Conveying jig of liquid crystal display panel

A technology for liquid crystal panels and fixtures, which is applied in the direction of rigid containers, fragile goods packaging, containers, etc. It can solve problems such as the inability to take out the panel, the panel is broken, and the amplitude is large, so as to avoid fragmentation of the liquid crystal panel, prevent deformation or fragmentation, reduce The effect of small vibration amplitudes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

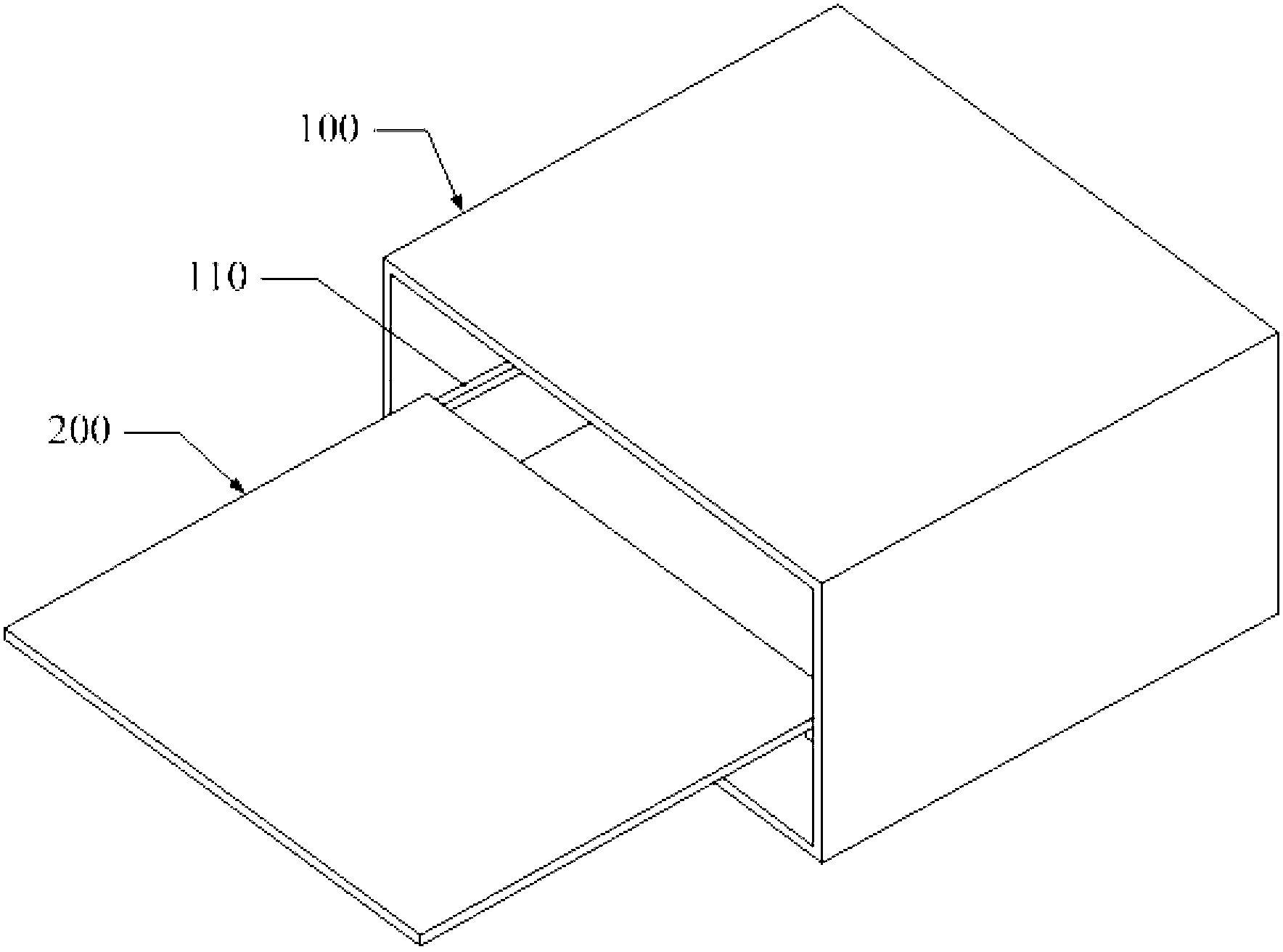

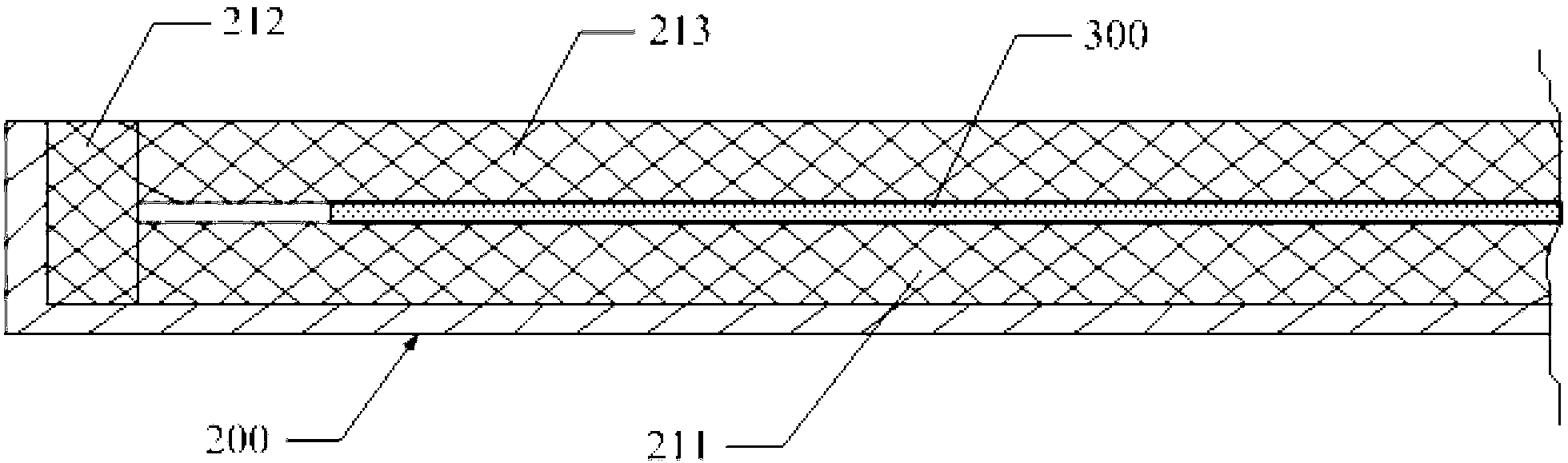

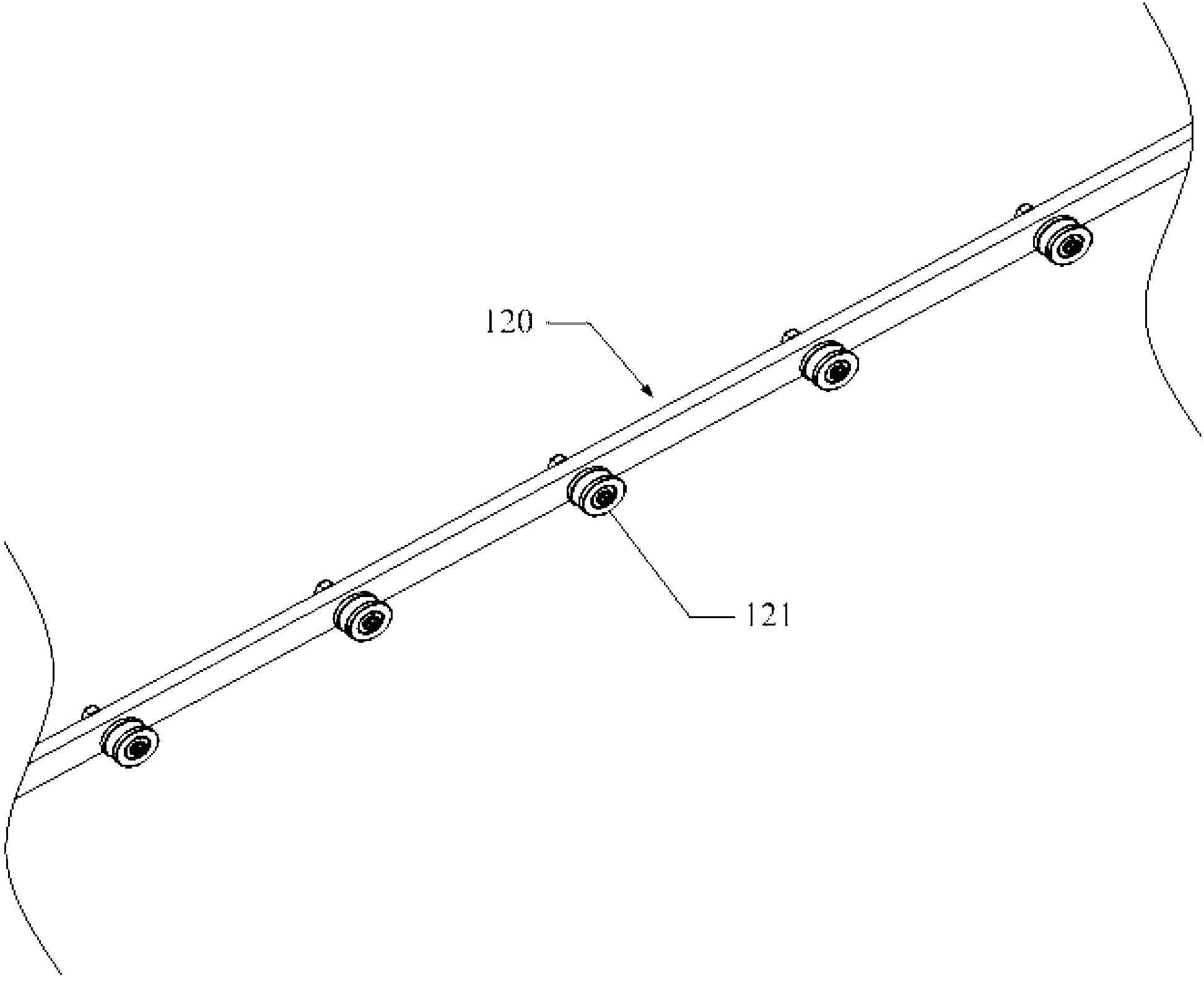

[0027] Such as figure 1 As shown, figure 1 It is a schematic structural diagram of the first embodiment of the liquid crystal panel transport jig of the present invention. The liquid crystal panel transport fixture mentioned in this embodiment includes a drawer 100 and at least one tray 200. The tray 200 is used to place a liquid crystal panel (not shown in the figure). At least one The support 110 is assembled, and the tray 200 is placed on the support 110 and slides into or out of the drawer 100 relative to the support 110. The tray 200 uses rigid hard materials to provide a flat support surface for the liquid crystal panel, increase the support point for the liquid crystal panel, reduce the vibration amplitude during the moving process, and effectively prevent the liquid crystal panel from deforming or breaking....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com