Novel 3D printing heat-preservation nozzle structure

A 3D printing and nozzle technology, applied in the field of 3D printing, can solve the problems of heat waste, asbestos paper and high temperature resistant tape insulation effect is not particularly good, nozzle temperature fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

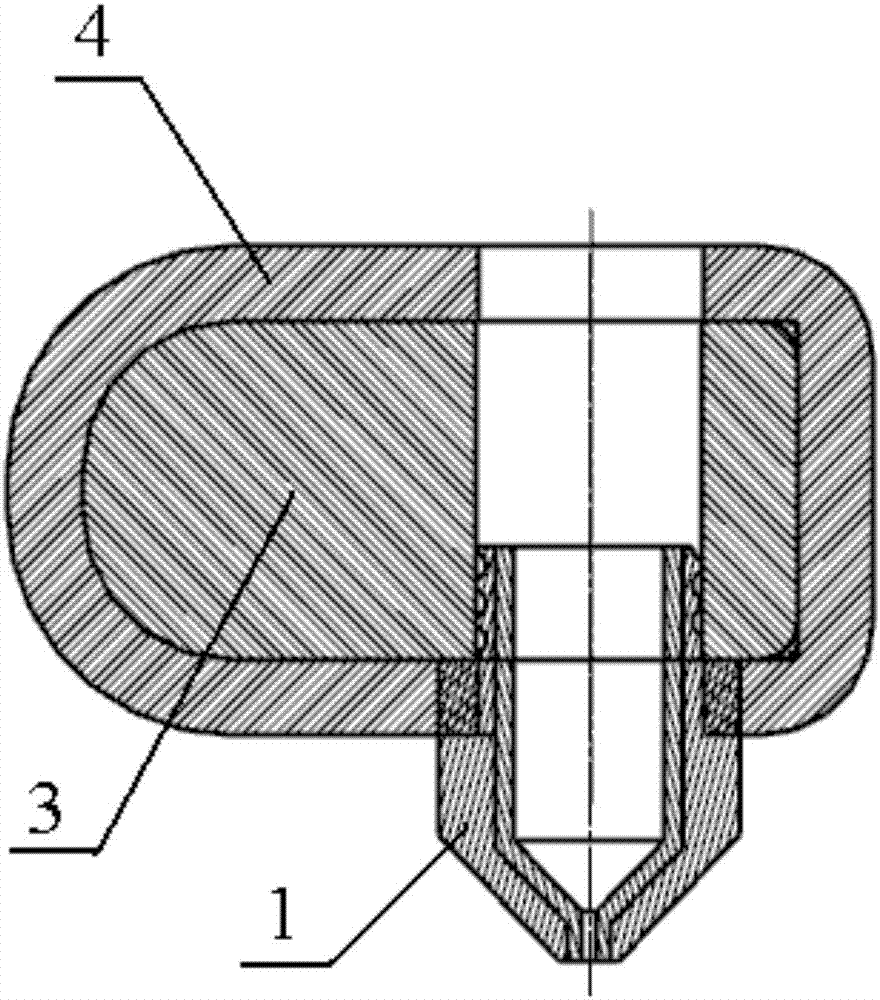

[0015] like figure 1 as shown, figure 1 It is a structural schematic diagram of a novel 3D printing thermal insulation nozzle structure proposed by the present invention.

[0016] refer to figure 1 , a new type of 3D printing thermal insulation nozzle structure proposed by the present invention, including: nozzle 1, wire feeding conduit, heating block 3, thermal insulation material 4;

[0017] Spray head 1 headquarters is provided with a through spray channel, spray head 1 includes a feed section, a heating section, and a discharge section that are sequentially arranged along the extension direction of the spray channel, and a wire feeding guide is installed at one end of the feed section for feeding The spraying channel is fed into filamentary consumables;

[0018] The middle part of the heating block 3 is provided with a through hole for cooperating with the heating section, which is sheathed outside the heating section, and the thermal insulation material 4 covers the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com