Tool facilitating assembly of aero model

A model and aviation technology, applied in manufacturing tools, workbenches, workpiece clamping devices, etc., can solve the problems of low assembly efficiency, wrong installation of model parts, and inconvenience in the completion of aviation model production, so as to improve assembly efficiency and increase fixation. performance, avoid surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

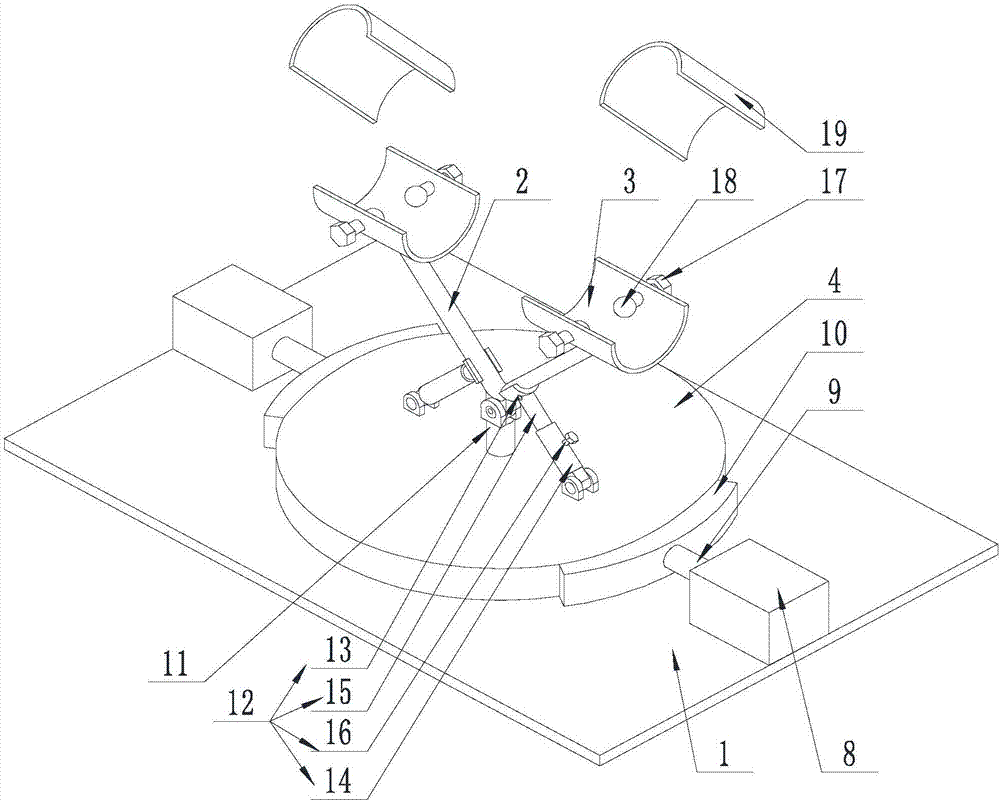

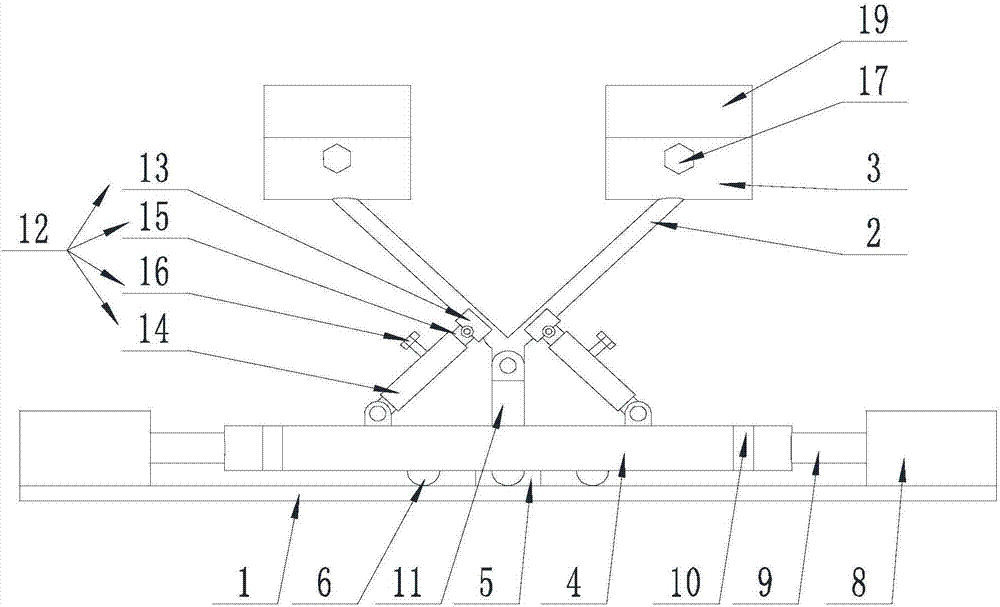

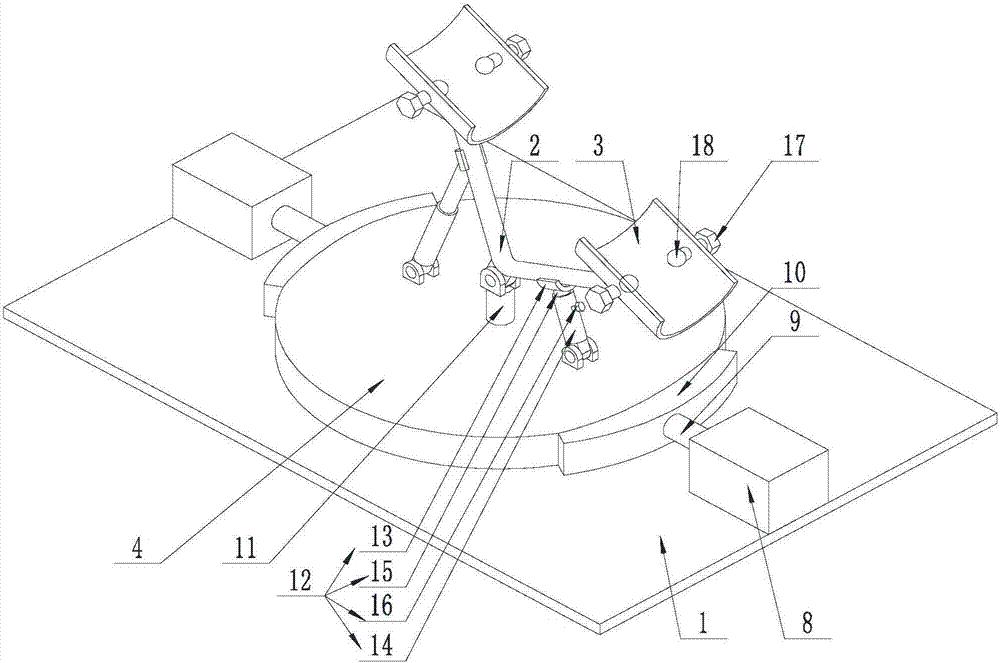

[0053] Such as Figure 1-Figure 7 As shown, the present invention facilitates the assembly of the aircraft model, including a support plate 1, on which a support rod 2 is arranged on the upper surface of the support plate 1, and the support rod 2 is bent into a V-shaped bar, and its tip is connected to the support plate. 1 connection, connecting plates 3 are arranged at their ends, and the connecting plates 3 are all arc-shaped plates, their axes coincide with each other, and their outer convex surfaces are connected with the ends of the support rods 2, and above the connecting plates 3 are provided with Pressing plate 19, on pressing plate 19, one end close to connecting plate 3 and the inner concave surface of connecting plate 3 are all provided with magnets, and the cross section of connecting plate 3 is a inferior arc shape;

[0054] Limiting bolts 17 are arranged on the side walls away from the support rod 2 on the connecting plate 3, and the limiting bolts 17 are threade...

Embodiment 2

[0060] This embodiment is based on Embodiment 1 to further illustrate the present invention.

[0061] Such as Figure 1-Figure 7 As shown, the present invention facilitates the assembly of aircraft models. Between the support plate 1 and the support rod 2, there are sequentially connected and coaxial rotating disks 4 and support shafts 5. One end of the support shaft 5 is connected to the support plate 1. Connected, the other end of the support shaft 5 is rotationally connected with the rotating disk 4; the rotating disk 4 can rotate around the axis of the supporting shaft 5, and the end of the rotating disk 4 away from the supporting shaft 5 is connected with the support rod 2, and the support rod 2 The center line coincides with the axis of the support shaft 5.

[0062] Further, three support balls 6 are arranged on the end of the rotating disk 4 close to the supporting plate 1, and the supporting balls 6 are evenly divided on the rotating disk 4 with the axis of the rotati...

Embodiment 3

[0066] This embodiment is based on the second embodiment, and further explains the position limitation of the support ball 6 .

[0067] Such as Figure 1-Figure 7 As shown, the present invention facilitates the assembly of the aircraft model. A limiting groove 7 is arranged on the upper surface of the support plate 1. The limiting groove 7 is an annular groove, and its axis coincides with the axis of the rotating disk 4, limiting The groove bottom of bit groove 7 is inferior arc shape, and its diameter is consistent with the ball diameter of support ball 6, and its center of circle is positioned in limit groove 7, and one end away from rotating disc 4 on described support ball 6 is positioned in limit groove 7, And contact with the groove bottom of limit groove 7.

[0068] Since the support ball 6 only supports the rotating disk 4, and when the rotating disk 4 is subjected to radial force, the connecting part of the supporting ball 6 and the rotating disk 4 will be subject to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com