Permeable plastic runway and preparing method thereof

A plastic track and breathable technology, applied in roads, roads, buildings, etc., can solve the problems of general impact resistance, poor air permeability, insufficient toughness and tensile strength, and achieve high toughness and tensile strength. Simple process and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The preparation method of above-mentioned air-permeable plastic runway comprises the following steps:

[0062] 1) Clean the surface of the concrete base, then pickling, washing and drying;

[0063] 2) Coating the adhesive on the concrete base to form a bonding layer;

[0064] 3) Pre-mix TPEE particles, EPDM particles and one-component polyurethane adhesive evenly, lay them on the adhesive layer, and dry to form an elastic layer;

[0065] 4) First mix polyurethane resin, filler, pigment, wetting and dispersing agent, antioxidant, bactericidal and antifungal agent and ultraviolet absorber evenly, then add EPDM particles, mix evenly, and then lay the obtained pre-mixture on the elastic layer , dried to form a polyurethane surface layer to obtain a breathable plastic runway.

Embodiment 1

[0068] A preparation method for a breathable plastic runway, comprising the following steps:

[0069] 1) Clean the surface of the concrete base, then pickling, washing and drying;

[0070] 2) Coating the one-component polyurethane adhesive on the concrete base to form a bonding layer;

[0071] 3) Pre-mix TPEE particles (particle size 3-5mm) and one-component polyurethane adhesive according to the mass ratio of 1:0.1, lay them on the adhesive layer, and dry to form an elastic layer (thickness 10mm);

[0072] 4) Polyurethane resin, kaolin, calcium carbonate, chrome red, polyoxyethylene alkyl ether, antioxidant 1010, antioxidant 168, 5-chloro-2-methyl-4-isothiazolin-3-one , iodopropynyl butyl carbamate and UV-326 mix uniformly, then add EPDM particles, mix uniformly, then lay the pre-mixture obtained on the elastic layer, dry, and form a polyurethane surface layer (thickness is 3mm), obtain Breathable plastic track.

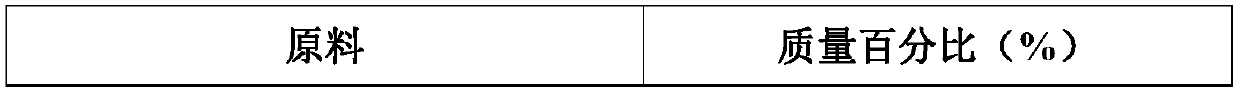

[0073] Step 4) the raw material composition of the polyuretha...

Embodiment 2

[0078] A preparation method for a breathable plastic runway, comprising the following steps:

[0079] 1) Clean the surface of the concrete base, then pickling, washing and drying;

[0080] 2) Coating the one-component polyurethane adhesive on the concrete base to form a bonding layer;

[0081] 3) Pre-mix TPEE particles (particle size 1-3mm), EPDM particles (particle size 1-3mm) and one-component polyurethane adhesive according to the mass ratio of 1:1:0.2, lay them on the adhesive layer, and dry , forming an elastic layer (thickness is 10mm);

[0082] 4) First mix polyurethane resin, kaolin, cobalt blue, polyoxyethylene alkyl ether, antioxidant 264, 1,2-benzisothiazol-3-one and UV-P, then add EPDM particles and mix well , and then lay the obtained premix on the elastic layer, and dry to form a polyurethane surface layer (thickness is 3mm), to obtain a breathable plastic track.

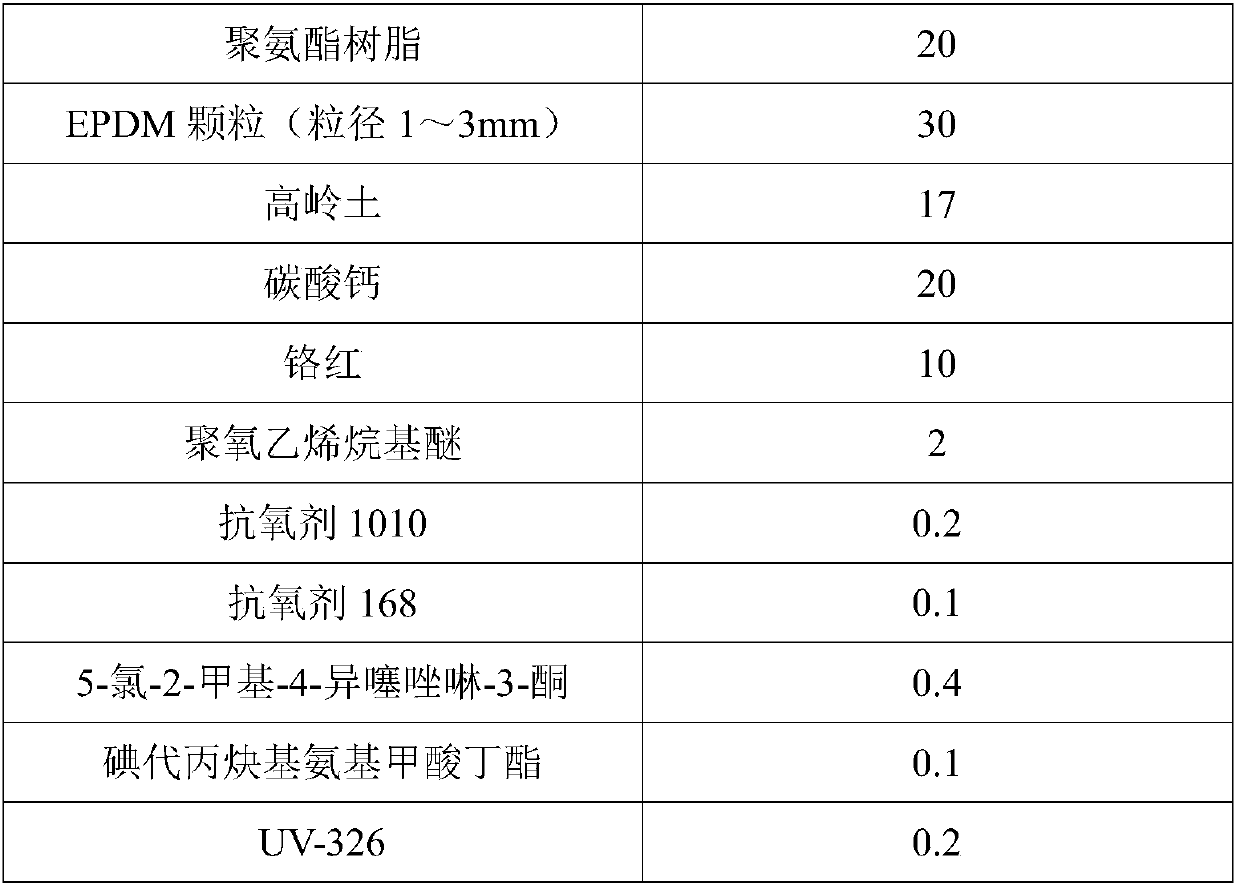

[0083] Step 4) the raw material composition of the polyurethane surface layer is as shown in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com