Monosodium glutamate centrifugal separation equipment for preventing solid phase residues

A technology for centrifugal separation and flavoring, applied in the field of centrifugation, can solve the problems of poor rotation stability of the rotating drum, reduce the service life, affect the separation effect, etc., and achieve the effects of preventing crystal residues, optimizing the structure design and improving the separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

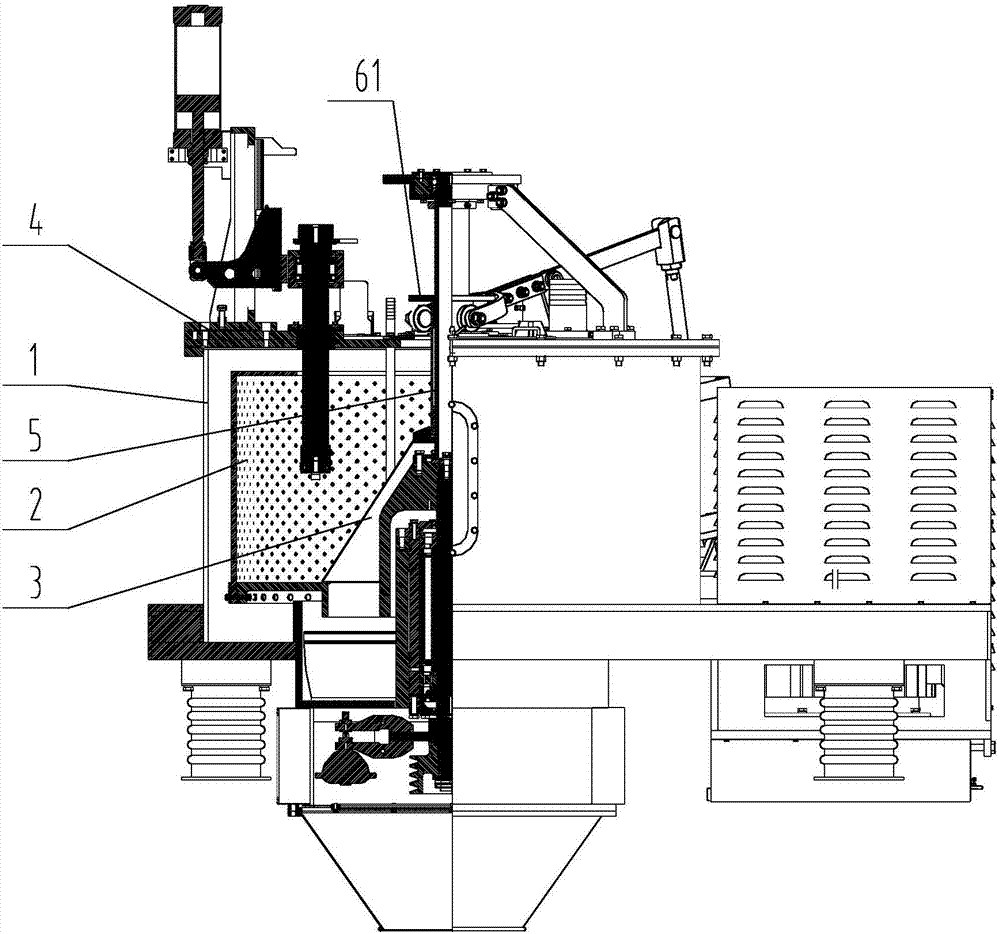

[0015] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a centrifuge separation device for monosodium glutamate that prevents solid phase residues proposed by the present invention.

[0016] refer to figure 1 , the present invention proposes a solid-phase residue-proof MSG centrifugal separation device, comprising: a casing 1, a drum 2, a sealing cover 3, a flange 4, and a driving mechanism;

[0017] The interior of the casing 1 is provided with an accommodating chamber with an open top, and the bottom of the accommodating chamber is provided with a liquid outlet, the inner diameter of the liquid outlet gradually decreases from top to bottom, and the flange 4 is installed at the opening;

[0018] The rotating drum 2 is vertically arranged in the containing chamber, and the rotating drum 2 divides the containing chamber into a separation chamber located inside the rotating drum 2 and a liquid drainage chamber located outside the rotating drum 2. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com