Self-locking zipper puller

A zipper puller and self-locking technology, which is applied in the field of zipper pullers, can solve the problems of poor stability in use, high manufacturing difficulty and cost, small contact surface between shrapnel and hook, etc., and achieve light shifting, low cost, and good contact effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

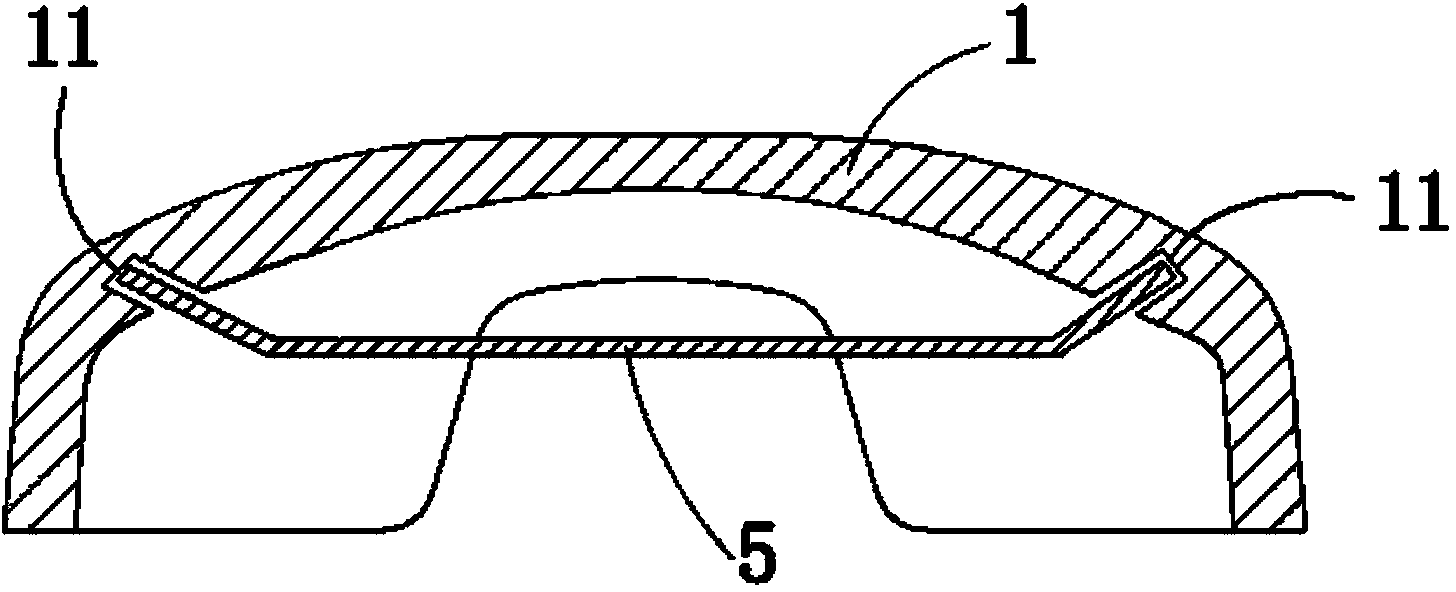

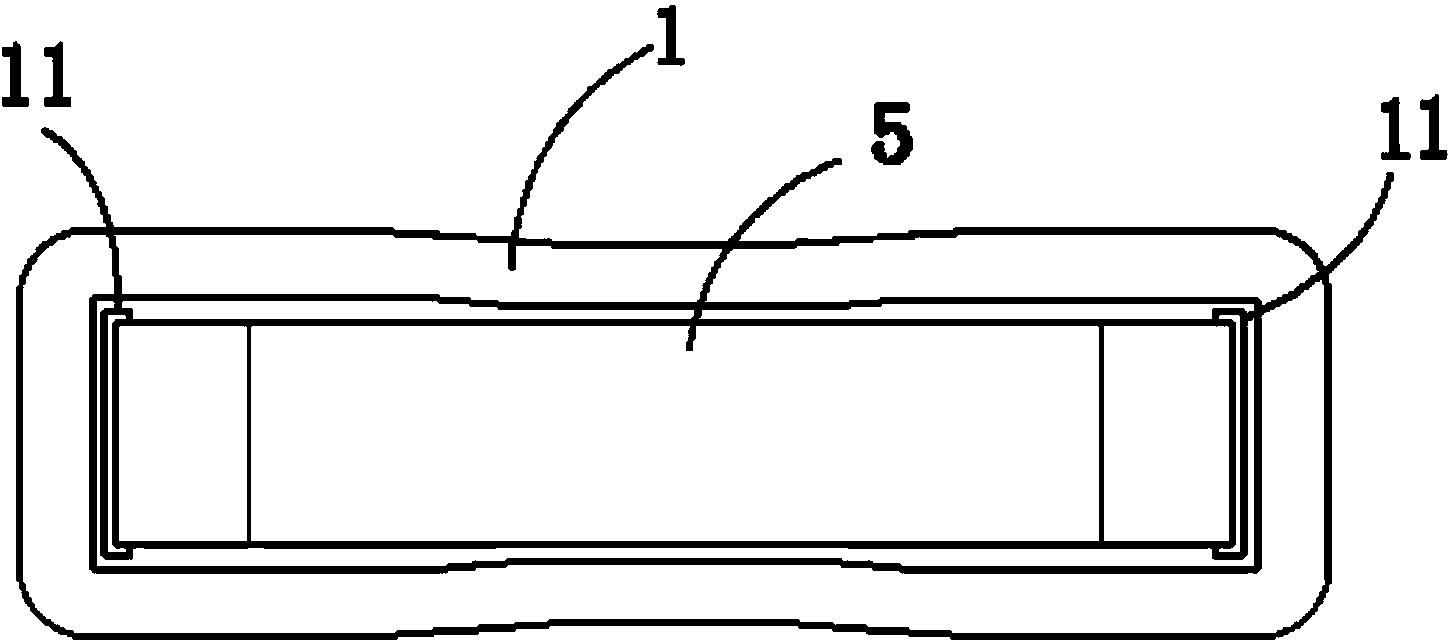

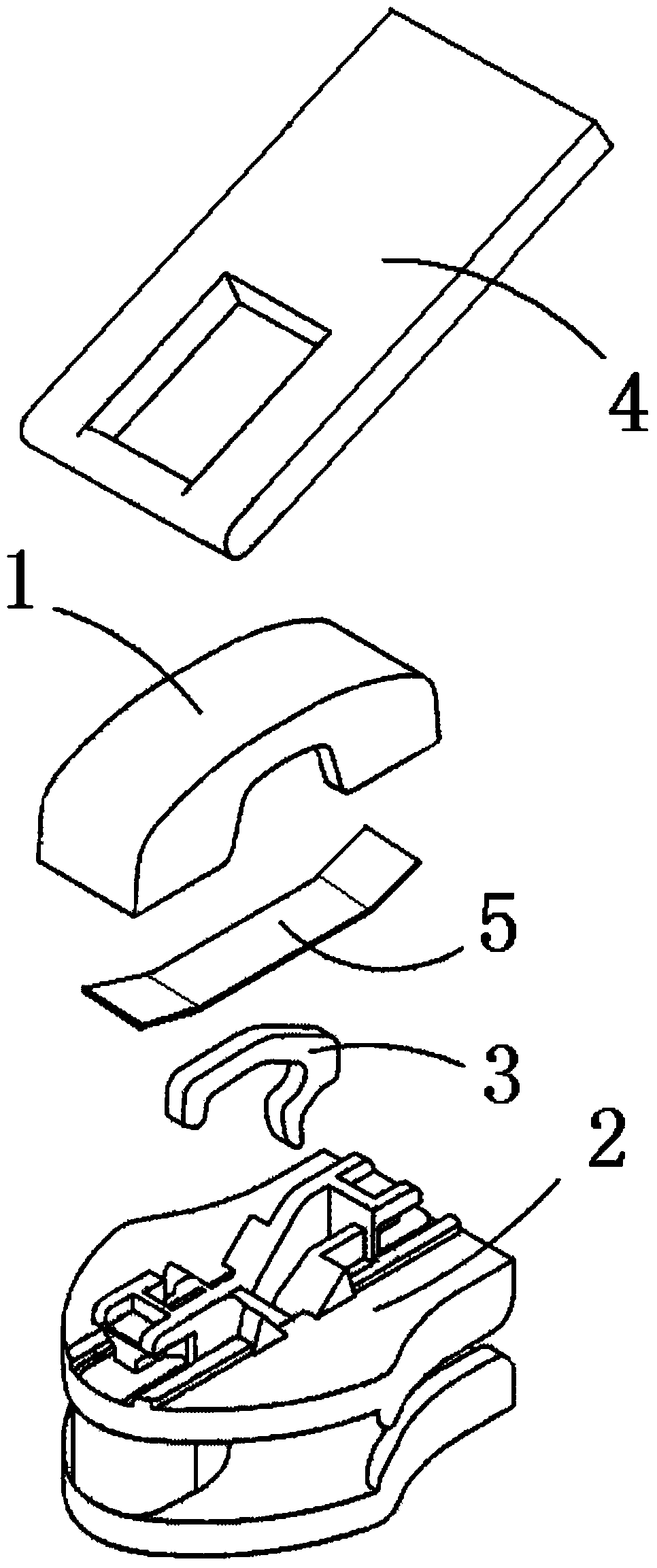

[0012] The following is the specific implementation manner of a preferred embodiment of the present invention, as Figures 1 to 3 As shown, a self-locking zipper puller, the zipper puller includes a slider body 2, a cap 1, an elastic piece 5, a hook 3 and a pull piece 4; the cap 1 is fastened on the slider body 2; the inside of the cap 1 The two corners of the top are respectively provided with a groove 11, the middle part of the shrapnel 5 is a flat plate, and the two ends are in the shape of an obtuse angle upwards, and the two ends of the shrapnel 5 are respectively located in the two grooves 11; the slider The upper surface of the upper wing of the body 2 is provided with the positioning device of the horse hook 3 and the fastening seat of the cap 1; one end of the horse hook 3 sits on the positioning device; the horse hook 3, the shrapnel 5 and the cap 1 pass through The rectangular opening of the pull piece 4 ; the lower surface of the elastic piece 5 presses against the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com