Tool for cutting double-sided adhesive tape between liquid crystal display panel and glue frame

A liquid crystal panel and double-sided adhesive technology, which is applied in metal processing and other directions, can solve the problems of liquid crystal panel fragmentation, low cutting efficiency, and difficult control of parallelism, and achieve the effect of ensuring flatness and preventing fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

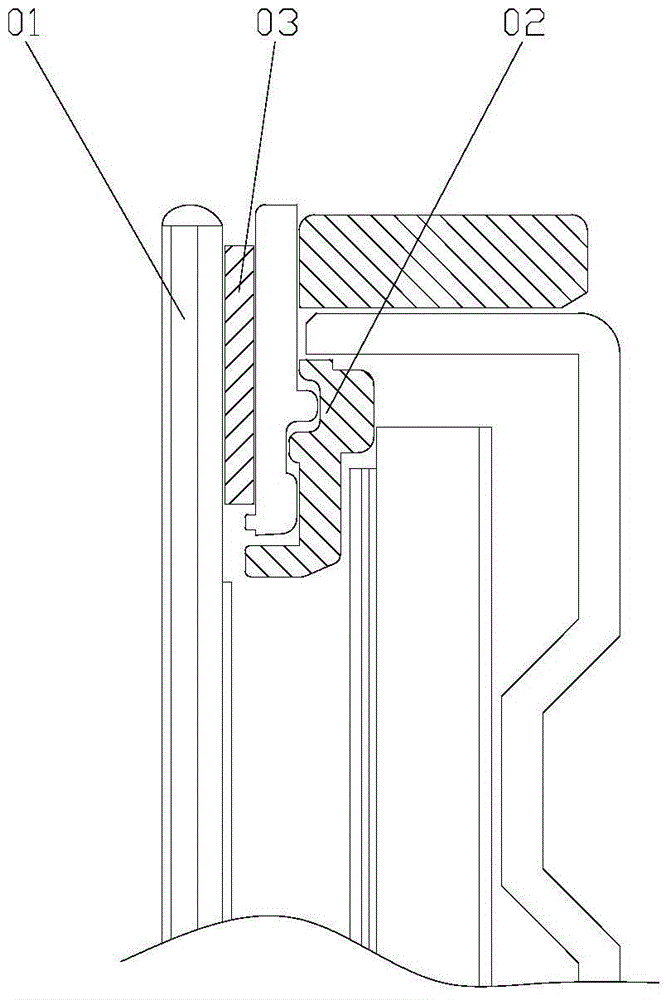

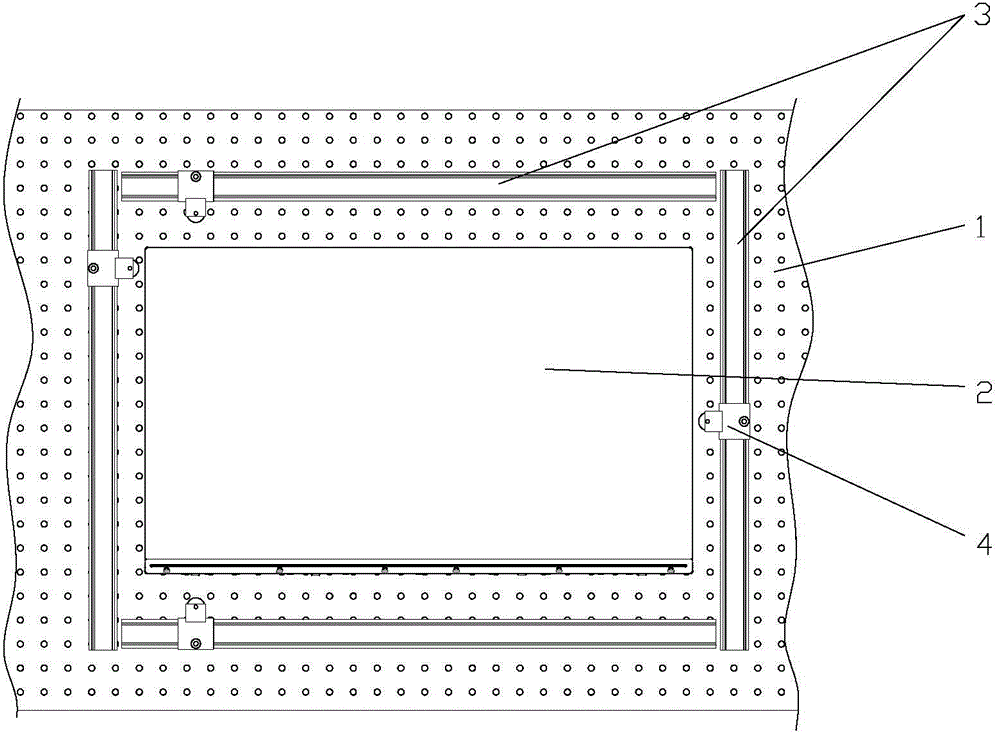

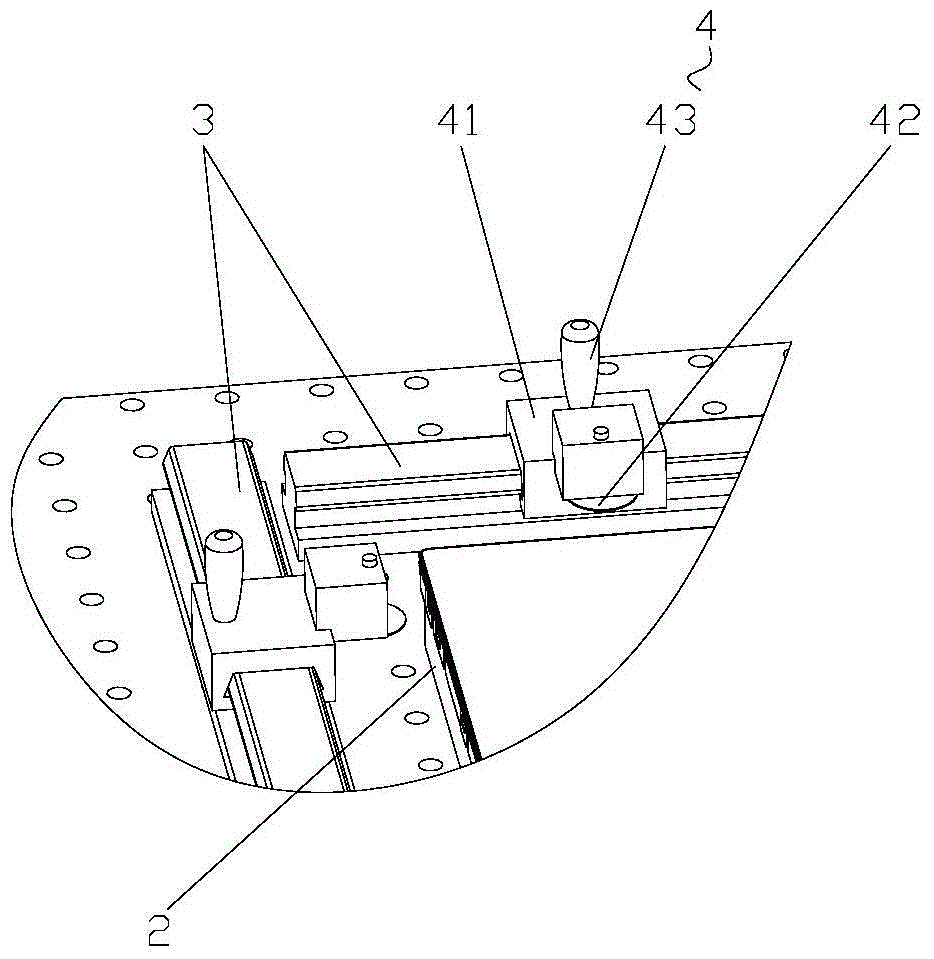

[0017] Such as figure 2 , image 3 or Figure 4 As shown, the present invention includes a bottom plate 1 and a plastic frame positioning plate 2, the plastic frame positioning plate 2 is fixed on the bottom plate 1, and the plastic frame with a liquid crystal panel is nested and positioned on the plastic frame positioning plate 2; the bottom plate 1 The four sides corresponding to the plastic frame positioning plate 2 are provided with slide rails 3 respectively, and each slide rail 3 is respectively provided with a cutting tool 4, the blade 42 of the cutting tool 4 faces the plastic frame positioning plate 2, when the cutting tool 4 When sliding along the slide rail 3, the blade 42 of the cutting tool 4 cuts and separates the double-sided adhesive tape between the liquid crystal panel and the plastic frame.

[0018] The cutting tool 4 includes a slide block slidably arranged on the slide rail 3, and the blade 42 is fixed on the slide block.

[0019] The slider is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com