Yarn-breaking-prevention yarn feeding device for textile equipment

A technology for textile equipment and wire feeding devices, which is applied in the field of wire feeding devices for textile equipment, can solve the problems of low spinning efficiency, increased replacement costs, and high production costs, and achieve optimized and reasonable structural design, reduced axial tension, and reduced The effect of small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

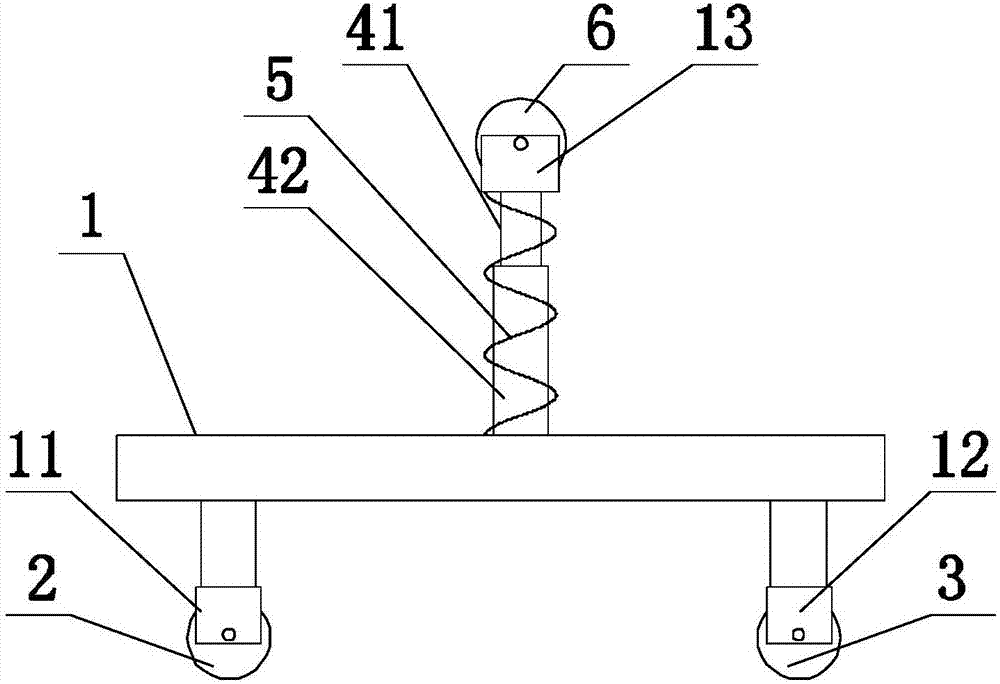

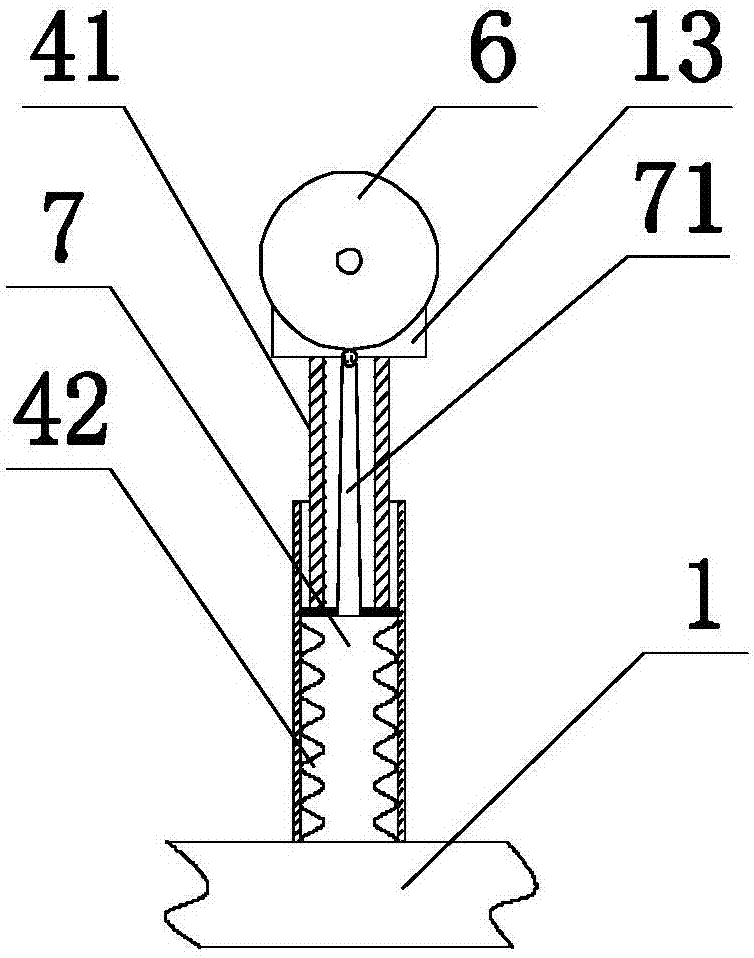

[0015] Such as figure 1 with 2 as shown, figure 1 It is a structural schematic diagram of a thread-breakage-proof textile equipment wire feeding device proposed by the present invention, figure 2 It is a structural schematic diagram of a tension adjustment mechanism of a thread-breakage-preventing textile equipment thread feeding device proposed by the present invention.

[0016] refer to figure 1 with 2 , the present invention proposes an anti-broken wire feeding device for textile equipment, comprising: a mounting frame 1, a first wire feeding roller 2, a second wire feeding roller 3, and a tension adjustment mechanism;

[0017] One side of the mounting frame 1 is provided with a first roller seat 11 and a second roller seat 12, the first wire feed roller 2 and the second wire feed roller 3 are arranged in parallel and the two are respectively rotatably mounted on the first roller seat 11 and the second roller seat 11. On the roller seat 12;

[0018] The tension adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com