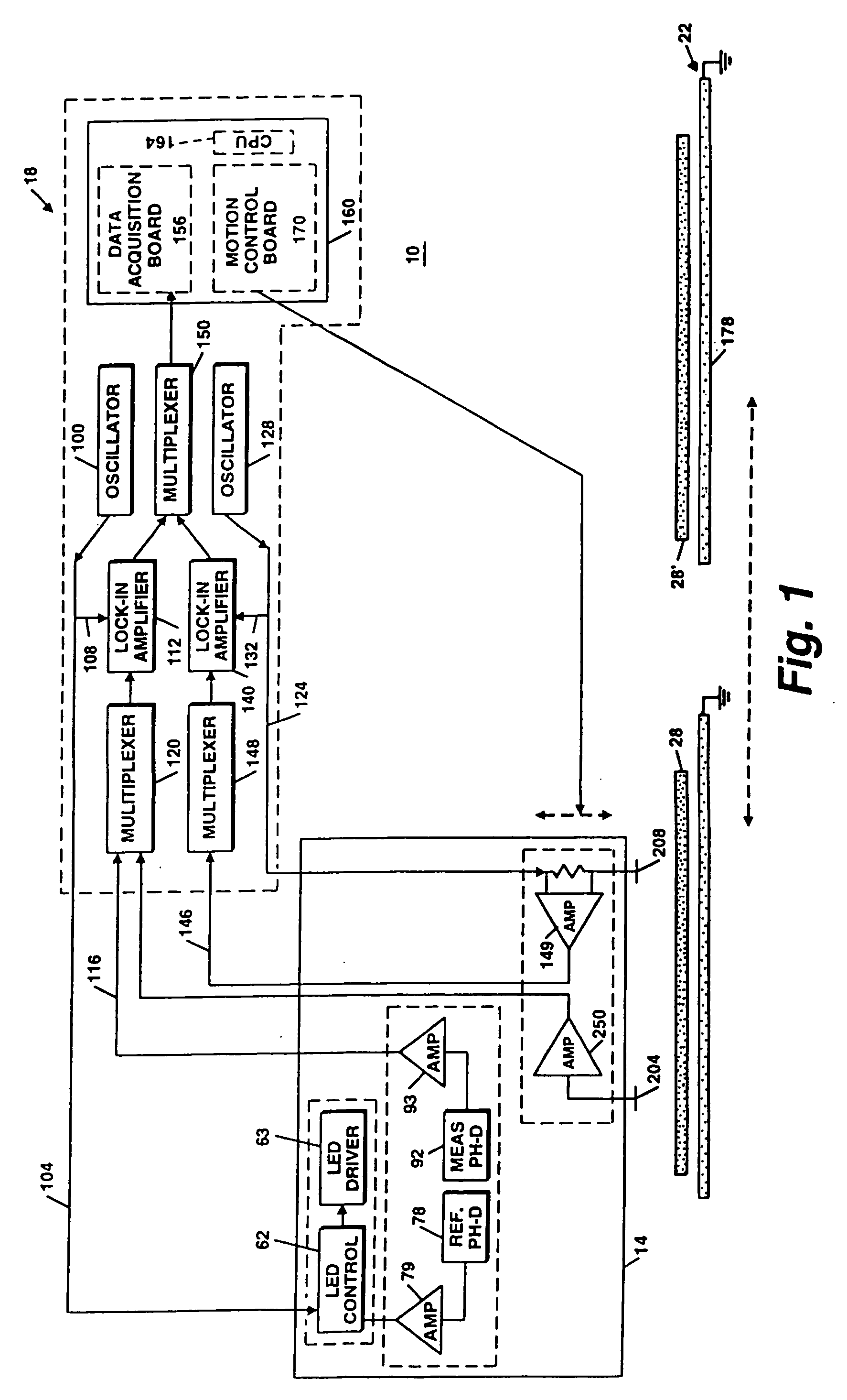

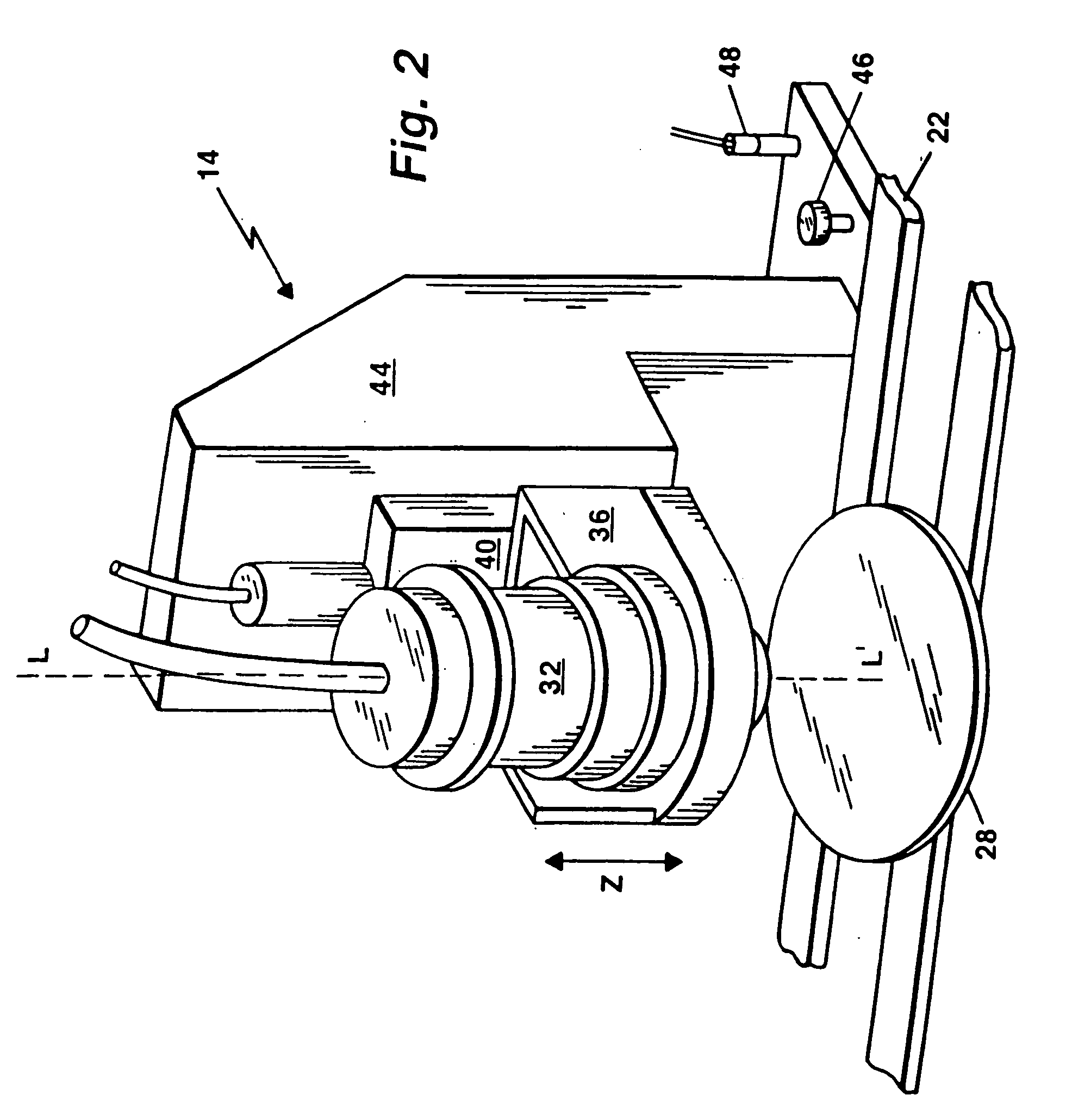

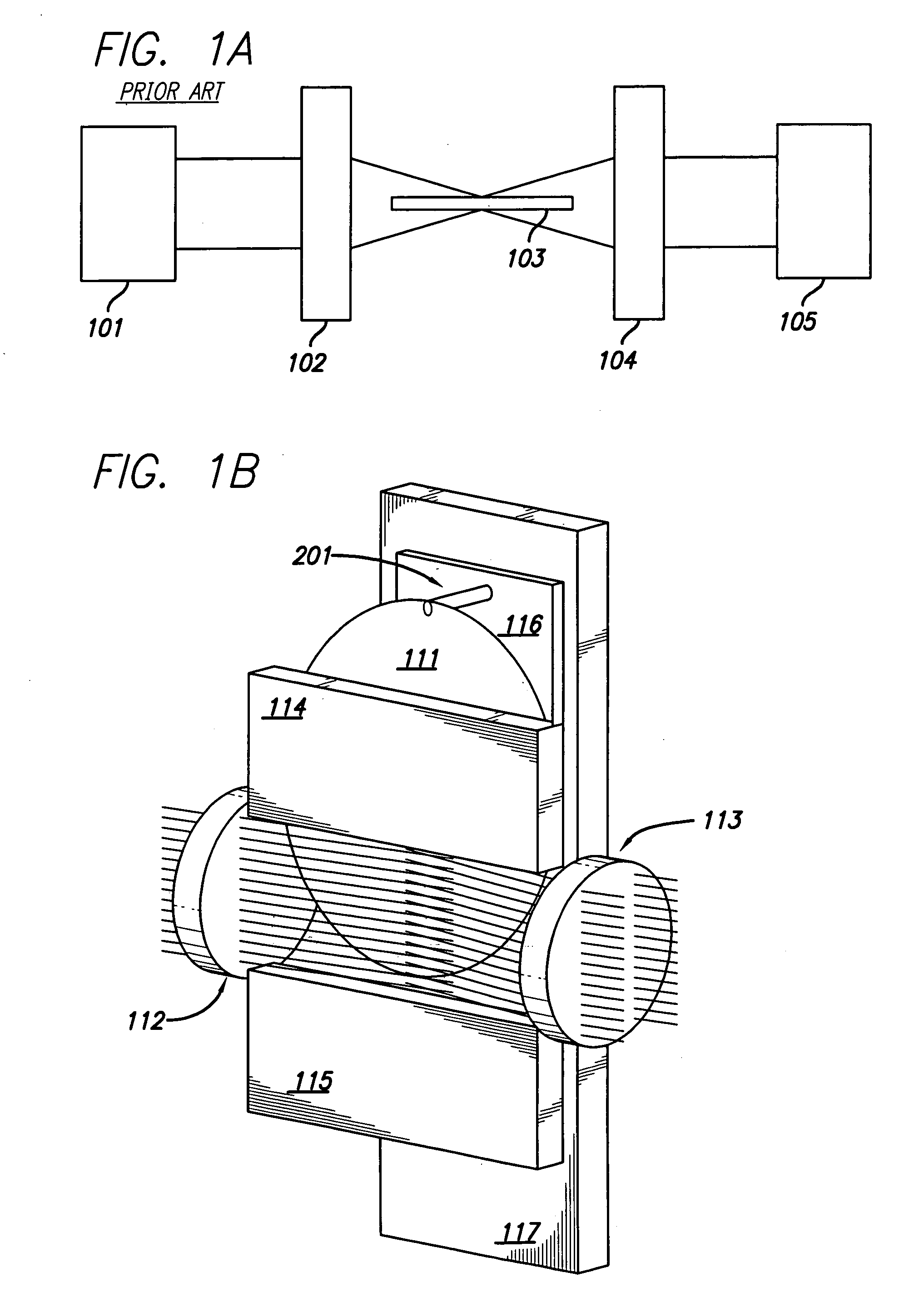

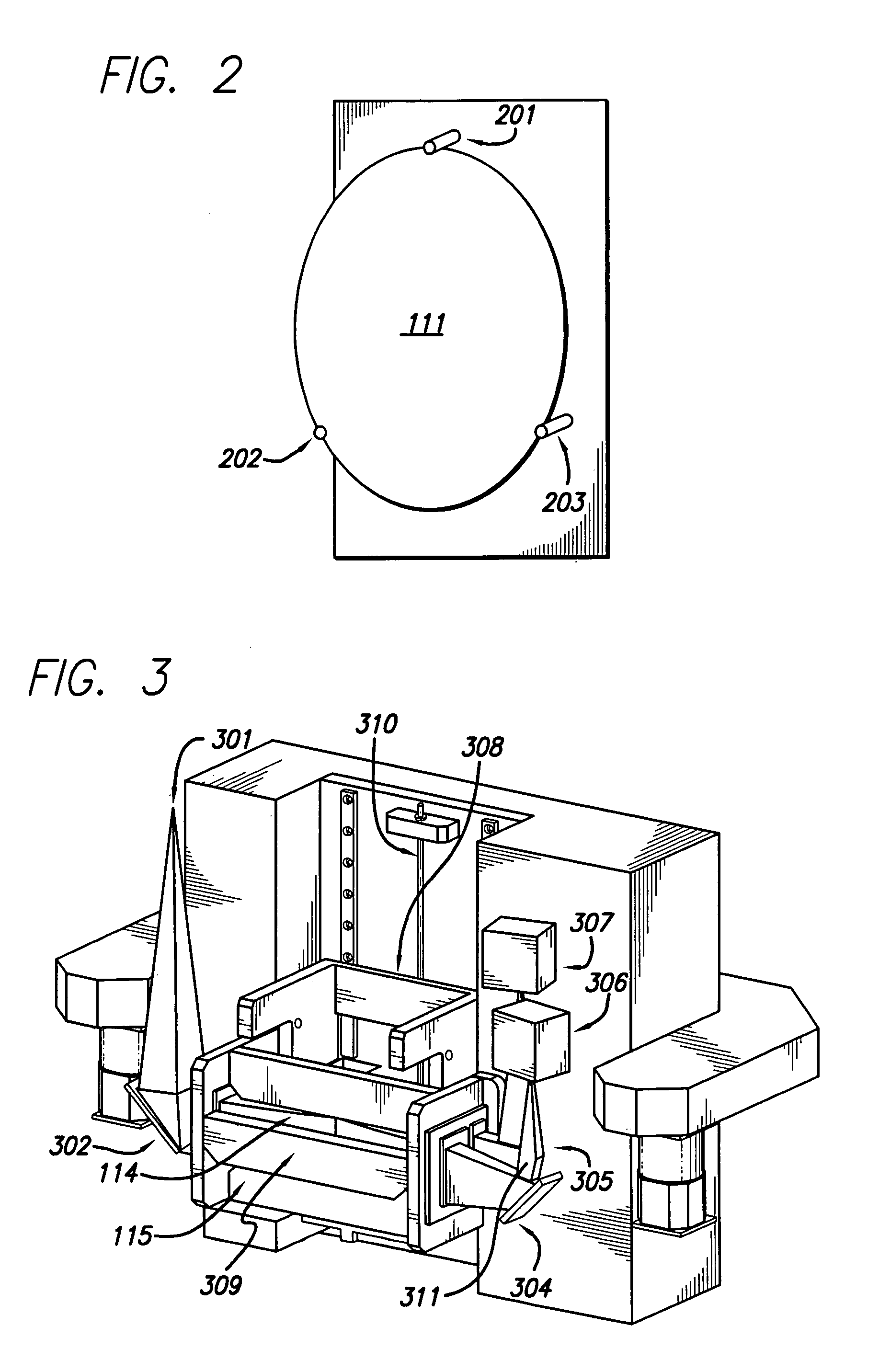

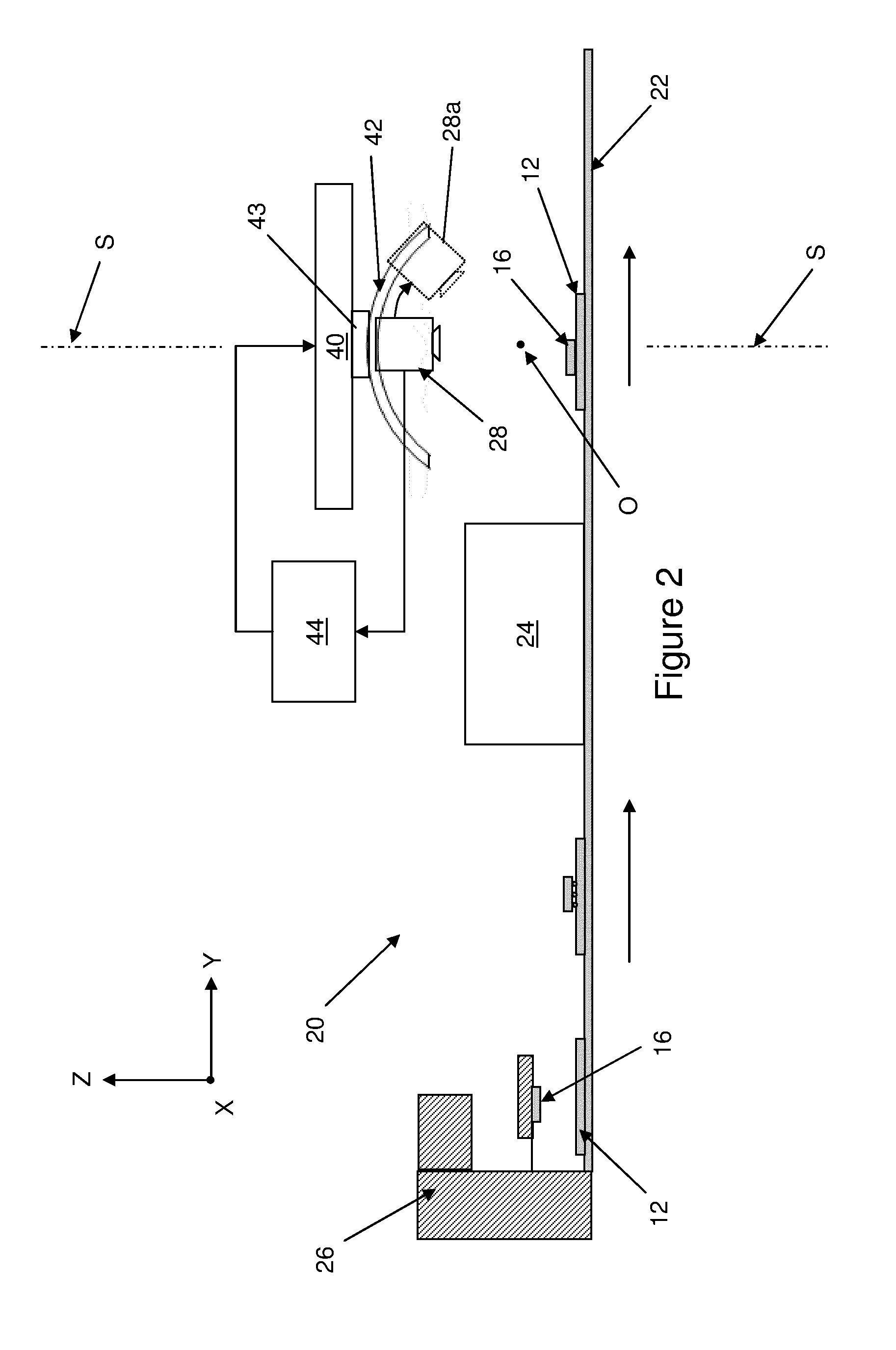

Real-time in-line testing of semiconductor wafers

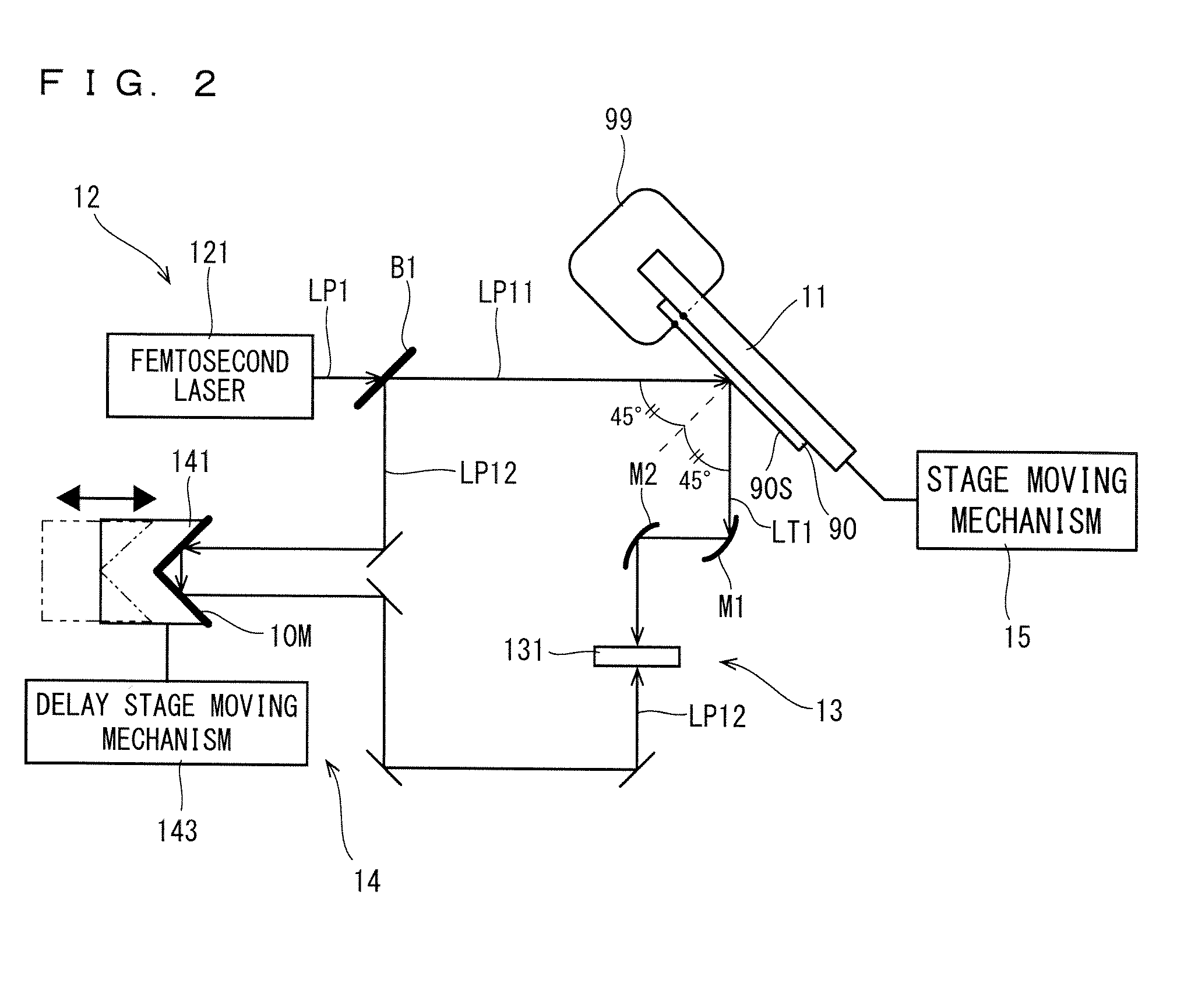

InactiveUS20050196882A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingLength waveFrequency modulation

A method and apparatus for measuring damage of an ion implanted semiconductor wafer during semiconductor processing. The method includes the steps of conveying the wafer such that a surface of the wafer is substantially parallel to a surface photovoltage electrode of a head assembly during the semiconductor processing and exposing at least a portion of said wafer to light having a wavelength, and an intensity and modulating the light intensity at a predefined frequency. The method also includes the step of varying the frequency of the light intensity modulation and detecting the surface photovoltage in response to light modulated at the various frequencies using the surface photovoltage electrode. The method then calculates an electrical property of the wafer from the photovoltage induced at the surface of the wafer at each of the light intensity modulation frequencies.

Owner:SEMILAB SEMICON PHYSICS LAB

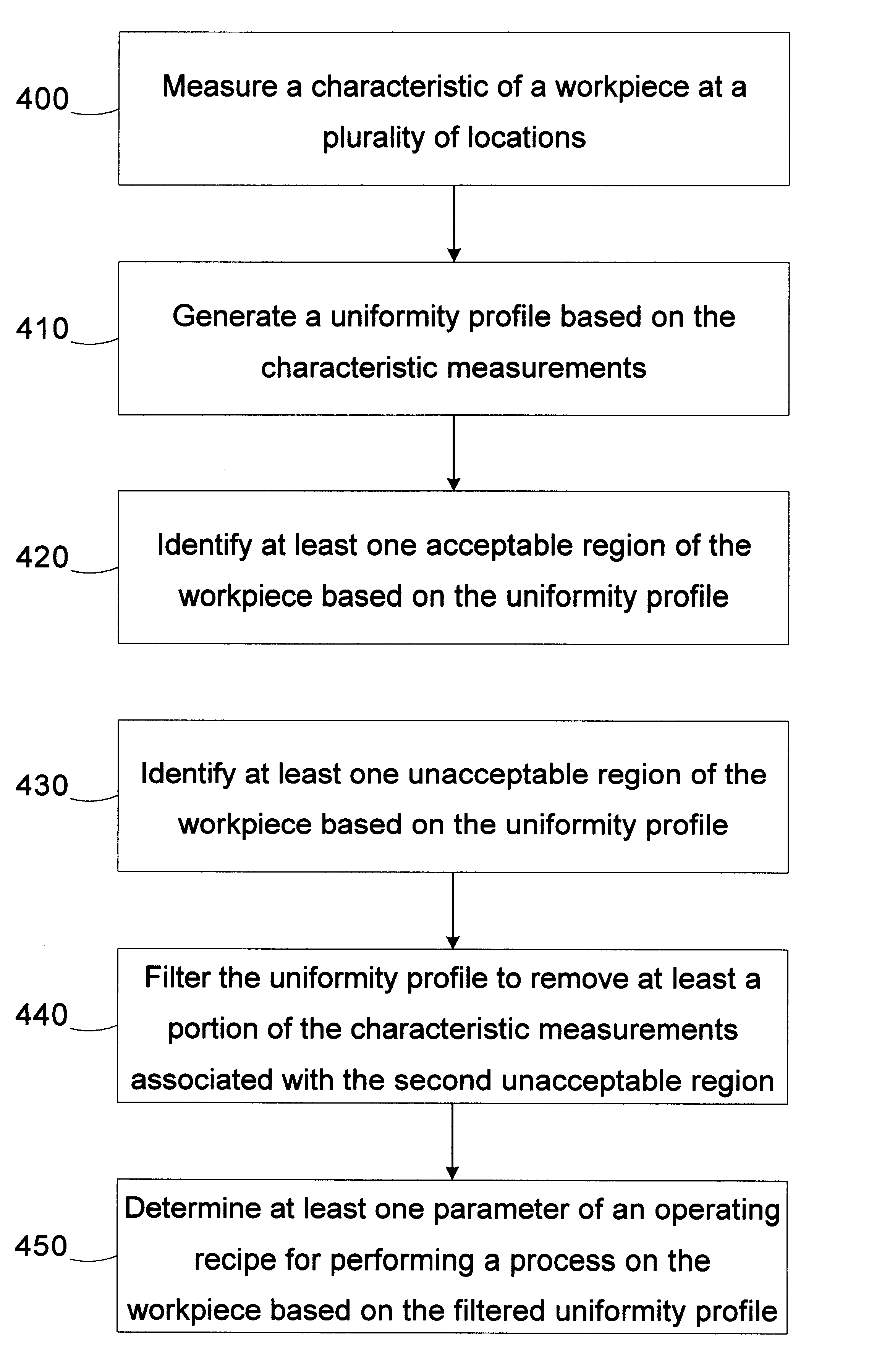

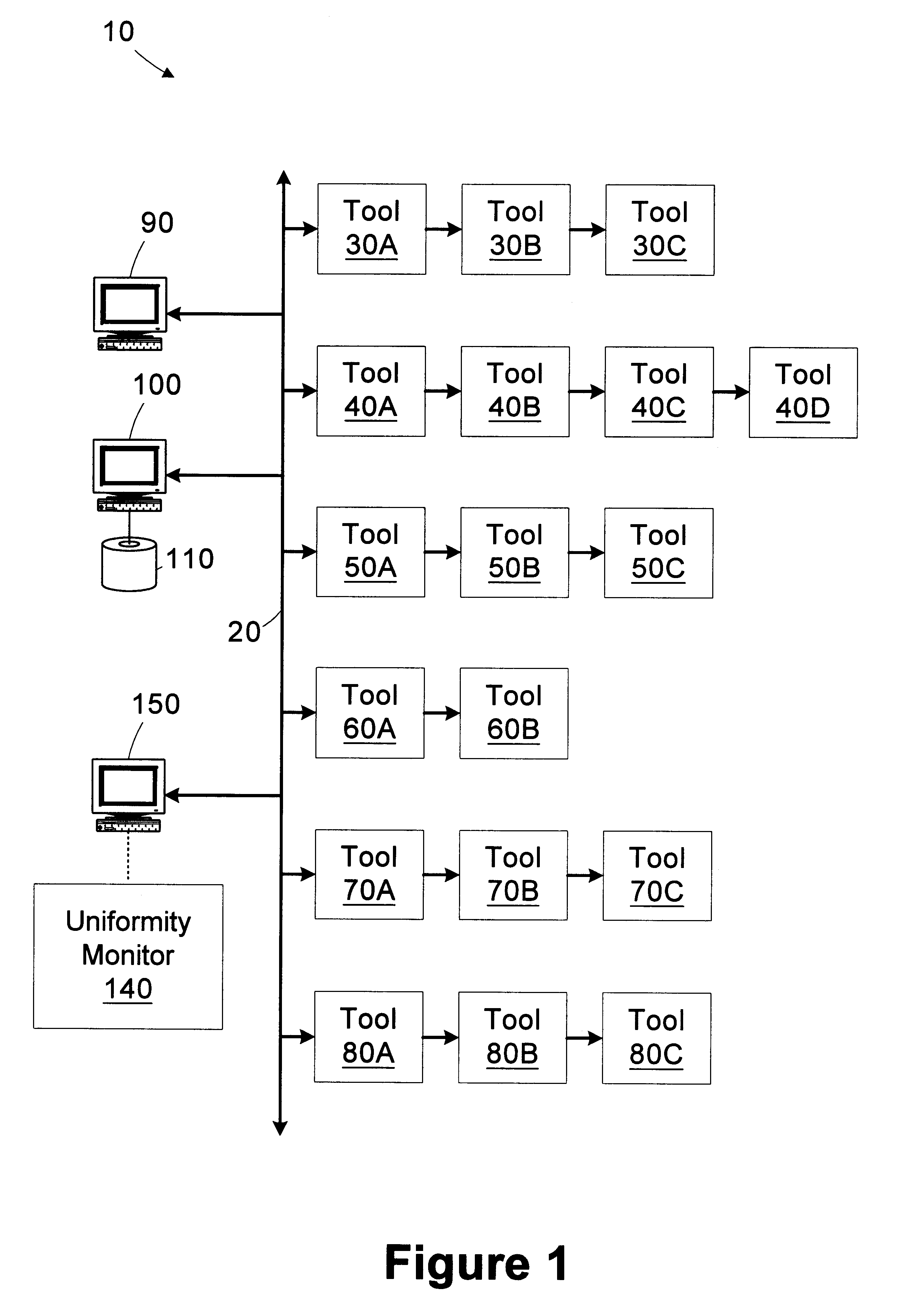

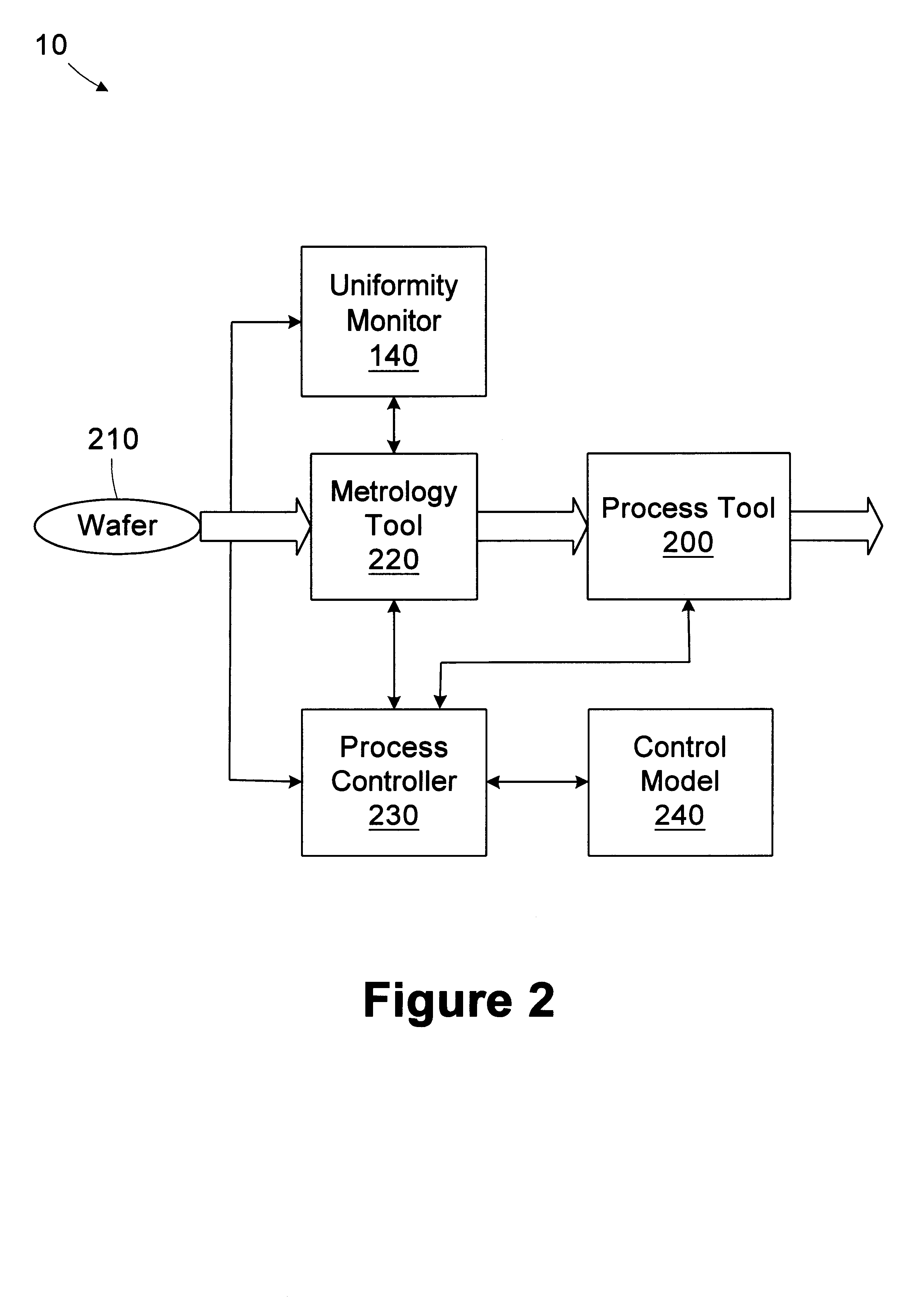

Method and apparatus for optimizing downstream uniformity

InactiveUS6665623B1Semiconductor/solid-state device testing/measurementElectronic circuit testingEngineeringFeature based

A method includes measuring a characteristic of a workpiece at a plurality of locations. A uniformity profile is generated based on the characteristic measurements. At least one acceptable region of the workpiece is identified based on the uniformity profile. At least one unacceptable region of the workpiece is identified based on the uniformity profile. The uniformity profile is filtered to remove at least a portion of the characteristic measurements associated with the second unacceptable region. At least one parameter of an operating recipe for performing a process on the workpiece is determined based on the filtered uniformity profile.

Owner:GLOBALFOUNDRIES INC

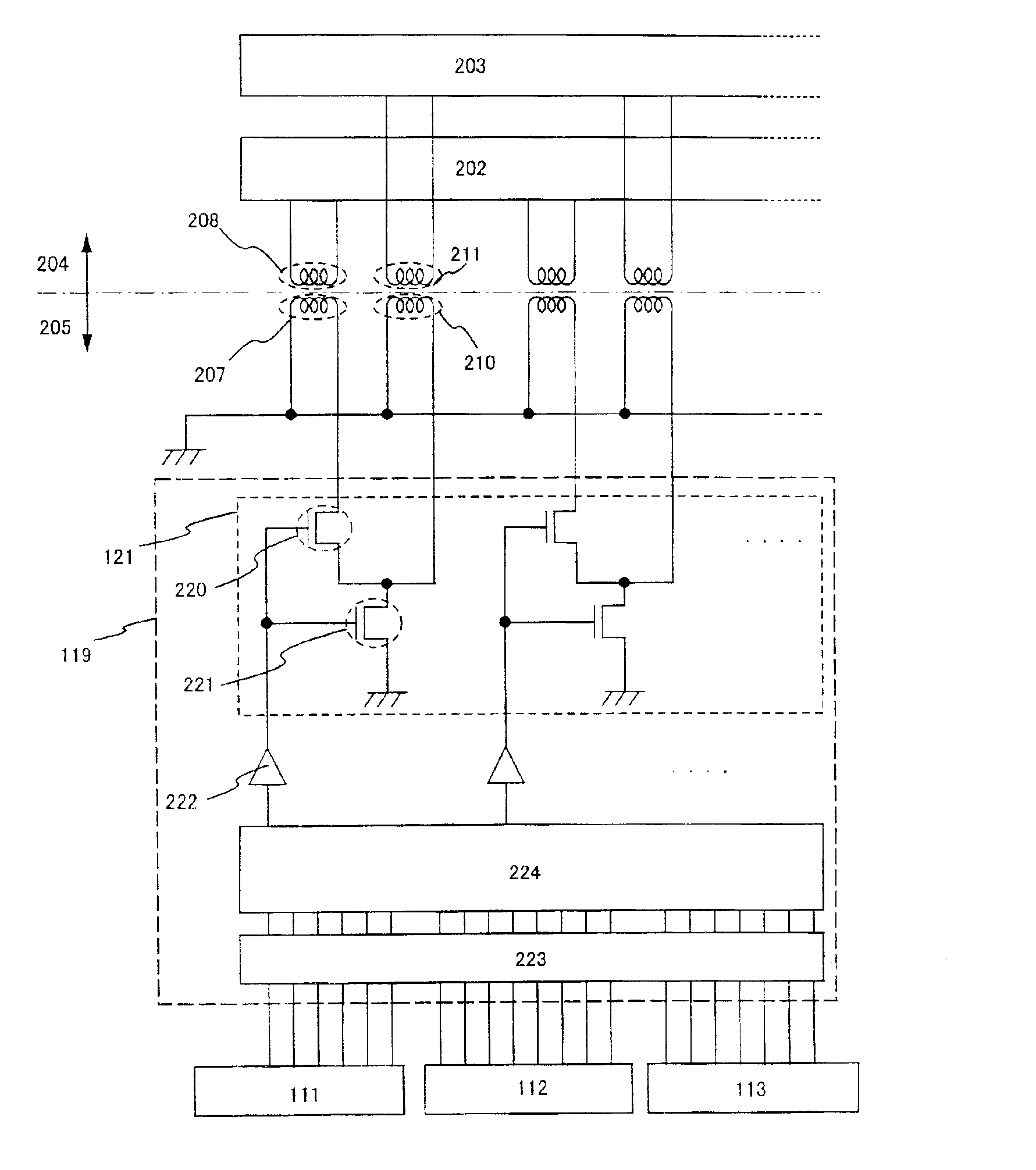

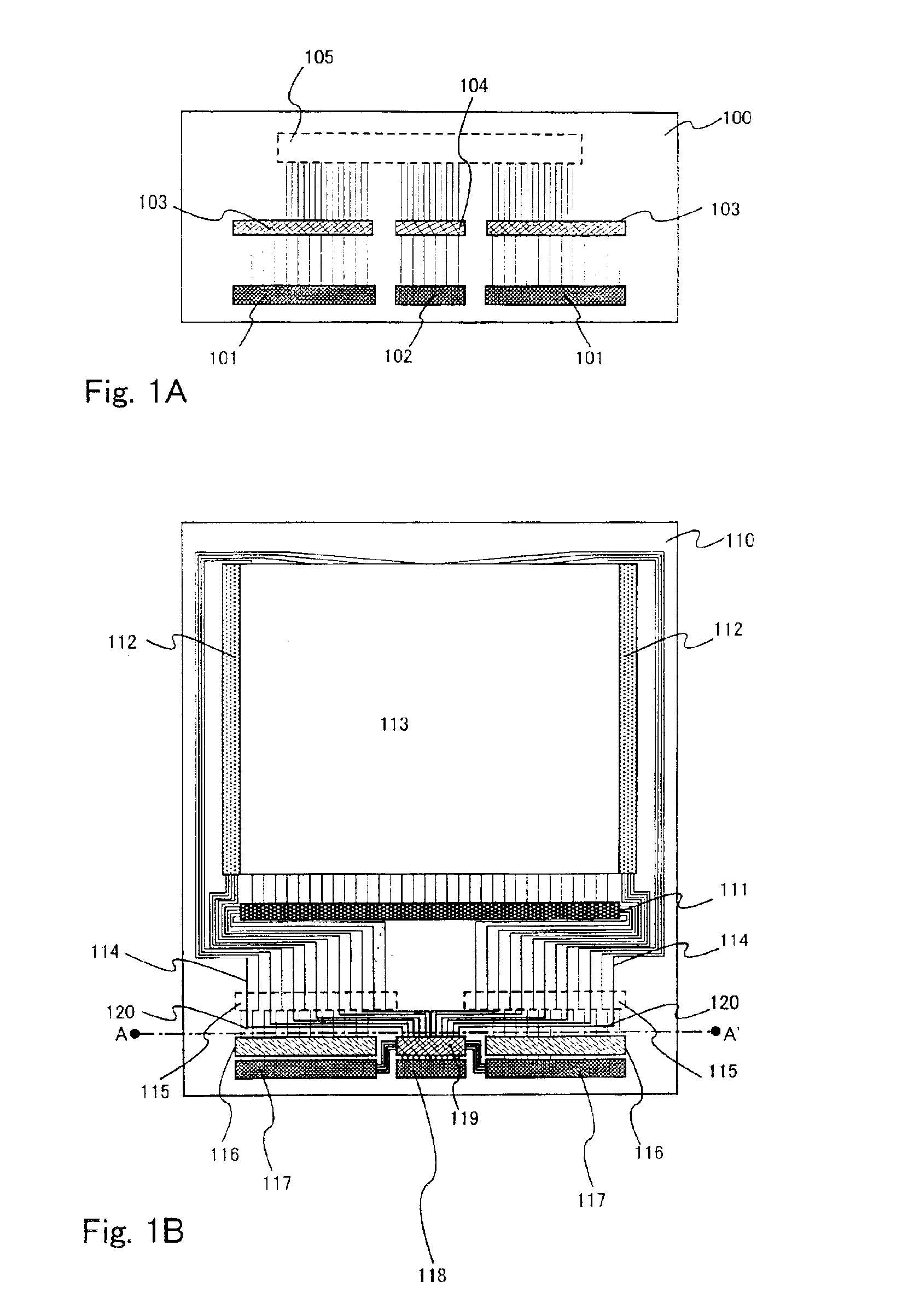

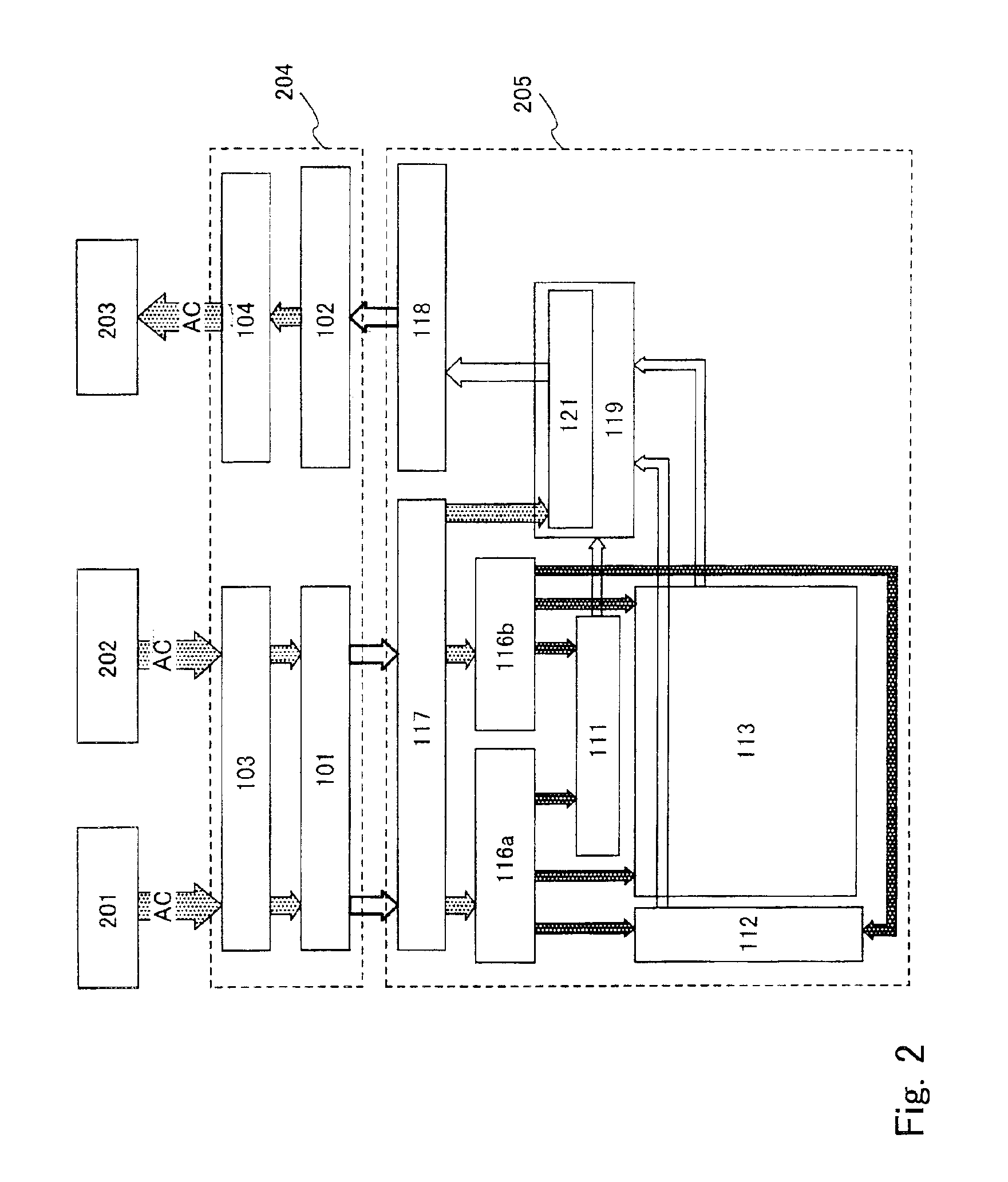

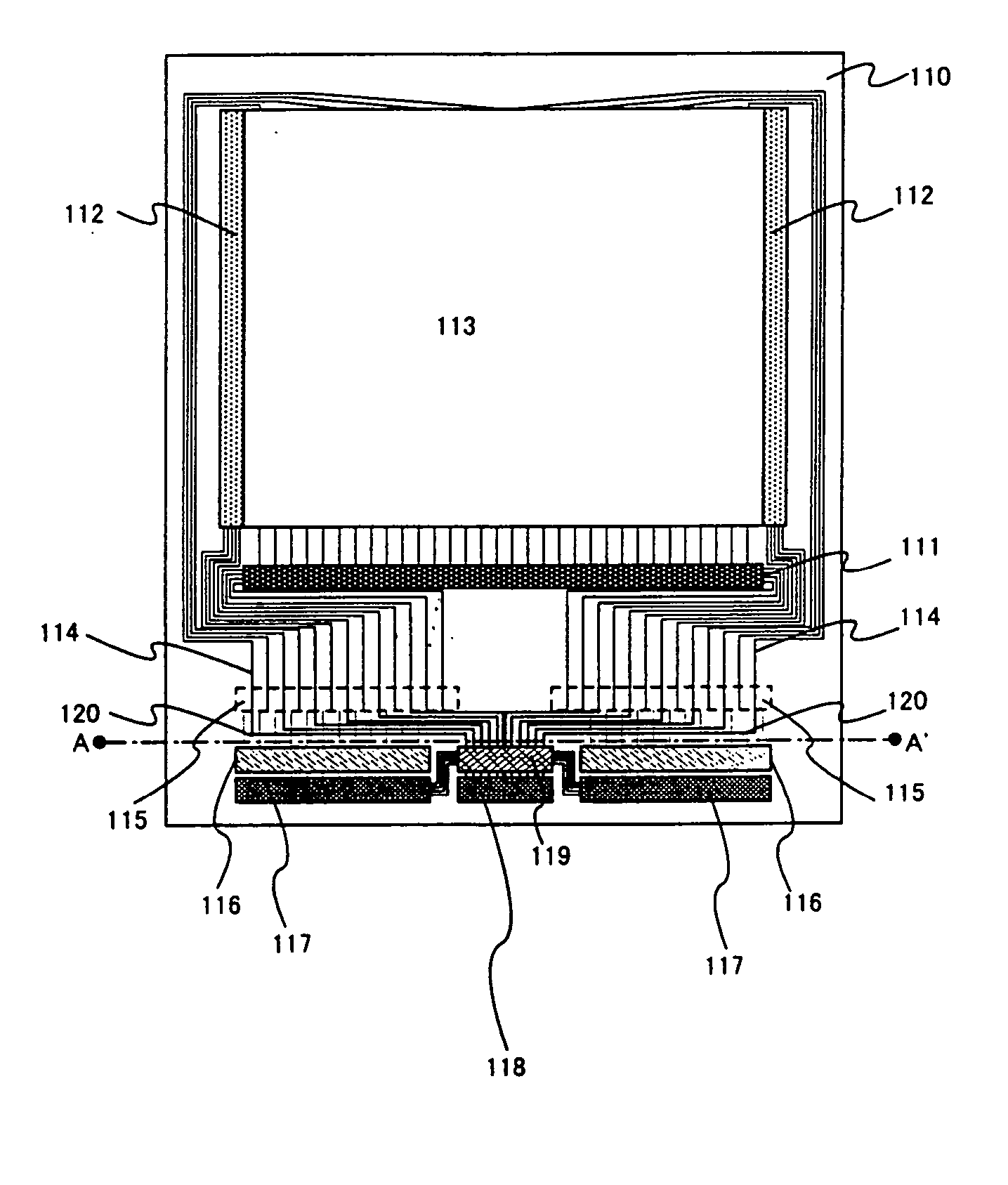

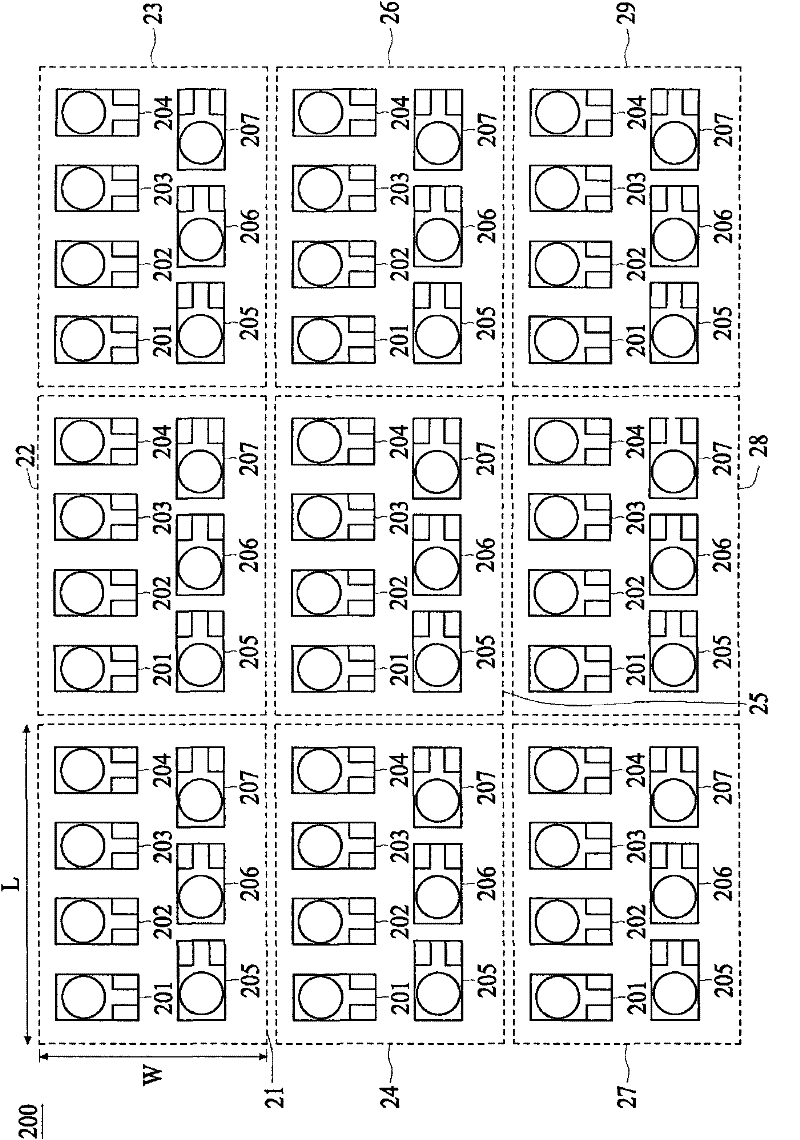

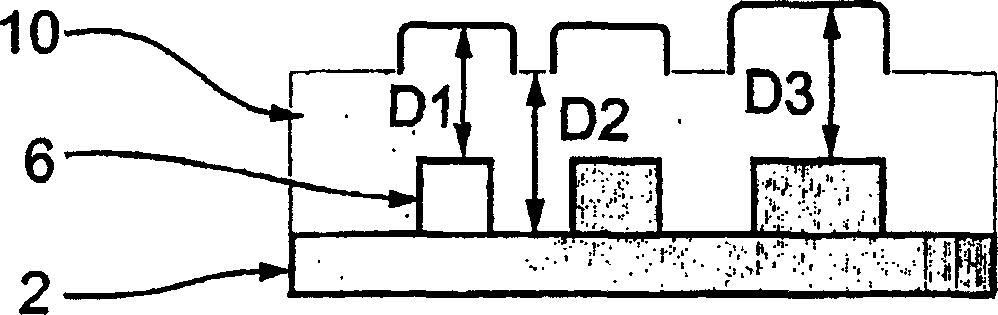

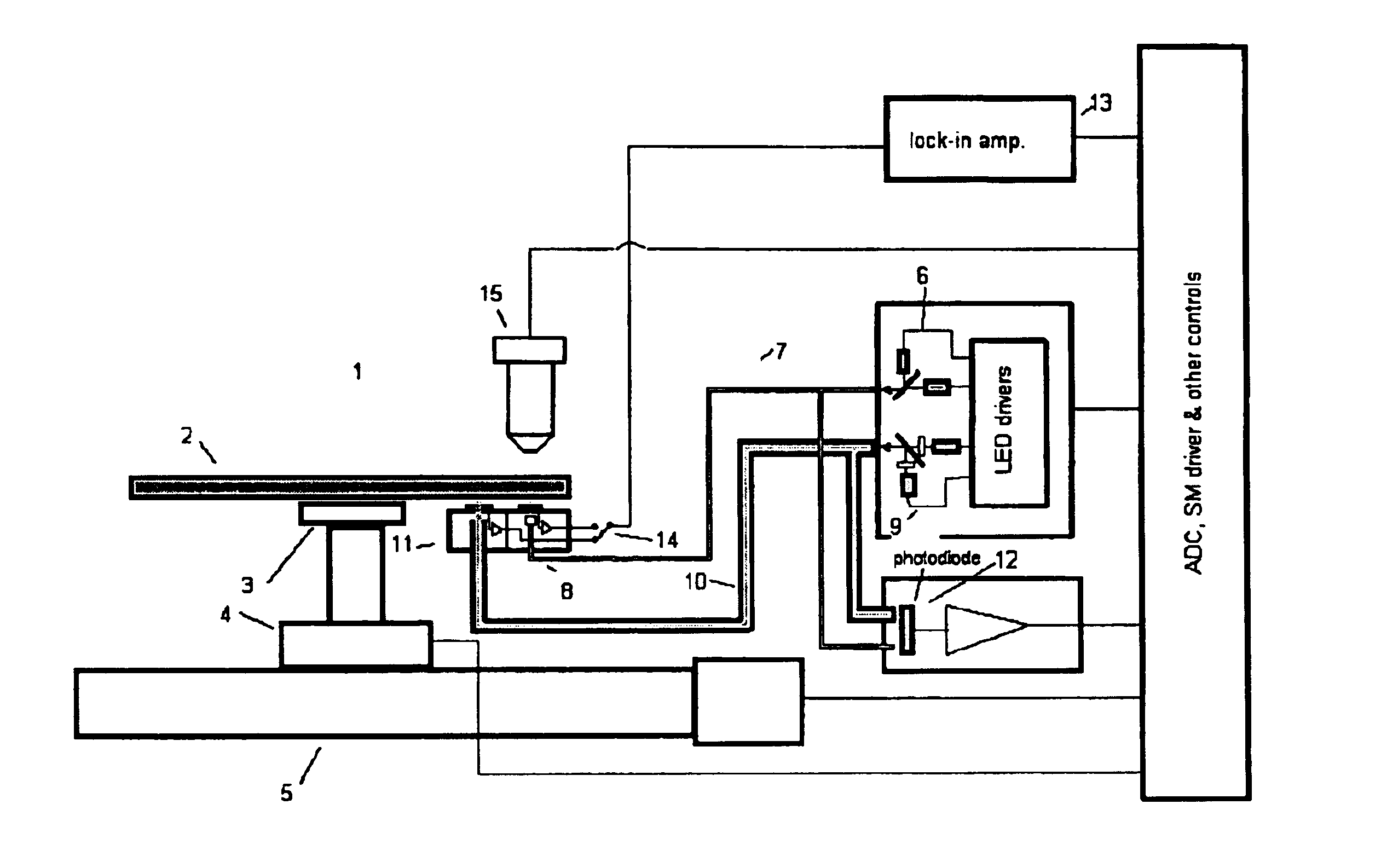

Measuring method, inspection method, inspection device, semiconductor device, method of manufacturing a semiconductor device, and method of manufacturing an element substrate

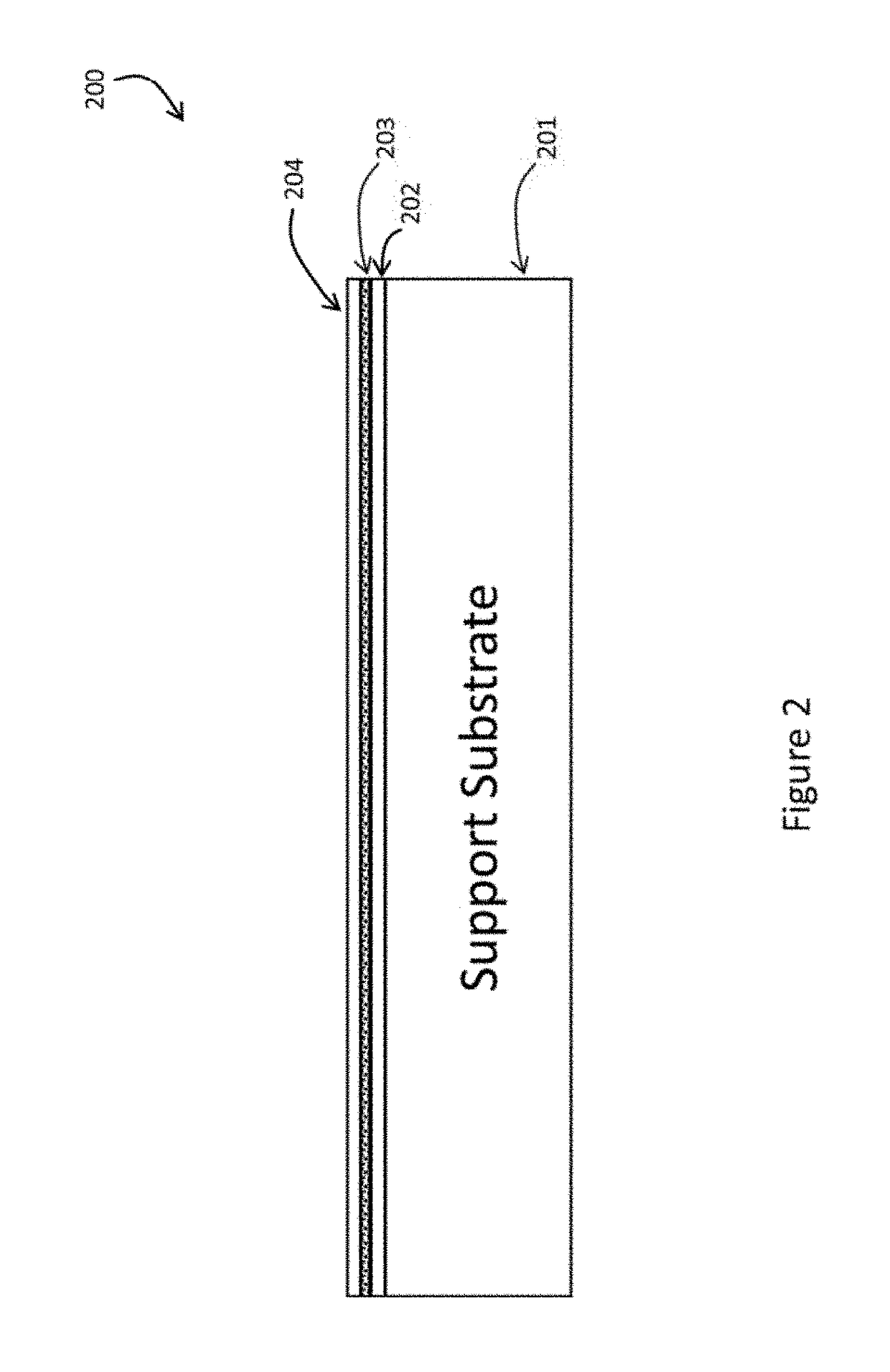

ActiveUS20050218926A1Simplify inspection stepsSemiconductor/solid-state device testing/measurementContactless testingDevice materialEngineering

An inspection method which simplifies an inspection step by eliminating the need to set probes on wiring or probe terminals, and an inspection device for performing the inspection step. A voltage is applied to each of inspected circuits or circuit elements to operate the same. Signal processing is performed on an output from each inspected circuit or circuit element during operation to form a signal (operation information signal) including information on the operating condition of the circuit or the circuit element. The operation information signal is amplified and the amplitude of an alternating current voltage separately input is modulated with the amplified operation information signal. The voltage of the modulated alternating current is read in a non-contact manner to determine whether the corresponding circuit or circuit element is non-defective or defective.

Owner:SEMICON ENERGY LAB CO LTD

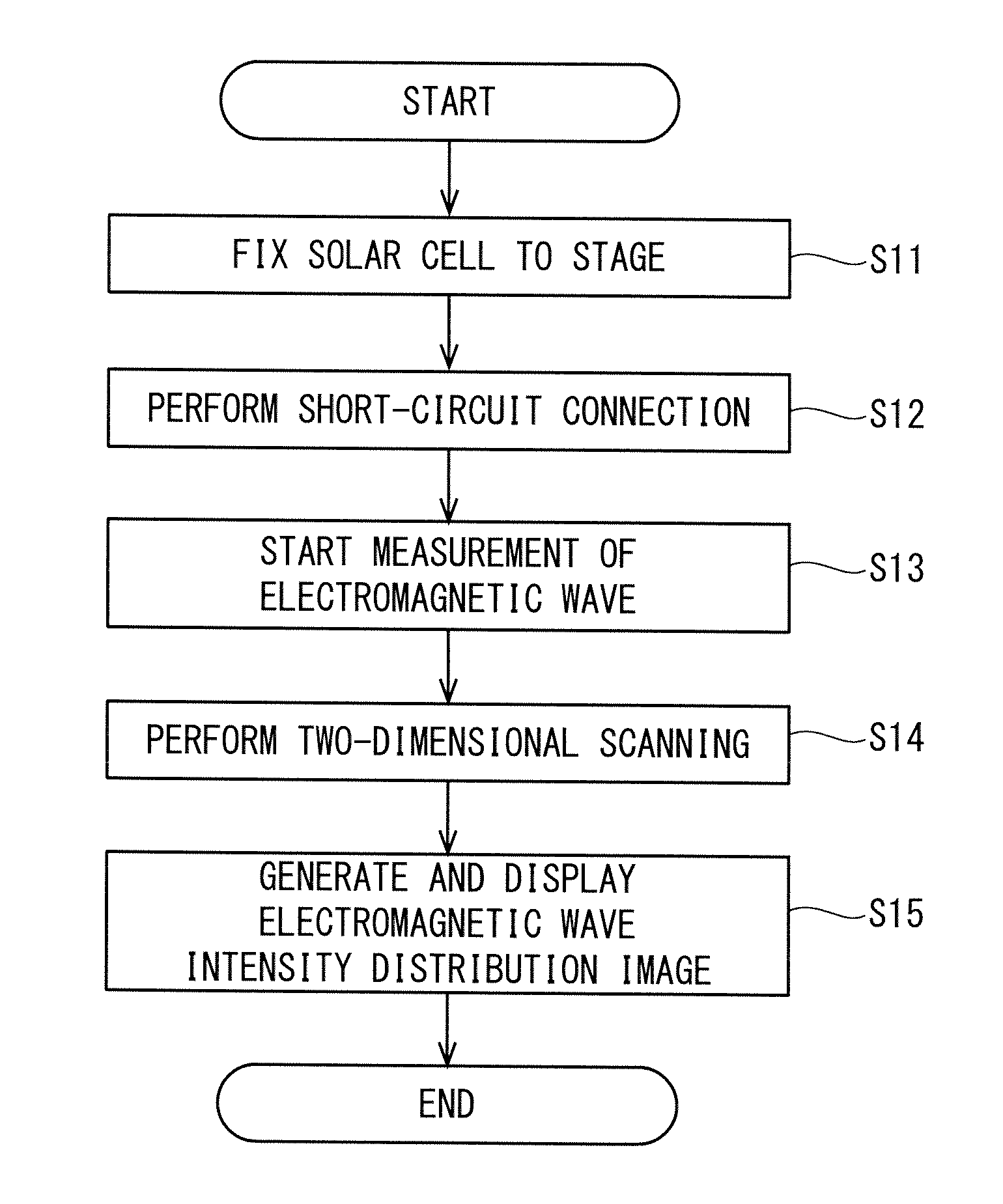

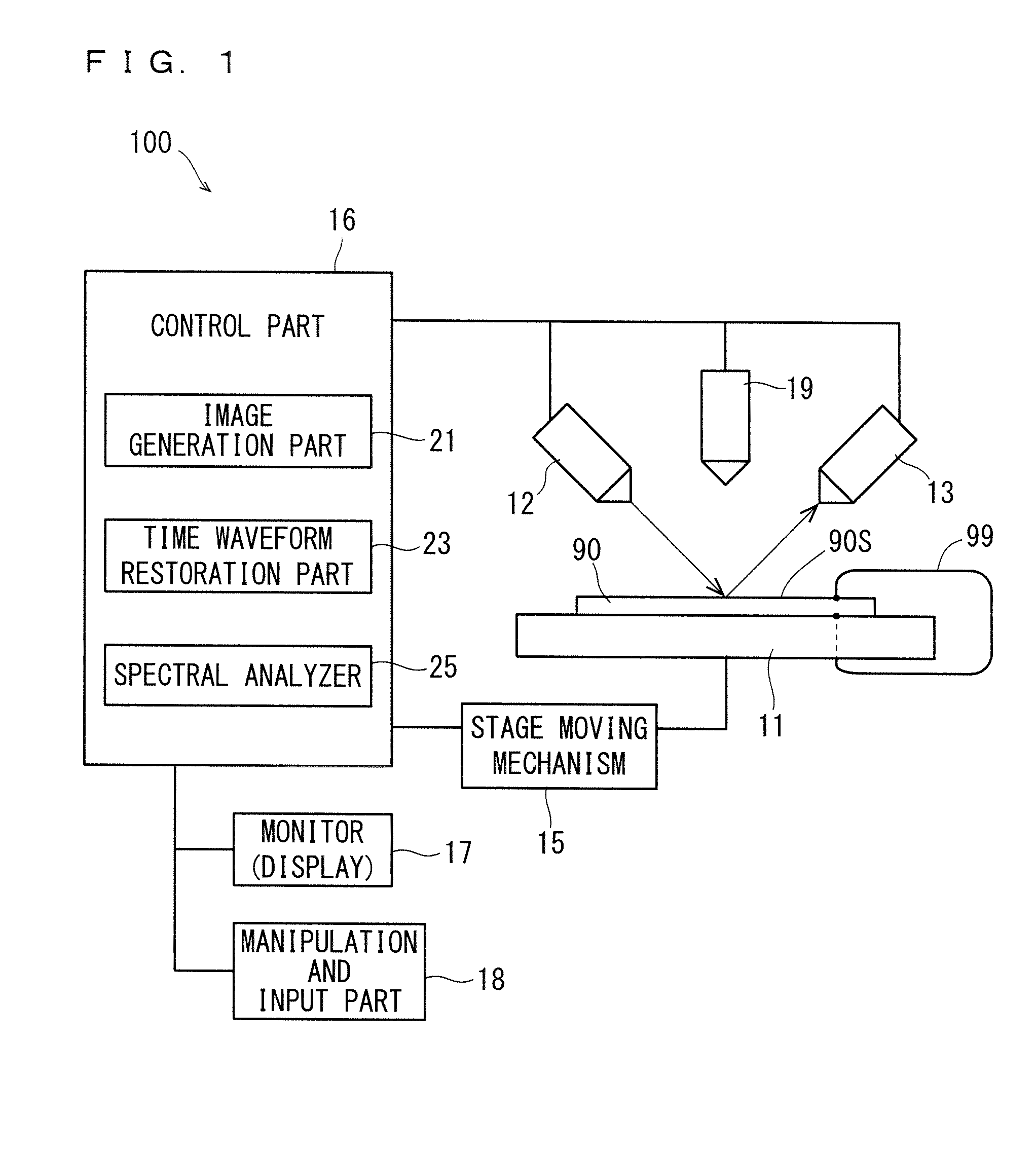

Inspection appratus and inspection method

InactiveUS20150162872A1Internal electric field can easily be enhancedIncrease intensityPhotovoltaic monitoringContactless testingElectricityElectromagnetic electron wave

An inspection apparatus inspects a solar cell. The inspection apparatus includes: a short-circuiting element that electrically connects an anode as a p-type semiconductor layer and a cathode as an n-type semiconductor layer of the solar cell to short-circuit the solar cell; an irradiation part that irradiates the solar cell short-circuited by the short-circuiting element with pulse light; and a detection part that detects an electromagnetic wave emitted from the solar cell in response to the irradiation of the solar cell with pulse light from the irradiation part.

Owner:DAINIPPON SCREEN MTG CO LTD +1

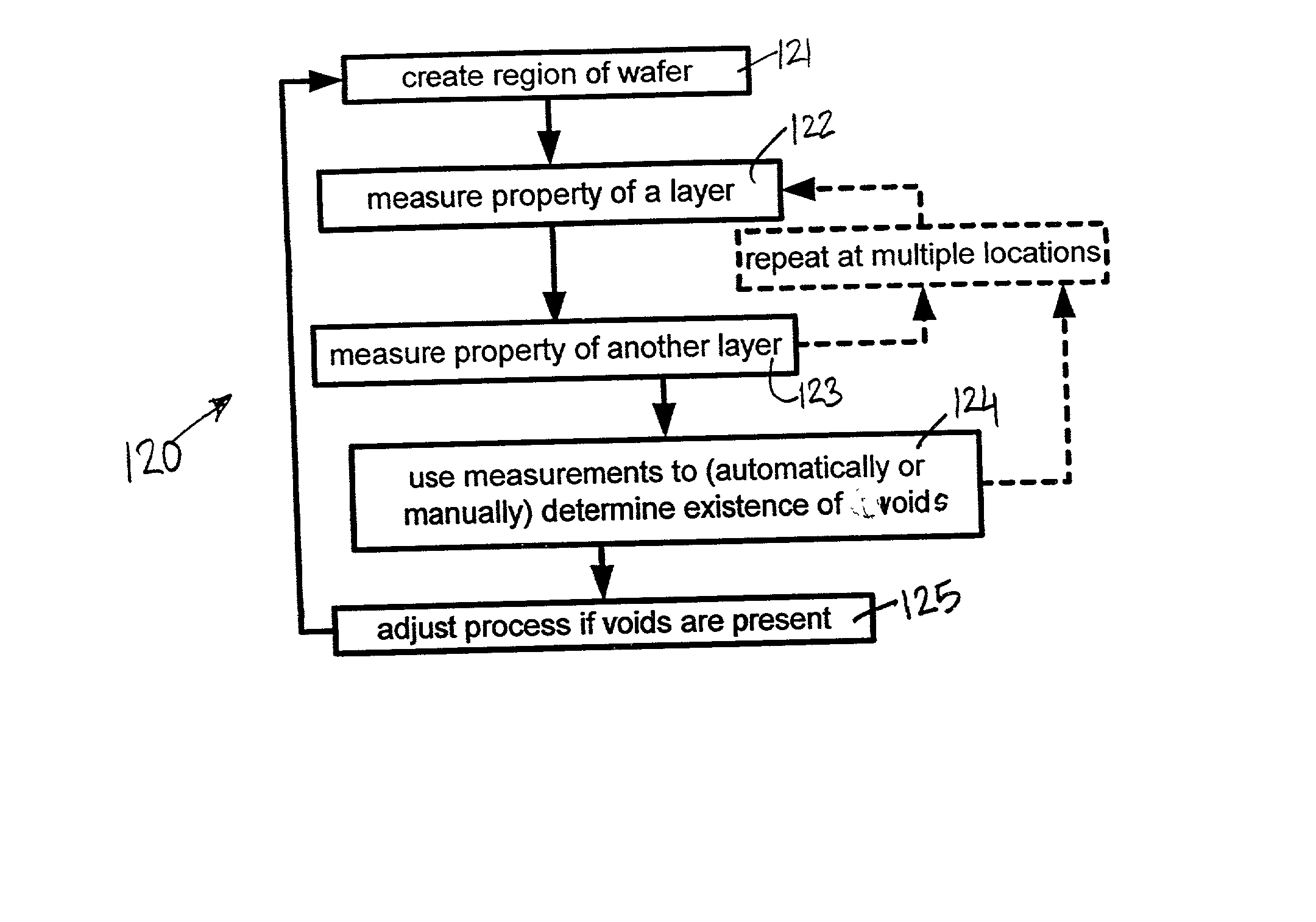

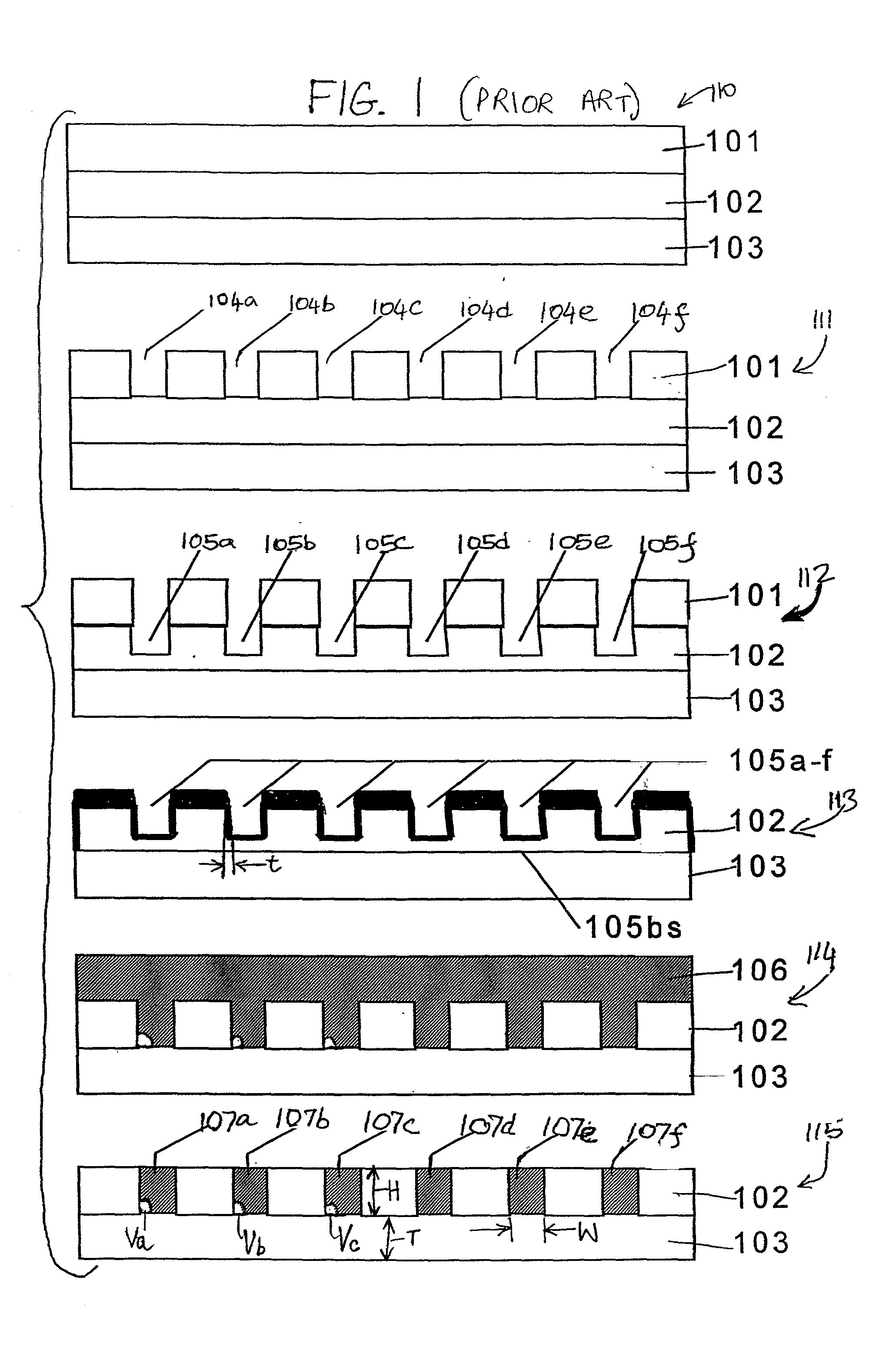

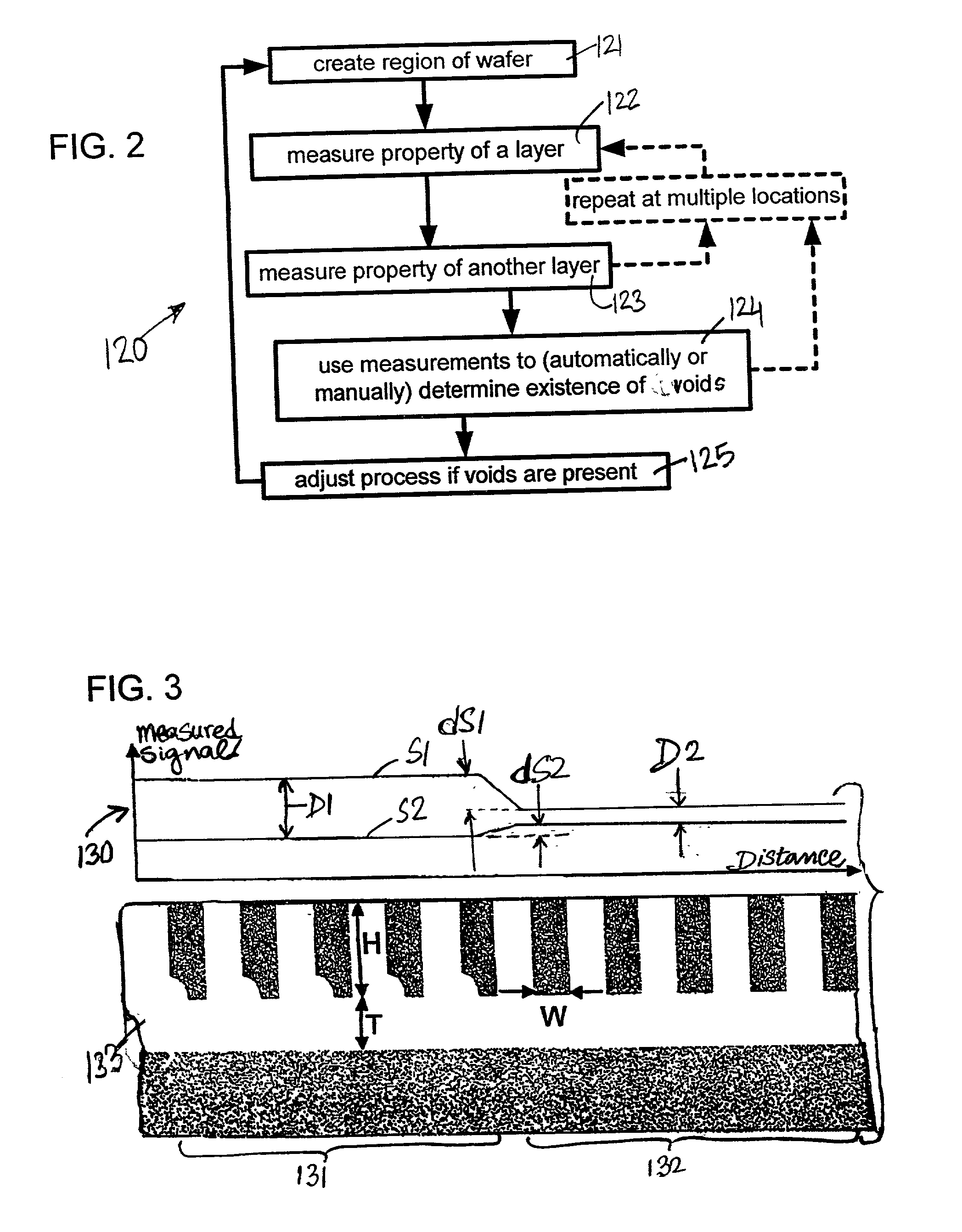

Evaluating a multi-layered structure for voids

InactiveUS20020125905A1Reduce and eliminate voidSemiconductor/solid-state device testing/measurementElectric discharge tubesEngineeringSilicon

A method and apparatus measure properties of two layers of a damascene structure (e.g. a silicon wafer during fabrication), and use the two measurements to identify a location as having voids. The two measurements may be used in any manner, e.g. compared to one another, and voids are deemed to be present when the two measurements diverge from each other. In response to the detection of voids, a process parameter used in fabrication of the damascene structure may be changed, to reduce or eliminate voids in to-be-formed structures.

Owner:APPLIED MATERIALS INC

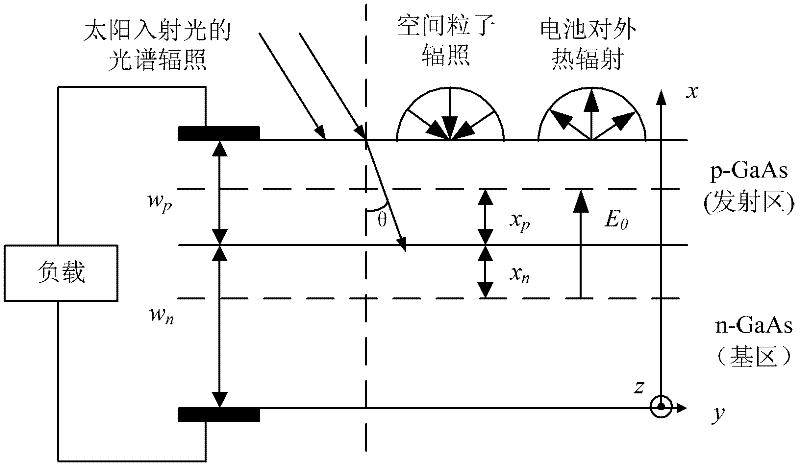

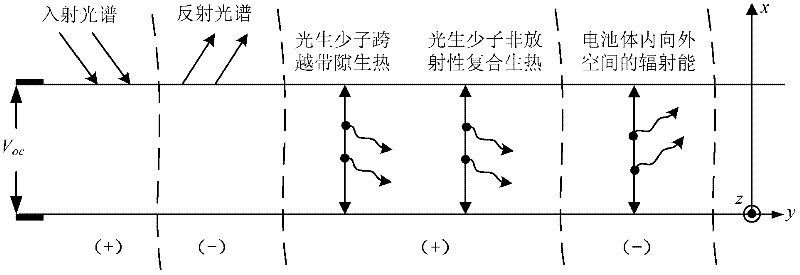

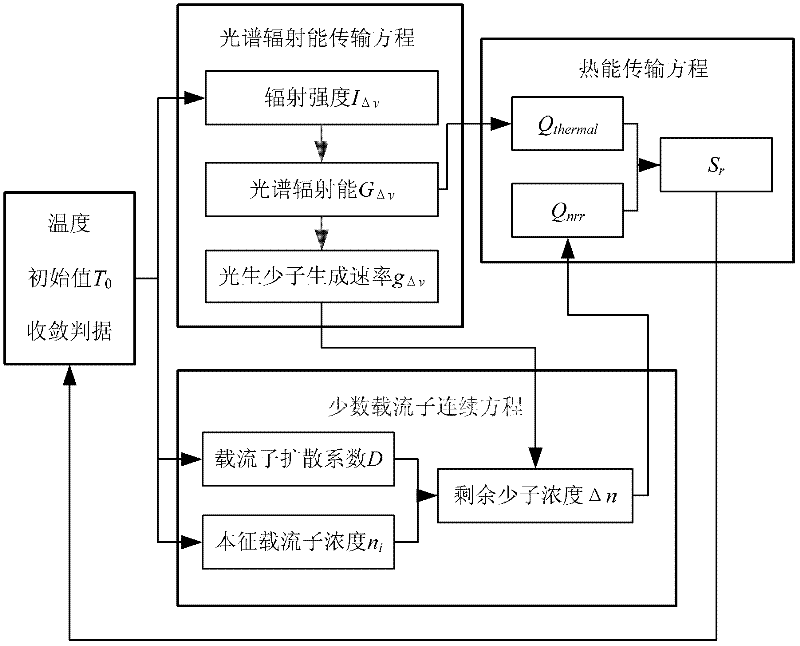

GaAs solar energy cell performance degeneration prediction method in space environment

The invention provides a GaAs solar energy cell performance degeneration prediction method in a space environment. The method comprises the following four steps: (1) establishment of a one-dimensional model of a GaAs solar energy cell in the space environment; (2) consideration of space particle radiation damage on an effective life of a carrier; (3) calculation of GaAs solar cell temperature; (4) realization of GaAs solar energy cell performance degeneration prediction through calculating a volt-ampere characteristic. According to the method, coupling effects of a space thermal vacuum environment and a radiation environment on the GaAs solar energy cell are considered, through establishing the one-dimensional model of the GaAs solar energy cell in the space environment, based on a minority continuity equation, degeneration case of the solar cell is analyzed and obtained through the volt-ampere characteristic. he invention has a practical value and a broad application prospect in the spatial solar cell electrical performance test technology field.

Owner:BEIHANG UNIV

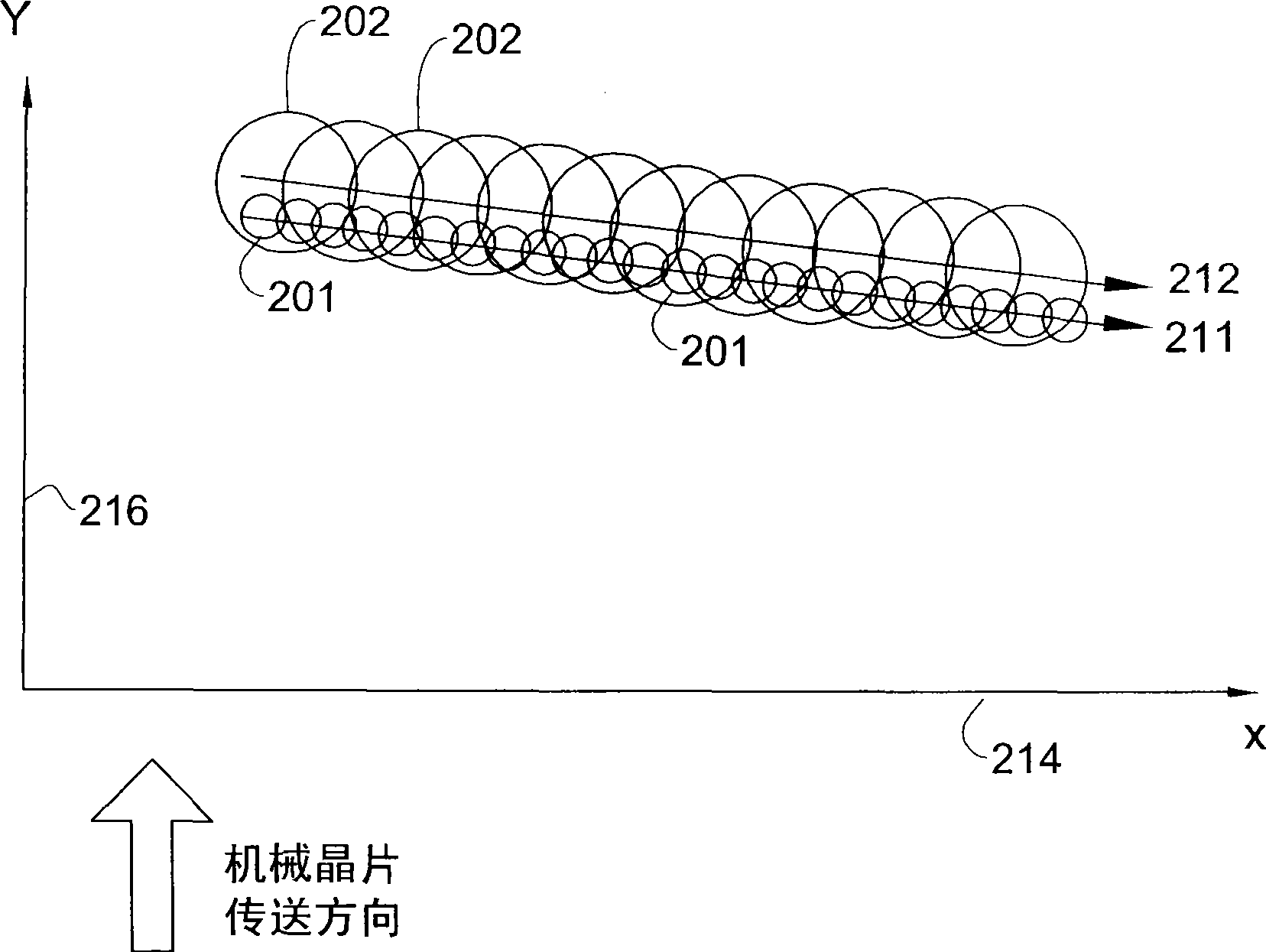

Method and apparatus for scanning, stitching, and damping measurements of a double-sided metrology inspection tool

InactiveUS7009696B2Minimizing bendingStress minimizationSemiconductor/solid-state device testing/measurementElectronic circuit testingMetrologyEngineering

A system for inspecting specimens such as semiconductor wafers is provided. The system provides scanning of dual-sided specimens using a damping arrangement which filters unwanted acoustic and seismic vibration, including an optics arrangement which scans a first portion of the specimen and a translation or rotation arrangement for translating or rotating the specimen to a position where the optics arrangement can scan the remaining portion(s) of the specimen. The system further includes means for stitching the scans together, thereby providing both damping of the specimen and the need for smaller and less expensive optical elements.

Owner:KLA TENCOR TECH CORP

Method and device for non-contact detection of LED luminescence properties

InactiveCN101561475ALow costAvoid contact damageContactless testingTesting optical propertiesP–n junctionSingle lead

The invention discloses a non-contact detection method of LED luminescence properties. The method comprises the following steps: a PN junction area for an LED device to be tested is irradiated with short-term pulsed light at the constant temperature, and the detection to the luminescence properties of the LED device to be tested is realized by detecting the self-luminescent spectrum of a PN junction; the invention also discloses a non-contact detection device based on the LED luminescence properties of the method; and the invention has the beneficial effects that the luminescence properties of the epitaxial wafer of the LED, the wafer or the single LED chip can be detected under the condition that the device to be tested is not contacted, therefore, the contact damage of the LED device to be tested is avoided, the detection and the screening of the LED products are propelled to the chip even to the epitaxial wafer link from the link of the finished products, and the cost of the LED is reduced.

Owner:CHONGQING UNIV

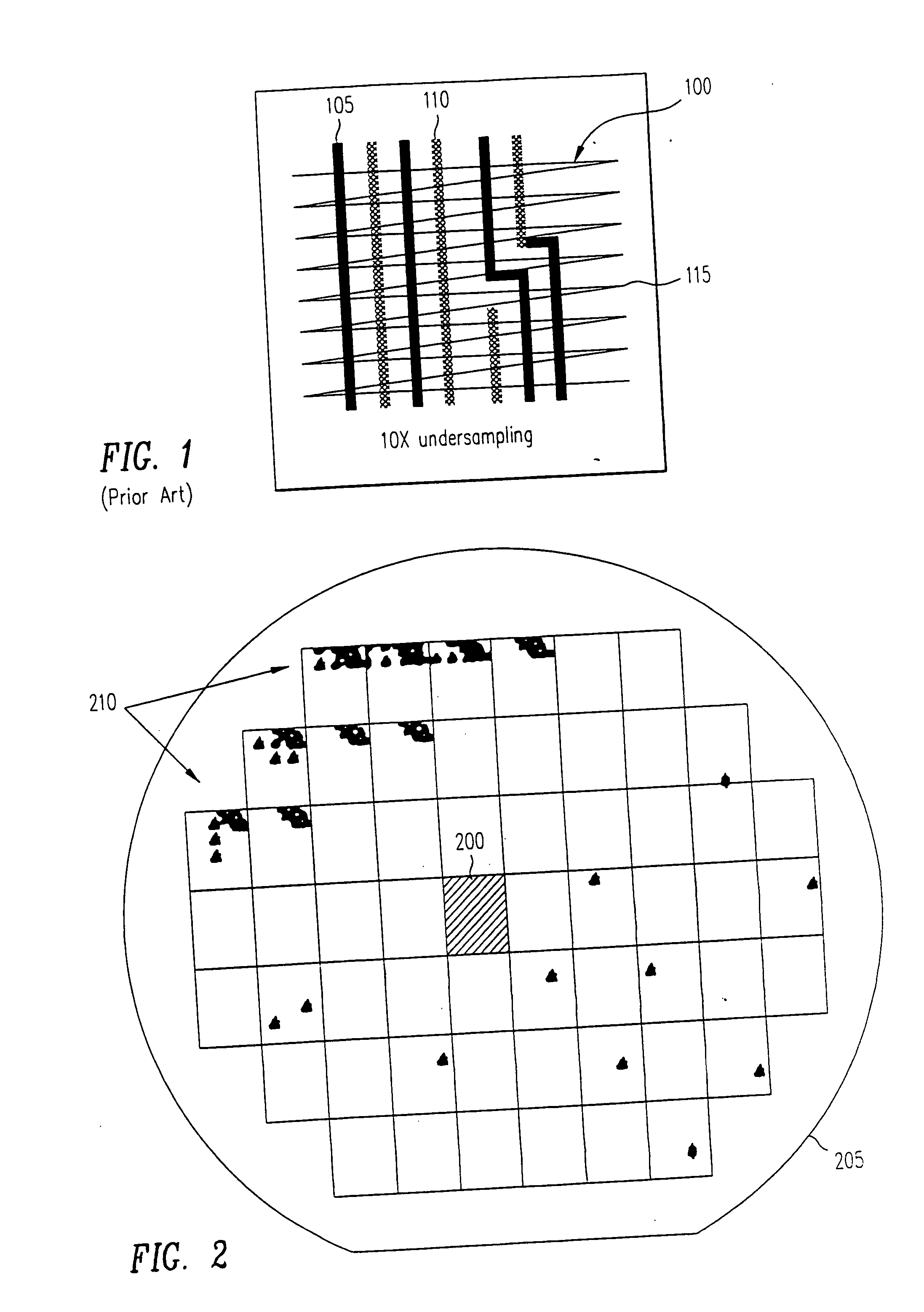

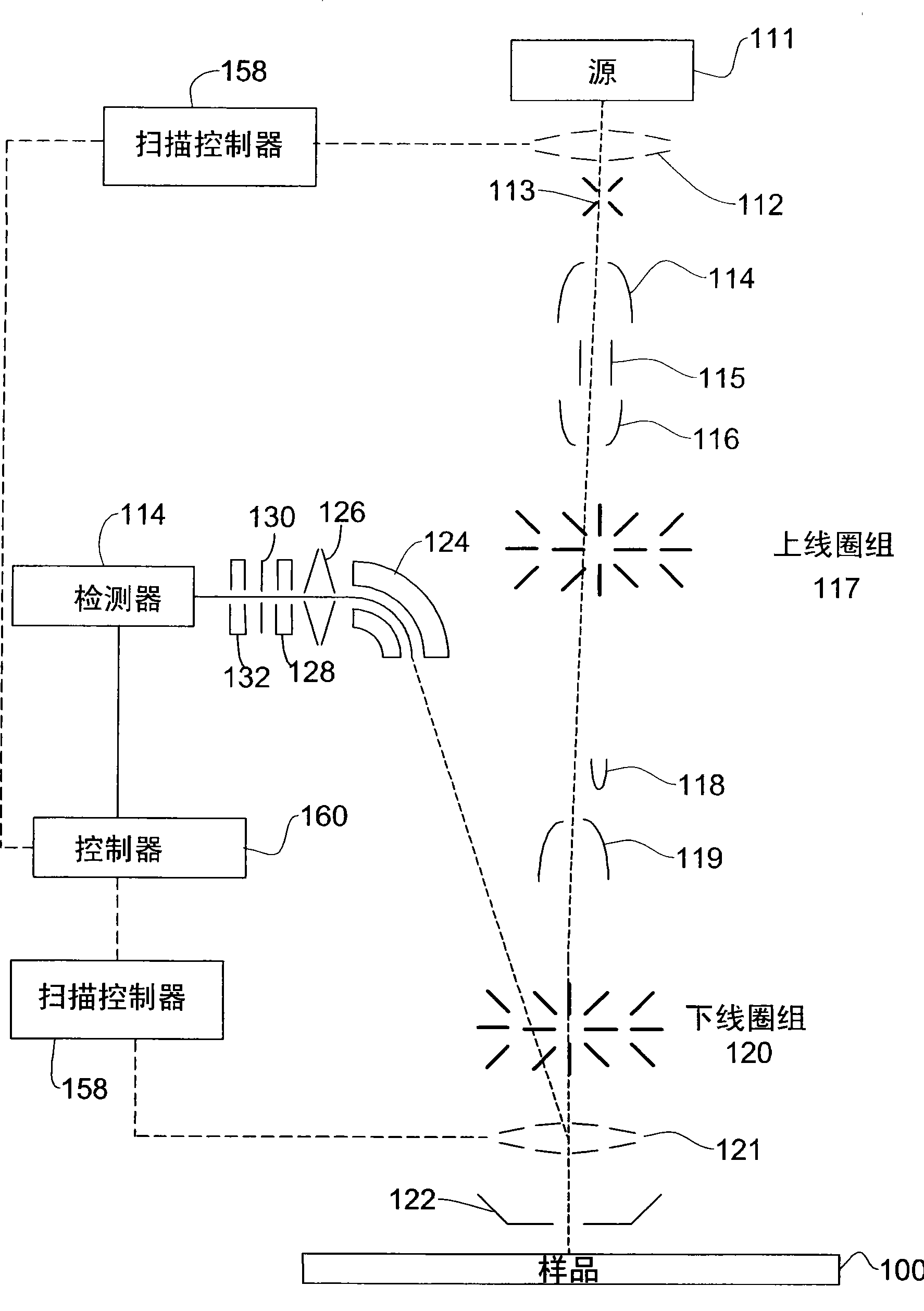

Detection of defects in patterned substrates

InactiveUS6914441B2Image analysisSemiconductor/solid-state device testing/measurementImage resolutionPatterned substrate

One embodiment of the present invention is a method of detecting defects in a patterned substrate, including: (a) positioning a charged-particle-beam optical column relative to a patterned substrate, the charged-particle-beam optical column having a field of view (FOV) with a substantially uniform resolution over the FOV; (b) operating the charged-particle-beam optical column to acquire images of a region of the patterned substrate lying within the FOV by scanning the charged-particle beam over the patterned substrate; and (c) comparing the acquired images to a reference to identify defects in the patterned substrate.

Owner:APPLIED MATERIALS INC

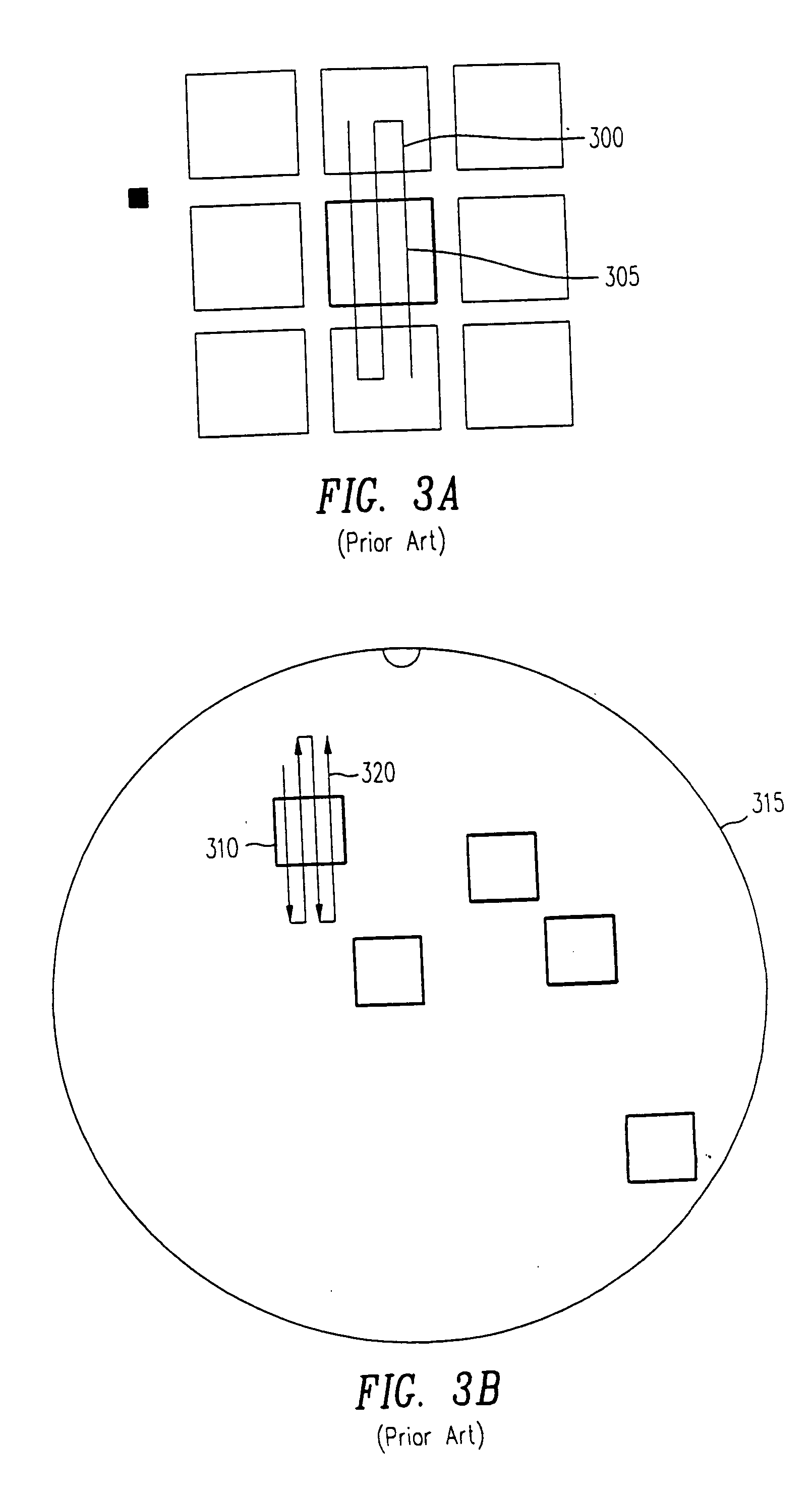

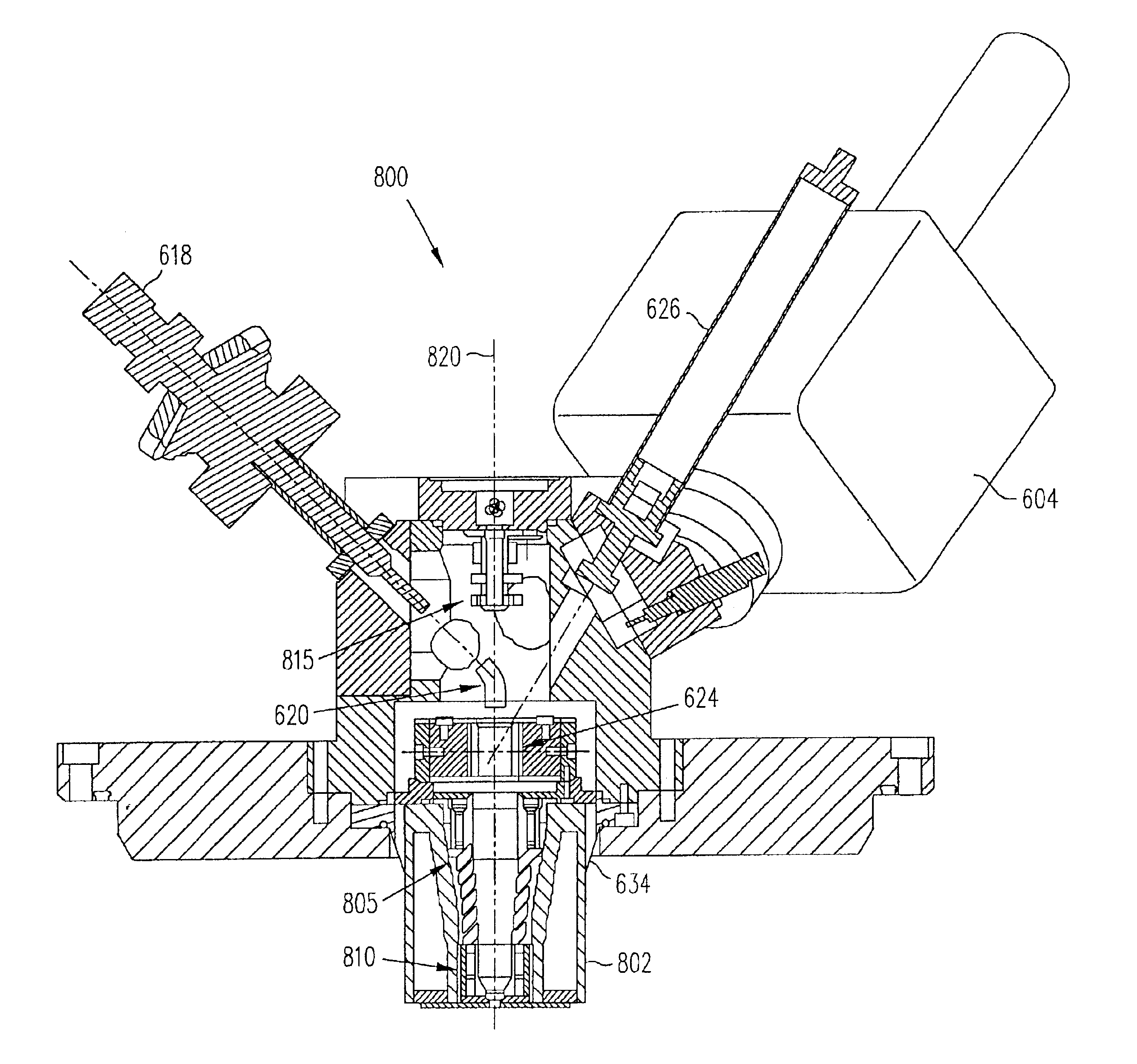

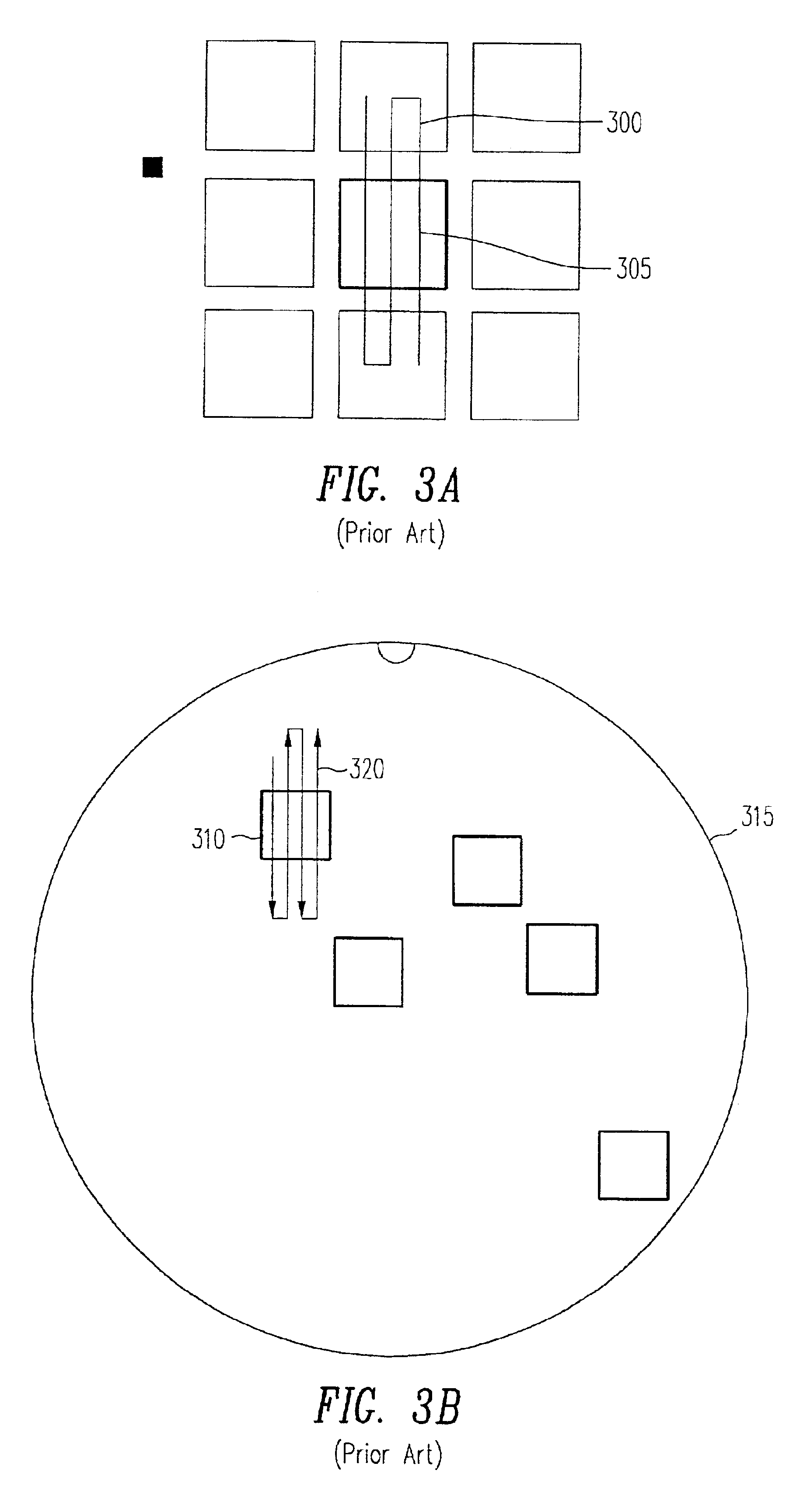

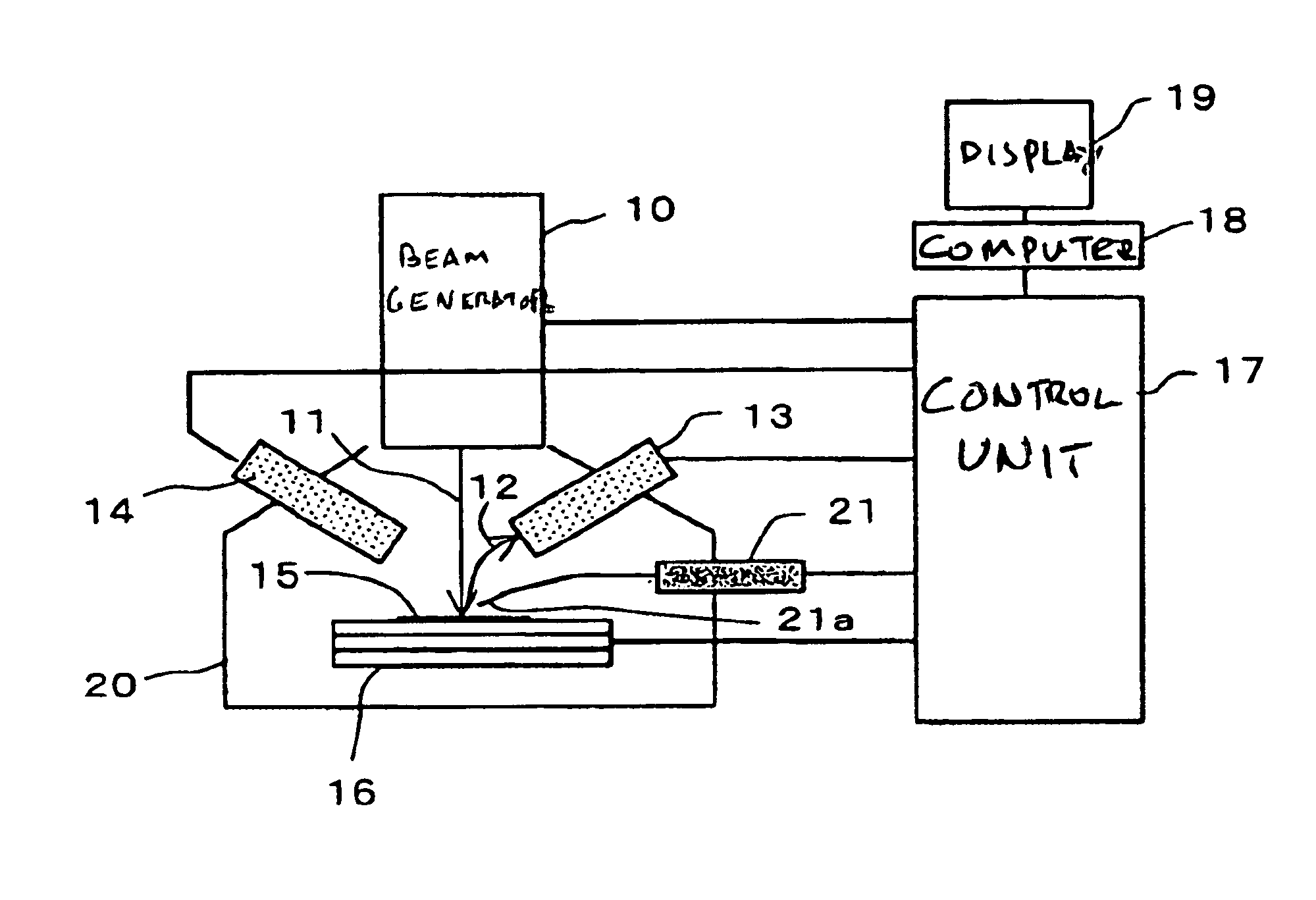

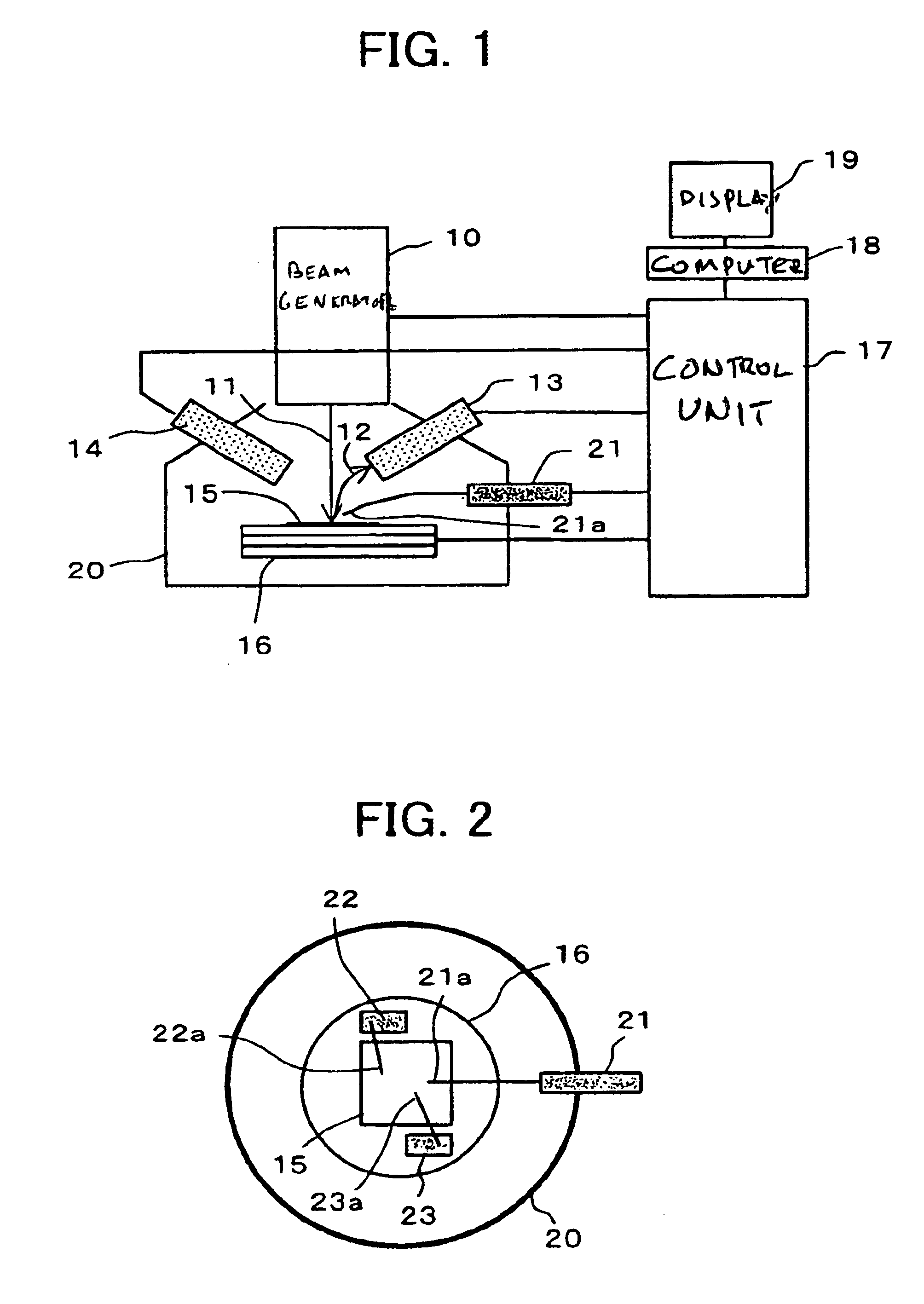

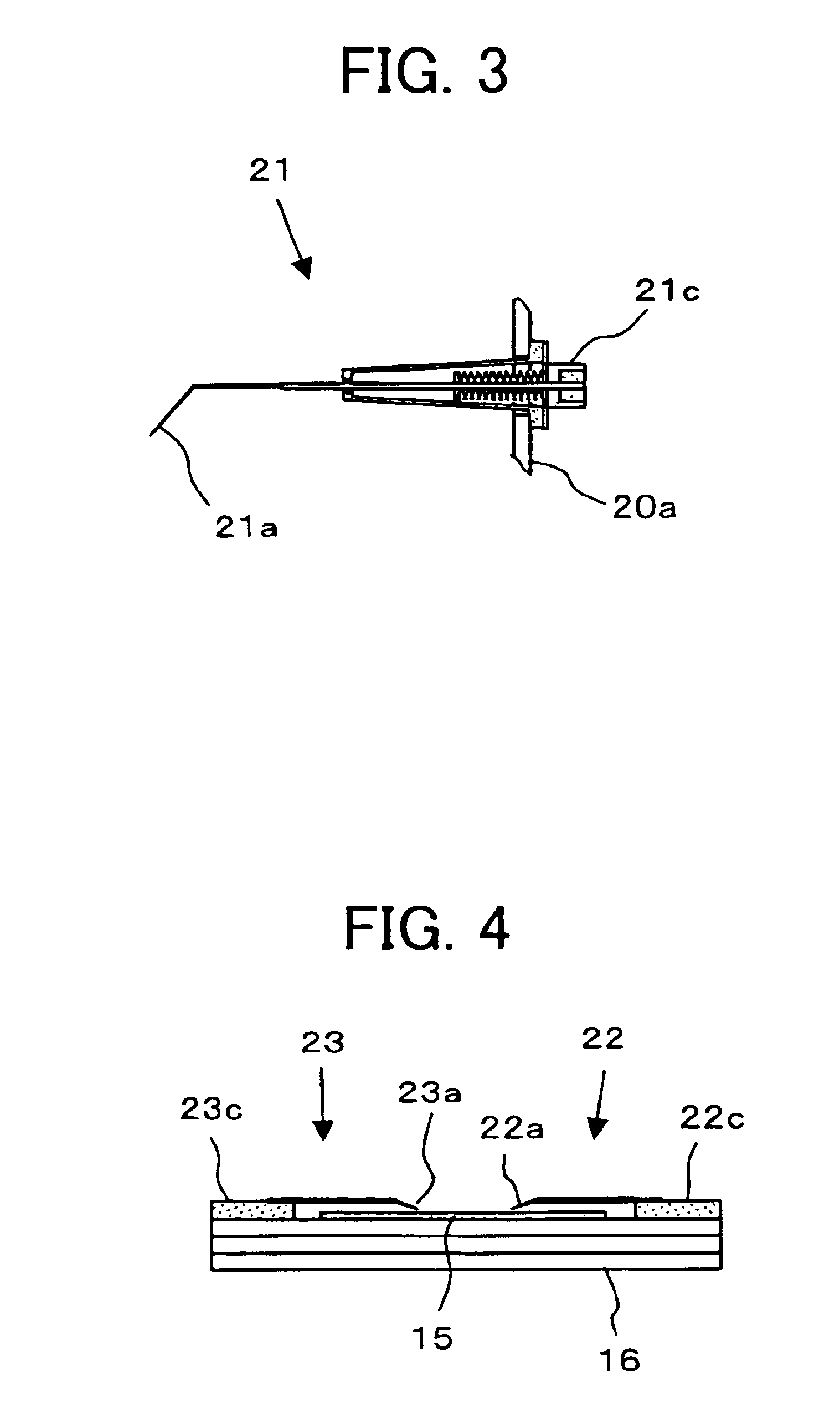

Apparatus for inspecting defects of devices and method of inspecting defects

InactiveUS6970004B2Improve reliabilityHigh positioning accuracyElectric discharge tubesSolid-state devicesElectrical conductorEngineering

Disconnection defects, short-circuit defects and the like in wiring patterns of submicron sizes within TEGs (a square of 1 to 2.5 mm for each) numerously arranged in a large chip (a square of 20 to 25 mm) can be inspected with respect to all the TEGs, with good operability, high reliability and high efficiency. A conductor probe for applying voltage to the wiring patterns by mechanical contact is composed of synchronous type conductor probe that synchronizes with movement of a sample stage (16), and fixed type conductor probe means (21) that is relatively fixed to an FIB generator (10). Positions of probe tips are superimposed to an SIM image and displayed on a display unit (19).

Owner:HITACHI LTD +1

Apparatus and method for inspecting pcb-mounted integrated circuits

A method and apparatus for testing the mounting of an integrated circuit on a printed circuit board using a ball grid array comprises directing an inclined laser beam from a line scan laser sensor at the integrated circuit, detecting the position of the lower edge of the integrated circuit from laser light backscattered from the integrated circuit and printed circuit board, determining through a trigonometric calculation the height of the integrated circuit above the printed circuit board following soldering of the ball grid array and comparing the height with reference data. The integrated circuit is deemed to have been successfully mounted to the printed circuit board if the height falls within a predetermined range.

Owner:TWENTY TWENTY VISION

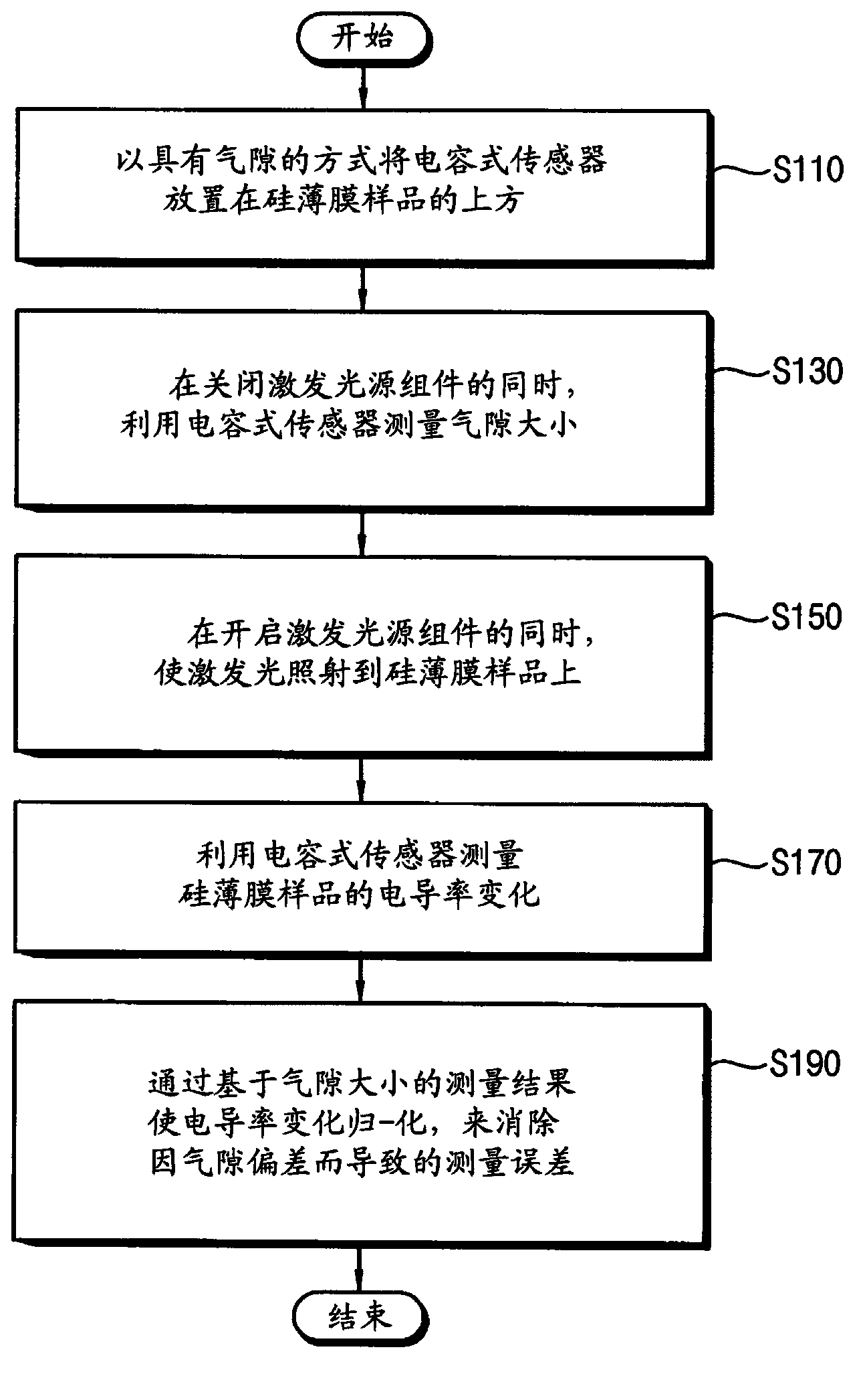

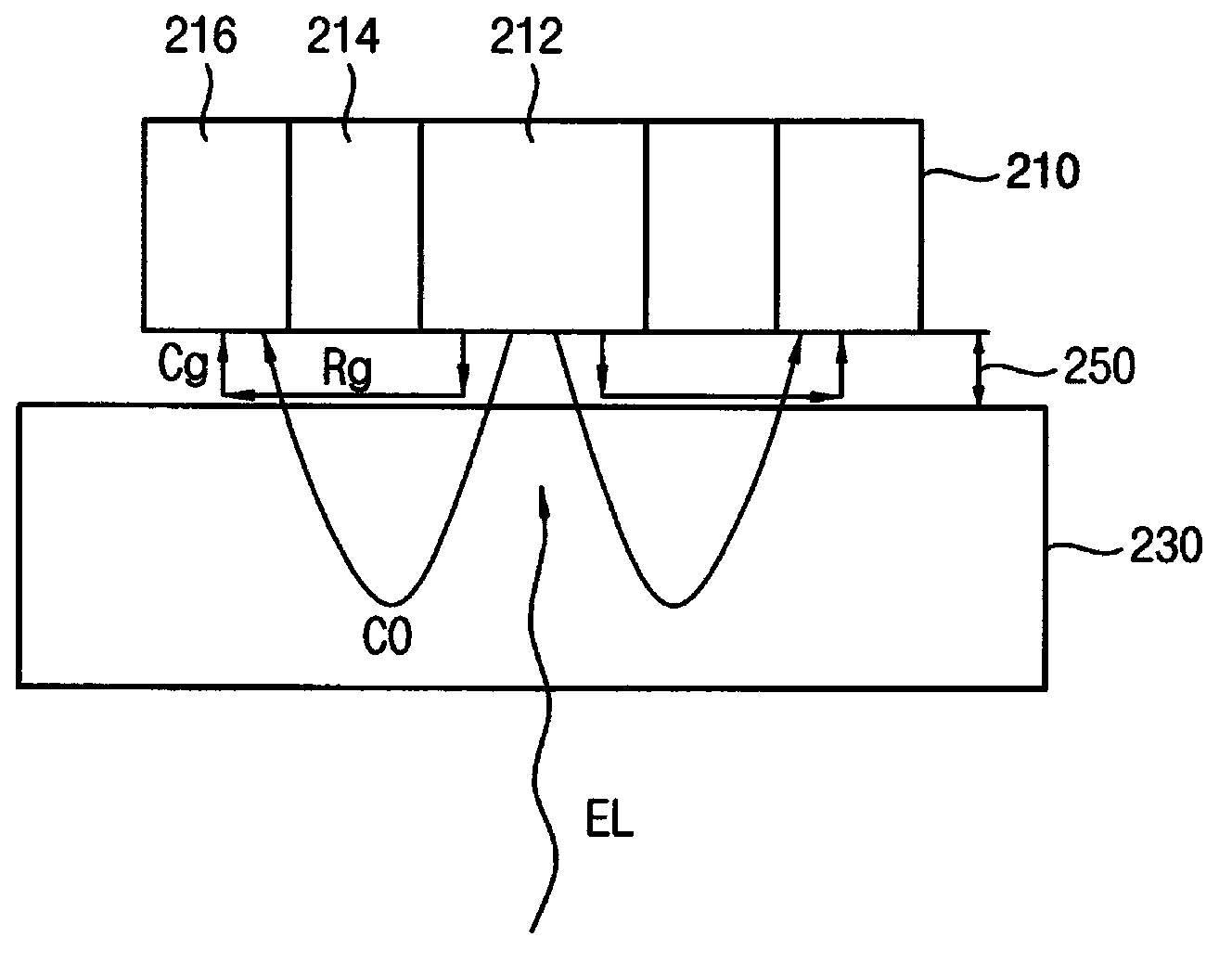

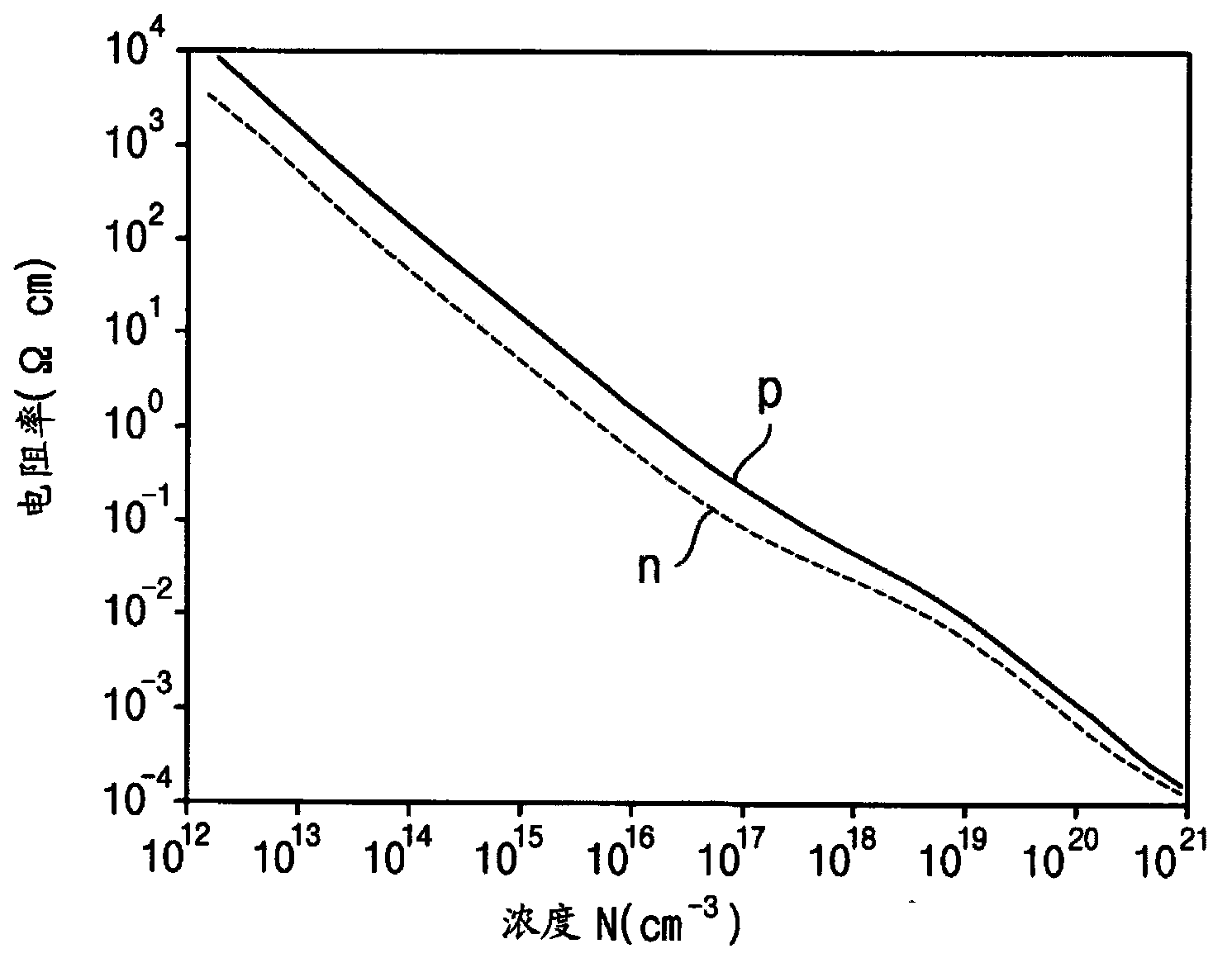

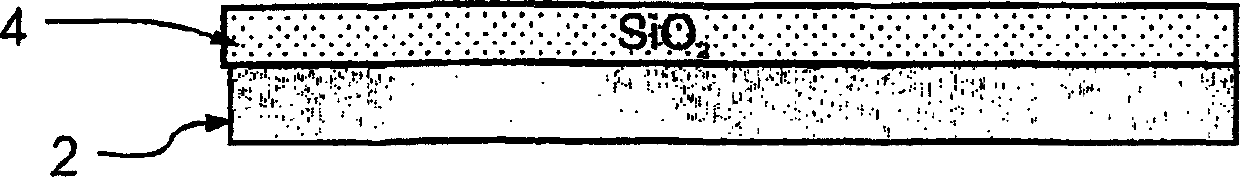

Method of measuring conductivity a silicon thin film, method of detecting defects in a silicon thin film, and silicon thin film defect detection device

ActiveCN103364638AResistance/reactance/impedenceAnalysis by material excitationObservational errorUltraviolet lights

A method of measuring conductivity of a silicon thin film is provided. By the method, a capacitive sensor is positioned over a silicon thin film sample with an air-gap between the sensor and the sample, a size of the air-gap is measured using the capacitive sensor while an excitation light source module is turned off, an excitation light is illuminated on the silicon thin film sample by turning on the excitation light source module, where the excitation light is an ultraviolet light, a conductivity change of the silicon thin film sample is measured using the capacitive sensor, and a measurement error due to a deviation of the air-gap is eliminated by normalizing the conductivity change based on a measurement result of the size of the air-gap.

Owner:SAMSUNG DISPLAY CO LTD

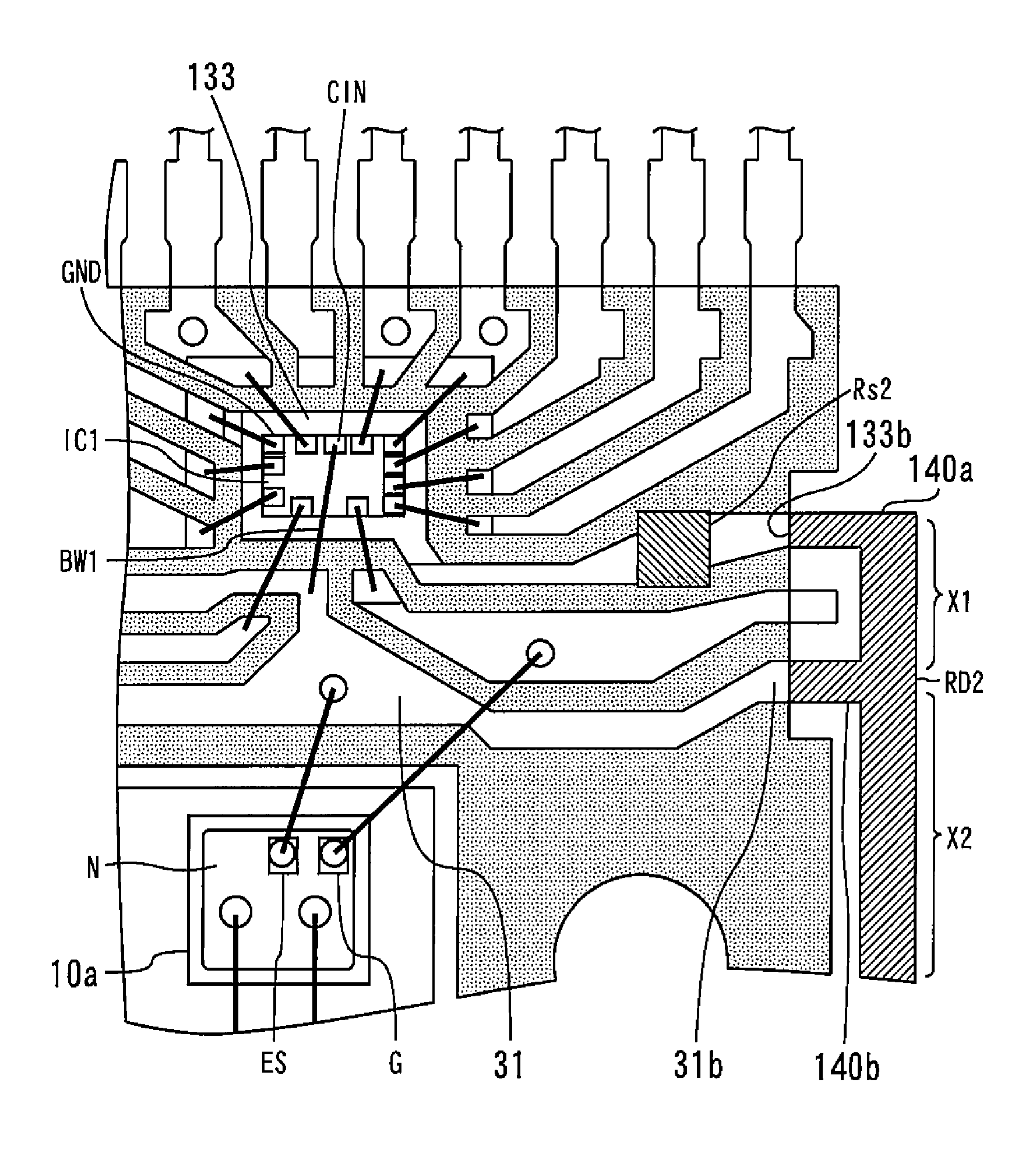

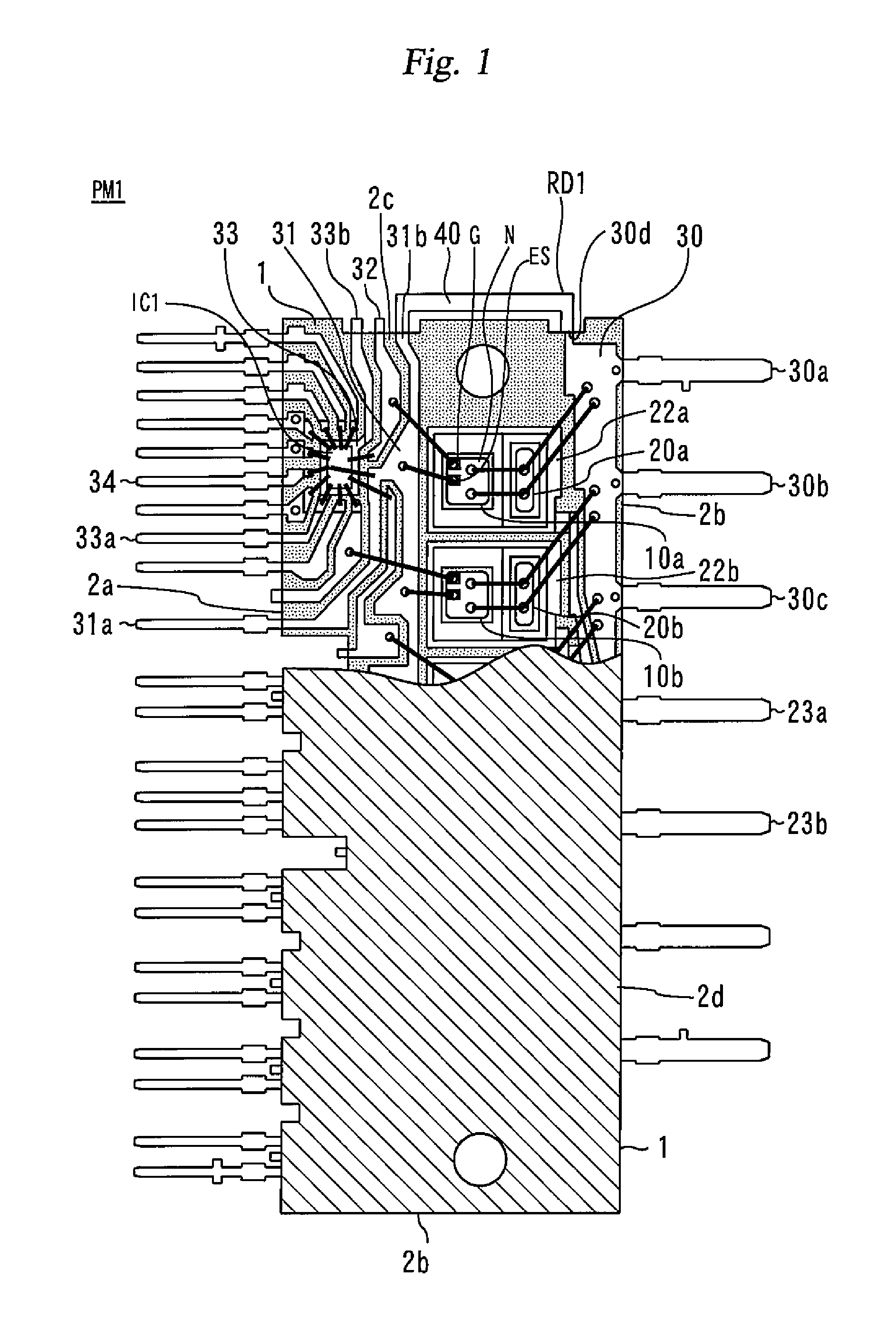

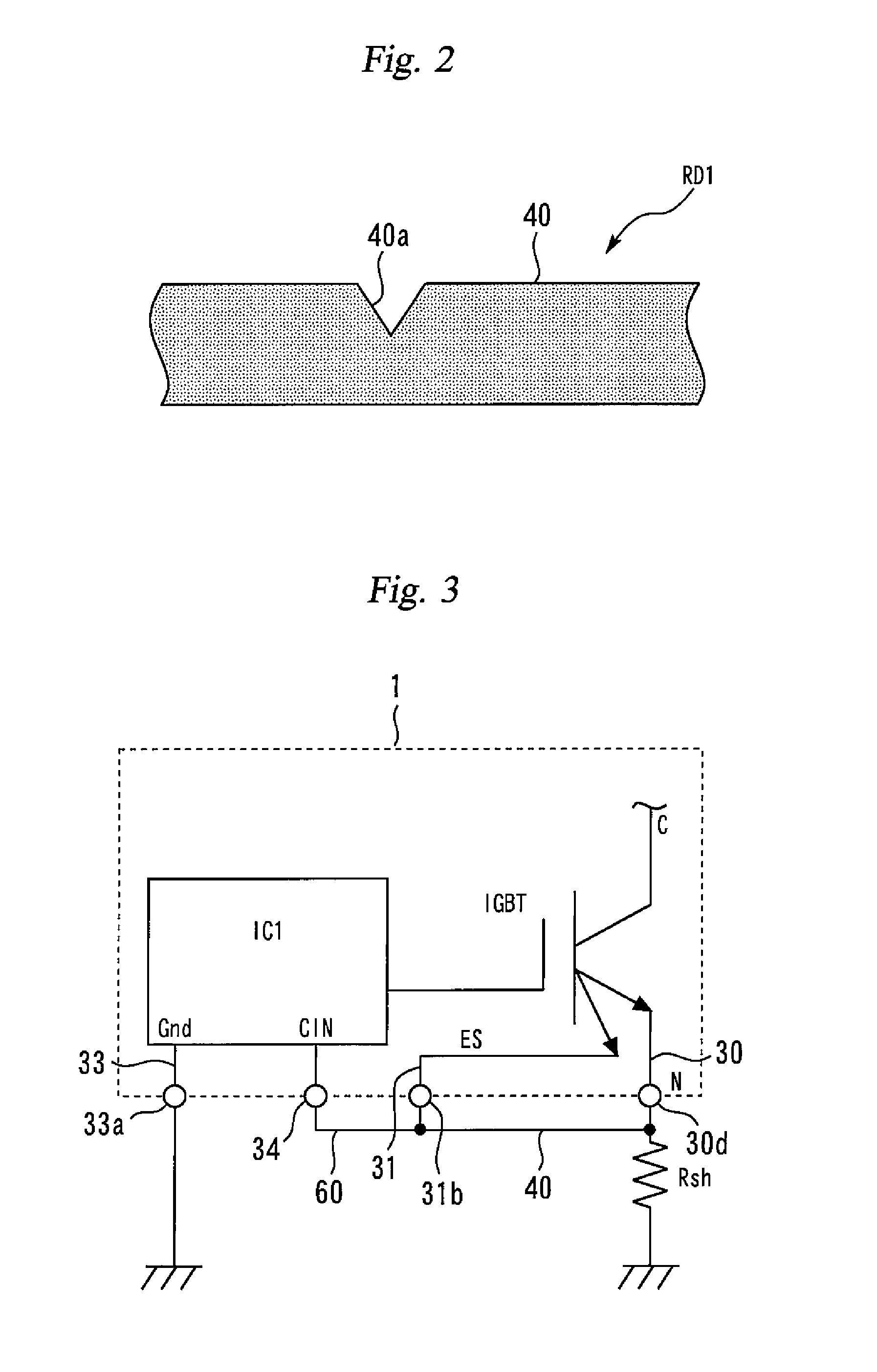

Semiconductor device

ActiveUS20150042373A1Improve user convenienceBipolar transistor testingElectrical measurement instrument detailsPower semiconductor deviceEngineering

A semiconductor device capable of simplifying wiring work is provided. A semiconductor device includes a semiconductor element (insulated gate bipolar transistor IGBT) provided with an emitter main electrode and an emitter sense electrode, an integrated circuit having a detection terminal and a mold resin body that seals the semiconductor element and the integrated circuit, and a lead. The lead is provided with an inner lead part sealed in the mold resin body and electrically connected to the emitter sense electrode, an inner lead part sealed in the mold resin body and electrically connected to the emitter main electrode, and an outer lead part connected to the lead part on one side, connected to the inner lead part on the other side and exposed outside the mold resin body.

Owner:MITSUBISHI ELECTRIC CORP

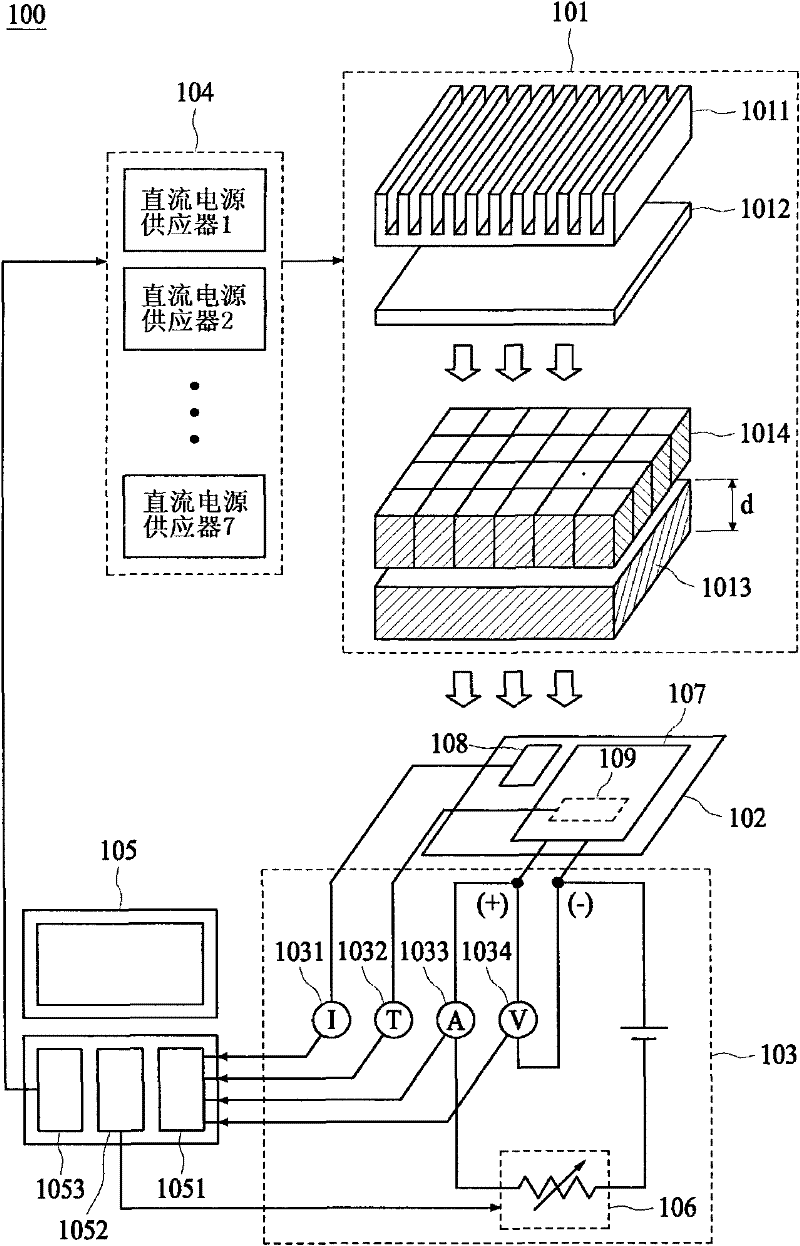

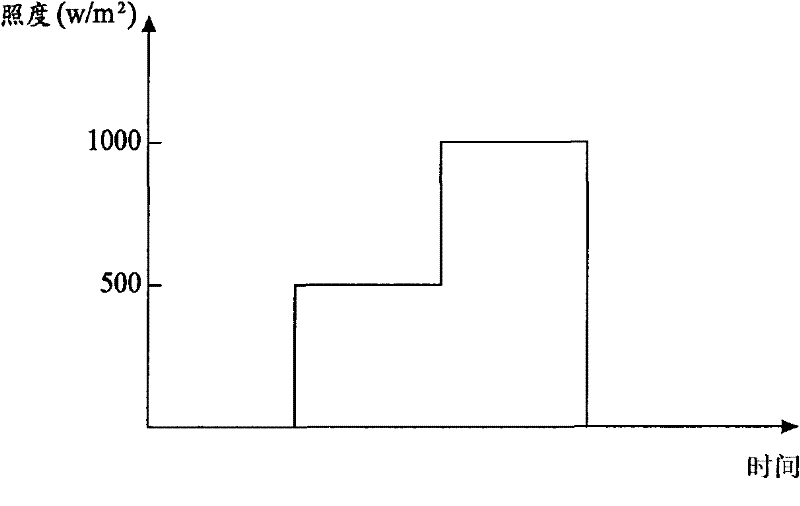

Measuring system for solar cell and sunlight simulator

ActiveCN102221669AElectrical measurement instrument detailsContactless testingFrequency spectrumEffect light

The invention relates to a measuring system for a solar cell and a sunlight simulator. The invention provides the measuring system, which comprises a light source generating device, a supporting device and a measuring device. The light source generating device is constructed so as to generate light sources. The light source generating device consists of a plurality of light emitting diodes giving off different wavelengths, and the lighting frequency spectrum of the light source generating device satisfies a preset specification. The supporting device is constructed to hold articles to be measured, and to measure currents and voltages generated by the articles to be measured after being irradiated by the light source.

Owner:IND TECH RES INST

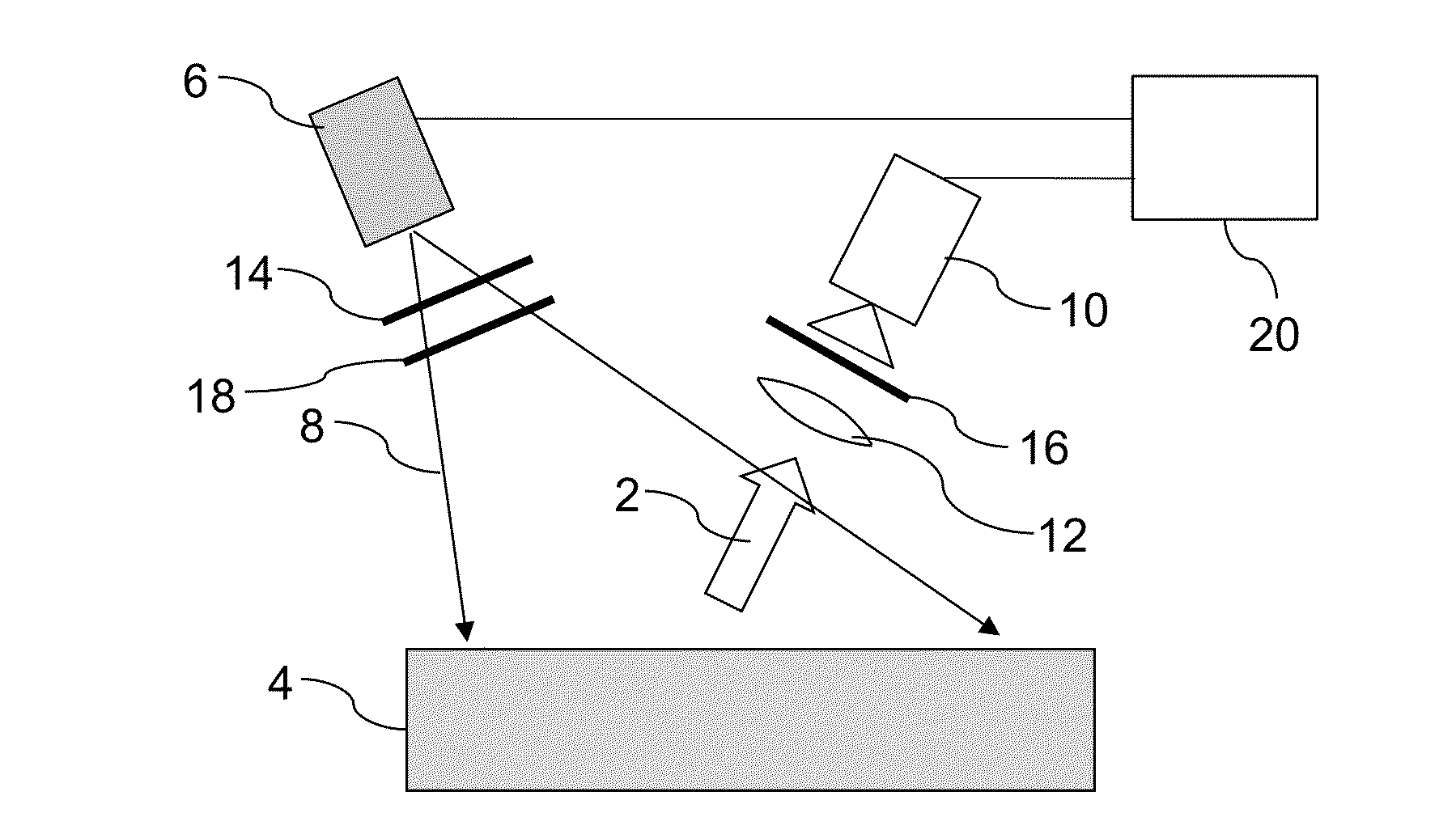

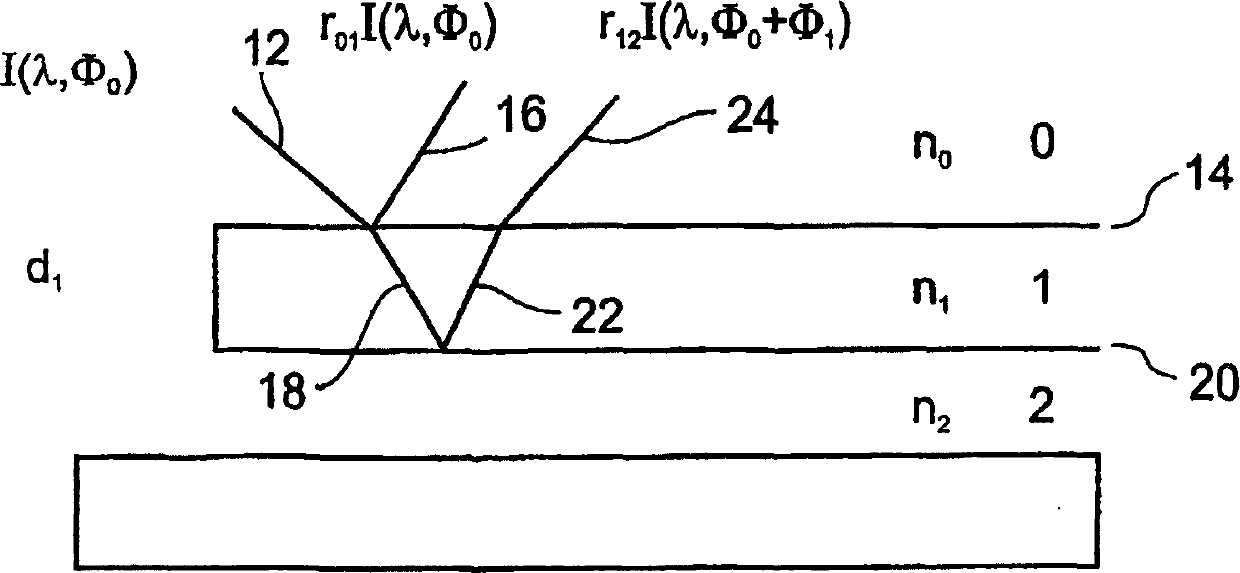

Method and apparatus for measuring stress in semiconductor wafers

InactiveCN1618004ASemiconductor/solid-state device testing/measurementElectronic circuit testingLayer thicknessTotal measurement

Integral measurement apparatus (50) and method for measuring layer thickness and bow in a wafer. The device comprises: a monochromatic light source (52), a white light source (100), a first switch (102) for switching between the white light source and the monochromatic light source, a switch for directing light from the switched light source to the semiconductor wafer A plurality of optical heads (56) at different locations on the surface (54), a first optical processor (104) for spectrally processing reflected light from the wafer, a second optical processor (104) for processing the reflected light to determine the degree of curvature in the wafer Two optical processors (58), and a second optical switch (106) for switching the reflected light from the wafer between the first optical processor and the second optical processor for spectral processing of white light to determine layer thickness , processes monochromatic light to determine the bend.

Owner:TEVET PROCESS CONTROL TECH

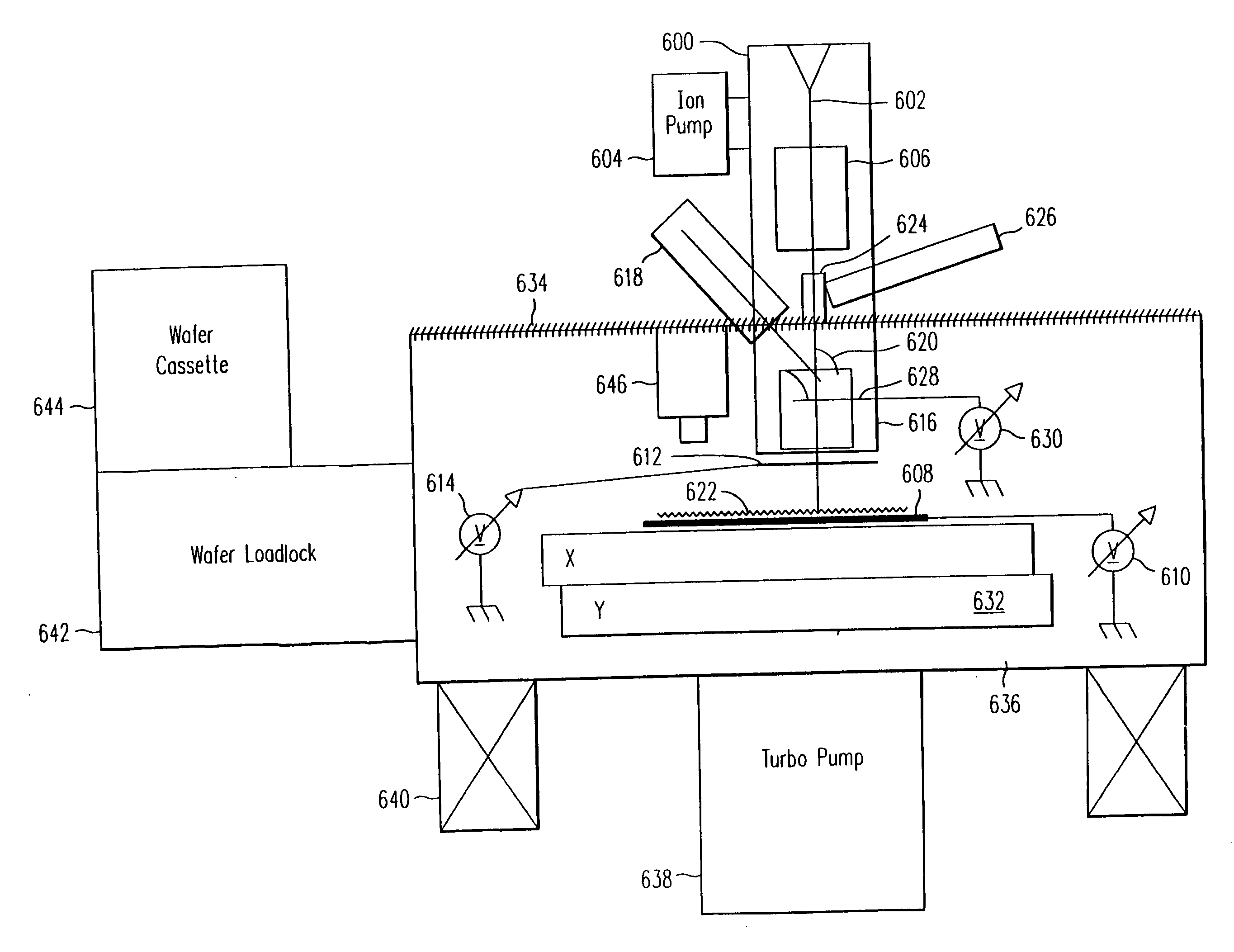

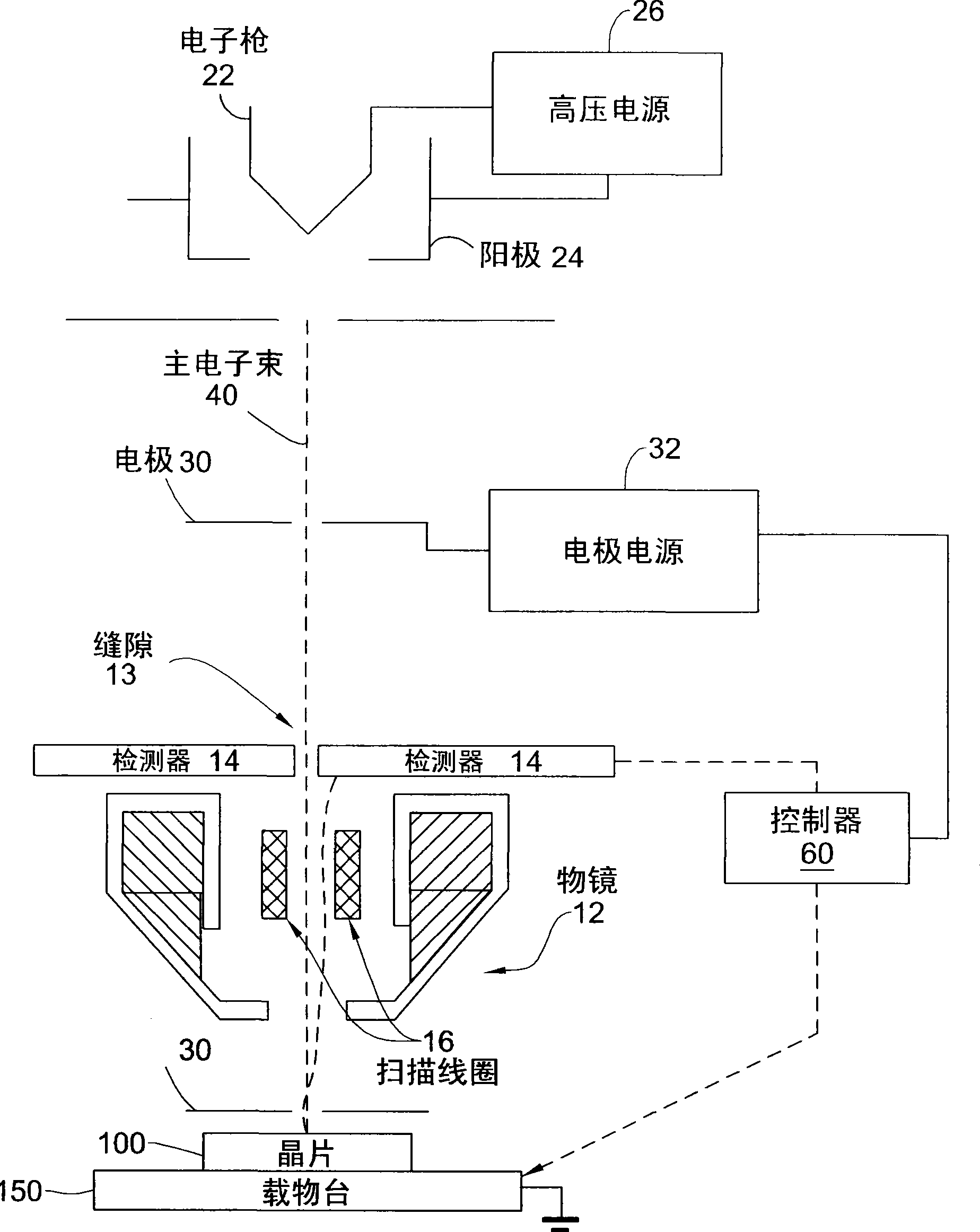

System and method for electric test of semiconductor wafer

InactiveCN101499433AEliminate distractionsSemiconductor/solid-state device testing/measurementElectric discharge tubesElectricitySemiconductor

A system for electrically testing a semiconductor wafer, the system including (a) at least one charged particle beam focus effecting component and (b) at least one detector adapted to collect charged particles scattered from the wafer; wherein the system is adapted to scan a first area of a sample by a de-focused charged particle beam so as to affect a charging of the first area, scan at least a portion of the first area by a focused charged particle beam and detect electrons scattered from the at least portion. The system scans the at least portion while the first area remains affected by the de-focused charged particle beam. A method for electrically testing a semiconductor wafer includes scanning a first area of a sample by a de-focused charged particle beam so as to affect a charging of the first area; and scanning at least a portion of the first area by a focused charged particle beam while detecting electrons scattered from the at least portion, the at least portion being scanned while the first area remains affected by charging introduced by the de-focused charged particle beam.

Owner:APPL MATERIALS ISRAEL LTD

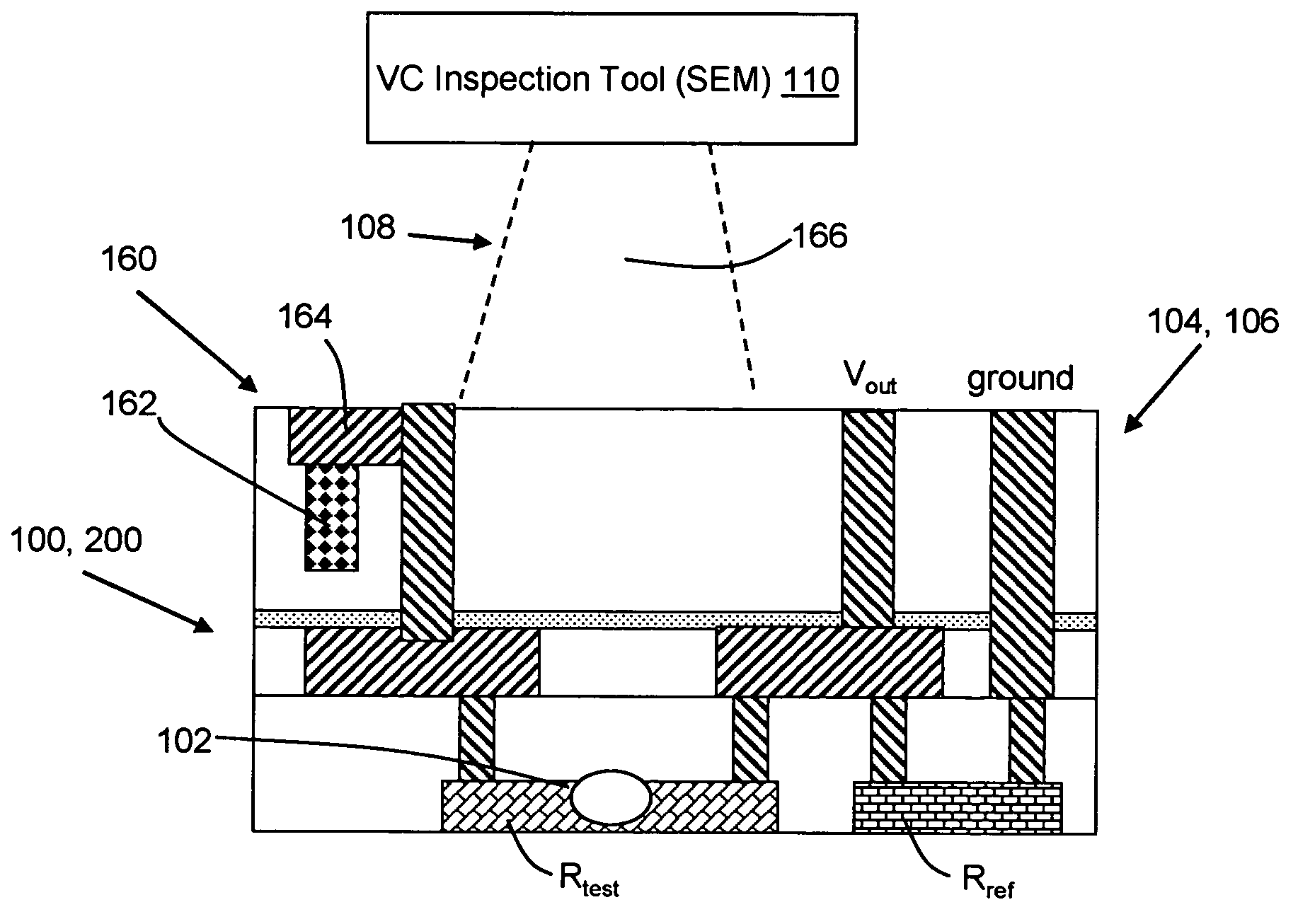

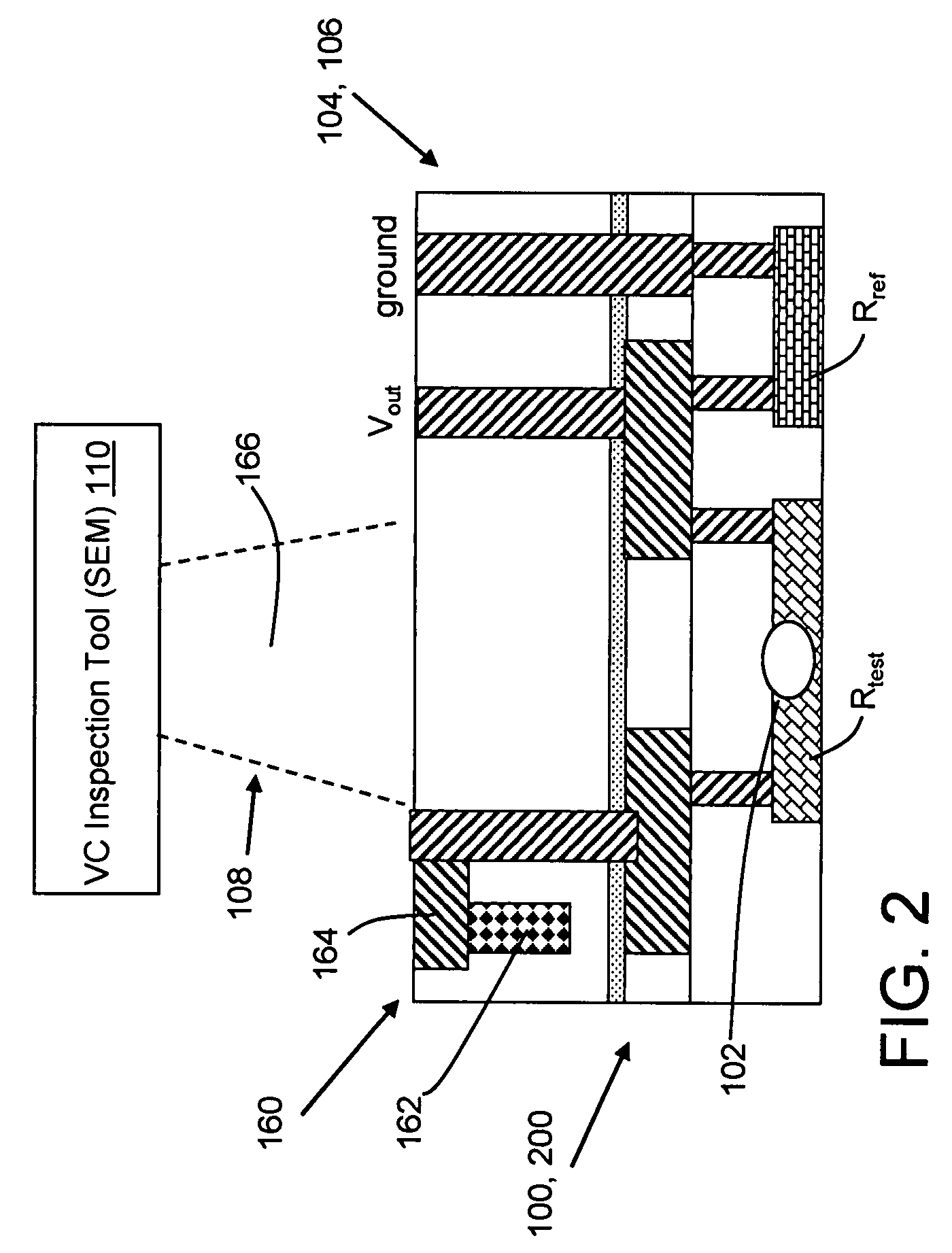

Test structure and method for resistive open detection using voltage contrast inspection

ActiveUS20090096461A1Semiconductor/solid-state device testing/measurementElectric discharge tubesElectrical resistance and conductanceOutput compare

A test structure for resistive open detection using voltage contrast (VC) inspection and method for using such structure are disclosed. The test structure may include a comparator within the IC chip for comparing a resistance value of a resistive element under test to a reference resistance and outputting a result of the comparing that indicates whether the resistive open exists in the resistive element under test, wherein the result is detectable by the voltage contrast inspection.

Owner:TWITTER INC

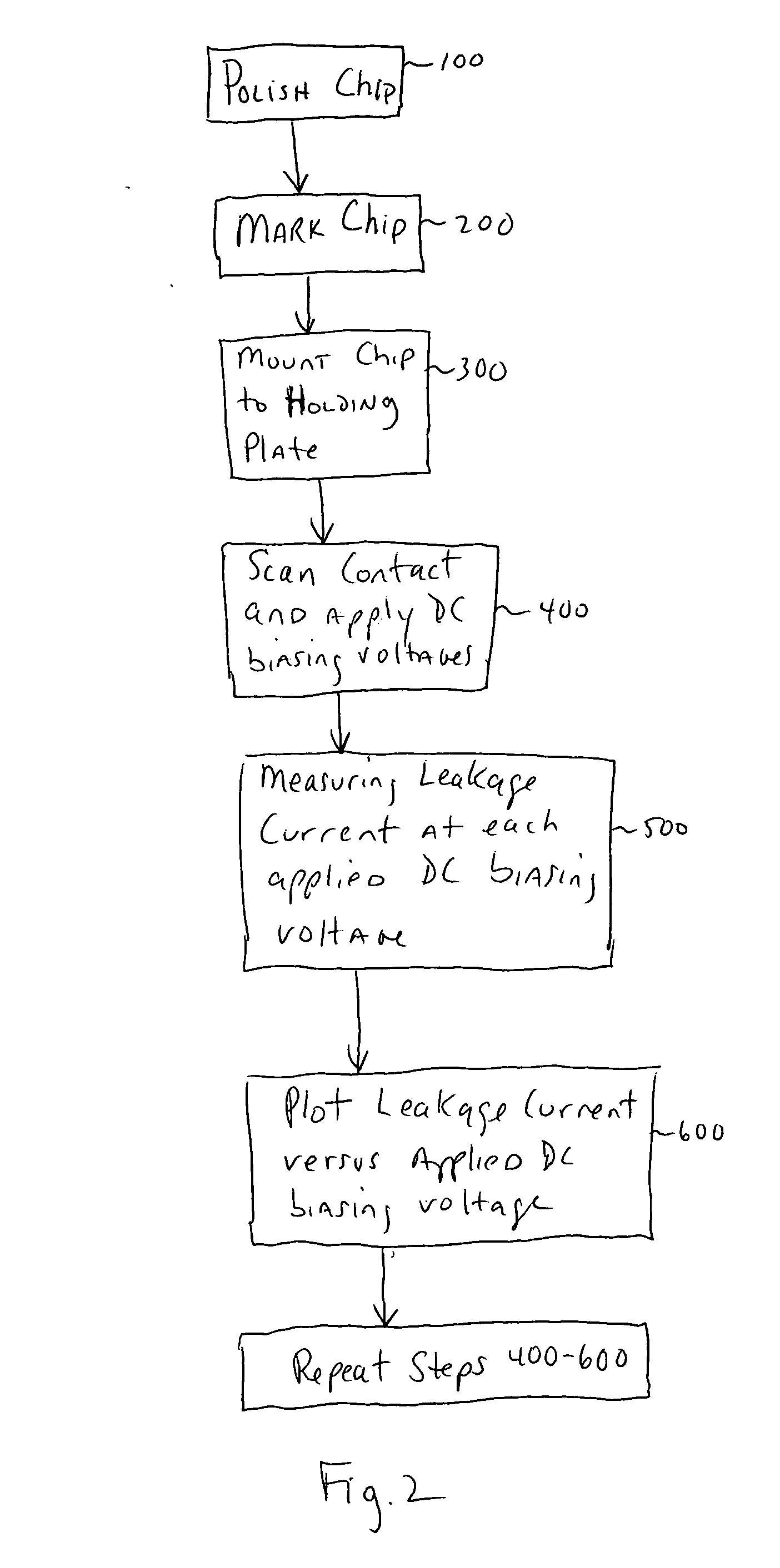

Method using conductive atomic force microscopy to measure contact leakage current

InactiveUS20050127926A1NanotechSemiconductor/solid-state device testing/measurementEngineeringSemiconductor

A method for measuring current leakage of a contact of a semiconductor device formed on or in a substrate, includes scanning the contact with a probe of a conductive atomic force microscope; applying a DC voltage between the substrate and a conductive tip of the probe; and measuring a value of a current passing through the contact to the substrate, in response to the applied DC voltage.

Owner:TAIWAN SEMICON MFG CO LTD

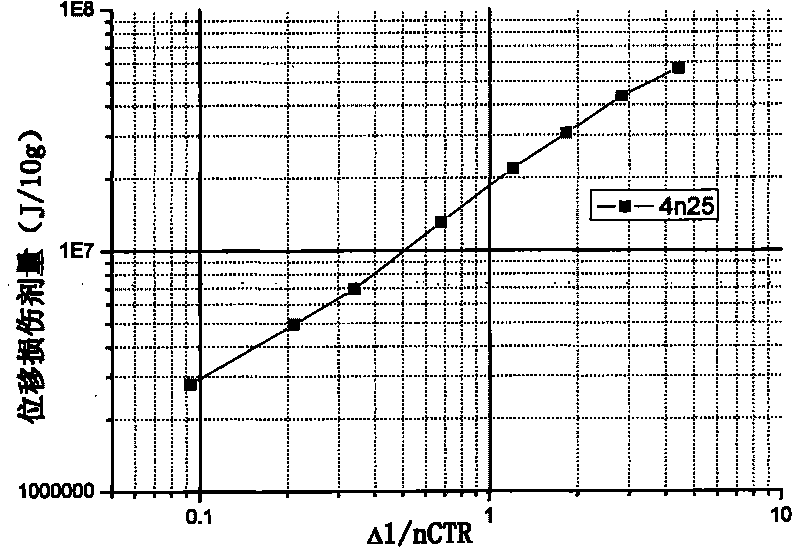

Displacement damage dose detecting method for spacecraft device

ActiveCN101697000AOvercoming non-ideal monoenergeticOvercome the effects of secondary radiationContactless testingNuclear technologySecondary radiation

The invention discloses a displacement damage dose detecting method for a spacecraft device, which belongs to the technical field of radiation detection in nuclear technology. The method comprises the following steps: scaling a photoelectric coupler integrated with an LED and a PD by using a radiation source to acquire a response curve of the increment of current transmission rate reciprocal of the photoelectric coupler during normalization and the displacement damage dose; then radiating the photoelectric coupler by using a ground displacement damage effect testing and evaluating source to acquire the increment of the current transmission rate reciprocal of the photoelectric coupler; and according to the increment of the current transmission rate reciprocal of the photoelectric coupler during specific radiation, searching the displacement damage dose corresponding to the increment in the response curve so as to detect the displacement damage dose at the moment. The method overcomes the influence of non-ideal single energy and secondary radiation of a general testing simulation source; and compared with the conventional method which only uses the LED to perform displacement damage detection, the testing system is simple and practical, and the error of optical coupling introduction is eliminated.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

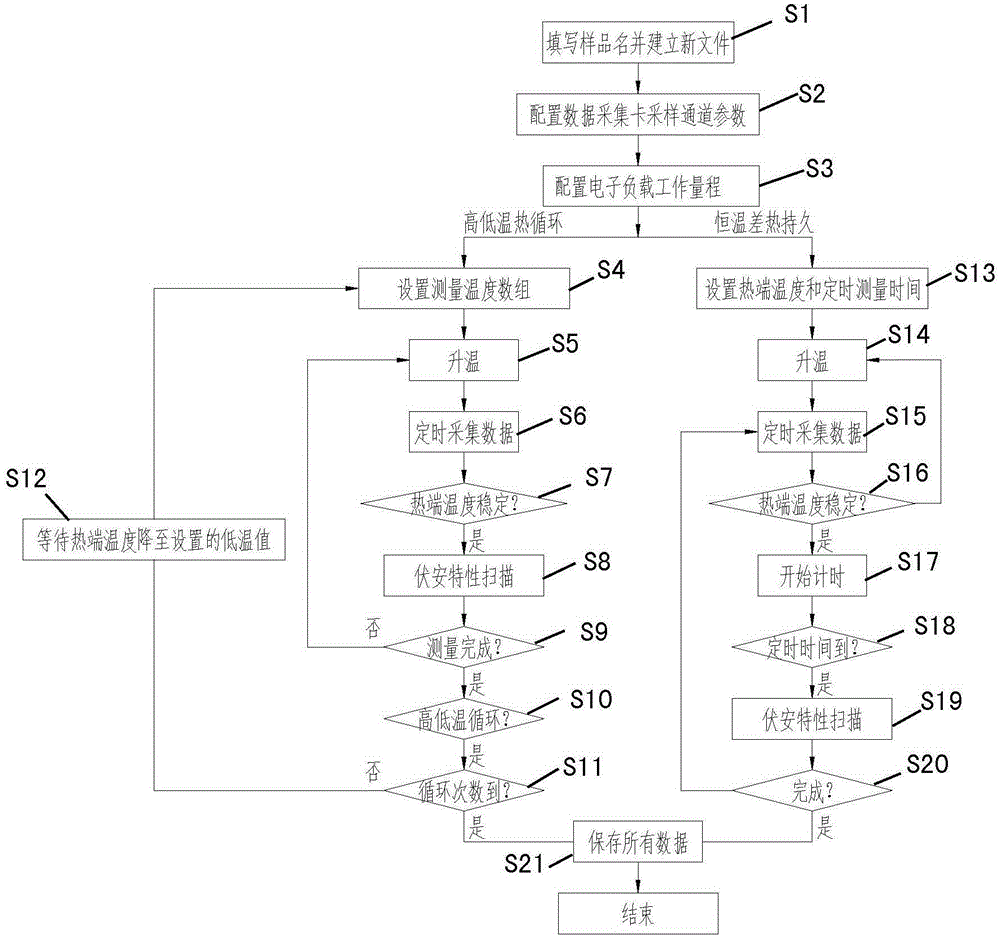

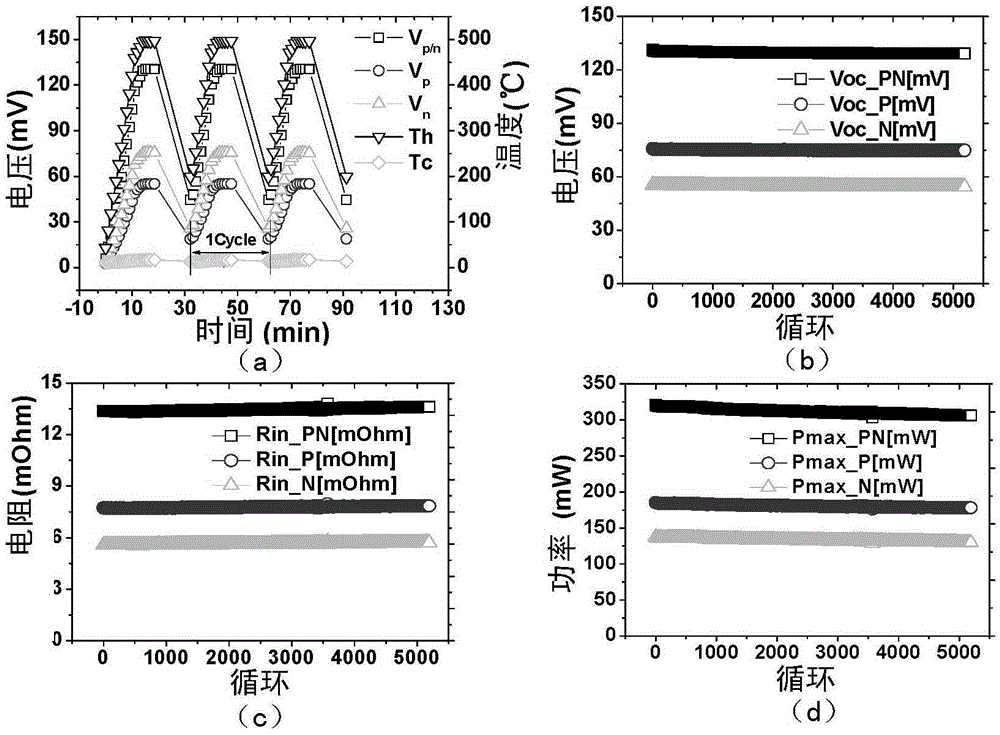

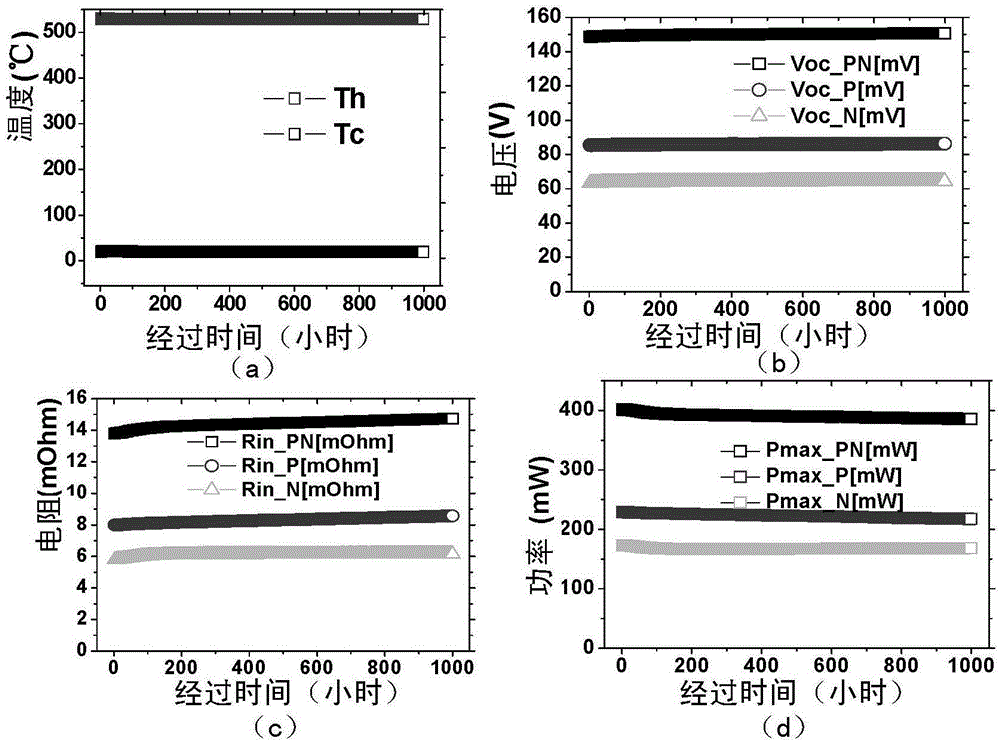

System and method for evaluating reliability of thermoelectric element

ActiveCN105203940AAvoid Manual Operation ErrorsShorten the timeContactless testingChannel dataTemperature control

The invention provides a system and method for evaluating reliability of a thermoelectric element. The system comprises a vacuum device with a vacuum cavity, a sample testing device used for clamping the thermoelectric element to be tested, a hot-end temperature control device used for controlling the temperature of a heat source in the sample testing device, a cold-end temperature control device used for controlling the temperature of a heat sink in the sample testing device, a load device, a multiple-channel data collecting device and a control unit. The sample testing device is located in the vacuum cavity and comprises the heat source and the heat sink, and the thermoelectric element is located between the heat source and the heat sink. The load device and the thermoelectric element constitute a series connection circuit, and the load device controls current output of the thermoelectric element. The multiple-channel data collecting device is connected with the load device as well as the cold side and the hot side of the thermoelectric element so as to collect measurement signals of the thermoelectric element. The control unit is connected with the load device, the multiple-channel data collecting device and the hot-end temperature control device.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

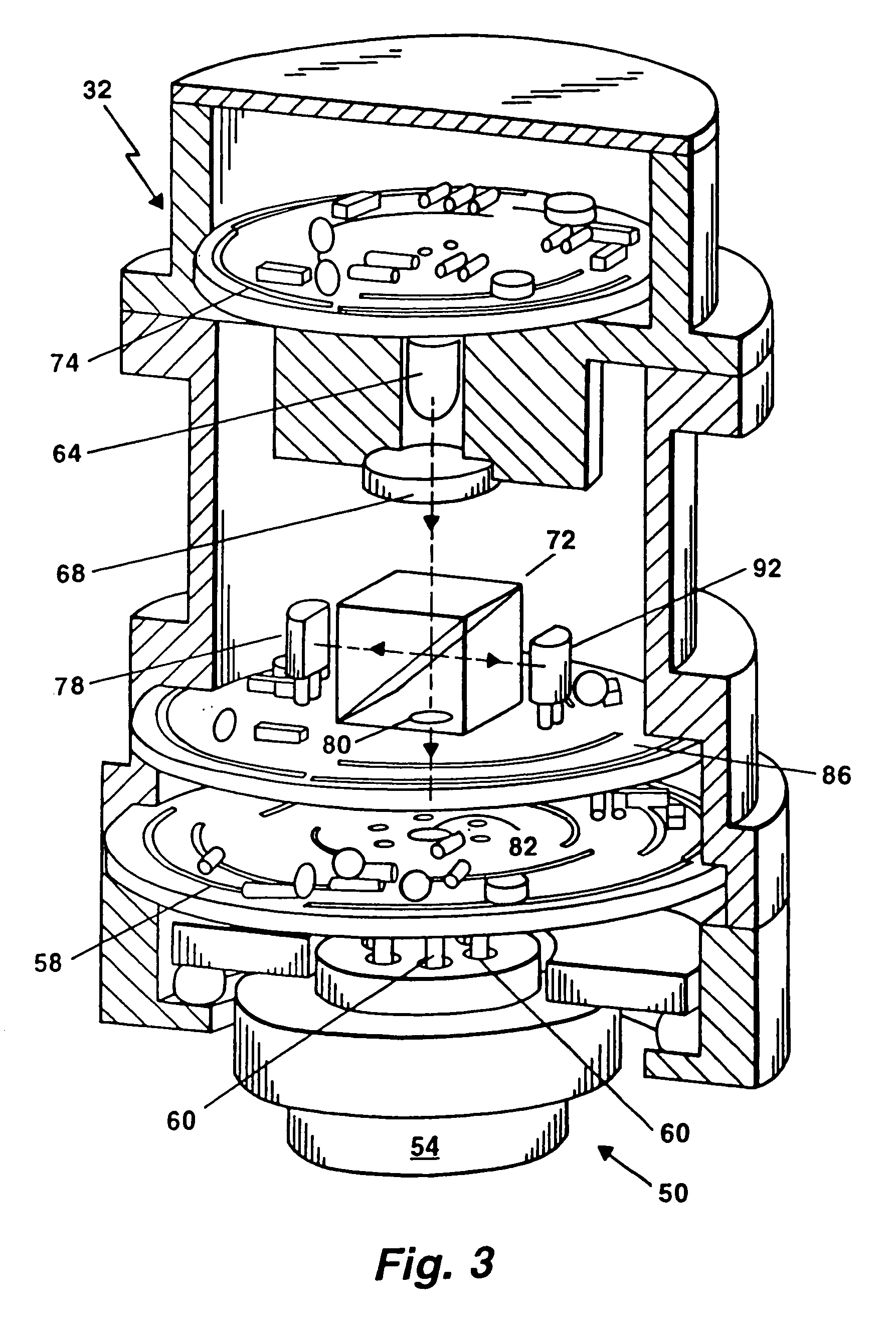

Determination of minority carrier diffusion length in solid state materials

ActiveUS6922067B1Improve spatial resolutionSpatial resolution is lowSemiconductor characterisationContactless testingDiffusionSolid mass

An apparatus and method is provided for determining the minority carrier diffusion length from the back side of the wafer within predetermined areas using pattern recognition system. In particular embodiments SPV probe includes transparent and non-transparent electrodes, to provide measurement of SPV and in area larger than optical beam and to provide accurate determination of diffusion length with spatial resolution <1 mm. The apparatus includes the ability to measure diffusion length from the areas under special areas within scribe line of patterned wafer. This apparatus and method provides a determination of the diffusion length to control metal contamination in product including patterned wafers including measurement within scribe lines and full wafer mapping.

Owner:APPLEJACK 199

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com