A floating wind turbine tower scale model for simulating tower shadow effect and yaw error

A technology of yaw error and scaled model, which is applied in the directions of wind turbines, engines, mechanical equipment, etc., can solve the problems of inability to consider tower shadow effect and yaw error, and limit the characterization ability of floating wind turbines. The effect of weight controllable and critical dimension error controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

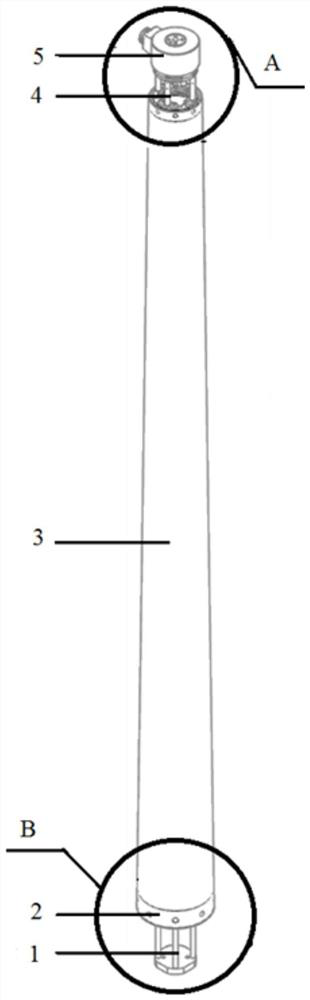

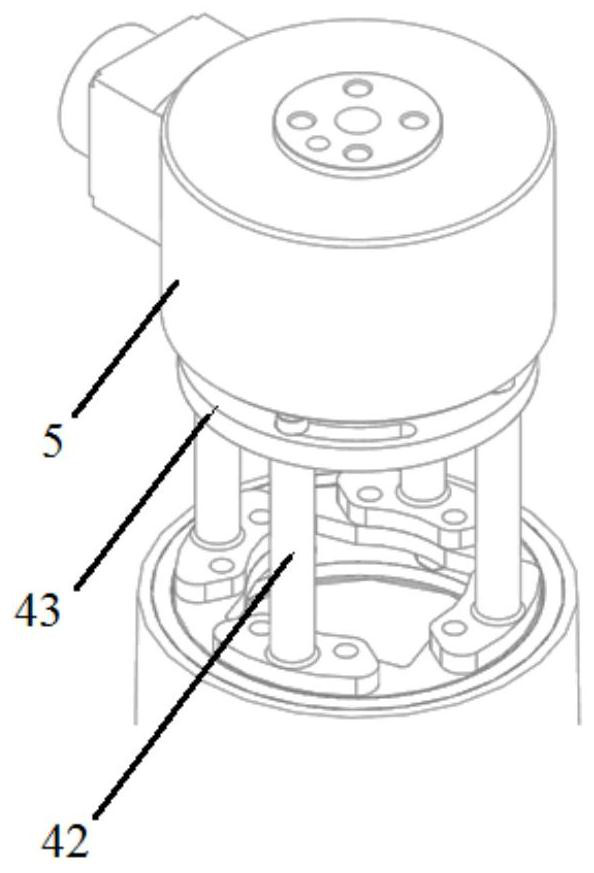

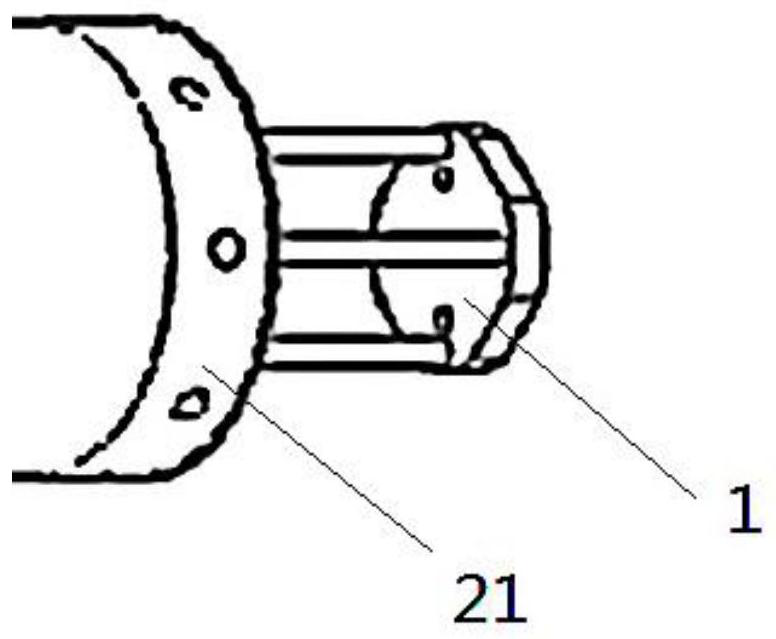

[0034] This embodiment provides a floating fan tower scale model for simulating the tower shadow effect and yaw error, such as figure 1 As shown, it includes the sextant force gauge 1 at the bottom of the tower, the connecting component 2 at the bottom of the tower, the conical tower tube component 3, the yaw adjustment component 4 and the sextant force gauge 5 at the top of the tower; the lower end surface of the sextant force gauge 1 at the bottom of the tower is fixed Installed on the floating platform, the upper end surface of the sextant force gauge 1 at the bottom of the tower is fixedly connected with the lower part of the connecting component 2 at the bottom of the tower, and the upper part of the connecting component 2 at the bottom of the tower is fixedly connected with the lower end of the conical tower tube component 3. The upper end of the tower assembly 3 is fixedly connected to the lower part of the yaw adjustment assembly 4, and the upper part of the yaw adjustm...

Embodiment 2

[0048] On the basis of Embodiment 1, the material of the tower body 31 is high-strength structural steel, and the yield strength of the high-strength structural steel is greater than 400 MPa. In this embodiment, it is preferably Q460B. The lower end of the tower body 31 is embedded with a connecting ring at the bottom of the tower. The upper part of 32 is fixedly connected by bolts or welding, and the upper end of tower body 31 is fixedly connected with the lower part of tower top embedded connecting ring 33 by bolts or welding.

[0049] For bolts with more than 4 connecting bolts in the same group, the bolts shall be pre-tightened in the order of P-shaped. The bolt pre-tightening tool is a hydraulic tensioner, and the bolt pre-tightening force is 50% to 60% of the effective load of the bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com