Patents

Literature

36results about How to "Controllable weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Snapshot-type multispectral image multiple-splitting spectral imaging method and spectral imager

InactiveCN105157835AControllable volumeControllable weightSpectrum investigationWollaston prismPrism

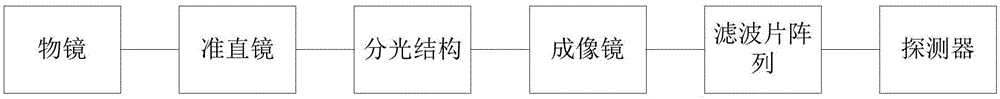

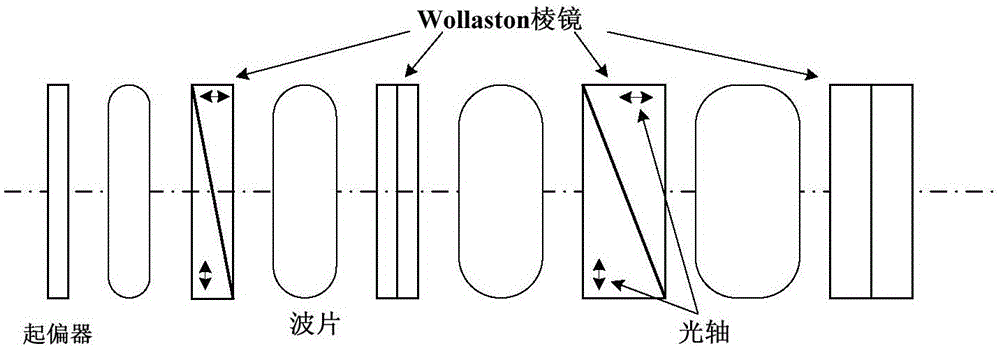

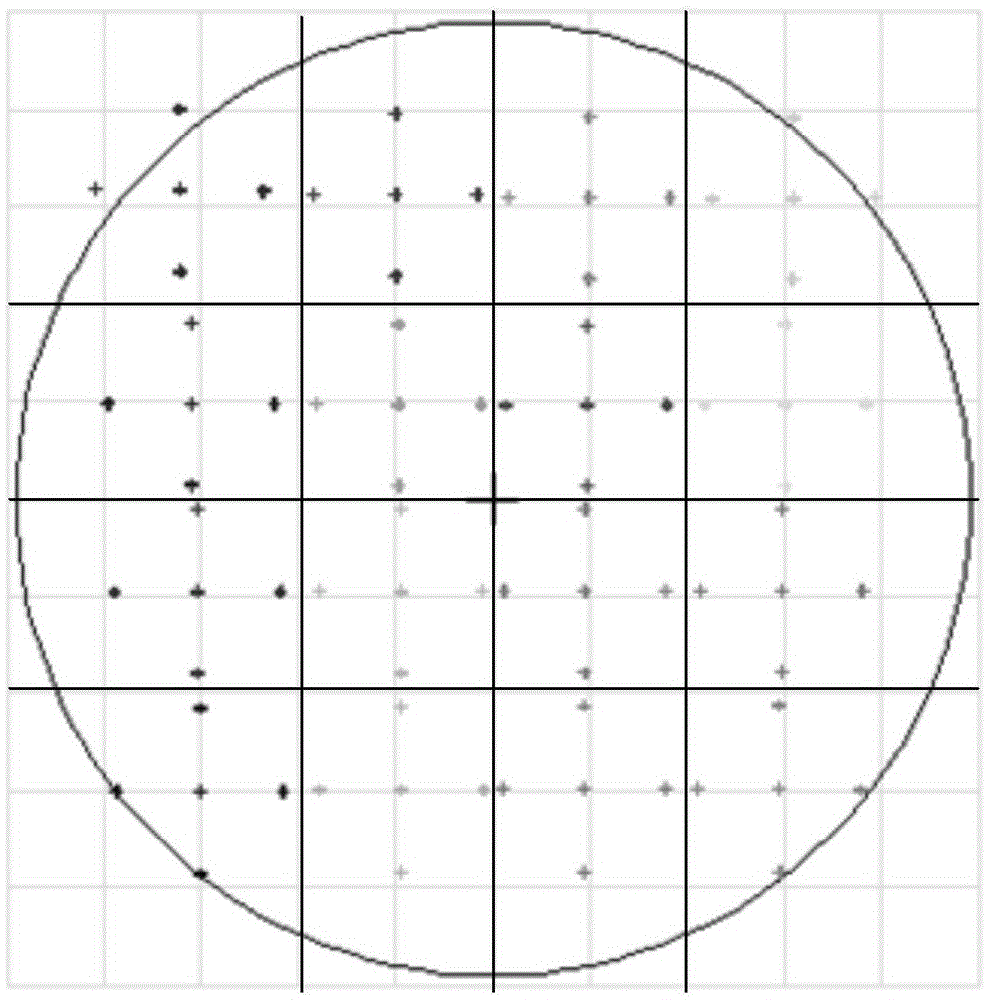

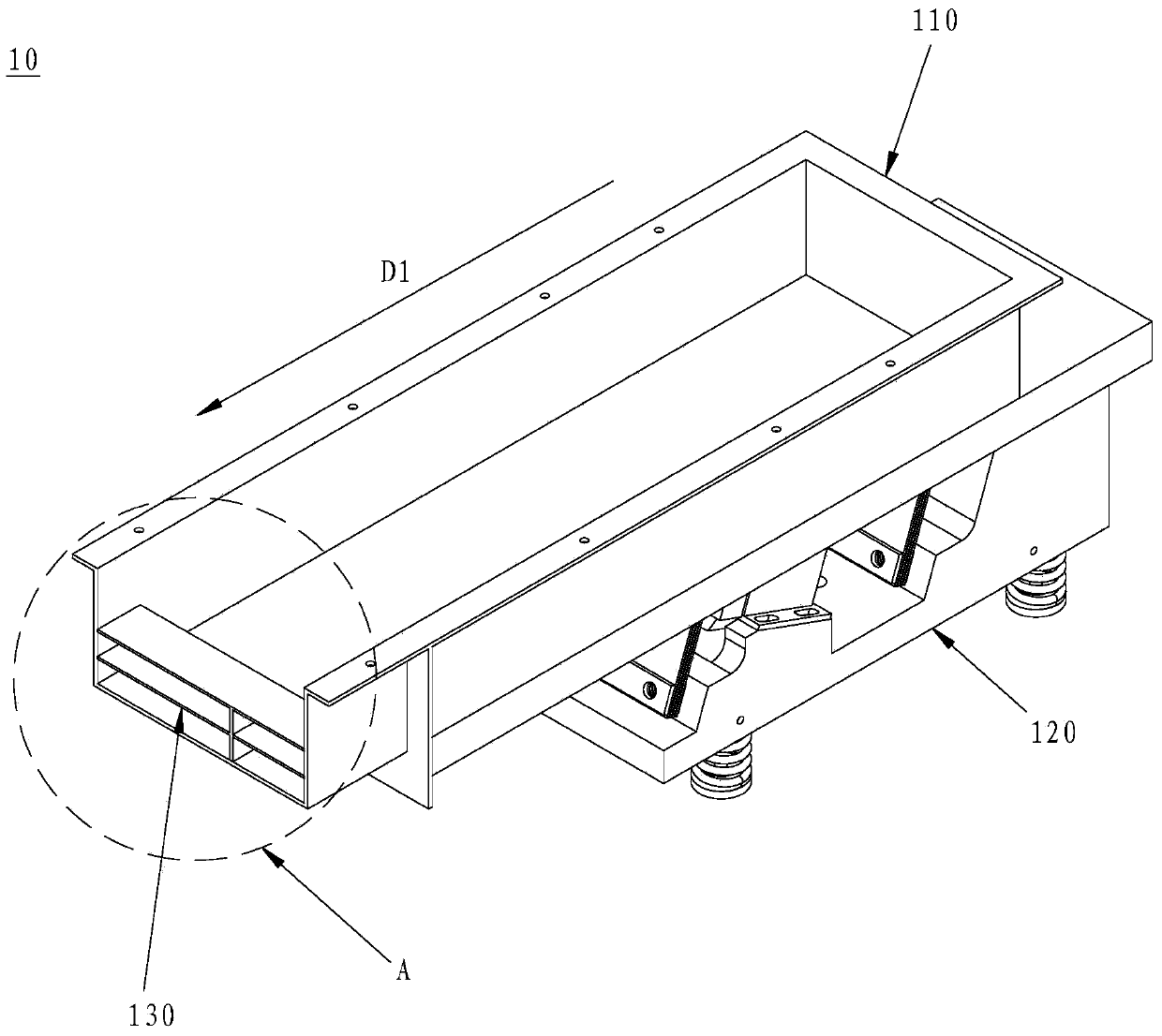

The invention discloses a snapshot-type multispectral image multiple-splitting spectral imaging method and a spectral imager. The related spectral imager comprises an objective lens, a collimating mirror, a light-splitting structure, an imaging lens, a filter plate array and a detector, which are mutually parallel and are arranged in sequence. The light-splitting structure is the light-splitting structure based on Wollaston prisms, and comprises a polarizer, four wave plates and four Wollaston prisms, which are arranged in parallel, wherein the four wave plates and four Wollaston prisms are arranged alternatively. According to the snapshot-type multispectral spectral imager, output images thereof can be used directly without follow-up data processing work; and meanwhile, the imager is simple in imaging principle, easy to process and low in cost, and meets requirement for miniature design.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

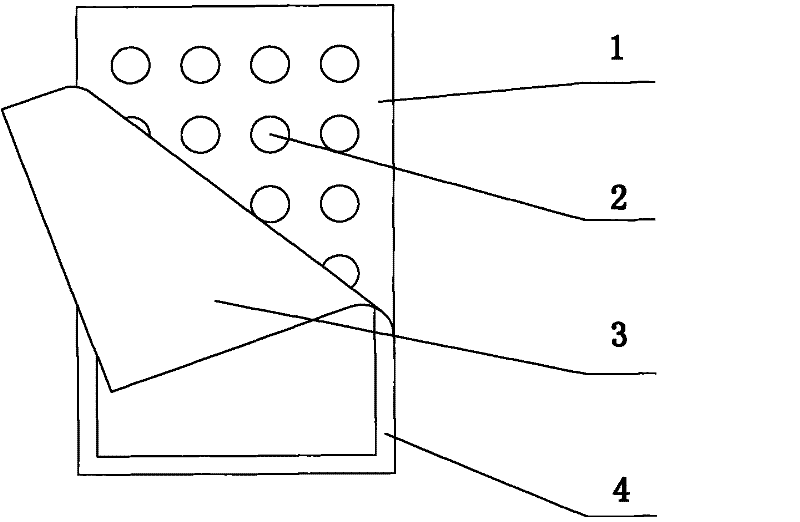

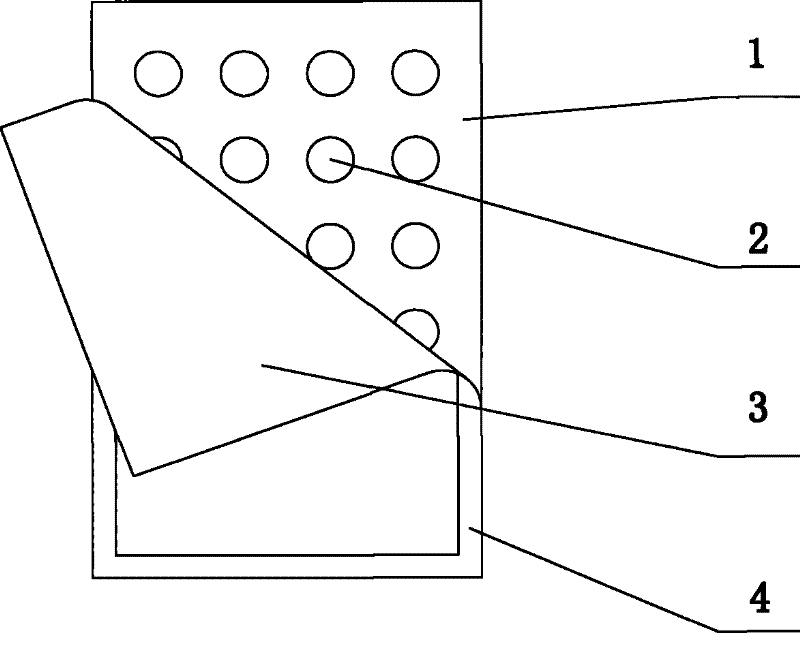

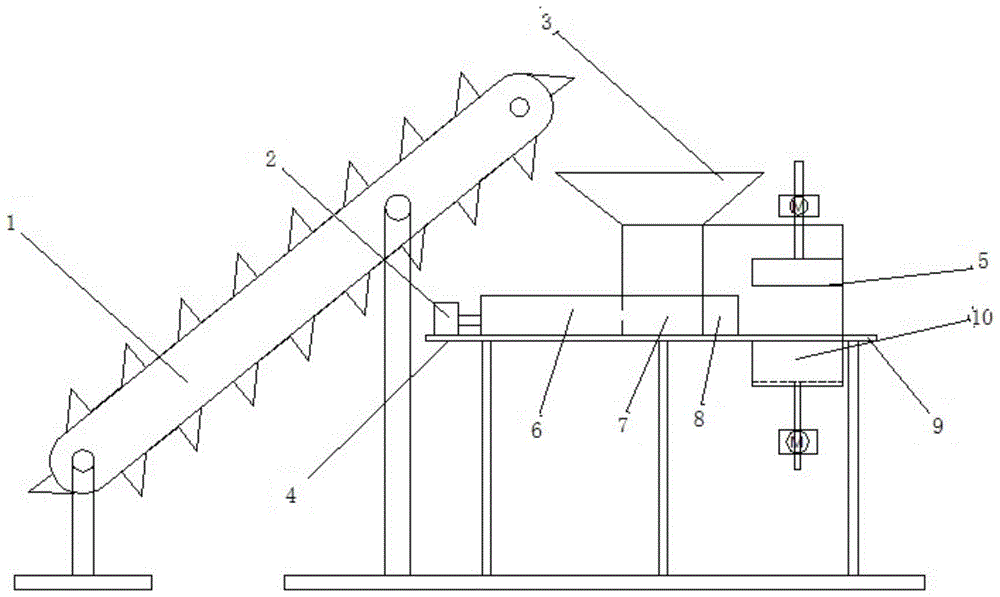

Feeding device

InactiveCN104176474ASmall weight changeShorten the timeSolid materialWeighing apparatus with automatic feed/dischargeMechanical engineering

The invention discloses a feeding device used in automatic weighting equipment. The feeding device comprises a material trough, a transmission mechanism and a distributing mechanism, wherein the transmission mechanism is used for driving the material trough to transport a material; the distributing mechanism is arranged at the discharge opening of the material trough; the distributing mechanism comprises one or more separating plates which divide the discharge opening into two or more discharging through openings. According to the feeding device disclosed by the invention, the distributing mechanism is arranged at the discharge opening to divide the discharge opening into multiple through openings, so that resistance is increased for the material sliding down; furthermore, the fast feeding time is prolonged, and the efficiency and the precision are improved during the entire feeding process.

Owner:SHENZHEN GENERAL MEASURE TECH

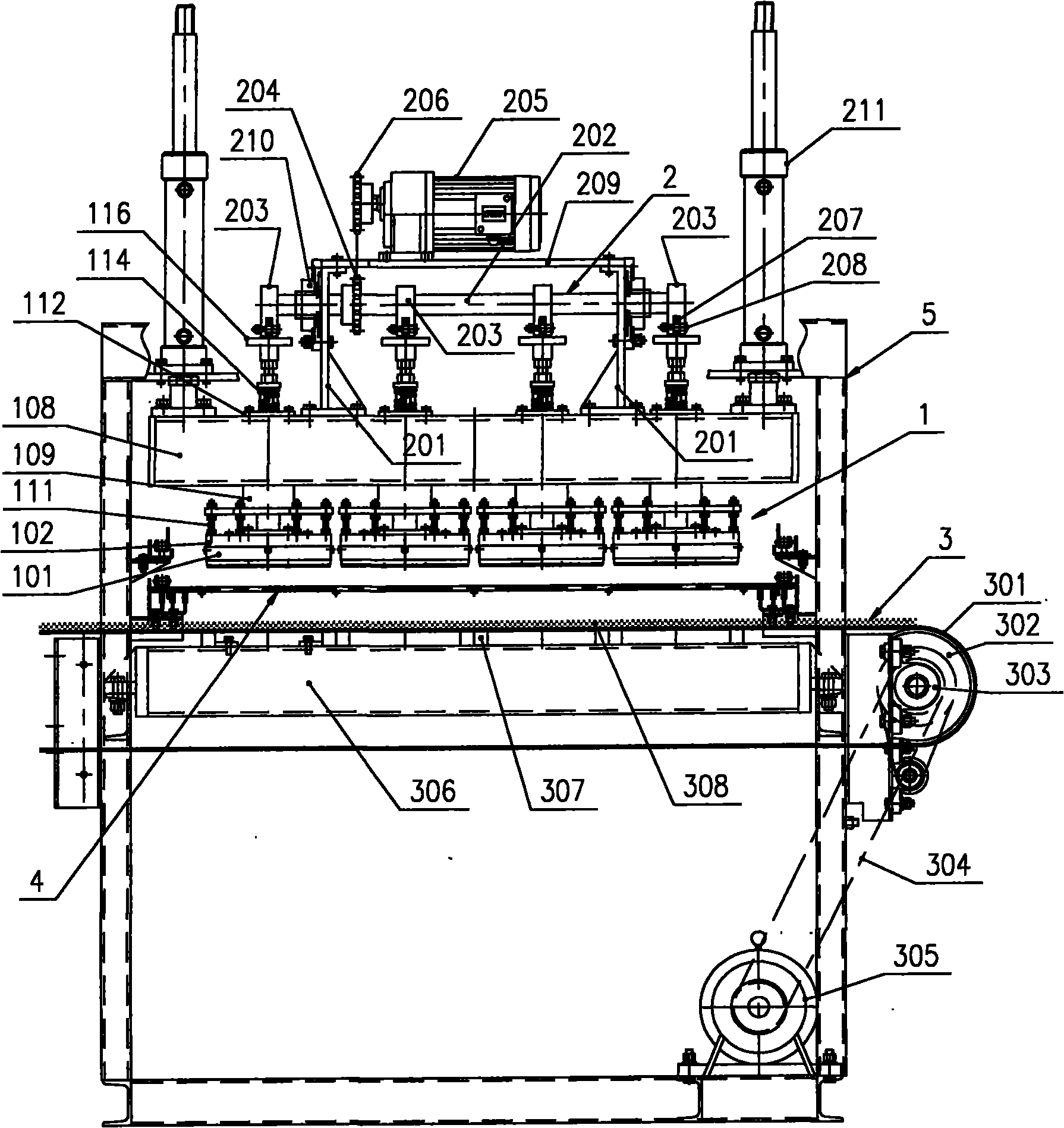

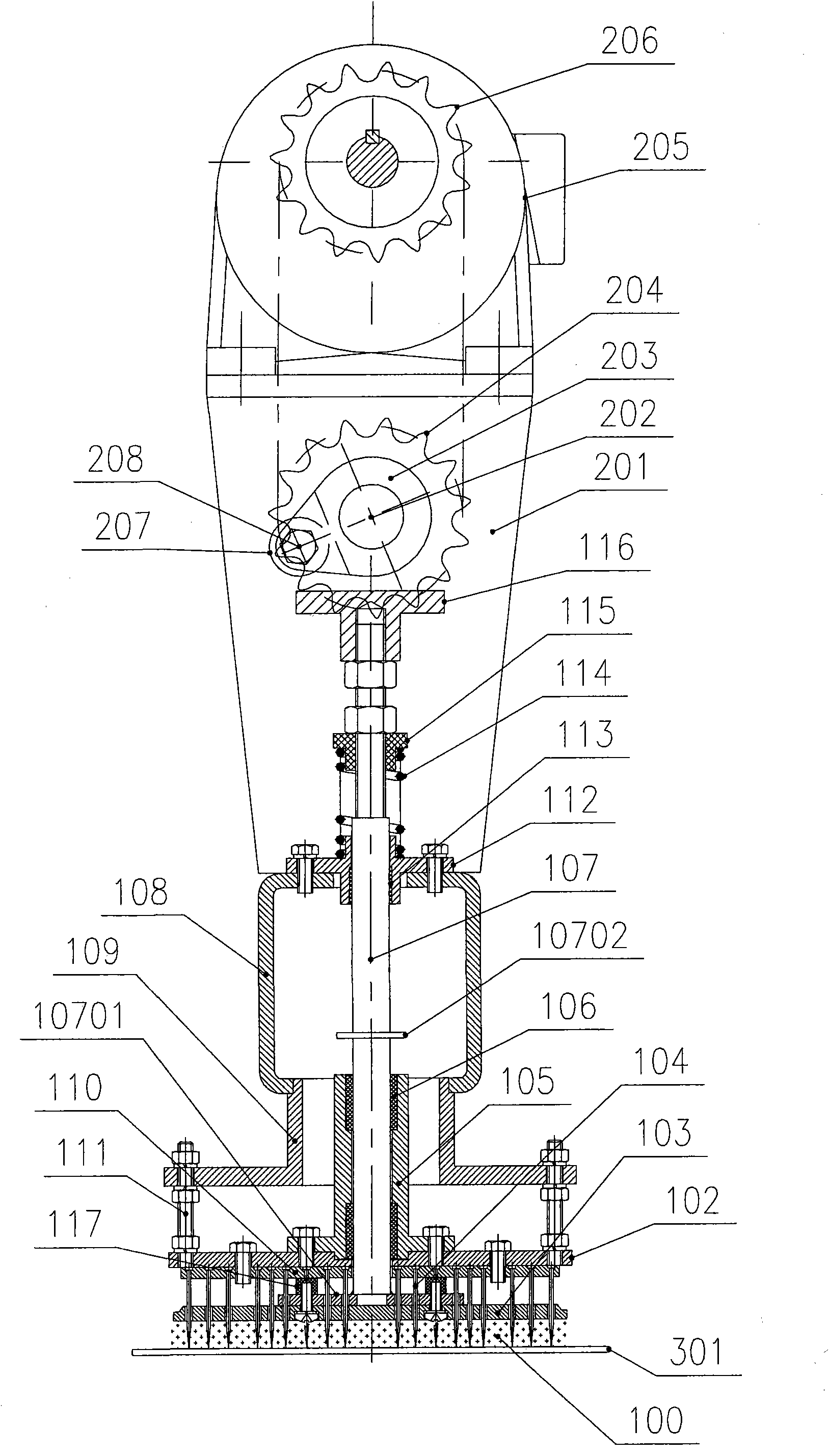

Cake taking component and algae or vegetable cake making device employing same

The invention provides a needle type cake taking component for processing algae or vegetables, which comprises a needle mounting disc, needles arranged on the needle mounting disc, a material returning disc and a transmission device, wherein the material returning disc is provided with through holes corresponding to the needles, so that the needles are allowed to move along the length direction of the needles relative to the material returning disc; a ring cutter is arranged outside the needle mounting disc and is arranged on a cutter base; and the transmission mechanism is used for making the material returning disc and the needle mounting disc generate relative movement, and is in transmission connection with the needle mounting disc and the material returning disc through a main beam. The invention also provides a cake making device, which can mechanically make cakes for dehydrated laver, and has the technical advantages of sanitary production, uniform cakes, high work efficiency, energy conservation, and uniform dimension, good bulkiness and controllable weight of the cakes.

Owner:王行安

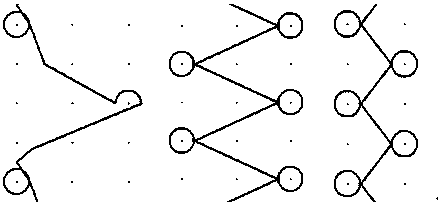

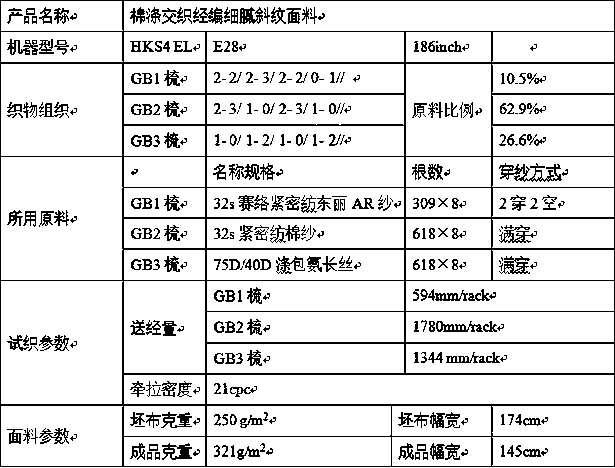

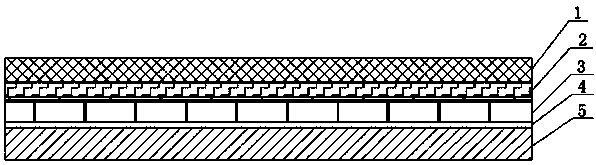

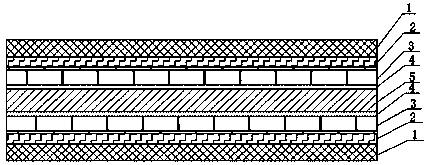

Warp-knitted speckled jacquard warm-keeping fabric and manufacturing technology thereof

ActiveCN108315866AModerate elasticityControllable weightWarp knittingManufacturing technologyEngineering

The invention relates to warp-knitted speckled jacquard warm-keeping fabric and a manufacturing technology thereof. The warp-knitted speckled jacquard warm-keeping fabric is composed of, by mass, thecomponents of 10.5% of 32 siro compact spinning Toray AR color yarn, 62.9% of 32 s compact spinning cotton color yarn and 26.6% of 75D / 40D polyester ammonia filaments. The manufacturing technology ofthe fabric includes the following steps that in material selection, 20-40% of Toray AR yarn, 20-40% of cotton yarn and 20-40% of polyester ammonia filaments are selected; in warping, the Toray AR yarn, the cotton yarn and the polyester ammonia filaments are warped on a warping machine; in knitting, a Tricot warp-knitting machine is adopted for knitting; in aftertreatment, grey cloth which is obtained through knitting is sequentially subjected to washing, setting and napping. The fabric is appropriate in elasticity, controllable in gram weight, good in warm-keeping performance, soft in hand feeling, fit and attractive, and the effect of speckled jacquard is obvious.

Owner:JIANGYIN FUBO TEXTILE CO LTD

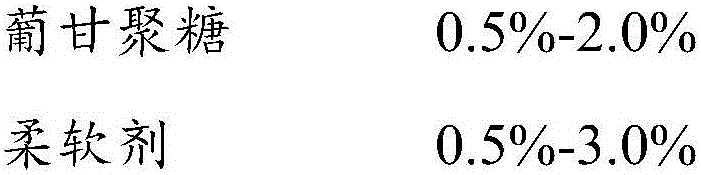

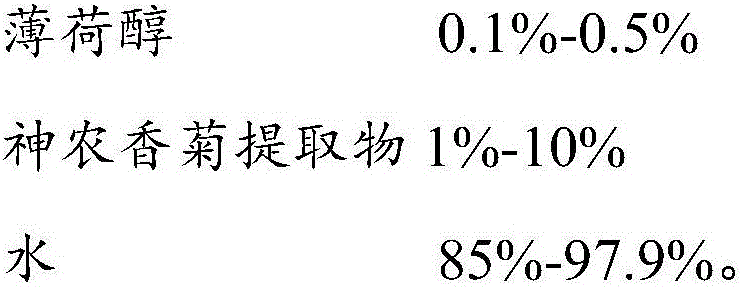

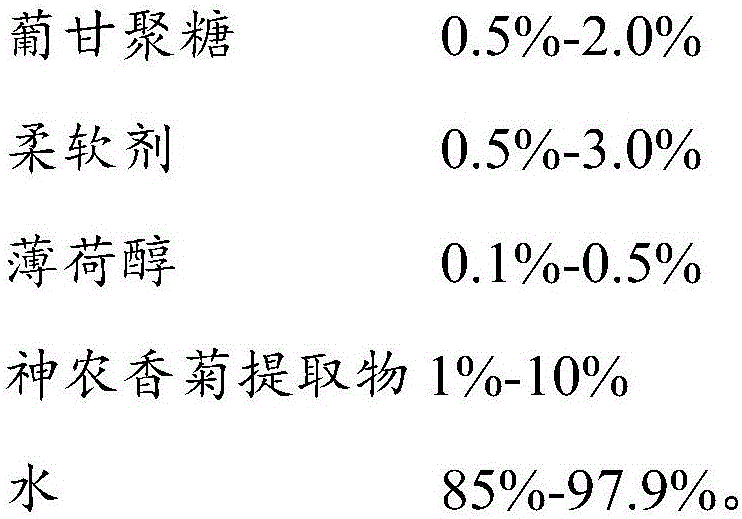

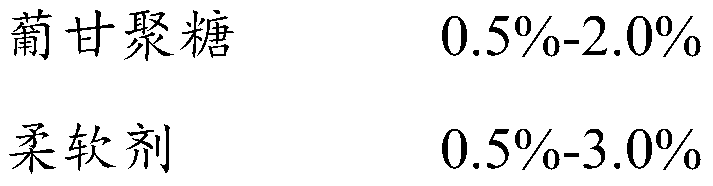

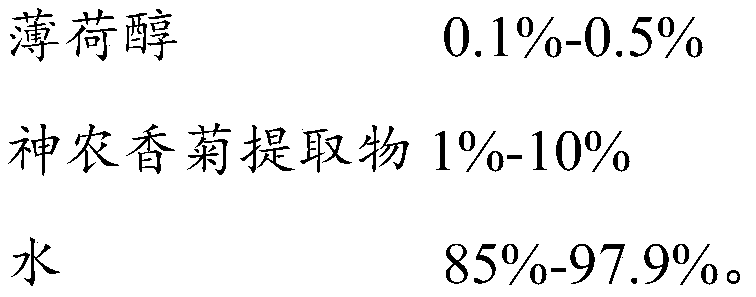

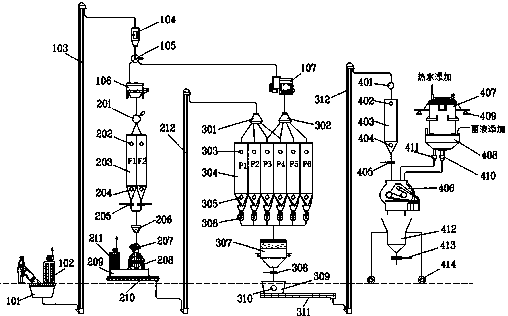

Composition for prevention and treatment of influenza virus and traditional Chinese medicine compound oral fast dissolving film preparation

ActiveCN106236807AObvious anti-influenza virus effectFacilitated releaseHydroxy compound active ingredientsAntiviralsMentholDrug release

The invention discloses a composition for prevention and treatment of influenza virus and a traditional Chinese medicine compound oral fast dissolving film preparation, and a preparing method of the traditional Chinese medicine compound oral fast dissolving film preparation. The composition for prevention and treatment of influenza virus comprises a chrysanthemum seticuspe extract and menthol with the effective amount weight ratio of (0.1-0.5) to (1-10). The traditional Chinese medicine compound oral instant film preparation comprises the following components by the weight percentage: 0.5%-2.0% of glucomannan, 0.5%-3.0% of a softener, 0.1%-0.5% of menthol, 1%-10% of a chrysanthemum seticuspe extract, and 85%-97.9% of water. The composition for prevention and treatment of influenza virus has obvious anti-influenza virus effect. The traditional Chinese medicine compound oral instant film preparation has good casting film-forming property, toughness and drug release property, and is safe and non-toxic.

Owner:SHENZHEN SHENNONG SPRING PLANT SUBSTANCES DEV CO LTD

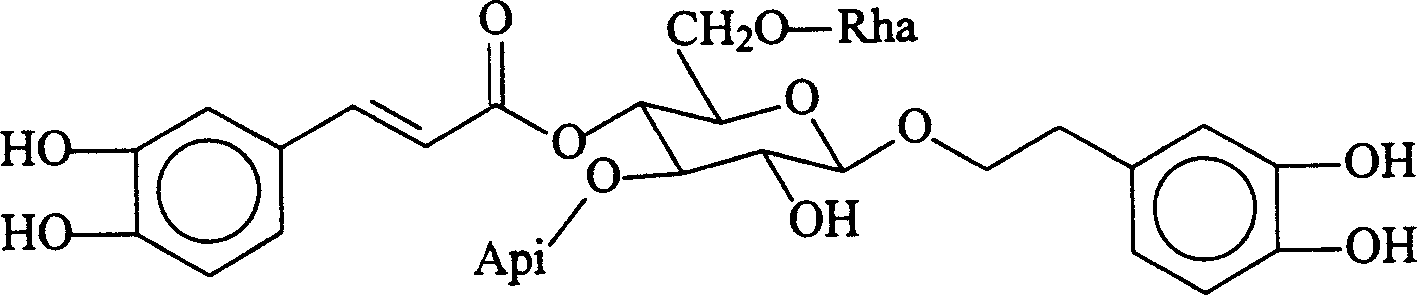

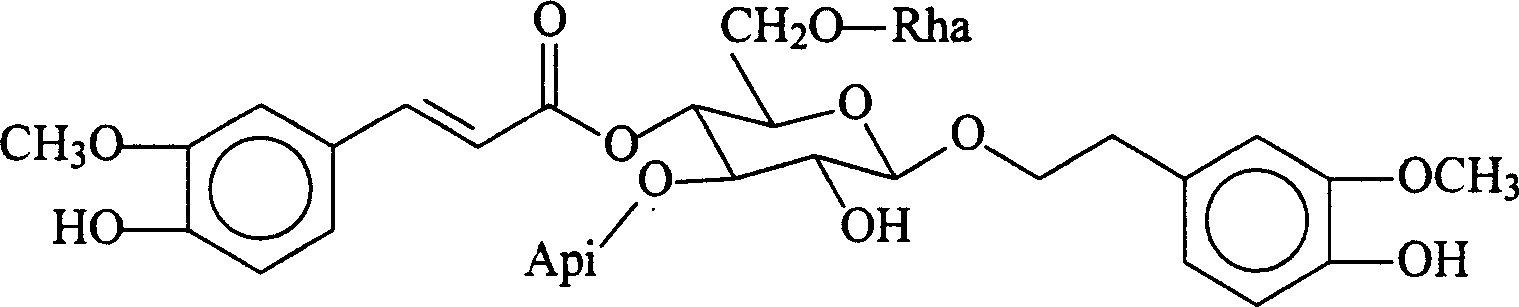

An injection containing phenylpropanolid glycosides, its preparation method and use

InactiveCN1876019AGood curative effectEasy to storePowder deliveryOrganic active ingredientsBenzeneGlycoside formation

The invention relates the injection containing propyl benzene glycosides and preparing method. The method comprises the following steps: using labiate as raw material, extracting it, separating it, getting medicinal findings, and getting solution injection or sterilized powder agent for injection. The solution injection contains 10-20mg propyl benzene glycosides per mg, and the sterilized powder agent for injection contains 20-40mg propyl benzene glycosides per mg. The invention has the advantages of high curative effect and quality.

Owner:GUANGZHOU HANFANG PHARMA

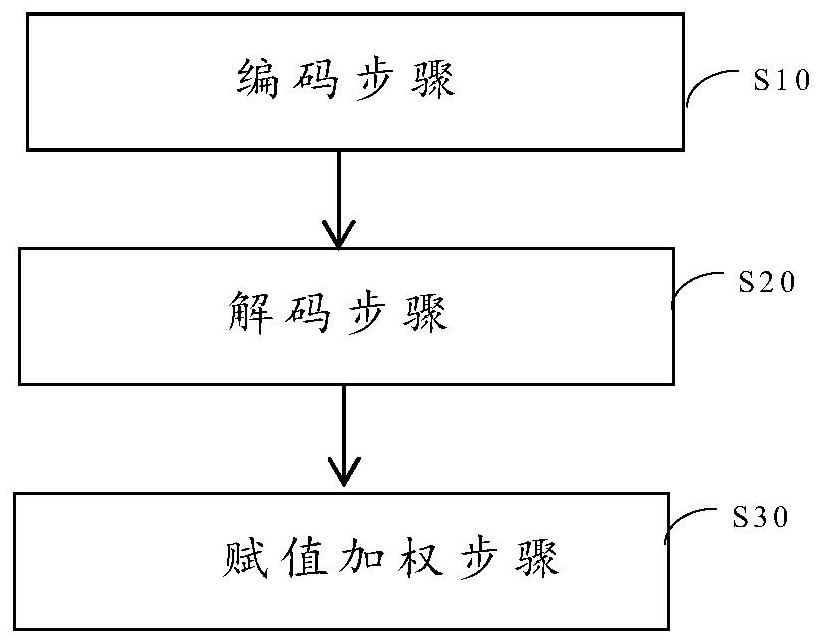

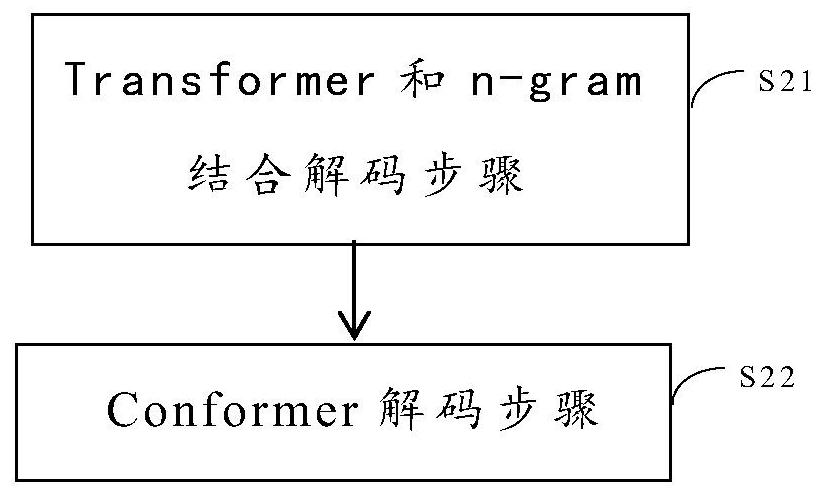

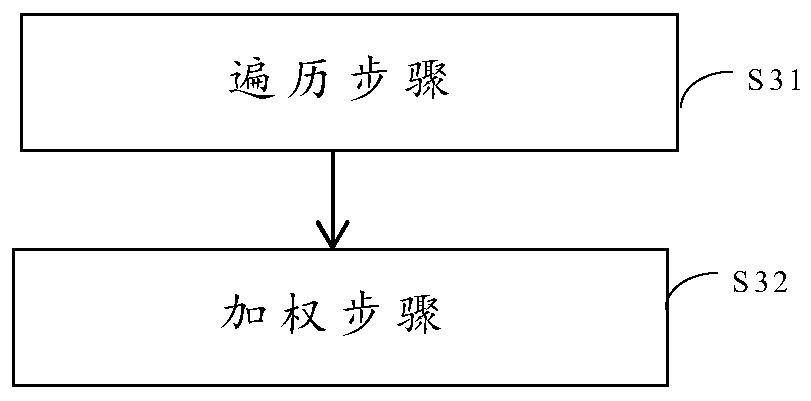

Information query method and system based on voice recognition, equipment and storage medium

PendingCN113674734AImprove estimation accuracyImprove recognition accuracySpeech recognitionText database queryingComputer equipmentEngineering

The invention discloses an information query method and system based on voice recognition, computer equipment and a computer readable storage medium. The method comprises the following steps of an encoding step, inputting audio data, performing feature value extraction by adopting a transformer encoder, and outputting a two-dimensional feature value sequence; a decoding step, based on the two-dimensional feature value sequence, adopting a transform and n-gram combined decoder to carry out streaming voice decoding and recognition, after screening and outputting M results of first text sorting, based on the two-dimensional feature value sequence and the M results of first matched text sorting, adopting a conformer model to carry out non-streaming voice decoding and recognition, outputting N results of second text sorting, N and M being positive integers larger than or equal to 1, and N being smaller than or equal to M; and the assignment weighting step is used for performing assignment weighting based on a hot word dictionary in the text sorting result output in the decoding step, and outputting an optimal query result. According to the method, through adding the language model and the hot word weight function, accuracy of speech recognition is improved.

Owner:INST OF COMPUTING TECH CHINA ACAD OF RAILWAY SCI +2

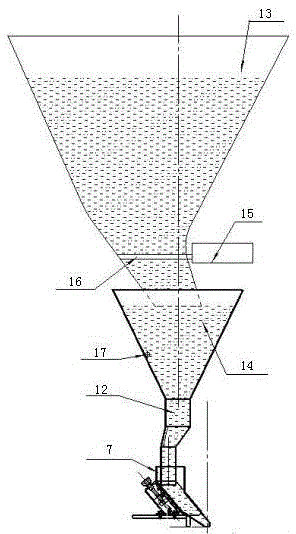

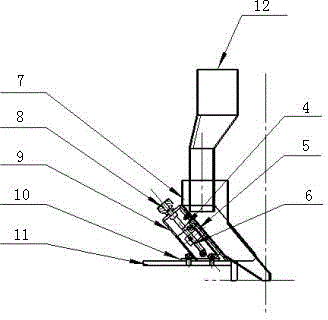

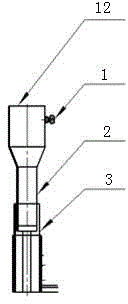

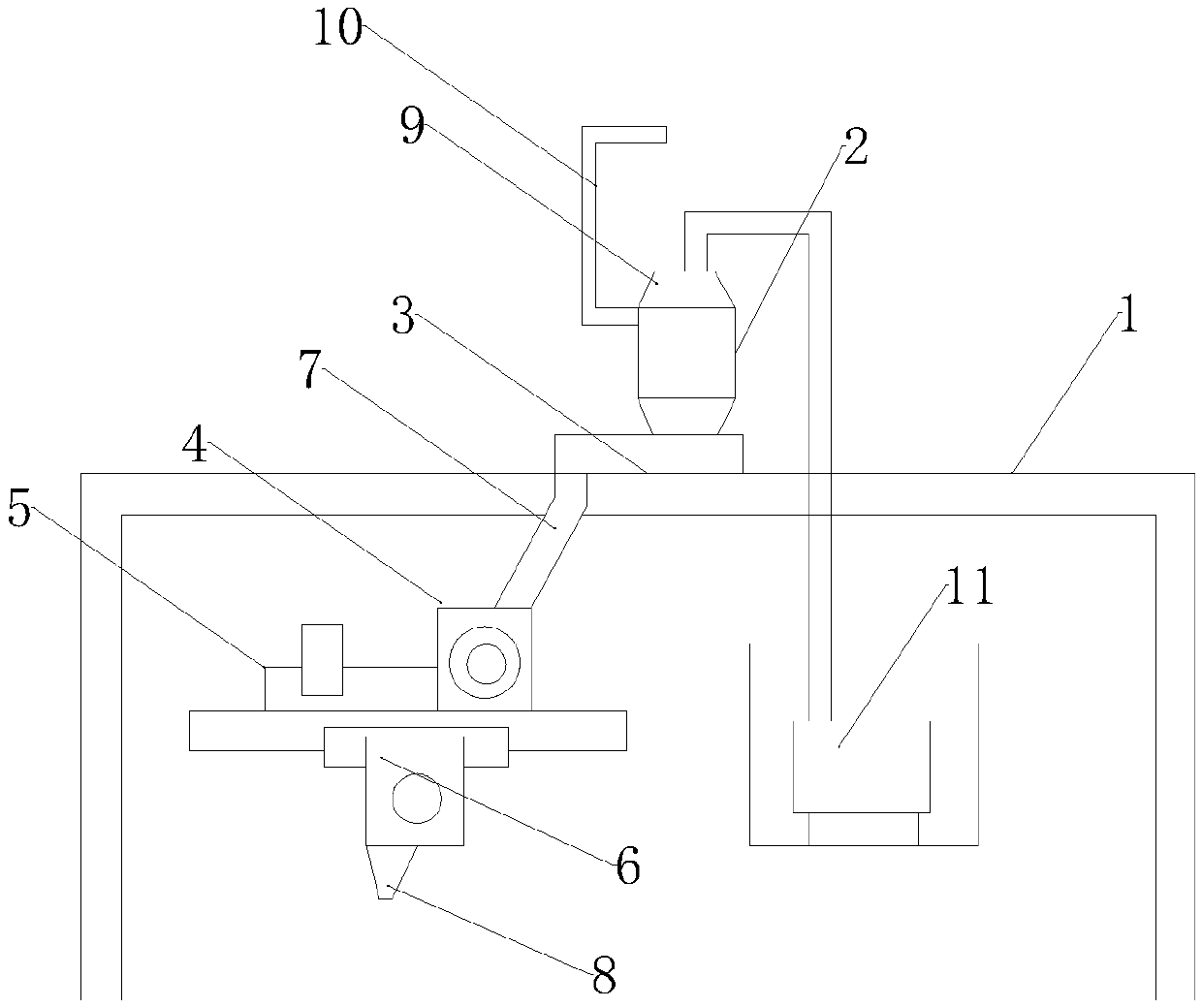

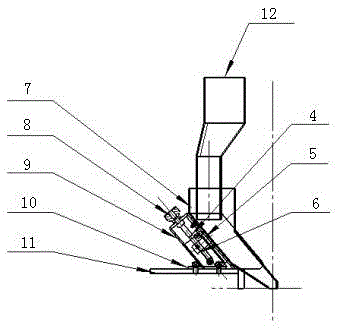

Quantitative feeding device for looping machine

The invention discloses a quantitative feeding device for a looping machine. The quantitative feeding device for the looping machine comprises a first stock bin, a second stock bin, a conveying hose, a material receiving opening, an inclined hopper, an adjustable discharging device and a fixed base, wherein the second stock bin is arranged at the upper end of the first stock bin, and the lower end of the first stock bin is fixedly connected with the conveying hose; the upper end of the material receiving opening is fixedly connected with the conveying hose, and the lower end of the material receiving opening is fixedly connected with the adjustable discharging device; the inclined hopper is arranged inside the adjustable discharging device, and an adjusting seat is welded on the bevel edge at the bottom of the inclined hopper; the fixed base is fixedly arranged on a fixed support through a screw, a slide base is fixedly arranged on the upper left side of the bottom of the fixed base in an upward slantwise manner, an adjusting rod is arranged inside the slide base, the adjusting rod is fixed with the adjusting seat through the screw to adjust the opening height of the inclined hopper. The quantitative feeding device for the looping machine has the benefits of good mechanism stability, accurate feeding target, precise feeding amount, convenience for control, uniform discharging, automatic feeding, uniform feeding and no blocking in the stock bins.

Owner:DANYANG QIRUI MACHINERY

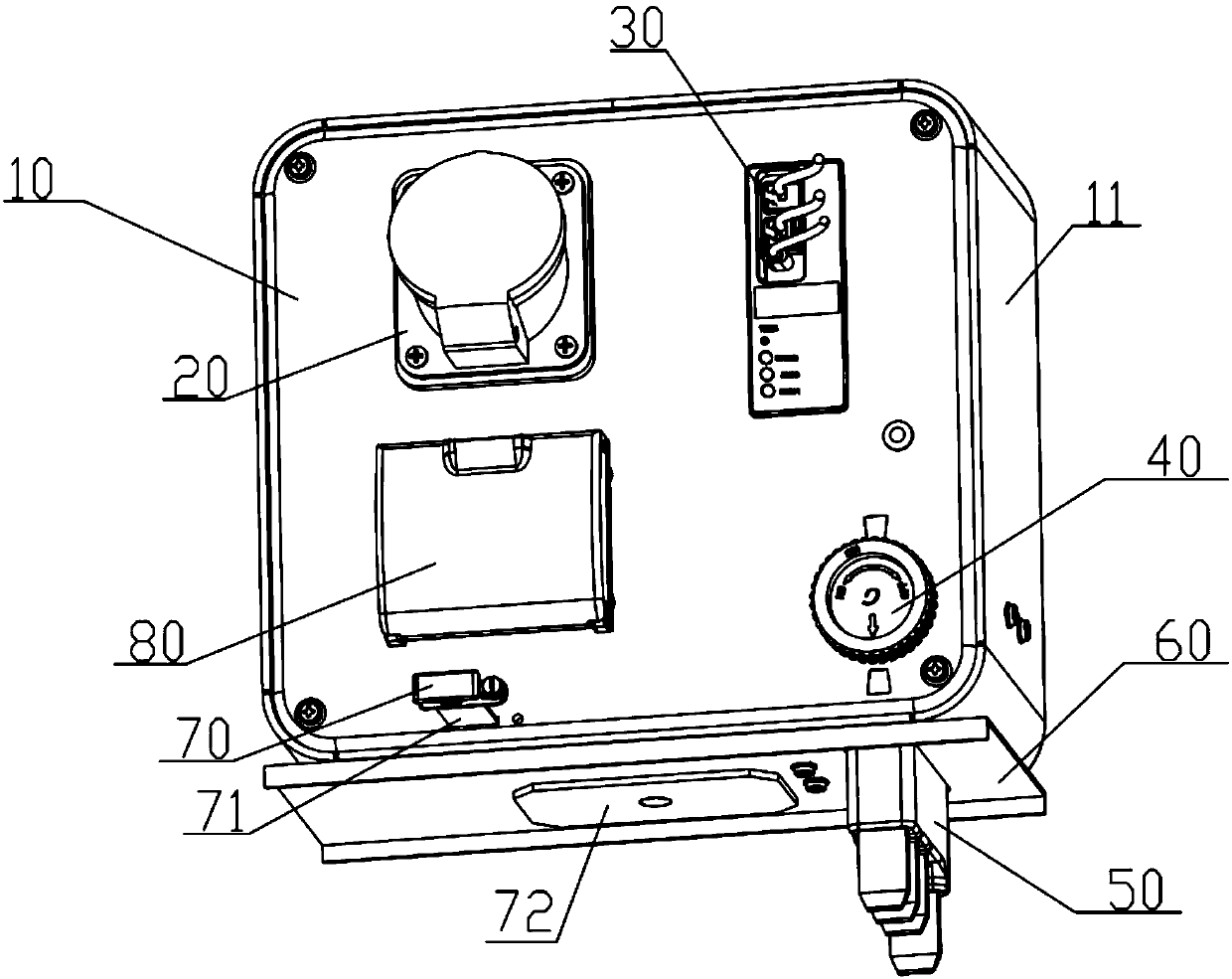

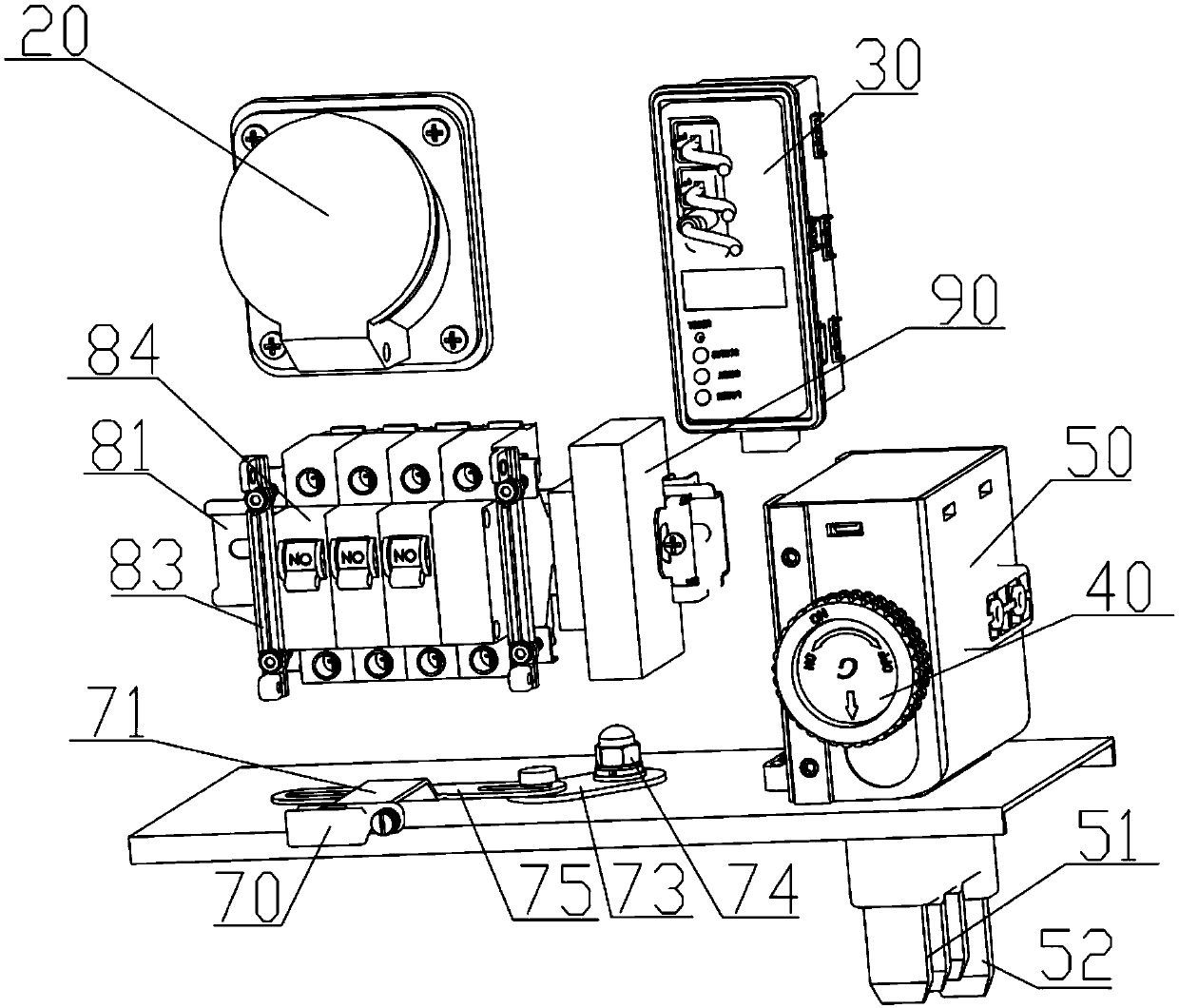

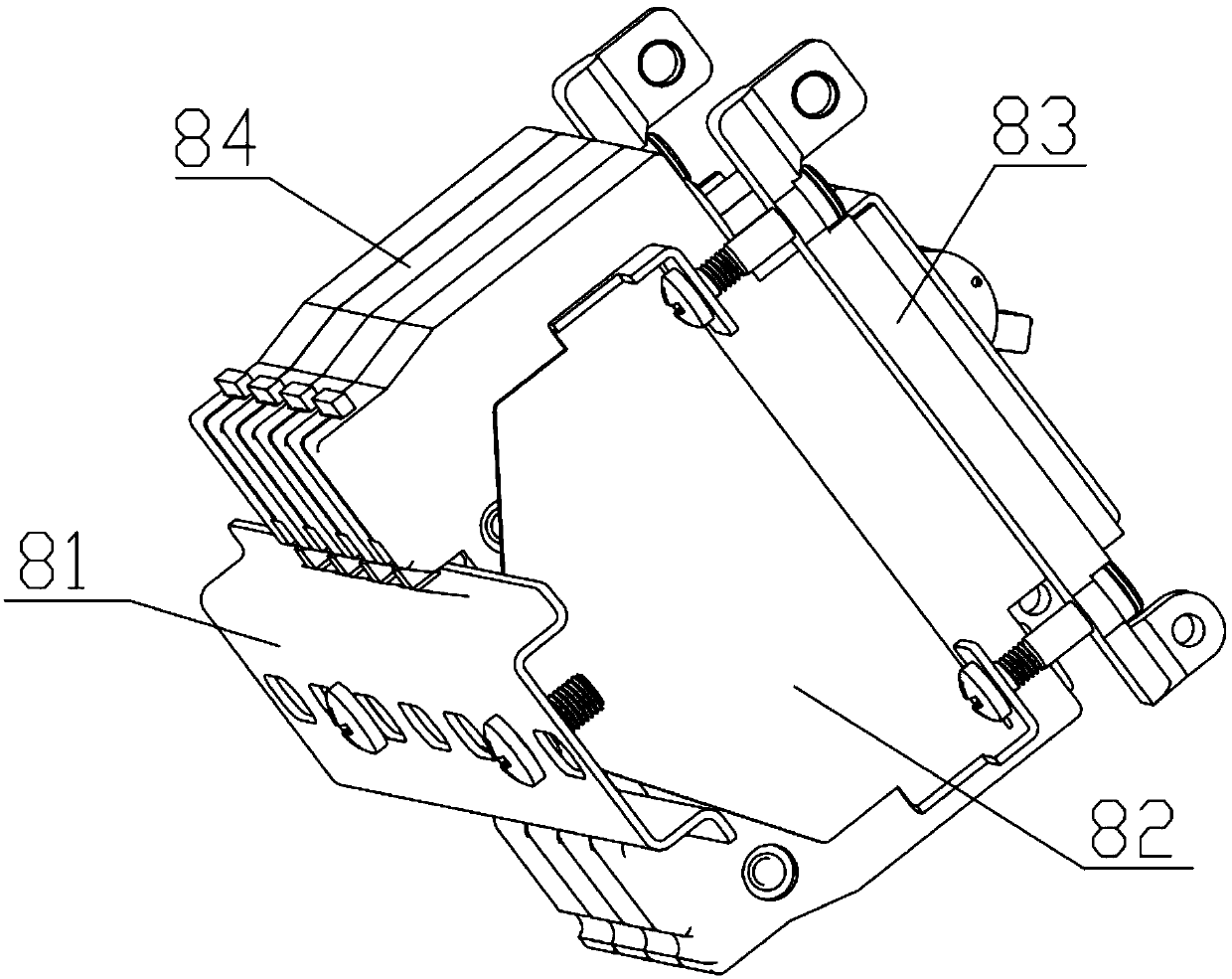

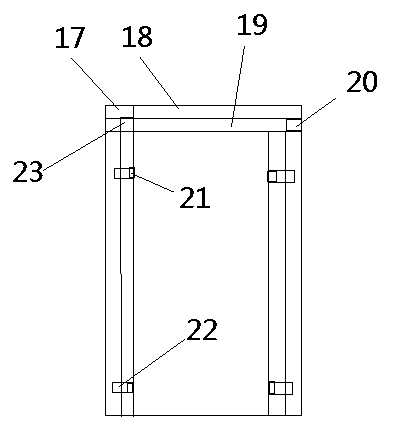

Plugging box for power distribution of bus duct

PendingCN109524903AImprove scalabilityCompact structureSubstation/switching arrangement detailsCoupling device detailsComputer moduleEngineering

The invention provides a plugging box for power distribution of a bus duct. A box body is encircled by a front panel, a rear panel, and a side panel. A connecting trough plate is fixedly arranged on the side panel. A power distribution coupler is arranged on the front panel; a miniature circuit breaker is arranged below the power distribution coupler; a terminal driving mechanism is arranged at one side of the miniature circuit breaker and is fixed on the inner side wall surface of the side panel; and a multi-function instrument is arranged above the terminal driving mechanism. The box body isconnected with a bus duct by a rotating blocking mechanism. According to the invention, plugging boxes with different amperages and the corresponding interface number can be matched based on the actual cabinet power requirement; the miniature circuit breaker and coupler socket numbers can be increased; power feeding out with different specifications can be realized; and power distribution demandswith different specifications are satisfied. Moreover, the plugging box has a compact structure; the space of the box body is divided reasonably to realize the high expansibility; different module mounting needs are met; and the post-stage mounting and maintenance work can be carried out conveniently.

Owner:郭乃彦

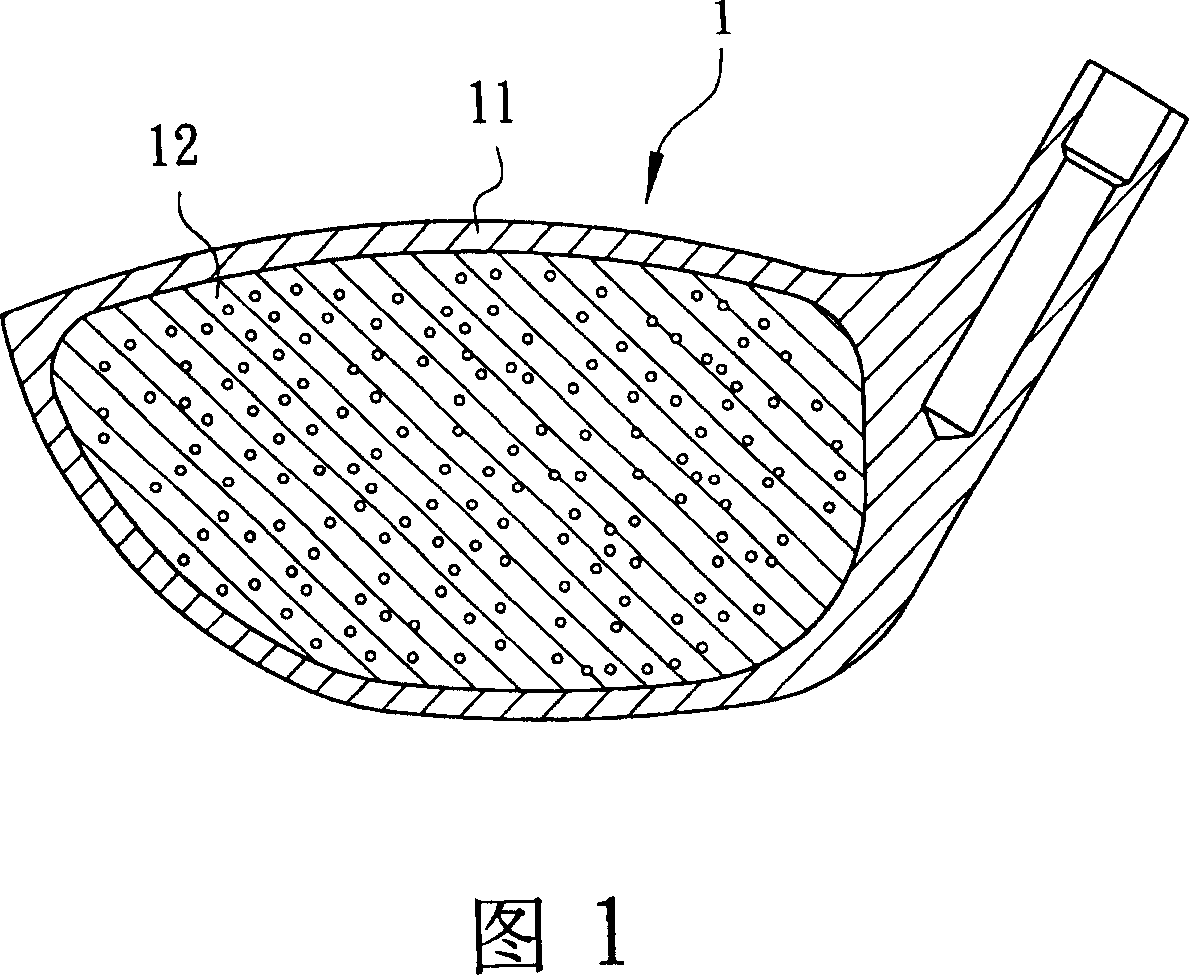

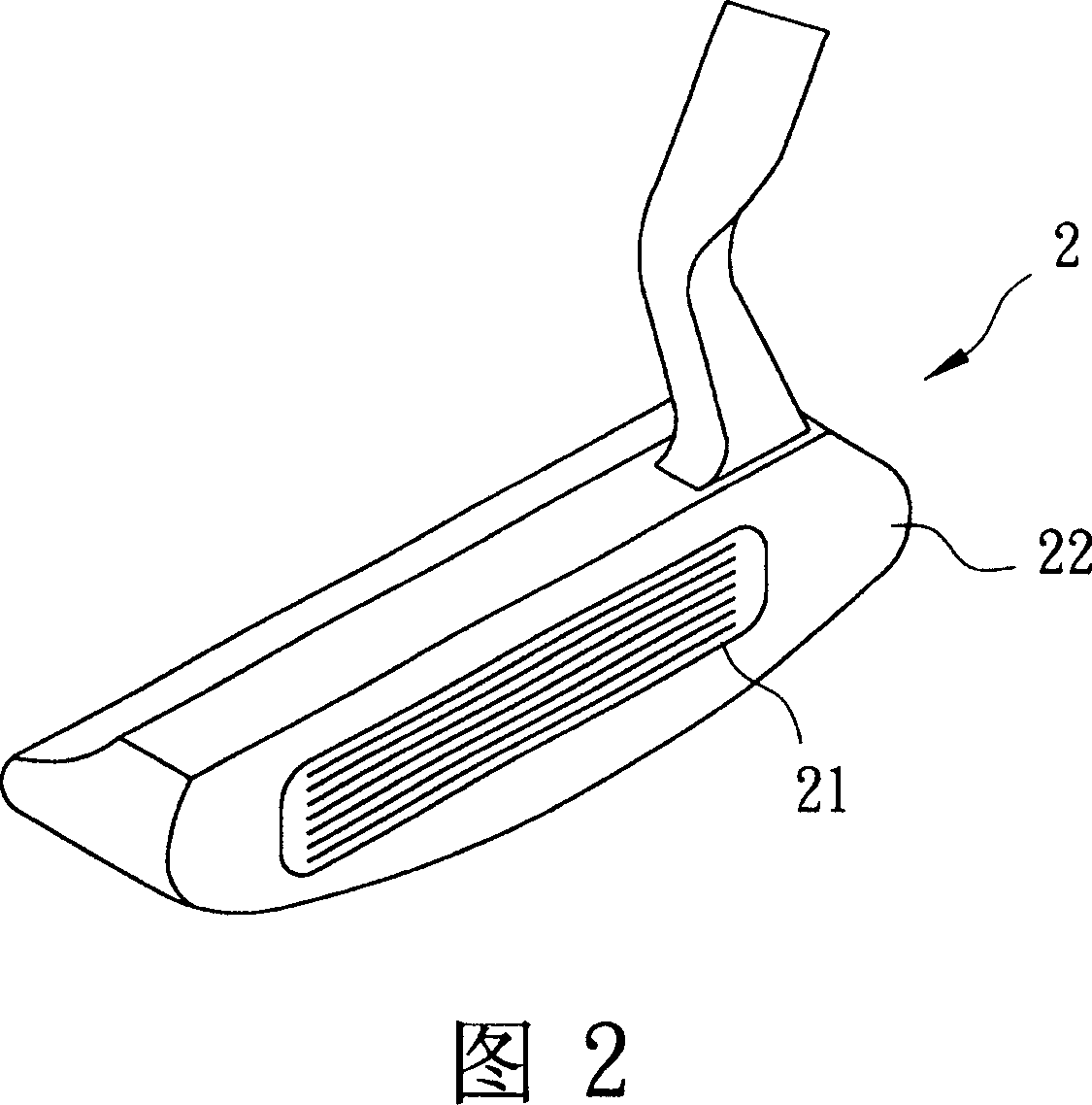

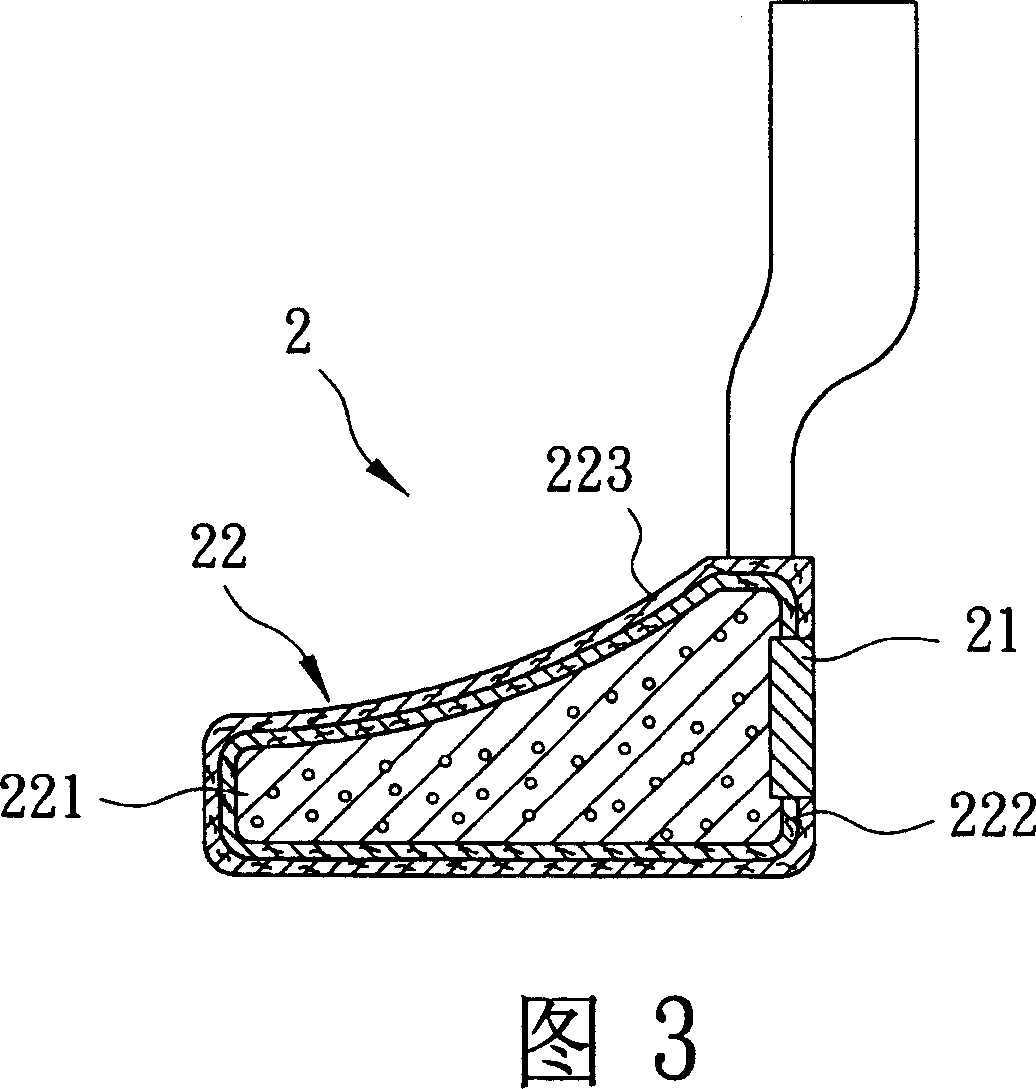

Golf club head with porous material and its making method

InactiveCN101045184AReduce weightEasy to manufactureGolf clubsRacket sportsFiberManufacturing cost reduction

Owner:ADVANCED INT MULTITECH CO LTD

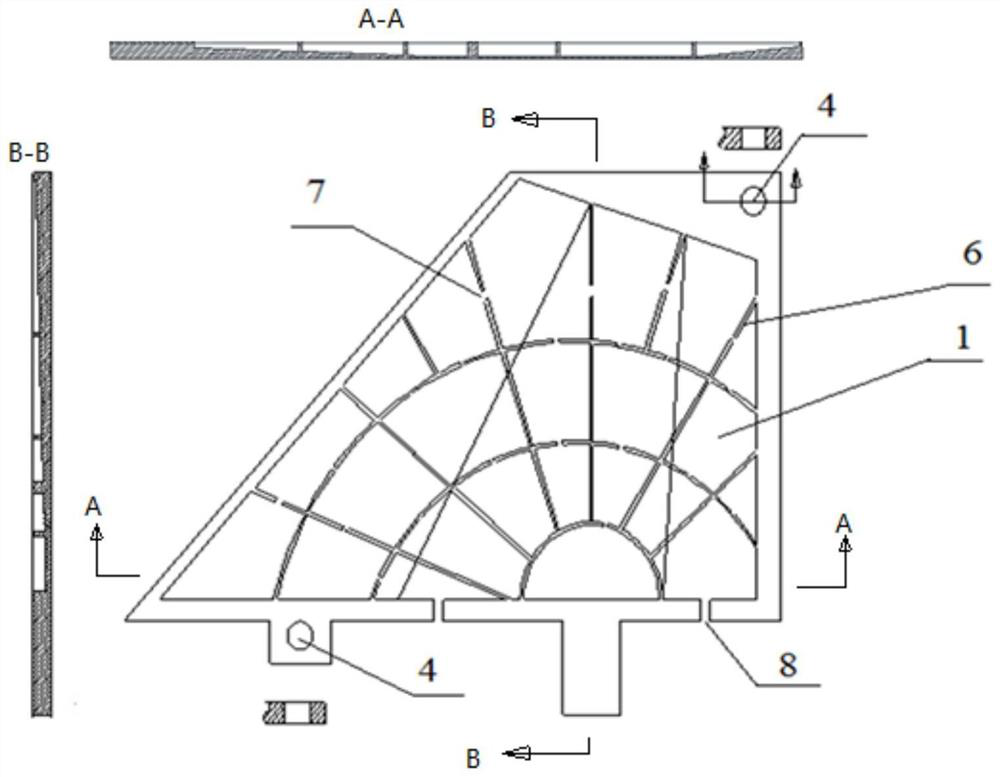

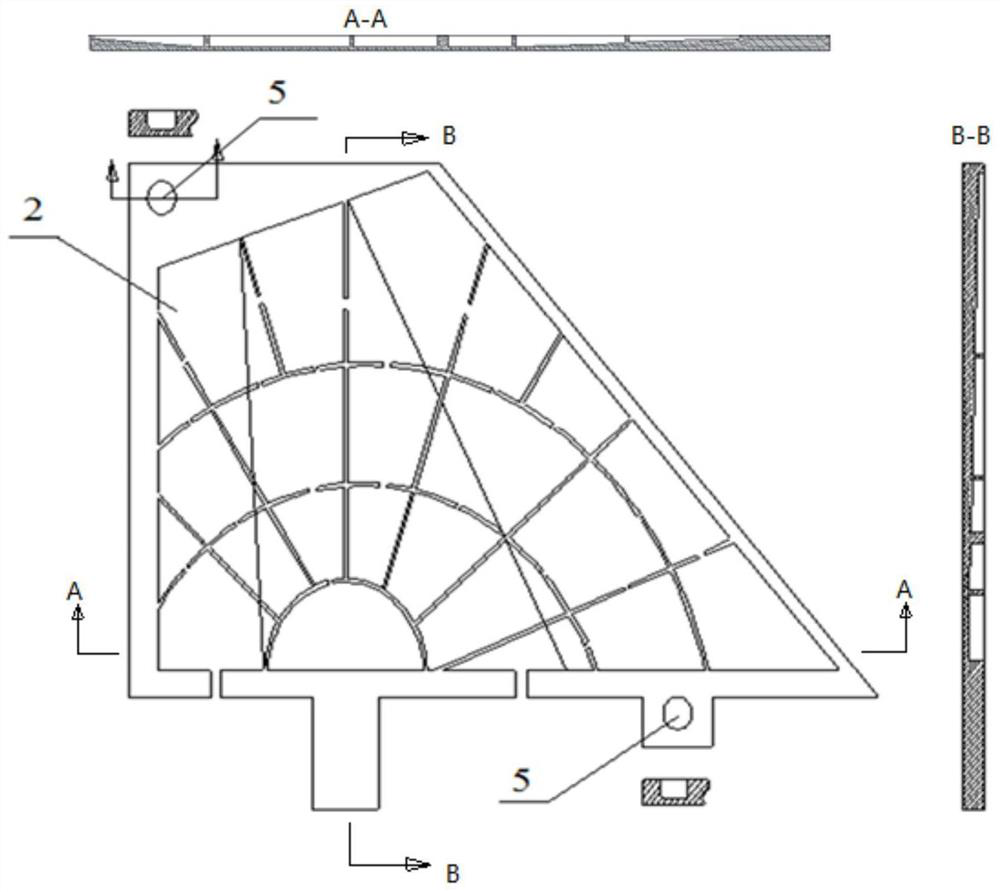

Slurry treatment system

ActiveCN109320041AAvoid build-up solidificationSave volume and spaceSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesPulp and paper industryControl valves

The invention provides a slurry treatment system. The slurry treatment system comprises a liquid collection box, a conveying pipeline, a centrifuge, a centrifuge motor, a control valve, a mixing barrel, a flocculating agent pump, a slurry pump, a slurry tank, a mixing barrel motor, a conveyor belt, a slurry feeding pipe, an unloading valve and a bracket, wherein the centrifuge comprises a first arc, a second arc, a third arc, a connection section, an outer wall, a middle wall, an inner wall, a scraping knife rod, a scraping knife, a multifunctional groove, an outer maintenance disc, an inner maintenance disc, a liquid discharging blowing opening, a liquid discharging pipe top wall, a liquid discharging pipe, an auxiliary blowing opening and a slurry discharging grid, wherein the slurry pump is used for conveying slurry in the slurry tank into the mixing barrel; the flocculating agent pump is used for conveying a flocculating agent into the mixing barrel; the mixing barrel motor is usedfor driving blades in the mixing barrel to stir; the control valve is connected between the mixing barrel and the centrifuge; the slurry enters the centrifuge through the slurry feeding pipe; liquiddischarged from the centrifuge enters the liquid collection box through the conveying pipeline; the slurry discharged from the centrifuge falls onto the conveyor belt through the unloading valve; theslurry treatment system further comprises a controller.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Composition for preventing and treating influenza virus and Chinese medicine compound oral instant film preparation

ActiveCN106236807BObvious anti-influenza virus effectFacilitated releaseHydroxy compound active ingredientsAntiviralsMentholPharmaceutical drug

Owner:SHENZHEN SHENNONG SPRING PLANT SUBSTANCES DEV CO LTD

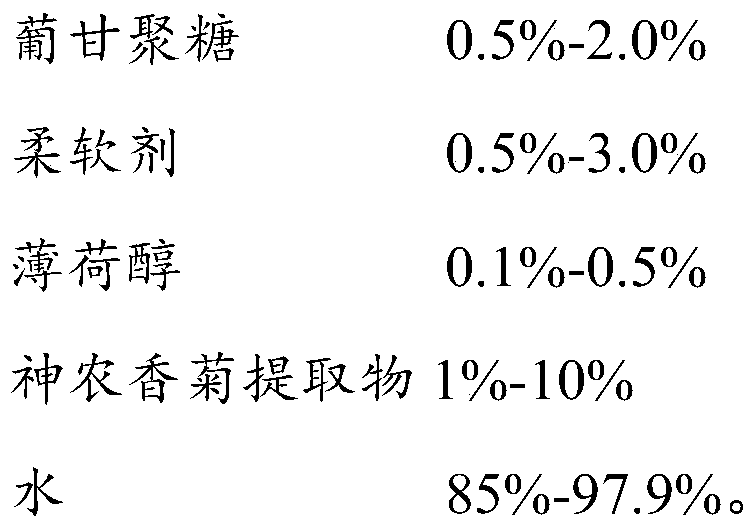

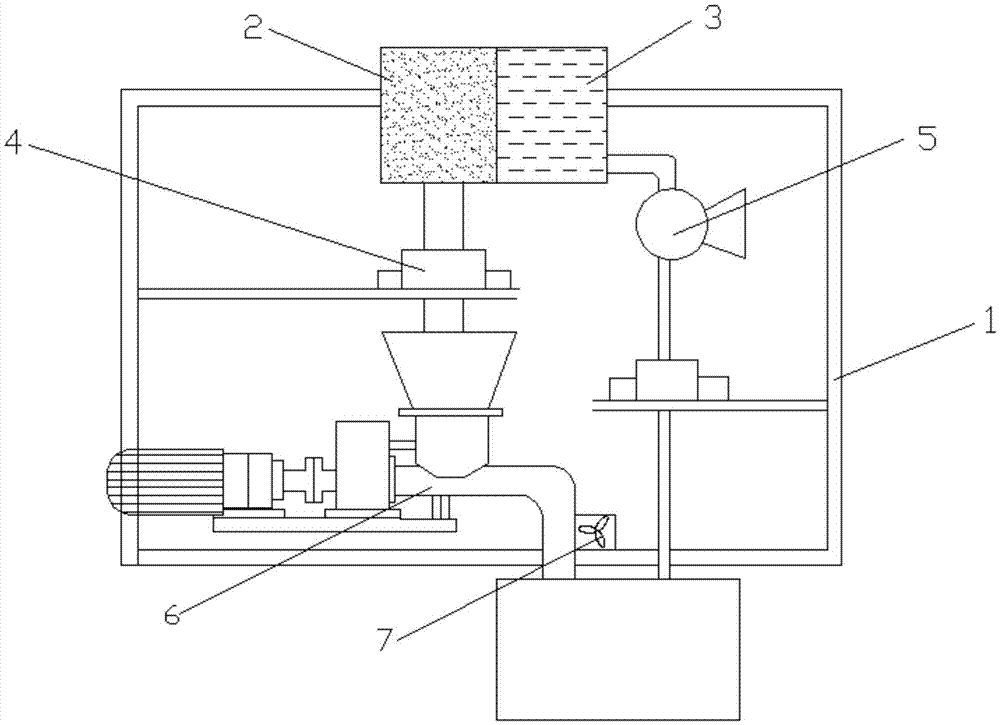

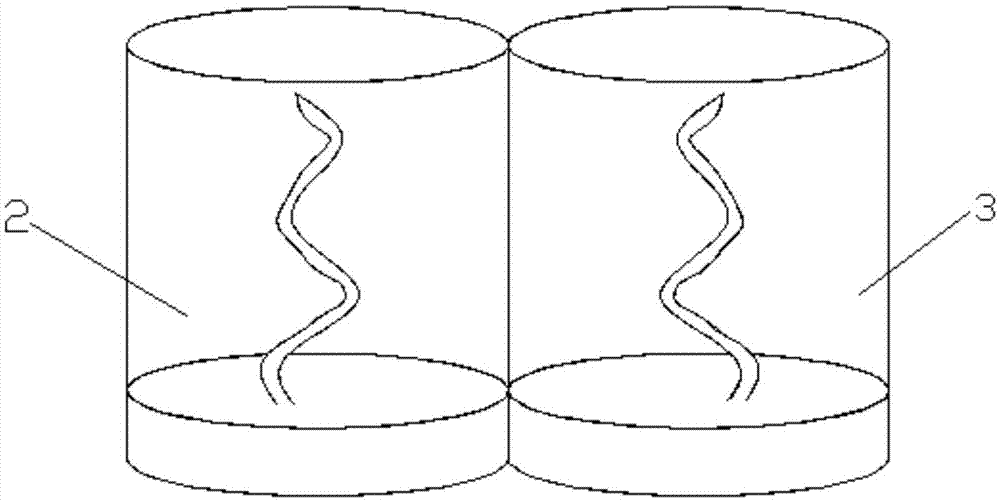

A multifunctional fermented feed production process equipment

ActiveCN106418616BHigh degree of mechanizationReduce manual laborFeeding-stuffProcess equipmentIn process control

The invention discloses multifunctional efficient feed fermentation production process equipment which comprises a particle raw material cleaning section, a particle raw material crushing section, a powdery raw material cleaning section, a blending section and a liquid adding and mixing section. The multifunctional efficient feed fermentation production process equipment is high in mechanization degree, more precise in process control, higher in fermentation efficiency, high in fermentation raw material adaptability, capable of achieving many functions, rich in produced product variety, simple and low in equipment mounting cost and plant building cost and making residual materials in inoculating equipment to be cleaned away easily.

Owner:WUHAN GUIYAN MACHINERY MFG CO LTD

Rubber carpet feeding system

The invention relates to carpet processing equipment, in particular to a rubber carpet feeding system. The rubber carpet feeding system comprises a machine frame, a feeding cylinder, material distributing machines, primary stirring machines, glue injection machines and secondary stirring machines, wherein the feeding cylinder, a material distributing machine, the primary stirring machines, the glue injection machines and the secondary stirring machines are arranged on the machine frame from top to bottom, the material distributing machine is arranged right below the feeding cylinder, the material distributing machine is connected with the primary stirring machines through a conveying device, the glue injection machines are arranged on one sides of the primary stirring machines, the secondary stirring machines are communicated with the primary stirring machines through pipelines, and material spreading openings are formed below the secondary stirring machines. The system has the advantages that the functions of the feeding, distribution and mixture of solid material and the mixture and stirring of solid material and liquid can be completed, the stirring is uniform and sufficient, the quality of raw materials is improved, the stirring is carried out for a plurality of times, so that the mixing of glue and rubber particles is facilitated, the weight of final product is controllable, the quality is greatly improved, and the method is suitable for volume production.

Owner:GUANGDONG MEISHI CARPET CO LTD

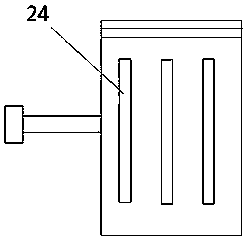

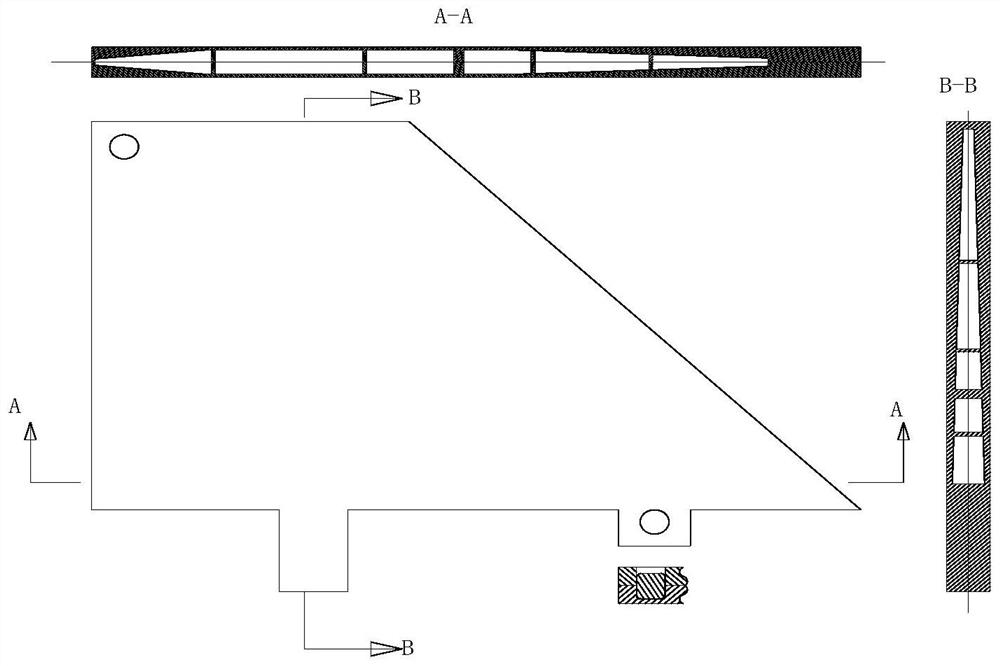

Preparation method of hollow grid structure wing rudder

The invention relates to a preparation method of a hollow grid structure wing rudder, belongs to the technical field of preparation of wing rudders, and solves the problems that a method for preparing a wing rudder in the prior art is complex in process and the prepared wing rudder is poor in performance. The preparation method comprises the following steps: a, according to the structure of the wing rudder, dividing the wing rudder into two parts which are symmetrical up and down along a chord plane, and designing an upper grid plate model and a lower grid plate model; b, preparing an upper grid plate and a lower grid plate according to the design model; and c, assembling the upper grid plate and the lower grid plate, and performing diffusion bonding. The method is simple in step and low in implementation difficulty, and the formed wing rudder is good in performance and high in precision.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Quantitative feeding device for ring ring machine

The invention discloses a quantitative feeding device for a looping machine. The quantitative feeding device for the looping machine comprises a first stock bin, a second stock bin, a conveying hose, a material receiving opening, an inclined hopper, an adjustable discharging device and a fixed base, wherein the second stock bin is arranged at the upper end of the first stock bin, and the lower end of the first stock bin is fixedly connected with the conveying hose; the upper end of the material receiving opening is fixedly connected with the conveying hose, and the lower end of the material receiving opening is fixedly connected with the adjustable discharging device; the inclined hopper is arranged inside the adjustable discharging device, and an adjusting seat is welded on the bevel edge at the bottom of the inclined hopper; the fixed base is fixedly arranged on a fixed support through a screw, a slide base is fixedly arranged on the upper left side of the bottom of the fixed base in an upward slantwise manner, an adjusting rod is arranged inside the slide base, the adjusting rod is fixed with the adjusting seat through the screw to adjust the opening height of the inclined hopper. The quantitative feeding device for the looping machine has the benefits of good mechanism stability, accurate feeding target, precise feeding amount, convenience for control, uniform discharging, automatic feeding, uniform feeding and no blocking in the stock bins.

Owner:DANYANG QIRUI MACHINERY

Multi-functional adding machine

The present invention discloses a multi-functional adding machine. The multi-functional adding machine comprises a machine body. A solid raw material cabin and a liquid raw material cabin are arranged at the upper side of a shell body of the machine body and extend into the interior of the shell body, a weighing cabin is connected below the solid raw material cabin via a pipeline, a weighing cabin is connected below the liquid raw material cabin via a pipeline, a screw output machine is connected below the corresponding weighing cabin located below the solid raw material cabin, a blower is arranged between the screw output machine and a receiving device, a plunger pump is arranged between the liquid raw material cabin and the corresponding weighing cabin, and the receiving device is connected below the corresponding weighing cabin located below the liquid raw material cabin via a pipeline. Two different adding channels are separately arranged in the machine body of the multi-functional adding machine, so that the multi-functional adding machine realizes the multiple adding functions, can add solid raw materials and liquid raw materials at the same time, and can also add water, etc. The weighing cabins are also arranged, so that the multi-functional adding machine can control the weight of the added raw materials, and is improved in adding accuracy. During the output of the solid raw materials, the dual functions of the screw output machine and the blower realize the full output of the solid raw materials.

Owner:CHONGQING JIAOYUYIBING AGRI DEV CO LTD

Preparation method of multi-point equispaced powder package bag

ActiveCN101380278BEvenly distributedControllable weightPharmaceutical containersMedical packagingBiomedical engineeringMulti point

Owner:GANSU CHEEZHENG TIBETAN MEDICINE CO LTD

Control method for slurry treatment system

InactiveCN111517616AAvoid build-up solidificationSave volume and spaceSludge treatment by de-watering/drying/thickeningElectric machineryProcess engineering

The invention discloses a control method for a slurry treatment system. The control method comprises the steps that a control valve is connected between a feeding and closing barrel and a centrifugalmachine; in the initial state, the control valve is closed, a mud pump conveys mud in the mud pit to the a barrel; a flocculating agent pump conveys a flocculating agent to the mixing barrel; a mixingbarrel motor drives blades in the mixing barrel to stir; after the uniform stirring, the control valve is opened, mud enters the centrifugal machine through the mud inlet pipe, the mud is thrown to the mud bearing arc-shaped wall and accumulated above a second gate plate, falling impact is relieved through the accumulated mud, then a second gate plate is opened, the mud falls onto the conveying belt, and thus the accumulated mud is formed on the conveying belt and is relatively concentrated to facilitate subsequent collection.

Owner:陈永福

Warp knitted sesame dot jacquard thermal fabric and its manufacturing process

The invention relates to warp-knitted speckled jacquard warm-keeping fabric and a manufacturing technology thereof. The warp-knitted speckled jacquard warm-keeping fabric is composed of, by mass, thecomponents of 10.5% of 32 siro compact spinning Toray AR color yarn, 62.9% of 32 s compact spinning cotton color yarn and 26.6% of 75D / 40D polyester ammonia filaments. The manufacturing technology ofthe fabric includes the following steps that in material selection, 20-40% of Toray AR yarn, 20-40% of cotton yarn and 20-40% of polyester ammonia filaments are selected; in warping, the Toray AR yarn, the cotton yarn and the polyester ammonia filaments are warped on a warping machine; in knitting, a Tricot warp-knitting machine is adopted for knitting; in aftertreatment, grey cloth which is obtained through knitting is sequentially subjected to washing, setting and napping. The fabric is appropriate in elasticity, controllable in gram weight, good in warm-keeping performance, soft in hand feeling, fit and attractive, and the effect of speckled jacquard is obvious.

Owner:JIANGYIN FUBO TEXTILE CO LTD

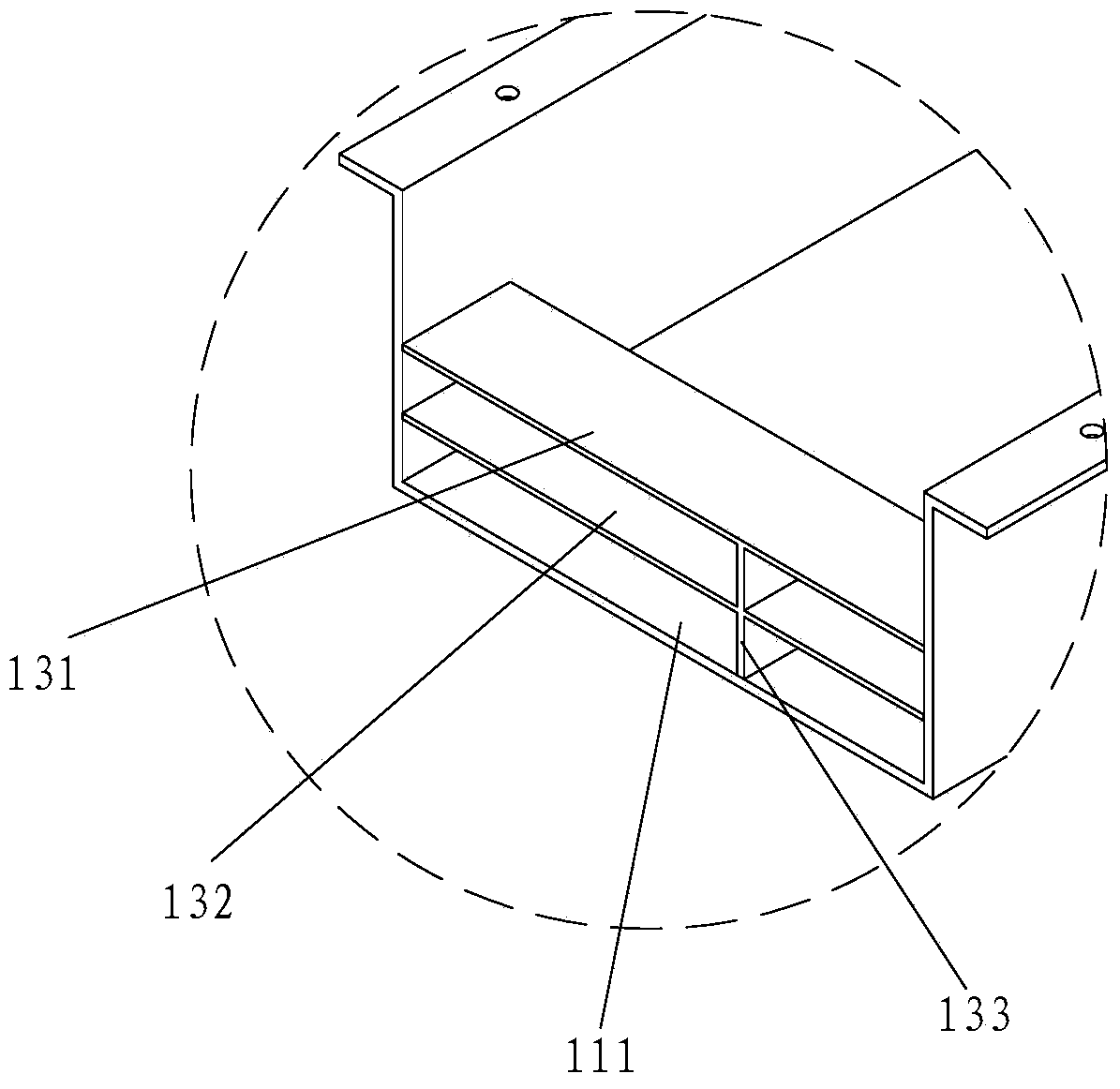

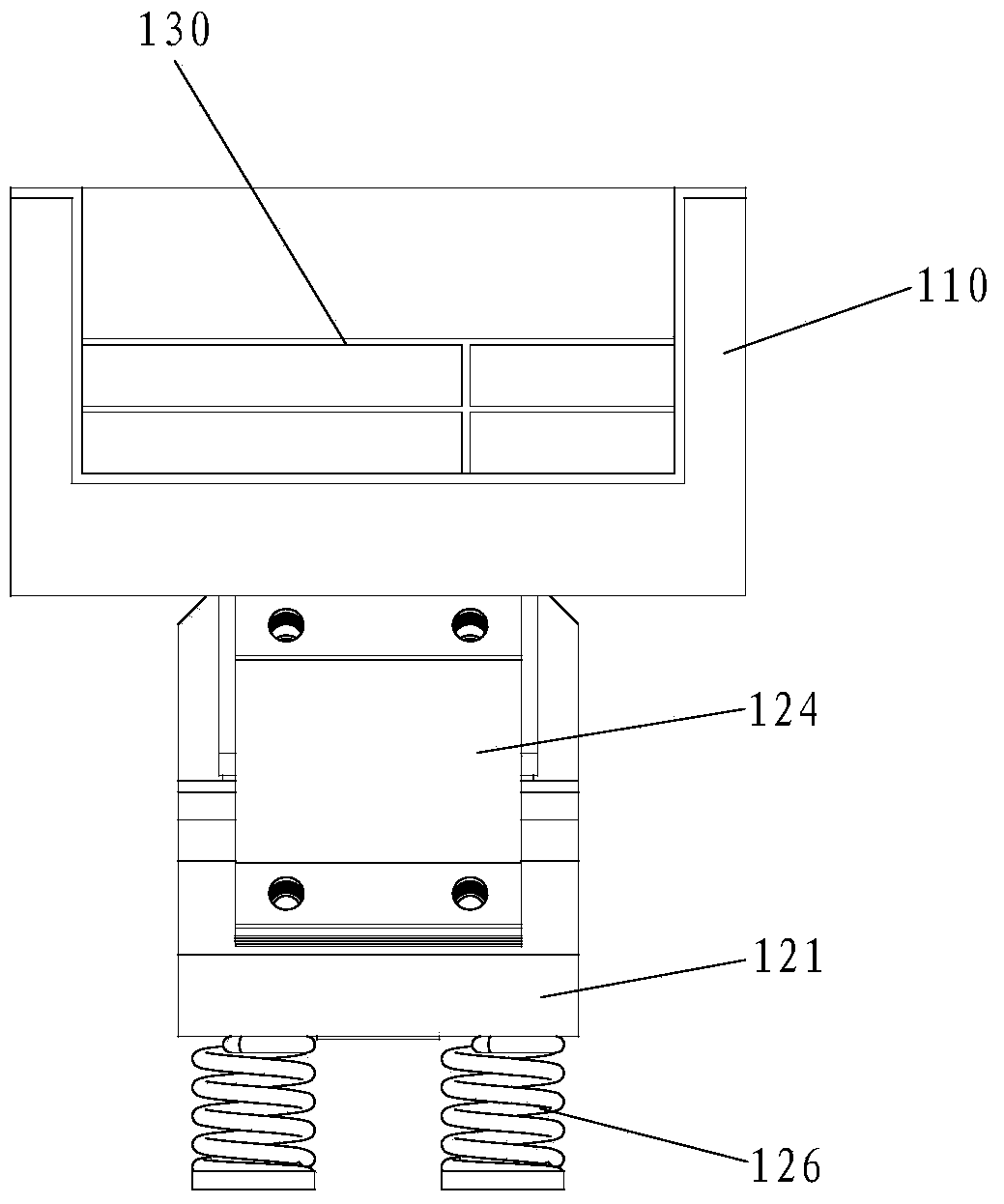

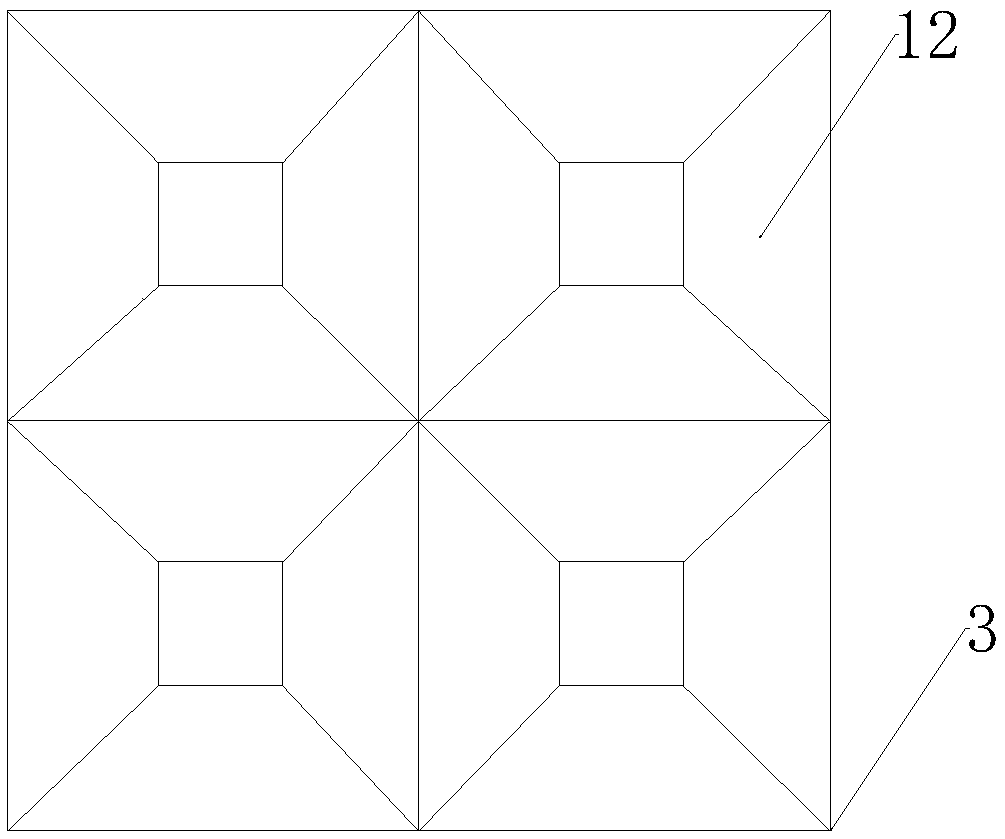

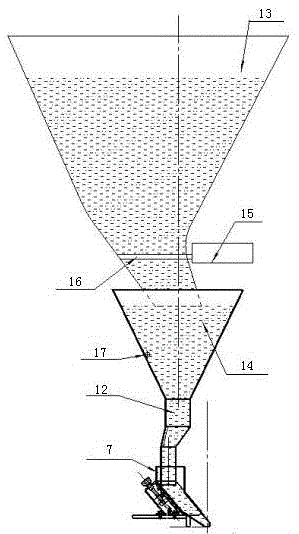

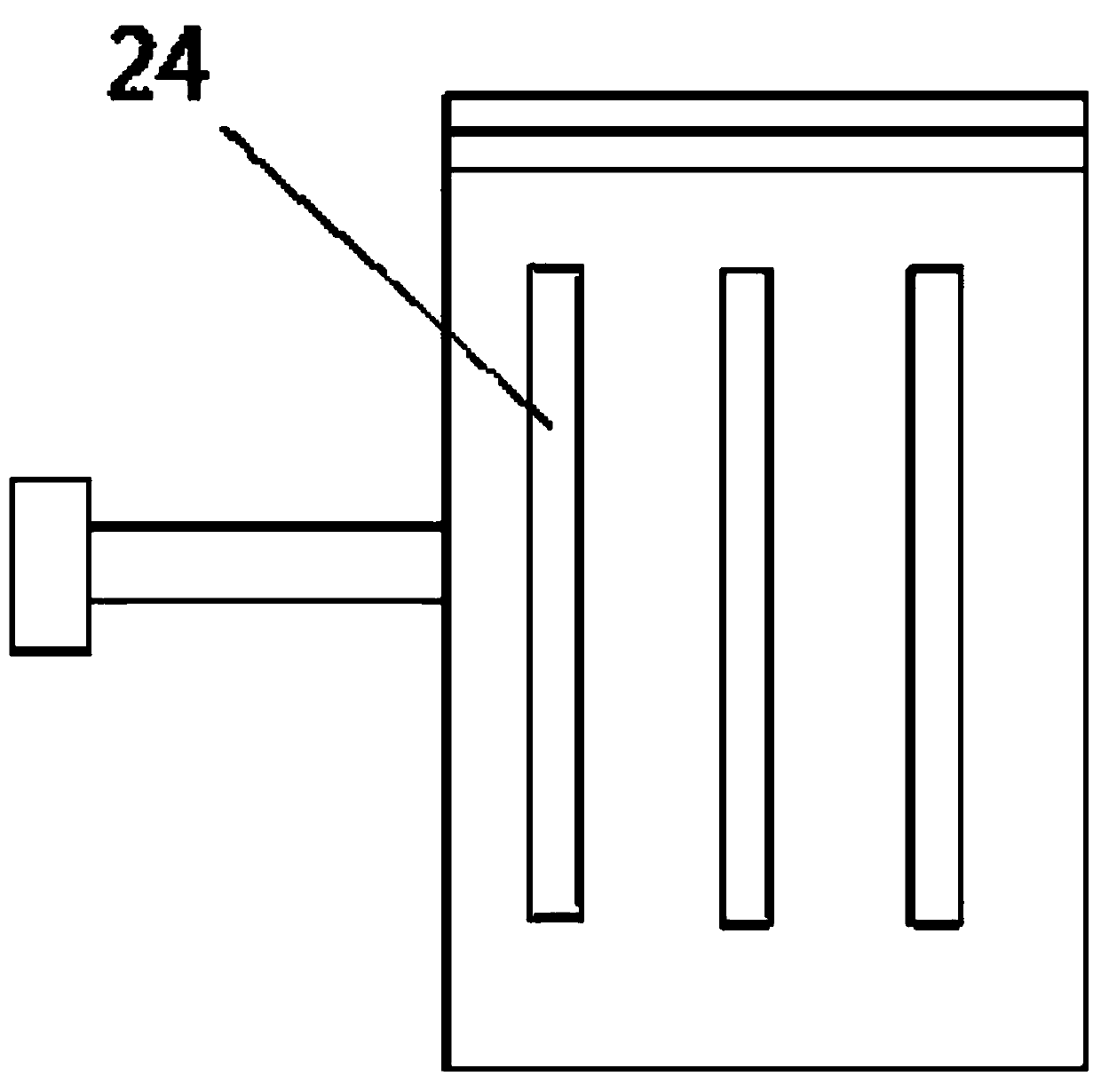

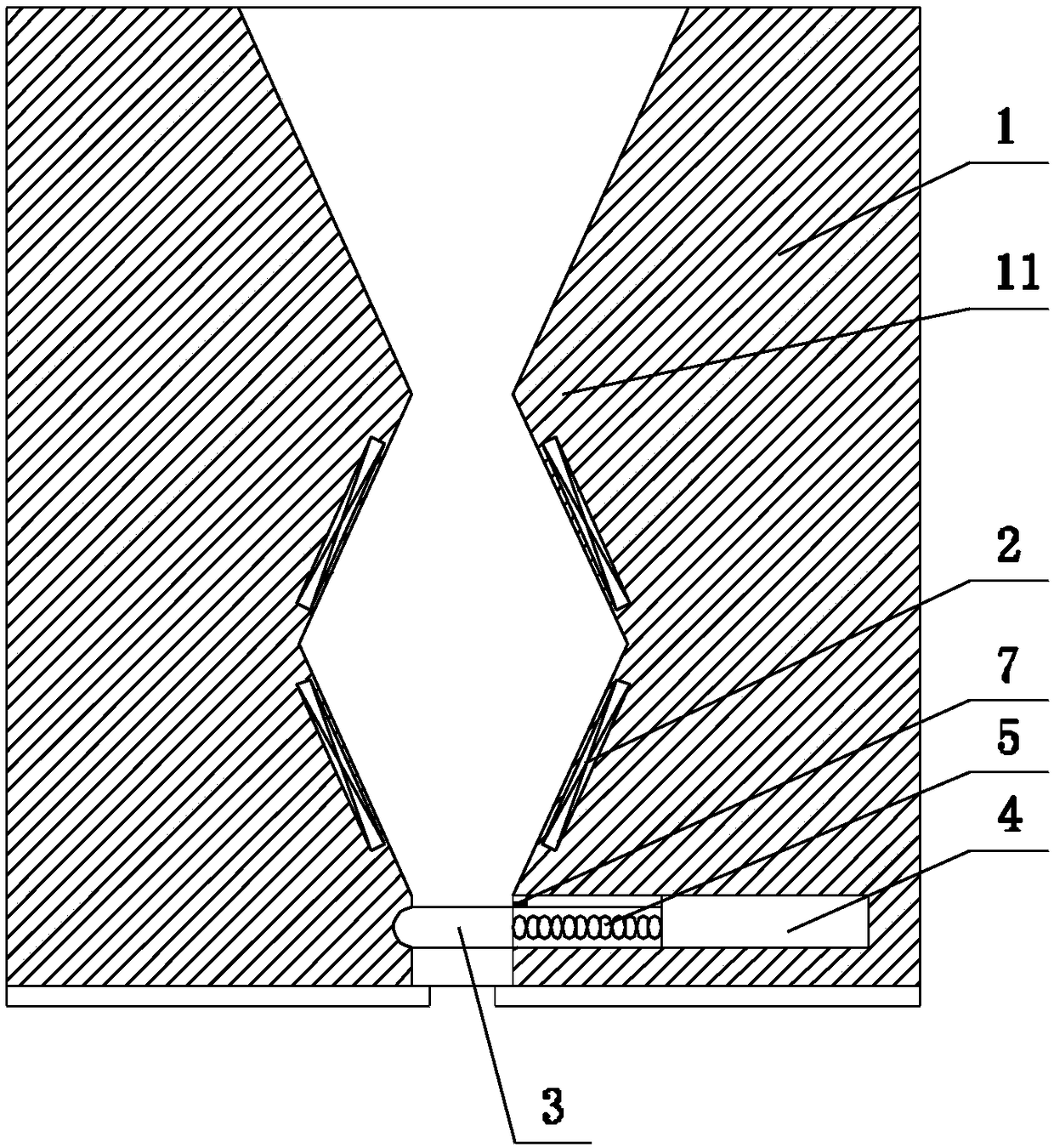

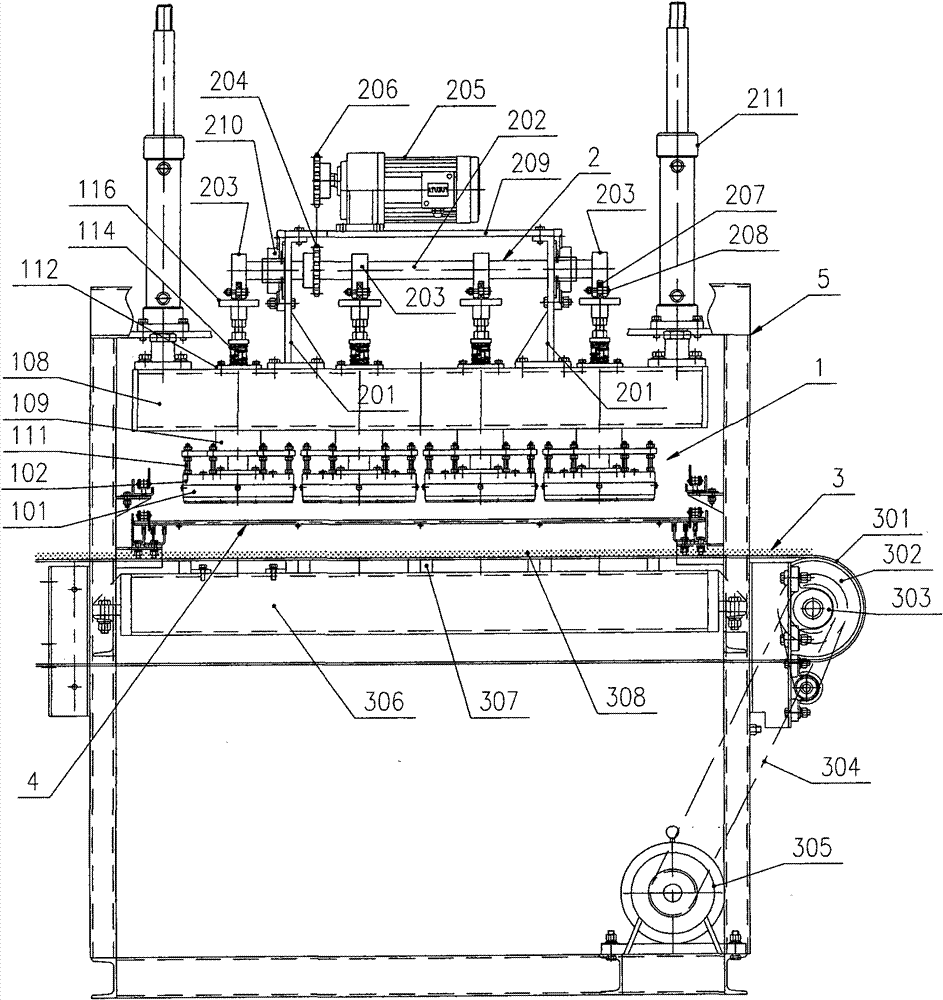

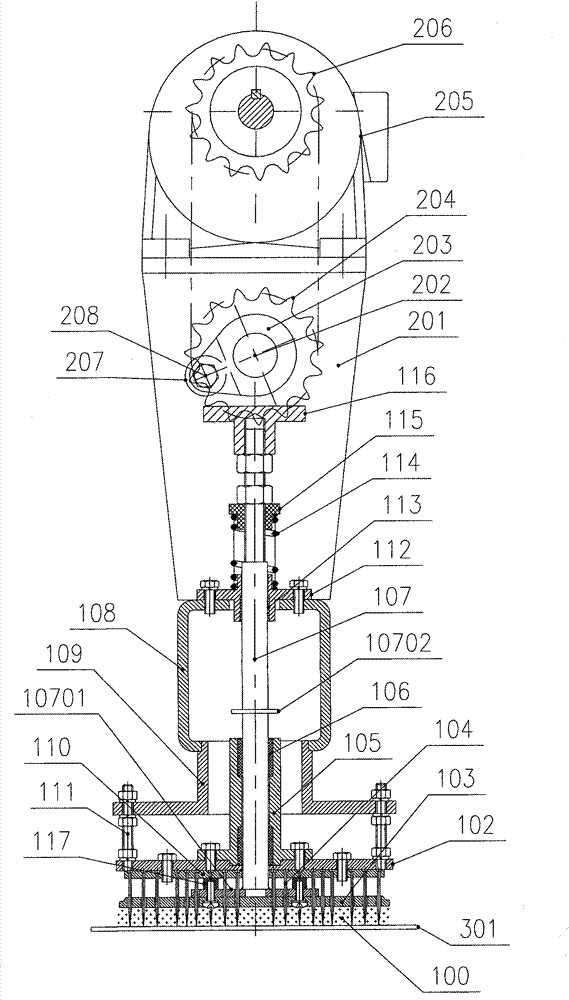

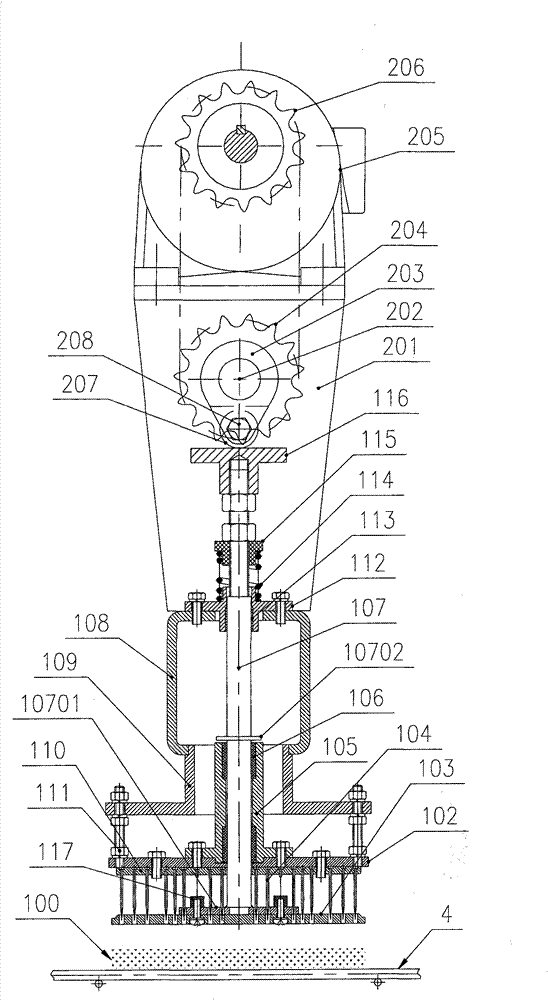

An automatic press molding system for the production of water glass expansion vitrified microbead lightweight insulation board

InactiveCN103878866BControllable weightCompaction density controllableFeeding arrangmentsVolumetric Mass DensityEngineering

The invention discloses an automatic compression forming system used for production of lightweight heat-insulating plates made of water glass expanded glass beads. The system comprises a conveying belt, a collection device, a transmission platform, a mould and a pressurizing device. The conveying device is used for conveying water glass expanded glass bead materials to the collection device; the collection device comprises a collection hopper and a storage bin; the collection hopper is funnel shaped and used for collecting the materials conveyed by the conveying belt and conveying the materials to the storage bin; the storage bin with the top and bottom open is provided with side walls all around; a force application device is arranged at one end of the transmission platform and connected with the storage bin to push the storage bin to move leftwards and rightwards; the other end of the transmission platform is provided with an opening, and the mould is positioned below the opening; the pressurizing device is used for pressurizing the materials in the mould to form the heat-insulating plates. The automatic compression forming system has the advantages of high production efficiency, light weight of the heat-insulating plates, controllability in compression density, uniformity in force applied to each portion of the heat-insulating plates and the like.

Owner:谭学俊

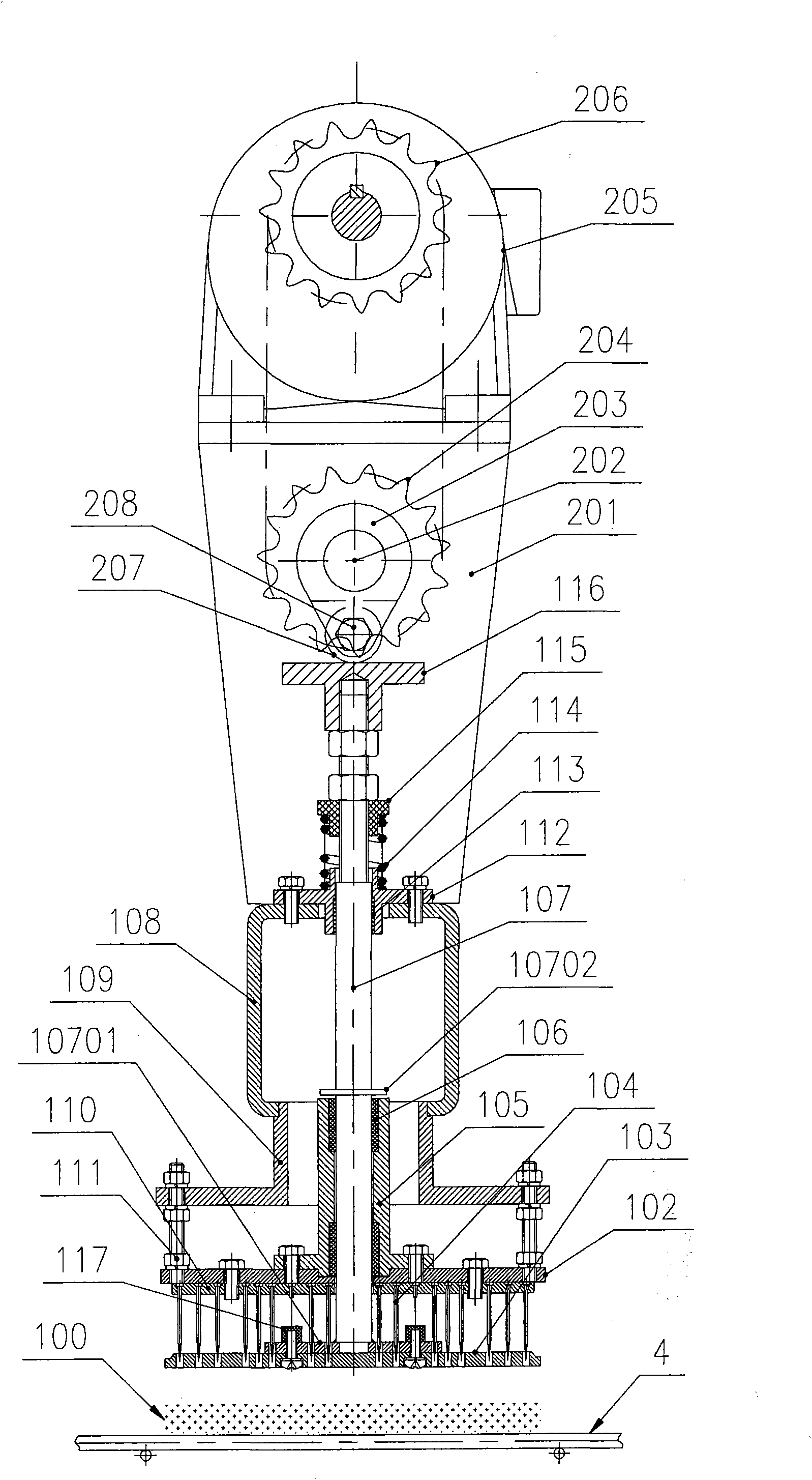

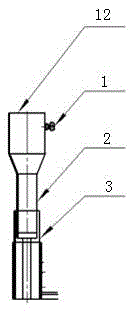

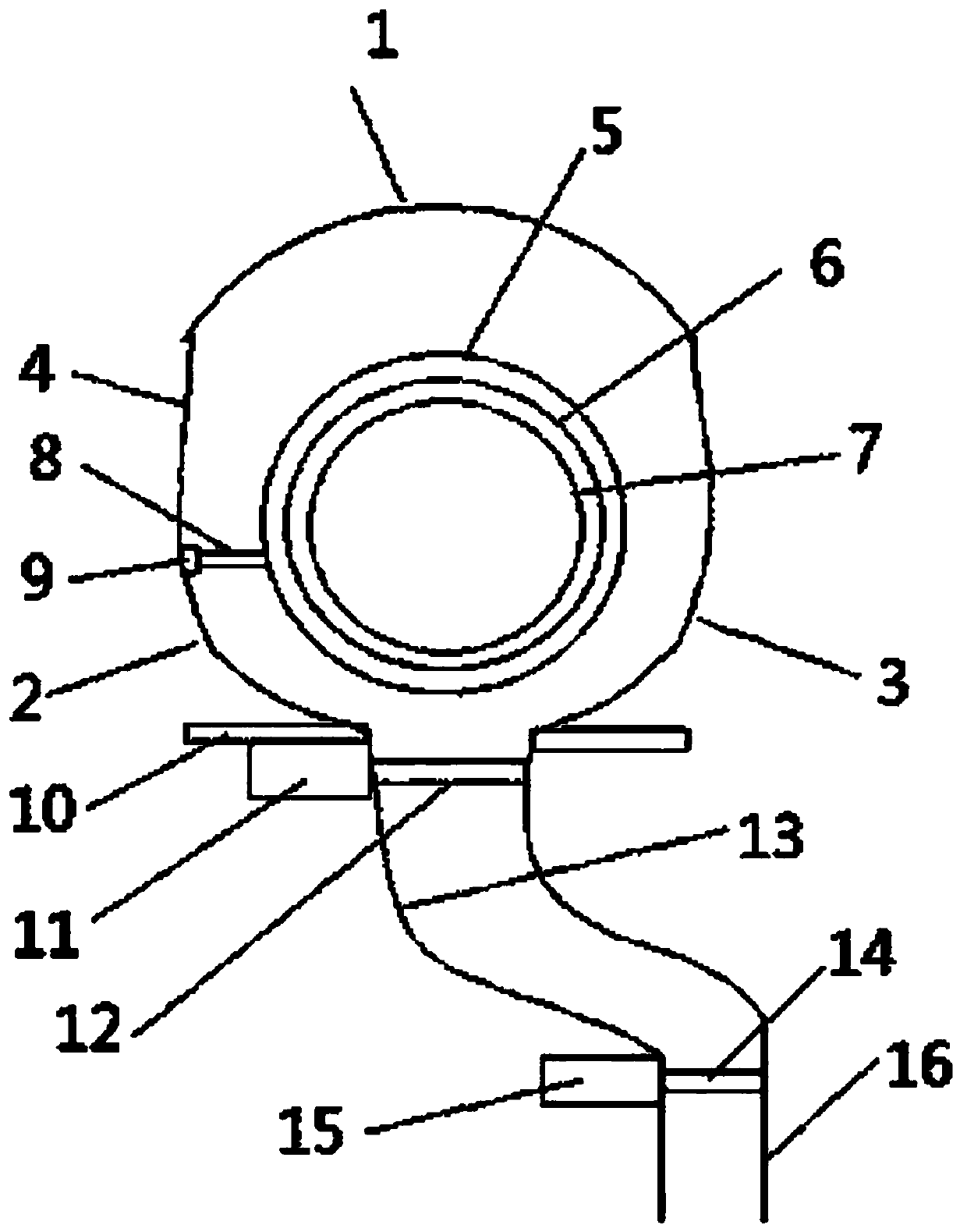

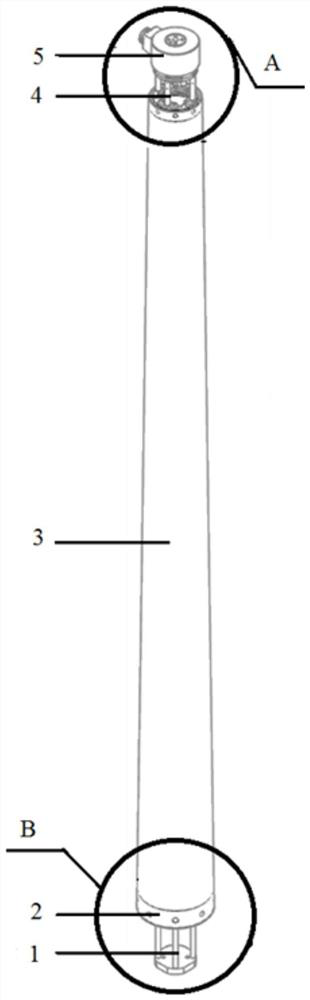

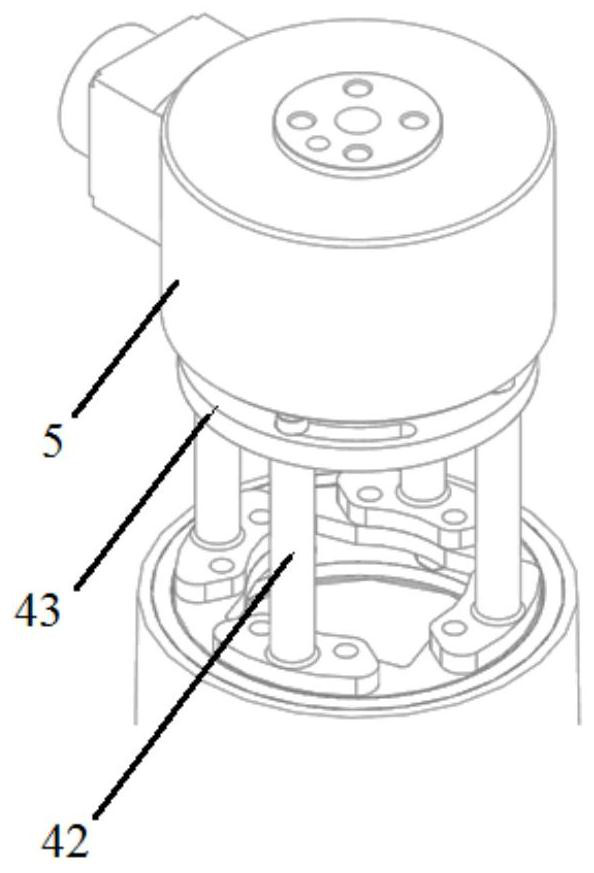

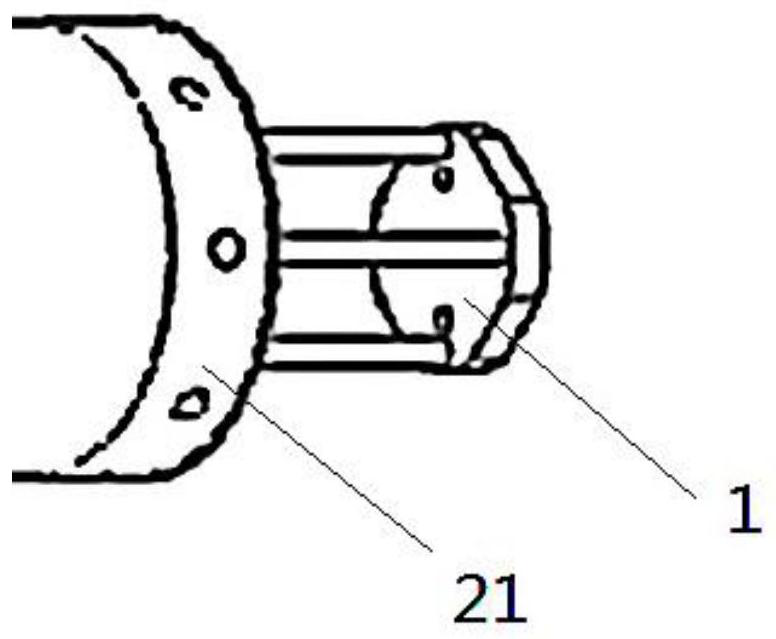

A floating wind turbine tower scale model for simulating tower shadow effect and yaw error

ActiveCN110285024BSimulation is accurateEffective simulationMachines/enginesWind motor monitoringScale modelTower shadow

The invention discloses a floating fan tower tube scale model capable of simulating tower shadow effects and yaw errors, and relates to the field of floating fan scale model tests. The floating fan tower tube scale model comprises a tower bottom six-component meter, a tower bottom connecting component, a conical tower tube component, a yaw adjusting component and a tower top six-component meter, wherein the lower end surface of the tower bottom six-component meter is fixedly mounted on a floating platform; the upper end surface of the tower bottom six-component meter is fixedly connected with the lower part of the tower bottom connecting component; the upper part of the tower bottom connecting component is fixedly connected with the lower end part of the conical tower tube component; the upper end part of the conical tower tube component is fixedly connected with the lower part of the yaw adjusting component; and the upper part of the yaw adjusting component is fixedly connected with the lower end part of the tower top six-component meter. Through the implementation of the floating fan tower tube scale model disclosed by the invention, the tower shadow effects and the yaw errors experienced by a real offshore floating fan can be accurately and efficiently simulated under the premise that other performance requirements of a scale model pool test are prevented from being influenced; and furthermore, the tower tube loads under various working conditions of the floating fan can be completely monitored.

Owner:SHANGHAI JIAO TONG UNIV

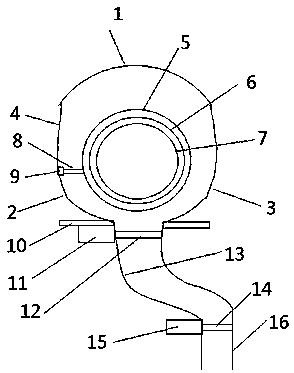

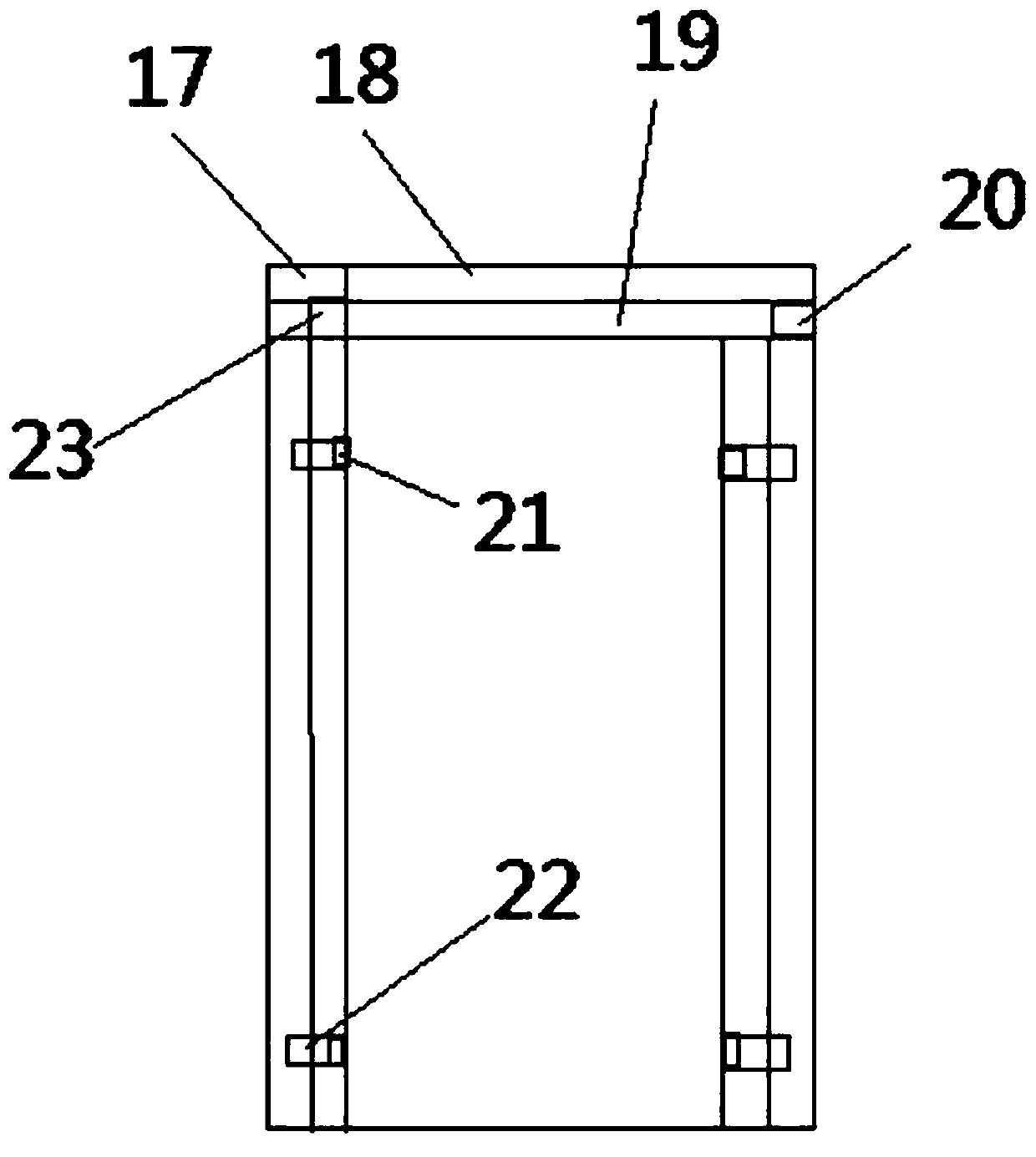

A Portable Water Body Vertical Profile Optical Measurement System and Its Application Method

InactiveCN103471568BAccurate measurement dataMeasuring elements have no effectOpen water surveyTesting waterIlluminanceRadiance

The invention belongs to the field of marine observation, and in particular relates to a portable optical measurement system for a water body with a vertical section and a using method of the system. The measurement system comprises a buoyancy block, an irradiance sensor, a supporting frame body, a gravity balance adjustment hammer and a radiance sensor, wherein the buoyancy block is arranged at the top of the supporting frame body; the irradiance sensor and the radiance sensor are arranged on two sides of the supporting frame body respectively; the gravity balance adjustment hammer is installed at the lower part of the supporting frame body in a relative moving manner; the irradiance sensor and the radiance sensor move on the supporting frame body by virtue of the gravity balance adjustment hammer, and are always in the vertical direction in water. The measurement system can float away from a boat body downstream and fall slowly and freely, can continuously measure the upstream radiance and the downstream irradiance of the water body with the vertical section from a water surface to set depth, has the characteristics of simple structure and small size, can be free from the influence of the boat body and shadow so as to ensure accuracy of an optical measuring parameter, and can be used for carrying out ocean water color research, satellite calibration and confirmation and the like.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

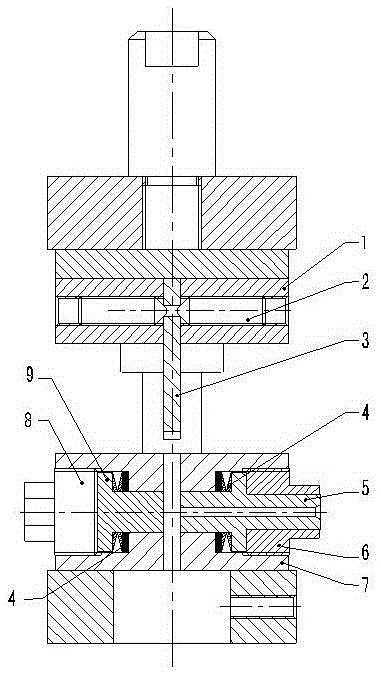

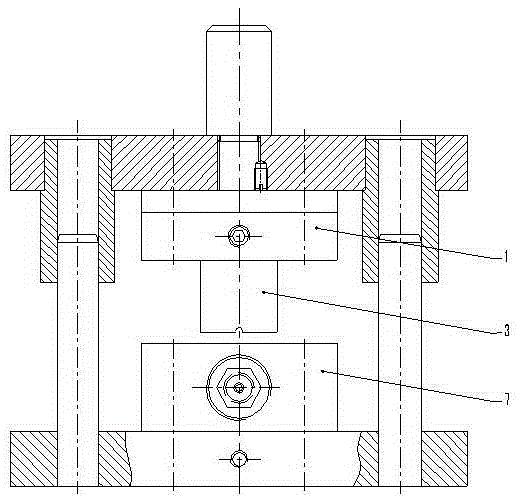

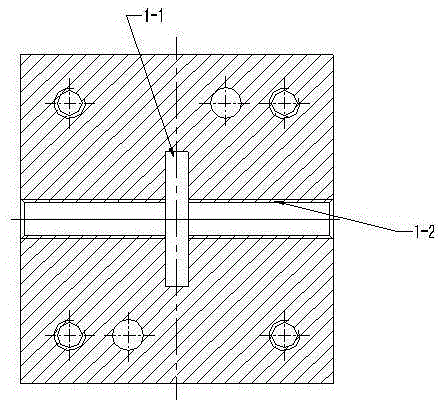

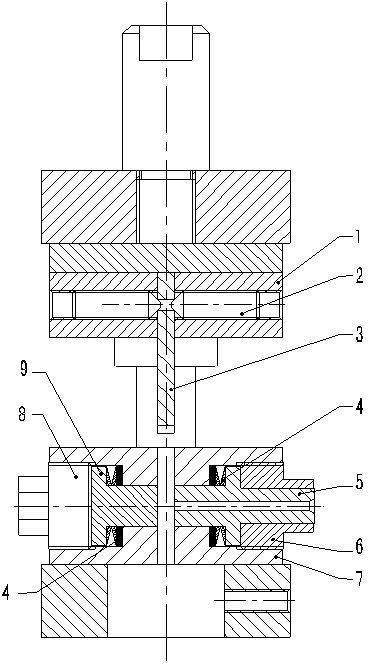

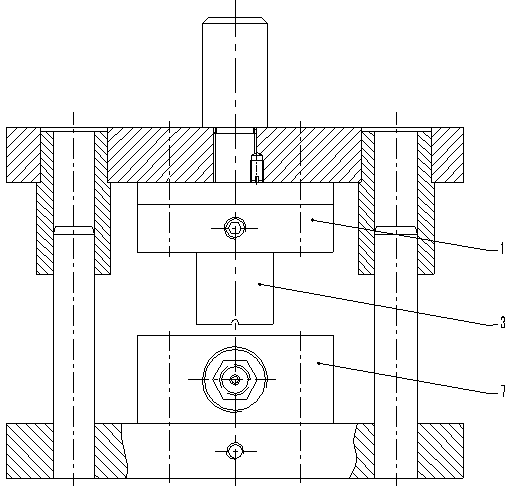

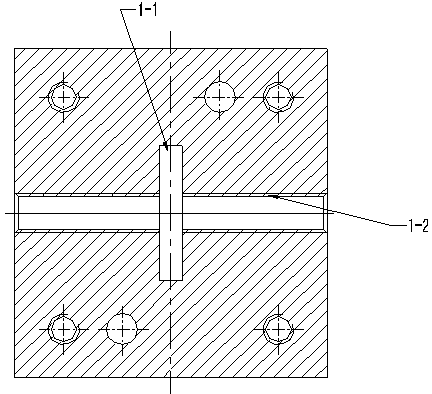

Adjustable quick-change gold grain punching die

The invention relates to an adjustable fast-replacement type gold grain punching die. The die is composed of an upper die with a punching blade and a lower die with an adjustable limiting device and a punching bottom base. The punching blade is in clearance fit with a blade fixing plate and is compressed through a screw, and fast placement can be achieved. A semicircular groove opening is formed in the cutting edge of the blade and is identical to gold grains in radius. The limiting device is composed of a limiting block, a belleville spring and an adjusting screw plug, and the limiting position can be adjusted by rotating the screw plug. The punching bottom die is in clearance fit with a bottom die fixing plate and is assembled to the bottom die fixing plate through the belleville spring and an adjusting screw sleeve, the clearance between the cutting edge of the bottom die and the blade can be adjusted by rotating the screw sleeve, and meanwhile fast replacement can also be achieved. A through hole is formed in the bottom die, and the hole diameter of the cutting edge is identical to the diameter of the gold grains. The end faces of the gold grains can be free of deformation and burrs, and efficient precise punching with the consistent weight of a single grain can be achieved.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Rubber injection molding preheating feeding equipment

InactiveCN108099103AStructural design is optimized and reasonableImprove heating efficiencyHeating efficiencyEngineering

The invention discloses rubber injection molding preheating feeding equipment. A horizontally-arranged annular protrusion is arranged on the inner wall of a containing cavity inside a shell. The containing cavity is divided by the annular protrusion into a feeding chamber and a heating chamber. The inner wall of a discharge outlet is provided with a baffle storage cavity used for containing a receiving baffle. A weighing mechanism is arranged on the receiving baffle. A driving assembly drives the receiving baffle through an electromagnet to move. By means of the optimally-designed rubber injection molding preheating feeding equipment, structural design optimization is reasonable, the feeding chamber and the heating chamber are isolated through the annular protrusion, the feeding chamber covers the inlet of the heating chamber through materials, heat preservation is carried out on the heating chamber, and heating efficiency is improved. Meanwhile, the heating chamber provides buffer formaterials falling to the receiving baffle, the weight of materials weighed on the receiving baffle is controllable, and the final discharge precision is greatly improved.

Owner:钱天朗

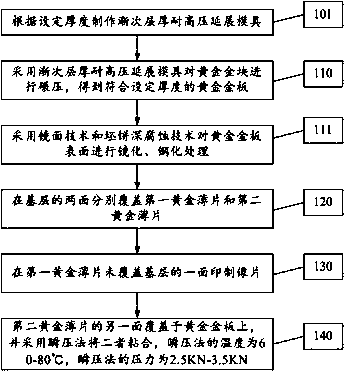

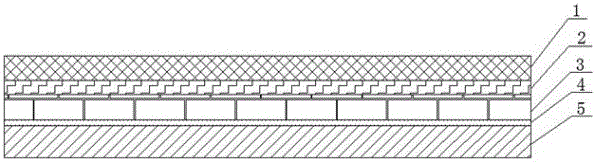

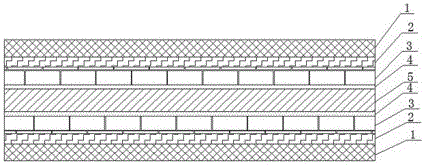

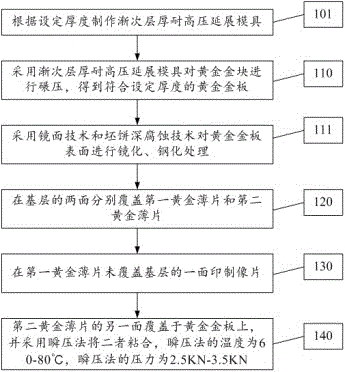

Manufacturing method of gold photo

The invention relates to the field of gold technological products, and discloses a manufacturing method of a gold photo with favorable collection and investment values, and the weight of gold in the gold photo is increased, so that the requirement of people on gold collection and investment is met. The manufacturing method of the gold photo comprises the following steps: manufacturing a gold board according to a set thickness; carrying out mirroring and toughening treatment on the surface of the gold board by adopting a mirror surface technique and a blank cake deep-etching technique; covering the two surfaces of a base layer with the gold so as to form a first gold thin sheet and a second gold thin sheet which coats the two surfaces of the base layer; printing the photo on one surface, which is not covered with the base layer, of the first gold thin sheet; and gluing one surface, which is not covered with the base layer, of the second gold thin sheet on the gold board.

Owner:靳鑫

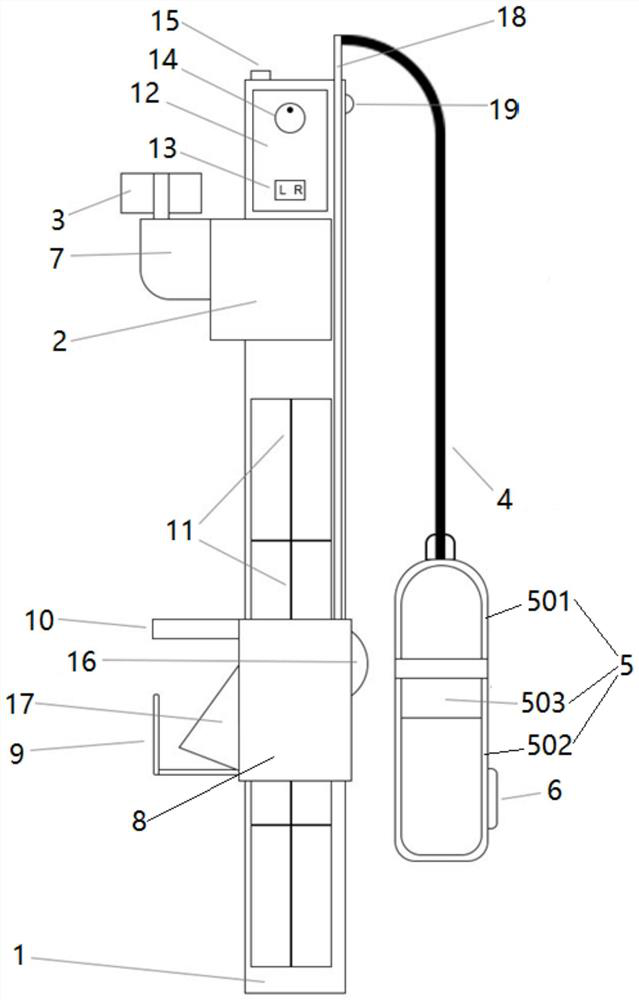

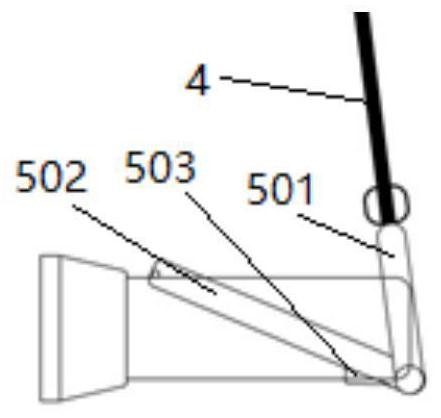

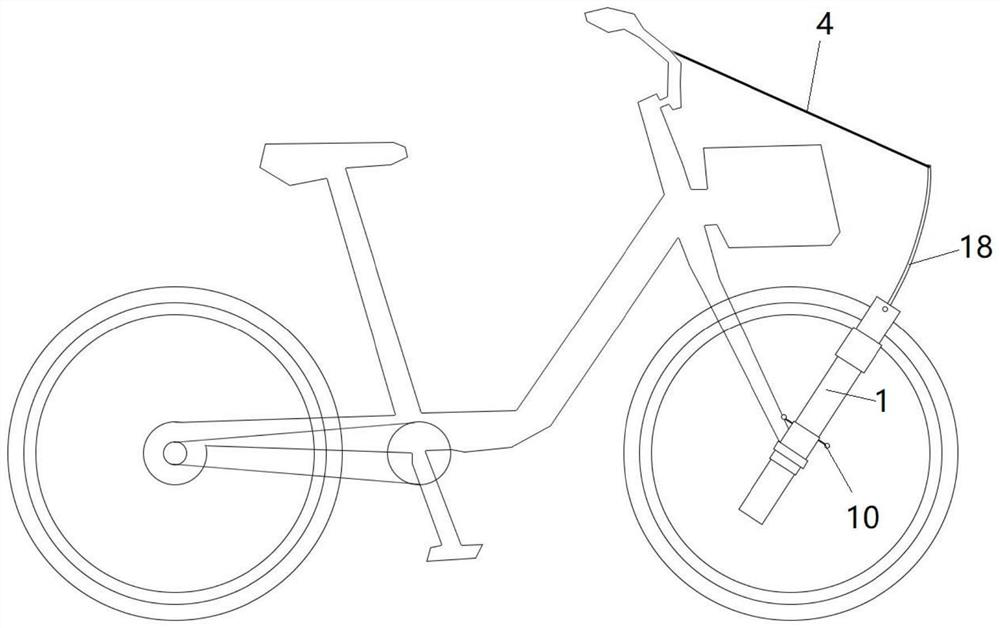

Bicycle power assisting device convenient to install

ActiveCN112455593AEasy to disassembleControllable weightRider propulsionElectric machineryElectrical and Electronics engineering

The invention belongs to the technical field of bicycles, and discloses a bicycle power assisting device convenient to install. The bicycle comprises a main machine part and a handle connecting part.The main machine part comprises a machine shell, a fixing mechanism, a transmission mechanism and a length adjusting mechanism, the transmission mechanism comprises a motor and a power wheel in transmission connection with the motor, the motor is fixed to the machine shell, and the motor drives the power wheel to rub with wheels of the bicycle to generate power; the length adjusting mechanism is connected to the machine shell in a sliding mode, and the length adjusting mechanism is connected with the handle connecting part through a tension cable. The bicycle handle can be quickly mounted on abicycle, is very convenient to dismount, does not need to consume extra materials, is convenient to carry, is suitable for various bicycles such as private bicycles or shared bicycles, can be fixed on any side of the bicycle, is convenient for people with different hand flexibility (such as left hand or right hand habits) to use, and improves the travel efficiency of people.

Owner:郝游

How to make a golden photo

The invention relates to the field of gold technological products, and discloses a manufacturing method of a gold photo with favorable collection and investment values, and the weight of gold in the gold photo is increased, so that the requirement of people on gold collection and investment is met. The manufacturing method of the gold photo comprises the following steps: manufacturing a gold board according to a set thickness; carrying out mirroring and toughening treatment on the surface of the gold board by adopting a mirror surface technique and a blank cake deep-etching technique; covering the two surfaces of a base layer with the gold so as to form a first gold thin sheet and a second gold thin sheet which coats the two surfaces of the base layer; printing the photo on one surface, which is not covered with the base layer, of the first gold thin sheet; and gluing one surface, which is not covered with the base layer, of the second gold thin sheet on the gold board.

Owner:靳鑫

Cake taking component and algae or vegetable cake making device employing same

The invention provides a needle type cake taking component for processing algae or vegetables, which comprises a needle mounting disc, needles arranged on the needle mounting disc, a material returning disc and a transmission device, wherein the material returning disc is provided with through holes corresponding to the needles, so that the needles are allowed to move along the length direction of the needles relative to the material returning disc; a ring cutter is arranged outside the needle mounting disc and is arranged on a cutter base; and the transmission mechanism is used for making the material returning disc and the needle mounting disc generate relative movement, and is in transmission connection with the needle mounting disc and the material returning disc through a main beam. The invention also provides a cake making device, which can mechanically make cakes for dehydrated laver, and has the technical advantages of sanitary production, uniform cakes, high work efficiency, energy conservation, and uniform dimension, good bulkiness and controllable weight of the cakes.

Owner:王行安

Adjustable fast-replacement type gold grain punching die

The invention relates to an adjustable fast-replacement type gold grain punching die. The die is composed of an upper die with a punching blade and a lower die with an adjustable limiting device and a punching bottom base. The punching blade is in clearance fit with a blade fixing plate and is compressed through a screw, and fast placement can be achieved. A semicircular groove opening is formed in the cutting edge of the blade and is identical to gold grains in radius. The limiting device is composed of a limiting block, a belleville spring and an adjusting screw plug, and the limiting position can be adjusted by rotating the screw plug. The punching bottom die is in clearance fit with a bottom die fixing plate and is assembled to the bottom die fixing plate through the belleville spring and an adjusting screw sleeve, the clearance between the cutting edge of the bottom die and the blade can be adjusted by rotating the screw sleeve, and meanwhile fast replacement can also be achieved. A through hole is formed in the bottom die, and the hole diameter of the cutting edge is identical to the diameter of the gold grains. The end faces of the gold grains can be free of deformation and burrs, and efficient precise punching with the consistent weight of a single grain can be achieved.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com