A multifunctional fermented feed production process equipment

A technology of fermented feed and production technology, which is applied in the direction of feed, food science, application, etc., can solve the unfavorable promotion of fermented feed industrialization and the enrichment of new products of fermented feed with low cost and high efficiency, the income of fermentation processing and the limitation of timely supply of raw materials, manual operation at will To avoid problems such as strong sex, achieve rapid growth and reproduction metabolism, reduce artificial labor, and ensure the quality of fermented products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

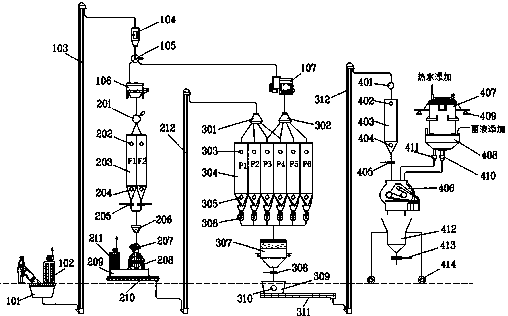

[0026] Such as figure 1 As shown, a multifunctional fermented feed production process equipment includes a granular raw material cleaning section, a granular raw material crushing section, a powdery raw material cleaning section, a batching section, and a liquid adding and mixing section, wherein the outlet of the granular raw material cleaning section is connected to the granular The feed port of the raw material crushing section, the discharge port of the particle raw material crushing section is connected to the feed port of 1# distributor 301 in the batching section, and the discharge port of the powder raw material cleaning section is connected to the feed port of 2# distributor 302 in the batching section , the discharge port of the batching section is connected to the feed port of the stainless steel horizontal twin-shaft paddle mixer 406 in the bacterial liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com