Patents

Literature

74results about How to "Structural design is optimized and reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

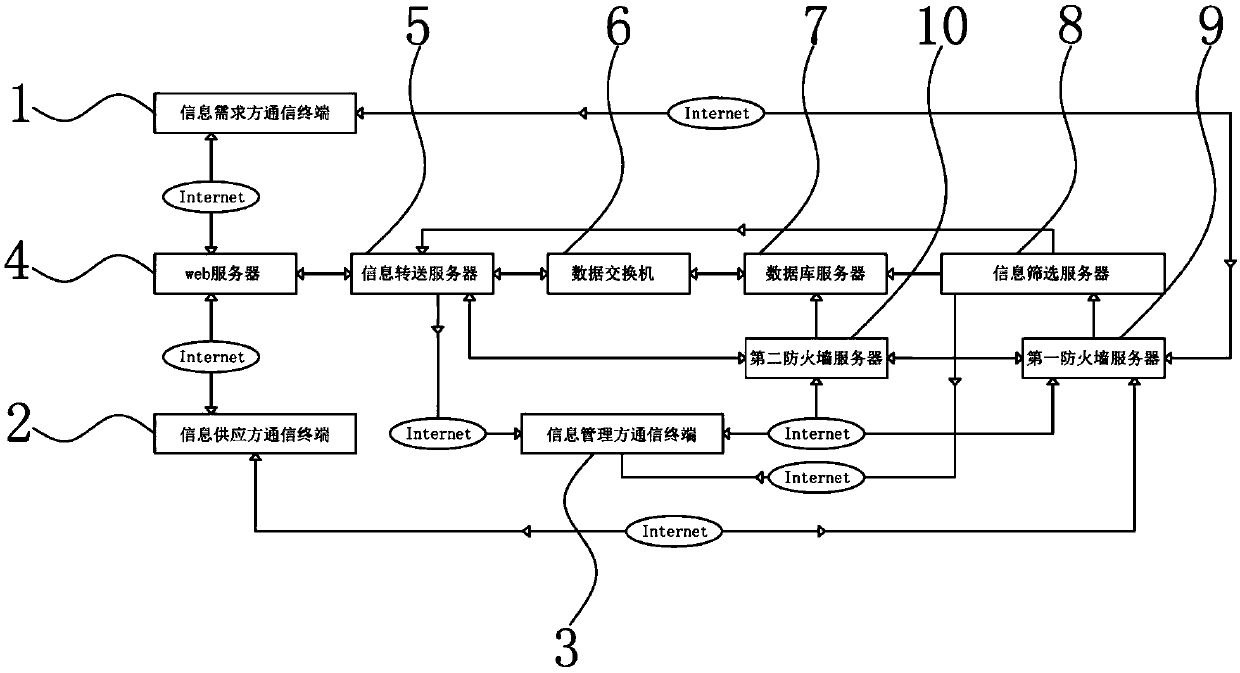

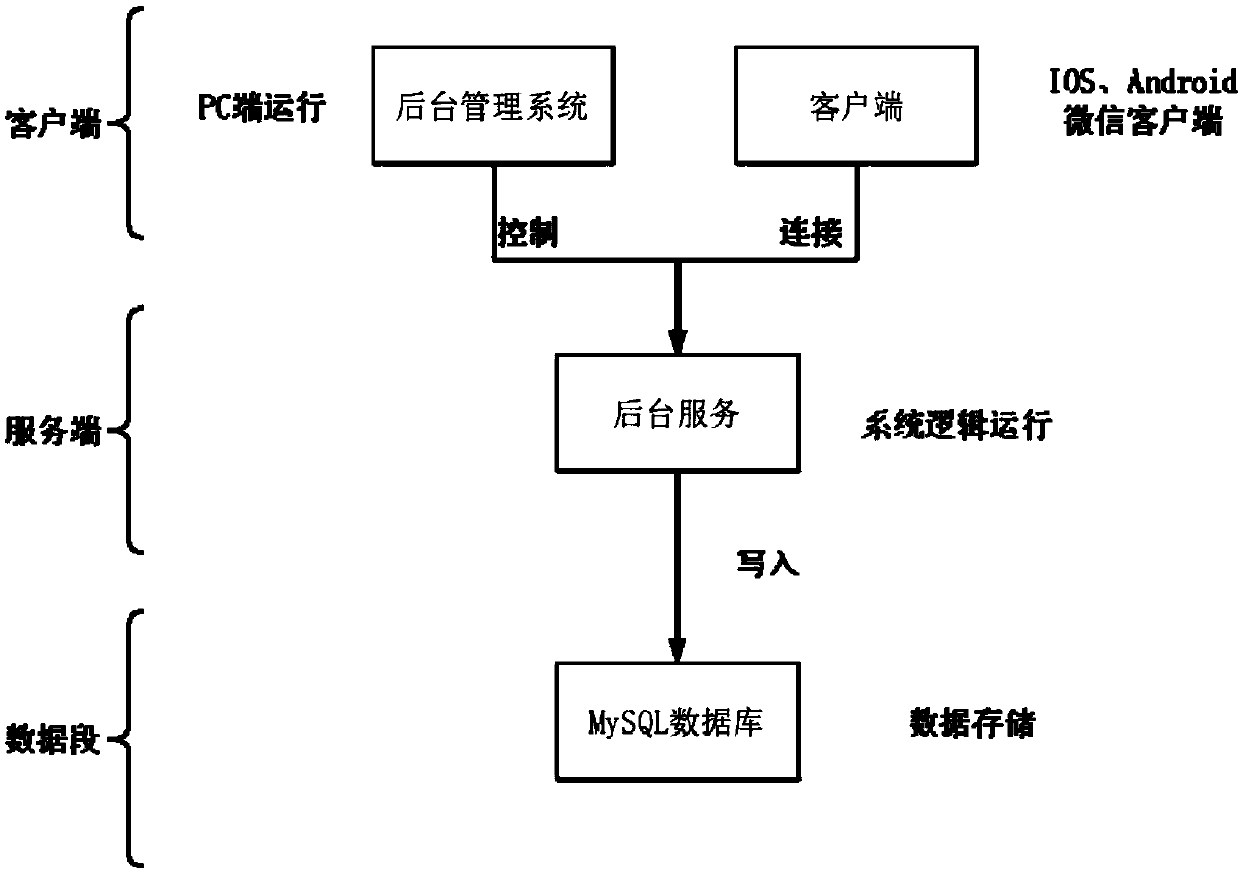

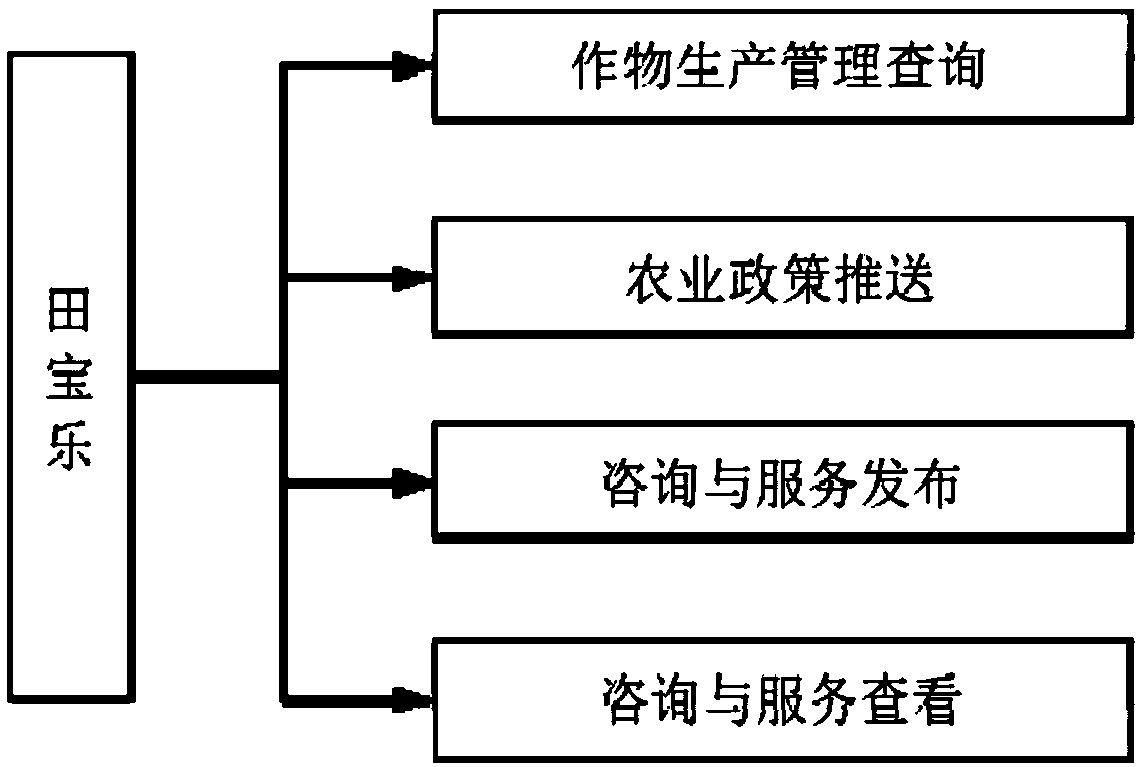

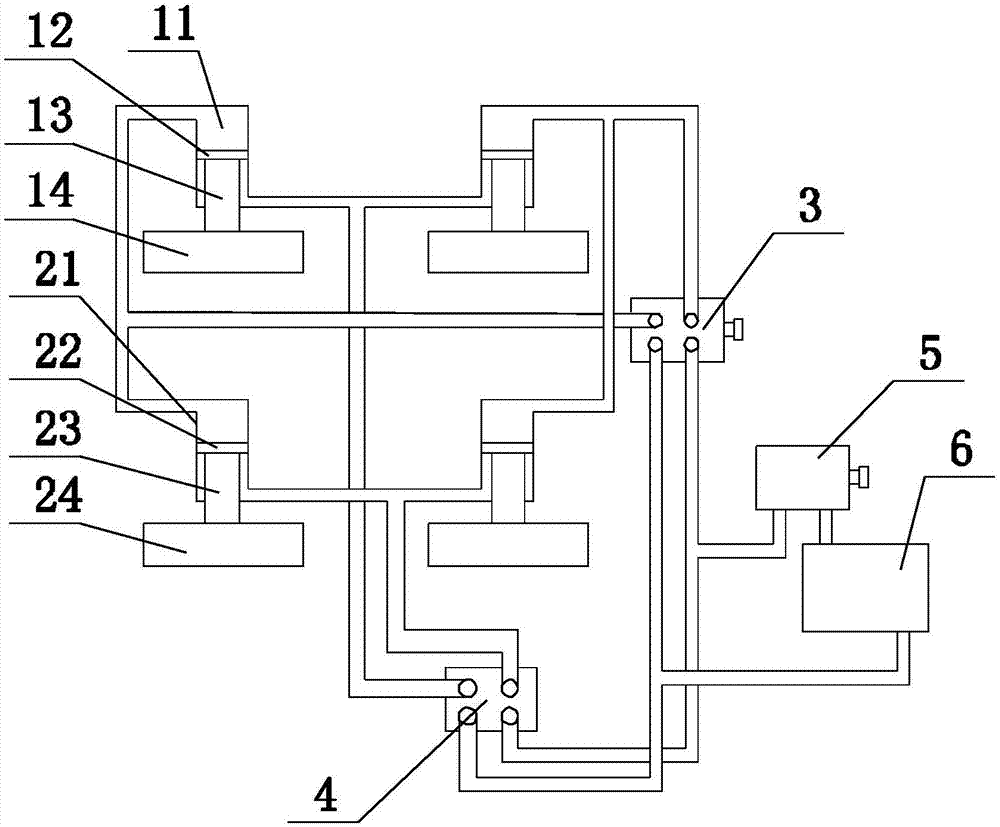

An information push service system based on web management and mobile phone applet application

PendingCN109684530ACompact layoutPerfect structural designData processing applicationsDatabase management systemsTransceiverWeb service

The invention discloses an information push service system based on web management and mobile phone applet application. Information technology field, Web server, Information transfer server, Data switch, Database server, the information screening server is sequentially connected in series with the optical fiber cable through the optical fiber transceiver; wherein the first firewall server and thesecond firewall server are connected with the optical fiber cable in series through the optical fiber transceiver, the first firewall server is connected with the information screening server, the information screening server is connected with the information transfer server, and the second firewall server is connected with the database server and the information transfer server. The mobile phonemini-program information pushing system specially serves a mobile phone mini-program information pushing function in a targeted mode, layout is more compact, and the structural design is more perfect,reasonable and optimized.

Owner:SHIHEZI UNIVERSITY

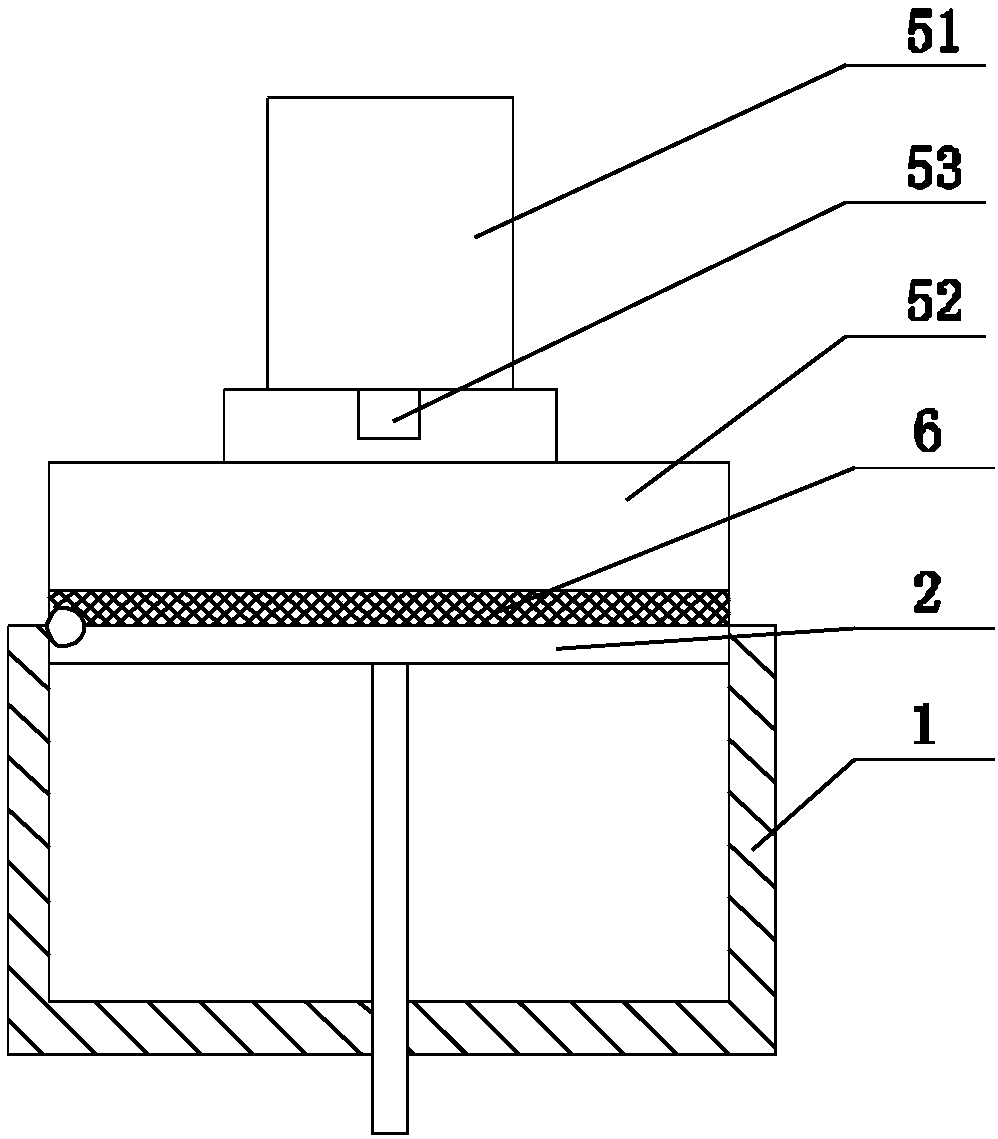

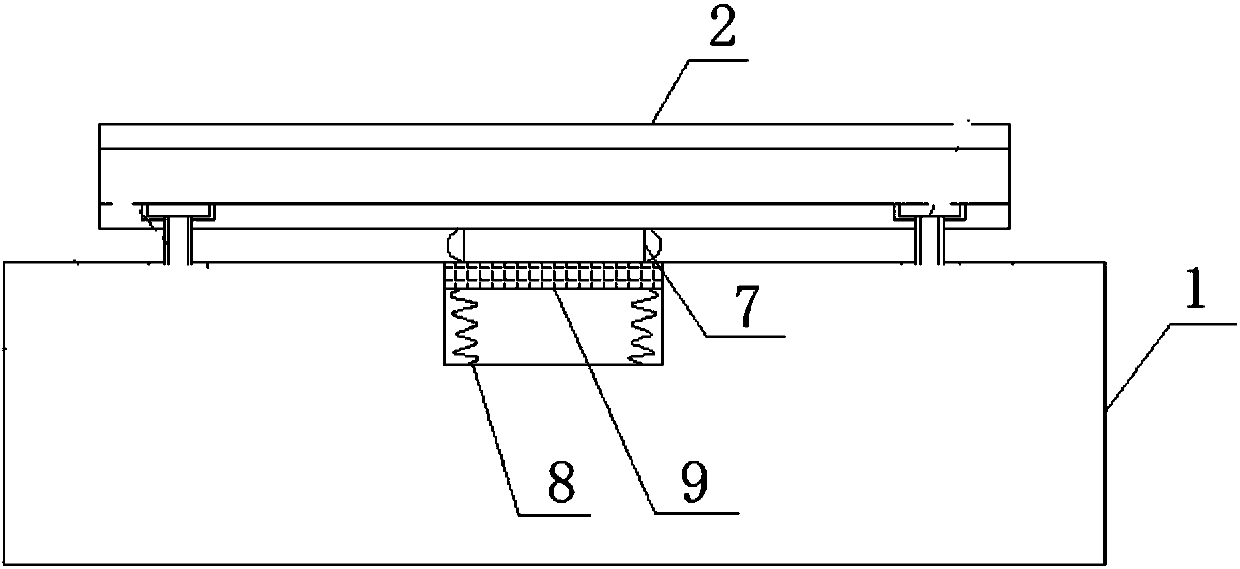

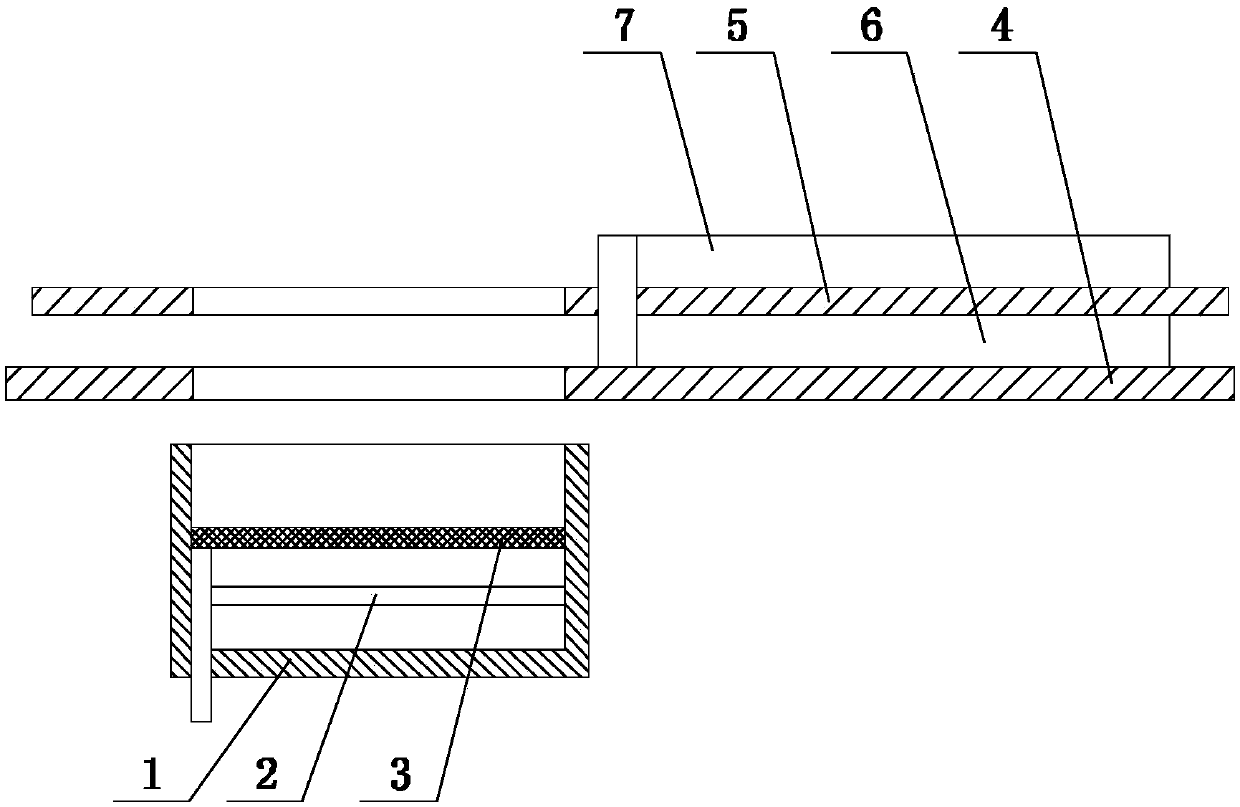

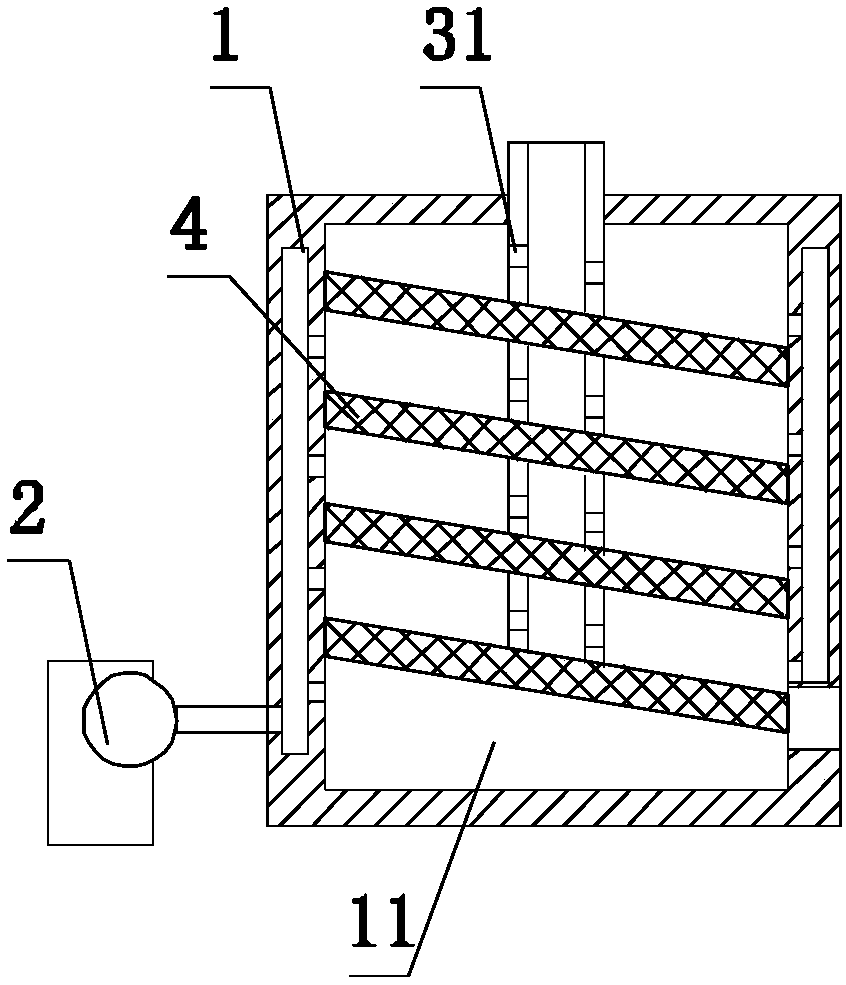

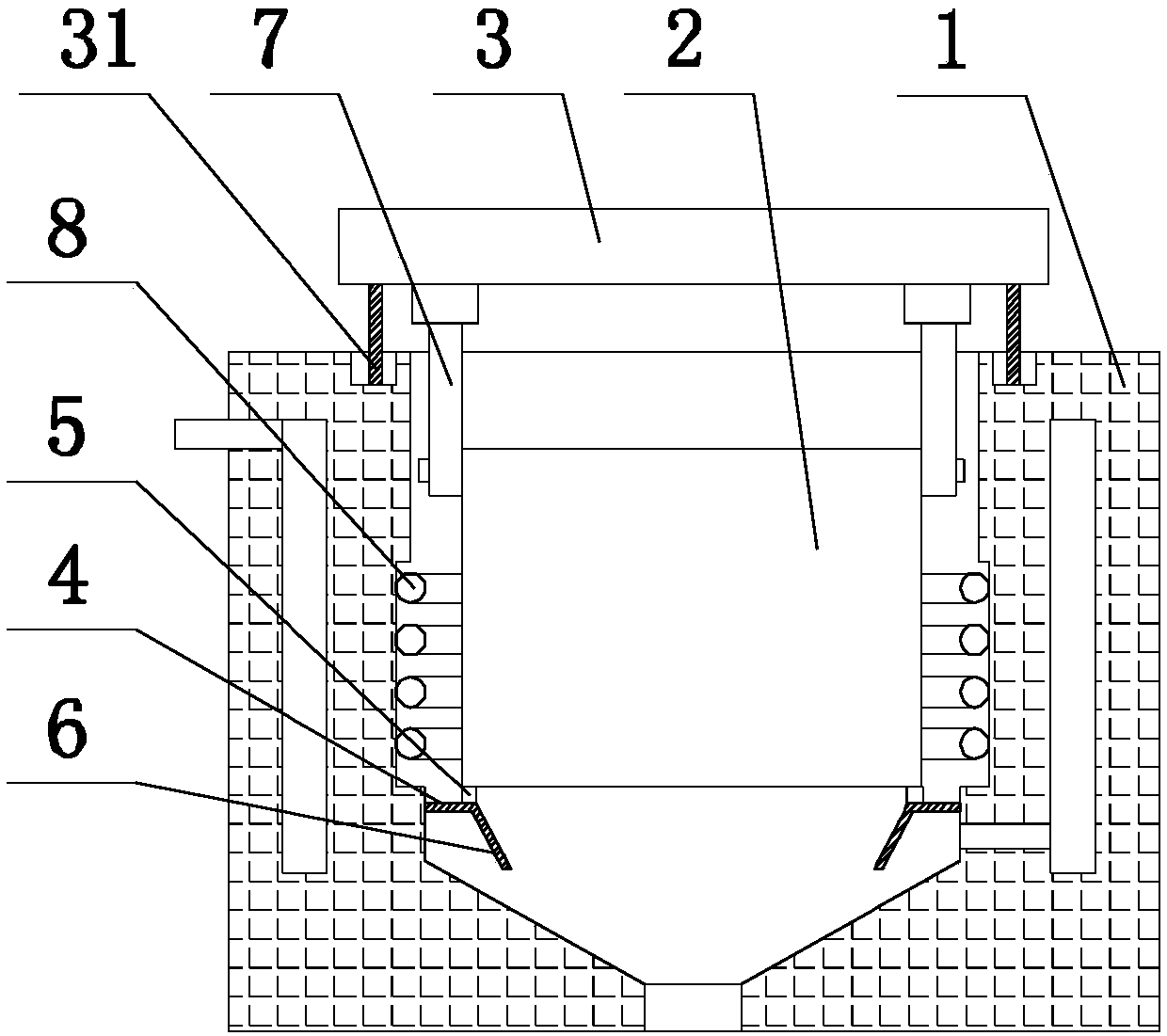

Starch processing, filtering and precipitating integrated equipment

PendingCN107617263AStructural design is optimized and reasonableSettling tanks feed/dischargeFiltration circuitsEngineeringMaterial storage

The invention discloses starch processing, filtering and precipitating integrated equipment. A precipitating plate is horizontally arranged in a precipitating tank, a first drive mechanism drives theprecipitating plate to lift, a scraper moves along a slide rail through a slide block, a guide plate is located on one side of the precipitating tank in the extending direction of the slide rail, theguide plate is arranged slantly, the higher end of the guide plate is connected with the top part of the precipitating tank, a material storage tank is located below the lower end of the guide plate,a precipitate on the surface of the precipitating plate is scraped in the moving process of the scraper, and the precipitate is conveyed to the material storage tank through the guide plate. Accordingto the optimally designed starch processing, filtering and precipitating integrated equipment, the structure design is reasonably optimized, the precipitating plate is driven to lift through the first drive mechanism, then the precipitated precipitating plate is periodically lifted from the precipitating tank to the plane at the upper end of the guide plate, then the scraper is driven by a seconddrive mechanism to slide along the rail, the material on the precipitating plate is scraped to the guide plate, and the operations of periodically unloading the precipitating plate thoroughly and collecting the precipitate are finished.

Owner:YINGSHANG TIANHAO FOOD

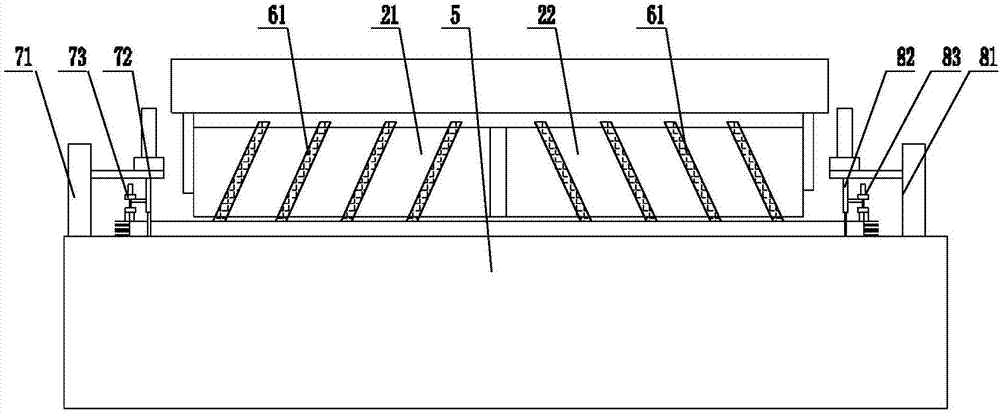

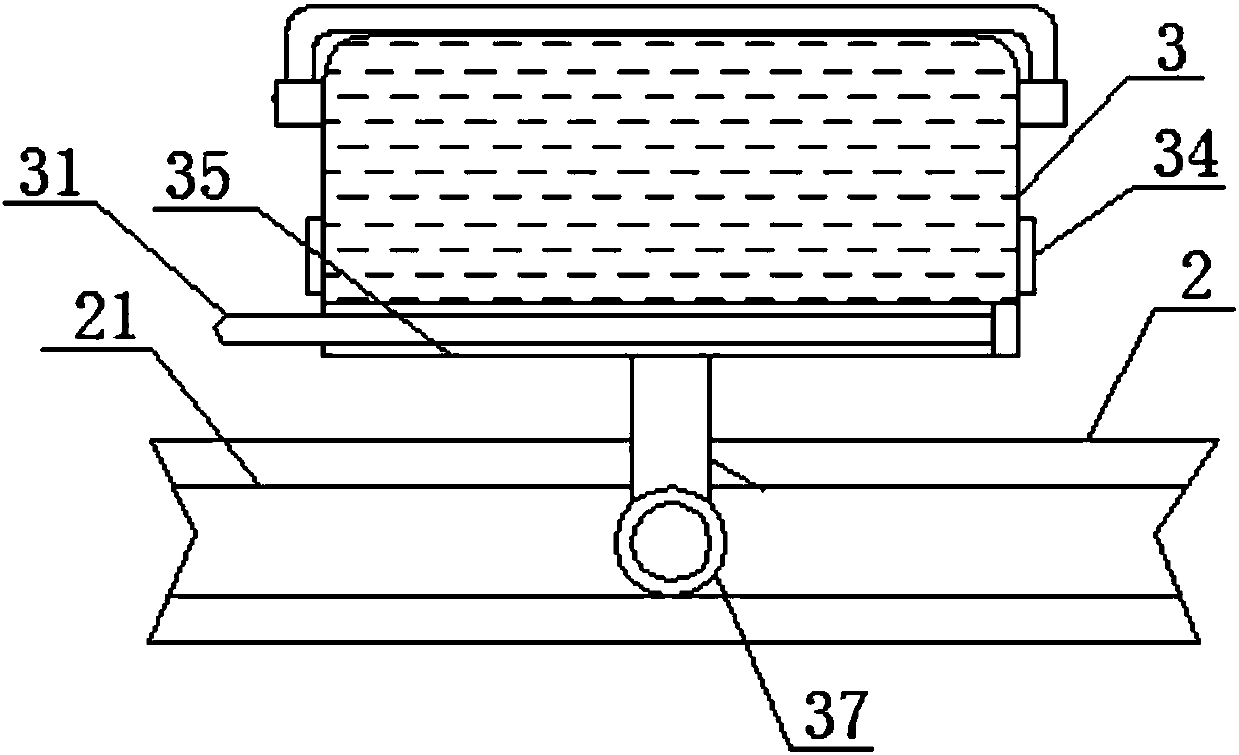

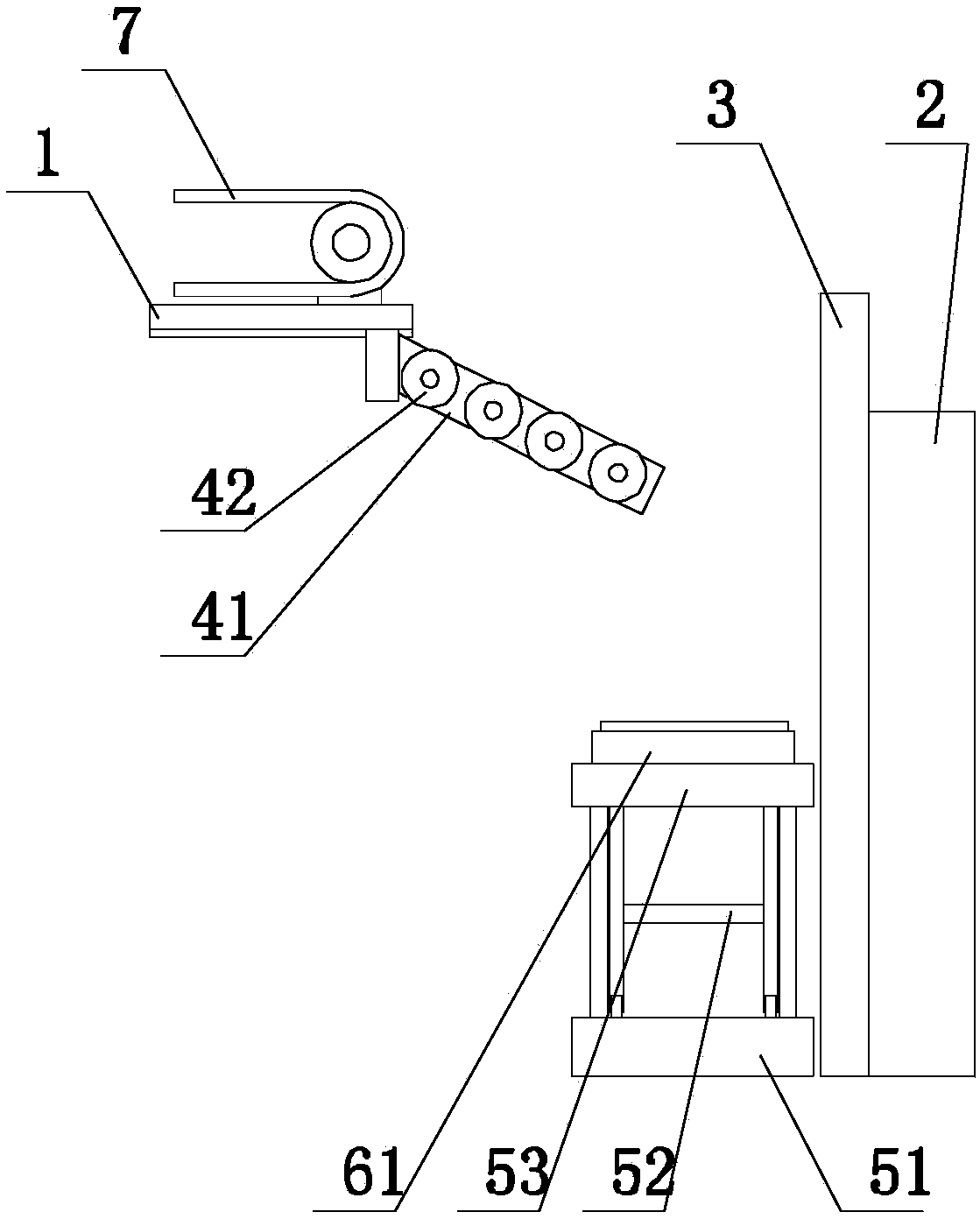

Surface pleat-removing equipment for coiled gray cloth

InactiveCN107326602AStructural design is optimized and reasonableAchieve ironing wrinkle removal effectMechanical cleaningPressure cleaningEngineeringSupport surface

The invention discloses surface pleat-removing equipment for coiled gray cloth. The equipment comprises a steaming device and a pleat-removing roller which are arranged in sequence on a supporting table in a direction of material feeding, the bottom part of the steaming device is provided with a steam outlet, a heating device is used for heating a second supporting surface below the pleat-removing roller, the pleat-removing roller comprises a first roller section and a second roller section, the outer wall of the first roller section is provided with a first spiral bulge arranged around the pleat-removing roller axially, the outer wall of the second roller section is provided with a second spiral bulge arranged around the pleat-removing roller axially, the first spiral bulge and the second spiral bulge are opposite in the direction of spiral. By means of the surface pleat-removing equipment for the coiled gray cloth with optimized design, the structure design optimization is reasonable, during the feeding process, steaming on the gray cloth is performed by the steaming device, then driving force is applied to two sides of the gray cloth through the spiral bulges on the pleat-removing roller, meanwhile, heating is carried out on the gray cloth from the bottom part, so as to realize the effects of ironing and pleat-removing.

Owner:ANHUI LIANGLIANG TEXTILE CO LTD

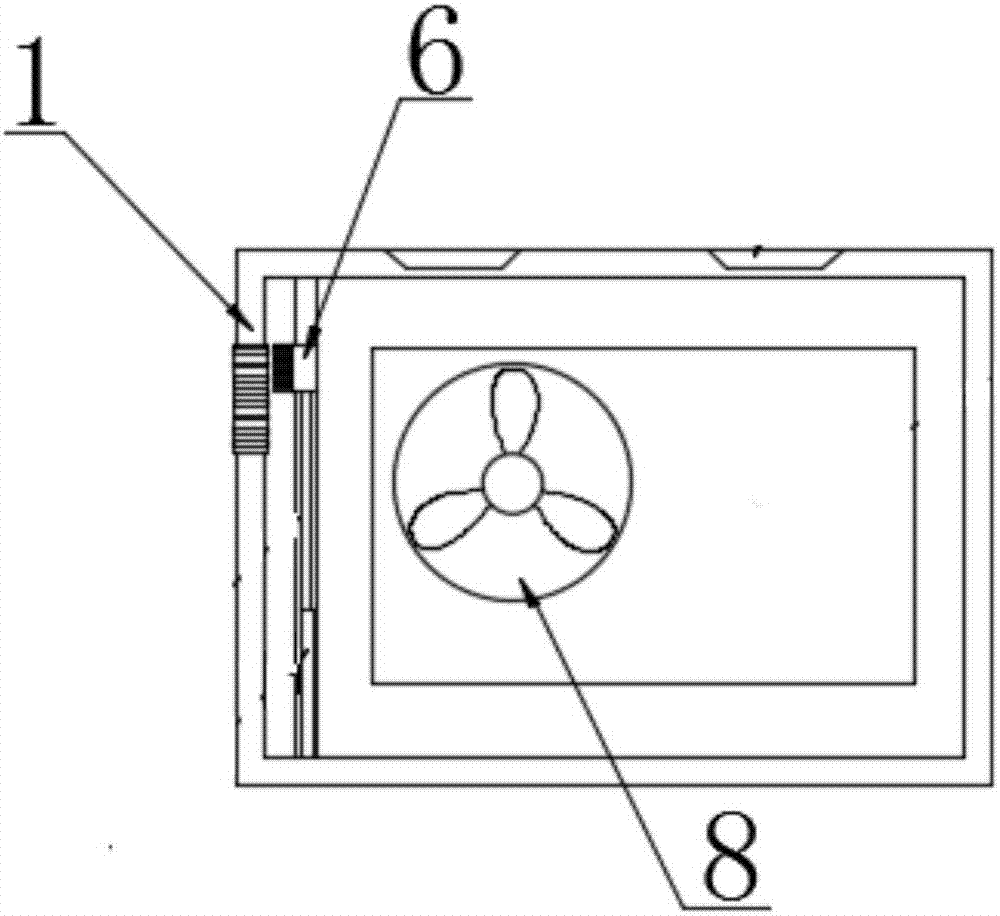

Computer main unit case with high cooling efficiency

ActiveCN107728747AImprove cooling effectStructural design is optimized and reasonableDigital processing power distributionCooling effectEngineering

The invention discloses a computer main unit case with high cooling efficiency; a drive motor is disposed on the inner wall of a case body, a spindle of the drive motor is perpendicular to the inner wall and is provided with a guide bar extended in radial direction, the inner wall of the case body is provided with a circular slide rail that is arranged around the drive motor, a cooling box is slidably mounted on the circular slide rail and is provided with a guide sleeve, the guide bar and the guide sleeve are coaxial, one end of the guide bar far away from the spindle of the drive motor is extended into the guide sleeve, and the drive motor drives the guide bar to rotate so as to drive the cooling box to move along the circular slide rail. The computer main unit case with high cooling efficiency which is optimized is optimal and reasonable in structural design; the circular slide rail allows the cooling box to circularly move in a rail device; the problem that a common cooling box provides non-uniform cooling for a main unit case and affected cooling effect is solved; cooling of a computer main unit is benefited; the service life of the computer main unit case is extended.

Owner:合肥迈斯软件科技有限公司

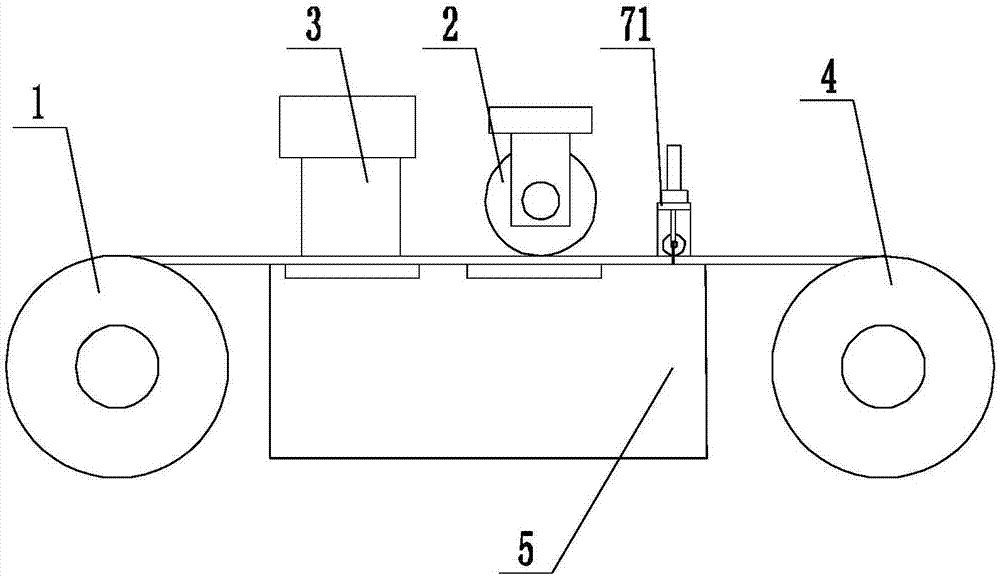

Double-layer tubular rice drying device with uniform material distribution

PendingCN107906927AImprove drying effectGuaranteed temperatureDrying gas arrangementsDrying chambers/containersEngineeringMaterial distribution

The invention discloses a double-layer tubular rice drying device with uniform material distribution. An inner barrel and an outer barrel define a double-layer structure, and a cover plate is arrangedat the top opening position of the outer barrel, and provided with an installation opening and a plurality of air outlets; a distributor is arranged at the installation opening, and used for feedingbetween the inner and outer barrels, and the inner barrel is internally provided with a blast cavity; and an upper barrel body of the inner barrel is provided with a conical guide surface of which theouter diameter is increased gradually from top to bottom, and the side wall of a lower barrel body of the inner barrel is provided with a plurality of blast holes. Through the optimized double-layertubular rice drying device with uniform material distribution, the structure design is optimal and rational, and material distribution is performed in the outer barrel through a distributor; dry air is fed through the blast cavity in the inner barrel, and moves upward after being used for drying grains, and the dry air with moisture and dust is discharged from the air outlets on the top; the drying effect between the inner and outer barrels is improved, so that hot air is thoroughly circulated in a drying barrel, and the temperature of the drying barrel is ensured at the middle part through adistribution barrel; and the utilization rate of heat is improved.

Owner:安徽正丰农业科技有限公司

Self-adjusting cloth wrinkle-removing and leveling device

InactiveCN106835580AGuaranteed anti-wrinkle effectStructural design is optimized and reasonableTextile treatment by spraying/projectingStretchingWrinkle skinElastic component

The invention discloses a self-adjusting cloth wrinkle-removing and leveling device. A spreading roll is arranged on a support shaft in a sleeved mode; elastic components are respectively arranged at the two ends of the spreading roll; the lateral position of the cloth can be self-adjusted in a spreading process; the spread cloth enters a wrinkle-removing space formed between a liquid storage tank and a support platform and then the wrinkles are removed; and in a wrinkle-removing process, the wrinkle-removing liquid is intermittently sprayed onto the cloth from the liquid storage tank through a liquid discharging mechanism, so that the cloth can be guaranteed to be smooth and level. Through the optimally designed self-adjusting cloth wrinkle-removing and leveling device, the structure design is optimized and reasonable; the spreading roll is used for spreading the cloth, so that wrinkle removal in advance can be realized; the spreading roll can self-adaptively adjust the feeding direction of the cloth; and the cloth enters the wrinkle-removing space and the wrinkle-removing liquid is sprayed for removing wrinkles andsetting, so that the wrinkle-removing effect of the cloth can be guaranteed.

Owner:安徽海天电器有限公司

Electrochromic intelligent display curtain wall and display system

InactiveCN106527010AStructural design is optimized and reasonableReduce energy consumptionNon-linear opticsWeak currentTransmittance

The invention discloses an electrochromic intelligent display curtain wall. The electrochromic intelligent display curtain wall is characterized in that a reflecting layer is arranged on the electrochromic intelligent display curtain wall, external light penetrating an electrochromic layer is reflected outwardly by the reflecting layer, curtain wall light emitting is achieved, and pattern change and information display on the curtain wall are achieved by regulating the light transmittance of the curtain wall. The design-optimized electrochromic intelligent display curtain wall has the advantages that the structural design of the curtain wall is optimized and reasonable, vertical-face pattern and information display of the building curtain wall are achieved by reflecting sunlight or other environment light, the weak-current-controlled electrochromic layer is used to replace a strong-current-supply light source, and energy consumption is lowered greatly. The invention further provides an electrochromic intelligent display system for a mansion. The electrochromic intelligent display system comprises the electrochromic intelligent display curtain wall, and display performance of the outer wall of the mansion can be achieved by unit modularized control.

Owner:合肥威迪变色玻璃有限公司

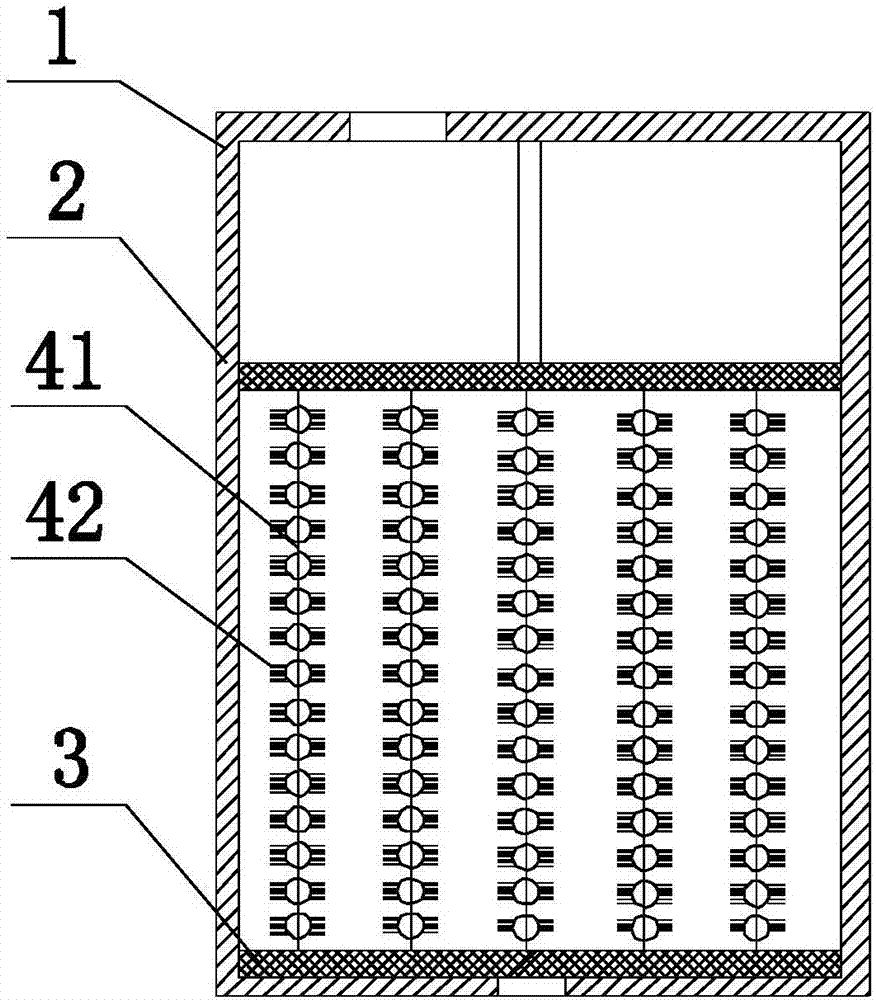

Computer shell built-in system with efficient heat dissipation and dust removal functions

ActiveCN107491149AGood removal effectImprove cooling efficiencyDigital processing power distributionComputer engineering

The invention discloses a computer shell built-in system with efficient heat dissipation and dust removal functions. A plurality of heat dissipation fins are sequentially vertically arranged at an opening of a computer shell, roll balls matched with a chute are arranged at the bottom ends of the heat dissipation fins, and rotating shafts are vertically arranged on the heat dissipation fins and are located on one side of the chute; a fin connecting rod is located on one side of the chute, is located at the opening, is parallel with the chute and is rotatably connected with the heat dissipation fins through the rotating shafts; and a first driving mechanism is connected with the fin connecting rod and is used for driving the fin connecting rod to move along the axial direction so as to drive the heat dissipation fins to rotate. By utilizing the optimized design, the structural design of the computer shell built-in system is optimized and reasonable, and the heat dissipation fins are driven to rotate by the fin connecting rod to change the included angle between the heat dissipation fins and the edge of the opening so as to change the size of a heat dissipation hole, so that the heat dissipation efficiency is relatively high, and dust on the heat dissipation fins is conveniently removed.

Owner:合肥迈斯软件科技有限公司

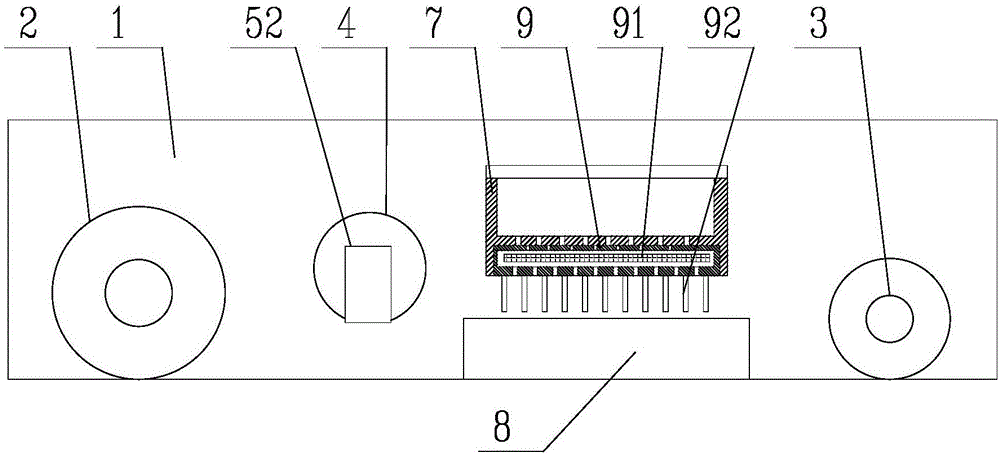

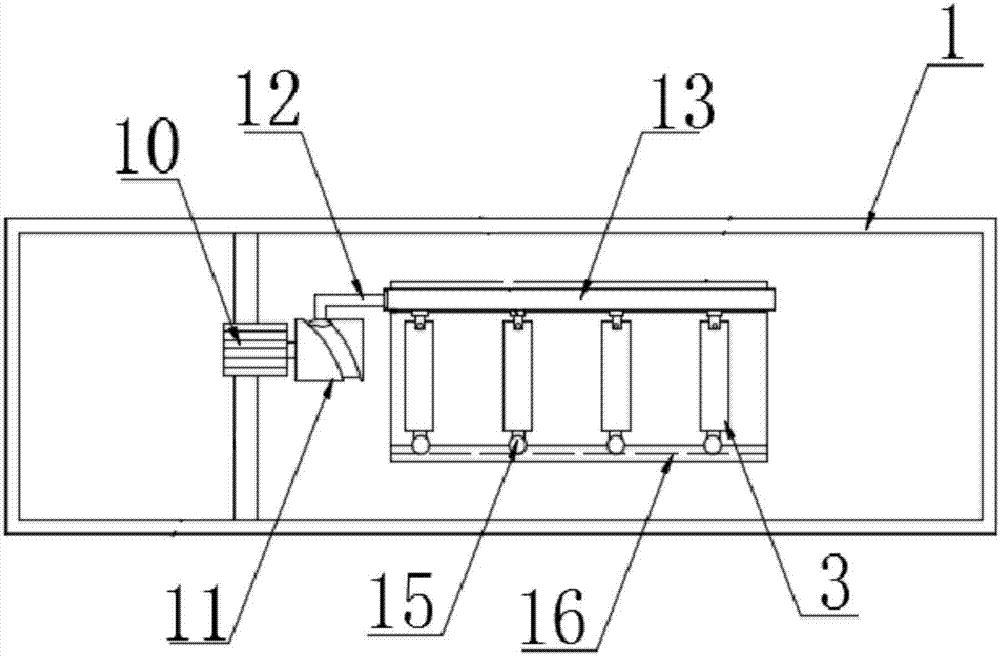

Starch processing equipment with settling, filtering and discharging integration

PendingCN107596778AStructural design is optimized and reasonableImprove product qualitySedimentation separationFiltration circuitsSettlingRaw material

The invention discloses starch processing equipment with settling, filtering and discharging integration. A settling plate and a filter screen are sequentially and horizontally arranged in a settlingtank; the filter screens is arranged above the settling plate at an interval and is fixed with the settling plate; a first driving mechanism drives the settling plate and the filter screen to lift; afirst discharging plate and a second discharging plate are horizontally arranged above the settling tank; a first scraping mechanism is used for scraping materials on the settling plate to the first discharging plate; and a second scraping mechanism is located above the second discharging plate and is used for scraping materials on the filter screen to the second discharging plate. According to the starch processing equipment with the settling, filtering and discharging integration and optimized design, structural design is reasonably optimized; filtering of uncrushed raw materials is realizedin the settling process, and the quality of a product is improved; and besides, after settlement is finished, a settled product and filtered impurities are discharged at the same time, so that the processing efficiency is greatly improved.

Owner:YINGSHANG TIANHAO FOOD

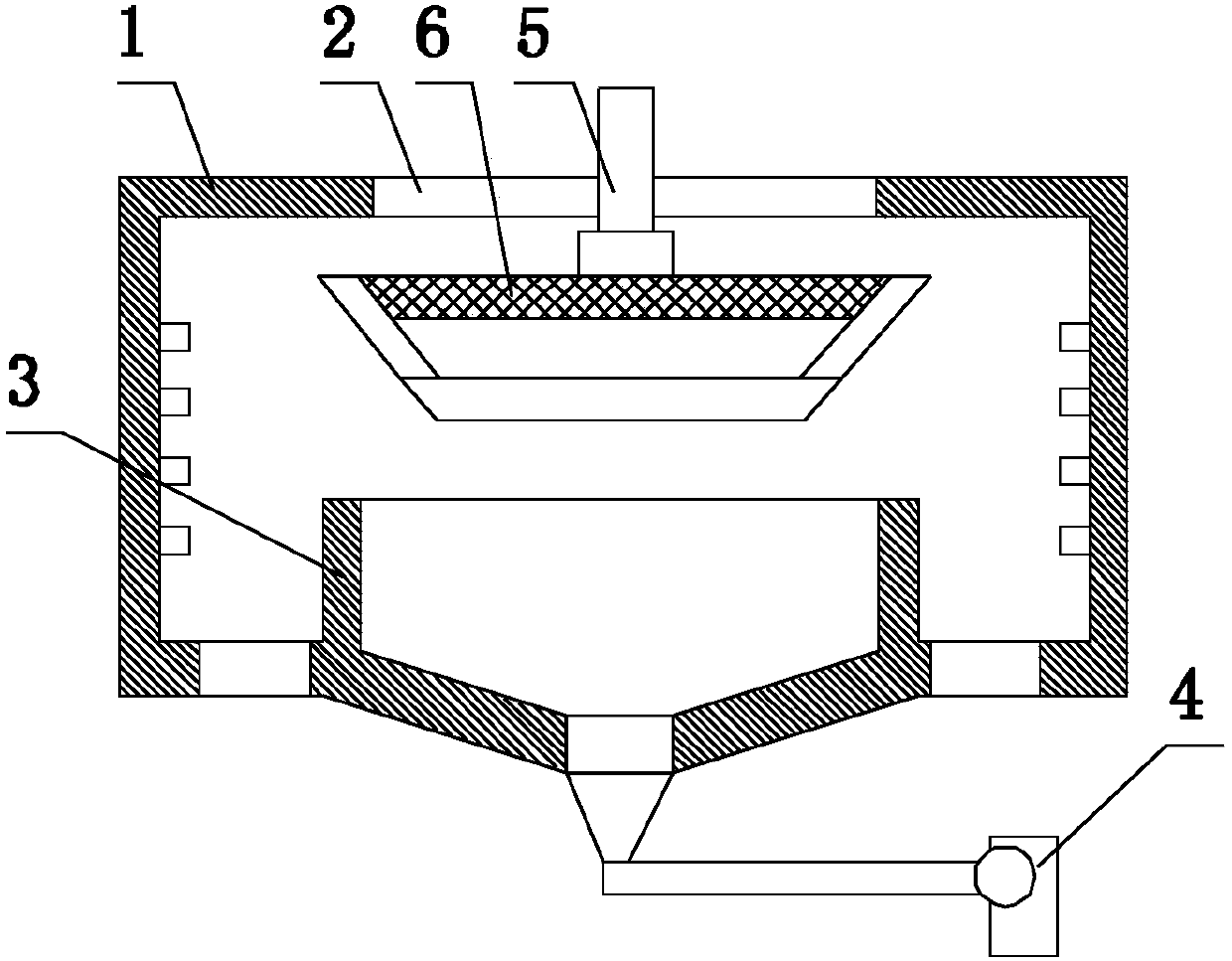

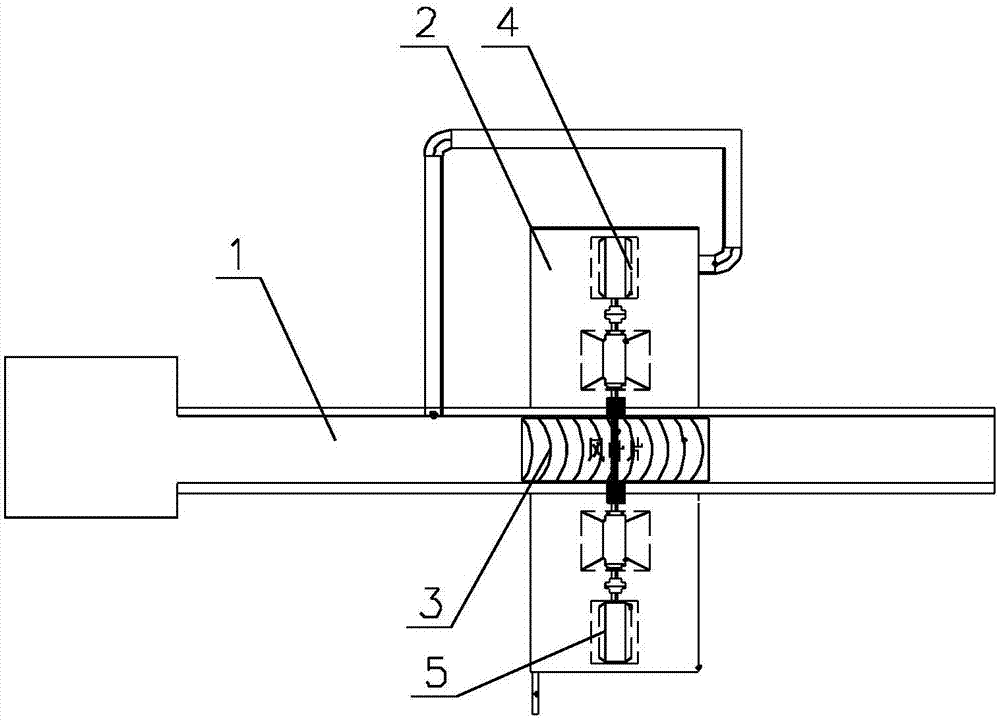

Winnowing and dedusting rice drying equipment

ActiveCN107790383AEasy to separateStructural design is optimized and reasonableGas current separationDrying gas arrangementsHuskEngineering

The invention discloses winnowing and dedusting rice drying equipment. A flange is horizontally arranged at the opening in the top of an outer shell; a plurality of blast holes are formed in the innerwall of an upper shell of the outer shell; a material distributing disc of a material distributing device is horizontally arranged in the upper shell of the outer shell; a feeding pipe is verticallyarranged at a mounting opening of the flange and the lower end of the feeding pipe is fixed to the material distributing disc; a material distributing hole is formed in the side wall of the feeding pipe; an annular partition plate is vertically arranged in a lower shell to divide the lower shell into a sundry cavity and a cereal cavity surrounding the sundry cavity; and an induced air port is formed in the bottom of the sundry cavity. By means of the optimal design of the winnowing and dedusting rice drying equipment, cereals entering the outer shell are distributed through the material distributing disc; under the action of the centrifugal force, cereal particles and straw dust impurities are separated, and meanwhile, air is blown inward through the blast holes in the outer shell, so thatthe cereal particles and the straw dust impurities are further separated, the cereal particles fall to the outer side of the annular partition plate, and the straw dust impurities fall into the annular partition plate, so that impurities are separated thoroughly from the cereals in the drying process.

Owner:合肥智权信息科技有限公司

Rice drying equipment with high thermal utilization rate

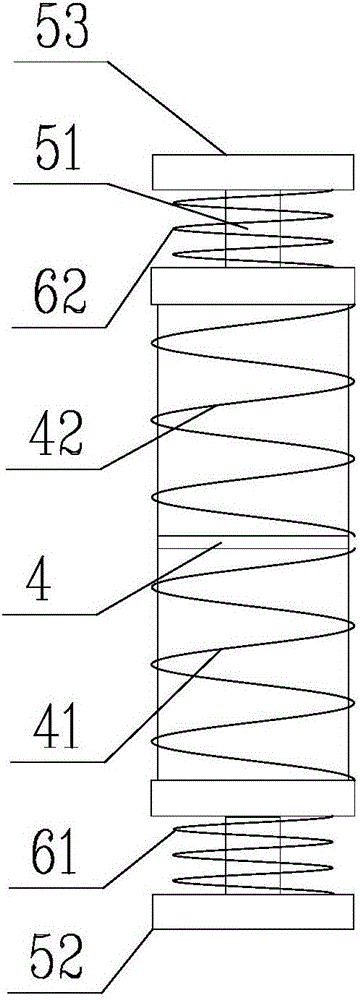

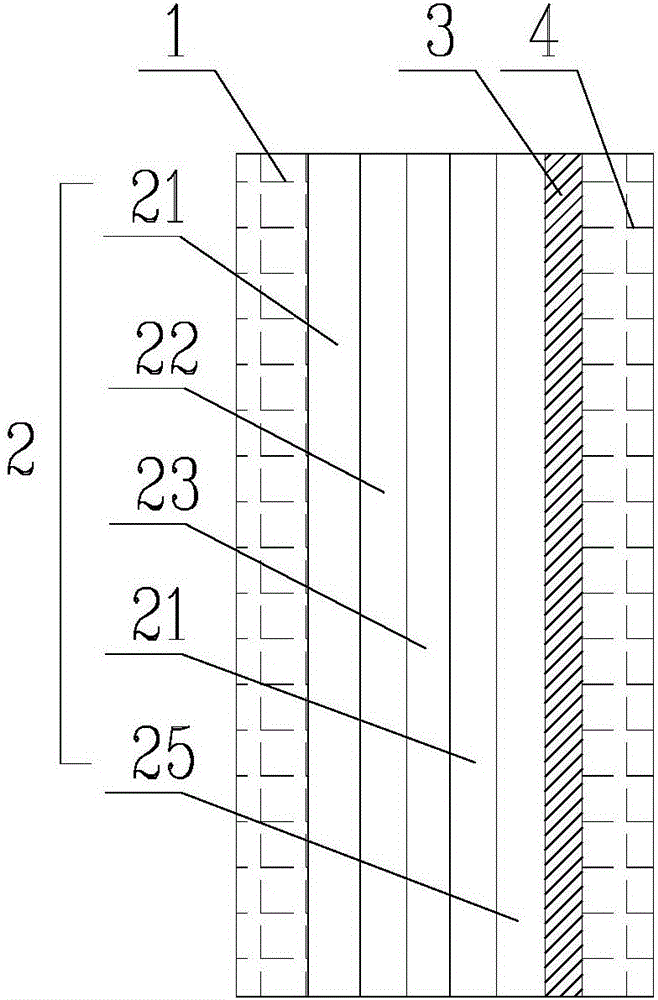

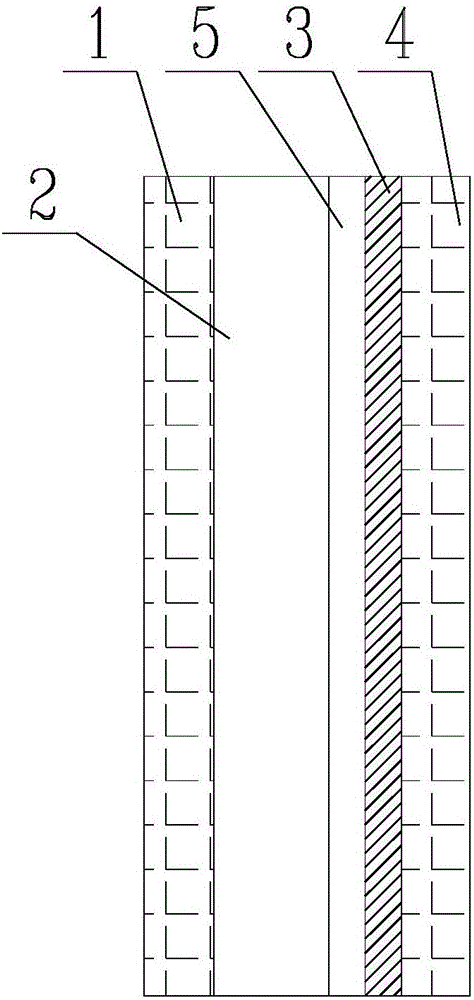

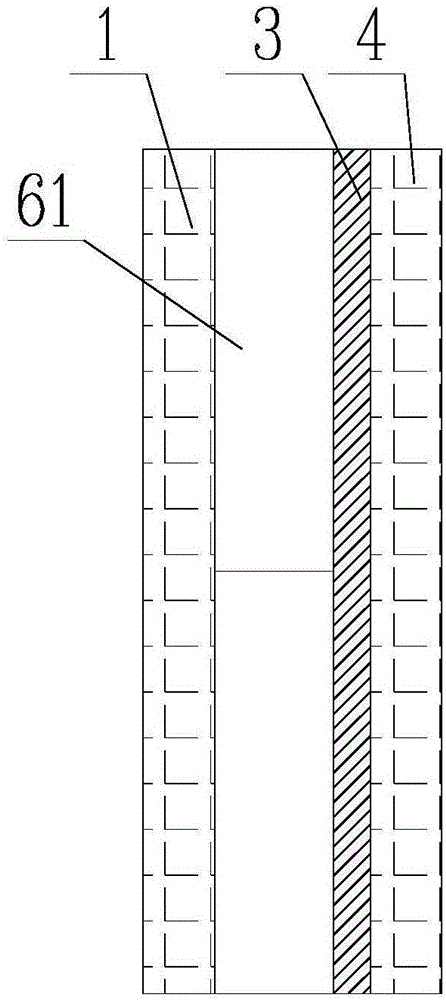

InactiveCN107860204AStructural design is optimized and reasonableAchieve drainageDrying gas arrangementsDrying solid materialsEngineeringUtilization rate

The invention discloses rice drying equipment with high thermal utilization rate. A drying cavity of a drying box is provided with a vertical cylindrical structure, a plurality of hot air blowing holes are formed in the side wall of the drying cavity; a feeding mechanism is positioned in the drying cavity and comprises an exhaust tube arranged vertically and a screen which is spirally arranged around an air inducing pipe; and a first driving mechanism drives the screen to vertically move in a reciprocating manner. The optimally designed rice drying equipment with high thermal utilization rateis optimal and reasonable in structural design; the spiral screen is driven to vibrate vertically, so that grains are fed from top to bottom; dry hot air is blown from the side wall through the hot air blowing holes, gas with water is taken away through the exhaust tube arranged in the middle after the grains are dried, and thus, the grains are dried in a feeding process; and the air blowing holescorrespond to air inlet holes, flow diverting of dry gas is realized, the drying effect is improved, and moreover, homogeneity of drying of the grains in a feeding process is ensured.

Owner:安徽正丰农业科技有限公司

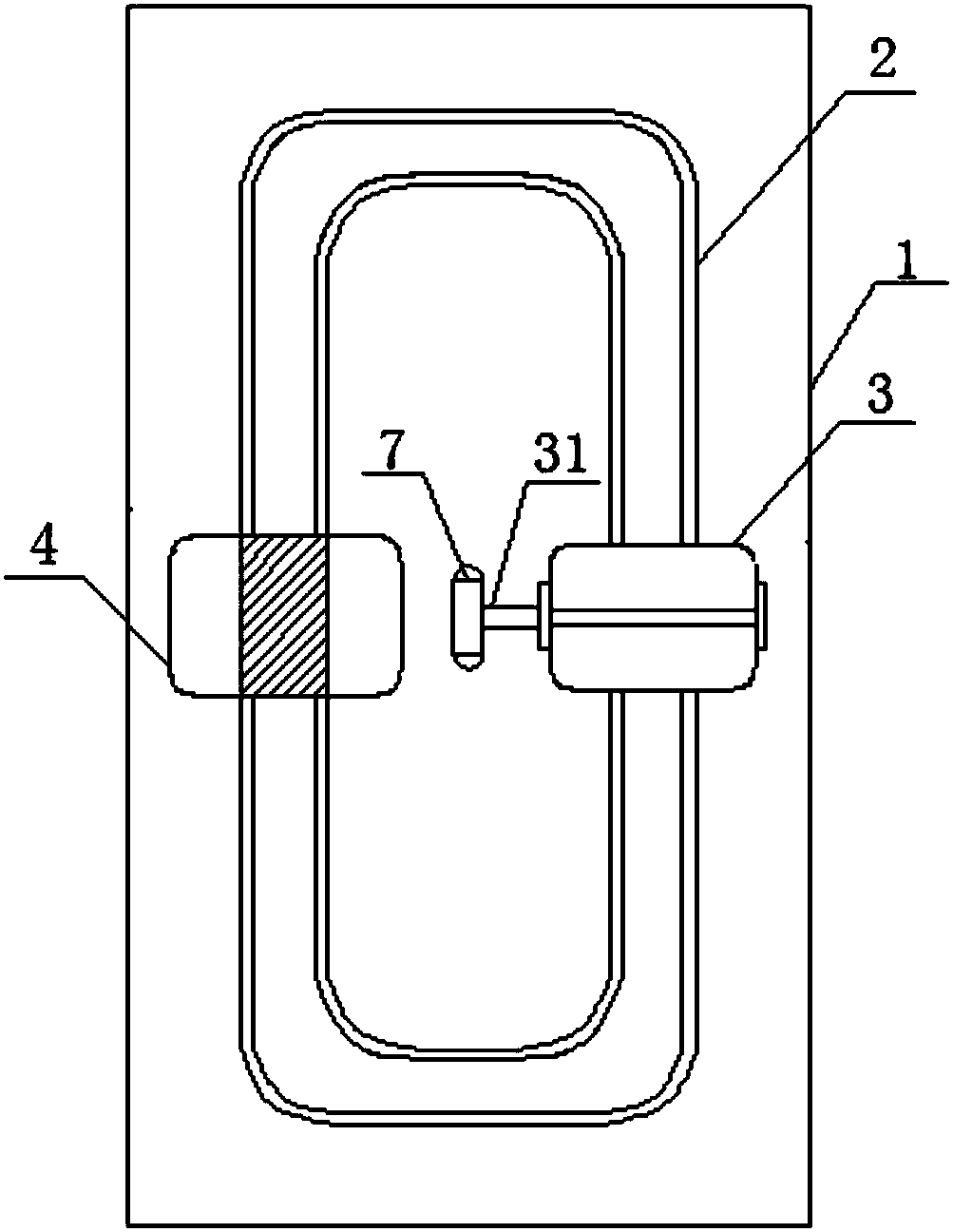

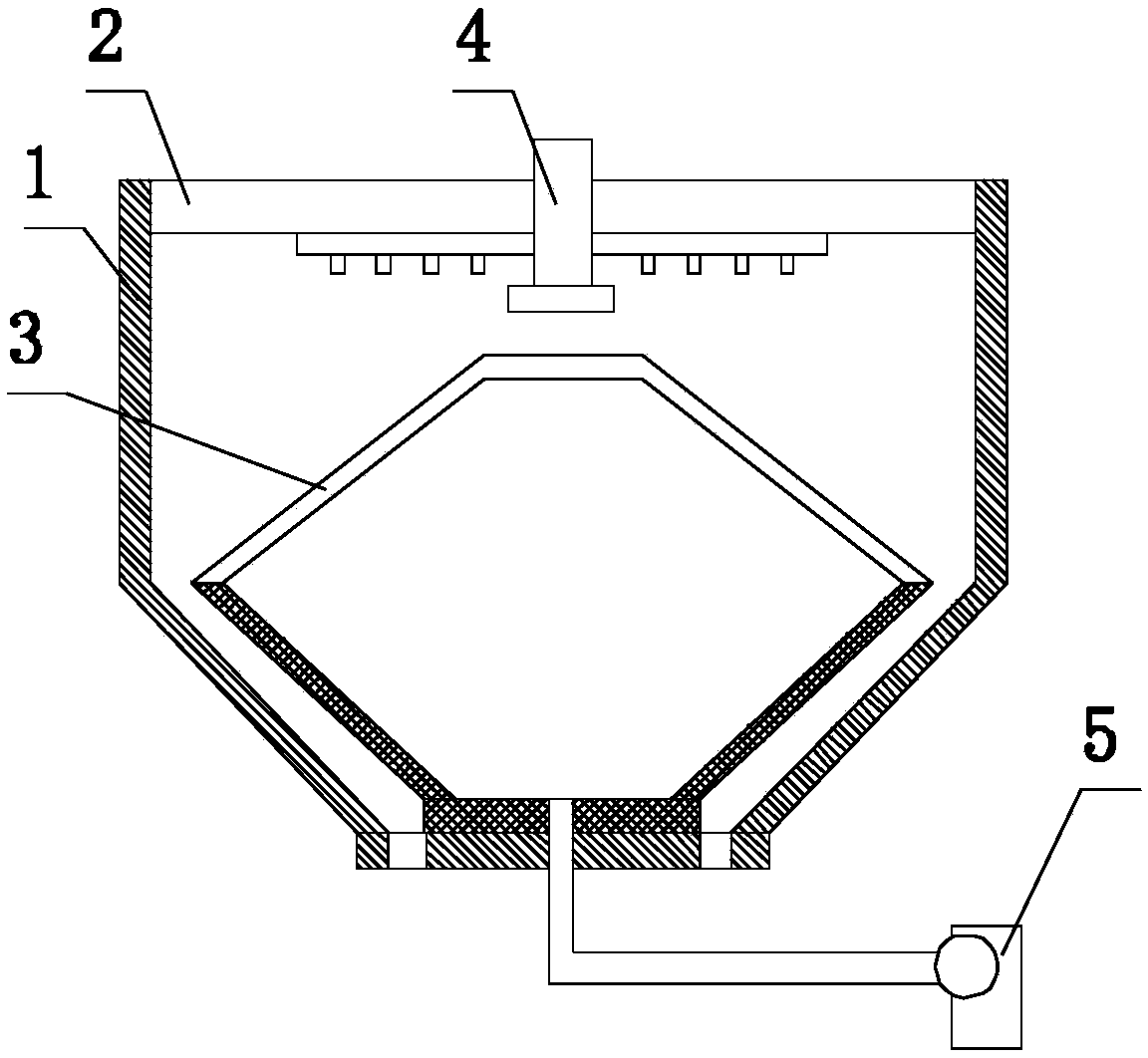

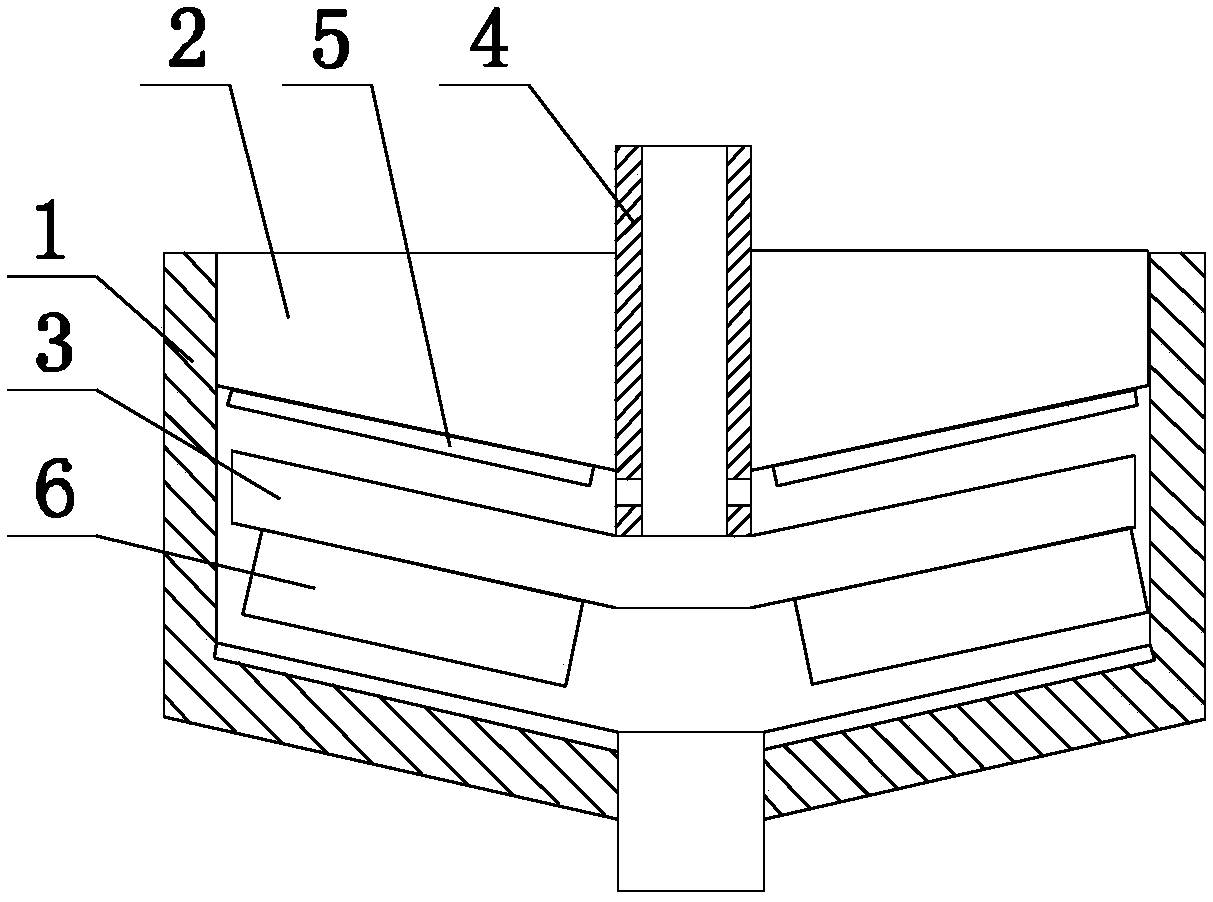

Rice hulling device for refined processing

ActiveCN107744846AStructural design is optimized and reasonableExtend milling timeGrain huskingGrain polishingEngineeringFlange

The invention discloses a rice hulling device for refined processing. A flange is arranged on the top of a processing barrel, and a rotating disk is located in the processing barrel; a grinding spacewith a conical structure is formed between the rotating disk and the flange; material twisting protrusions matched with the rotating disk are arranged at the bottom of the flange; a rotating shaft ofthe rotating disk penetrates an installing opening in the middle portion of the flange; a feeding channel used for performing feeding towards the grinding space is arranged in the rotating shaft; a material sweeping brush is arranged at the bottom of the rotating disk; and a driving mechanism drives a lower rotating disk to rotate. Due to the optimized rice hulling device for refined processing, the structural design is optimized and reasonable; due to the conical design of the grinding space, the grinding time of unhusked rice in the grinding space is prolonged, the grinding effect is improved, ground materials enter the processing barrel, rice cores and husks after being separated are subjected to thorough peeling under the effects of the material sweeping brush, and the separating efficiency is greatly improved.

Owner:全椒县崇明米业有限公司

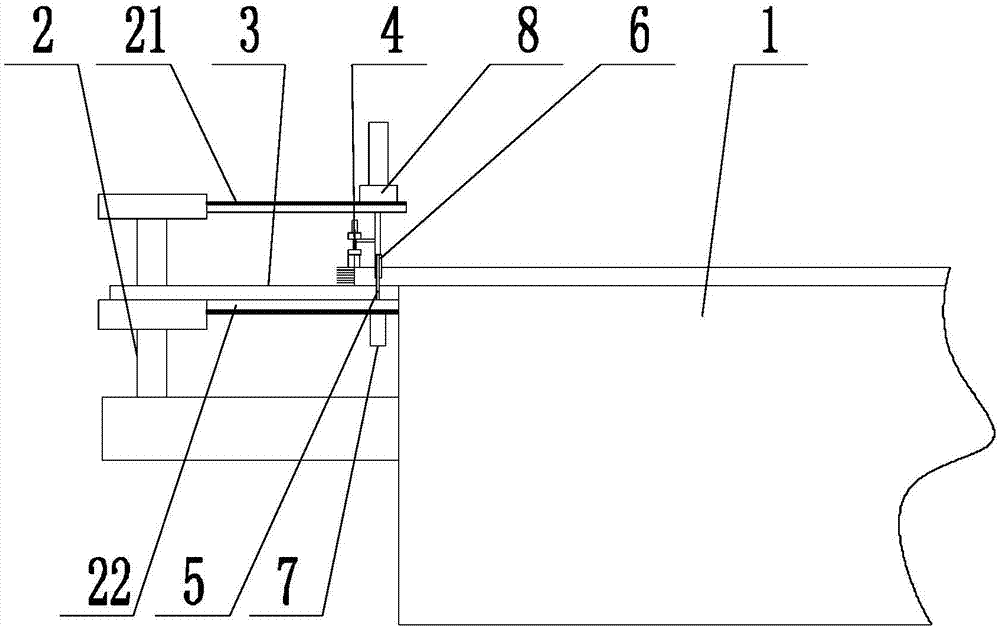

Adjustable gray cloth rough edge trimming equipment

InactiveCN107299520AGuaranteed trimming accuracyAvoid influenceSevering textilesEngineeringMechanical engineering

The invention discloses an adjustable gray cloth trimming device. A positioning plate is horizontally fixed on a mounting frame. A pressure wheel is located above the positioning plate to press the burr on the positioning plate. A limit sleeve is slidably installed on the positioning plate through a slide frame And it is provided with the accommodating groove that is used for accommodating the shearing knife, telescopic mechanism can be slidably installed under the positioning plate, the shearing knife is installed on the telescopic mechanism, and the shearing knife extends upwards through the positioning through hole from the telescopic mechanism into the limit. in the holding groove of the bit cover. Through the above optimized design of the adjustable gray cloth trimming equipment, the structural design is optimized and reasonable. By sliding and installing the trimming mechanism along the width direction of the gray cloth, the cutting position can be adjusted according to the width of the raw edge, so as to realize the precise trimming of the raw edge and greatly reduce the trimming waste. At the same time, the positioning holes on the limit sleeve and the positioning plate ensure the trimming accuracy of the shears and prevent the impact on the surrounding area of the trimming position during trimming.

Owner:ANHUI LIANGLIANG TEXTILE CO LTD

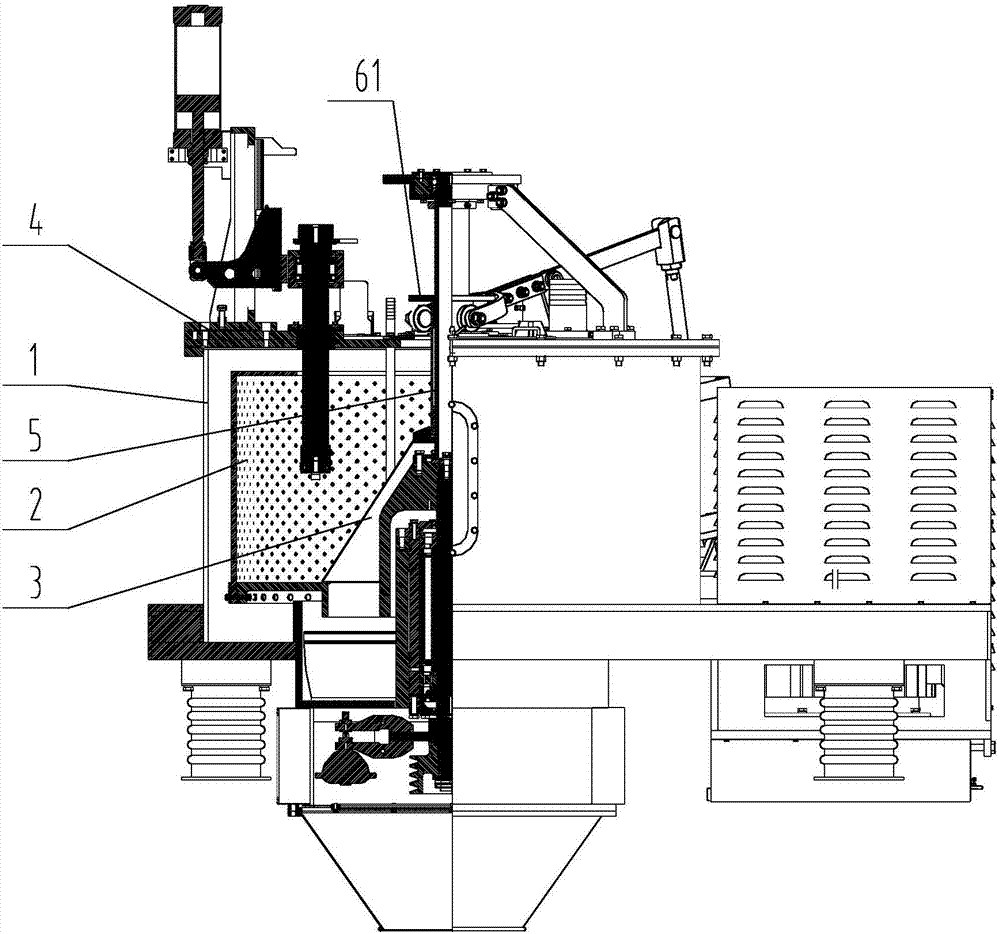

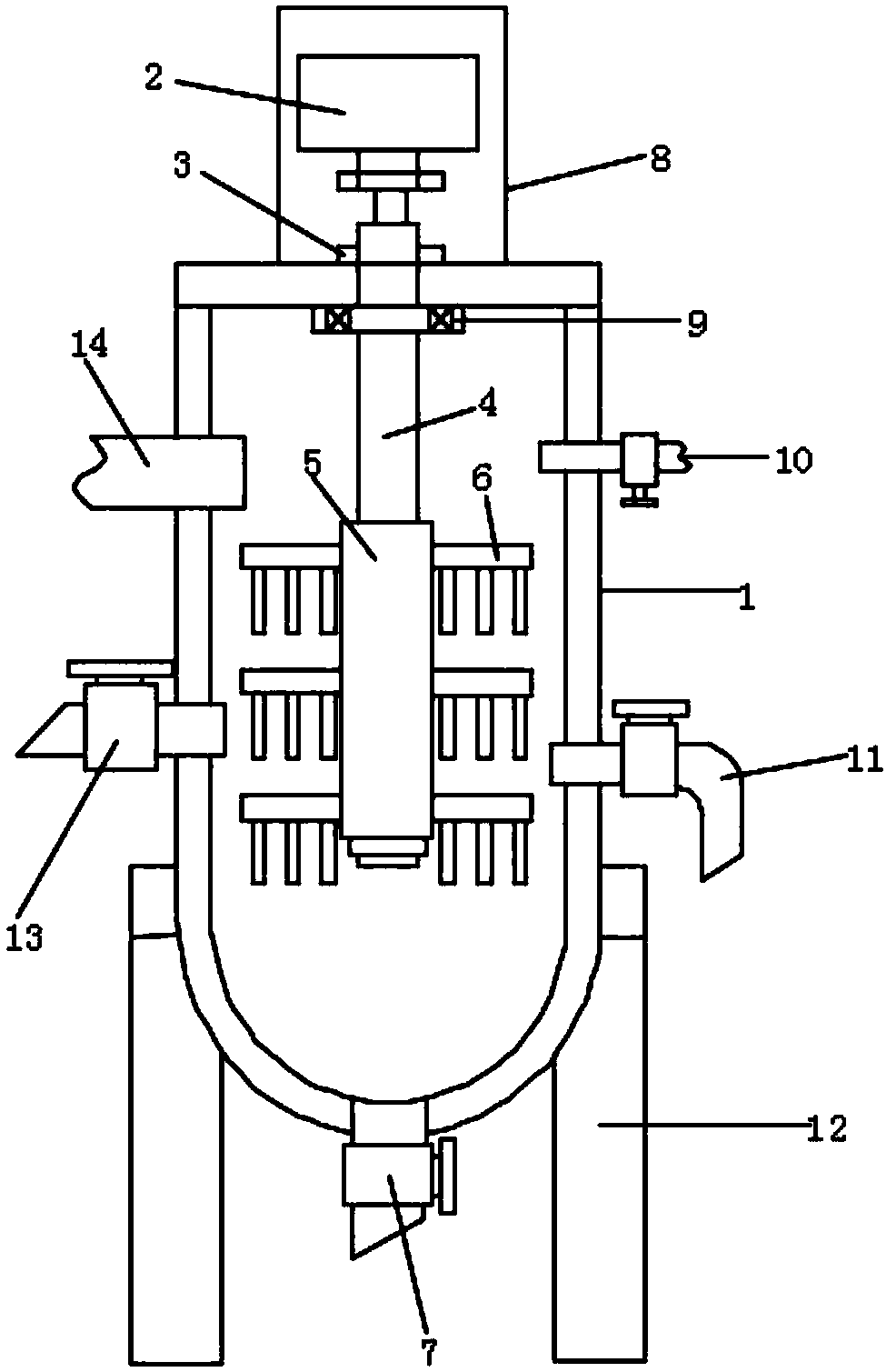

Metal smelting electric furnace with dust collector

ActiveCN107677124AGuaranteed heat utilizationImprove heat utilizationCharge treatment typeCrucible furnacesElectric arc furnaceEngineering

The invention discloses a metal smelting electric furnace with a dust collector. A cover body is located at a top opening of an outer furnace shell. A heating cavity and an exhaust cavity located below the heating cavity are formed in the outer furnace shell. An annular support plate is arranged on the side wall of the exhaust cavity and is located above an exhaust opening. A plurality of supportblocks used for supporting an inner furnace lining arranged at intervals are arranged at the top of the annular support plate. The inner furnace lining is supported in the heating cavity through the multiple support blocks. A downwards-extending annular baffle is arranged at the inner edge of the annular support plate. Through the optimally designed metal smelting electric furnace with the dust collector, the structure design is optimal and reasonable, gas is discharged at the bottom of the outer furnace shell, the inside heat utilization efficiency of the outer furnace shell is ensured effectively, meanwhile, the exhaust cavity provides a buffer area for the gas, tail gas stays at the bottom of the outer furnace shell before discharged, thus dust in the gas drops, then the gas is discharged, and dust contained in the discharged gas is reduced effectively while the heat utilization efficiency is improved.

Owner:ANHUI NINGGUO NINGHU STEEL BALL

Yarn-breaking-prevention yarn feeding device for textile equipment

ActiveCN107473003AReduce frictionStructural design is optimized and reasonableFilament handlingTextile yarnStructural engineering

The invention discloses a yarn-breaking-prevention yarn feeding device for textile equipment. A first yarn feeding roller and a second yarn feeding roller are arranged on an installation frame, and a tension adjustment mechanism is arranged between the first yarn feeding roller and the second yarn feeding roller; in the tension adjustment mechanism, an adjusting roller is arranged on an inner pipe body of a telescopic casing pipe, and an oil storage bag is located in an outer pipe body and communicates with the outside through the inner pipe body; and the two ends of an elastic reset piece are connected with a third roller seat and the installation frame correspondingly, and a textile yarn sequentially winds across the first yarn feeding roller, the adjusting roller and the second yarn feeding roller. Through the optimally-designed yarn-breaking-prevention yarn feeding device for the textile equipment, optimization of structural design is reasonable, when tension of the textile yarn is too large and force is applied to the adjusting roller, the telescopic casing pipe is compressed, and under the compressing effect of the inner pipe body, lubricating oil in the oil storage bag is extruded out and lubricate the surface of the adjusting roller through the inner pipe body, so that the textile yarn is lubricated; and friction force between the textile yarn and the adjusting roller is effectively reduced, so that the axial tension of the textile yarn is reduced, and yarn breaking is prevented.

Owner:安徽新生纺织股份有限公司

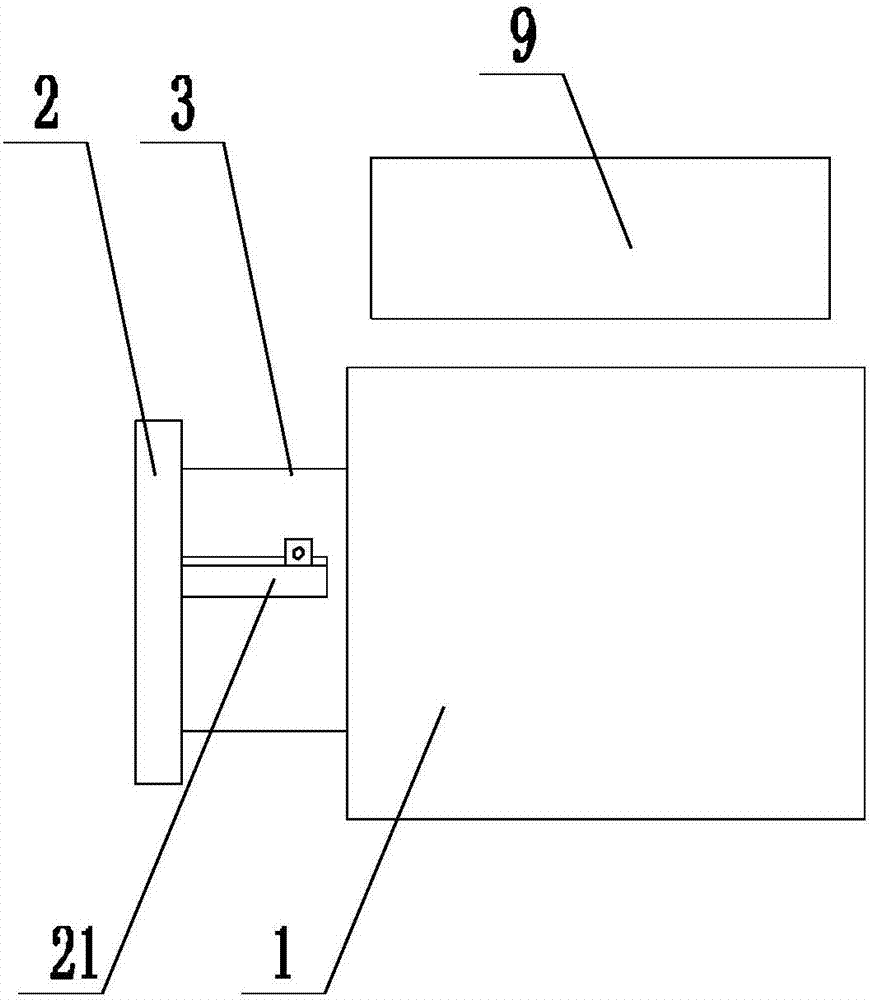

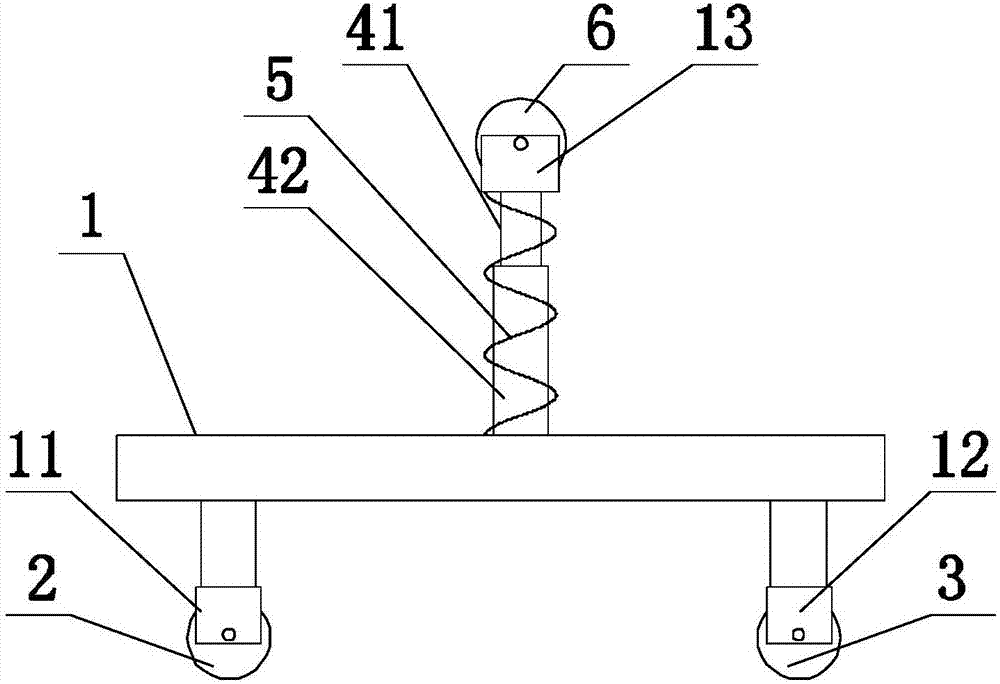

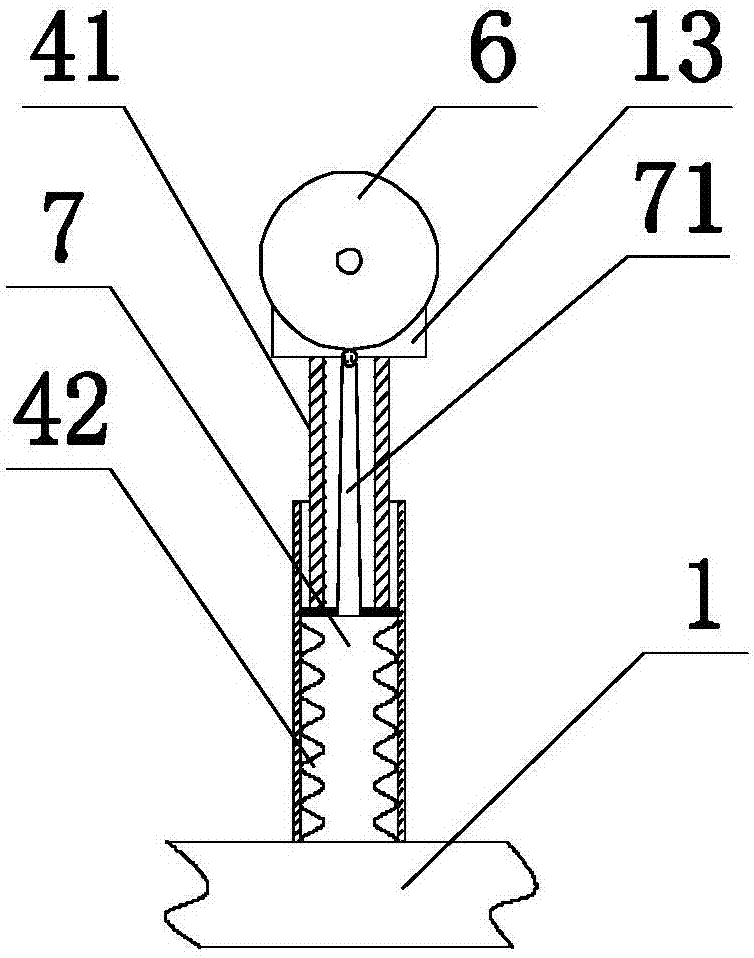

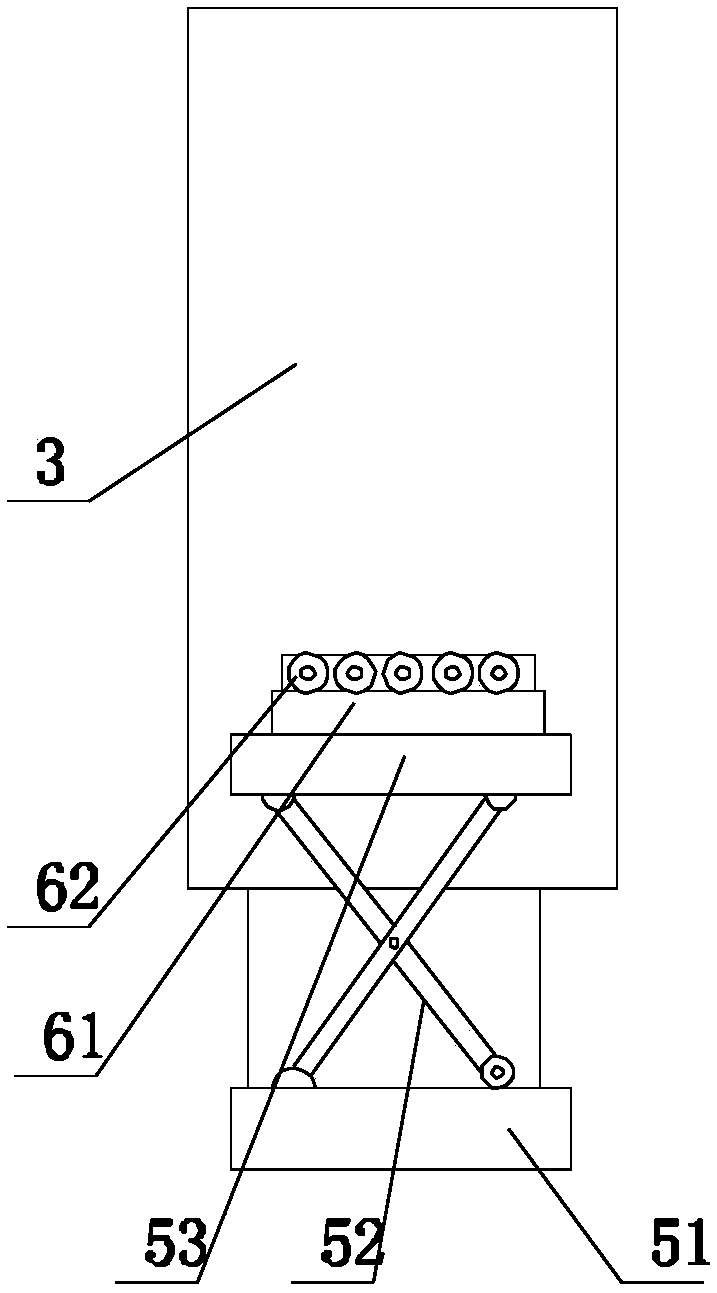

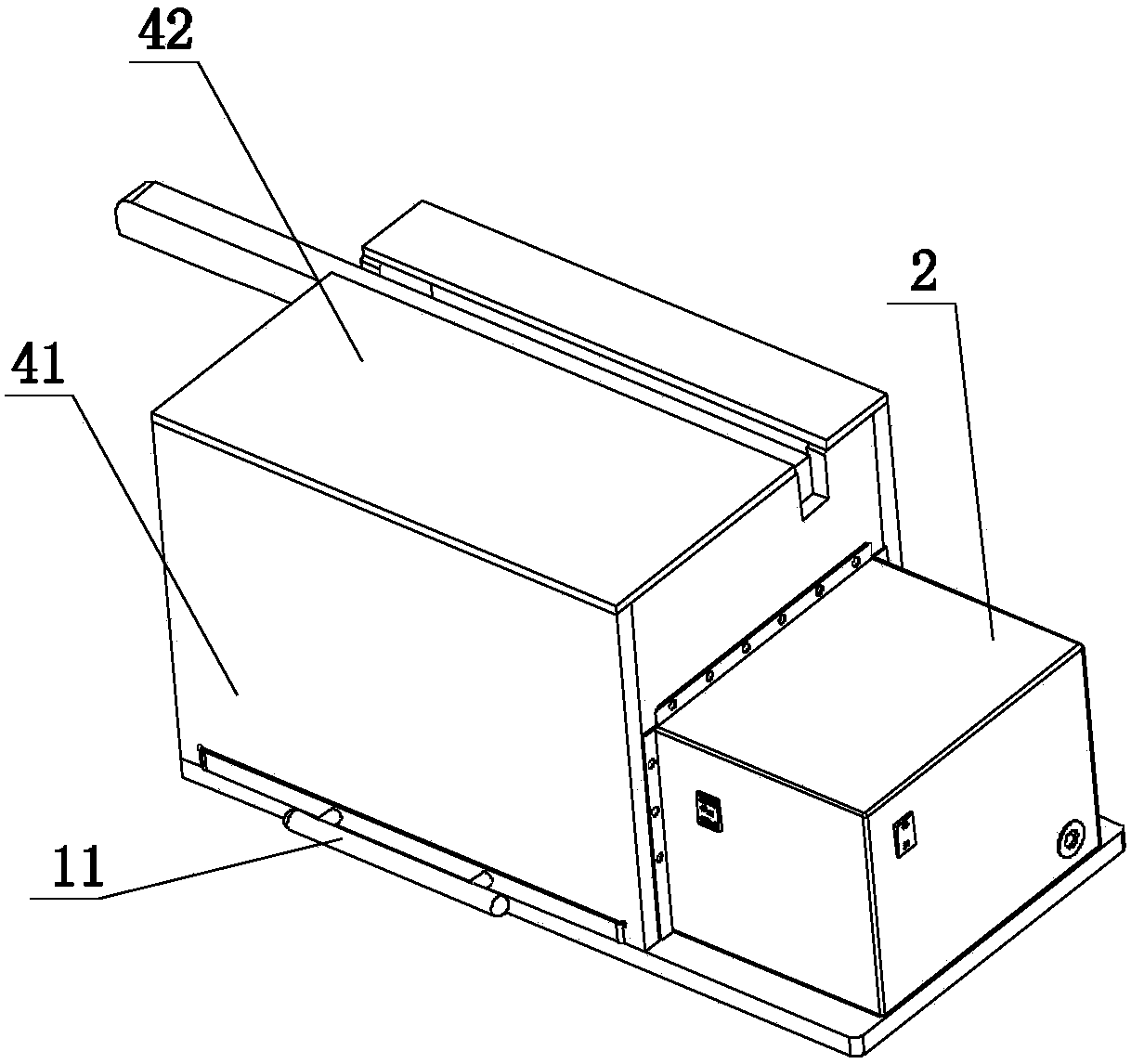

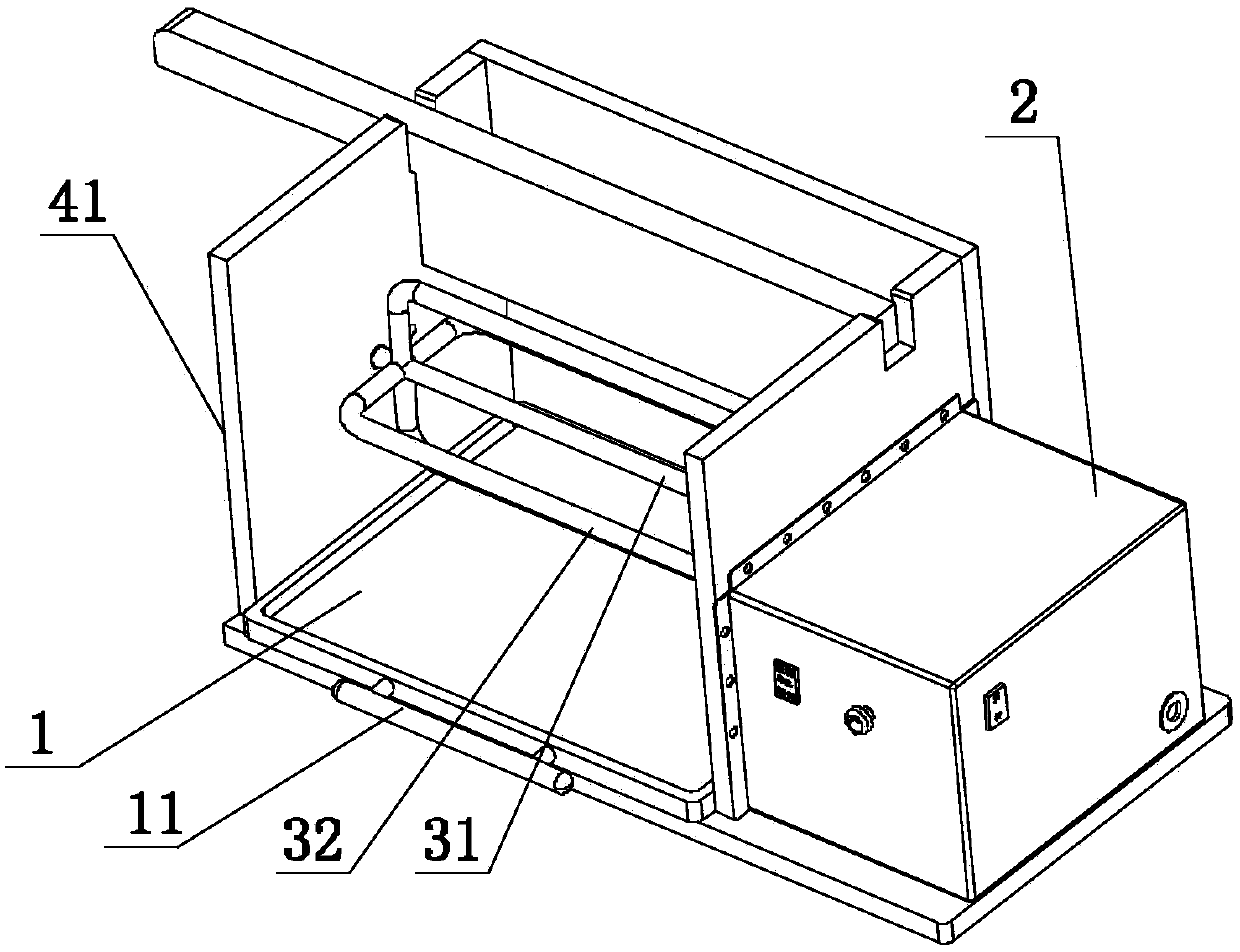

Cement stacking device provided with lifting platform

ActiveCN108584447ARealize neat stackingStructural design is optimized and reasonableStacking articlesMechanical engineeringCement

The invention discloses a cement stacking device provided with a lifting platform. The device is characterized in that a rack and a support are correspondingly arranged at two sides of the lifting platform, wherein a conveying mechanism is positioned above the lifting platform and is mounted on the rack; a vertical first slide rail is arranged on the support; a baffle plate is positioned above thelifting platform and is vertically arranged at one side, far away from the conveying mechanism, of the lifting platform; the baffle plate is glidingly mounted on the first slide rail; a first drivingmechanism is connected to the baffle plate and is used for driving the baffle plate to lift. According to the device adopting the abovementioned optimized design, the structure design is optimized and reasonable; goods are sequentially stacked to the lifting platform through the conveying mechanism; the lifting platform is lifted down based on the stacking height during stacking, and the baffle plate is lifted up at the same time, thus the goods can be regularly stacked, and as a result, the stacking efficiency is greatly improved.

Owner:芜湖固高自动化技术有限公司

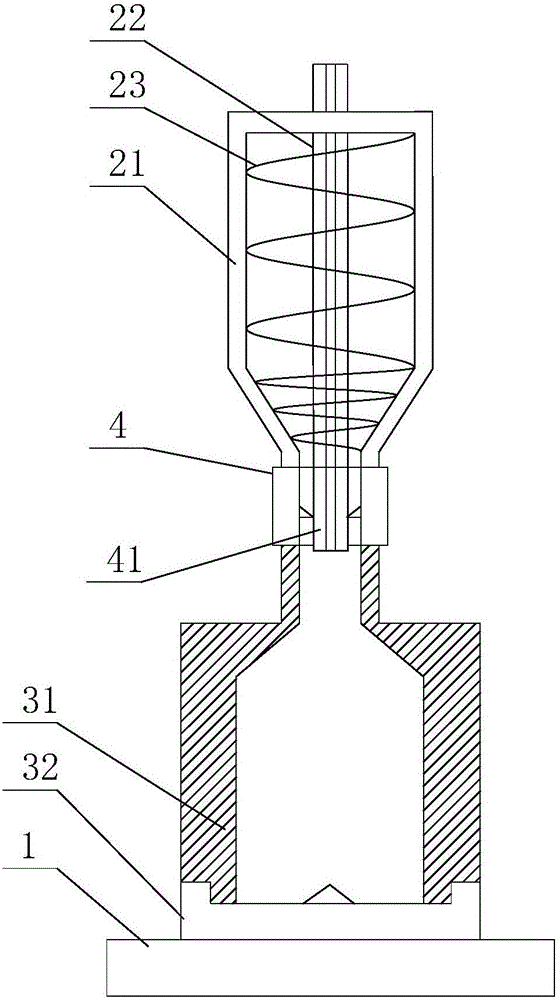

Plastic bottle processing device for even forming

InactiveCN105965856AUniform shapeStructural design is optimized and reasonableDomestic articlesHollow articlesEngineeringMechanical engineering

The invention discloses a uniformly formed plastic bottle processing equipment. The mold base is rotatably installed on the base and its rotating shaft is vertically arranged. The upper mold is located above the mold base, and a vertically extending forming mold is formed between the upper mold and the mold base. cavity, the cutting device is located above the upper die, the cutting device is provided with a vertically penetrating cooling cavity, the cooling cavity is provided with an inner support tube, the inner wall of the cooling cavity is provided with a cutting piece, the barrel is located above the cutting device, A screw feeding mechanism is arranged in the barrel, and an air inlet cavity is arranged in the screw feeding mechanism, and the air inlet cavity communicates with the molding cavity through the cooling cavity. The uniformly formed plastic bottle processing equipment proposed by the present invention has an optimized and reasonable structural design. On the one hand, the screw feeding mechanism ensures uniform feeding of the blank during feeding; The inner molding is uniform, and it is convenient for the plastic bottle to be released from the upper mold after molding.

Owner:北京佑众全椒制药有限公司

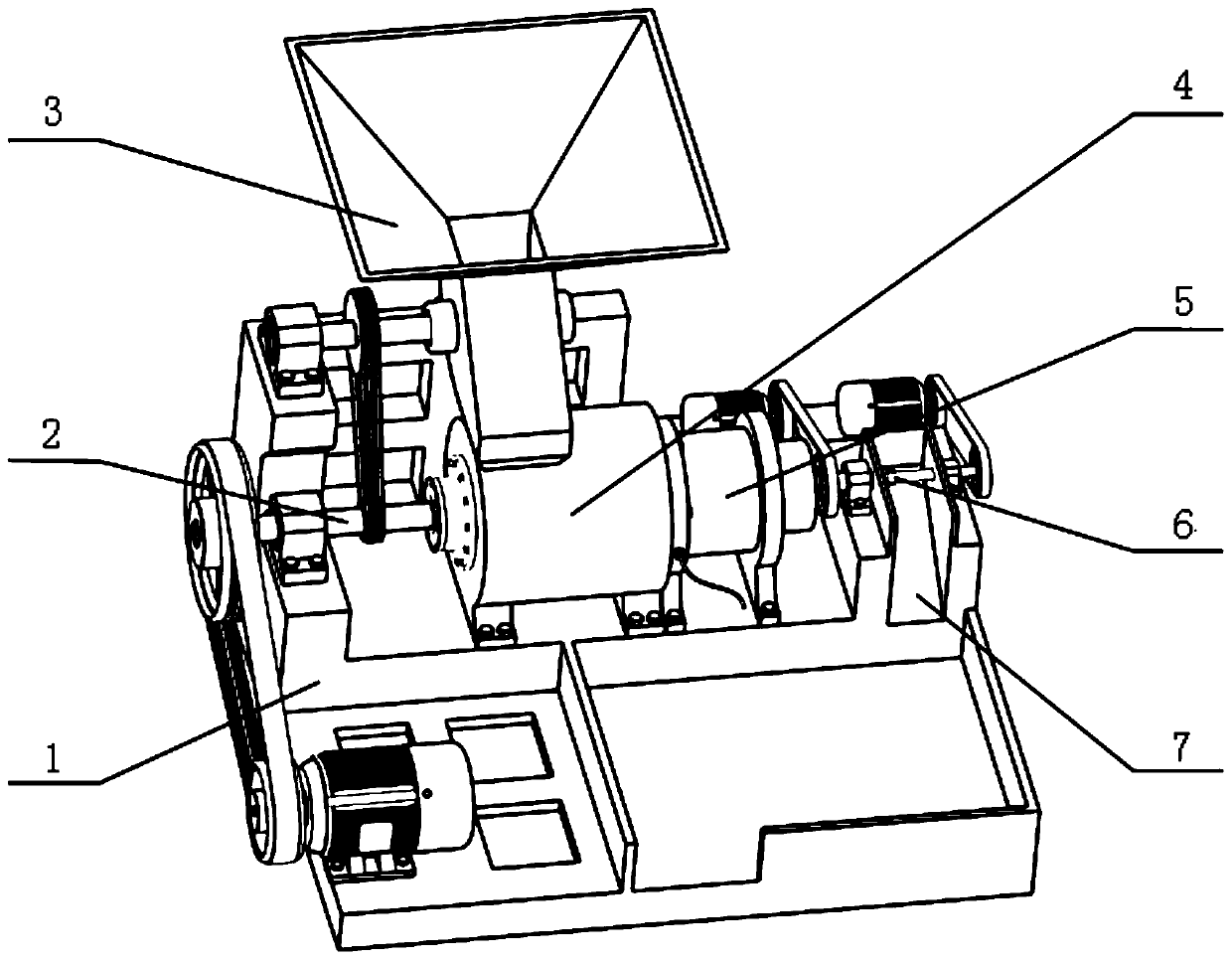

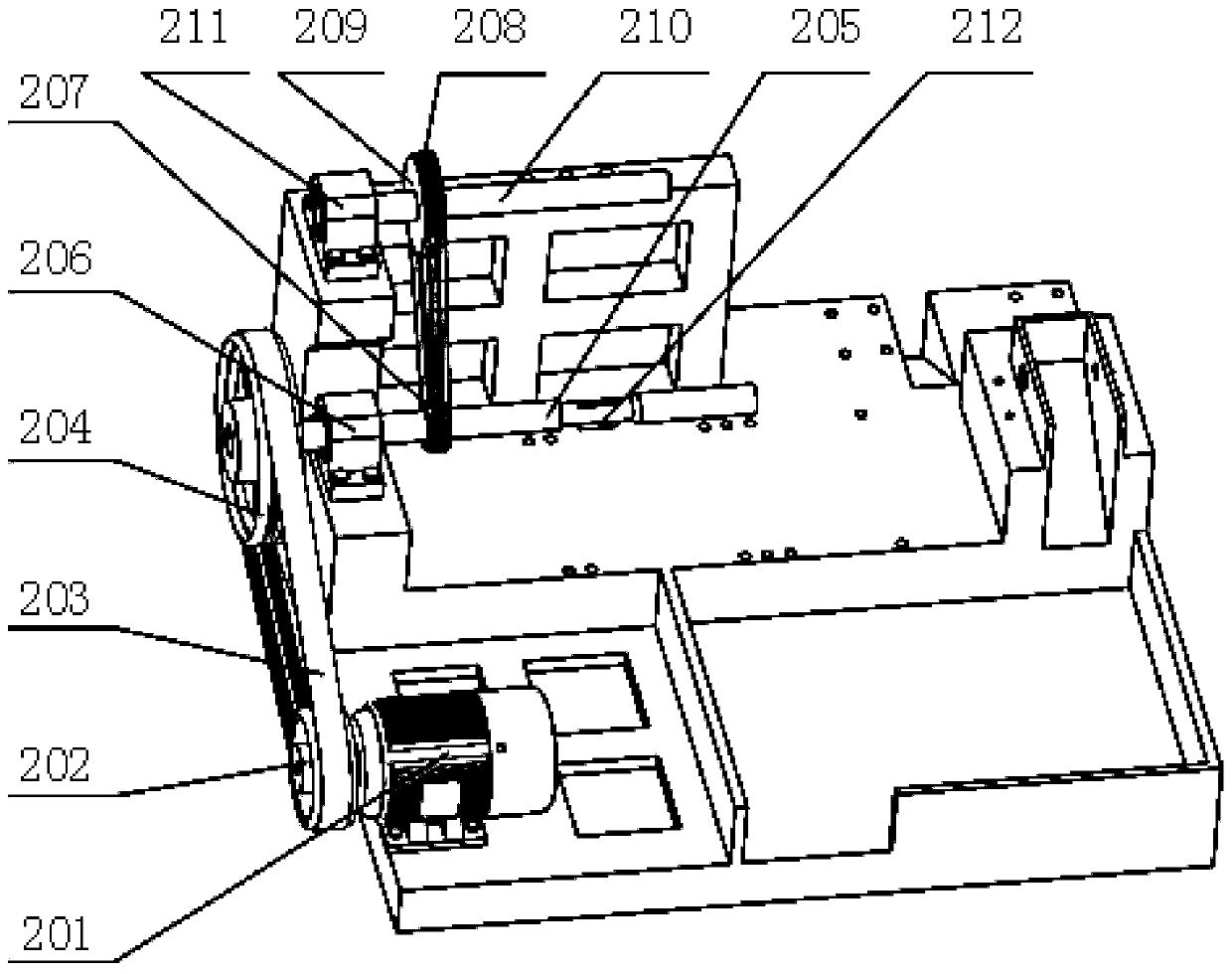

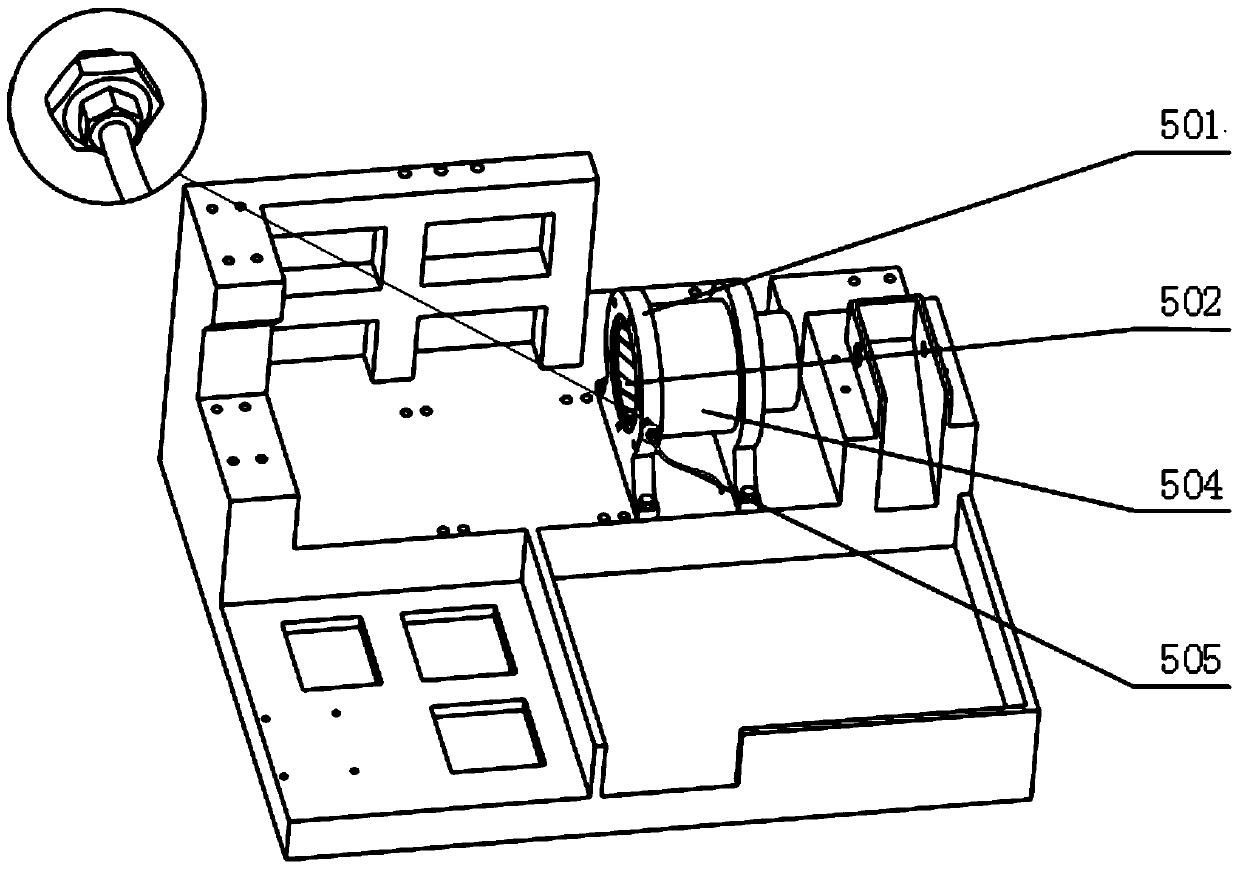

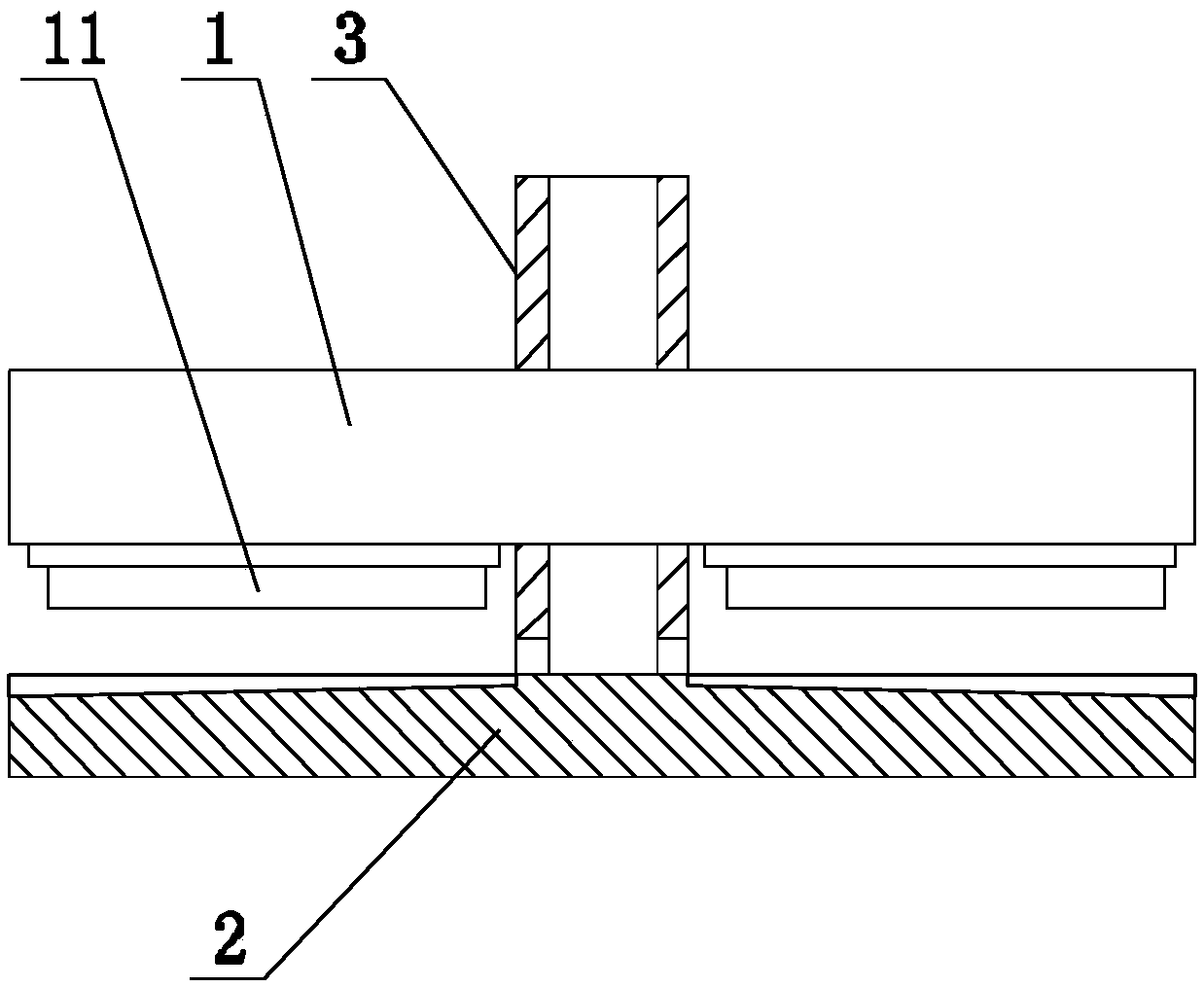

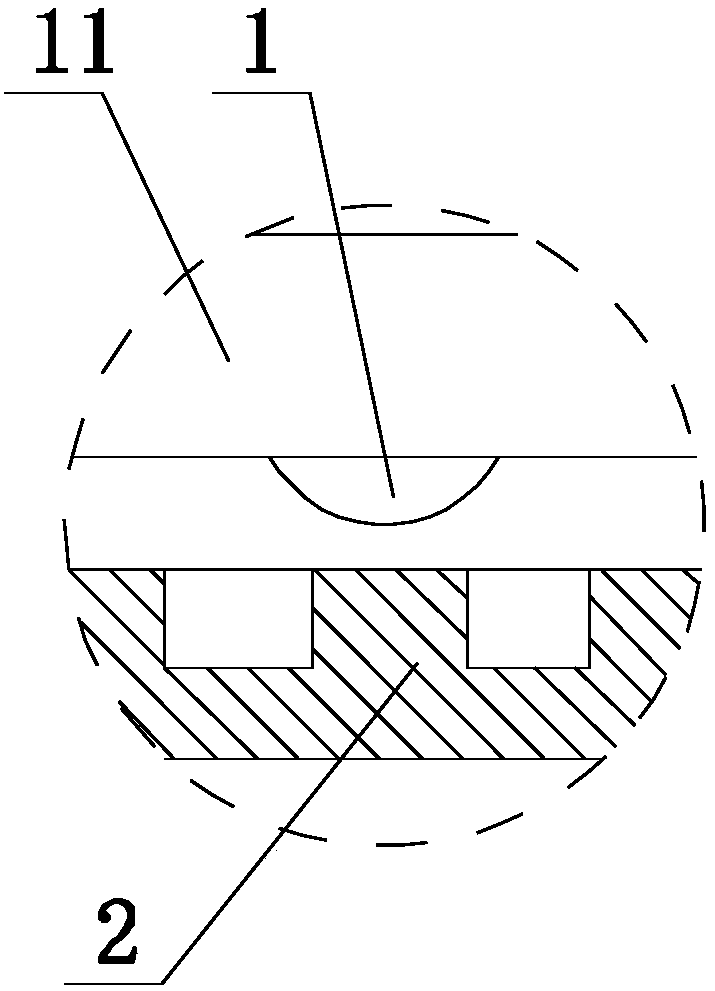

Secondary smashing extruder for straw and method

PendingCN109998139AReduce the probability of cloggingAvoid cloggingFeeding-stuffChinese charactersEngineering

The invention relates to a secondary smashing extruder for straw and a method, and belongs to the field of agricultural machines. A transmission system is fixedly installed on the left side of a rackthrough bolts; a material smashing and pushing system is fixedly installed at the position in the middle of a groove of the rack through bolts and located on the right side of the transmission system;a feeding system is fixedly installed on a support shaped like the Chinese character tian behind the rack through bolts and located above the material smashing and pushing system; a high-temperatureand high-pressure extrusion system is fixedly installed on the right side of the groove of the rack through bolts and located on the right side of the material smashing and pushing system; a discharging system is fixedly installed on the right side of the rack through bolts; a material collecting system is fixedly installed on the front right portion of the rack and located below the discharging system. The secondary smashing extruder has the advantages that the situation that excessive materials are fed at a time so as to block an inlet is avoided, and the using safety of the machine is improved; the smashing efficiency is easily improved, and the blocking rate of the machine is easily reduced; the temperature in a heating extrusion bin is ensured, and the extrusion efficiency is improved.

Owner:JILIN UNIV

Efficient rice hulling device

ActiveCN107855153AStructural design is optimized and reasonableUnpackingGrain huskingGrain polishingEngineeringCentrifugal force

The invention discloses an efficient rice hulling device. An upper grinding plate and a lower rotating plate are horizontally and coaxially arranged; an opening is formed in the middle of the upper grinding plate, and a feed pipe vertically penetrates through the opening; the feed pipe is coaxial with the lower rotating plate, and the lower end of the feed pipe is fixed to the lower rotating plate; the feed pipe is provided with a distribution hole between the upper grinding plate and the lower rotating plate; the upper grinding plate is provided with a grinding protrusion, and the lower rotating plate a guide tank; and a drive mechanism drives the lower rotating plate to rotate to achieve distribution. By means of the efficient rice hulling device of the optimized design, the structural design is optimized and reasonable, materials are fed to the position between the upper grinding plate and the lower rotating plate through the feed pipe, through rotation of the lower rotating plate,on the one hand, rice in the feed pipe can be distributed in the distribution hole under the action of centrifugal force, on the other hand, the grinding protrusion on the upper grinding plate can grind the rice, besides, rice kernels obtained after hulling fall into the guide tank and are discharged towards the periphery under the action of centrifugal force, and accordingly integration of feeding, hulling and discharging is achieved.

Owner:全椒县崇明米业有限公司

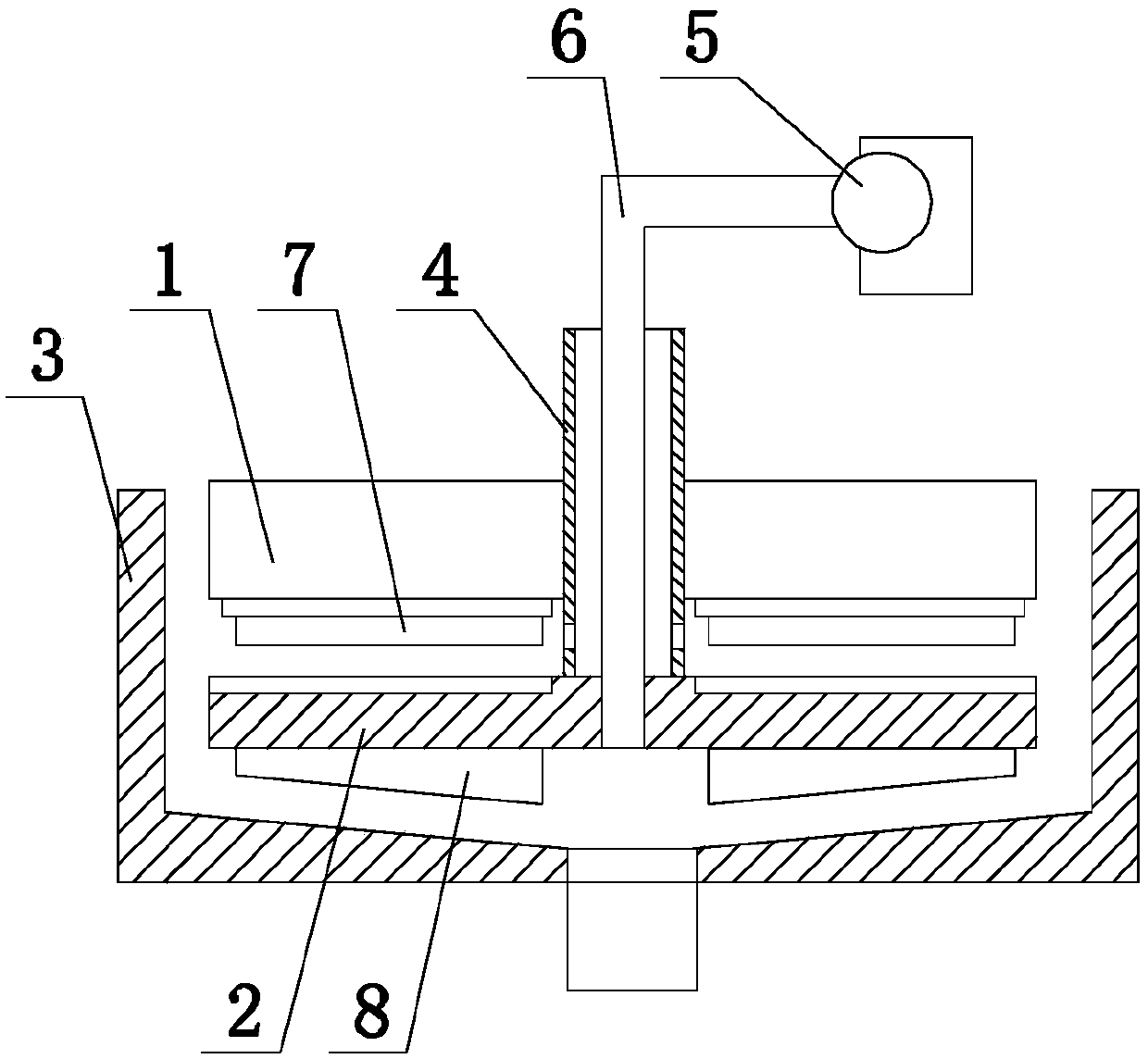

Monosodium glutamate centrifugal separation equipment for preventing solid phase residues

InactiveCN107225051AStructural design is optimized and reasonableGuaranteed smooth flowRotary centrifugesMonosodium glutamateEngineering

The invention discloses monosodium glutamate centrifugal separation equipment for preventing solid phase residues. A liquid outlet in the bottom of a machine shell is gradually reduced from top to bottom, a flange is installed at the top of the machine shell, the bottom of a separation cavity inside a rotary barrel is provided with a discharging opening, and a liquid discharging cavity between the rotary barrel and the machine shell communicates with the liquid outlet; a sealing cover is located in the rotary barrel and is in sealed fit with the discharging opening, the outer wall of the sealing cover is provided with an annular flow guide face of a conical structure, and the outer diameter of the annular flow guide face is gradually increased from top to bottom. Through the optimally-designed monosodium glutamate centrifugal separation equipment for preventing the solid phase residues, the structural design is optimized and reasonable, the outer wall of the sealing cover and the inner wall of the liquid outlet are provided with the flow guide faces, smooth flowing of liquid is guaranteed, on one hand, the separation effect is greatly improved, and on the other hand, crystal residues generated in the leading-out process of liquid phase matters are prevented.

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

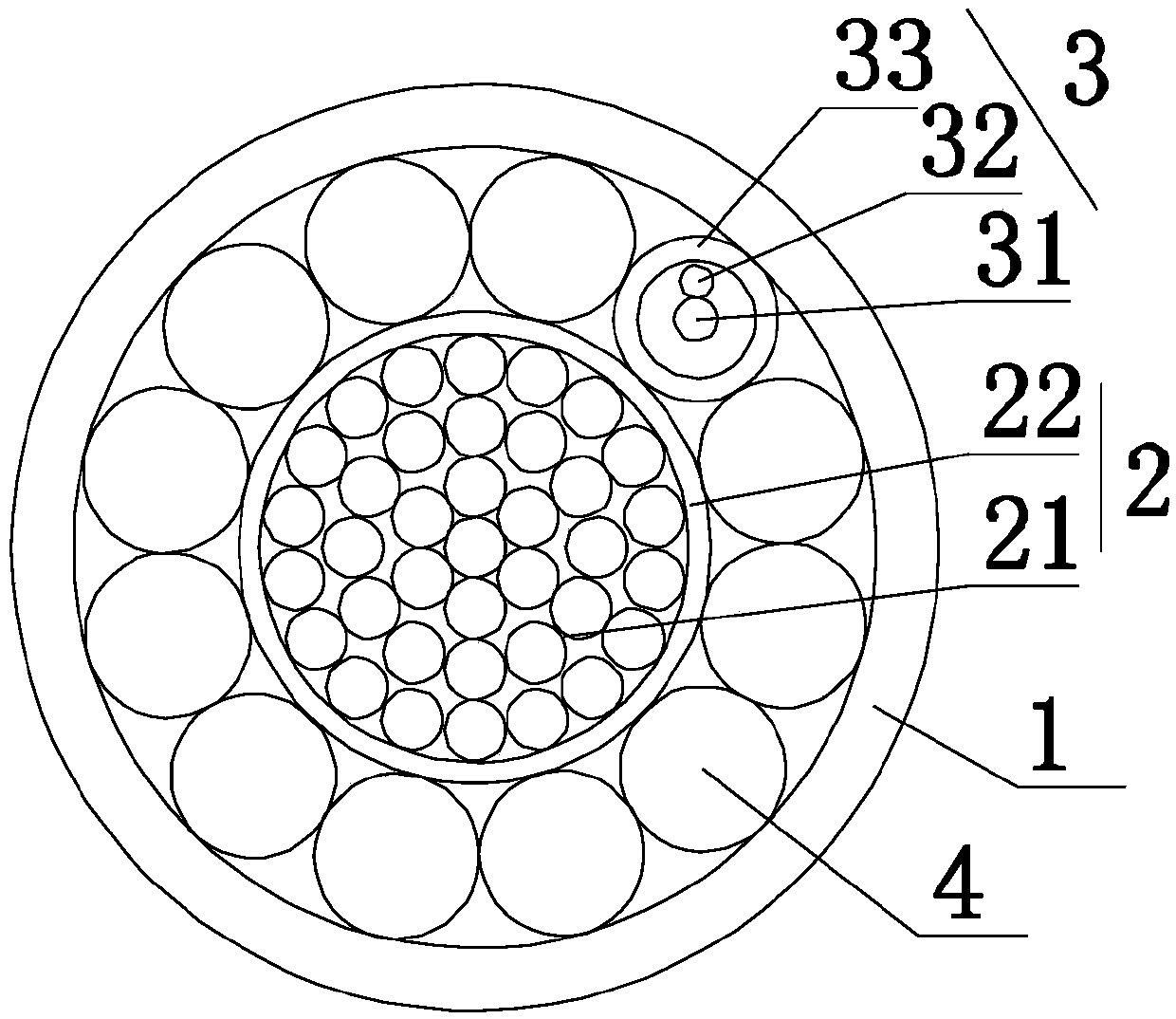

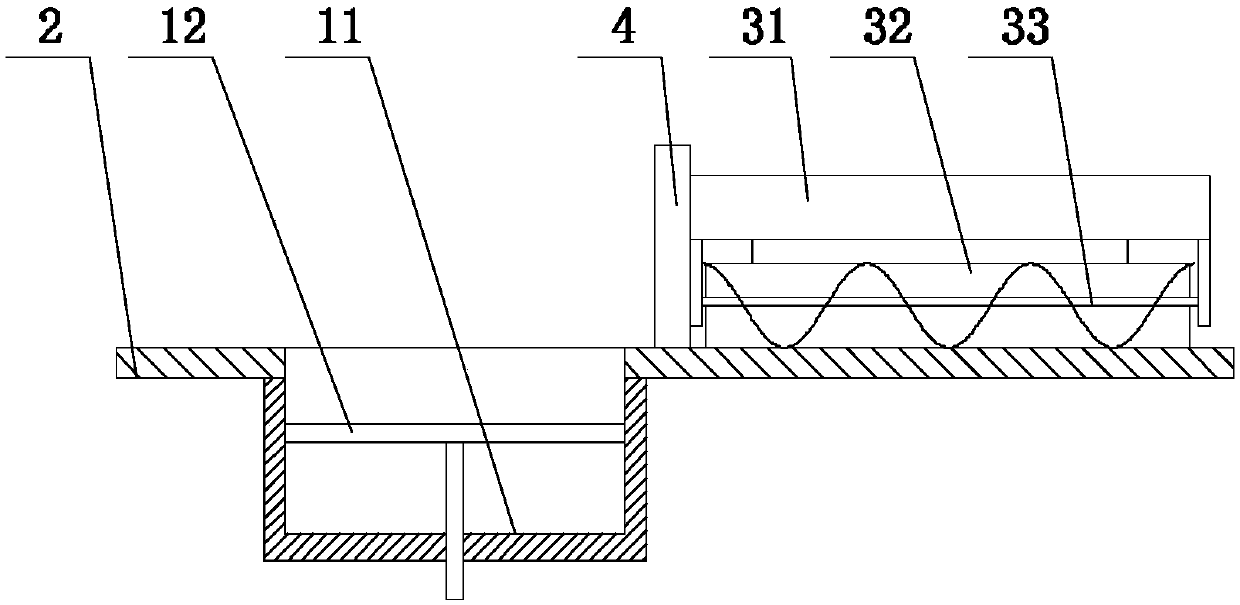

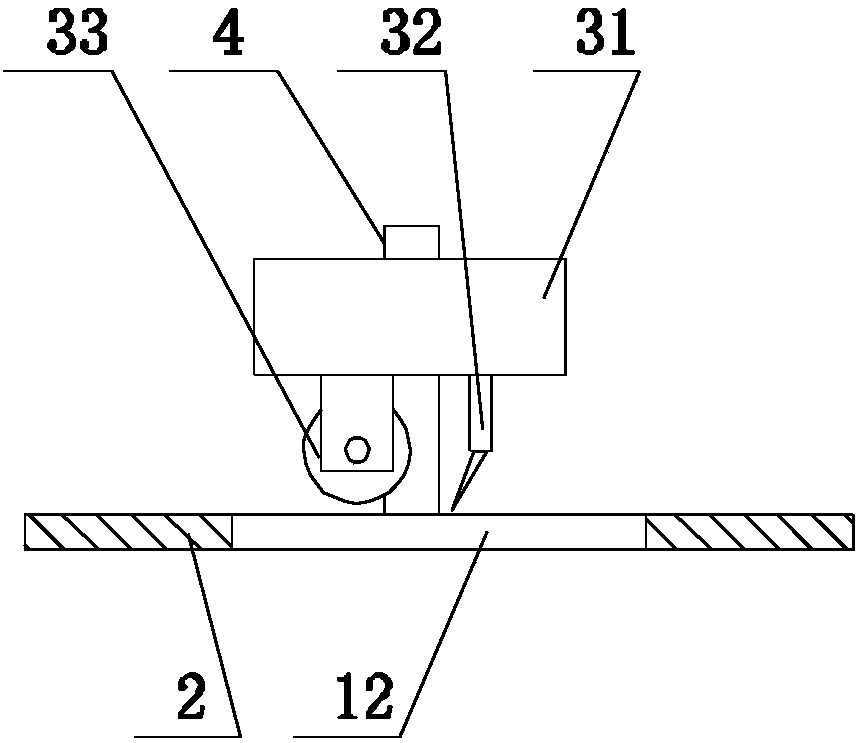

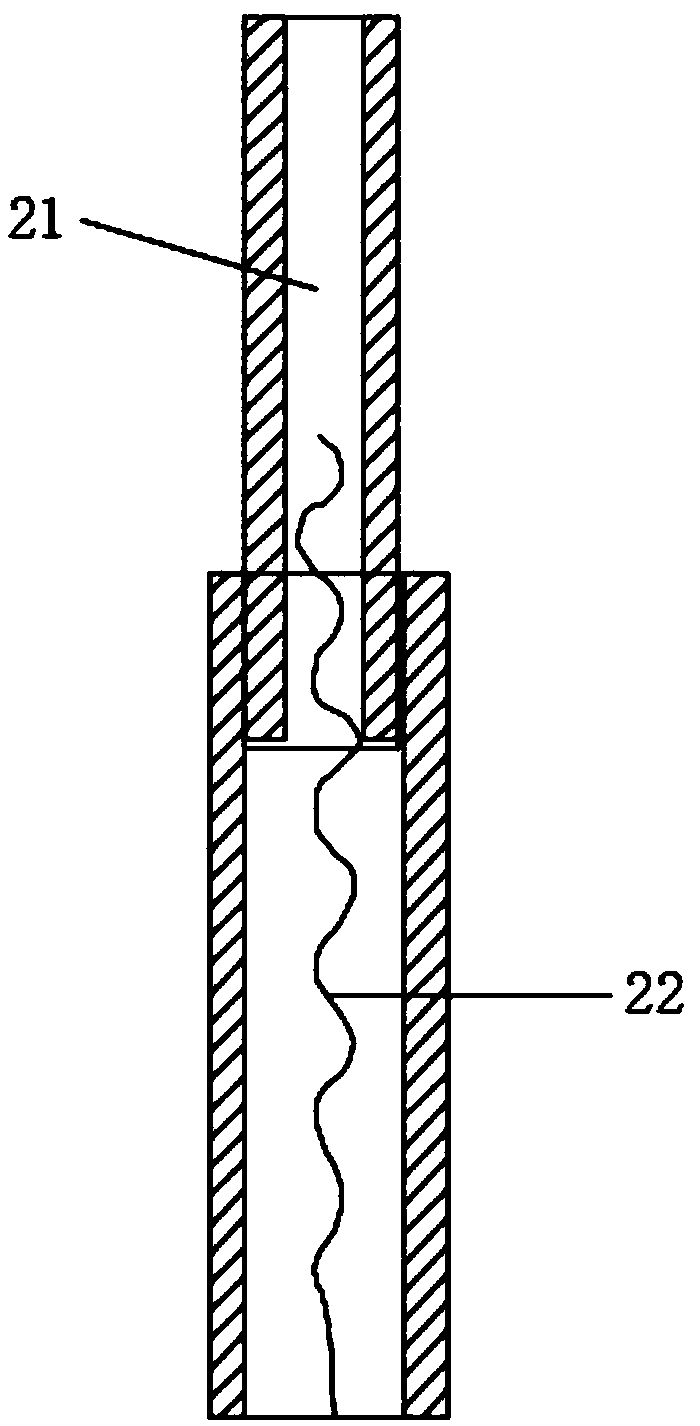

Intelligent double-wire encircling type temperature monitoring single-core cable based on optical fiber grating

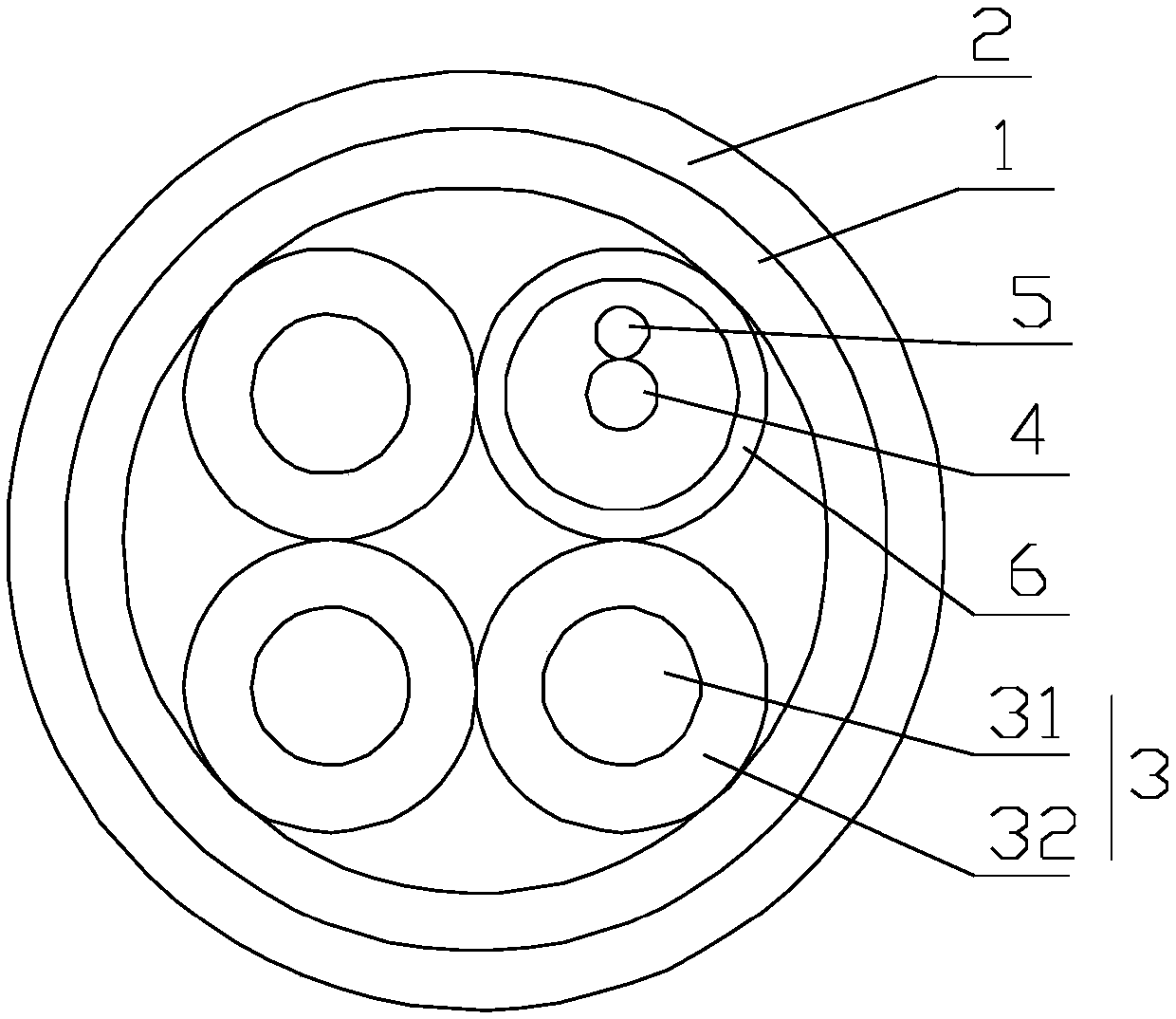

InactiveCN107945981AGuaranteed axial tensile strengthGuaranteed fixed effectInsulated cablesCommunication cablesEngineeringTemperature monitoring

The invention discloses an intelligent double-wire encircling type temperature monitoring single-core cable based on an optical fiber grating. A cable core comprises a wire and optical fiber sensing units, the wire is located at the central part of the cable core, the wire comprises conductors and an insulating layer wrapping the external parts of the conductors, the optical fiber sensing units are located at the external part of the wire, each of the optical fiber sensing units comprises a tensile core, a grating optical fiber and a protection pipe, the tensile core and the grating optical fiber are located in the protection pipe, and the external part of the insulating layer is wrapped by filling materials to form a cable core with a circular cross section. According to the intelligent double-wire encircling type temperature monitoring single-core cable based on the optical fiber grating with an optimized design, the structure and the design are optimized and reasonable, the gratingoptical fibers used for monitoring the temperature are arranged in the cable core so that the temperature of the cable can be rapidly and accurately monitored, the grating optical fibers are arrangedaround the tensile core so that the axial tensile strength of the grating optical fiber can be guaranteed, and the cable core is filled with the filling materials so that it is effectively guaranteedthat during usage, the position of the optical fiber sensing unit is fixed and the movement is avoided.

Owner:安徽龙联智能光电有限公司

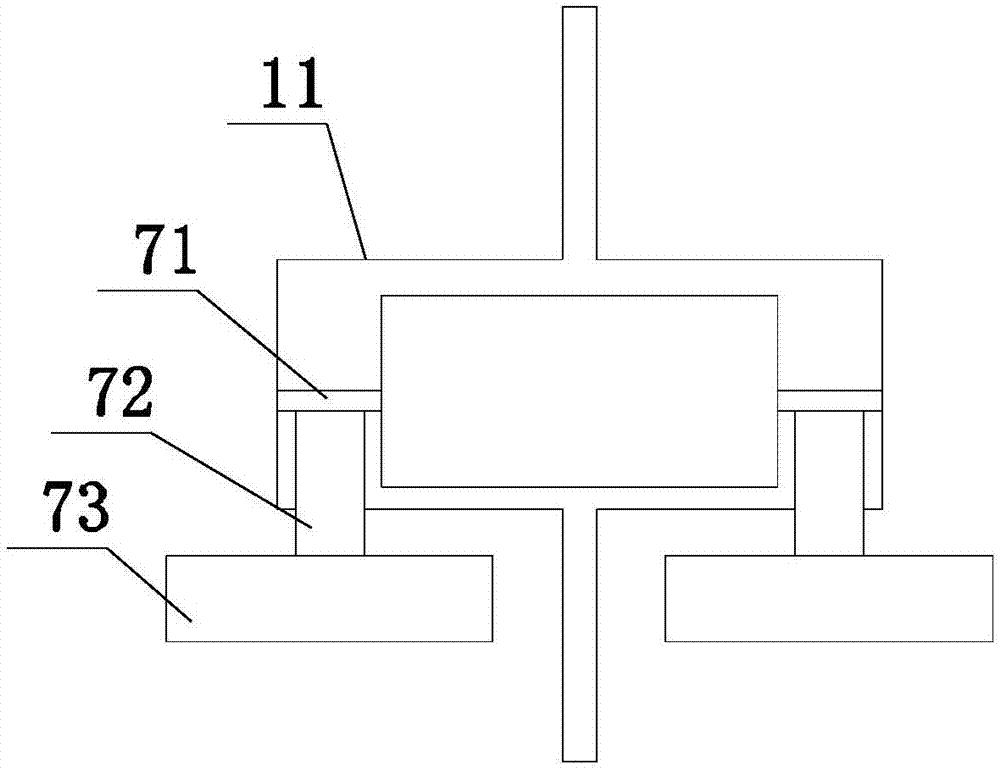

Deposition device for completely unloading materials in starch processing

PendingCN107744676AStructural design is optimized and reasonableImprove scraping efficiencySettling tanks feed/dischargeSedimentation settling tanksEngineeringStructural engineering

The invention discloses a deposition device for completely unloading materials in starch processing. A deposition plate is horizontally disposed in a deposition chamber of a deposition tank. A first driving mechanism drives the deposition plate to ascend or descend. A material unloading bench is horizontally disposed above the deposition tank. A deposition tank accommodating place is formed on thematerial unloading bench. A material unloading assembly is rotatably installed above the material unloading bench through a vertical rotary shaft. A mounting frame of the material unloading assemblyis provided with a horizontal spiral mechanism and a scraper plate located at one side of the spiral mechanism. By means of the optimized structure, the deposition device for completely discharging materials in starch processing has reasonable design, wherein switching between a deposition work station and an unloading work station is achieved via the ascending and descending of the deposition plate. During unloading, the spiral mechanism rotates before materials being scraped so that sediment on the deposition plate is cut into pieces and is loosened, and then the scraper plate moves the sediment on the deposition plate to the unloading bench, so that the scraper plate can completely scraping the materials off during unloading, thus greatly improving scraping efficiency.

Owner:YINGSHANG TIANHAO FOOD

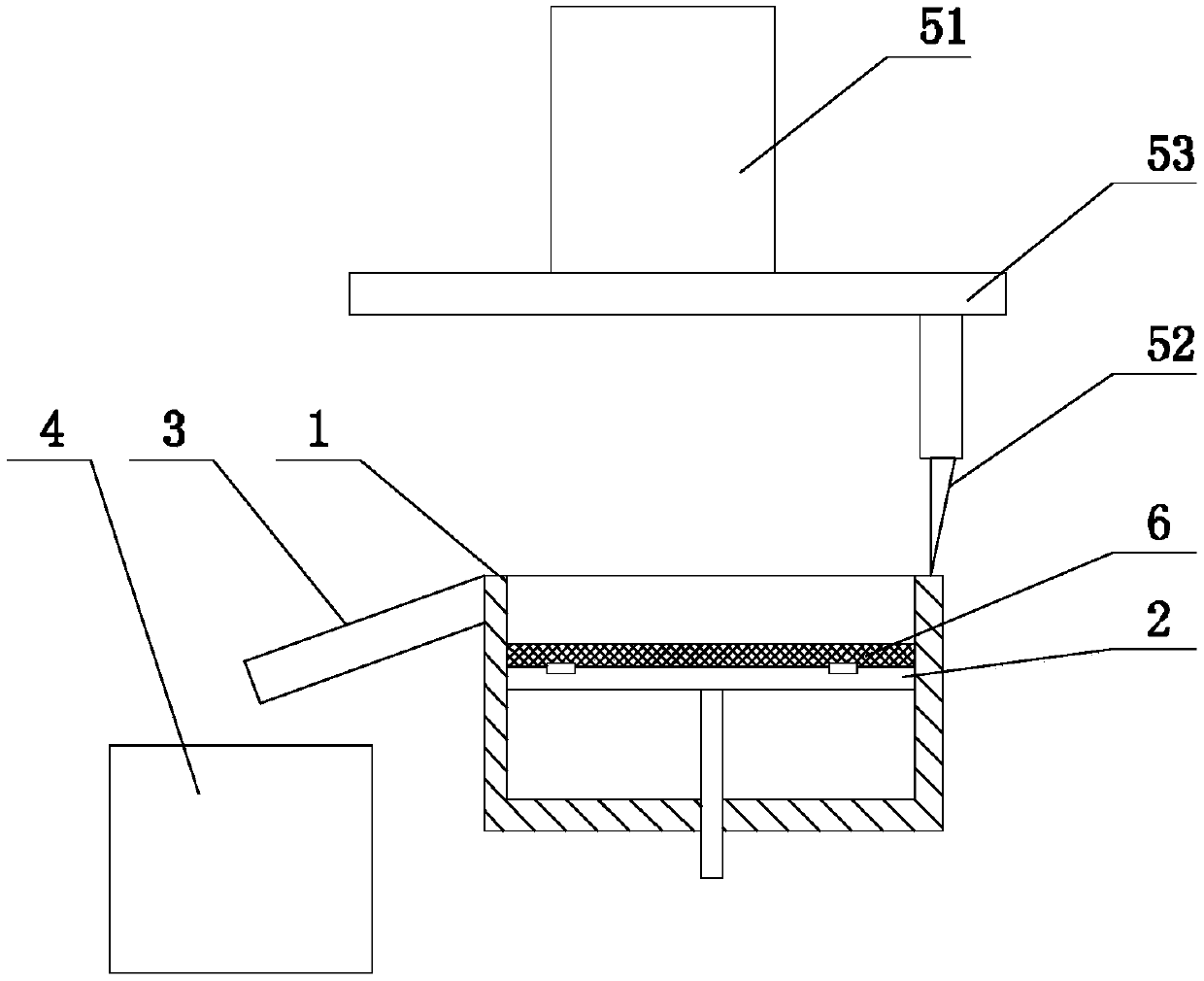

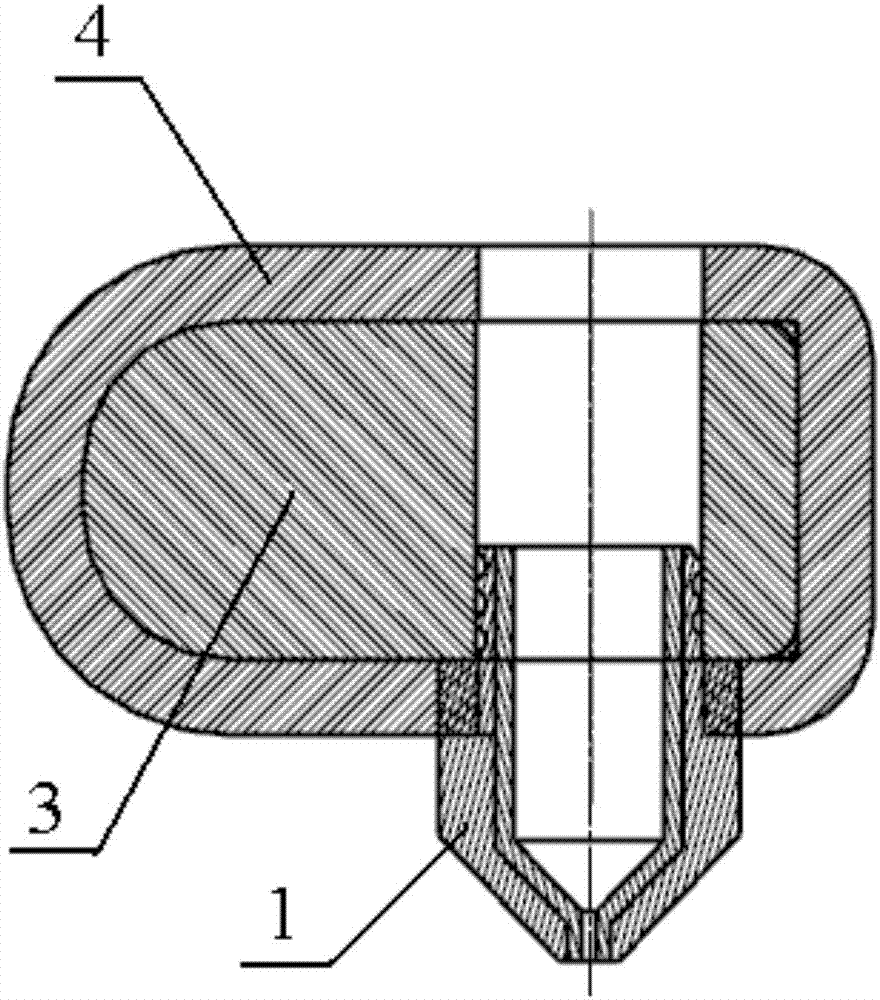

Novel 3D printing heat-preservation nozzle structure

InactiveCN107187043AImprove heat utilizationEnsure flow uniformityManufacturing heating elementsAdditive manufacturing with liquidsSpray nozzleElectrical and Electronics engineering

The invention discloses a novel 3D printing heat-preservation nozzle structure. A through spray channel is formed in the middle of a spray head. The spray head comprises a feeding section, a heating section and a spraying-out section, and the feeding section, the heating section and the spraying-out section are sequentially arranged in the extension direction of the spray channel. A filament feeding guide pipe is mounted at one end of the feeding section and used for feeding filamentous consumables into the spray channel. A mounting through hole matched with the heating section is formed in the middle of a heating block, and the heating section is sleeved with the heating block. The heating block and the spray head are wrapped with heat-preservation materials. According to the optimally-designed novel 3D printing heat-preservation nozzle structure, the heating block and the spray head are wrapped with the heat-preservation materials, heat generated by heating of the heating block is effectively isolated in the heating block and the spray head, and thus the heat utilization rate is higher when the filamentous consumables are molten; and meanwhile, under the heat insulation effect of the heat-preservation materials, the situation that heat generated by the heating block is upwards conducted to the filament feeding guide pipe, and consequentially the filamentous consumables are molten before entering the spray head is avoided, the flow uniformity of the consumables is ensured, and the printing effect is improved.

Owner:合肥开目管理咨询合伙企业(有限合伙)

Hot air utilizing device realizing high-efficiency utilization of energy

InactiveCN107965910AImprove recycling ratesStructural design is optimized and reasonableAir heatersMachines/enginesEngineeringUtilization rate

The invention discloses a hot air utilization device for efficient energy utilization. Hot air inlets and hot air outlets are respectively provided at both ends of the hot air passage, and wind-driven blades are arranged in the hot air passage. An annular energy utilization chamber is set outside the channel, and the kinetic energy conversion mechanism is located in the annular energy utilization chamber. The kinetic energy conversion mechanism rotates with the wind blades to heat the gas in the annular energy utilization chamber. The hot air utilization device with efficient energy utilization through the above optimized design has an optimized and reasonable structural design. By setting a ring-shaped energy utilization chamber outside the hot air channel, on the one hand, the kinetic energy conversion mechanism frictionally heats the gas inside by rotating and doing work, and on the other hand On the one hand, the annular energy utilization chamber insulates the hot air passage, and the heat dissipated in the hot air passage can exchange heat with the gas in the annular energy utilization chamber, further improving the recycling rate of hot air.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

Comet filler filtering equipment

InactiveCN107362595ASimple structural designStructural design is optimized and reasonableLoose filtering material filtersGravity filtersFilter materialFilter effect

The invention discloses comet filler filtering equipment. A filter chamber is arranged in a filter cartridge, the filter chamber has a vertically arranged columnar structure, an upper pressure plate and a lower pressure plate are horizontally arranged in the filter cavity, a first filter hole is formed in the upper pressure plate and a second filter hole is formed in the lower pressure plate, a driving mechanism is connected to the upper pressure plate and the lower pressure plate for driving the upper pressure plate and the lower pressure plate to move relatively, and filter units is located between the upper pressure plate and the lower pressure plate and two ends of the filter unit are separately connected to the upper pressure plate and the lower pressure plate. According to the comet filler filtering equipment of an optimization design, the upper pressure plate and the lower pressure plate press the filter units together during filtration to form a filter structure. A plurality of comet type filter bodies are connected together through a connecting line to prevent movement of the comet type filter bodies between the upper pressure plate and the lower pressure plate, filter materials in filter positions are uniform. In addition, during back washing, the distance from the upper pressure plate to the lower pressure plate is increased to provide a flushing space for the filter materials, so that the filter effect is improved greatly and the back washing is facilitated.

Owner:HEFEI SANFAN WATER TREATMENT EQUIP

Efficient and thorough husking device for rice processing

ActiveCN107837841AStructural design is optimized and reasonableUnpackingGrain huskingGrain polishingEngineeringCentrifugal force

The invention discloses an efficient and thorough husking device for rice processing. An upper fixed disk and a lower rotating disk are horizontally arranged in a material cavity of a discharging cylinder. A feeding pipe vertically penetrates through an installation opening of the upper fixed disk, and the lower end of the feeding pipe is fixed to the lower rotating disk. The side wall of the feeding pipe is provided with material distributing holes. The bottom of the upper fixed disk is provided with material twisting protrusions matched with material guiding grooves of the lower rotating disk. The bottom of the lower rotating disk is provided with multiple material sweeping brushes. A first driving mechanism drives the lower rotating disk to rotate. According to the optimally designed efficient and thorough husking device for rice processing, the structural design optimization is reasonable, rice materials enter the space between the upper fixed disk and the lower rotating disk through the feeding pipe, after the rice materials are grinded by the upper fixed disk and the lower rotating disk, rice husks and rice cores are separated, under the action of centrifugal force, the ricehusks and the rice cores are thrown into the discharging cylinder, under the action of the material sweeping brushes at the bottom of the lower rotating disk, the rice husks are stripped away from thesurfaces of the rice cores, and husking is achieved.

Owner:全椒县崇明米业有限公司

Active balancing wave-resistant ship

ActiveCN107985521AAchieve tilt adjustmentStructural design is optimized and reasonableVessel safetyVessel movement reduction by mass displacementPistonMarine engineering

The invention discloses an active balancing wave-resistant ship. A first adjusting unit comprises two first adjusting components, a second adjusting unit comprises two second adjusting components, each adjusting component drives a floating body to rise and fall through a piston and a hydraulic cylinder, hydraulic cavities of hydraulic cylinders of the two adjusting components of each adjusting unit are communicated, the two adjusting units are communicated, and expanding and contracting of four adjusting units are controlled by a hydraulic commutator and a liquid pump. The active balancing wave-resistant ship is optimized, so that the ship is optimized and reasonable in structure design, four adjusting components of the two adjusting units are distributed at the bottom of the ship, the twoadjusting components in each adjusting unit are hydraulically adjusted by the hydraulic commutator, so that rising and falling are switched, or the two adjusting units are hydraulically adjusted to switch rising and falling, and rising and falling of the floating bodies are adjusted according to the conditions of wind waves, so that inclined alignment of the ship is achieved.

Owner:山东格新精工有限公司

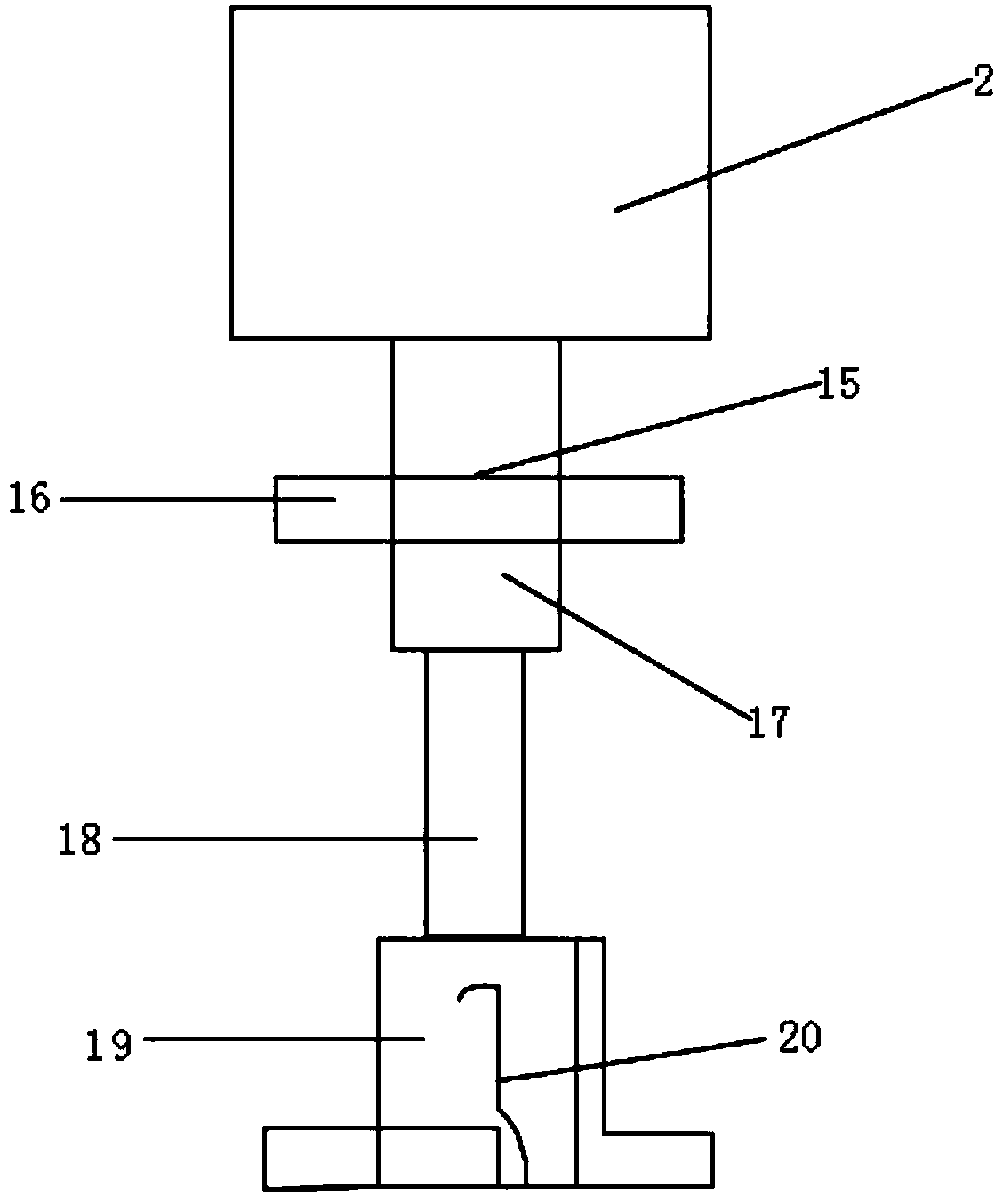

Equipment for detecting effective components of Chinese herbal medicine helleborus thibetanus

InactiveCN107684737AStructural design is optimized and reasonableShort extraction cycleWithdrawing sample devicesSolid solvent extractionDrive shaftEngineering

The invention discloses equipment for detecting effective components of Chinese herbal medicine helleborus thibetanus. The equipment comprises an extracting tank; a drive motor is arranged at the topof the extracting tank, and a rotating shaft of the drive motor is connected with the top of a drive shaft through a flexible transmission structure; a connecting shaft sleeve is sheathed at the bottom of the outer wall of the drive shaft, stirring rods are uniformly arranged on each of the left side and the right side of the outer wall of the connecting shaft sleeve, a feeding tube and a samplingtube are respectively arranged on the left side wall of the extracting tank, an extracting liquid feeding tube and an extracting liquid discharging tube are respectively arranged on the right side wall of the extracting tank, and a waste discharge tube is arranged at the bottom of the extracting tube. The equipment disclosed by the invention has the beneficial effects that the structural design optimization is reasonable; the sampling detection can be performed in the extracting process of the Chinese herbal medicine helleborus thibetanus; extracting liquid is purified and extracted again according to sampling detection results, so that the extracting period is reduced, and the production speed is improved; meanwhile, the extracting process is simplified, the production efficiency is improved, the production cost is reduced, and the operation is convenient.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

Intelligent double wire center temperature monitoring single core cable based on fiber grating

InactiveCN108053940AStructural design is optimized and reasonableGuaranteed tensile strengthCommunication cablesInsulated cablesEngineeringTemperature monitoring

The invention discloses an intelligent double wire center temperature monitoring single core cable based on a fiber grating. A cable core comprises multiple leads and one fiber sensing unit, wherein the fiber sensing unit comprises a tensile core, a grating fiber and a protective tube, the tensile core and the grating fiber are arranged in the protective tube, the grating fiber is arranged aroundthe tensile core, the cable core is externally wrapped in a wrapping layer, and the wrapping layer is externally wrapped in a sheath layer. The intelligent double wire center temperature monitoring single core cable based on the fiber grating is advantaged in that structure design is optimized and reasonable, through arranging the grating fiber among the leads of the cable core, change of the pathof light in the fiber is detected, rapid accurate monitoring of the cable temperature is carried out, moreover, the grating fiber is arranged around the tensile core, axial tensile strength of the grating fiber is guaranteed, and service life of the fiber is improved.

Owner:安徽龙联智能光电有限公司

Brush cleaning device for LCD cutting

InactiveCN107838062AStructural design is optimized and reasonablePrevent splashDirt cleaningCleaning using toolsGlass chipDrive motor

The invention discloses a brush cleaning device for LCD cutting. A groove used for storing the brush is formed in the top of an outer cover, and an opening allowing a chip receiving plate to be inserted is formed in the side wall of the outer cover; the chip receiving plate is horizontally arranged in a removing cavity and can be pulled out through the opening; a rotating mechanism is located in the removing cavity and located above the chip receiving plate and comprises a rotating shaft and knocking rotary arms; and the knocking rotary arms are rotatably installed on the outer cover through the rotating shaft. The brush cleaning device for LCD cutting is designed in an optimized mode, so that the structural design is optimized and is reasonable; a driving motor drives the rotating mechanism to rotate, so that the knocking rotary arms knock the brush continuously, and accordingly glass chips on the brush are removed; and the falling glass chips are collected onto the chip receiving plate and prevented from spattering, and thus concentrated removing is facilitated.

Owner:BENGBU GUOXIAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com