Cake taking component and algae or vegetable cake making device employing same

A component, all-in-one technology, applied in application, food preparation, food science, etc., can solve problems such as poor sanitation, low work efficiency, uneven vegetable cakes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

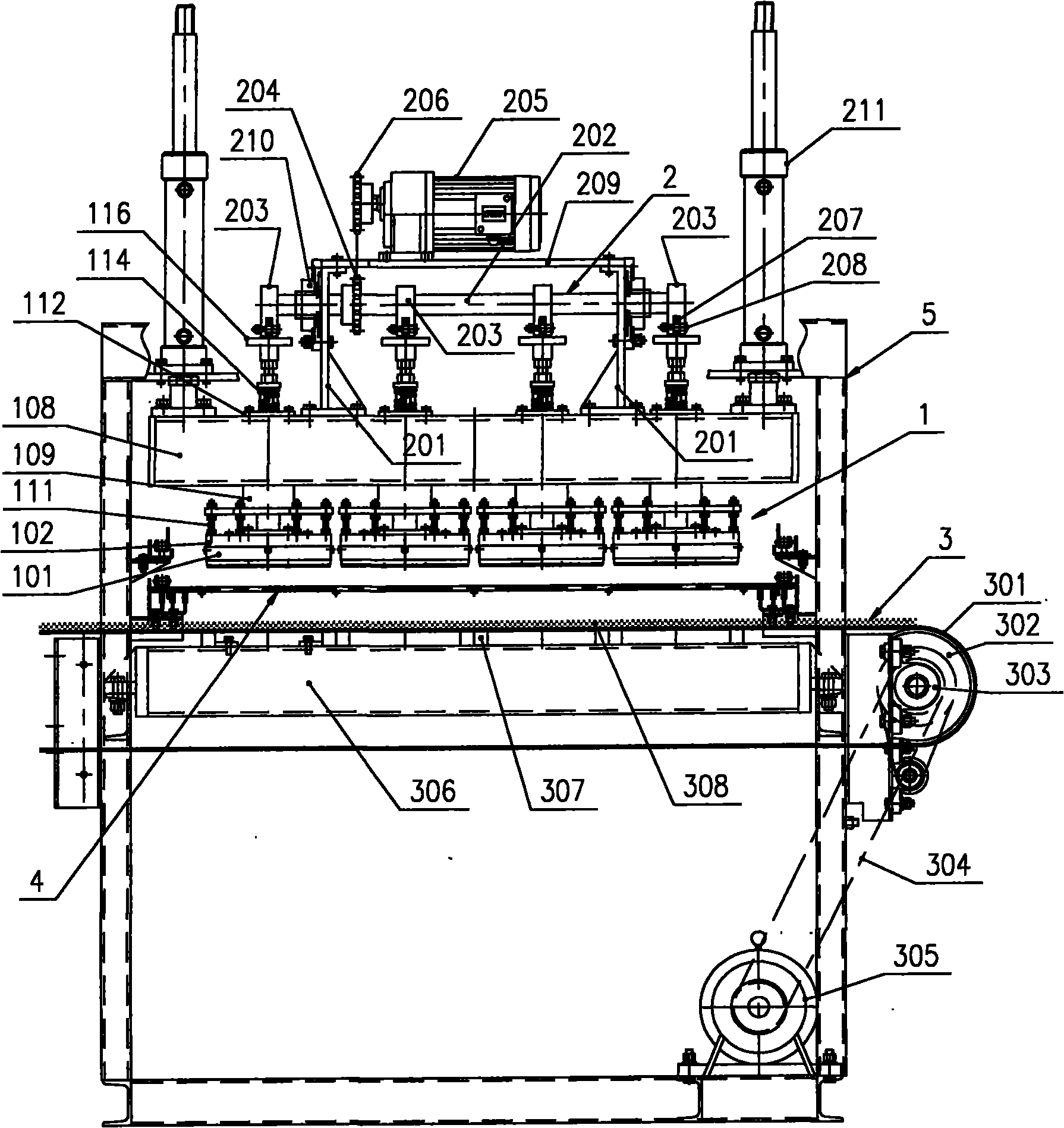

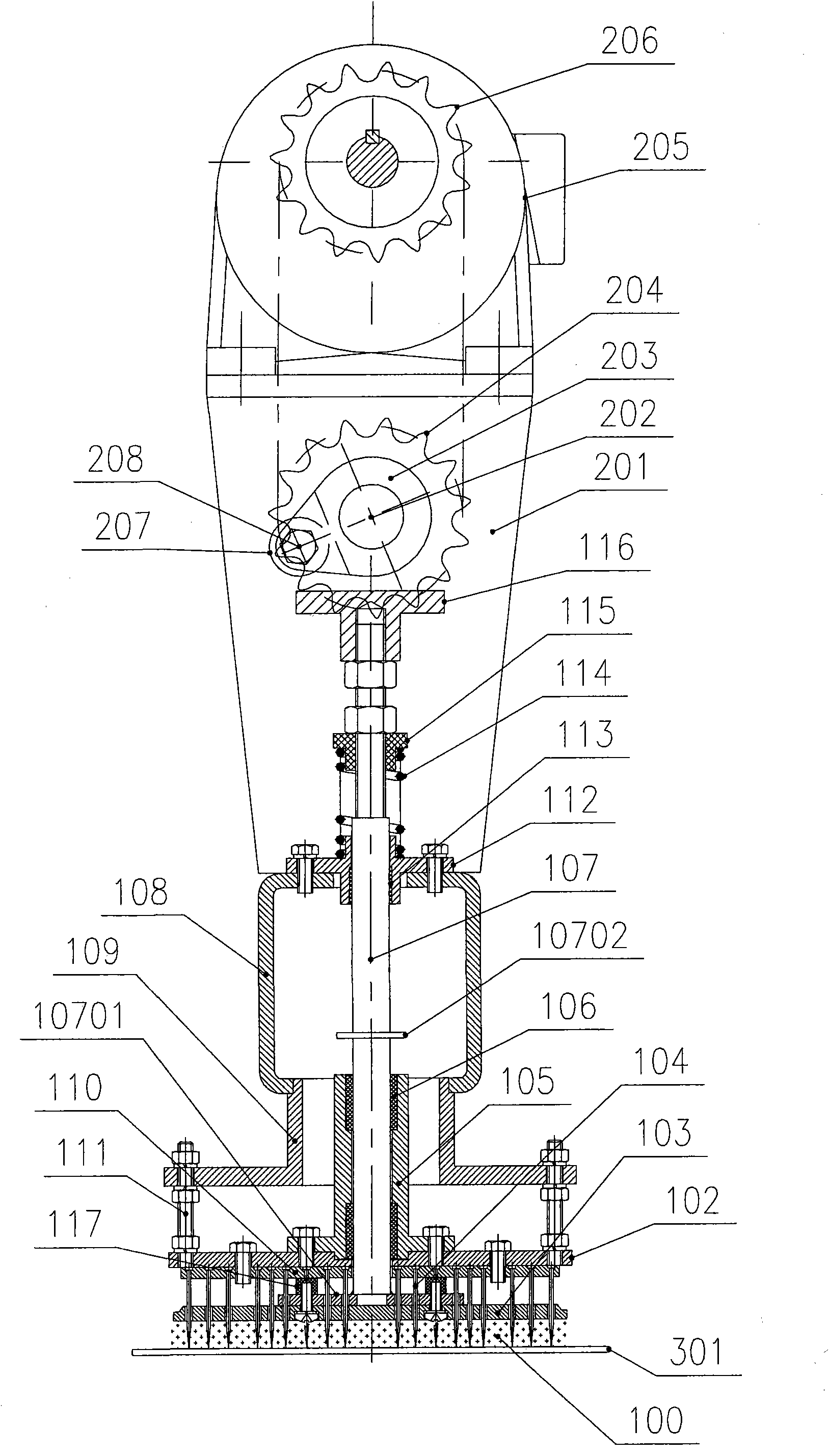

[0042] Such as figure 2 and 3 As shown in the figure, the first embodiment of the piercing needle type cake taking assembly according to the present invention is shown. 104 can be mechanically installed on the needle mounting plate 110, for example, the needle 104 can be directly welded to the needle mounting plate 110, or a structure similar to a nail cap can be made at the needle tail 10420, and the needle 104 can be inserted into the needle mounting plate 110. In the mounting hole of the mounting plate 110, in addition, the needles 104 can also be installed on the needle mounting plate 110 through tight fit. After the needles are installed in place, the direction of the needle point 10401 is downward; The connection plates 102 are connected together, and the center of the lancet mounting plate 110 is provided with a through hole, the stripping rod 107 passes through the through hole and is connected with the stripping plate 103 through the stripping rod end flange 10701, ...

no. 2 example

[0045] Such as Figure 4 As shown in the figure, the piercing needle type cake taking assembly 1 according to the second embodiment of the present invention is shown. Ring cutter 101 and cutter seat 102' outside the needle. The addition of a ring cutter can realize the functions of cutting, cake making and cake taking at the same time, which is conducive to simplifying the overall structure of the cake making device and improving production efficiency.

[0046] Specifically, the ring cutter 101 is a closed-loop cutting tool with a cutting edge at one end. The so-called closed-loop cutting tool refers to a cutting tool whose cross-sectional shape is a closed curve, such as a circle, a square, a rectangle or other curves. The ring cutter 101 can be fixedly installed on the cutter seat 102' with bolts, and the cutting edge is downward; the needle mounting plate 110 is installed in the cutter seat 102'; the cutter seat 102' is connected with the lower connecting plate 102 or conn...

no. 3 example

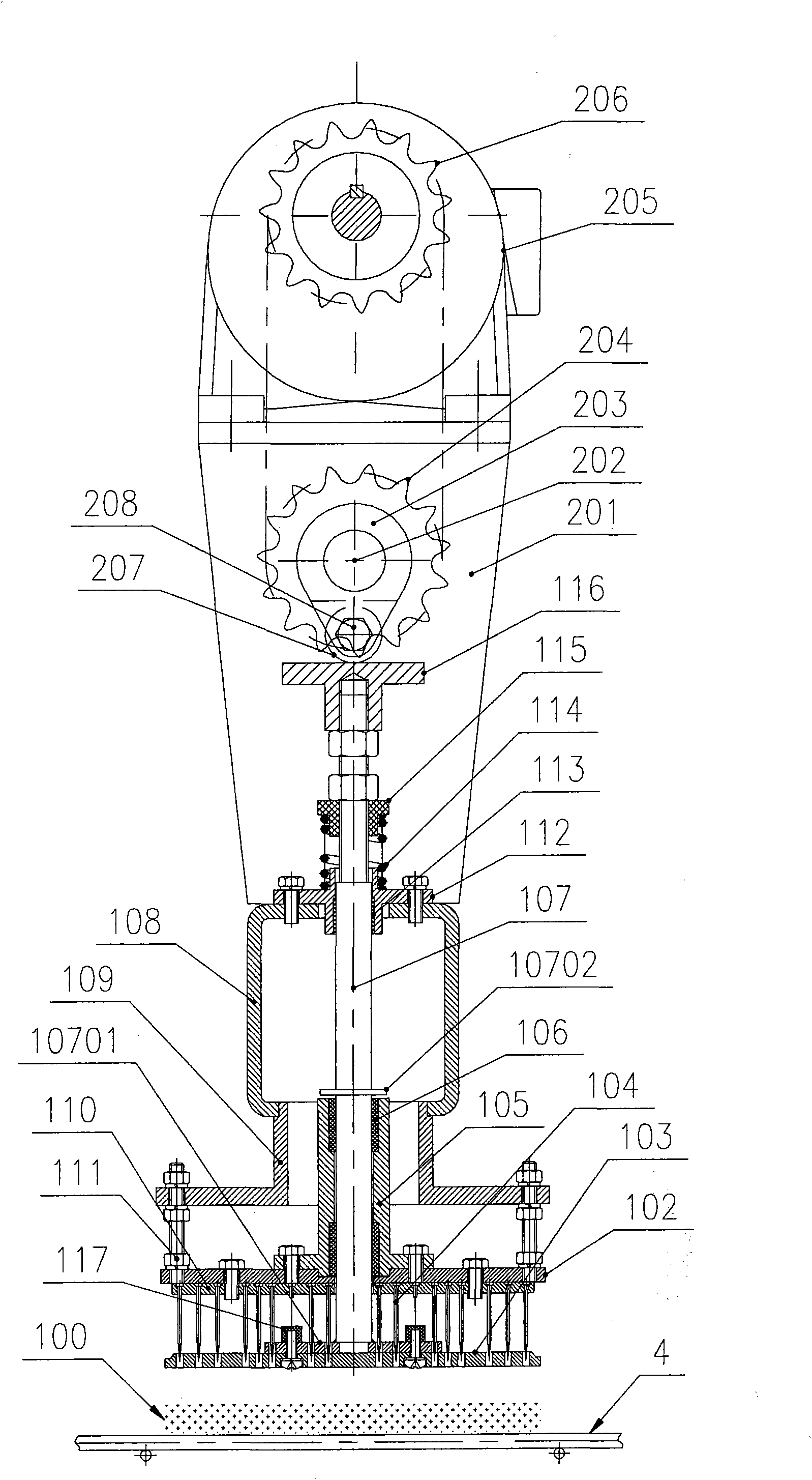

[0050] Such as Figure 7 and 8 As shown, the figure shows the third embodiment of the piercing needle type cake taking assembly according to the present invention, the difference between this embodiment and the second embodiment is only that the limit buffer in the second embodiment is omitted parts; the stripping tray 103 is changed from a movable installation up and down to a fixed installation, that is, the stripping tray 103 is connected with the cutter seat 102'; and the lancet mounting tray 110 is changed from the original fixed installation to the stripping rod end method. Lan 10701 is connected, so that the needle mounting plate 110 can move up and down together with the ejector rod, but the working principle of the two is the same, and they are both through relative movement between the ejection plate and the needle mounting plate to change the ejection rod. The relative distance between the material tray and the needle mounting plate enables the vegetable cake to fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com