Thermoelectric power generating component performance measuring device and method thereof

A technology for thermoelectric power generation and measurement device, which is applied in measurement device, thermoelectric device manufacturing/processing, semiconductor/solid-state device testing/measurement, etc. to avoid heat loss, direct and effective measurement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

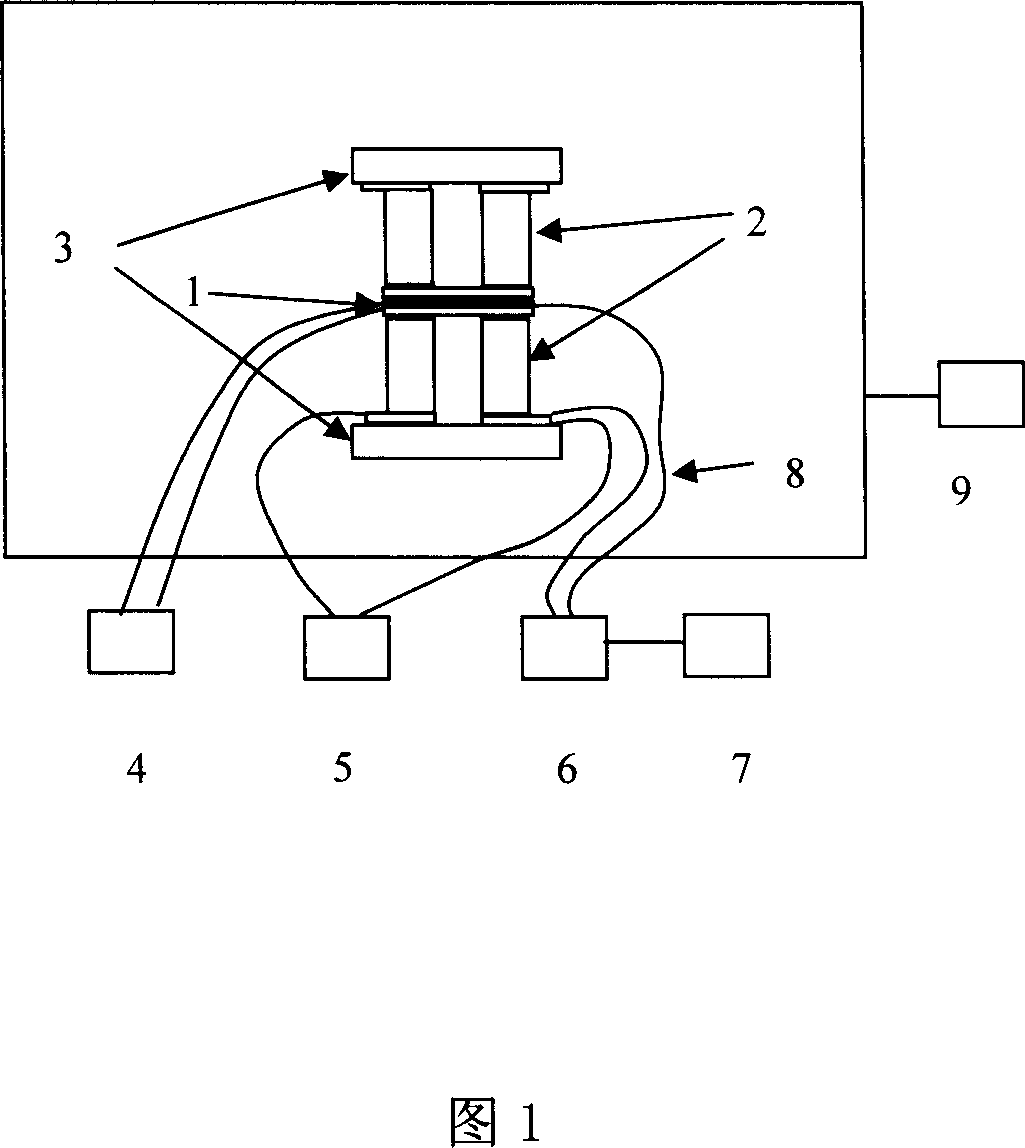

[0023] During measurement, the thermoelectric power generation component 2 is first installed between the heat source 1 and the cold end 3, and the output end of the component is connected to a standard load resistance 5; the vacuum pump 9 is started to establish a vacuum; the DC power supply 4 is connected, and the heat source 1 generates heat. Establish a temperature difference with the cold end 3, the temperature of the hot end and the cold end are measured by the thermocouple 7, and collected by the multi-channel data recorder 6; the thermoelectric power generation components generate a thermoelectric force, change the standard load resistance 5, and the output current and voltage of the components change with the The value is collected by the multi-channel recorder 6; the computer 7 performs data processing, and outputs the open circuit voltage, output power and energy conversion efficiency of the components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com