Metal smelting electric furnace with dust collector

A dust removal device and metal technology, which is applied in the field of metal smelting furnaces, can solve environmental damage and other problems, achieve the effect of improving heat utilization rate, optimizing and reasonable structural design, and ensuring heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

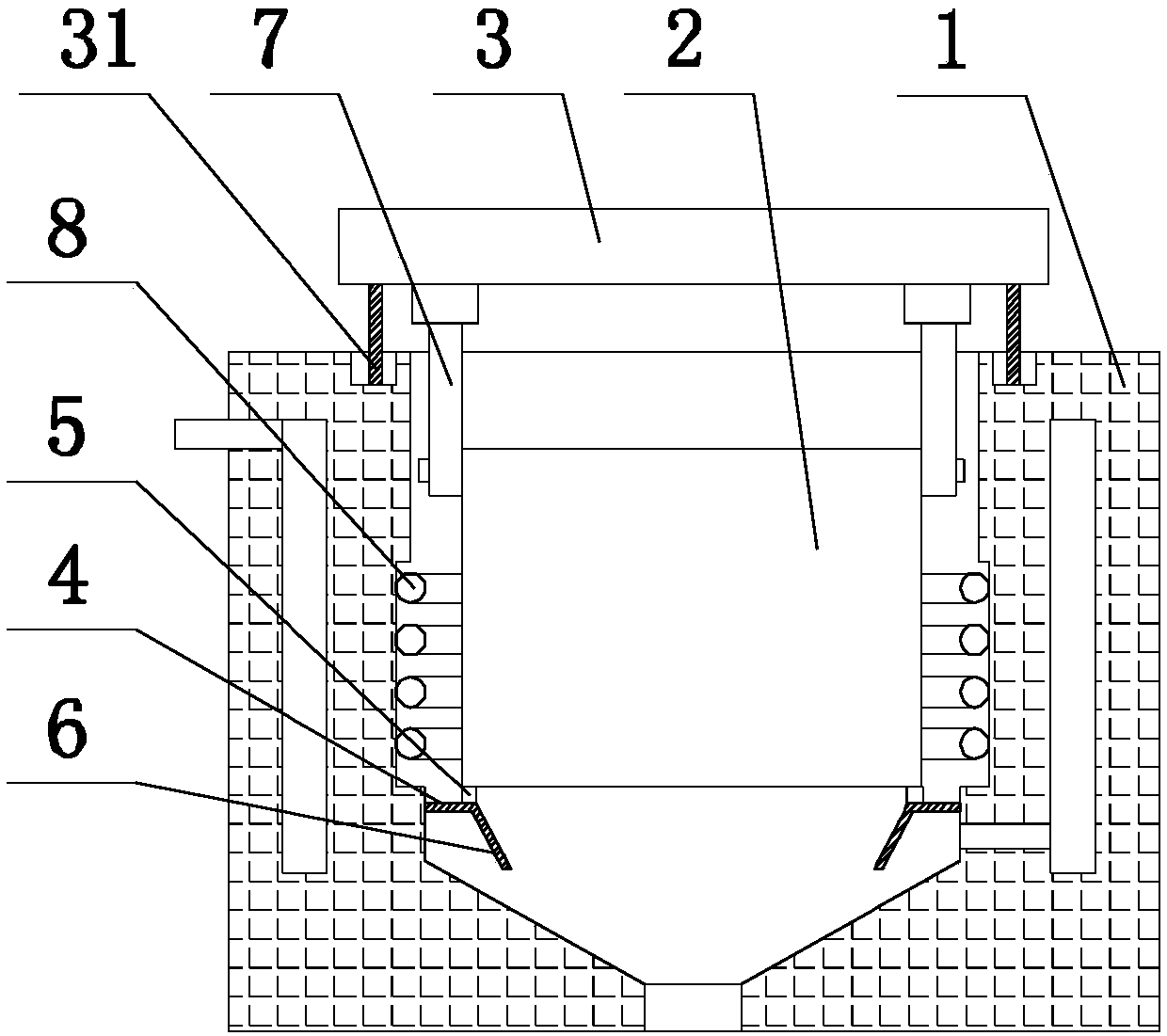

[0014] like figure 1 shown, figure 1 It is a schematic structural diagram of a metal smelting electric furnace with a dust removal device proposed by the present invention.

[0015] refer to figure 1 , a metal smelting electric furnace with a dust removal device proposed by the present invention includes: an outer furnace shell 1, an inner furnace 2, and a cover body 3;

[0016] The outer furnace shell 1 is provided with a accommodating chamber with a top opening, and the cover body 3 is located at the top opening of the accommodating chamber. The accommodating chamber includes a heating chamber and an exhaust chamber that communicate with each other, and the heating chamber is located in the Above the exhaust chamber, the inner wall of the heating chamber is provided with an electric heating tube 8, the side wall of the exhaust chamber is provided with an exhaust port and the bottom is provided with a slag discharge port, and the side wall of the exhaust chamber is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com