Warp knitted sesame dot jacquard thermal fabric and its manufacturing process

A manufacturing process, sesame point technology, which is applied in the field of warp knitted sesame point jacquard thermal insulation fabric and its manufacturing process, can solve the problems of poor cotton yarn strength and elongation, low production efficiency, easy to produce flying flowers, etc., and achieve soft hand feeling and no sense of restraint , Sesame dot jacquard effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

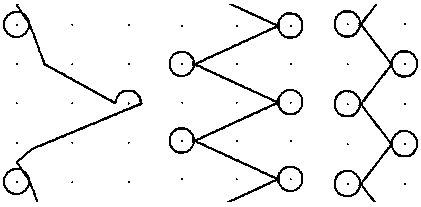

[0028] see figure 1 , a kind of warp-knitted sesame dot jacquard warm-keeping fabric related to the present invention is composed of the following mass percentage components: 10.5% for 32s siro compact spinning Toray AR colored yarn, 62.9% for 32s compact spun cotton colored yarn, 75D / The 40D polyester-coated ammonia filament is 26.6%; the reverse side of the fabric technology reveals Toray AR yarn, which has good thermal performance after napping. As the reverse side of the fabric, the front side of the technology is a sesame-dot jacquard effect, and the front comb is used to wear the Toray AR yarn on the full surface. The base fabric formed by the middle-carded cotton dyed yarn and the full-wear bottom carded polyester-coated ammonia filament is formed into a loop according to the need, and the front side of the process is the front side of the dress.

[0029] The manufacturing process of the warp-knitted sesame point jacquard thermal fabric comprises the following steps: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com