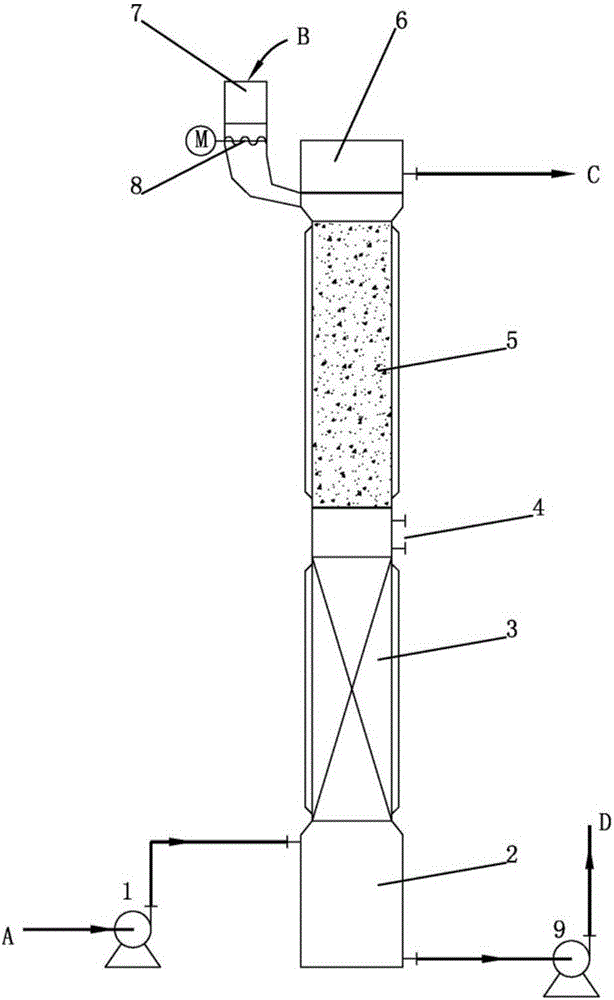

Continuous salting-out and drying device and use method thereof

A drying device and salting-out technology, used in separation methods, drying solid materials, chemical instruments and methods, etc., can solve the problems of many supporting equipment, poor working environment, long process flow, etc., to improve the working environment, simplify equipment, The effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Salting out and drying treatment of pyridine aqueous solution with potassium hydroxide: prepare potassium hydroxide particles in the solid feed bin 7, open the solid feeding valve 8, and fill the drying section 5 with potassium hydroxide B, which has a water content of 42%. Pyridine aqueous solution A is pumped in with the feed pump 1, and the liquid level rises slowly. When the liquid touches the solid particles at the lower end of the drying section 5, the solution begins to dissolve potassium hydroxide. At this time, the solid feeding valve 8 is opened to stabilize the drying section 5. After the potassium hydroxide dissolved in the solution reaches a certain concentration, the feed liquid is layered, and the discharge of the waste water discharge pump 9 is adjusted through the oil-water interface meter to control the oil-water two-phase interface in the middle of the interface control section 4, and the pyridine aqueous solution A passes through the inlet The materia...

Embodiment 2

[0036] Triethylamine acetate aqueous solution is salted out with sodium hydroxide, drying treatment: the operation in embodiment 1 is basically the same, solid particles and aqueous solution are changed into sodium hydroxide and triethylamine acetate aqueous solution, and In the salting-out section, there is a chemical reaction and heat is released. It is necessary to add a jacket to the lower part of the tower and pass cooling water to cool down; the others are the same. The triethylamine acetate aqueous solution with a water content of 60% is subjected to alkali analysis and drying to obtain triethylamine with a water content of less than 0.1%, with a yield of 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com