System and method for evaluating reliability of thermoelectric element

A technology for evaluating system and reliability, applied in the direction of measuring electricity, measuring electrical variables, testing of single semiconductor devices, etc., can solve the problems of not evaluating the reliability of components, not involving the reliability evaluation method of components, etc., and achieve the evaluation results. Reliable, avoid manual operation errors, save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

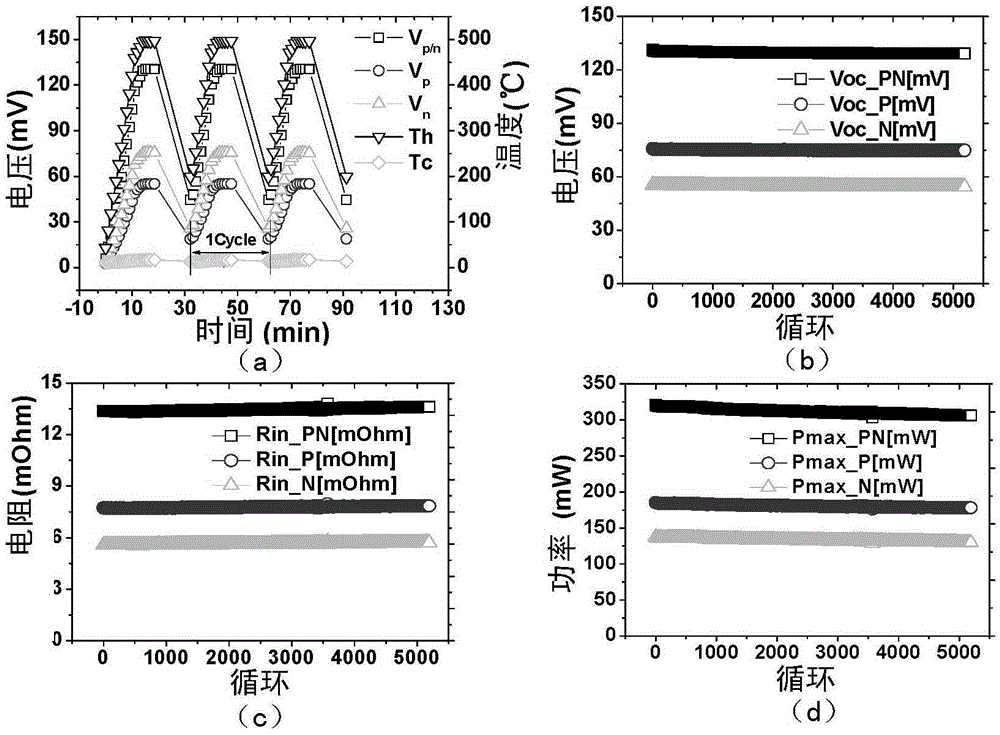

[0090]Example 1: The 1# thermoelectric device sample is used for high and low temperature thermal cycle experiments. The hot end is oscillated between 500°C and 200°C. The thermal cycle period is controlled to be about 30 minutes, and the temperature of the cold end is controlled to be about 15°C. After more than 5,000 cycles After the cycle, analyze its performance changes such as Figure 4 shown. The total open-circuit voltage of thermoelectric elements dropped from 131mV to 129mV, down 1.5%, among which, the open-circuit voltage of P-type elements dropped from 75.7mV to 74.7mV, down 1.3%, and the open-circuit voltage of N-type elements dropped from 55.4mV to 54.4mV, down 1.8% ;The total internal resistance of thermoelectric elements increased from 13.372mOhm to 13.589mOhm, an increase of 1.6%, among which, the internal resistance of P-type components increased from 7.731mOhm to 7.85mOhm, an increase of 1.5%, and the internal resistance of N-type components increased from 5....

Embodiment 2

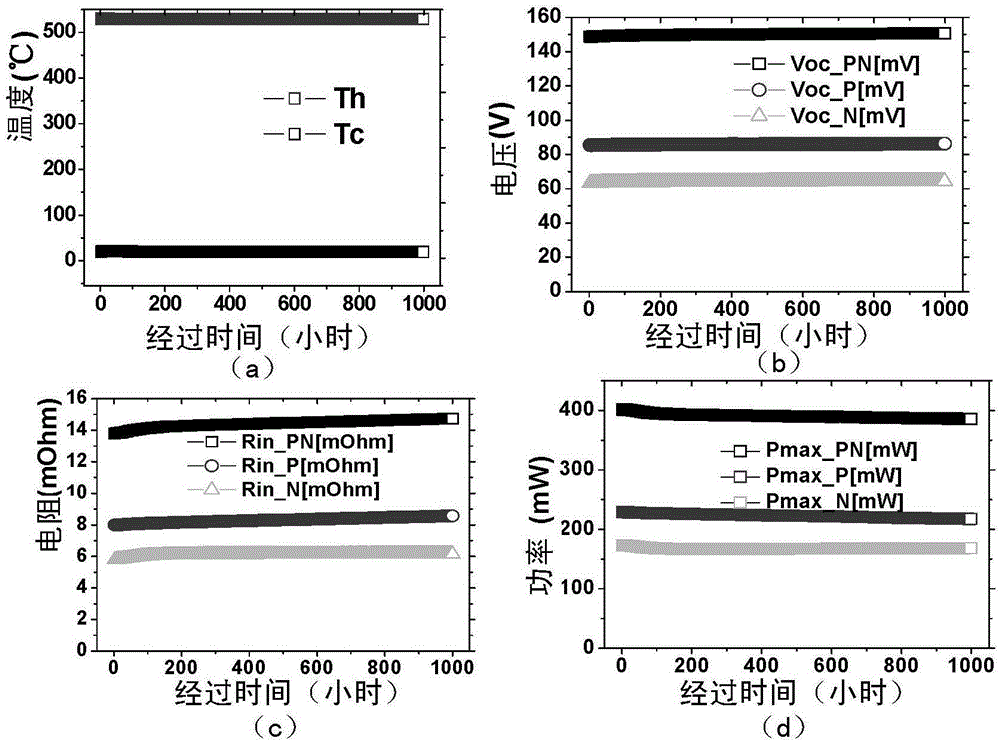

[0091] Example 2: The 2# thermoelectric device sample is used for the constant temperature differential heat endurance experiment. The hot end is controlled at 530°C, the cold end is controlled at 20°C, and the timing measurement period is 1 hour. After 1000 hours, the performance change is analyzed as shown in the attached Figure 5 shown. The total open-circuit voltage of thermoelectric elements increased from 148.77mV to 150.695mV, an increase of 1.2%, among which, the open-circuit voltage of P-type elements increased from 85.538mV to 86.33mV, an increase of 0.9%, and the open-circuit voltage of N-type elements increased from 63.249mV to 64.381mV, an increase of 1.7%; the total internal resistance of thermoelectric elements increased from 13.78mOhm to 14.725mOhm, an increase of 6.8%, of which, the internal resistance of P-type components increased from 7.992mOhm to 8.567mOhm, an increase of 7.2%, and the internal resistance of N-type components increased from 5.788mOhm to 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com