Display module and assembling method thereof

A technology for displaying modules and assembly methods, applied to static indicators, nonlinear optics, instruments, etc., which can solve problems such as difficult to remove, difficult to rework polarizers, bright or dark spots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

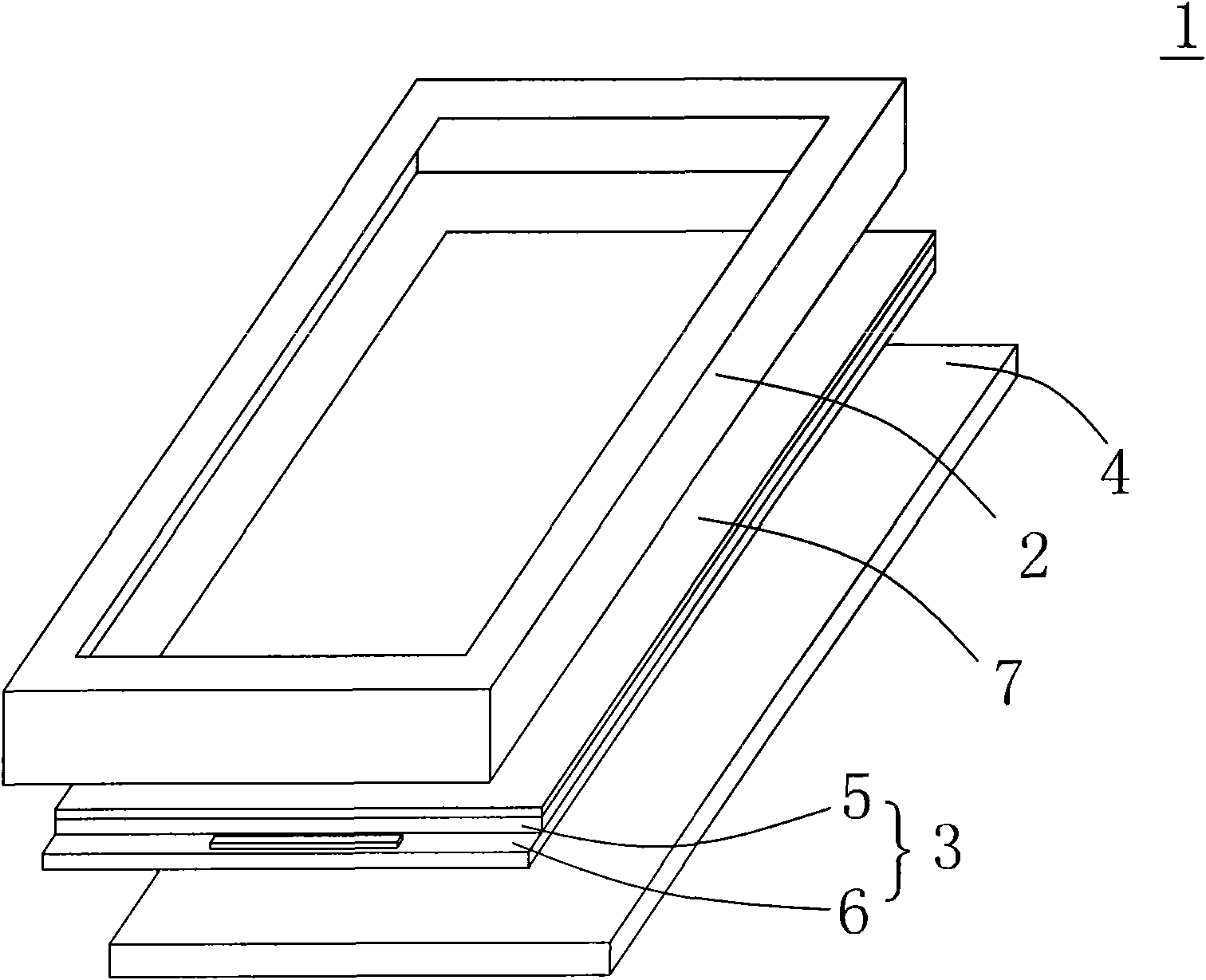

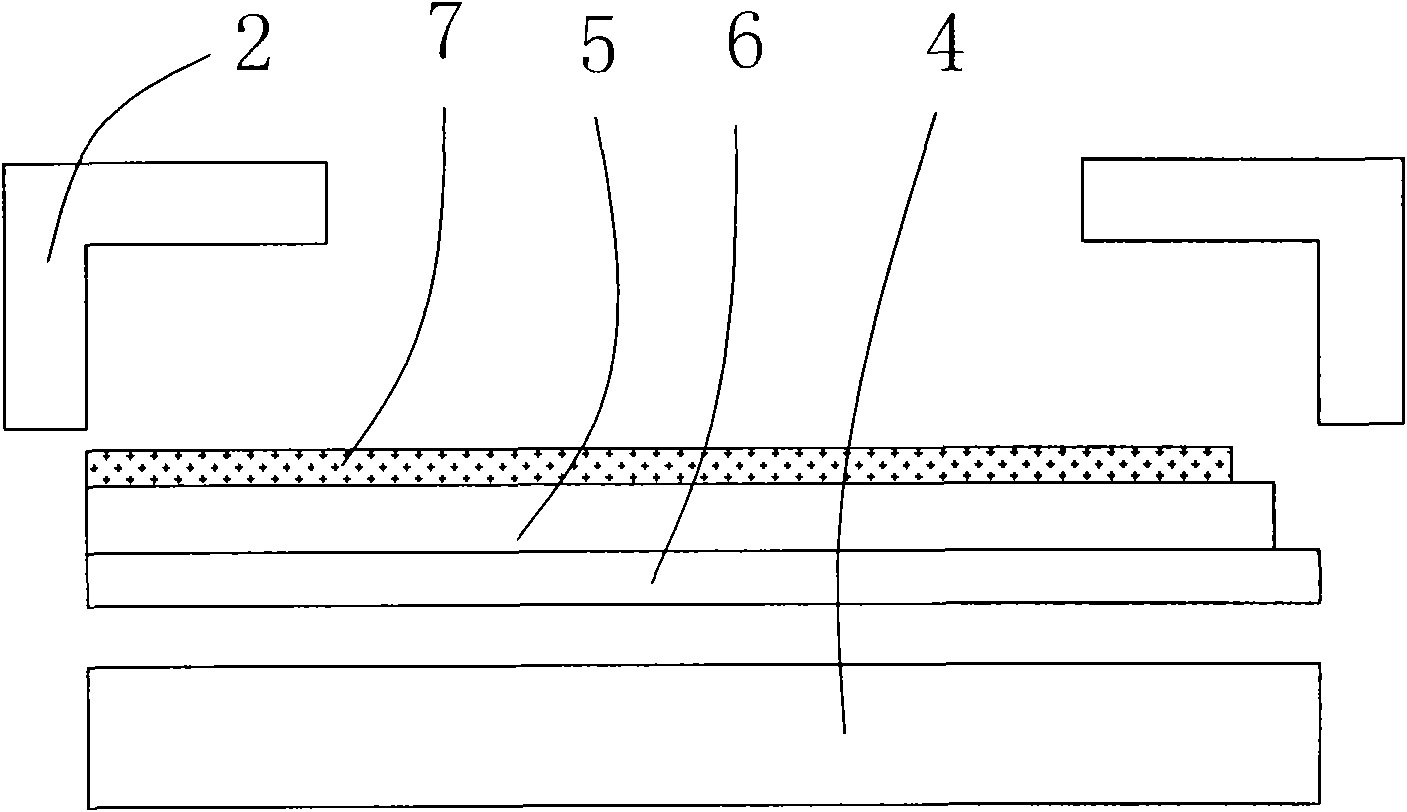

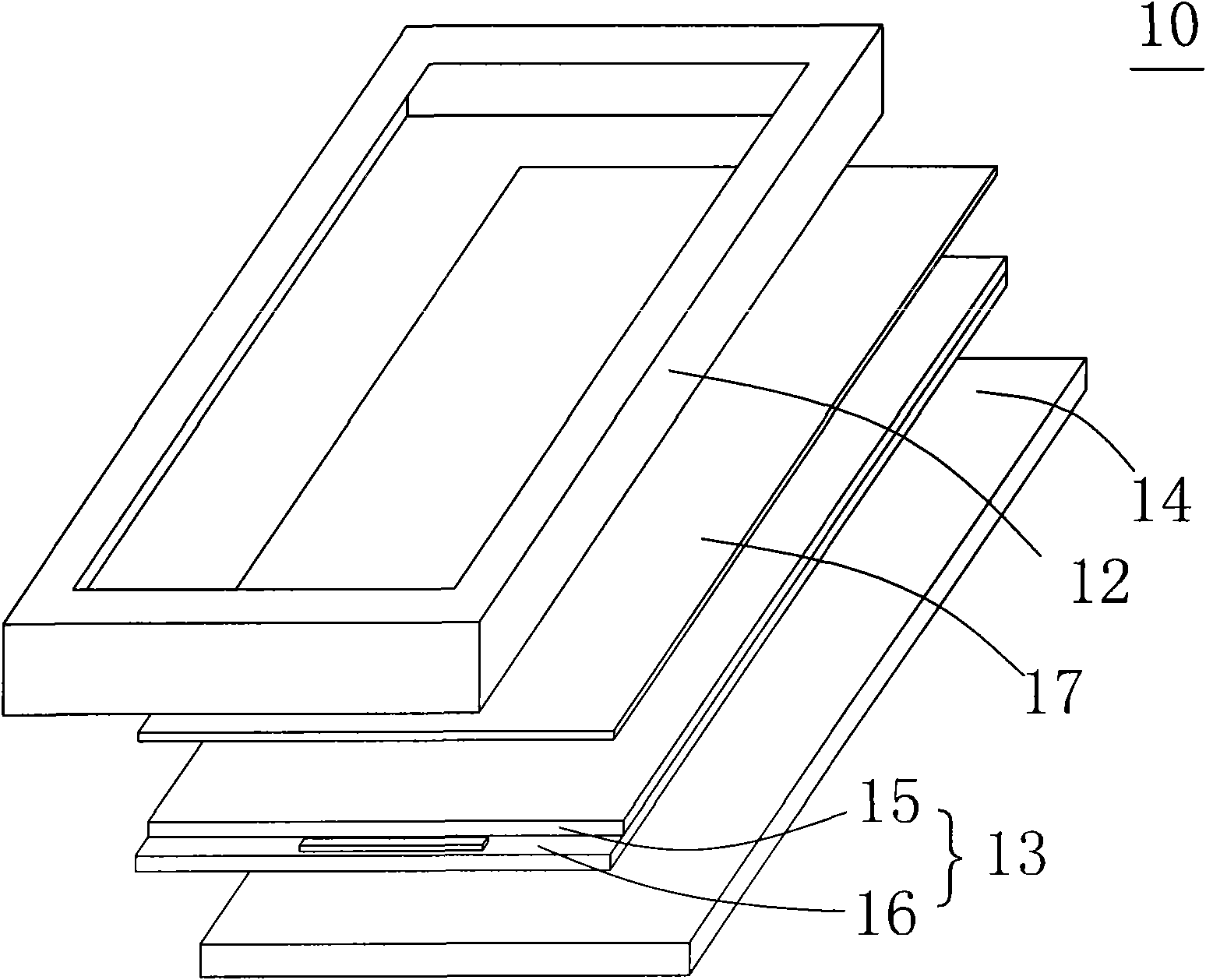

[0028] See Figure 2A and Figure 2B , Figure 2A Shown is a schematic diagram of a first embodiment of a display device according to the present invention, Figure 2B shown as Figure 2A A schematic cross-sectional view of the display device in . The display module 10 provided by the present invention includes a display panel 13 , a front frame 12 and a first polarizer 17 . The display module 10 is, for example, a liquid crystal display module, and the corresponding display panel 13 is a liquid crystal display panel. The liquid crystal display panel 13 includes a first substrate 15 and a second substrate 16 opposite to each other. In this embodiment, the first substrate 15 is a color filter substrate as an example, and the second substrate 16 is a thin film transistor array substrate.

[0029] The front frame 12 is disposed on a side of the first substrate 15 opposite to the second substrate 16 , and the front frame 12 has a first surface 21 and a second surface 22 oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com